In the fast-paced world of automotive services, sourcing an AutoZone portable air compressor can be a pivotal factor in ensuring operational efficiency and customer satisfaction. Flat tires and low tire pressure can disrupt business operations and lead to costly downtime, making it essential for international B2B buyers to equip themselves with reliable inflators. This guide delves into the diverse landscape of portable air compressors, exploring various types, their applications, and critical features that cater to different operational needs.

Our comprehensive analysis not only highlights the technical specifications and functionalities of AutoZone’s offerings but also provides strategic insights into supplier vetting processes, pricing structures, and market trends. For businesses in regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Brazil—understanding these elements is crucial for making informed purchasing decisions.

By addressing common challenges faced in tire maintenance and air inflation, this guide empowers B2B buyers to select the right portable air compressor tailored to their unique operational demands. Equip your fleet or service center with the right tools to enhance productivity and reliability in the field, ensuring that you are always prepared to tackle unexpected tire-related issues head-on.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| 12-Volt Tire Inflators | Plugs into vehicle’s power outlet; lightweight; portable design | Automotive service; fleet maintenance | Vorteile: Easy to use; compact; affordable. Nachteile: Limited power for larger vehicles. |

| Battery-Powered Inflators | Self-contained power source; versatile for various inflatables | Emergency roadside assistance; outdoor events | Vorteile: No need for vehicle connection; multi-use. Nachteile: Requires charging; heavier. |

| High-Performance Compressors | Higher PSI capacity; built for rapid inflation | Heavy-duty vehicle servicing; industrial use | Vorteile: Fast inflation; durable; suitable for larger tires. Nachteile: More expensive; bulkier. |

| Digital Tire Inflators | Digital pressure gauge; automatic shut-off; user-friendly interface | Automotive repair shops; tire retailers | Vorteile: Accurate inflation; easy monitoring. Nachteile: May require batteries; can be pricier. |

| Multi-Function Inflators | Includes additional attachments for various applications | Sports facilities; recreational businesses | Vorteile: Versatile; can inflate multiple items. Nachteile: Complexity may confuse users; potential for wear on multiple parts. |

12-volt tire inflators are designed for portability and ease of use. These devices plug into a vehicle’s power outlet, making them ideal for on-the-go inflation needs. They are particularly suited for automotive service applications, such as fleet maintenance or emergency roadside assistance. When considering a purchase, B2B buyers should evaluate the inflator’s power output, inflation speed, and compatibility with different tire types. The affordability and compact design make them attractive, though their power limitations may restrict use with larger vehicles.

Battery-powered inflators offer the advantage of independence from a vehicle’s power source. This feature makes them highly versatile, suitable for inflating tires of bicycles, sports equipment, or even air mattresses at outdoor events. B2B buyers should consider the battery life, inflation speed, and overall weight when selecting a model. While they provide convenience and multi-use capabilities, the necessity for regular charging and potentially heavier design can be drawbacks.

High-performance compressors are engineered for rapid inflation and higher PSI capacities, making them essential for heavy-duty vehicle servicing and industrial applications. These compressors are ideal for businesses that require quick and reliable inflation for large tires or equipment. Buyers should assess the durability, inflation speed, and maintenance requirements of these models. Although they offer significant advantages in performance, their higher cost and bulkier design may not be suitable for all B2B contexts.

Digital tire inflators incorporate advanced features like digital pressure gauges and automatic shut-off mechanisms, enhancing user experience and safety. They are commonly used in automotive repair shops and tire retailers, where accuracy is paramount. B2B buyers should focus on the accuracy of readings, ease of use, and additional functionalities when making a selection. While they provide precise inflation and user-friendly interfaces, the potential need for batteries and higher price points may be considerations for budget-conscious buyers.

Multi-function inflators are designed to cater to a variety of inflation needs, often including attachments for inflating sports balls, pool floats, and more. This versatility makes them a valuable asset for businesses in recreational industries or sports facilities. When purchasing, B2B buyers should evaluate the range of attachments, ease of use, and durability. Although they can perform multiple tasks, the complexity of features might overwhelm some users, and the wear on various components could lead to increased maintenance costs.

| Industrie/Sektor | Specific Application of AutoZone Portable Air Compressor | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparatur | Tire inflation and maintenance for vehicles | Reduces downtime by enabling quick tire repairs on-site | Power source compatibility, portability, and pressure range |

| Transport und Logistik | Emergency tire inflation for fleet vehicles | Minimizes operational delays and enhances vehicle uptime | Durability, ease of use, and battery life |

| Construction & Heavy Equipment | Inflating pneumatic tools and equipment | Increases efficiency by ensuring tools are operational | Pressure capacity, weight, and attachment versatility |

| Sports & Recreation | Inflating sports equipment and recreational vehicles | Provides convenience and readiness for events and activities | Size, ease of transport, and multi-functionality |

| Landwirtschaft | Maintaining tire pressure on farm equipment | Improves safety and efficiency in agricultural operations | Adaptability to various tire types and ruggedness |

In the automotive repair industry, the AutoZone portable air compressor is essential for tire inflation and maintenance. Mechanics can quickly inflate tires on-site, addressing flat tires or low-pressure warnings without the need for specialized equipment. This capability not only enhances service speed but also reduces vehicle downtime, which is critical for customer satisfaction and operational efficiency. Buyers in this sector should consider compatibility with various power sources and the compressor’s pressure range to meet diverse vehicle requirements.

Within the transportation and logistics sector, the AutoZone portable air compressor serves as a vital tool for emergency tire inflation of fleet vehicles. When a vehicle experiences a flat tire, the compressor allows for immediate inflation, minimizing operational delays and keeping delivery schedules on track. For international buyers, especially in regions like Africa and South America, sourcing a durable and easy-to-use compressor is crucial to withstand varying road conditions and ensure consistent performance across diverse fleet types.

In construction and heavy equipment operations, the AutoZone portable air compressor is used for inflating pneumatic tools and machinery. Ensuring that tools remain operational is essential for maintaining productivity on job sites. The compressor’s portability allows workers to transport it easily, providing flexibility in various locations. Key sourcing considerations for buyers in this industry include the compressor’s pressure capacity, weight, and compatibility with different tool attachments to maximize utility.

The sports and recreation sector benefits from the AutoZone portable air compressor for inflating sports equipment such as balls, rafts, and inflatable structures. Its compact design makes it easy to transport to events, ensuring readiness and convenience. For B2B buyers in this field, factors such as size, ease of transport, and multi-functionality are critical, as they seek solutions that can serve multiple purposes while being lightweight and efficient.

Illustrative image related to autozone portable air compressor

In agriculture, maintaining proper tire pressure on farm equipment is crucial for operational efficiency and safety. The AutoZone portable air compressor enables farmers to quickly inflate tires on tractors and trailers, reducing the risk of accidents and improving fuel efficiency. Buyers in this sector should prioritize adaptability to various tire types and ruggedness, ensuring the compressor can withstand harsh working conditions typical in agricultural environments.

Das Problem:

Many B2B buyers in regions with inconsistent electrical infrastructure face challenges when trying to power portable air compressors. For instance, businesses operating in remote areas of Africa or South America may not have reliable access to a vehicle’s 12V outlet or a stable power source. This can lead to frustration when trying to inflate tires or equipment, causing potential delays in operations and affecting overall productivity.

Die Lösung:

To mitigate this issue, buyers should consider investing in battery-powered portable air compressors that come equipped with their own rechargeable power sources. These compressors not only eliminate reliance on vehicle power but also provide versatility for various applications, such as inflating tires, sports equipment, or air mattresses. When sourcing these devices, B2B buyers should prioritize models with high-capacity batteries that offer longer operational times between charges. Additionally, ensuring compatibility with local power supply standards for charging can further enhance usability and convenience.

Illustrative image related to autozone portable air compressor

Das Problem:

Another common pain point for B2B buyers is the risk of over-inflating tires, especially in high-pressure situations like fleet operations or emergency roadside assistance. Many users may not have a clear understanding of the appropriate tire pressure for different vehicles, leading to potential tire damage, increased wear, or even blowouts, which can significantly impact operational efficiency and safety.

Die Lösung:

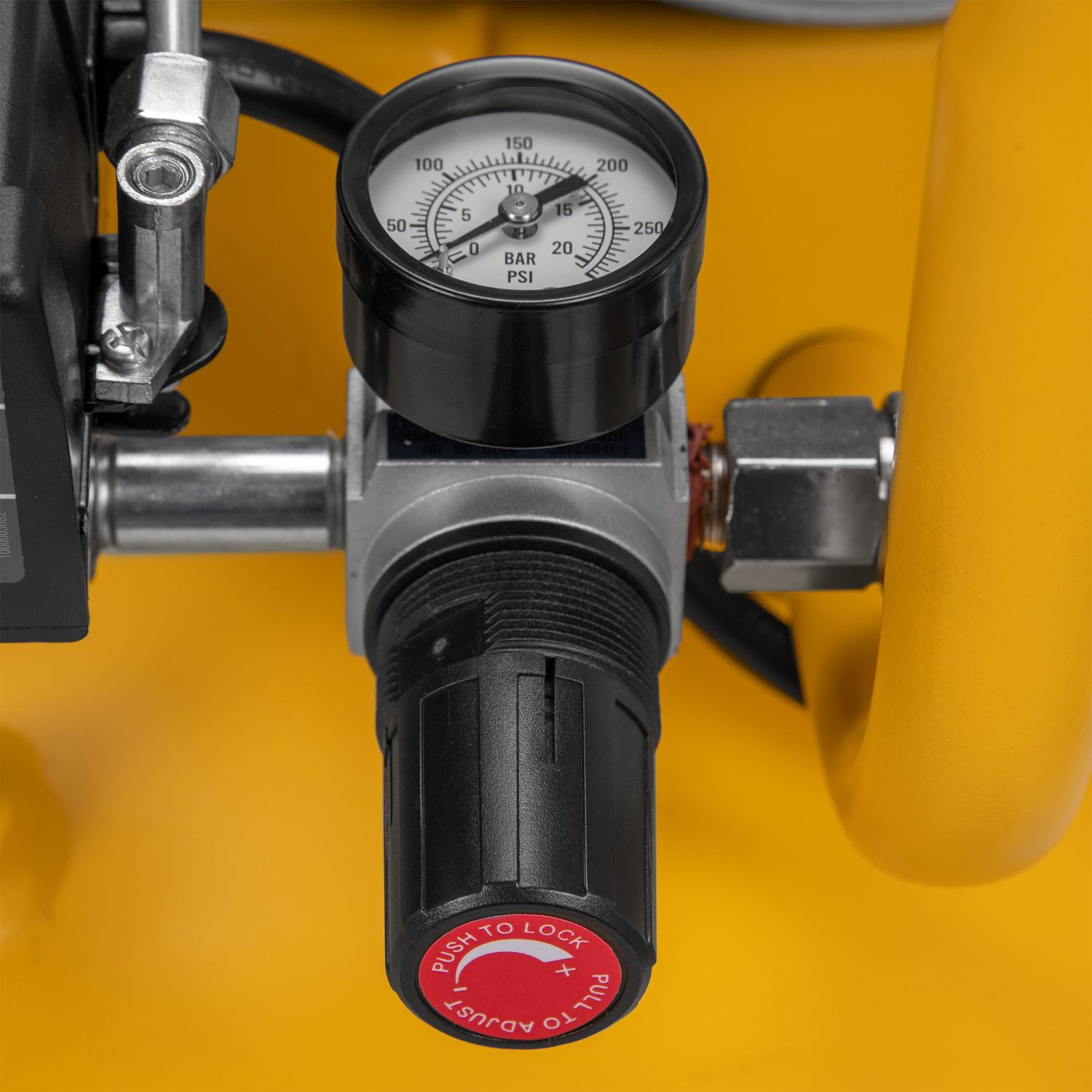

To address this concern, buyers should select portable air compressors that feature integrated digital pressure gauges and automatic shut-off functionalities. These features allow users to set the desired tire pressure, ensuring accuracy and safety during inflation. Additionally, B2B buyers should provide training for their teams on how to read tire pressure specifications, which are usually found on the driver’s door pillar or in the vehicle’s manual. Regular maintenance checks and establishing a routine to monitor tire pressure can also prevent over-inflation and promote tire longevity.

Das Problem:

In industrial settings or when servicing larger vehicles, B2B buyers often encounter challenges with the reach of the air hose from the portable air compressor. A short air hose can make it difficult to inflate tires, especially in awkward positions, leading to inconvenience and potential inefficiencies during operations.

Die Lösung:

To overcome this issue, buyers should look for portable air compressors with longer hoses or those that offer expandable hose options. Additionally, consider investing in hose extensions that can be easily connected to existing inflators. When evaluating products, B2B buyers should also assess the compressor’s design to ensure it allows for easy maneuverability and access to hard-to-reach areas. Furthermore, having multiple portable compressors within a fleet can ensure that there is always a unit available nearby, reducing downtime and enhancing operational efficiency. Regularly reviewing and updating the tools and accessories based on the specific needs of the workforce can also lead to improved service delivery and employee satisfaction.

When selecting materials for portable air compressors, particularly those available through AutoZone, several options stand out based on their properties, costs, and suitability for various applications. Here, we analyze four common materials used in these devices: aluminum, steel, plastic, and rubber. Each material has unique characteristics that impact performance and usability, especially for international B2B buyers.

Aluminum is a popular choice for the housing and components of portable air compressors due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate pressures, making it suitable for tire inflation tasks.

Vorteile: Aluminum is highly resistant to corrosion, which is essential for outdoor use in various climates, including humid environments found in parts of Africa and South America. Its lightweight nature enhances portability, making it easier for users to transport the compressor.

Nachteile: While aluminum is durable, it can be more expensive than other materials and may require more complex manufacturing processes. Additionally, it can be prone to dents and scratches, which may affect aesthetics over time.

Auswirkungen auf die Anwendung: Aluminum components are compatible with various media, including air and non-corrosive gases, making them versatile for different applications.

Überlegungen für internationale Käufer: Buyers from regions like the Middle East and Europe should ensure that aluminum parts meet local standards (such as ASTM or DIN) for quality and safety.

Steel is often utilized in the construction of portable air compressors, particularly for structural components and pressure vessels. It offers high strength and can handle pressures exceeding 150 PSI, making it suitable for heavy-duty applications.

Vorteile: Steel is incredibly durable and resistant to wear and tear, making it ideal for long-term use. It also has a lower cost compared to aluminum, which can be advantageous for budget-conscious buyers.

Nachteile: Steel is heavier than aluminum, which may detract from the portability of the compressor. Additionally, it is susceptible to rust and corrosion if not properly coated or maintained, especially in humid or coastal environments.

Auswirkungen auf die Anwendung: Steel is compatible with various gases and can withstand high-pressure applications, making it suitable for more demanding tasks.

Überlegungen für internationale Käufer: Buyers should ensure that the steel used complies with international standards to avoid issues with quality and safety, especially in regions with strict regulatory frameworks.

Plastic is commonly used for non-structural components, such as housing, knobs, and connectors. It is lightweight and can be molded into complex shapes, making it suitable for various design requirements.

Vorteile: Plastic is resistant to corrosion and is generally less expensive than metal options. Its lightweight nature enhances portability, making it easier for users to handle.

Nachteile: Plastic may not withstand high temperatures or pressures as effectively as metal, limiting its use in certain applications. Additionally, it can be less durable over time, especially under mechanical stress.

Auswirkungen auf die Anwendung: Plastic components are typically used for air intake and exhaust systems, where high pressure is not a primary concern.

Überlegungen für internationale Käufer: Buyers should verify that the plastic materials meet relevant safety standards to ensure reliability, particularly in regions with varying climate conditions.

Rubber is primarily used in seals, hoses, and gaskets within portable air compressors. It provides flexibility and ensures airtight connections, which is critical for maintaining pressure.

Vorteile: Rubber is highly elastic and can withstand a range of temperatures, making it suitable for various environments. It also provides excellent sealing capabilities, preventing air leaks.

Nachteile: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures, necessitating regular replacement. Its performance can also be affected by certain chemicals.

Auswirkungen auf die Anwendung: Rubber components are essential for maintaining the integrity of the air compressor, particularly in high-pressure scenarios.

Überlegungen für internationale Käufer: Buyers should ensure that rubber materials comply with international standards for durability and safety, particularly in regions with extreme weather conditions.

Illustrative image related to autozone portable air compressor

| Material | Typical Use Case for AutoZone Portable Air Compressor | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Housing and lightweight components | Corrosion resistance and lightweight | Höhere Kosten und Anfälligkeit für Beulen | Mittel |

| Stahl | Structural components and pressure vessels | Hohe Festigkeit und Haltbarkeit | Heavier and susceptible to rust | Niedrig |

| Kunststoff | Non-structural components (knobs, housing) | Leicht und korrosionsbeständig | Limited pressure tolerance and durability | Niedrig |

| Gummi | Seals, hoses, and gaskets | Excellent sealing and flexibility | Degrades over time and affected by chemicals | Mittel |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in AutoZone portable air compressors, helping them make informed purchasing decisions based on performance, cost, and compliance with international standards.

The manufacturing process of an AutoZone portable air compressor involves several critical stages to ensure high performance and reliability. This process typically includes material preparation, forming, assembly, and finishing.

Material Preparation: The first step involves sourcing high-quality raw materials, such as metals for the compressor housing and durable plastics for components like the casing and handles. Manufacturers often prioritize materials that can withstand high pressure and provide insulation against heat. Ensuring that these materials meet international quality standards is essential for durability and safety.

Forming: After material preparation, the forming stage takes place. This may involve processes such as stamping, molding, and machining. For instance, the metal components are often stamped or cut into precise shapes that fit the design specifications. Advanced machining techniques are used to ensure tight tolerances, which are crucial for the compressor’s performance. This stage may also include the production of the motor and pump mechanisms, which are vital for the compressor’s efficiency.

Illustrative image related to autozone portable air compressor

Assembly: Once the components are formed, they proceed to the assembly stage. This involves integrating various parts, including the motor, pump, pressure gauge, and air hose. Automated assembly lines are frequently employed to enhance precision and speed. Quality control checkpoints are established during this phase to ensure that components are correctly fitted and function as intended.

Finishing: The final stage of manufacturing involves finishing processes such as painting, coating, and testing. A protective coating is often applied to prevent corrosion, especially for models intended for diverse climates, including those found in Africa, South America, the Middle East, and Europe. This stage also includes rigorous testing to verify that the compressor meets the specified performance criteria.

Quality assurance (QA) is an integral part of the manufacturing process for AutoZone portable air compressors, ensuring that the final product meets both international and industry-specific standards.

Illustrative image related to autozone portable air compressor

International Standards: Manufacturers typically adhere to ISO 9001, which provides a framework for quality management systems. This certification ensures that companies maintain consistent quality in their products and services. Compliance with CE marking is also crucial for products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

Industry-Specific Standards: Additional certifications may include API (American Petroleum Institute) for products that may be used in oil-related applications. These certifications ensure that the compressors meet specific safety and performance criteria relevant to their intended use.

Quality control (QC) is implemented at various stages of the manufacturing process through specific checkpoints:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Materials must meet predefined specifications before they are accepted for production. Any discrepancies are documented and addressed to prevent defects in the final product.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, IPQC is performed to monitor the production stages. Operators conduct regular inspections to ensure that components are being manufactured correctly and that assembly processes adhere to quality standards. This proactive approach helps identify issues early, reducing the risk of defects in the final product.

Endgültige Qualitätskontrolle (FQC): After assembly, the compressors undergo FQC to ensure they meet all performance specifications. This includes pressure testing, leak detection, and functionality assessments. Any units that do not pass these tests are reworked or discarded, maintaining the integrity of the product line.

Several testing methods are employed to ensure the quality and reliability of portable air compressors:

Druckprüfung: This is a critical method used to verify that the compressor can maintain specified pressure levels without leaking. Units are subjected to pressure beyond their operational limits to ensure safety and durability.

Leistungstests: Compressors are tested for their ability to inflate tires and other objects within specified time frames. This testing assesses airflow rates, noise levels, and overall performance efficiency.

Dauerhaftigkeitsprüfung: To simulate real-world usage, compressors undergo durability tests, including continuous operation at maximum pressure for extended periods. This helps identify potential failure points and ensures longevity.

For B2B buyers, especially those sourcing from international markets, verifying supplier quality control practices is paramount. Here are actionable steps:

Lieferanten-Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control measures, and adherence to standards. This firsthand observation can provide insights into the supplier’s operational capabilities.

Qualitätsberichte: Requesting detailed quality reports and certifications from suppliers can help verify their compliance with international standards. This documentation should include results from various testing phases, indicating that the products have undergone thorough quality checks.

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can be scheduled at different stages of production, ensuring transparency and accountability.

International B2B buyers should be aware of specific nuances when it comes to quality control.

Understanding Regional Standards: Different regions may have varying standards and certifications. For instance, products sold in the European Union must comply with CE marking, while buyers in the Middle East may require adherence to GCC standards. Familiarizing oneself with these requirements is crucial for ensuring compliance.

Illustrative image related to autozone portable air compressor

Kulturelle Erwägungen: Communication barriers can affect quality assurance practices. Buyers should establish clear lines of communication with suppliers to address quality expectations and standards. This may involve multilingual documentation and regular updates on production statuses.

Logistics and Transportation: The quality of portable air compressors can be impacted during shipping. Buyers should consider suppliers that implement protective measures during transportation, as well as those who offer warranties or guarantees that cover potential shipping damages.

By understanding the manufacturing processes and quality assurance practices of AutoZone portable air compressors, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality products for their markets.

This guide serves as a practical checklist for B2B buyers interested in procuring the AutoZone portable air compressor. With the increasing demand for reliable vehicle maintenance tools, particularly in regions like Africa, South America, the Middle East, and Europe, understanding how to source the right product is essential. This checklist will help streamline your purchasing process, ensuring that you select a compressor that meets your operational needs.

Establishing clear technical specifications is crucial for ensuring that the portable air compressor meets your business requirements. Consider factors such as maximum pressure capacity, power source (12V or battery-operated), and inflation speed. Tailoring your specifications to match the types of vehicles or equipment your business services can lead to more efficient operations.

Conduct thorough market research to understand current trends in portable air compressors, including pricing and feature sets. This step is vital as it allows you to gauge the competitive landscape and identify opportunities for cost savings. Pay attention to fluctuations in pricing based on features such as digital displays or built-in lights, which may enhance usability.

Before committing to a supplier, conduct a comprehensive evaluation. Request company profiles, product samples, and references from businesses in similar industries or geographic areas. Look for suppliers with a proven track record of reliability and customer service, as these factors are critical in maintaining your supply chain’s integrity.

Ensuring that the portable air compressor complies with relevant safety and quality standards is essential. Check for certifications like ISO and CE, which indicate adherence to international safety regulations. This verification protects your business from potential liability issues and ensures that the product is safe for use in various environments.

Illustrative image related to autozone portable air compressor

Inquire about the warranty terms and after-sales support provided by the supplier. A robust warranty can safeguard your investment, while reliable customer support is invaluable for troubleshooting and maintenance. Evaluate the supplier’s responsiveness to inquiries and their availability of replacement parts, as this can significantly impact your operational efficiency.

If possible, request a trial period or a sample unit of the portable air compressor. This allows you to evaluate its performance in real-world conditions and determine if it meets your operational needs. Pay attention to factors such as ease of use, reliability, and how well it maintains tire pressure under various conditions.

Once you have selected a supplier and assessed all relevant factors, finalize your order details. Clearly outline payment terms, delivery schedules, and any bulk purchasing discounts. Establishing clear communication with your supplier at this stage can prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can make informed decisions when sourcing the AutoZone portable air compressor, ultimately leading to enhanced operational efficiency and customer satisfaction.

When sourcing AutoZone portable air compressors, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materialien: The materials used in manufacturing portable air compressors, such as metal casings, plastic components, and electronic parts, significantly influence the overall cost. The choice of materials affects durability and performance, which are critical factors for international buyers.

Arbeit: Labor costs can vary based on the location of manufacturing. Regions with lower labor costs may provide cost advantages, but this can come at the expense of quality. It’s crucial to evaluate the skill level of the workforce involved in production.

Fertigungsgemeinkosten: This includes expenses such as facility maintenance, utilities, and administrative costs. Efficient production processes can help minimize these overheads.

Werkzeugbau: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider how these costs will impact overall pricing and whether they can be amortized over larger order volumes.

Qualitätskontrolle (QC): Ensuring product quality through rigorous QC processes is vital. While it may add to costs, it can prevent returns and enhance customer satisfaction, particularly important in B2B transactions.

Logistik: Shipping costs, including freight, customs duties, and insurance, must be factored into the total cost. Logistics can become more complex for international buyers due to varying import regulations and tariffs.

Marge: The supplier’s profit margin will also affect pricing. Understanding the market dynamics and competitive landscape can help buyers negotiate better terms.

Several factors can influence the pricing of portable air compressors, particularly for international buyers.

Volumen/MOQ (Mindestbestellmenge): Larger orders often result in lower per-unit costs. Establishing a good relationship with suppliers can provide leverage for negotiating favorable terms, especially for bulk purchases.

Spezifikationen und Anpassungen: Custom features or unique specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materialien: High-quality materials may command higher prices but can lead to better performance and longevity, which is crucial in regions with diverse climates and usage scenarios.

Qualität und Zertifizierungen: Products that meet international safety and quality standards may incur higher costs but can be crucial for market acceptance and legal compliance.

Lieferanten-Faktoren: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge a premium for their experience and track record.

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers should understand the implications of terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) to optimize their logistics costs.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency in sourcing AutoZone portable air compressors.

Verhandlung: Leverage your purchasing power by negotiating terms that align with your business objectives. Don’t hesitate to ask for discounts based on order volume or long-term contracts.

Gesamtbetriebskosten (TCO): Evaluate the TCO, which includes not only the purchase price but also maintenance, operational efficiency, and potential replacement costs. Opt for compressors that offer longer life and better performance to minimize TCO.

Nuancen der Preisgestaltung verstehen: Be aware of regional pricing differences and market trends. Factors such as currency fluctuations and local demand can impact pricing, so staying informed can lead to better purchasing decisions.

Beziehungen zu den Lieferanten: Cultivating strong relationships with suppliers can lead to better pricing and service. Regular communication can also help in addressing any issues promptly.

Stay Informed on Regulations: Understanding import regulations and tariffs in your region can prevent unexpected costs. This is particularly important in international transactions where compliance is critical.

Prices for portable air compressors can vary widely based on the factors discussed. It is advisable to obtain quotes from multiple suppliers and consider all cost components when making purchasing decisions.

When considering options for inflating tires or powering pneumatic tools, the AutoZone portable air compressor stands out as a reliable choice. However, various alternatives exist that may better suit specific needs or preferences. B2B buyers must evaluate these options to determine the most effective solution for their operational requirements, taking into account factors such as performance, cost, and ease of use.

| Vergleich Aspekt | AutoZone Portable Air Compressor | Slime 12 Volt Tire Inflator | Battery-Powered Tire Inflator |

|---|---|---|---|

| Leistung | Moderate PSI, suitable for cars | 12V, fills standard tires in 8 mins | Varies widely, up to 150 PSI |

| Kosten | $50 – $200 depending on model | $34.99 | $30 – $150 |

| Leichte Implementierung | Plug-and-play, minimal setup | Simple button operation | Requires battery charging |

| Wartung | Low, occasional filter checks | Minimal, replace if damaged | Moderate, depends on battery life |

| Bester Anwendungsfall | General vehicle maintenance | Emergency tire inflation | Versatile for various inflatables |

The Slime 12 Volt Tire Inflator is an efficient and cost-effective solution for basic tire inflation needs. It features a compact design and a built-in LED light, making it ideal for emergency situations, especially at night. While its performance is adequate for standard car tires, it may not be suitable for larger vehicles or high-demand applications. The low cost and ease of use make it a great option for budget-conscious buyers, but its limitations in power and versatility should be considered.

Battery-powered tire inflators offer significant flexibility, as they do not require an external power source to operate. This independence allows for easy use in remote locations or while on the go. With varying PSI capabilities, some models can handle heavy-duty tires, making them suitable for trucks and SUVs. However, the need for regular battery charging can be a drawback, especially in high-usage scenarios. These inflators can range in price, so it’s essential to choose one that meets the specific inflation requirements without exceeding budget constraints.

Illustrative image related to autozone portable air compressor

When selecting a portable air compressor or inflator, B2B buyers should consider the specific use cases relevant to their operations. The AutoZone portable air compressor is a solid choice for general maintenance and everyday tire inflation. In contrast, the Slime 12 Volt Tire Inflator excels in emergency situations and offers a lower price point. For those needing a versatile solution capable of handling a range of inflation tasks, a battery-powered inflator may be the best fit, despite its maintenance requirements. By carefully assessing performance, cost, and ease of use, buyers can make an informed decision that aligns with their business needs and operational contexts.

When considering an AutoZone portable air compressor, several technical specifications are crucial for international B2B buyers. These properties not only reflect the quality and functionality of the product but also influence purchasing decisions and operational efficiency.

Maximum Pressure Rating (PSI)

The maximum pressure rating, measured in pounds per square inch (PSI), indicates the compressor’s capability to inflate tires to the required pressure. For instance, a typical portable air compressor might have a maximum PSI of 130. Understanding this specification is vital for ensuring compatibility with various vehicle types and tire requirements, especially in markets where larger vehicles or heavy-duty tires are common.

Stromquelle

Portable air compressors can be powered through different sources, primarily 12-volt DC (cigarette lighter) or battery-operated. The choice between these power sources impacts usability in remote areas, particularly in regions like Africa and South America, where access to electricity may be limited. Buyers should consider the availability of power and the intended use case when selecting a compressor.

Aufblasgeschwindigkeit

This specification refers to how quickly a compressor can inflate a standard car tire, usually measured in minutes. For example, some compressors can fill a tire in approximately 8 minutes. This efficiency is particularly important for businesses that require rapid service turnaround, such as automotive repair shops or fleet services.

Gewicht und Tragbarkeit

The weight of the compressor, often around 3.5 lbs for compact models, is a critical factor for portability. A lightweight design allows for easy transport and storage, making it suitable for roadside assistance or emergency kits. Buyers should assess the compressor’s dimensions and weight to ensure it meets their logistical needs.

Built-in Features

Many modern compressors come equipped with additional features such as LED lights for nighttime use, integrated pressure gauges, and automatic shut-off mechanisms. These enhancements improve user experience and safety, making them attractive to businesses that prioritize customer service.

Durability and Material Grade

The construction material of the compressor affects its longevity and performance under varying environmental conditions. High-quality plastics or metal casings are preferred for their resistance to wear and tear, especially in harsh climates. Understanding material grade is crucial for B2B buyers to ensure that the compressor can withstand the rigors of everyday use.

To navigate the purchasing process effectively, familiarity with industry jargon is essential. Here are several key trade terms that B2B buyers should know:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality products and their sources, ensuring they invest in reliable compressors.

MOQ (Mindestbestellmenge)

This specification indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is important for budgeting and inventory management, especially for businesses looking to purchase in bulk.

RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to request pricing and availability on specific products. This process is vital for obtaining competitive pricing and ensuring that the selected supplier can meet the buyer’s needs.

Incoterms (Internationale Handelsklauseln)

These are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and insurance responsibilities, facilitating smoother cross-border trade.

Gewährleistungsfrist

The warranty period specifies how long the manufacturer guarantees the product against defects. This term is critical for buyers as it reflects the manufacturer’s confidence in their product quality and provides assurance for potential repairs or replacements.

After-Sales-Unterstützung

This term encompasses the services provided after the purchase, including installation, maintenance, and customer service. Strong after-sales support is crucial for ensuring long-term satisfaction and operational efficiency, especially for businesses relying heavily on portable air compressors.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting an AutoZone portable air compressor that meets their operational needs and expectations.

The global market for portable air compressors, particularly the AutoZone sector, is witnessing significant growth driven by several factors. Increased vehicle ownership across emerging markets in Africa, South America, and the Middle East is a primary driver. With the rise in car ownership, the demand for essential vehicle maintenance tools, such as portable air compressors, has surged. Moreover, the trend towards DIY vehicle maintenance is gaining traction, especially among urban consumers who prefer compact and easy-to-use solutions for roadside emergencies.

Illustrative image related to autozone portable air compressor

Technological advancements are also reshaping the landscape. Innovations such as digital pressure gauges, auto-stop features, and multi-functionality (e.g., inflating sports equipment) are becoming standard in portable air compressors. This evolution is influencing buyers’ preferences, as they seek products that combine ease of use with enhanced functionality. Additionally, the rise of e-commerce platforms enables international B2B buyers to access a broader range of products, facilitating competitive pricing and better sourcing opportunities.

Another notable trend is the increasing emphasis on safety and reliability. As consumers become more aware of the potential hazards associated with improper tire inflation, they are opting for compressors that prioritize safety features. This shift presents an opportunity for suppliers to highlight the advanced safety mechanisms of their products, thereby appealing to the growing base of safety-conscious consumers.

Sustainability is becoming a focal point for B2B buyers in the portable air compressor market. As environmental concerns rise globally, companies are under pressure to adopt sustainable practices throughout their supply chains. For portable air compressors, this means sourcing components from suppliers that utilize eco-friendly materials and processes. Buyers are increasingly looking for products that have received green certifications, indicating compliance with environmental standards.

Illustrative image related to autozone portable air compressor

The importance of ethical sourcing cannot be overstated. B2B buyers are prioritizing suppliers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices are ethical. Brands that can provide documentation of their sustainable practices and certifications are likely to stand out in a competitive marketplace.

Moreover, innovation in materials is influencing purchasing decisions. For instance, manufacturers are exploring the use of recyclable plastics and energy-efficient components in their compressors. By aligning product offerings with eco-friendly practices, suppliers can not only appeal to the growing demographic of environmentally conscious buyers but also potentially reduce costs associated with waste and inefficiency.

The portable air compressor market has evolved significantly over the last few decades. Initially, these devices were primarily utilized in industrial settings, but advancements in technology and design have transformed them into essential tools for everyday consumers. The introduction of lightweight, compact models has made it possible for individuals to carry these devices in their vehicles, facilitating easy access during emergencies.

In recent years, the market has shifted towards greater functionality and user-friendliness. Features such as built-in LED lights for nighttime use and integrated digital gauges have become commonplace, catering to the needs of modern consumers. As automotive technology continues to advance, portable air compressors are expected to incorporate even more sophisticated features, further cementing their place in the toolkit of both DIY enthusiasts and professionals alike.

This evolution reflects broader trends in consumer behavior, where convenience, safety, and sustainability are paramount. As the market continues to grow, suppliers who stay ahead of these trends will be better positioned to meet the needs of international B2B buyers.

Illustrative image related to autozone portable air compressor

How do I troubleshoot common issues with the AutoZone portable air compressor?

To troubleshoot issues with your portable air compressor, first check the power source to ensure it’s properly connected, whether to a 12V outlet or a battery. If the compressor is not inflating, inspect the air hose for kinks or blockages, and ensure the connection to the tire valve is secure. If overheating occurs, allow the compressor to cool down between uses. If problems persist, consult the user manual for specific troubleshooting steps or consider contacting customer support for further assistance.

What is the best portable air compressor for international shipping?

When selecting a portable air compressor for international shipping, consider factors such as size, weight, and energy source. The Slime 12-volt tire inflator is popular due to its compact design and efficiency, inflating a standard tire in about eight minutes. Ensure the compressor complies with international safety and electrical standards, as well as shipping regulations in your target market. Additionally, assess the availability of replacement parts and service support in your region to ensure long-term usability.

What are the minimum order quantities (MOQ) for purchasing AutoZone portable air compressors?

Minimum order quantities (MOQ) for AutoZone portable air compressors can vary based on the supplier and specific product line. Generally, for bulk purchases, suppliers may set an MOQ ranging from 50 to 100 units to ensure cost-effectiveness. It’s advisable to discuss your requirements with the supplier to negotiate favorable terms, especially if you are looking to enter a new market or test demand with a smaller initial order.

What payment terms should I expect when sourcing portable air compressors?

Payment terms for sourcing portable air compressors typically involve a combination of upfront deposits and final payments upon delivery. Common practices include a 30% deposit to secure the order, with the balance due before shipping or upon receipt of the goods. For international transactions, be prepared for additional considerations such as currency exchange, wire transfer fees, and potential escrow services to protect both parties involved in the transaction.

How can I verify the quality assurance processes of my supplier?

To verify the quality assurance (QA) processes of your supplier, request documentation of their quality control standards and certifications, such as ISO 9001. Conducting an on-site audit or inspection can provide deeper insights into their manufacturing practices. Additionally, consider reviewing customer feedback and product reviews to gauge the reliability of their products. Engaging a third-party inspection service can also help ensure that the products meet your specifications before shipment.

What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider logistics factors such as shipping methods, customs clearance, and local regulations. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your timeline and budget. Ensure compliance with import duties and taxes, and prepare all necessary documentation for customs. Partnering with a reliable freight forwarder can streamline the logistics process and help you navigate potential challenges.

Can I customize the features of the portable air compressor for my business needs?

Yes, many suppliers offer customization options for portable air compressors, allowing you to tailor features such as pressure capacity, design, and branding. Discuss your specific requirements with the supplier to understand the feasibility of customizations and any associated costs. Customization can enhance your brand visibility and ensure that the product aligns with the unique needs of your target market.

What accessories should I consider when purchasing a portable air compressor?

When purchasing a portable air compressor, consider essential accessories that enhance its functionality, such as a tire pressure gauge, additional air hose extensions, and adapters for various tire valves. A carrying case can also be beneficial for portability. Some models come with built-in LED lights for nighttime use, which can be advantageous for roadside assistance scenarios. Assess your specific operational needs to select accessories that will improve the overall utility of the compressor.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Portable tire inflator recommendations sought. Key criteria include: price under $65, powered by cigarette lighter with a preference for a wall plug, no battery operation, fast inflation speed, ability to inflate to at least 65 PSI, and no need for a light on the device.

The strategic sourcing of AutoZone’s portable air compressors presents a compelling opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By understanding the diverse features and types of portable tire inflators available, businesses can select products that align with their operational needs and customer preferences. The ability to provide a compact, efficient solution for tire maintenance not only enhances customer satisfaction but also reduces the dependency on costly roadside assistance services.

Investing in quality portable air compressors, such as those offered by AutoZone, ensures reliability and performance, factors crucial in markets where roadside assistance may be limited. As global demand for automotive accessories grows, strategic sourcing can position your business advantageously, allowing you to tap into emerging markets and cater to the increasing need for vehicle upkeep.

Looking ahead, we encourage international B2B buyers to explore partnerships with reputable suppliers like AutoZone. By leveraging strategic sourcing, your business can enhance product offerings, streamline operations, and ultimately drive profitability in a competitive landscape. Take the next step in securing your supply chain and expand your market presence with high-quality portable air compressors today.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.