In today’s fast-paced global economy, sourcing small air compressors portable enough to meet diverse operational needs can present a significant challenge for international B2B buyers. Whether you’re in Nigeria, Germany, or Brazil, the pressure to find reliable and efficient equipment that suits various applications—from automotive maintenance to construction tasks—can be daunting. This guide is designed to simplify that process by providing a comprehensive overview of the types of small portable air compressors available, their applications, and essential considerations for supplier vetting.

Navigating the nuances of international procurement requires an understanding of local market dynamics, product specifications, and cost-effectiveness. Our guide delves into the key aspects of small air compressors, highlighting factors such as performance metrics, energy efficiency, and durability. Additionally, it addresses the importance of aligning your purchasing decisions with local regulations and supplier reliability, ensuring you make informed choices that enhance your operational efficiency.

By equipping B2B buyers with actionable insights and practical strategies, this resource empowers you to confidently navigate the global market for portable air compressors. From understanding the latest technological advancements to assessing the best suppliers, our guide aims to facilitate a seamless purchasing experience that meets your business needs, no matter where you operate.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Pfannkuchen-Kompressoren | Compact, lightweight, quick recovery time | Automotive repair, small workshops | Vorteile: Easy to transport, stable base. Nachteile: Limited air volume for larger tasks. |

| Hot-Dog-Kompressoren | Long, cylindrical tank, often quieter | Home improvement, light industrial use | Vorteile: Quiet operation, portable. Nachteile: Less durable than other types. |

| Portable Electric Compressors | Versatile, can be used indoors or outdoors, runs on standard outlets | General construction, maintenance tasks | Vorteile: Easy to use, reliable power source. Nachteile: Dependent on electricity. |

| Cordless Battery-Powered Compressors | Rechargeable, highly portable, no cords | Fieldwork, remote locations | Vorteile: Maximum portability, no power source needed. Nachteile: Limited run time, charging time required. |

| Heavy-Duty Portable Compressors | Higher CFM ratings, robust construction | Heavy machinery, commercial applications | Vorteile: Powerful, suitable for demanding tasks. Nachteile: Heavier, less portable. |

Pancake compressors are characterized by their compact, round tanks that provide stability and quick recovery times. These units are particularly suited for automotive repair shops and small workshops where space is at a premium. B2B buyers should consider the air delivery rate (CFM) to ensure it meets their specific requirements for tire inflation or powering pneumatic tools. While they are easy to transport, their air volume may limit their use in larger applications.

Hot dog compressors, with their elongated cylindrical tanks, are typically quieter than their pancake counterparts. This makes them ideal for home improvement projects and light industrial applications where noise levels are a concern. B2B buyers looking for a portable solution that doesn’t compromise on noise should consider these models. However, it’s essential to assess their durability as they may not withstand heavy use over time.

Portable electric compressors are versatile units that can be utilized both indoors and outdoors, making them a popular choice for general construction and maintenance tasks. They operate on standard electrical outlets, providing a reliable power source. Buyers should evaluate the unit’s weight and portability, especially if it will be moved frequently between job sites. While they are easy to operate, their reliance on electricity can be a drawback in remote areas without power access.

Cordless battery-powered compressors offer unparalleled portability, allowing for use in remote locations without needing a power source. These compressors are ideal for fieldwork and jobs that require mobility, such as landscaping or outdoor maintenance. B2B buyers should be aware of the limited run time and potential charging requirements, making it crucial to have backup batteries for extended tasks.

Heavy-duty portable compressors are designed for demanding applications, featuring higher CFM ratings and robust construction. They are well-suited for industries that require powering heavy machinery or performing commercial tasks. Buyers should consider their weight and portability, as these units can be more cumbersome to transport. However, their powerful performance makes them a worthwhile investment for businesses that need reliability and efficiency in their air compression needs.

| Industrie/Sektor | Specific Application of small air compressor portable | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | Reifendruck und Wartung | Ensures vehicle safety and optimal performance | Look for models with high PSI capacity and portability |

| Bauwesen | Operating pneumatic tools | Enhances productivity and efficiency on job sites | Consider durability and power source options (AC/DC) |

| Landwirtschaft | Sprühen und Bewässerung von Kulturpflanzen | Improves efficiency in farm operations and yields | Evaluate compatibility with various spray systems |

| HVAC/R | Pressure testing and refrigerant recovery | Ensures system integrity and efficiency | Check for specific pressure requirements for HVAC work |

| Erholung im Freien | Inflating sports equipment and camping gear | Increases convenience and enhances outdoor experiences | Look for lightweight and battery-operated options |

In the automotive sector, small portable air compressors are invaluable for tire inflation and maintenance. They enable quick inflation of tires, ensuring optimal pressure for safety and performance. This application is especially critical in regions where road conditions can vary dramatically, such as in Nigeria or rural areas in South America. Buyers should prioritize compressors with high PSI capacities and features like automatic shut-off to enhance usability and safety.

Portable air compressors are essential on construction sites for operating pneumatic tools such as nail guns and impact wrenches. Their compact size and portability facilitate easy transport between job sites, significantly improving productivity. In the Middle East, where construction projects are often extensive and varied, the ability to quickly set up and use these compressors can lead to substantial time and cost savings. Buyers should consider durability and the power source (AC or DC) to match their specific site requirements.

In agriculture, small portable air compressors are commonly used for crop spraying and irrigation systems. They allow farmers to efficiently manage their resources and improve crop yields through precise application of fertilizers and pesticides. In regions like South America, where farming practices can greatly influence economic outcomes, having reliable and efficient spraying equipment is critical. Buyers should evaluate compatibility with existing systems and the compressor’s ability to handle different spray pressures.

For HVAC/R professionals, small portable air compressors are vital for pressure testing and refrigerant recovery. They help ensure system integrity and efficiency, which is crucial in maintaining comfortable indoor environments. In European markets, where regulations around energy efficiency are stringent, the ability to quickly and accurately test systems can be a significant competitive advantage. Buyers should check for specific pressure requirements and the compressor’s ability to handle refrigerants safely.

Outdoor enthusiasts benefit from small portable air compressors for inflating sports equipment, such as balls and camping gear. Their lightweight and often battery-operated designs make them convenient for activities like camping or hiking. In regions with vast outdoor spaces, such as parts of Africa and Europe, these compressors enhance the overall outdoor experience by ensuring that equipment is ready for use at a moment’s notice. Buyers should focus on models that offer both performance and portability for ease of use.

Das Problem: For many B2B buyers in regions with unreliable electricity, using a small portable air compressor can lead to significant challenges. Inconsistent power supply can cause compressors to underperform, leading to incomplete tasks such as tire inflation or tool operation. This can delay projects, frustrate workers, and ultimately increase operational costs. Buyers often find themselves in situations where they need to use their compressors on the go, but without a stable power source, their investment becomes less effective.

Die Lösung: To mitigate this issue, B2B buyers should consider sourcing dual-power portable air compressors that can operate on both AC and DC power. This versatility allows for use in various environments, whether connected to a standard outlet or a vehicle’s battery. When selecting a compressor, look for models that include features like an automatic shut-off function and built-in battery indicators. These features not only enhance usability but also ensure that the compressor maintains optimal performance regardless of the power source. Furthermore, consider investing in portable power stations or solar generators, which can provide a reliable power supply in remote areas. This approach ensures that your operations remain seamless, regardless of the local power situation.

Das Problem: Another common pain point for buyers is the limited air pressure and flow rate of small portable air compressors. Many businesses require specific air pressure for tasks such as pneumatic tool operation, tire inflation, or spray painting. A compressor that cannot deliver the necessary PSI (pounds per square inch) or CFM (cubic feet per minute) can lead to downtime and unmet production targets. Buyers often experience frustration when their chosen compressor cannot meet the demands of their applications, especially in sectors like automotive repair or construction.

Die Lösung: To address this, buyers should conduct a thorough assessment of their air consumption requirements before purchasing a compressor. Identify the specific tools and applications that will be used and calculate the required PSI and CFM. When selecting a portable air compressor, prioritize models that offer adjustable pressure settings and sufficient airflow. Many modern compressors come equipped with gauges and regulators that allow users to fine-tune their output. Additionally, consider compressors with a higher CFM rating to ensure they can handle multiple tools simultaneously. This proactive approach to specification not only enhances efficiency but also prevents operational bottlenecks.

Das Problem: For businesses that need to transport their equipment frequently—such as those in landscaping, maintenance, or remote construction—weight and portability are critical factors. Heavy or bulky compressors can be cumbersome to move, leading to inefficiencies and increased labor costs. Buyers often find themselves stuck with equipment that is not designed for easy transport, resulting in wasted time and effort, especially when dealing with tight project timelines.

Die Lösung: Buyers should prioritize lightweight and compact designs when selecting a small portable air compressor. Look for models that feature ergonomic handles and wheels for easy maneuverability. Additionally, consider compressors that offer collapsible or compact storage options. Investing in models specifically designed for portability—such as those with battery-powered options—can greatly enhance flexibility on the job site. When making a purchase, also check user reviews and specifications regarding weight and size to ensure they meet your transportation needs. By choosing the right compressor, businesses can improve productivity and reduce the physical strain on workers, ultimately leading to better operational outcomes.

When selecting materials for small portable air compressors, various factors such as performance, durability, and cost-effectiveness come into play. Understanding the properties, advantages, and limitations of common materials can help international B2B buyers make informed decisions.

Aluminum is widely used in the construction of portable air compressors due to its lightweight nature and excellent corrosion resistance. With a temperature rating of up to 150°C (302°F) and a pressure rating that can exceed 200 PSI, aluminum is suitable for various applications.

Vorteile: Its lightweight characteristic enhances portability, making it ideal for mobile applications. Additionally, aluminum’s resistance to corrosion extends the lifespan of the compressor, particularly in humid or coastal environments.

Nachteile: While aluminum is generally durable, it can be prone to dents and scratches, which may affect its aesthetic and structural integrity over time. The manufacturing process can also be more complex, leading to higher production costs.

Auswirkungen auf die Anwendung: Aluminum is compatible with a wide range of media, including air and non-corrosive gases, making it versatile for different industries.

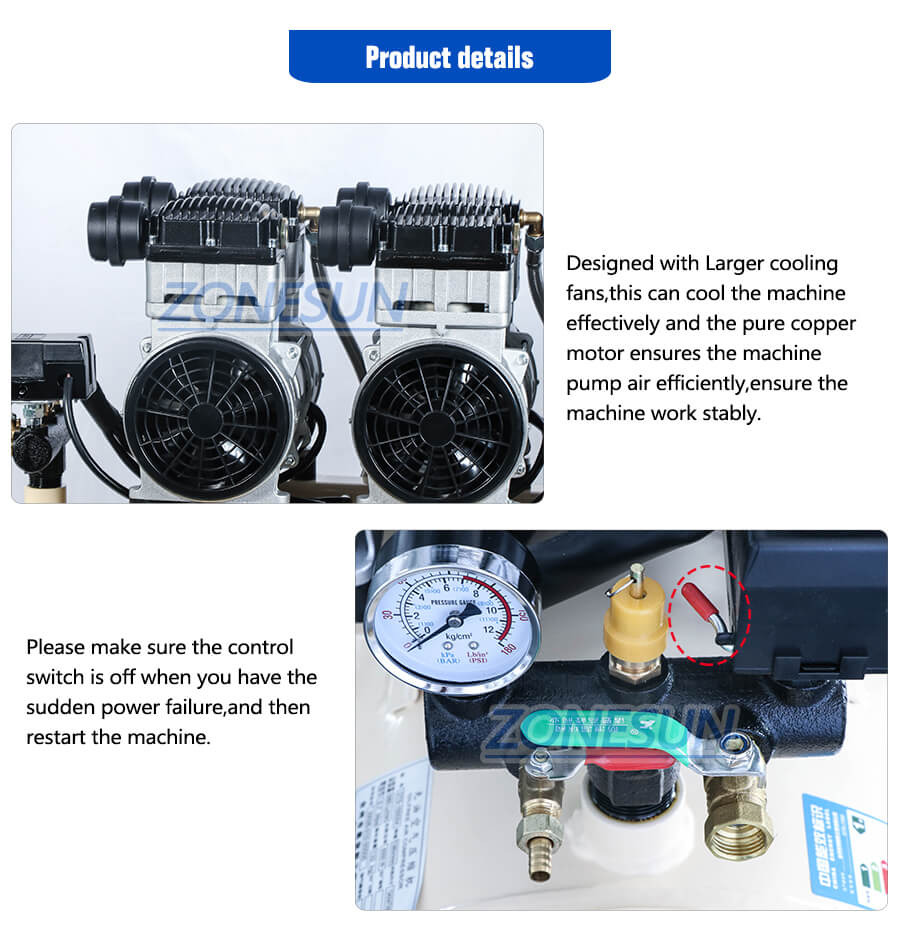

Illustrative image related to small air compressor portable

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe may prefer aluminum for its lightweight properties, while those in Africa and South America may consider cost-effectiveness as a priority.

Steel is another common material used in portable air compressors, particularly in the tank and frame constructions. It boasts a high-temperature rating of around 250°C (482°F) and can handle pressures exceeding 300 PSI.

Vorteile: Steel’s durability makes it ideal for heavy-duty applications. It is generally more cost-effective than aluminum, making it a popular choice for budget-conscious buyers.

Nachteile: However, steel is heavier than aluminum, which may hinder portability. Additionally, it is susceptible to rust and corrosion unless properly treated or coated.

Auswirkungen auf die Anwendung: Steel is suitable for air and other non-corrosive media. Its robustness makes it ideal for industrial applications where durability is paramount.

Überlegungen für internationale Käufer: Buyers in the Middle East may favor steel for its strength, while European buyers may prioritize compliance with environmental standards regarding emissions and noise.

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly being used in portable air compressors, especially in components like housing and covers. These materials can withstand temperatures up to 80°C (176°F) and moderate pressures.

Vorteile: Plastic is lightweight and resistant to corrosion, making it suitable for outdoor applications. It can also be molded into complex shapes, allowing for innovative designs.

Nachteile: While plastic is cost-effective, it may not be suitable for high-pressure applications due to its lower strength compared to metals. Additionally, its durability can be compromised under extreme temperatures.

Auswirkungen auf die Anwendung: Plastic is mainly used for non-pressurized components and is compatible with air and non-corrosive gases.

Überlegungen für internationale Käufer: Buyers from regions like Africa may appreciate the low cost and lightweight nature of plastic components, while European buyers may focus on recyclability and compliance with environmental standards.

Illustrative image related to small air compressor portable

Composite materials, such as fiberglass-reinforced plastics, are gaining traction in portable air compressor manufacturing. They can handle temperatures up to 120°C (248°F) and moderate pressures.

Vorteile: Composites are lightweight and offer excellent resistance to corrosion and environmental factors. They also allow for greater design flexibility.

Nachteile: The manufacturing process can be complex and costly, making composites more expensive than traditional materials. Additionally, their long-term durability under high stress is still under evaluation.

Auswirkungen auf die Anwendung: Composites are ideal for applications requiring lightweight solutions without compromising on strength.

Überlegungen für internationale Käufer: Buyers in advanced markets like Germany may be more inclined to invest in composite materials for their innovative properties, while buyers in developing regions might prioritize cost over advanced material technology.

| Material | Typical Use Case for small air compressor portable | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Lightweight portable compressors | Excellent corrosion resistance | Anfällig für Dellen und Kratzer | Mittel |

| Stahl | Heavy-duty industrial compressors | High durability and strength | Schwerer und anfällig für Rost | Niedrig |

| Kunststoff | Non-pressurized components in compressors | Leicht und kostengünstig | Lower strength under pressure | Niedrig |

| Komposit | Innovative designs in portable compressors | Excellent corrosion resistance | Higher manufacturing costs | Hoch |

This guide provides a comprehensive overview of material selection for small portable air compressors, assisting B2B buyers in making informed decisions based on their specific regional requirements and applications.

The manufacturing process of portable small air compressors typically involves several key stages, each critical to ensuring a high-quality final product.

The first step involves sourcing high-quality materials, including metals, plastics, and rubber. Manufacturers often utilize aluminum for the compressor tank due to its lightweight and corrosion-resistant properties. Steel is commonly used for structural components due to its strength. Quality assurance begins with incoming material inspections, where suppliers are evaluated for compliance with international standards such as ISO 9001. This ensures that the materials meet specific performance criteria before they enter the production line.

Once materials are prepared, they undergo forming processes. This can include casting, machining, and welding. For instance, compressor tanks may be manufactured through aluminum casting, while other components may be precision-machined to achieve the necessary tolerances. Advanced techniques like CNC (Computer Numerical Control) machining are often employed to ensure consistency and precision, which is crucial for the efficient operation of the compressor.

The assembly phase brings together all the components. This includes the installation of the motor, pump, and various control systems. Automation in assembly lines helps reduce human error, but many manufacturers still employ skilled labor to oversee critical assembly tasks. Quality control checkpoints, such as in-process quality checks (IPQC), are established to monitor the assembly process, ensuring each component is correctly fitted and operational.

After assembly, compressors undergo finishing processes that may include painting, polishing, and protective coating. These finishes not only enhance the aesthetic appeal but also provide protection against environmental factors. Manufacturers often conduct final quality checks (FQC) to ensure that the product meets all specifications before it is packaged and shipped. This stage may also include performance testing to validate the compressor’s operational efficiency and safety standards.

Illustrative image related to small air compressor portable

Quality assurance (QA) in the manufacturing of portable small air compressors is paramount, particularly for international B2B buyers who may have specific compliance requirements.

Manufacturers typically adhere to several international standards, including:

Quality control checkpoints are essential throughout the manufacturing process. These include:

Several testing methods are employed to ensure the quality and performance of portable air compressors. These methods may include:

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure product reliability. Here are some effective strategies:

Illustrative image related to small air compressor portable

Conducting supplier audits is a direct way to assess a manufacturer’s adherence to quality standards. Buyers can request access to quality management system documentation, production processes, and employee training records.

Manufacturers should provide quality reports that detail inspection results and compliance with international standards. These documents should be available upon request and should cover various quality control checkpoints.

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These inspections can be conducted at various stages of production and can assure buyers of compliance with agreed-upon specifications.

International B2B buyers should be aware of specific nuances when dealing with quality control:

By understanding the manufacturing processes and quality assurance measures for portable small air compressors, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality and performance expectations.

Procuring a portable small air compressor involves careful consideration of various factors that can significantly impact performance and usability. This guide provides a step-by-step checklist designed to help B2B buyers navigate the sourcing process effectively, ensuring they select the right equipment for their needs.

Illustrative image related to small air compressor portable

Establishing clear technical specifications is crucial to ensure the air compressor meets your operational requirements. Consider factors such as the required PSI (pounds per square inch), CFM (cubic feet per minute), and tank size. These specifications will guide you in selecting a model that can efficiently handle your tasks, whether it’s inflating tires or powering pneumatic tools.

Understanding current market trends is vital for making informed purchasing decisions. Investigate how portable air compressors are being utilized across different industries in your target regions, such as construction, automotive, or agriculture. This knowledge can help identify specific features that are in demand, such as portability, energy efficiency, or noise levels.

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies that demonstrate their experience in the market. It’s also beneficial to seek references from other businesses in similar sectors to gauge the supplier’s reliability and product quality.

Ensure that the air compressors meet relevant industry standards and regulations, especially if you’re sourcing from international suppliers. Look for certifications such as ISO, CE, or local compliance marks relevant to your region. Compliance not only assures product quality but can also mitigate legal risks associated with non-compliant equipment.

A robust warranty and reliable after-sales support are essential for minimizing downtime and maintenance costs. Check the warranty period and what it covers, including parts and labor. Additionally, inquire about the availability of spare parts and the supplier’s response time for service requests, which can be critical for ongoing operations.

Whenever possible, request samples or arrange for demonstrations of the air compressors you are considering. This hands-on evaluation allows you to assess the build quality, ease of use, and overall performance in real-world conditions. It also provides an opportunity to clarify any technical questions with the supplier.

Finally, engage in negotiations to secure favorable pricing and payment terms. Be transparent about your budget constraints while also discussing volume discounts if you plan to make bulk purchases. Understanding the total cost of ownership, including shipping and potential tariffs, is crucial for accurate budgeting.

By following this checklist, B2B buyers can navigate the complexities of sourcing portable small air compressors with confidence, ensuring that they make informed decisions that meet their operational needs.

Illustrative image related to small air compressor portable

When sourcing portable small air compressors, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materialien: The choice of materials significantly impacts the cost. High-quality components, such as durable motors and corrosion-resistant tanks, typically increase the price. Buyers should evaluate whether the additional cost correlates with the expected lifespan and performance of the product.

Arbeit: Labor costs vary depending on the manufacturing location. Countries with higher labor costs may yield higher prices. Understanding the labor market in the supplier’s region can help in anticipating pricing.

Fertigungsgemeinkosten: This includes costs associated with factory operations, including utilities and maintenance. Efficient factories may offer lower prices, while those with high overheads might pass these costs onto buyers.

Werkzeugbau: Initial tooling costs can be significant, especially for customized or complex designs. Buyers should consider how tooling costs are amortized across production runs, as larger orders typically reduce per-unit costs.

Qualitätskontrolle (QC): Investing in rigorous QC processes ensures product reliability but can also add to costs. Buyers should assess the supplier’s QC standards and how they impact overall pricing.

Logistik: Shipping costs can vary widely depending on distance, mode of transport, and Incoterms. Understanding these logistics can help buyers manage total costs effectively.

Marge: The supplier’s profit margin is influenced by market competition and brand positioning. Buyers should be aware of typical margins in the industry to gauge whether a quoted price is fair.

Several factors can influence the pricing of portable small air compressors:

Volumen/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders may lead to discounts, while smaller quantities might incur higher per-unit costs.

Spezifikationen und Anpassungen: Custom features or specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

Materialien und Qualitätszertifikate: Products made with superior materials or those that meet specific quality certifications (such as ISO standards) generally command higher prices. Buyers should weigh the benefits of these certifications against their budget constraints.

Lieferanten-Faktoren: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

Incoterms: The agreed-upon Incoterms can influence the total landed cost. For instance, terms like CIF (Cost, Insurance, and Freight) include shipping costs, while EXW (Ex Works) places the shipping burden on the buyer.

Negotiating effectively can lead to better pricing and terms for portable small air compressors. Here are key strategies:

Research and Benchmarking: Understand the market landscape and typical pricing for similar products. This knowledge equips buyers to negotiate from a position of strength.

Beziehungen aufbauen: Establishing a good rapport with suppliers can lead to more favorable terms. Suppliers may be more willing to offer discounts or flexible payment terms to trusted partners.

Konzentration auf die Gesamtbetriebskosten (TCO): Highlighting the long-term cost benefits of higher-quality compressors can justify a higher upfront price. For instance, a more efficient compressor may save on energy costs over time.

Be Clear About Requirements: Clearly communicating specifications and quantities can streamline negotiations and avoid misunderstandings that lead to extra costs.

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique pricing challenges:

Currency Fluctuations: Exchange rates can impact costs, especially if payments are made in different currencies. Locking in exchange rates or negotiating prices in a stable currency can mitigate risks.

Import Duties and Tariffs: Understanding local import regulations and associated costs is vital. These additional expenses can significantly affect the total price paid.

Cultural Differences in Negotiation Styles: Different regions may have distinct negotiation norms. Familiarizing oneself with these cultural nuances can enhance communication and lead to better deals.

Prices for portable small air compressors can vary widely based on the factors discussed above. The information provided serves as a guideline and should not be considered definitive. Buyers are encouraged to conduct thorough market research and engage with multiple suppliers to obtain accurate pricing tailored to their specific needs.

In the realm of air compression, portable small air compressors are often favored for their versatility and convenience. However, various alternative solutions exist that can fulfill similar functions, such as inflating tires, powering pneumatic tools, or operating in remote locations. Understanding these alternatives is crucial for B2B buyers who need to evaluate which technology best aligns with their operational requirements, budget constraints, and maintenance capabilities.

| Vergleich Aspekt | Small Air Compressor Portable | Tire Inflator (12V/AC) | CO2 Tank System |

|---|---|---|---|

| Leistung | Up to 150 PSI, versatile use | 100 PSI, limited to tires | High pressure, rapid inflation |

| Kosten | Moderate ($100-$500) | Low ($30-$100) | High initial cost ($200+) |

| Leichte Implementierung | Simple setup, user-friendly | Plug-and-play | Requires installation and refills |

| Wartung | Low maintenance, oil-free models available | Minimal maintenance | Regular refilling and checking required |

| Bester Anwendungsfall | General use, multiple applications | Tire inflation, small jobs | High-demand applications, commercial use |

Tire inflators are compact, lightweight devices that can easily connect to a vehicle’s power source or home AC outlet. They are primarily designed for inflating tires and are user-friendly, often featuring automatic shut-off functions to prevent over-inflation. The cost is significantly lower than that of a portable air compressor, making it an attractive option for budget-conscious buyers. However, their performance is limited to lower pressure applications and they lack the versatility required for powering pneumatic tools or heavy-duty tasks.

A CO2 tank system provides a high-pressure solution for tasks that require quick inflation and consistent power. These systems can rapidly inflate tires and operate air-powered tools, making them suitable for commercial applications or environments with high demand. However, the initial investment is substantial, and ongoing maintenance involves regularly refilling the CO2 tank, which can be a logistical challenge. This option is ideal for businesses that require fast and reliable performance but may not be practical for smaller operations or occasional use.

When selecting an air compression solution, B2B buyers should carefully assess their operational needs, budget, and maintenance capabilities. Small air compressors are versatile and suitable for a range of applications, while tire inflators are cost-effective for basic tasks, and CO2 tank systems offer high performance for demanding environments. By weighing the advantages and disadvantages of each option, businesses can make informed decisions that enhance their operational efficiency and meet their specific requirements.

Illustrative image related to small air compressor portable

When evaluating portable small air compressors, several technical specifications are crucial for decision-making in B2B environments. Understanding these properties can enhance procurement efficiency and ensure the selection of equipment that meets operational requirements.

PSI (Pounds per Square Inch)

PSI measures the air pressure generated by the compressor. Most portable compressors range from 90 to 150 PSI, depending on their intended use. For businesses, selecting a compressor with the appropriate PSI is essential for achieving optimal performance in tasks such as inflating tires or powering pneumatic tools. Higher PSI ratings often correlate with faster inflation times and better tool performance.

CFM (Cubic Feet per Minute)

CFM indicates the volume of air the compressor can deliver at a given pressure. This specification is vital for determining the compressor’s capability to run specific tools simultaneously. A higher CFM rating allows for more substantial air supply, which is particularly important in industrial applications where multiple tools may be in use. Businesses must match the CFM rating to their operational needs to avoid inefficiencies.

Tank Size (Gallons)

The tank size of a portable air compressor influences how much compressed air is stored for immediate use. Smaller tanks (1-4 gallons) are generally more portable but require frequent cycling, while larger tanks (5 gallons and above) can store more air and sustain longer tool usage without interruption. For B2B buyers, selecting the right tank size is critical to balancing portability with productivity.

Motor Type and Power Rating

The motor type (direct drive vs. belt drive) and power rating (measured in horsepower) impact the compressor’s efficiency, noise level, and longevity. Direct drive motors are often lighter and more compact but may be noisier, while belt-driven models typically offer greater durability and quieter operation. Understanding these characteristics helps businesses choose compressors that align with their work environments and noise regulations.

Gewicht und Tragbarkeit

The weight of portable air compressors can significantly affect mobility, especially for fieldwork. Compressors typically range from under 20 pounds to over 100 pounds. For B2B buyers, considering the weight is essential for ensuring ease of transport without compromising on performance.

Familiarity with industry jargon is crucial for successful negotiations and transactions in the portable air compressor market. Here are some common terms that B2B buyers should know:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of air compressors, understanding OEM relationships can help businesses identify reputable suppliers and quality products that meet industry standards.

MOQ (Mindestbestellmenge)

MOQ is the smallest number of units a supplier is willing to sell. This term is particularly important for businesses looking to negotiate bulk purchases or those with specific budget constraints. Knowing the MOQ can help B2B buyers plan their inventory and procurement strategies effectively.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ is a strategic way to compare pricing and ensure they are getting the best deal for their air compressor needs.

Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping, insurance, and tariffs. For businesses purchasing portable air compressors from overseas suppliers, understanding Incoterms is critical to avoid unexpected costs and delays.

Warranty and Service Agreements

These are contractual commitments from the manufacturer regarding the repair or replacement of defective parts. A solid warranty can provide peace of mind and is an essential consideration for B2B buyers investing in portable air compressors.

In conclusion, understanding both the technical properties and industry terminology related to portable small air compressors can empower B2B buyers to make informed decisions, ensuring they select the right equipment for their operational needs while navigating the complexities of procurement.

Illustrative image related to small air compressor portable

The small air compressor portable market is experiencing robust growth driven by several global factors. Firstly, the increasing demand for portable power solutions across various industries, including automotive, construction, and DIY sectors, is a significant driver. This trend is particularly pronounced in emerging markets such as Africa and South America, where infrastructure development is accelerating. Additionally, the rise in recreational activities, such as off-road biking and camping, further fuels the demand for compact and efficient air compressors.

Technological advancements also play a crucial role in shaping market dynamics. Innovations such as battery-operated compressors and digital tire inflators are becoming increasingly popular due to their convenience and efficiency. B2B buyers are now seeking products that offer enhanced portability, ease of use, and multi-functionality—such as the ability to inflate tires and power pneumatic tools. Moreover, the integration of smart technology, like automatic shut-off features and inflation progress indicators, is appealing to modern buyers looking for reliability and performance.

For international B2B buyers, understanding local market nuances is essential. In regions like Nigeria and Germany, preferences may vary significantly; Nigerian buyers may prioritize affordability and ruggedness, while German buyers might focus on energy efficiency and advanced features. Furthermore, the ongoing global supply chain challenges necessitate strategic sourcing partnerships that prioritize reliability and cost-effectiveness.

Sustainability is becoming a cornerstone of purchasing decisions in the B2B sector, and the small air compressor portable market is no exception. The environmental impact of manufacturing processes and product life cycles is under scrutiny, making it imperative for buyers to consider the sustainability credentials of their suppliers. The use of eco-friendly materials and practices not only reduces carbon footprints but also aligns with the growing consumer demand for responsible sourcing.

B2B buyers should seek suppliers who demonstrate a commitment to ethical supply chains, which includes transparency in sourcing materials and adhering to labor rights standards. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. Moreover, adopting energy-efficient technologies in product design can further enhance market appeal, especially in regions where energy costs are high or where sustainability regulations are tightening.

Incorporating sustainability into procurement strategies not only fosters goodwill among consumers but can also lead to cost savings in the long run. Products designed with longevity and efficiency in mind can reduce waste and lower operational costs, making them a more attractive option for businesses focused on both profitability and corporate responsibility.

The evolution of portable air compressors dates back to the early 20th century, initially designed for industrial applications. As technology advanced, the focus shifted towards creating lighter, more efficient units suitable for a broader range of uses. The introduction of electric and battery-powered models in the latter part of the century marked a significant turning point, making air compressors accessible for personal and recreational use.

In the 21st century, the market has continued to evolve with an emphasis on portability, convenience, and multi-functionality. The rise of e-commerce has also transformed how B2B buyers source small air compressors, allowing for a wider selection and easier access to global suppliers. As the market progresses, innovations continue to cater to the diverse needs of industries, further solidifying the role of portable air compressors as essential tools across various applications.

Wie wähle ich den richtigen tragbaren Luftkompressor für meine geschäftlichen Anforderungen aus?

Choosing the right portable air compressor involves assessing your specific applications and requirements. Consider factors like the compressor’s CFM (cubic feet per minute) rating, which indicates its airflow capacity, and PSI (pounds per square inch), which measures the pressure it can deliver. Additionally, evaluate the compressor’s weight, size, and power source (electric or gas) based on your operational environment. Conducting a needs analysis will help you determine whether you need a lightweight model for easy transport or a heavy-duty option for more demanding tasks.

What are the common applications for small portable air compressors in B2B sectors?

Small portable air compressors are versatile tools used across various industries. They are ideal for inflating tires, powering pneumatic tools, and supporting maintenance tasks in automotive, construction, and manufacturing sectors. Additionally, they can be utilized for spraying paints and cleaning machinery. Understanding your industry’s specific needs will guide you in selecting a compressor that enhances productivity and efficiency.

What should I consider regarding Minimum Order Quantities (MOQs) when sourcing?

MOQs can vary significantly between suppliers and depend on factors like production capabilities and shipping logistics. When sourcing portable air compressors, inquire about the supplier’s MOQ and assess whether it aligns with your purchasing plans. If you anticipate needing multiple units over time, negotiating lower MOQs can be beneficial. Additionally, consider potential cost savings with larger orders, but ensure you have adequate storage and demand for the units.

How can I vet suppliers for portable air compressors?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching their business history, customer reviews, and industry reputation. Request references from previous clients and look for certifications that attest to their manufacturing standards. It’s also beneficial to visit the supplier’s facility if possible, or conduct video calls to inspect their operations. Establishing clear communication and understanding their production processes will further help in assessing their capability to meet your needs.

What payment terms are typically offered for international purchases?

Payment terms can vary widely based on supplier policies and your business relationship. Common options include upfront payment, partial payments (e.g., 30% deposit and 70% upon delivery), or letters of credit for larger transactions. Ensure to clarify the terms in your purchase agreement, including currency, payment methods (bank transfer, PayPal, etc.), and any applicable taxes or duties. Establishing favorable terms can improve cash flow while ensuring supplier accountability.

What quality assurance measures should I expect from suppliers?

Quality assurance (QA) is essential in ensuring that portable air compressors meet industry standards. Reputable suppliers should provide documentation of their QA processes, which may include inspections, testing certifications, and compliance with international standards like ISO. Request samples before placing bulk orders to evaluate the product’s performance and reliability. Discuss any warranty or return policies to safeguard your investment against defects.

How do logistics and shipping impact the purchasing process?

Logistics play a critical role in the timely delivery of portable air compressors. Understand the shipping options available, including air freight for faster delivery or sea freight for cost-effective solutions. Discuss lead times with suppliers, as these can impact your project schedules. Be aware of customs regulations in your country, as they may affect shipping costs and delivery times. Proper planning and clear communication with your supplier can help mitigate potential delays.

Can I customize portable air compressors for my specific needs?

Many suppliers offer customization options for portable air compressors to better fit your business requirements. Customizations can include modifications in capacity, design, color, or additional features like pressure gauges or noise reduction technologies. When discussing custom orders, clearly outline your specifications and confirm any impacts on pricing and lead times. Collaborating with suppliers to create a tailored solution can enhance your operational efficiency and brand identity.

Bereich: jacosuperiorproducts.com

Registriert: 2014 (11 Jahre)

Einleitung: SmartPro™ Digital Tire Inflator – 100 PSI (12V DC) – $49.95 (was $79.99) – Ultra compact, powerful, and efficient portable air compressor pump designed for performance and reliability.

SmartPro 2.0™ AC/DC Digital Tire Inflator – 100 PSI (12V DC, 120V AC) – $69.95 (was $99.99) – Fast, powerful, quiet, and efficient with automatic shut-off and inflation progress bar.

TrailPro™ Heavy Duty Portabl…

In the competitive landscape of portable air compressors, strategic sourcing emerges as a critical driver for businesses looking to optimize their procurement processes. By focusing on quality, reliability, and performance, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can secure products that meet diverse operational needs—from automotive repairs to construction tasks. Leveraging partnerships with reputable manufacturers ensures access to innovative technologies and superior customer support, which are vital for sustaining long-term business relationships.

Illustrative image related to small air compressor portable

As the market continues to evolve, the demand for compact, efficient, and versatile air compressors is likely to increase. Buyers should remain proactive in exploring emerging trends, such as eco-friendly models and advanced digital features that enhance usability. The ability to adapt to these trends will not only improve operational efficiency but also provide a competitive edge.

Now is the time to invest in strategic sourcing initiatives that align with your business objectives. By prioritizing quality and supplier relationships, you can position your company to thrive in a rapidly changing marketplace. Engage with suppliers who demonstrate a commitment to innovation and customer satisfaction, ensuring your air compressor solutions are not only effective but also future-proof.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to small air compressor portable

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.