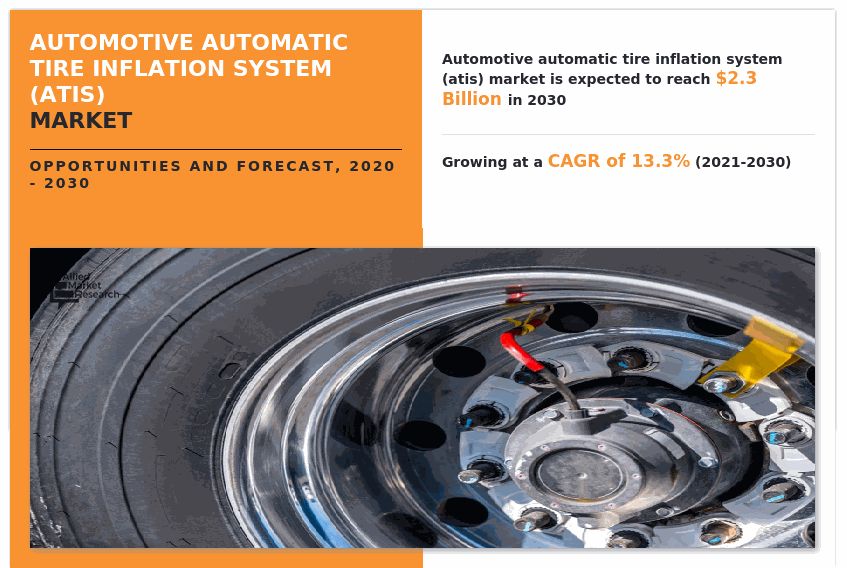

In today’s fast-paced logistics and transportation industries, sourcing an automatic tire inflation system has become a critical challenge for B2B buyers across the globe. As fleets expand and the demand for efficiency increases, maintaining optimal tire pressure is essential to ensure safety, enhance fuel efficiency, and reduce downtime. This comprehensive guide delves into the various types of automatic tire inflation systems available, their applications in diverse sectors, and the intricate process of vetting reliable suppliers.

Buyers will find detailed insights on the cost factors involved, installation requirements, and the long-term benefits of adopting these systems. Furthermore, the guide addresses specific considerations for international buyers from regions such as Africa, South America, the Middle East, and Europe—including market trends, regulatory compliance, and cultural nuances in procurement practices.

By leveraging the information in this guide, B2B buyers will be empowered to make informed purchasing decisions, ensuring they select a tire inflation solution that meets their operational needs while navigating the complexities of the global market. From understanding the features that enhance durability and ease of use to recognizing the importance of robust customer support and warranty options, this guide serves as a vital resource for companies aiming to optimize their fleet performance and operational efficiency.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Central Tire Inflation System | Automatically adjusts tire pressure via a centralized control unit. | Fleet management, logistics, transportation | Vorteile: Enhanced tire longevity; improved fuel efficiency. Nachteile: Higher initial investment; complex installation. |

| Onboard Air Compressor Systems | Portable compressors that connect directly to tires for inflation and deflation. | Off-road vehicles, emergency services | Vorteile: Versatile use; quick inflation/deflation. Nachteile: Dependent on compressor availability; limited by compressor capacity. |

| Automatic Tire Pressure Monitoring System (TPMS) | Monitors tire pressure and alerts drivers to deficiencies. | Automotive manufacturing, fleet operations | Vorteile: Prevents tire blowouts; enhances safety. Nachteile: Requires regular maintenance; potential false alerts. |

| Dual Air Source Inflation Systems | Connects to both onboard and portable compressors for flexibility. | Overlanding, outdoor recreational vehicles | Vorteile: Flexibility in air source; simultaneous inflation. Nachteile: Potential for increased complexity; may require more space for installation. |

| Smart Tire Management Systems | Integrates with telematics to provide real-time tire pressure data. | Logistics, transportation, fleet management | Vorteile: Data-driven insights; proactive maintenance. Nachteile: Higher cost; reliance on technology. |

Central Tire Inflation Systems (CTIS) are designed for fleet management and heavy-duty vehicles, allowing for automatic adjustments to tire pressure based on road conditions. This system enhances tire longevity and improves fuel efficiency, making it ideal for logistics and transportation companies. B2B buyers should consider the initial investment and installation complexity, as these systems often require professional setup.

Onboard Air Compressor Systems enable quick inflation and deflation of tires, making them a popular choice for off-road vehicles and emergency services. These systems are portable and can be used in various scenarios, providing versatility for buyers. However, businesses must consider the compressor’s capacity, as it can limit the efficiency of the inflation process.

Automatic Tire Pressure Monitoring Systems (TPMS) are essential for enhancing safety in fleet operations and automotive manufacturing. They continuously monitor tire pressure and alert drivers to deficiencies, which can prevent accidents due to tire blowouts. While TPMS significantly boosts safety, regular maintenance is necessary to ensure accuracy, and buyers should be mindful of the potential for false alerts.

Dual Air Source Inflation Systems are particularly beneficial for overlanding and outdoor recreational vehicles, as they provide the flexibility to connect to both onboard and portable compressors. This allows users to inflate multiple tires simultaneously, saving time during outdoor adventures. However, the complexity of the system and the space required for installation should be carefully evaluated by potential buyers.

Illustrative image related to automatic tire inflation system

Smart Tire Management Systems leverage telematics to provide real-time tire pressure data, making them invaluable for logistics and transportation sectors. These systems offer data-driven insights that enable proactive maintenance, ultimately reducing downtime and increasing operational efficiency. While they offer significant advantages, the higher cost and reliance on technology may pose challenges for some businesses in adopting this solution.

| Industrie/Sektor | Specific Application of Automatic Tire Inflation System | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Transport und Logistik | Fleet Management for Commercial Trucks | Reduces downtime and maintenance costs | Compatibility with existing fleet vehicles and ease of installation |

| Mining & Construction | Heavy Equipment Tire Management | Enhances safety and operational efficiency | Durability in harsh environments and support for high-pressure systems |

| Landwirtschaft | Agricultural Vehicle Tire Pressure Control | Increases productivity and reduces fuel consumption | Adaptability to various agricultural machinery and weather conditions |

| Automotive Manufacturing | Quality Control in Tire Production | Ensures consistent product quality | Precision in pressure management and compliance with industry standards |

| Off-Road & Recreational | Tire Management for Off-Road Vehicles | Improves performance and traction | Versatility for different terrains and ease of use during expeditions |

In the transportation and logistics sector, automatic tire inflation systems are pivotal for fleet management. They help maintain optimal tire pressure across commercial trucks, which directly impacts fuel efficiency and tire longevity. By reducing downtime due to tire-related issues, businesses can significantly decrease maintenance costs. For international buyers, compatibility with existing vehicles and the ease of installation are crucial factors when sourcing these systems.

In mining and construction, heavy equipment often operates under extreme conditions where tire pressure is critical for safety and efficiency. Automatic tire inflation systems ensure that tires remain at the correct pressure, thereby enhancing equipment performance and reducing the risk of blowouts. Buyers in these sectors should consider the durability of the systems in harsh environments and the ability to support high-pressure systems, which are essential for large machinery.

Agricultural vehicles require precise tire pressure control to optimize performance and reduce fuel consumption. Automatic tire inflation systems enable farmers to maintain the correct tire pressure, which can lead to increased productivity during planting and harvesting seasons. For buyers in regions with varying weather conditions, the adaptability of these systems to different agricultural machinery is a key consideration.

Illustrative image related to automatic tire inflation system

In automotive manufacturing, maintaining consistent tire pressure is essential for quality control during the production process. Automatic tire inflation systems ensure that each tire meets the required specifications, thereby enhancing overall product quality. Buyers need to focus on systems that offer precision in pressure management and compliance with industry standards to ensure their products meet regulatory requirements.

For off-road and recreational vehicles, automatic tire inflation systems are critical for managing tire pressure in varying terrains. These systems allow users to adjust tire pressure on-the-fly, improving traction and performance on rough surfaces. Buyers should look for versatile systems that can handle different terrains and are easy to operate, especially during expeditions where quick adjustments may be necessary.

Das Problem: B2B buyers managing fleets often face the challenge of inconsistent tire pressure across vehicles, which can significantly compromise safety and increase operational costs. Inadequate tire pressure can lead to tire blowouts, decreased fuel efficiency, and accelerated tire wear. This issue is particularly concerning for companies operating in regions with diverse road conditions, like Africa and South America, where the risk of tire-related accidents is heightened.

Illustrative image related to automatic tire inflation system

Die Lösung: To mitigate these risks, businesses should invest in automatic tire inflation systems equipped with predictive tire management technology. Such systems continuously monitor tire pressure and can automatically adjust it to optimal levels. When sourcing these systems, look for models that have undergone rigorous testing for durability in harsh environments, such as those used by Aperia Technologies. Additionally, prioritize systems that offer real-time monitoring capabilities and mobile alerts, enabling fleet managers to address issues proactively before they escalate. Implementing this technology not only enhances safety but also improves fuel efficiency and extends tire lifespan, leading to significant cost savings.

Das Problem: Many B2B buyers are deterred by the complexity associated with installing and maintaining automatic tire inflation systems. In particular, companies may struggle with systems that require specialized tools or extensive modifications to existing vehicles, causing delays in deployment and increasing installation costs. This is a significant concern for businesses that need to maintain operational efficiency without incurring additional downtime.

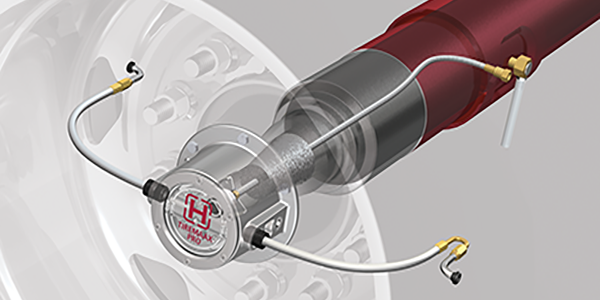

Die Lösung: To streamline the installation process, select automatic tire inflation systems designed for easy installation, such as those that can be fitted directly to the wheel hub without specialized tools. Systems like the Halo Tire Inflator from Aperia Technologies can be installed in as little as 5-10 minutes, making them ideal for fleets that cannot afford lengthy downtimes. When negotiating with suppliers, ask for detailed installation guidelines and training resources for your maintenance team. Furthermore, opt for systems that promise minimal maintenance and come with robust warranties, ensuring long-term reliability and reducing the need for frequent repairs or replacements.

Illustrative image related to automatic tire inflation system

Das Problem: B2B buyers often struggle with understanding the specifications and compatibility of automatic tire inflation systems, leading to poor purchasing decisions. This knowledge gap can result in selecting systems that do not fit the specific needs of their fleet or are incompatible with existing equipment, leading to wasted resources and operational inefficiencies.

Die Lösung: To avoid these pitfalls, it is crucial to conduct thorough research and engage with suppliers who can provide comprehensive product specifications and compatibility information. Before making a purchase, create a detailed list of your fleet’s requirements, including the types of vehicles, existing air systems, and operational conditions. Look for systems that offer dual air source compatibility, allowing for integration with both onboard compressors and portable pumps, as seen in products like the Overland Vehicle Systems Gen2 Air Delivery System. Additionally, consider suppliers that offer personalized consultations to help determine the best fit for your fleet. This approach not only ensures compatibility but also enhances operational effectiveness and reduces long-term costs.

When selecting materials for automatic tire inflation systems, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in the construction of these systems: aluminum, stainless steel, rubber, and composite materials.

Aluminum is widely used in automatic tire inflation systems due to its lightweight and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand pressures exceeding 200 psi, making it suitable for various applications.

Vorteile: Aluminum is durable and cost-effective, allowing for easy manufacturing and assembly. Its lightweight nature contributes to overall vehicle efficiency.

Nachteile: While aluminum is resistant to corrosion, it can be prone to fatigue over time, particularly in high-stress applications. Additionally, the initial cost may be higher than other materials.

Auswirkungen auf die Anwendung: Aluminum is compatible with air and nitrogen, making it ideal for tire inflation systems. However, it may not be suitable for systems exposed to extreme conditions without additional protective coatings.

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East may prefer aluminum for its lightweight properties, while those in Africa and South America may consider cost-effectiveness.

Stainless steel is another popular material choice due to its superior strength and corrosion resistance. It can handle high temperatures (up to 300°C) and pressures (up to 500 psi), making it suitable for demanding environments.

Vorteile: Stainless steel offers excellent durability and longevity, making it ideal for heavy-duty applications. Its resistance to rust and corrosion ensures a longer lifespan.

Nachteile: The primary drawback is the higher cost compared to aluminum and rubber. Additionally, stainless steel can be heavier, which may affect vehicle performance.

Auswirkungen auf die Anwendung: Stainless steel is highly compatible with various gases, including air and nitrogen, and is ideal for systems that require robust performance in harsh conditions.

Überlegungen für internationale Käufer: Buyers should ensure compliance with standards such as JIS and ASTM. In regions like Germany, the preference for stainless steel may be driven by its durability and reliability.

Illustrative image related to automatic tire inflation system

Rubber is commonly used for seals and hoses in automatic tire inflation systems due to its flexibility and resilience. It can withstand temperatures ranging from -30°C to 100°C and pressures around 150 psi.

Vorteile: Rubber is cost-effective and provides excellent sealing capabilities, preventing air leaks. Its flexibility allows for easy installation in various configurations.

Nachteile: Rubber can degrade over time, especially when exposed to UV light and extreme temperatures. It may also require regular maintenance to ensure optimal performance.

Illustrative image related to automatic tire inflation system

Auswirkungen auf die Anwendung: Rubber is compatible with air and nitrogen but may not be suitable for systems exposed to harsh chemicals or extreme conditions.

Überlegungen für internationale Käufer: Buyers should look for rubber materials that meet specific industry standards. In regions like Saudi Arabia, where temperatures can be extreme, selecting high-quality rubber is crucial.

Composite materials, such as reinforced plastics, are increasingly being used in tire inflation systems due to their lightweight and high strength. They can generally handle temperatures up to 120°C and pressures around 200 psi.

Vorteile: Composites offer excellent resistance to corrosion and chemicals, making them suitable for a variety of environments. Their lightweight nature contributes to overall vehicle efficiency.

Illustrative image related to automatic tire inflation system

Nachteile: The manufacturing process can be more complex and costly compared to traditional materials. Additionally, composites may not have the same longevity as metals in high-stress applications.

Auswirkungen auf die Anwendung: Composite materials are compatible with air and nitrogen and can be tailored for specific applications, providing flexibility in design.

Überlegungen für internationale Käufer: Compliance with international standards is essential, especially in regions with strict regulations. Buyers in Europe may prefer composites for their innovative properties, while those in Africa may weigh cost against performance.

| Material | Typical Use Case for Automatic Tire Inflation System | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Housings, valves, and connectors | Leicht und korrosionsbeständig | Prone to fatigue over time | Mittel |

| Rostfreier Stahl | Heavy-duty components and fittings | Superior strength and durability | Higher cost and weight | Hoch |

| Gummi | Dichtungen und Schläuche | Excellent sealing and flexibility | Verschlechtert sich mit der Zeit | Niedrig |

| Komposit | Lightweight structural components | Corrosion and chemical resistance | Komplexer Herstellungsprozess | Mittel |

This analysis provides B2B buyers with actionable insights into the material selection process for automatic tire inflation systems, ensuring informed decisions that align with their specific operational needs and regional considerations.

Manufacturing automatic tire inflation systems involves several critical stages that ensure the final product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

The manufacturing process begins with the careful selection of raw materials, which typically include high-grade plastics, metals, and rubber components. These materials are sourced from certified suppliers to ensure quality and compliance with international standards. The preparation phase includes cutting, treating, and inspecting materials for defects. Advanced techniques such as laser cutting and CNC machining may be employed to achieve precise dimensions and tolerances.

Forming techniques vary based on the materials and components being produced. Common methods include injection molding for plastic parts, stamping for metal components, and extrusion for hoses. Each technique is chosen based on the design requirements and expected durability of the finished parts. For instance, injection molding allows for complex shapes and is efficient for high-volume production, while stamping is ideal for producing flat metal parts with high accuracy.

The assembly stage is where individual components come together to form the complete system. This can involve manual assembly or automated processes, depending on the scale of production. During assembly, components such as valves, hoses, and electronic sensors are integrated. Ensuring proper alignment and secure connections is critical, as these factors directly impact the system’s performance and reliability. Assembly lines are often designed for efficiency, allowing for quick transitions between different models or configurations.

Illustrative image related to automatic tire inflation system

Quality assurance (QA) is integral to the manufacturing of automatic tire inflation systems. It involves systematic monitoring and evaluation of the manufacturing process to ensure compliance with established standards.

For B2B buyers, recognizing internationally accepted quality standards is crucial. ISO 9001 is a widely recognized standard that focuses on quality management systems. It emphasizes continuous improvement and customer satisfaction, making it essential for manufacturers aiming to export their products globally. Additionally, compliance with industry-specific certifications such as CE (for European markets) and API (for petroleum-related applications) can further assure buyers of the product’s quality and safety.

Quality control checkpoints are established throughout the manufacturing process to catch defects early and ensure that the final product meets specifications. These checkpoints typically include:

Illustrative image related to automatic tire inflation system

Eingehende Qualitätskontrolle (IQC): This involves inspecting raw materials upon delivery to verify they meet quality standards and specifications.

Prozessbegleitende Qualitätskontrolle (IPQC): During production, samples are regularly tested to ensure that processes are producing components within the specified tolerances. This can include dimensional checks, functional tests, and stress testing.

Endgültige Qualitätskontrolle (FQC): Before shipment, the finished products undergo a comprehensive inspection to confirm they meet all performance and safety criteria. This may include pressure testing for tire inflation systems to ensure they can withstand operational conditions.

Testing methods play a crucial role in ensuring the reliability and safety of automatic tire inflation systems. Common testing methods include:

Leistungstests: This verifies that the system can maintain the desired tire pressure under various conditions. It may involve simulating different environmental factors and usage scenarios.

Dauerhaftigkeitsprüfung: This assesses the product’s long-term performance by subjecting it to rigorous conditions, such as temperature extremes, vibration, and humidity. Products are often tested for extended periods to simulate real-world usage.

Sicherheitsprüfung: This ensures that the system complies with safety regulations, including electrical safety standards and pressure vessel regulations.

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product reliability. Here are effective strategies:

Lieferanten-Audits: Conducting on-site audits can provide insights into a manufacturer’s operations, quality control procedures, and adherence to standards. This allows buyers to assess the manufacturing environment and practices firsthand.

Anforderung von Qualitätsberichten: Suppliers should be able to provide documentation of their quality control processes, including test results, inspection reports, and certifications. This transparency is crucial for building trust.

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control measures. These services can conduct inspections at various stages of production, offering an added layer of assurance.

Quality control nuances can vary significantly based on the buyer’s region and the supplier’s location. For buyers in Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is vital.

Regionale Übereinstimmung: Different regions may have specific regulations regarding product safety, environmental impact, and manufacturing practices. Buyers should be aware of these regulations to ensure compliance and avoid potential legal issues.

Kulturelle Erwägungen: Cultural differences can affect communication and negotiation styles, impacting the buyer-supplier relationship. Establishing clear communication channels and expectations from the outset is essential for successful partnerships.

Market Expectations: Buyers should understand the specific needs and expectations of their target markets, which can influence product design, features, and pricing strategies.

By navigating these manufacturing processes and quality assurance measures effectively, B2B buyers can make informed decisions when sourcing automatic tire inflation systems, ensuring they receive reliable products that meet their operational needs.

In the competitive landscape of B2B procurement, sourcing an automatic tire inflation system requires careful consideration and due diligence. This guide provides a structured checklist to help international buyers streamline their sourcing process, ensuring they make informed decisions that align with their operational needs.

Clearly outlining your technical requirements is essential for ensuring compatibility with your existing fleet. Consider factors such as tire sizes, vehicle types, and operating conditions. This will help you identify systems that can efficiently operate under the specific demands of your business environment.

Investigate potential suppliers to gauge their reliability and industry standing. Look for reviews, testimonials, and ratings from other businesses that have purchased similar systems. This will provide insights into product quality and customer service.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a well-rounded understanding of the supplier will help mitigate risks.

Illustrative image related to automatic tire inflation system

Inquire about warranty terms and after-sales support offered by the supplier. A robust warranty can protect your investment and minimize downtime due to unexpected failures.

Understanding the total cost of ownership is crucial when evaluating different systems. Consider not only the upfront costs but also installation, maintenance, and potential downtime costs.

Evaluate the supplier’s shipping capabilities and lead times, especially if your operations are time-sensitive. Timely delivery can significantly impact your operational efficiency.

Understand the installation process and any specific requirements your team might need to meet. A system that promises easy installation can save you time and labor costs.

By following this checklist, you can ensure a more efficient and effective procurement process for automatic tire inflation systems, enabling you to enhance your fleet’s performance and safety.

Illustrative image related to automatic tire inflation system

When evaluating the cost structure of automatic tire inflation systems, several key components contribute to the overall pricing. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materialien: The choice of materials significantly affects the cost. Durable components such as high-grade plastics, metals, and specialized rubber for seals are common. Systems that incorporate advanced technology, like predictive tire management, may utilize more expensive sensors and software.

Arbeit: Labor costs vary based on the region and the complexity of the assembly process. Skilled labor is often required for precision assembly and quality checks, particularly for systems that involve electronic components.

Fertigungsgemeinkosten: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can reduce overhead costs, which in turn can impact pricing positively.

Werkzeugbau: The initial investment in tooling for manufacturing can be substantial. This cost is typically amortized over the production volume, meaning larger orders can help lower the per-unit tooling cost.

Qualitätskontrolle (QC): Ensuring that each unit meets safety and performance standards incurs costs related to testing and certification. Systems that comply with international safety standards may require additional investment in QC processes.

Logistik: Shipping and handling costs can vary based on the location of the supplier and the buyer. For international shipments, customs duties and tariffs may also add to the total cost.

Marge: Suppliers will include a profit margin in their pricing, which can vary widely based on the competitive landscape and perceived value of the product.

Several factors can influence the pricing of automatic tire inflation systems, particularly for B2B buyers looking to optimize their procurement strategies.

Volumen/MOQ (Mindestbestellmenge): Larger orders typically lead to lower per-unit prices due to economies of scale. Buyers should negotiate volume discounts where possible.

Spezifikationen und Anpassungen: Custom features or specifications can significantly increase costs. Buyers should carefully assess their needs versus the available standard options to avoid unnecessary expenses.

Materialien und Qualitätszertifikate: Higher quality materials and certifications (e.g., ISO standards) can increase initial costs but may provide better long-term value through durability and lower maintenance requirements.

Lieferanten-Faktoren: The supplier’s reputation, reliability, and service capabilities can influence pricing. Established suppliers may charge more due to their proven track record, but they can also offer better support and warranty terms.

Incoterms: Understanding international shipping terms is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the product.

B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, should consider several strategies to ensure cost efficiency.

Leverage Local Knowledge: Familiarize yourself with local market conditions and supplier capabilities. Engaging local representatives can enhance negotiation leverage.

Bewertung der Gesamtbetriebskosten (TCO): Consider not just the purchase price but also long-term costs such as maintenance, downtime, and energy consumption. Systems with lower TCO may justify higher upfront costs.

Be Clear About Specifications: Providing clear and detailed requirements can help suppliers quote more accurately and avoid unexpected costs later in the process.

Explore Alternative Suppliers: Don’t hesitate to shop around. Compare offerings from multiple suppliers to find the best combination of price, quality, and service.

Understand Pricing Nuances for International Transactions: Be mindful of currency fluctuations, shipping costs, and potential import taxes that can impact the overall pricing when sourcing internationally.

Understanding the comprehensive cost structure and pricing dynamics of automatic tire inflation systems is crucial for B2B buyers. By focusing on the key cost components, recognizing price influencers, and implementing effective negotiation strategies, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary widely; thus, it’s advisable to request indicative pricing and explore multiple options before finalizing a purchase.

Illustrative image related to automatic tire inflation system

In the quest for optimal tire management, businesses often explore various solutions to ensure tire pressure is maintained effectively. While automatic tire inflation systems (ATIS) offer a high-tech approach, alternatives like manual inflation systems and dual tire inflation systems can also meet operational needs. Each solution has unique features that may suit different business models and operational environments.

| Vergleich Aspekt | Automatic Tire Inflation System | Dual Tire Inflation System | Manual Inflation System |

|---|---|---|---|

| Leistung | Continuous pressure monitoring and adjustment; reduces tire wear and improves fuel efficiency. | Simultaneous inflation/deflation of all tires; good for off-road applications. | Requires manual monitoring and adjustments; prone to human error. |

| Kosten | Higher initial investment; potential for long-term savings on maintenance and fuel. | Moderate cost; varies by brand and features. | Low initial cost; often requires additional tools. |

| Leichte Implementierung | Quick installation; typically requires no specialized tools. | Moderate installation complexity; may require specific vehicle modifications. | Simple to implement; minimal setup required. |

| Wartung | Low maintenance; designed for durability and minimal upkeep. | Moderate maintenance; requires regular checks for hose integrity. | High maintenance; frequent manual checks and adjustments needed. |

| Bester Anwendungsfall | Ideal for fleets focusing on fuel efficiency and uptime. | Best for off-road vehicles needing rapid tire pressure adjustments. | Suitable for smaller operations with limited budgets or infrequent use. |

Dual tire inflation systems allow for the simultaneous inflation and deflation of all tires. These systems are particularly beneficial for off-road vehicles and those that frequently operate in varied terrains. The ability to adjust tire pressure on-the-fly enhances vehicle performance and safety. However, the installation can be moderately complex, requiring specific modifications depending on the vehicle model. While they are generally more affordable than ATIS, ongoing maintenance checks are necessary to ensure the system’s integrity, which can lead to additional costs over time.

Manual inflation systems involve the traditional method of inflating tires using a portable air compressor or tire inflator. This method is straightforward and cost-effective, making it appealing for small businesses or individual users. However, it requires constant vigilance and manual adjustments, which can lead to inconsistencies in tire pressure. Additionally, the reliance on human intervention increases the likelihood of errors, potentially impacting vehicle safety and efficiency. While the initial investment is low, the time and labor involved in regular manual checks can accumulate, leading to higher overall costs in the long run.

When choosing the right tire inflation solution, B2B buyers should consider their specific operational needs, budget constraints, and the importance of tire management in their overall business strategy. Automatic tire inflation systems offer advanced technology with long-term cost benefits and low maintenance, making them suitable for larger fleets prioritizing efficiency. Conversely, dual tire inflation and manual systems may be appropriate for smaller operations or specialized applications where budget and simplicity are primary concerns. Assessing the unique requirements of your fleet and operational environment will guide you in selecting the most effective tire inflation solution.

When evaluating automatic tire inflation systems (ATIS), several technical specifications play a pivotal role in decision-making for B2B buyers. Understanding these properties ensures that organizations can select the right systems for their operational needs.

The durability of an ATIS is often determined by the materials used in its construction. High-grade materials, such as industrial-grade polymers and metals, enhance resistance to wear, corrosion, and extreme environmental conditions. For instance, systems tested for durability over a million miles demonstrate reliability and longevity. This is crucial for businesses operating in harsh environments, ensuring minimal downtime and maintenance costs.

Illustrative image related to automatic tire inflation system

An effective ATIS should operate within a specific pressure range (often measured in PSI). A system with a wider operating pressure range can accommodate various vehicle types and tire specifications. Tolerance levels indicate how accurately the system can maintain the desired tire pressure. For example, a system with a tolerance of ±1 PSI is more precise and beneficial for optimizing fuel efficiency and tire lifespan, which is vital for fleet management.

Installation efficiency is a significant factor for B2B buyers. Systems that can be installed in less than 10 minutes without specialized tools are preferred, as they reduce labor costs and operational interruptions. The ease of installation is particularly important for companies managing multiple vehicles or fleets, allowing for rapid deployment of inflation systems.

The ability of an ATIS to integrate with existing vehicle systems, such as onboard air compressors, is a critical specification. Compatibility ensures that businesses do not incur additional costs for new equipment. Systems designed with dual air source compatibility, allowing connection to both onboard and portable pumps, provide flexibility and ease of use.

A robust warranty (often five years or more) signifies the manufacturer’s confidence in their product and offers peace of mind for buyers. Additionally, the availability of dedicated customer service is crucial for addressing any issues that may arise post-purchase. Buyers should consider these factors as they indicate the level of support and reliability they can expect.

Illustrative image related to automatic tire inflation system

Understanding industry jargon is essential for effective communication and negotiation in the B2B sector. Here are several common terms related to automatic tire inflation systems.

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of ATIS, buyers may prefer systems designed by OEMs for specific vehicle models, ensuring compatibility and reliability.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management, especially when procuring ATIS for fleets.

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. This is a common practice in B2B transactions, enabling buyers to compare offers and negotiate favorable terms.

Illustrative image related to automatic tire inflation system

Incoterms are internationally recognized rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with these terms helps buyers understand shipping costs, risks, and logistics involved in acquiring ATIS from international suppliers.

Lead time is the amount of time from placing an order to receiving it. For businesses relying on ATIS, understanding lead times is essential for planning and ensuring that vehicles are equipped promptly to minimize operational delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions regarding automatic tire inflation systems, ultimately enhancing operational efficiency and vehicle performance.

The automatic tire inflation system (ATIS) market is witnessing significant growth, driven by several global factors. Increasing concerns over road safety, fuel efficiency, and tire lifespan are compelling businesses to adopt advanced technologies. The rise in e-commerce and logistics in regions like Africa and South America is further amplifying the demand for efficient tire management solutions. Additionally, the integration of IoT (Internet of Things) technologies is reshaping the landscape, allowing for real-time monitoring and predictive maintenance of tire pressure.

Illustrative image related to automatic tire inflation system

Emerging trends include the shift towards compact and user-friendly designs that require minimal installation time, catering to a growing preference for maintenance-free systems. For international B2B buyers, particularly from regions such as the Middle East and Europe, understanding these dynamics is crucial. Companies are increasingly looking for suppliers that offer robust warranties and exceptional customer service, as these elements enhance trust and reliability in the supply chain.

Moreover, there is a notable trend towards dual compatibility systems that allow for integration with both onboard compressors and portable pumps. This flexibility is particularly appealing to businesses operating in diverse environments, from urban settings to off-road conditions. As the market continues to evolve, the focus on durability, ease of installation, and technological integration will remain paramount for B2B buyers seeking competitive advantages in tire management.

Sustainability is becoming an essential consideration in the automatic tire inflation system sector, as businesses increasingly recognize their environmental impact. The production and disposal of tire inflation systems can contribute to waste and pollution; therefore, B2B buyers are prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes using recyclable materials and minimizing carbon footprints during manufacturing processes.

Ethical sourcing is equally important. Buyers are looking for suppliers that ensure fair labor practices throughout their supply chains, promoting social responsibility alongside environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are becoming prerequisites for many buyers, as they signify a commitment to sustainable and ethical operations.

Furthermore, the adoption of ‘green’ materials in product design—such as biodegradable components or low-impact manufacturing processes—can enhance a company’s reputation and marketability. For international buyers, particularly those in Europe where regulations around sustainability are stringent, partnering with manufacturers who prioritize these values can lead to improved compliance and customer loyalty.

The evolution of automatic tire inflation systems dates back several decades, with initial developments focusing primarily on enhancing vehicle safety and performance. Early systems were often cumbersome and required significant manual intervention. However, technological advancements have transformed ATIS into sophisticated, automated solutions that require little to no maintenance.

Illustrative image related to automatic tire inflation system

In recent years, the integration of smart technology has revolutionized the sector, allowing for real-time data collection and analysis. This evolution is not only about improving the functionality of tire inflation systems but also about addressing the growing demand for sustainability and efficiency in supply chains. As global transportation networks become more complex, the need for reliable, efficient tire management systems will continue to drive innovation in this field.

For B2B buyers, understanding the historical context of ATIS can provide valuable insights into current market offerings and future developments, enabling more informed sourcing decisions.

How do I solve inconsistent tire pressure in my fleet?

Inconsistent tire pressure can lead to increased fuel consumption, reduced tire lifespan, and safety hazards. Implementing an automatic tire inflation system (ATIS) can effectively address this issue. These systems continuously monitor and adjust tire pressure, ensuring optimal inflation across all vehicles. When sourcing an ATIS, look for solutions that offer real-time monitoring and compatibility with your fleet’s specifications. Additionally, consider systems that are robust and designed for various environmental conditions, as this will enhance durability and performance.

What is the best automatic tire inflation system for large commercial fleets?

The best automatic tire inflation system for large commercial fleets should be durable, easy to install, and provide real-time monitoring capabilities. Systems like the Halo Tire Inflator or Overland Vehicle Systems’ Gen2 Air Delivery System are excellent choices. They offer features such as quick installation, compatibility with various air compressors, and rugged designs suited for challenging environments. It’s essential to evaluate the specific needs of your fleet, including vehicle types and operational conditions, to determine the most suitable system.

How can I ensure the quality and reliability of my automatic tire inflation system supplier?

To ensure quality and reliability, conduct thorough research on potential suppliers. Look for certifications, customer reviews, and case studies that highlight their experience in the industry. Request samples and inquire about warranties and after-sales support. It’s also beneficial to visit their manufacturing facilities, if possible, to assess their production processes and quality control measures. Establishing a good relationship and communication with your supplier can further enhance reliability and service quality.

What customization options are available for automatic tire inflation systems?

Many manufacturers offer customization options for automatic tire inflation systems to meet specific fleet requirements. Customizations can include size adjustments, specific valve types, and integration with existing vehicle systems. When discussing customization, clarify your fleet’s unique needs, such as the types of vehicles and their operational conditions. Engaging with the supplier early in the design process can help ensure the final product aligns perfectly with your requirements.

What are the typical minimum order quantities (MOQs) for automatic tire inflation systems?

Minimum order quantities (MOQs) can vary significantly based on the supplier and the specific product. Generally, MOQs for automatic tire inflation systems can range from a few units to several hundred, depending on the manufacturer’s production capabilities. For larger purchases, suppliers may offer better pricing or terms. Always confirm MOQs during negotiations and consider how they fit within your budget and operational needs.

What payment terms should I expect when purchasing automatic tire inflation systems?

Payment terms can vary widely between suppliers and may include options such as upfront payment, net 30, net 60, or installment plans. It’s essential to discuss payment terms early in the negotiation process to ensure they align with your financial planning. Be aware that international transactions may involve additional considerations, such as currency exchange rates and banking fees. Establishing clear payment terms can help prevent misunderstandings and ensure a smooth purchasing experience.

How do I manage logistics and shipping for international orders of automatic tire inflation systems?

Managing logistics for international orders involves coordinating shipping, customs clearance, and delivery. First, confirm the shipping options with your supplier, including air or sea freight, and understand the associated costs. You should also inquire about the estimated delivery times and any potential customs duties or taxes. It’s advisable to work with a freight forwarder experienced in international shipping to streamline the process and ensure compliance with all regulations.

What quality assurance (QA) measures should I look for in an automatic tire inflation system?

When sourcing an automatic tire inflation system, inquire about the supplier’s quality assurance measures. Look for ISO certifications, adherence to industry standards, and documented testing procedures. Request information on the warranty offered, as a robust warranty often indicates confidence in the product’s quality. Additionally, ask about regular maintenance and support options to ensure long-term reliability and performance of the system in your fleet.

Bereich: shop.aperiatech.com

Registriert: 2010 (15 Jahre)

Einleitung: Product Name: Halo Tire Inflator

Price: $600.00

Discount: Limited Time Offer! 22% Off

Included in Kit: All Halos, Brackets, and necessary Hoses for full vehicle installation

Target Pressure Options: 80 PSI, 85 PSI, 90 PSI, 95 PSI, 100 PSI, 105 PSI, 110 PSI, 115 PSI, 120 PSI

Wheel Configurations Available:

– Single Axle – Dual Tire Kit

– Single Axle – Wide-Base Tire Kit

– Tandem Axle – Dual Tire K…

Bereich: cummins.com

Registered: 1990 (35 years)

Einleitung: Meritor Tire Inflation System (MTIS™) is designed to maintain proper tire inflation, reducing wear and increasing fuel economy. Key features include:

– Installed on over 1 million trailers, it helps prevent tire pressure loss.

– Equipped with ThermALERT wheel-end heat-sensing technology that alerts drivers to overheating wheel-ends.

– Compatible with all major trailer axle models in North America …

Bereich: haltec.com

Registriert: 1998 (27 Jahre)

Einleitung: Automatic Tire Inflation Systems (ATIS) by Haltec are designed for trucks, trailers, fleets, and aircraft. Key features include:

– Customizable branded faceplates available.

– Hardwired and mountable to mobile service trucks.

– Calibration confirmation every 6 minutes during use and at power on.

– Accuracy of 0.5% FS.

– Die cast aluminum housing for durability and weather protection (IP66 rating)….

Bereich: ti.systems

Einleitung: STIS | Semi-automatic Tire Inflation System

– Precise tire pressure adjustment when vehicle is stationary

– Can be retrofitted to any vehicle

– Inflate/deflate all tires simultaneously

– No preparations required

– Patented ti.systems tire valve screwed directly onto regular tire valve after inner valve core is removed

– Airflow up to 900l/min

– Easy to use with quick coupling system

– Simultaneous…

Bereich: alltiresupply.com

Registriert: 2001 (24 Jahre)

Einleitung: [{‘product_name’: ‘Coats 60″ Inflator Hose For Tire Changer, Euro Chuck – 8182052’, ‘price’: ‘$32.95’}, {‘product_name’: ‘PCL AFG6H04 High-Pressure Tire Inflator – 300 PSI, 1.8m Hose, Clip-On Connector’, ‘price’: ‘$335.72’}, {‘product_name’: ‘PCL RHA2144 21″ OEM Replacement Hose Assemblies for DAC1, AFG1, DTI’, ‘price’: ‘$29.47’}, {‘product_name’: ‘PCL DS158 Solenoid Assembly for QUBE 0/4/5/6/9 Ti…

In conclusion, the strategic sourcing of automatic tire inflation systems is essential for businesses looking to optimize fleet performance and reduce operational costs. By prioritizing durability and ease of installation, such as those offered by systems like the Halo Tire Inflator and Overland Vehicle Systems’ Gen2 Air Delivery System, companies can ensure that they are investing in reliable solutions that withstand challenging environments. Furthermore, leveraging warranties, exceptional customer service, and efficient shipping options can significantly enhance the procurement experience and provide peace of mind.

As international B2B buyers from diverse regions including Africa, South America, the Middle East, and Europe, it is crucial to align your purchasing strategies with suppliers who offer both quality and support. This approach not only strengthens your supply chain but also positions your organization for future growth.

Looking ahead, consider how automatic tire inflation systems can be integrated into your broader fleet management strategy. Take action today to explore partnerships with reputable suppliers, ensuring that your investments yield long-term benefits in performance and safety.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.