The global market for the yiobude air pump presents a unique challenge for B2B buyers seeking reliable and efficient solutions for their operational needs. As businesses increasingly prioritize energy efficiency and sustainability, sourcing the right air pump can significantly impact productivity and operational costs. This comprehensive guide delves into the various types of yiobude air pumps, their applications across diverse industries, and critical factors to consider when evaluating suppliers.

From understanding the intricacies of performance specifications to navigating the complex landscape of international shipping and compliance, this guide equips buyers with actionable insights to make informed purchasing decisions. We will explore cost considerations, supplier vetting processes, and best practices for integrating yiobude air pumps into existing workflows.

For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Vietnam—this resource serves as an essential tool. By leveraging the information provided, businesses can streamline their procurement processes, reduce risks associated with supplier selection, and ultimately enhance their operational efficiency. Whether you are a seasoned procurement professional or a new entrant in the market, this guide is designed to empower you with the knowledge needed to confidently navigate the complexities of sourcing yiobude air pumps in today’s dynamic global economy.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Diaphragm Air Pump | Uses a flexible diaphragm for air movement | Medical devices, aquaculture | Vorteile: Quiet operation, low maintenance. Nachteile: Limited flow rate. |

| Piston Air Pump | Utilizes a piston mechanism for high pressure | Industrial machinery, automotive | Vorteile: High efficiency, robust construction. Nachteile: Noisy operation, requires lubrication. |

| Rotary Vane Air Pump | Employs rotating vanes to compress air | HVAC systems, pneumatic tools | Vorteile: Continuous operation, compact design. Nachteile: Higher initial cost, complex maintenance. |

| Scroll Air Pump | Features two spiral scrolls for air compression | Refrigeration, air conditioning | Vorteile: Energy-efficient, low vibration. Nachteile: Higher upfront investment, limited pressure range. |

| Centrifugal Air Pump | Uses rotational energy to move air | Water treatment, chemical processing | Vorteile: High flow rates, suitable for large volumes. Nachteile: Less effective at high pressure. |

Diaphragm air pumps are characterized by their use of a flexible diaphragm that creates a vacuum to draw air in and push it out. These pumps are particularly suitable for applications in medical devices and aquaculture, where quiet operation and low maintenance are critical. When purchasing diaphragm pumps, B2B buyers should consider factors such as the required flow rate and compatibility with specific fluids, as these pumps may have limitations on the types of materials they can handle.

Piston air pumps are known for their high efficiency and ability to generate substantial pressure, making them ideal for industrial machinery and automotive applications. These pumps are robustly constructed to withstand demanding environments. Buyers should weigh the benefits of their efficiency against the downsides of noise and the need for regular lubrication, which can affect operational costs.

Rotary vane air pumps are distinguished by their rotating vanes that facilitate continuous air compression. This design makes them a popular choice for HVAC systems and pneumatic tools, where consistent airflow is required. Although they come with a higher initial cost and complex maintenance, their compact design and reliability make them a valuable investment for businesses looking to enhance operational efficiency.

Scroll air pumps utilize two spiral scrolls to compress air and are particularly favored in refrigeration and air conditioning applications. Their energy-efficient operation and low vibration levels contribute to a quieter environment. B2B buyers should consider the higher upfront investment and limited pressure range when evaluating these pumps, as they may be more suitable for specific applications rather than general use.

Centrifugal air pumps leverage rotational energy to move air and are ideal for applications requiring high flow rates, such as water treatment and chemical processing. These pumps excel in handling large volumes but may be less effective at generating high pressures. Buyers should assess their operational needs and the specific characteristics of centrifugal pumps to ensure they align with their intended applications and efficiency requirements.

| Industrie/Sektor | Specific Application of yiobude air pump | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Landwirtschaft | Irrigation Systems | Enhances water distribution efficiency | Durability, energy consumption, and compatibility with local water sources. |

| Herstellung | Pneumatic Conveying Systems | Increases productivity and reduces downtime | Pressure ratings, maintenance requirements, and availability of spare parts. |

| Food and Beverage | Packaging and Bottling Processes | Ensures product integrity and shelf life | Compliance with health standards, energy efficiency, and ease of integration. |

| Bauwesen | Concrete Mixing and Delivery | Improves consistency and quality of materials | Load capacity, portability, and resistance to harsh environments. |

| Automobilindustrie | Tire Inflation and Maintenance | Enhances operational safety and efficiency | Adaptability to various tire sizes, inflation speed, and reliability. |

In the agricultural sector, the yiobude air pump plays a crucial role in irrigation systems by ensuring efficient water distribution across fields. It helps in delivering water to crops in a controlled manner, reducing wastage and enhancing crop yield. For international buyers, particularly in regions like Africa and South America, sourcing pumps that are durable and compatible with local water sources is essential. Additionally, energy consumption is a significant consideration, as many agricultural operations look to minimize costs while maximizing output.

In manufacturing, yiobude air pumps are integral to pneumatic conveying systems, which transport bulk materials efficiently. These pumps increase productivity by streamlining the movement of materials, thus reducing downtime associated with manual handling. For B2B buyers in Europe and the Middle East, it is vital to consider pressure ratings and maintenance requirements to ensure optimal performance in demanding environments. Availability of spare parts is also critical to minimize operational disruptions.

In the food and beverage industry, the yiobude air pump is essential for packaging and bottling processes, where maintaining product integrity and extending shelf life are paramount. The pump facilitates the removal of air from packaging, preventing spoilage and ensuring freshness. International buyers must prioritize compliance with health standards and energy efficiency when sourcing these pumps, as well as their ease of integration into existing production lines to avoid costly modifications.

In construction, the yiobude air pump is utilized in concrete mixing and delivery systems, enhancing the consistency and quality of concrete. By providing a reliable air supply, it ensures that the concrete mix is uniform, reducing the risk of structural failures. Buyers from regions with challenging environments, such as the Middle East, should focus on the pump’s load capacity and portability. Additionally, resistance to harsh conditions is a key factor to ensure longevity and performance on construction sites.

In the automotive sector, the yiobude air pump is commonly used for tire inflation and maintenance, contributing significantly to operational safety and efficiency. By providing quick and reliable inflation, these pumps help maintain optimal tire pressure, which is crucial for vehicle performance and safety. For international buyers, adaptability to various tire sizes and inflation speed are important considerations. Reliability is also crucial, as automotive operations cannot afford downtime due to equipment failure.

Das Problem: B2B buyers often face challenges in sourcing reliable replacement parts for ‘yiobude air pumps’, especially in regions where access to quality components is limited. This can lead to extended downtime in operations, ultimately affecting productivity and profitability. Buyers may find themselves in a situation where a crucial part fails, and local suppliers do not carry the required components or offer subpar alternatives that compromise the pump’s performance.

Die Lösung: To mitigate this issue, buyers should establish relationships with reputable suppliers and manufacturers that specialize in ‘yiobude air pumps’ and their components. Conducting thorough research on suppliers, including reviews and performance history, can ensure that only high-quality replacement parts are sourced. Additionally, creating a proactive inventory management system that tracks the lifecycle of pump components can help in anticipating replacement needs before they arise. This system can also include a list of verified suppliers for quick reference, ensuring that replacements are always available when required.

Das Problem: Many B2B buyers struggle with maintaining ‘yiobude air pumps’ due to a lack of understanding of best practices. This can lead to premature wear and tear, decreased efficiency, and ultimately higher operational costs. Without a proper maintenance routine, pumps may operate below their optimal capacity, resulting in increased energy consumption and potential production halts.

Die Lösung: Implementing a comprehensive training program for staff on maintenance best practices can significantly improve the longevity and performance of ‘yiobude air pumps’. Buyers should seek out resources such as manufacturer-provided manuals, online courses, or workshops that cover essential maintenance tasks, including regular inspections, lubrication schedules, and troubleshooting common issues. Additionally, establishing a routine maintenance checklist can ensure that all necessary tasks are completed systematically, reducing the risk of unexpected breakdowns.

Das Problem: Another common pain point for buyers is compatibility issues between ‘yiobude air pumps’ and existing machinery or systems. This is particularly prevalent in industries where equipment has been in use for several years. Misalignment in specifications can lead to inefficiencies, increased costs, and difficulty in integration, causing frustration for operations teams.

Die Lösung: To address compatibility concerns, it is crucial for buyers to conduct a thorough compatibility assessment before purchasing a ‘yiobude air pump’. This involves analyzing existing equipment specifications and operational requirements to ensure seamless integration. Working closely with technical teams or consultants during the selection process can provide valuable insights into whether the air pump will meet the necessary criteria. Furthermore, buyers should inquire about customization options or accessories that may facilitate better integration with current systems, ensuring a smoother transition and operation. Regular communication with the manufacturer can also aid in troubleshooting any compatibility issues that may arise post-installation.

When selecting materials for the yiobude air pump, it is essential to consider various factors that directly impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of air pumps, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Aluminum is a widely used material in the manufacturing of air pumps due to its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels. The lightweight nature of aluminum makes it an ideal choice for portable air pumps, enhancing ease of transport and installation.

Pro und Kontra: The primary advantage of aluminum is its durability and resistance to rust, making it suitable for various environments. However, it can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized techniques such as extrusion or die-casting.

Auswirkungen auf die Anwendung: Aluminum is compatible with a wide range of media, including air and non-corrosive gases. International buyers should ensure compliance with relevant standards such as ASTM and ISO, particularly in regions where regulations are stringent.

Stainless steel is another popular choice for air pump components, particularly in applications requiring high corrosion resistance and strength. It can handle temperatures up to 300°C and high-pressure environments, making it suitable for heavy-duty applications.

Pro und Kontra: The key advantage of stainless steel is its exceptional durability and longevity, which can lead to lower maintenance costs over time. However, it is generally more expensive than aluminum and can be heavier, which may impact portability.

Auswirkungen auf die Anwendung: Stainless steel is compatible with a broader range of media, including corrosive gases and liquids. Buyers in Africa and South America should consider the local availability of stainless steel and its compliance with standards like ASTM A240.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in air pump manufacturing due to their lightweight and cost-effective properties. These materials can typically withstand temperatures up to 80°C and moderate pressure levels.

Pro und Kontra: The main advantage of plastic is its low cost and ease of manufacturing, allowing for rapid production and design flexibility. On the downside, plastics may not be suitable for high-temperature or high-pressure applications, limiting their use in certain environments.

Auswirkungen auf die Anwendung: Plastic materials are generally compatible with air and non-corrosive gases. However, international buyers must consider the potential for regulatory restrictions on plastic materials in their regions, particularly in Europe, where environmental regulations are stringent.

Rubber, particularly synthetic rubber compounds, is often used for seals and gaskets in air pumps due to its excellent elasticity and sealing properties. It can typically withstand temperatures between -30°C and 100°C, depending on the specific type of rubber used.

Pro und Kontra: The primary advantage of rubber is its ability to create airtight seals, which is crucial for the efficient operation of air pumps. However, rubber can degrade over time when exposed to certain chemicals or UV light, necessitating regular replacements.

Auswirkungen auf die Anwendung: Rubber is compatible with air and various gases, but international buyers should be aware of the specific rubber grades that meet local compliance standards, such as JIS in Japan or DIN in Germany.

| Material | Typical Use Case for yiobude air pump | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Lightweight air pumps for portable applications | Ausgezeichnetes Verhältnis von Stärke zu Gewicht | Höhere Kosten und komplexe Herstellung | Mittel |

| Rostfreier Stahl | Heavy-duty air pumps in corrosive environments | Exceptional durability and longevity | Higher weight and cost | Hoch |

| Kunststoff | Cost-effective air pumps for non-corrosive applications | Geringe Kosten und Designflexibilität | Limited temperature and pressure resistance | Niedrig |

| Gummi | Seals and gaskets in air pumps | Creates airtight seals for efficiency | Degradation over time with exposure | Mittel |

In summary, selecting the right material for the yiobude air pump involves balancing performance requirements, cost considerations, and compliance with international standards. Understanding the properties and implications of each material can help B2B buyers make informed decisions that align with their specific application needs.

The manufacturing process of Yiobude air pumps is designed to ensure efficiency, durability, and high performance. It typically encompasses four main stages: material preparation, forming, assembly, and finishing.

Vorbereitung des Materials: This initial stage involves selecting high-quality raw materials, such as high-strength plastics, metals, and rubber components. Suppliers must adhere to strict specifications to guarantee that materials meet industry standards. Advanced technologies like Computer Numerical Control (CNC) machining may be employed to ensure precision in cutting and shaping materials.

Bildung von: In this stage, the prepared materials undergo various forming techniques. Techniques such as injection molding for plastic components and die casting for metal parts are commonly utilized. These processes not only allow for complex shapes but also improve the consistency and quality of the components. The use of automation in forming stages increases production efficiency and reduces human error.

Montage: Once the components are formed, they move to the assembly line. This stage requires skilled labor and often incorporates automated assembly systems to enhance precision. Each component is meticulously fitted together, ensuring that the air pumps meet their design specifications. The assembly process may also include integrating electronic controls and other technologies that enhance the functionality of the air pump.

Fertigstellung: The final stage of manufacturing involves surface treatment, painting, or coating to enhance the durability and aesthetics of the air pumps. Techniques such as powder coating or anodizing are often used to protect against corrosion and wear. This step is crucial for ensuring that the air pumps can withstand various environmental conditions, especially in diverse markets.

Quality control (QC) is an integral part of the manufacturing process for Yiobude air pumps, ensuring that each unit meets international standards and customer expectations. The QC process generally follows several key checkpoints:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers conduct tests to verify that materials meet specified standards. This step prevents defective materials from entering the production process, thereby maintaining product integrity.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the production process. This includes checking dimensions, tolerances, and the functionality of components. Any anomalies are addressed promptly to minimize waste and ensure that production schedules are maintained.

Endgültige Qualitätskontrolle (FQC): Once the air pumps are assembled, FQC is performed to verify that finished products meet quality specifications. This includes rigorous testing of functionality, performance, and safety features. Tests such as pressure testing and performance benchmarking are common to ensure that the pumps operate as intended under various conditions.

B2B buyers should be aware of various international standards that govern the quality and safety of Yiobude air pumps. Compliance with these standards not only enhances product reliability but also facilitates smoother transactions across borders.

ISO 9001: This internationally recognized standard focuses on quality management systems. Compliance indicates that the manufacturer has processes in place to ensure consistent quality in products and services. Buyers can look for ISO 9001 certification as a sign of a reputable supplier.

CE-Kennzeichnung: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards. This certification is crucial for buyers in Europe, as it assures that the product meets European Union regulations.

API-Zertifizierung: For air pumps used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is essential. API certification signifies that the products have been tested and verified for specific performance criteria.

Various testing methods are employed to ensure that Yiobude air pumps meet industry standards and customer requirements. Understanding these methods can help B2B buyers assess the quality assurance processes of potential suppliers.

Performance Testing: This includes assessing the operational efficiency and functionality of the air pumps under simulated conditions. Parameters such as flow rate, pressure, and energy consumption are measured to ensure compliance with specifications.

Dauerhaftigkeitsprüfung: To evaluate the longevity of the pumps, manufacturers conduct stress tests that mimic real-world usage. This might involve subjecting the pumps to extreme temperatures, humidity, or continuous operation.

Sicherheitsprüfung: Ensuring that the pumps meet safety standards is paramount. Testing may include electrical safety assessments, pressure leak tests, and material safety evaluations to prevent hazards during operation.

For B2B buyers, verifying the quality control measures of a supplier is crucial in maintaining product integrity and ensuring reliability. Here are actionable steps to confirm QC processes:

Lieferanten-Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and compliance with industry standards. This hands-on evaluation can provide valuable insights into a supplier’s commitment to quality.

Qualitätsberichte: Requesting detailed quality reports from suppliers can provide transparency into their QC processes. These reports should outline testing methods, results, and any corrective actions taken in response to quality issues.

Inspektionen durch Dritte: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspections can be scheduled at various stages of the production process, ensuring that products meet agreed-upon standards before shipment.

International B2B buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control and certification processes:

Regulatory Variations: Different regions may have varying regulations and standards that must be adhered to. It’s essential for buyers to understand the specific requirements applicable in their markets to avoid compliance issues.

Cultural and Economic Factors: Factors such as local manufacturing capabilities, economic conditions, and cultural attitudes towards quality can influence supplier practices. Buyers should consider these factors when evaluating potential suppliers.

Documentation Requirements: Ensure that suppliers can provide necessary documentation for certifications, quality checks, and testing results. Proper documentation is crucial for customs clearance and compliance in international trade.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and establish strong partnerships with Yiobude air pump suppliers, ensuring the delivery of high-quality products that meet their operational needs.

In the competitive landscape of B2B procurement, sourcing the right products is crucial for success. This checklist is designed to guide international buyers through the process of procuring the Yiobude air pump, ensuring that all critical aspects are considered for a smooth transaction.

Start by determining the specific requirements for the Yiobude air pump that meet your operational needs. This includes understanding the pressure ratings, flow capacity, power source, and any additional features that may be necessary for your application. Clear specifications will help streamline the sourcing process and enable suppliers to provide accurate quotes.

Engage in thorough market research to identify potential suppliers and understand the pricing landscape. Look into different manufacturers, their product offerings, and customer reviews. This information will equip you with insights on market standards and help you negotiate better terms.

Before making a commitment, it’s essential to vet suppliers rigorously. Request comprehensive company profiles, certifications, and references from previous clients, especially those in similar industries or regions. This evaluation helps ensure that the supplier is reliable and capable of meeting your quality and delivery expectations.

Ensure that the suppliers hold relevant certifications that comply with international standards. Certifications such as ISO 9001 for quality management systems or CE marking for compliance with European health, safety, and environmental protection standards are indicators of a reputable supplier. This step is vital for mitigating risks associated with subpar products.

Before finalizing your order, request samples of the Yiobude air pump to assess quality firsthand. This allows you to evaluate the product’s performance, durability, and suitability for your application. Additionally, performing tests on the samples can reveal any potential issues before committing to a larger purchase.

Once you’ve selected a supplier, enter negotiations regarding pricing, delivery timelines, payment terms, and after-sales support. Clear agreements on these aspects are essential to avoid misunderstandings later. Consider drafting a formal purchase agreement that outlines all agreed-upon terms.

Finally, ensure you have a logistics plan in place for transporting the Yiobude air pump to your location. Familiarize yourself with import regulations, tariffs, and customs procedures in your country. Proper planning in this area will help prevent delays and additional costs during the shipping process.

By following this checklist, B2B buyers can effectively navigate the sourcing process for the Yiobude air pump, ensuring that they make informed decisions that align with their business needs.

When sourcing Yiobude air pumps, understanding the cost structure is crucial for B2B buyers. The primary components contributing to the overall cost include:

Materialien: The quality and type of materials used in manufacturing directly affect the cost. High-grade materials may increase the initial price but can lead to better performance and longevity, ultimately offering a better return on investment.

Arbeit: Labor costs can vary significantly depending on the location of the manufacturing facility. Regions with higher wage standards may lead to increased costs, while areas with lower labor costs may provide more competitive pricing.

Fertigungsgemeinkosten: This includes utilities, rent, and administrative costs that are essential for the production process. Efficient manufacturing practices can help minimize these costs, impacting the final pricing.

Werkzeugbau: Initial tooling costs for specialized or customized pumps can be significant. Buyers should factor in these costs when considering unique specifications or custom designs.

Qualitätskontrolle (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. However, investing in quality control can reduce returns and complaints, which is vital for maintaining a good relationship with clients.

Logistik: Transportation costs, including shipping and handling, can vary widely based on distance and method. Understanding the best shipping options and terms can help buyers optimize logistics costs.

Marge: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s position in the market and their value-added services.

Several factors influence the pricing of Yiobude air pumps, especially for international B2B buyers:

Volumen und Mindestbestellmenge (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate more favorable terms and lower unit costs.

Spezifikationen und Anpassungen: Custom designs or specific features may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected price increases.

Materials and Certifications: The choice of materials and any necessary certifications (such as ISO standards) can impact costs. Buyers should assess whether the additional expense for certified products aligns with their quality needs.

Lieferanten-Faktoren: The supplier’s reputation, experience, and production capabilities can affect pricing. Established suppliers may charge higher prices due to their reliability and quality assurance.

Incoterms: The terms of shipping and delivery can significantly affect the final price. Understanding the responsibilities and costs associated with different Incoterms (like FOB, CIF, etc.) is crucial for accurate budgeting.

International B2B buyers can adopt several strategies to ensure cost-efficiency when sourcing Yiobude air pumps:

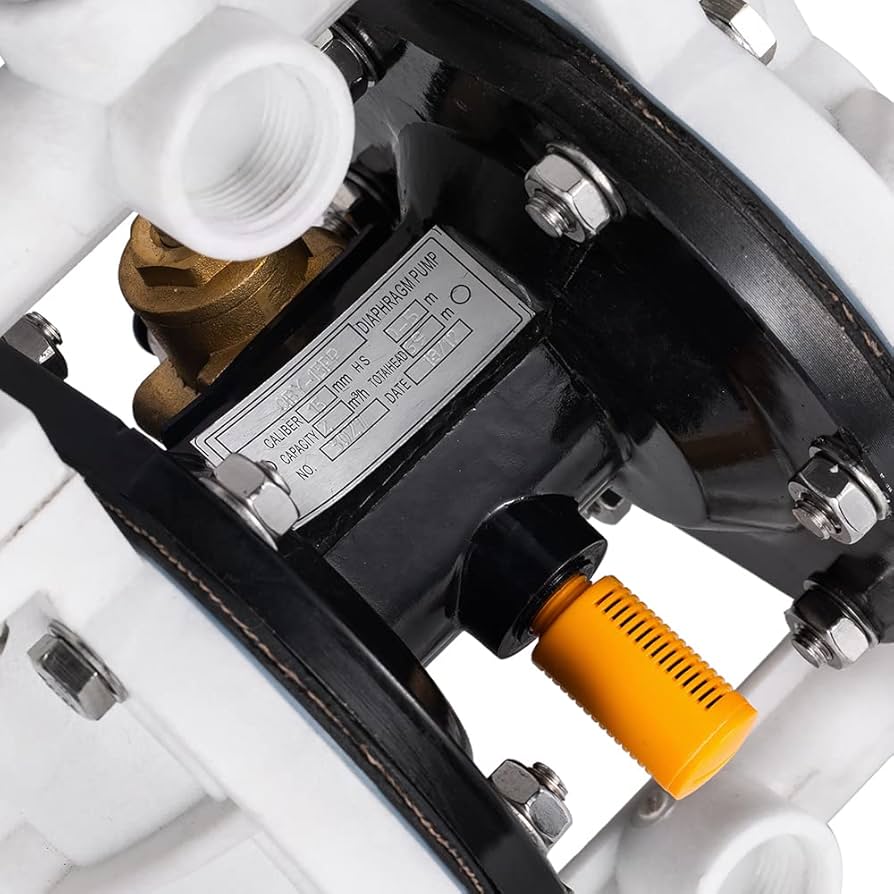

Illustrative image related to yiobude air pump

Führen Sie gründliche Marktforschung durch: Understanding market rates and competitor pricing can provide leverage in negotiations. Buyers should compare quotes from multiple suppliers to find the best deal.

Emphasize Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing and terms in the long run. Loyalty often results in discounts and priority service.

Bewertung der Gesamtbetriebskosten (TCO): Rather than focusing solely on the initial purchase price, consider the total cost of ownership, including maintenance, operational efficiency, and lifecycle costs. This broader perspective can inform better purchasing decisions.

Communicate Clearly: Providing clear and detailed specifications can minimize misunderstandings and additional costs. Clear communication can also foster trust and collaboration between buyers and suppliers.

Stay Informed on Pricing Nuances: Buyers should be aware of regional price variations and economic factors affecting costs in their specific markets, such as tariffs, currency fluctuations, and supply chain disruptions.

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is essential for buyers to conduct due diligence and obtain current pricing directly from suppliers to ensure accurate budgeting and sourcing decisions.

When considering air pump solutions for various applications, it is essential for B2B buyers to evaluate the available alternatives to ensure they select the most effective option. The ‘yiobude air pump’ is a notable product in the market, but other technologies also offer unique benefits that may align better with specific operational needs or budget constraints. This section will provide a comparative analysis of the yiobude air pump against two viable alternatives: the diaphragm air pump and the rotary vane pump.

| Vergleich Aspekt | Yiobude Air Pump | Diaphragm Air Pump | Rotary Vane Pump |

|---|---|---|---|

| Leistung | High efficiency in various applications | Consistent flow rates, suitable for low-viscosity fluids | High pressure output, ideal for industrial use |

| Kosten | Moderate pricing | Im Allgemeinen niedrigere Kosten | Higher initial investment |

| Leichte Implementierung | User-friendly, requires minimal setup | Simple installation, can be compact | More complex, requires professional installation |

| Wartung | Low maintenance, durable design | Moderate maintenance, needs regular checks | High maintenance due to wear on vanes |

| Bester Anwendungsfall | General-purpose applications, suitable for small to medium operations | Ideal for chemical transfer and low-pressure applications | Best for high-volume industrial operations |

Diaphragm Air Pump

Diaphragm air pumps are known for their reliability in transferring fluids, particularly in applications involving chemicals and low-viscosity substances. They are generally more cost-effective than the yiobude air pump, making them an attractive option for budget-conscious buyers. However, while they offer consistent flow rates, their performance may not match the efficiency of the yiobude air pump in high-demand scenarios. Maintenance is moderate, requiring regular checks to ensure optimal operation.

Rotary Vane Pump

Rotary vane pumps excel in delivering high pressure and are particularly suited for large-scale industrial applications. They can handle a wide range of fluids, including those with varying viscosities. However, the initial investment is often higher compared to the yiobude air pump, which may deter smaller businesses or those with limited budgets. Additionally, these pumps require professional installation and have higher maintenance needs due to the wear and tear on the vanes, which can increase operational costs over time.

Choosing the right air pump solution depends on several factors, including performance requirements, budget, and operational context. The yiobude air pump is an excellent choice for businesses seeking a balance between efficiency and cost-effectiveness, particularly in general-purpose applications. However, if your operations require specialized fluid handling or high-pressure capabilities, you may find the diaphragm or rotary vane pumps to be more suitable despite their higher initial costs and maintenance needs.

Ultimately, assessing your specific operational requirements and financial constraints will guide you in selecting the best air pump solution for your business. Engaging with suppliers and considering long-term operational costs will further ensure that your investment aligns with your strategic objectives.

When evaluating the Yiobude air pump, several technical specifications are crucial for ensuring optimal performance and compatibility with your business needs. Understanding these properties can significantly impact your purchasing decision.

Material Klasse

The Yiobude air pump is typically constructed from high-quality materials such as aluminum, stainless steel, or reinforced plastics. The material grade directly influences the pump’s durability, corrosion resistance, and weight. For industries operating in harsh environments, selecting a pump with superior material properties can enhance lifespan and reduce maintenance costs.

Pressure Rating

Pressure rating indicates the maximum pressure the air pump can handle safely. This specification is critical for applications requiring high pressure, such as industrial manufacturing or automotive services. Understanding the pressure rating helps businesses match the pump to their operational needs, ensuring efficiency and safety.

Flow Rate

The flow rate measures the volume of air the pump can deliver over a specific period, typically expressed in liters per minute (LPM) or cubic feet per minute (CFM). A higher flow rate can improve productivity in applications like tire inflation or pneumatic tool operation. It is essential to choose a pump with a flow rate that aligns with your operational demands to avoid bottlenecks.

Power Consumption

This specification details the energy required for the pump’s operation, usually expressed in watts. Power consumption is a vital consideration for businesses aiming to manage energy costs effectively. An air pump that operates efficiently can lead to significant savings over time, making it a financially sound investment.

Lärmpegel

Noise level is measured in decibels (dB) and indicates how loud the air pump operates during use. For businesses operating in noise-sensitive environments, such as laboratories or healthcare facilities, selecting a low-noise air pump is crucial to maintaining a conducive working atmosphere.

Navigating the B2B landscape involves understanding specific trade terminology that can impact procurement and operational efficiency. Familiarity with these terms can facilitate smoother transactions and negotiations.

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s product. In the context of the Yiobude air pump, knowing whether the product is an OEM part can inform buyers about its compatibility with existing systems and the potential for customization.

MOQ (Mindestbestellmenge)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for businesses, especially smaller ones, as it affects inventory management and capital investment. Understanding the MOQ helps buyers plan their purchasing strategy and avoid overcommitting financially.

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. For businesses looking to procure the Yiobude air pump, submitting an RFQ can help compare different suppliers and negotiate better pricing. It is an essential tool for ensuring that you receive the best possible value.

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help businesses mitigate risks and manage logistics effectively when importing the Yiobude air pump from international suppliers.

Vorlaufzeit

Lead time refers to the time it takes from placing an order to receiving the product. For businesses that rely on the Yiobude air pump for operational efficiency, knowing the lead time is essential for planning and minimizing downtime in production processes.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed decisions that enhance operational efficiency and align with your business goals.

The global yiobude air pump market is experiencing significant growth, driven by rising demand across various industries, including automotive, manufacturing, and consumer goods. International B2B buyers are increasingly seeking reliable air pumps due to the surge in automation and the need for efficient pneumatic systems. Key trends influencing this sector include the integration of smart technology, which enhances functionality and efficiency. Furthermore, the demand for portable and energy-efficient air pumps is on the rise, particularly in regions such as Africa and South America, where infrastructure development is rapidly advancing.

Emerging technologies such as IoT (Internet of Things) are reshaping the sourcing landscape, enabling real-time monitoring and predictive maintenance of air pumps. This trend is critical for buyers looking to optimize their supply chains and reduce downtime. Additionally, the shift towards e-commerce platforms for procurement is transforming how international buyers engage with suppliers, offering greater transparency and efficiency in the sourcing process.

As market dynamics evolve, buyers should focus on understanding local regulations and adapting to the unique needs of their target markets. For instance, in Europe, sustainability regulations are becoming increasingly stringent, while in regions like the Middle East, the emphasis is on cost-effectiveness and reliability. Staying informed about these regional trends is crucial for making strategic sourcing decisions.

In today’s B2B landscape, sustainability and ethical sourcing have become paramount concerns for businesses globally. The environmental impact of manufacturing processes, including those related to yiobude air pumps, is under scrutiny. Buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and minimizing waste. This not only aligns with corporate social responsibility goals but also enhances brand reputation in increasingly eco-conscious markets.

The use of ‘green’ certifications and materials is gaining traction within the yiobude air pump sector. Suppliers who invest in sustainable materials and environmentally friendly manufacturing processes are likely to gain a competitive edge. For example, sourcing pumps made from recyclable materials or utilizing energy-efficient production methods can appeal to buyers looking to enhance their sustainability credentials.

Moreover, ethical supply chains are crucial for ensuring compliance with labor standards and fair trade practices. International buyers, particularly in Africa and South America, should consider the social implications of their sourcing decisions. By partnering with suppliers who prioritize ethical practices, companies can mitigate risks associated with reputational damage and contribute positively to the communities involved in the supply chain.

The yiobude air pump market has evolved significantly over the past few decades, influenced by technological advancements and changing consumer demands. Initially, air pumps were primarily mechanical, serving basic functions in various industries. However, as automation became more prevalent, the demand for sophisticated air pumps that could integrate with complex systems surged.

Over time, innovations in materials and design have led to the development of more efficient and reliable air pumps. The introduction of digital technology has transformed the sector, allowing for enhanced performance monitoring and improved user interfaces. This evolution has positioned the yiobude air pump as a critical component in modern industrial applications, making it essential for B2B buyers to stay abreast of these developments to ensure they are sourcing the most advanced and effective solutions available.

As the market continues to grow and diversify, understanding this historical context can help buyers make informed decisions that align with both current trends and future expectations in the yiobude air pump industry.

How do I select the right yiobude air pump for my business needs?

To select the appropriate yiobude air pump, begin by assessing your specific application requirements, including pressure range, airflow capacity, and power source. Consider the operating environment—whether it is for industrial, agricultural, or recreational use—as this will influence durability and performance. Additionally, consult product specifications and request samples if possible to evaluate the pump’s efficiency and reliability. Engaging with the supplier for expert recommendations based on your operational needs can also facilitate a better match.

What are the customization options available for yiobude air pumps?

Yiobude offers various customization options to cater to specific business needs. These may include alterations in size, power specifications, and additional features such as built-in sensors or enhanced filtration systems. To explore customization, communicate your requirements clearly to the supplier, including any unique branding or functionality preferences. A well-defined customization request can lead to more tailored solutions that optimize performance for your particular applications.

What is the minimum order quantity (MOQ) for yiobude air pumps?

The minimum order quantity (MOQ) for yiobude air pumps can vary based on the model and the supplier’s production capabilities. Typically, MOQs may range from a few units to several hundred. It is advisable to discuss your purchasing volume with the supplier, as they may offer flexibility based on your commitment to future orders or partnership potential. Understanding MOQ can aid in budgeting and inventory planning, especially for larger projects.

What payment terms are typically offered for international purchases?

When sourcing yiobude air pumps, payment terms may differ among suppliers, but common options include advance payment, letters of credit, or partial payment upon order confirmation. Discussing payment methods early in the negotiation process is crucial to ensure smooth transactions. Be aware of any additional fees related to currency exchange or international wire transfers. Establishing clear payment terms can foster trust and streamline the purchasing process.

How can I ensure quality assurance (QA) when sourcing yiobude air pumps?

To ensure quality assurance when purchasing yiobude air pumps, request detailed product specifications and certifications, such as ISO compliance or safety standards relevant to your industry. It’s beneficial to conduct factory audits or quality inspections, either in-person or through third-party services, to verify manufacturing practices. Additionally, consider requesting samples for testing before committing to larger orders, as this can provide insight into the pump’s performance and reliability.

What logistics considerations should I be aware of when importing yiobude air pumps?

When importing yiobude air pumps, logistics considerations include shipping methods, customs regulations, and potential tariffs. Determine the most cost-effective shipping option, whether by air or sea, and factor in transit times. Familiarize yourself with import regulations specific to your country to avoid delays. Engaging a reliable freight forwarder can help navigate these complexities, ensuring timely and compliant delivery to your location.

How do I vet suppliers of yiobude air pumps to ensure reliability?

Vetting suppliers involves researching their reputation, production capacity, and customer reviews. Start by checking online reviews, industry certifications, and references from other clients. Request detailed information about their manufacturing processes and quality control measures. Establishing direct communication with the supplier can also provide insights into their responsiveness and customer service quality. Consider visiting their facilities if feasible, as this can significantly enhance your assessment of their reliability.

What after-sales support can I expect with yiobude air pumps?

After-sales support is crucial for maintaining operational efficiency. Most reputable suppliers of yiobude air pumps provide warranty services, technical support, and access to spare parts. It’s important to clarify the terms of warranty, including duration and coverage specifics. Additionally, inquire about training resources or manuals that may be available to help your team operate and maintain the pumps effectively. A strong after-sales support framework can significantly enhance your overall satisfaction and performance outcomes.

We are currently compiling a detailed list of top yiobude air pump suppliers. Please check back later.

The strategic sourcing of the Yiobude air pump represents a significant opportunity for international B2B buyers looking to enhance their operational efficiencies and product offerings. By focusing on quality, reliability, and cost-effectiveness, companies can leverage the competitive advantages that Yiobude air pumps provide. The emphasis on sustainable practices and innovative technology aligns well with the growing demand for environmentally friendly solutions across various industries.

In engaging with suppliers, it’s crucial to evaluate not just the product specifications but also the supplier’s track record, customer service, and after-sales support. Building strong partnerships with manufacturers can lead to better pricing structures, improved supply chain management, and ultimately, increased customer satisfaction.

Looking ahead, the demand for air pumps is expected to rise in emerging markets, particularly in Africa, South America, the Middle East, and Europe. This trend presents a compelling case for B2B buyers to act now and secure favorable sourcing agreements. By investing in strategic sourcing of Yiobude air pumps, businesses can position themselves for long-term success, tapping into new markets and maximizing operational efficiency. Engage with suppliers today to stay ahead in this dynamic market landscape.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.