In the fast-evolving landscape of automotive services, sourcing automatic tyre inflators presents a significant challenge for international B2B buyers. With the increasing need for efficient and reliable tire maintenance solutions, businesses must navigate a diverse market landscape to find products that meet their specific operational requirements. This guide aims to demystify the global market for automatic tyre inflators by exploring various types, applications, and key features that enhance tire inflation efficiency.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including regions like Saudi Arabia and Germany—will benefit from insights into supplier vetting processes and cost considerations. Understanding these elements is crucial for making informed purchasing decisions that align with both budget constraints and quality expectations.

By providing a comprehensive overview of the automatic tyre inflator market, this guide empowers businesses to identify and procure the most suitable solutions for their needs. From evaluating product specifications to recognizing potential suppliers, we aim to equip B2B buyers with actionable insights that facilitate smarter investments in tire inflation technology. As the demand for reliable tire maintenance grows, having the right tools in place can significantly enhance operational efficiency and customer satisfaction.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Wall-Mounted Inflators | Fixed installation, often with digital gauges, high PSI capabilities | Automotive service centers, tire shops | Vorteile: Space-saving, reliable, high efficiency. Nachteile: Not portable, installation required. |

| Portable Electric Inflators | Compact, battery or 12V powered, often with auto shut-off | Roadside assistance, personal vehicles | Vorteile: Easy to store, versatile for various tires. Nachteile: Limited PSI, may require frequent recharging. |

| Heavy-Duty Air Compressors | High output, suitable for larger vehicles, multiple attachments | Fleet maintenance, heavy machinery | Vorteile: Powerful, suitable for diverse applications. Nachteile: Bulky, higher cost. |

| Handheld Tire Inflators | Lightweight, often cordless, designed for quick use | Emergency kits, personal vehicles | Vorteile: Highly portable, user-friendly. Nachteile: Lower PSI, limited to small tires. |

| Smart Tire Inflators | Integrated with apps for monitoring, presetting PSI | Fleet management, tech-savvy users | Vorteile: Remote monitoring, precise control. Nachteile: Higher cost, requires tech familiarity. |

Wall-mounted inflators are designed for fixed installation in service centers or tire shops. They typically feature high PSI capabilities and digital gauges for precise inflation. These inflators are ideal for businesses that require frequent tire servicing, as they offer efficiency and speed. When purchasing, consider the required PSI range and compatibility with nitrogen inflation, which is increasingly popular in professional tire maintenance.

Portable electric inflators are compact and powered by either a rechargeable battery or a vehicle’s 12V outlet. They are versatile and can be used for a range of tire types, making them suitable for roadside assistance and personal vehicles. B2B buyers should evaluate the inflator’s PSI range and battery life, especially for use in emergency situations where time and efficiency are critical.

Heavy-duty air compressors are built for high output and can accommodate larger vehicles, making them essential for fleet maintenance and heavy machinery applications. They often come with multiple attachments for various inflation tasks. Buyers should consider the compressor’s capacity, portability, and power requirements, as these factors can significantly affect operational efficiency.

Handheld tire inflators are lightweight and designed for quick, on-the-go use. They are perfect for emergency kits and personal vehicle maintenance. While they provide convenience, they typically have lower PSI capabilities, which limits their use to smaller tires. Businesses should assess their specific needs for portability versus power when selecting these inflators.

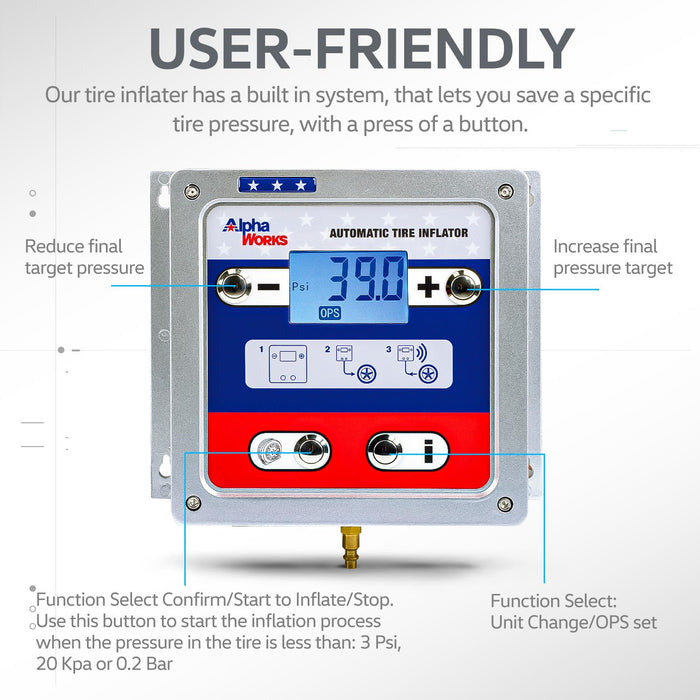

Illustrative image related to automatic tyre inflator

Smart tire inflators integrate with mobile apps to monitor tire pressure and allow for preset inflation levels. This technology is particularly beneficial for fleet management, enabling real-time monitoring of tire conditions and reducing the risk of blowouts. Buyers should weigh the initial investment against long-term savings in maintenance and safety, as well as ensure compatibility with existing fleet management systems.

| Industrie/Sektor | Specific Application of Automatic Tyre Inflator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Transport und Logistik | Fleet maintenance for commercial vehicles | Ensures optimal tire pressure, improving fuel efficiency and safety | Compatibility with various vehicle types and PSI requirements |

| Automotive Services | Quick service stations for tire inflation | Reduces waiting times for customers, enhancing service efficiency | Digital gauges and automatic shut-off features for user convenience |

| Construction & Heavy Equipment | Tire inflation for construction machinery | Minimizes downtime due to flat tires, ensuring continuous operations | Robust design to withstand harsh environments and high PSI capabilities |

| Sports & Recreation | Inflation of recreational vehicles and equipment | Facilitates rapid inflation for various applications, enhancing user experience | Portability and multiple nozzle attachments for versatility |

| Retail & Consumer Goods | Tire inflation services at retail gas stations | Attracts customers looking for convenience and quick service | Compact design and ease of use for non-technical staff |

In the transportation and logistics sector, automatic tyre inflators are vital for maintaining the fleet’s tire health. By ensuring that all commercial vehicles are operating at optimal tire pressure, businesses can significantly enhance fuel efficiency and safety. This application is particularly crucial in regions like Africa and South America, where long-haul trips are common. Buyers should consider inflators that are compatible with various vehicle types and can meet specific PSI requirements to ensure reliability across their fleet.

Automatic tyre inflators are increasingly used in quick service stations to provide rapid tire inflation services. By equipping service stations with these devices, businesses can reduce customer wait times, thereby enhancing overall service efficiency. In markets like Germany and the Middle East, where customer service is paramount, the inclusion of digital gauges and automatic shut-off features can further enhance user convenience. Sourcing inflators with easy-to-read displays and user-friendly interfaces is essential for attracting a diverse customer base.

In the construction industry, maintaining tire pressure in heavy machinery is crucial for operational efficiency. Automatic tyre inflators help minimize downtime due to flat tires, allowing construction projects to stay on schedule. This is especially important in regions with challenging terrains, where equipment reliability is paramount. Buyers should look for robust inflators designed to withstand harsh environments, with high PSI capabilities to cater to heavy-duty applications.

In the sports and recreation sector, automatic tyre inflators facilitate the quick inflation of tires for recreational vehicles, bicycles, and sports equipment. This application enhances the user experience, allowing for more time spent enjoying activities rather than preparing for them. For international buyers, especially in Europe and the Middle East, portability and the availability of multiple nozzle attachments are key considerations, ensuring the inflator can serve various purposes effectively.

Retail gas stations can significantly benefit from offering tire inflation services using automatic tyre inflators. This service not only attracts customers seeking convenience but also provides an additional revenue stream. In regions with heavy vehicle traffic, such as urban areas in Africa and South America, the demand for quick and efficient tire inflation solutions is high. Retailers should prioritize sourcing compact and easy-to-use inflators, ensuring that even non-technical staff can operate them efficiently, thereby enhancing customer satisfaction.

Das Problem: Many B2B buyers, particularly those managing fleets of vehicles or operating in the automotive service industry, often face challenges with achieving and maintaining accurate tire pressure using automatic tire inflators. Inaccurate pressure readings can lead to underinflation or overinflation, resulting in poor vehicle performance, increased fuel consumption, and heightened safety risks. This scenario is particularly critical in regions with extreme weather conditions, where tire pressure can fluctuate significantly, impacting overall vehicle safety and efficiency.

Die Lösung: To address this issue, B2B buyers should focus on sourcing automatic tire inflators equipped with advanced digital gauges that provide precise pressure readings. When evaluating potential inflators, ensure they have features such as automatic shut-off, allowing the device to halt operation once the desired pressure is reached. Additionally, it is vital to regularly calibrate the inflators against known standards to verify accuracy. Establishing a maintenance routine, including periodic checks of the inflators and tires, will ensure consistent performance and reliability. Investing in high-quality inflators that are compatible with nitrogen inflation can also help maintain tire pressure more effectively under varying conditions.

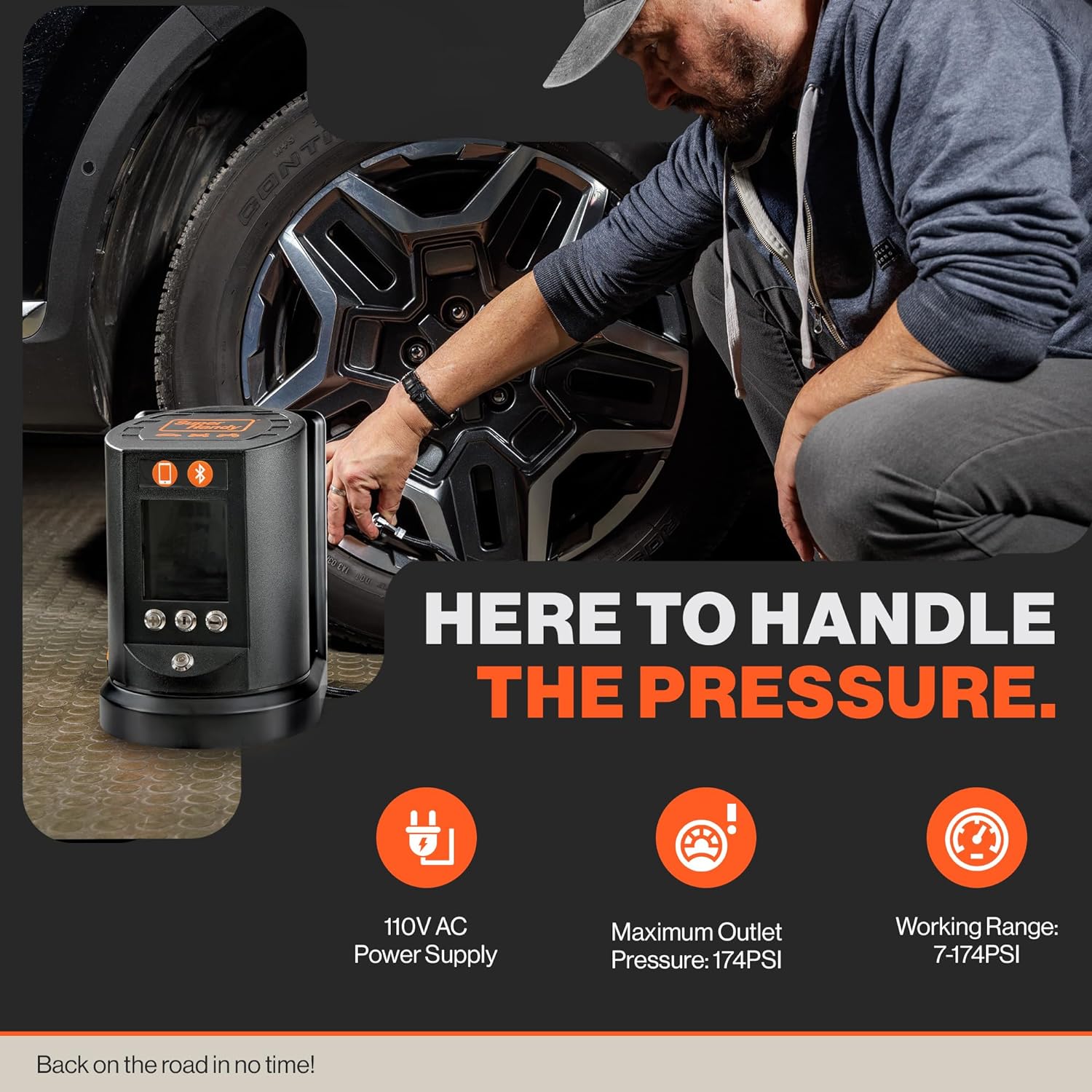

Illustrative image related to automatic tyre inflator

Das Problem: B2B buyers, especially those in logistics and remote operations, often struggle with the portability of automatic tire inflators. Many models are bulky or require a constant power source, which can be impractical for on-the-go tire maintenance. This limitation can hinder timely responses to tire issues, leading to downtime and affecting overall operational efficiency.

Die Lösung: Buyers should prioritize the acquisition of compact and portable tire inflators that offer multiple power options, such as 12V car outlets, rechargeable batteries, and AC wall outlets. When evaluating models, look for lightweight designs that can easily fit into vehicle compartments, ensuring they are readily available during emergencies. Additionally, consider inflators that come with a variety of nozzle attachments, enabling them to handle different tire types and other inflatables as needed. Training staff on the proper use and storage of these inflators will also enhance their effectiveness in roadside situations, allowing for quicker resolutions to tire-related issues.

Das Problem: B2B buyers often encounter challenges in sourcing tire inflators that can handle a wide range of applications, from inflating vehicle tires to sports equipment and recreational gear. This lack of versatility can lead to additional expenses as companies may need to purchase multiple inflators for different purposes, complicating inventory management and increasing costs.

Die Lösung: To combat this issue, buyers should seek out automatic tire inflators designed for multi-use functionality. When conducting market research, identify models that provide adjustable PSI settings and include various nozzle attachments suitable for inflating items beyond just tires. It’s also beneficial to look for inflators with features such as built-in LED lights and emergency functions, which enhance their utility in diverse scenarios. By consolidating equipment needs into one versatile device, companies can simplify their operations, reduce costs, and improve overall efficiency. Ensuring that all team members are trained on the different uses of the inflator will further maximize its value across various applications.

When selecting materials for automatic tyre inflators, it is crucial to consider factors such as durability, performance under pressure, and compatibility with various media. Below, we analyze four common materials used in the construction of these devices, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to automatic tyre inflator

Wichtige Eigenschaften: Aluminum is lightweight and exhibits excellent corrosion resistance, making it suitable for various environmental conditions. It can withstand moderate temperature fluctuations and has good pressure ratings, which are essential for inflators that need to operate effectively under high pressure.

Pro und Kontra: The primary advantage of aluminum is its weight, which contributes to the portability of the inflator. Additionally, it is relatively easy to manufacture and can be molded into complex shapes. However, aluminum can be more expensive than some alternatives and may not be as durable against physical impacts.

Auswirkungen auf die Anwendung: Aluminum is compatible with air and nitrogen, common media for tyre inflation. Its lightweight nature makes it ideal for portable models, but care must be taken to avoid dents and scratches that could compromise performance.

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM and DIN is critical, especially for buyers in Europe and the Middle East. Buyers should also consider the availability of aluminum in their region, as sourcing can affect overall costs.

Wichtige Eigenschaften: Steel is known for its high strength and durability, with excellent resistance to deformation under pressure. It can handle high temperatures and is often used in components that require robust construction.

Illustrative image related to automatic tyre inflator

Pro und Kontra: The main advantage of steel is its durability and ability to withstand harsh conditions, making it suitable for heavy-duty applications. However, its heavier weight can be a disadvantage for portable models. Steel is also prone to corrosion if not properly treated, which can lead to maintenance issues.

Auswirkungen auf die Anwendung: Steel is suitable for high-pressure applications and can be used in both stationary and portable inflators. Its strength allows for the design of more robust inflators capable of handling demanding environments.

Überlegungen für internationale Käufer: Buyers should ensure that the steel used complies with relevant standards, particularly in regions like Europe where regulations are stringent. Corrosion resistance treatments may also be necessary for buyers in humid or coastal areas.

Wichtige Eigenschaften: Plastics, particularly high-density polyethylene (HDPE) and polypropylene, offer good chemical resistance and are lightweight. They can operate effectively within a wide temperature range and are often used for housing and non-structural components.

Pro und Kontra: The lightweight nature of plastics makes them ideal for portable inflators. They are generally cost-effective and can be produced in various colors and finishes. However, plastics may not withstand high pressures as well as metals and can degrade under UV exposure unless treated.

Auswirkungen auf die Anwendung: Plastics are suitable for components that do not bear heavy loads, such as casings and external parts. They are compatible with air and nitrogen and can be used in various environments, although care should be taken regarding exposure to extreme temperatures.

Überlegungen für internationale Käufer: Buyers should look for plastics that meet international safety standards. In regions with high UV exposure, selecting UV-stabilized plastics is essential to ensure longevity.

Illustrative image related to automatic tyre inflator

Wichtige Eigenschaften: Rubber is flexible and elastic, providing excellent sealing capabilities. It can withstand a wide range of temperatures and is resistant to many chemicals, making it suitable for various applications.

Pro und Kontra: The primary advantage of rubber is its ability to create airtight seals, which is critical for maintaining pressure in inflators. However, rubber can degrade over time, especially when exposed to ozone, heat, or certain chemicals, leading to potential failures.

Auswirkungen auf die Anwendung: Rubber is essential for seals and gaskets in tyre inflators, ensuring that air does not leak during operation. Its compatibility with air and nitrogen makes it a reliable choice for these applications.

Überlegungen für internationale Käufer: Buyers should ensure that rubber components meet international standards for durability and chemical resistance. In regions with extreme weather conditions, selecting high-quality rubber that can withstand temperature fluctuations is vital.

Illustrative image related to automatic tyre inflator

| Material | Typical Use Case for automatic tyre inflator | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Housing and structural components | Leicht und korrosionsbeständig | Higher cost and less impact resistance | Mittel |

| Stahl | High-pressure components | Hohe Festigkeit und Haltbarkeit | Schwerer und korrosionsanfälliger | Hoch |

| Kunststoff | Casings and non-structural parts | Kostengünstig und leicht | Less pressure resistance and UV sensitivity | Niedrig |

| Gummi | Seals and gaskets | Hervorragende Dichtungseigenschaften | Degradation over time | Mittel |

This analysis provides a comprehensive overview of material options for automatic tyre inflators, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

Manufacturing an automatic tyre inflator involves several critical stages that ensure the final product meets performance, safety, and durability standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

The manufacturing process begins with the careful selection and preparation of materials. Key components include plastic housings, metal valves, motors, and digital displays. Suppliers typically source these materials from certified vendors to ensure quality. For example, plastic components must meet specific impact resistance and thermal stability criteria, while metal parts should be corrosion-resistant to enhance longevity.

Illustrative image related to automatic tyre inflator

Before production, materials undergo inspections to verify they meet predefined specifications. This initial Quality Control (QC) step is essential to prevent defects downstream, ensuring that only the highest quality materials proceed to the next stage.

The next stage is forming, where raw materials are shaped into components using various techniques such as injection molding for plastics and stamping for metals. This stage is crucial, as precision in forming directly impacts the functionality of the inflator.

Advanced technologies such as Computer Numerical Control (CNC) machining may also be employed to achieve high precision in metal parts. Each formed component is inspected for dimensional accuracy and surface finish, which are critical for optimal assembly and performance.

During the assembly stage, individual components are brought together to create a complete tyre inflator. This process may involve manual assembly or the use of automated assembly lines, depending on the production scale.

Illustrative image related to automatic tyre inflator

Key assembly operations include:

The finishing stage involves applying coatings, labels, and other aesthetic elements. This may also include final adjustments to ensure the inflator meets specified pressure and performance standards.

After finishing, each unit undergoes Final Quality Control (FQC), which includes comprehensive testing of all functions. Common tests include:

Quality assurance is a critical aspect of the manufacturing process for automatic tyre inflators. Compliance with international standards is essential, especially for B2B buyers looking for reliable suppliers.

One of the most recognized standards in quality management is ISO 9001, which outlines criteria for an effective quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate a commitment to quality, continuous improvement, and customer satisfaction.

Illustrative image related to automatic tyre inflator

In addition to ISO certifications, specific products may require CE marking to indicate compliance with European safety, health, and environmental protection standards. This is particularly relevant for buyers in Europe, as it assures that the inflators meet stringent EU regulations.

Depending on the application, manufacturers may also seek certifications from industry organizations such as the American Petroleum Institute (API). These certifications can be crucial for inflators designed for commercial or heavy-duty use, ensuring they meet rigorous operational standards.

Quality control is woven into every stage of the manufacturing process, with specific checkpoints to ensure compliance with standards and specifications.

IQC involves inspecting raw materials and components upon arrival at the manufacturing facility. This step ensures that all materials meet the required specifications before they enter production. Common checks include visual inspections and material testing for strength, durability, and other essential properties.

During the assembly and forming stages, IPQC checks are vital for identifying defects early. This may involve:

Illustrative image related to automatic tyre inflator

Once assembly is complete, FQC is conducted to verify that the final product meets all performance and safety standards. This stage often includes comprehensive functional testing, pressure validation, and safety checks before the product is packaged for shipment.

For B2B buyers, verifying the quality control practices of potential suppliers is crucial to ensuring product reliability and performance.

Regular supplier audits can provide insights into the manufacturing processes and quality control practices employed. These audits should focus on:

Requesting quality reports from suppliers can also be beneficial. These reports should outline the results of inspections and testing conducted during the manufacturing process, including any corrective actions taken in response to identified issues.

Illustrative image related to automatic tyre inflator

For added assurance, engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and quality control measures. Third-party inspectors can conduct on-site evaluations, ensuring that the supplier adheres to both international and industry-specific standards.

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe may face unique challenges when it comes to quality control in automatic tyre inflators.

Different regions may have specific compliance requirements that manufacturers must meet. For instance, products entering the European market must comply with CE marking, while products in other regions may have different certifications. Buyers should be aware of these requirements to avoid regulatory issues and ensure product acceptance in their markets.

Illustrative image related to automatic tyre inflator

Cultural differences can impact communication regarding quality standards and expectations. B2B buyers should ensure that they have clear, documented agreements with suppliers regarding quality expectations and that there is mutual understanding of the terms.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the tyre inflator market. By focusing on these aspects, buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality and performance needs.

To assist B2B buyers in sourcing automatic tyre inflators effectively, this guide outlines essential steps to ensure that your procurement process is both efficient and meets your operational needs. By following this checklist, you can make informed decisions and secure the best inflator for your requirements.

Illustrative image related to automatic tyre inflator

Clearly outlining your technical specifications is crucial for identifying the right automatic tyre inflator. Consider factors such as the maximum PSI (pounds per square inch) needed for your vehicles, the type of power source (12V, AC, or battery-operated), and any additional features like automatic shut-off or digital gauges. Establishing these parameters upfront will streamline the evaluation of potential suppliers.

Stay informed about the latest trends in tyre inflator technology. Innovations such as enhanced portability, faster inflation rates, and multi-functionality (e.g., compatibility with various types of vehicles and equipment) can greatly impact your choice. Understanding market dynamics will help you select a product that not only meets current needs but is also future-proof.

Before making a purchasing decision, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies to assess their credibility and experience. Look for reviews or testimonials from other businesses in your industry to gauge reliability and performance. This step ensures you partner with a supplier that aligns with your quality and service expectations.

Ensure that the suppliers you are considering have the necessary certifications and comply with international standards. This could include ISO certifications, CE marking, or other relevant quality assurance labels. Compliance not only guarantees product safety but also enhances your brand’s reputation by ensuring that you are sourcing from reputable manufacturers.

Illustrative image related to automatic tyre inflator

Before finalizing your order, request samples or arrange for product demonstrations. This allows you to evaluate the performance and ease of use of the tyre inflators in real-world scenarios. Pay attention to features such as inflation speed, noise levels, and user-friendly interfaces, as these factors significantly impact operational efficiency.

Consider the level of after-sales support offered by your potential suppliers. A robust warranty and responsive customer service can save you time and money in case of defects or issues. Ensure that the supplier provides clear information regarding warranty terms, repair services, and access to replacement parts.

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms. Discuss pricing, payment options, delivery timelines, and any bulk purchase discounts. Finalizing these details before placing your order can lead to significant cost savings and improved supply chain efficiency.

By following this practical sourcing checklist, you can streamline your procurement process for automatic tyre inflators, ensuring you select the best product for your specific operational needs while minimizing risks associated with purchasing decisions.

When sourcing automatic tyre inflators, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materialien: The type of materials used significantly impacts the overall cost. Common materials include high-grade plastics for casing, metals for internal components, and electronic parts for digital gauges. Buyers should evaluate the durability and performance of these materials, as premium options may lead to higher upfront costs but can enhance product longevity.

Arbeit: Labor costs vary by region, with countries in Africa and South America typically having lower labor costs compared to Europe. However, skilled labor is essential for quality assembly and testing, particularly for complex models with advanced features.

Fertigungsgemeinkosten: This includes costs related to factory utilities, equipment depreciation, and indirect labor. Efficient factories may offer lower overhead rates, impacting the pricing structure favorably for buyers.

Werkzeugbau: Initial tooling costs can be significant, especially for custom designs. Buyers should inquire about the supplier’s tooling capabilities and any potential costs associated with customization, which can affect pricing.

Qualitätskontrolle (QC): Rigorous QC processes ensure product reliability. Suppliers with robust QC standards may charge more, but this investment can reduce long-term costs associated with defects and returns.

Logistik: Shipping costs can vary based on the destination. International buyers should consider Incoterms, which define responsibilities for shipping, insurance, and tariffs. This can influence the final price significantly.

Marge: Suppliers typically include a margin based on the perceived value of their product and market demand. Understanding the competitive landscape can help buyers gauge whether the margin is justified.

Several factors can influence the pricing of automatic tyre inflators:

Volumen/MOQ: Ordering in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs) that can affect pricing; thus, buyers should assess their needs carefully.

Spezifikationen und Anpassungen: Tailoring products to specific requirements can increase costs. Buyers should weigh the benefits of customization against potential price increases.

Materialien und Qualität/Zertifizierungen: Higher-quality materials and certifications (e.g., ISO, CE) can increase costs but may be necessary for certain markets. Understanding the regulatory environment in your region is vital.

Lieferanten-Faktoren: The supplier’s reputation, experience, and location can impact pricing. Established suppliers may charge more due to their reliability and service levels, while newer entrants may offer lower prices to gain market share.

To maximize value when sourcing automatic tyre inflators, buyers should consider the following strategies:

Verhandlung: Engaging in open discussions with suppliers can yield better pricing. Be prepared to discuss volume commitments and long-term partnerships to leverage discounts.

Gesamtbetriebskosten (TCO): Evaluate not just the purchase price but also the long-term operational costs, including maintenance, energy consumption, and potential downtime. A slightly higher upfront investment may result in lower TCO over time.

Nuancen in der Preisgestaltung für internationale Käufer: For buyers from Africa, South America, the Middle East, and Europe, it’s essential to consider currency fluctuations, import duties, and local market conditions that may affect pricing. Understanding these factors can lead to better budgeting and cost management.

While the indicative prices of automatic tyre inflators can vary widely, ranging from basic models to advanced, feature-rich units, buyers should conduct thorough market research and supplier evaluations. By understanding the cost components and price influencers, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

In the realm of tire maintenance, automatic tyre inflators are a popular choice for their convenience and efficiency. However, understanding alternative solutions can help B2B buyers make informed decisions based on their specific operational needs. This analysis compares automatic tyre inflators with two viable alternatives: manual tire pumps and centralized tire inflation systems.

| Vergleich Aspekt | Automatic Tyre Inflator | Manual Tire Pump | Centralized Tire Inflation System |

|---|---|---|---|

| Leistung | High accuracy and speed; can inflate multiple tire types | Slower; accuracy depends on user skill | Very high; can inflate multiple tires simultaneously |

| Kosten | Moderate to high; initial investment can vary | Low; very affordable | High; significant upfront costs and installation required |

| Leichte Implementierung | Easy to use; minimal training required | Requires manual effort; may need user training | Complex; requires installation and regular maintenance |

| Wartung | Low; requires occasional checks | Low; minimal upkeep needed | High; regular maintenance and checks are essential |

| Bester Anwendungsfall | Ideal for quick roadside assistance and regular maintenance | Suitable for personal use and emergency kits | Best for commercial fleets or high-volume operations |

Manual tire pumps are a traditional approach to tire inflation. They are simple to operate and require no power source, making them ideal for emergency situations. However, they are labor-intensive and can be time-consuming, especially for larger vehicles. While they are cost-effective and portable, the accuracy of inflation largely depends on the user’s skill, which may lead to inconsistent pressure levels.

Centralized tire inflation systems represent a more advanced solution, commonly used in commercial settings. These systems allow for simultaneous inflation of multiple tires, which can significantly reduce downtime for fleets. While they offer high performance and precision, the initial setup cost is substantial, and ongoing maintenance is more demanding. They are best suited for operations with a high volume of vehicles, where efficiency and speed are paramount.

When considering the best tire inflation solution, B2B buyers should evaluate their specific operational requirements and budget constraints. Automatic tyre inflators offer a balance of convenience and performance, making them suitable for various scenarios, from emergency roadside assistance to regular maintenance. On the other hand, manual tire pumps may be more appropriate for individual or infrequent use, while centralized systems are ideal for large fleets requiring high efficiency.

Illustrative image related to automatic tyre inflator

Ultimately, the choice between these alternatives should be guided by factors such as cost, ease of use, required performance, and the scale of tire maintenance operations. By carefully assessing these aspects, businesses can select the most effective solution to enhance their tire management strategies.

When evaluating automatic tyre inflators, several technical specifications play a critical role in ensuring optimal performance and reliability. Understanding these properties is essential for B2B buyers, as they directly affect the efficiency and usability of the inflators in various applications.

The pressure rating, typically measured in pounds per square inch (PSI), indicates the maximum air pressure the inflator can achieve. Most automotive applications require a range of 30-35 PSI. For B2B buyers, selecting an inflator with the appropriate PSI range ensures compatibility with the vehicles or equipment being serviced, minimizing the risk of under- or over-inflation.

Automatic tyre inflators can be powered by various sources, including 12V car outlets, AC wall outlets, or rechargeable batteries. Understanding the power options available is vital for businesses that operate in different environments. A versatile inflator that can adapt to multiple power sources enhances operational flexibility and reduces downtime during tire inflation tasks.

Illustrative image related to automatic tyre inflator

The inflation speed, often measured in cubic feet per minute (CFM), reflects how quickly the inflator can fill a tire. Higher CFM ratings indicate faster inflation, which is crucial for businesses that require quick turnaround times, such as service stations or fleet maintenance operations. Evaluating this property helps buyers choose inflators that can keep up with their workflow demands.

The materials used in the construction of the inflator, such as high-grade plastics or metals, significantly impact its durability and longevity. Buyers should look for inflators with robust builds to withstand the rigors of daily use, especially in harsh environments. A durable product reduces the frequency of replacements and maintenance, leading to long-term cost savings.

Many modern tyre inflators feature digital displays that provide real-time pressure readings and controls for setting desired inflation levels. This technology not only improves accuracy but also enhances user experience. For B2B buyers, investing in inflators with advanced digital features can streamline operations and minimize human error during tire inflation.

Illustrative image related to automatic tyre inflator

The design and weight of an inflator affect its portability. Compact models are easier to store and transport, making them ideal for roadside assistance or mobile tire service operations. Buyers should consider the balance between size and functionality to ensure that the inflator meets their specific operational needs.

Familiarity with industry-specific jargon can significantly enhance communication and negotiation processes for B2B buyers. Here are several essential terms that frequently arise in the context of purchasing automatic tyre inflators.

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tyre inflators, buyers often seek OEM products to ensure compatibility and reliability, as these components are designed to meet specific industry standards.

MOQ represents the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to determine their purchasing strategy and manage inventory effectively. Buyers must balance their needs with the supplier’s requirements to negotiate favorable terms.

Illustrative image related to automatic tyre inflator

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products. For automatic tyre inflators, submitting an RFQ allows businesses to compare pricing and features across multiple vendors, facilitating informed purchasing decisions.

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery obligations associated with purchasing tyre inflators from different regions.

Warranty refers to the manufacturer’s promise to repair or replace a defective product within a specified period. Understanding warranty terms is vital for B2B buyers, as robust after-sales support can significantly affect long-term operational efficiency and product reliability.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing automatic tyre inflators, ensuring they select products that align with their business needs and operational requirements.

Illustrative image related to automatic tyre inflator

The automatic tyre inflator market is experiencing robust growth, driven by several global factors. Increasing vehicle ownership in developing regions such as Africa and South America is a primary driver, as more consumers seek convenience and safety features. In established markets like Europe and the Middle East, regulatory standards for vehicle safety and environmental performance are pushing manufacturers to innovate. As a result, automatic tyre inflators are evolving with advanced technologies, including digital pressure gauges, automatic shut-off features, and compatibility with nitrogen inflation, enhancing their appeal to both consumers and businesses.

Emerging trends in sourcing indicate a shift towards integrated solutions that combine inflators with additional functionalities, such as battery charging capabilities or portable air compressors. This versatility is particularly attractive to B2B buyers looking for multi-functional tools that can cater to diverse needs, from automotive workshops to roadside assistance providers. Moreover, the rise of e-commerce platforms is facilitating easier access to a broader range of products, enabling international buyers to compare and source automatic tyre inflators more efficiently.

Sustainability is becoming a critical factor for B2B buyers in the automatic tyre inflator sector. Companies are increasingly scrutinizing the environmental impact of their supply chains, seeking partners who prioritize eco-friendly practices. This includes using recyclable materials in product design and packaging, as well as ensuring that manufacturing processes minimize waste and energy consumption.

Additionally, certifications such as ISO 14001 for environmental management systems and adherence to REACH regulations for chemicals are gaining importance. B2B buyers are more likely to partner with suppliers who can demonstrate compliance with these standards, as they reflect a commitment to sustainability and responsible sourcing. By prioritizing ethical supply chains, companies can enhance their brand reputation and appeal to environmentally conscious consumers, thereby driving sales.

The evolution of the automatic tyre inflator market is a testament to technological advancement and changing consumer needs. Initially, inflators were manual devices requiring significant user input, but advancements in digital technology have transformed them into automated solutions that enhance user experience. The introduction of features such as preset pressure settings and automatic shut-off has simplified operation, making inflators more accessible to a broader audience.

As safety concerns and environmental regulations have intensified, manufacturers have responded by developing more efficient, reliable, and eco-friendly inflators. The integration of smart technology, including mobile app connectivity and real-time monitoring, is poised to further revolutionize the market, catering to the demands of modern consumers and businesses alike. This ongoing evolution presents significant opportunities for B2B buyers to invest in innovative products that meet contemporary safety and performance standards.

1. How do I solve issues with inconsistent tire pressure readings?

Inconsistent tire pressure readings can stem from various factors, including faulty inflators or environmental conditions. First, ensure you are using a high-quality automatic tire inflator with a reliable digital gauge. Regularly calibrate the inflator to maintain accuracy and check for any air leaks in the tire or valve stem. If problems persist, consider sourcing from suppliers known for quality assurance protocols. Additionally, investing in a model that allows for preset pressures and automatic shut-off can help mitigate human error during tire inflation.

2. What is the best automatic tire inflator for commercial fleet use?

When selecting an automatic tire inflator for commercial fleet applications, look for models with high PSI ratings, robust build quality, and rapid inflation capabilities. Features such as digital gauges, automatic shut-off, and compatibility with nitrogen inflation are essential for efficiency and accuracy. Brands known for their reliability, such as AstroAI and Martins Industries, often provide specialized solutions tailored to the demands of commercial fleets. Always consider the specific needs of your fleet, including tire sizes and expected usage frequency, to make an informed decision.

3. How can I vet suppliers for automatic tire inflators?

To effectively vet suppliers, start by researching their reputation in the industry. Look for customer reviews, testimonials, and case studies that showcase their products’ performance and reliability. Verify their certifications and compliance with international quality standards, such as ISO. Request product samples and inquire about their quality assurance processes. Establish communication to gauge their responsiveness and willingness to provide ongoing support. Networking within industry groups can also yield recommendations for reputable suppliers.

4. What are typical minimum order quantities (MOQs) for automatic tire inflators?

Minimum order quantities for automatic tire inflators can vary significantly based on the supplier and product specifications. Generally, MOQs range from 50 to 200 units for commercial orders. However, larger suppliers may offer more flexibility, especially for repeat customers or bulk orders. Always discuss your specific needs with potential suppliers to negotiate favorable terms. Understanding your projected sales volume can help you determine the right quantity to order without overextending your inventory.

5. What payment terms should I expect when sourcing tire inflators internationally?

International payment terms can differ based on the supplier’s location and the nature of the transaction. Common terms include net 30, 60, or 90 days, but upfront payments or deposits are often required, especially for first-time orders. Consider using secure payment methods such as letters of credit, which can provide protection for both parties. It’s essential to clarify payment terms during negotiations to avoid any misunderstandings that could disrupt your supply chain.

6. How do I ensure quality assurance for automatic tire inflators?

To ensure quality assurance, request detailed information on the supplier’s manufacturing processes and quality control measures. Certifications like ISO 9001 can indicate a commitment to quality. Consider implementing a third-party inspection service to evaluate products before shipment. Establish clear acceptance criteria and conduct regular audits of the supplier’s operations. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations.

7. What logistics considerations should I keep in mind for importing tire inflators?

When importing automatic tire inflators, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with international shipping and import regulations in your target market. Calculate total landed costs, including shipping, duties, and taxes, to accurately assess profitability. Additionally, ensure that your supplier provides the necessary documentation for customs clearance to avoid delays in delivery.

8. Can I customize automatic tire inflators for my brand?

Yes, many suppliers offer customization options for automatic tire inflators, including branding, color schemes, and specific features tailored to your market needs. Discuss your requirements during the initial negotiations and request samples of customized products. Be aware that customization may affect MOQs and lead times, so factor these into your planning. Establishing a strong relationship with your supplier can enhance the customization process and lead to better outcomes for your brand.

Bereich: martinsindustries.com

Registriert: 2005 (20 Jahre)

Einleitung: Automatic Tire Inflators for Professionals, Wall-mounted and handheld options, compatible with nitrogen inflation, digital gauge for accurate inflation/deflation, various models available including: Handheld digital tire inflator – Flate Mate Handheld MH-30 ($107.72), Analog Handheld Tire Inflator – Flate Mate Analog Handheld MH-31-PSI (Pre-order $107.72), Automatic Tire Inflator – Flatematic Hand…

Bereich: jamecpem.com

Registriert: 2012 (13 Jahre)

Einleitung: 14 Products Found: 1. 4 Way Inflator Manifold – $419.95 2. Digital Tyre Inflator ACS1500 – $169.95 3. Spider Kit – $389.99 (Out Of Stock) 4. Tyre Inflator – $119.95 5. Tyre Inflator – $134.99 (Out Of Stock) 6. Tyre Inflator – Bar Style – $99.95 7. Tyre Inflator – Clip On Chuck – $59.95 8. Tyre Inflator – Deluxe Automatic – $789.95 9. Tyre Inflator – Hold On Chuck – $89.95 10. Tyre Inflator – TDR 5…

Bereich: morrflate.com

Registriert: 2019 (6 Jahre)

Einleitung: MORRFlate offers a range of off-road air inflation and deflation tools and accessories, including:

1. **Air Hub**: Digital user PSI selection, Automagic Inflation and Deflation, Patent pending Set Your Pressure Technology.

2. **MORRFlate TenSix™ PSI Pro™**: A 12v Portable Compressor designed for off-road adventures, allowing users to set their PSI and walk away. Stronger and faster than previous…

In conclusion, strategic sourcing plays a pivotal role in optimizing the procurement of automatic tyre inflators, ensuring that international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, can secure high-quality products that meet their operational needs. Key takeaways emphasize the importance of understanding the specific requirements of your market, such as compatibility with local tire standards and the availability of service support.

Investing in automatic tyre inflators not only enhances efficiency in tire maintenance but also reduces downtime and improves safety for end-users. As the market continues to evolve with advancements in technology, buyers should consider models that offer features like digital gauges, automatic shut-off, and multi-purpose functionality. These features can significantly improve user experience and operational effectiveness.

Looking ahead, the demand for reliable and efficient tyre inflators is expected to grow, driven by increasing vehicle ownership and the emphasis on safety. Now is the time to engage with reputable suppliers and explore innovative solutions that align with your business goals. By leveraging strategic sourcing, you can position your organization for success in a competitive landscape.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.