In today’s global automotive market, sourcing a reliable AutoZone tire pressure gauge is essential for businesses aiming to enhance vehicle performance and safety. One of the key challenges B2B buyers face is ensuring that they select a product that meets their specific operational needs while also adhering to regional standards. This guide is designed to navigate the complexities of sourcing tire pressure gauges, providing insights into various types available, their applications across different vehicle models, and practical advice on supplier vetting.

By delving into the costs associated with tire pressure gauges and exploring the nuances of tire pressure monitoring systems, this comprehensive resource empowers international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia. With a clear understanding of product specifications and market trends, businesses can make informed purchasing decisions that not only optimize their fleet operations but also contribute to overall customer satisfaction.

The guide serves as a valuable tool for establishing robust supplier relationships and enhancing procurement strategies, ensuring that your organization remains competitive in a rapidly evolving market. Whether you are looking to purchase in bulk or seeking specialized equipment, this resource will help streamline your sourcing process while maximizing value.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Analog Tire Pressure Gauge | Mechanical dial for pressure reading; no batteries required | Automotive repair shops, fleet maintenance | Vorteile: Durable, simple operation; Nachteile: Less precise than digital models |

| Digital Tire Pressure Gauge | Digital display for precise readings; often includes features like backlighting | Car dealerships, tire service centers | Vorteile: Accurate, easy to read; Nachteile: Requires batteries, can be pricier |

| Stick Tire Pressure Gauge | Compact, portable design; pressure reading via a sliding scale | Mobile mechanics, personal use | Vorteile: Lightweight, cost-effective; Nachteile: Limited visibility in low light |

| Bluetooth Tire Pressure Gauge | Connects to smartphones for real-time monitoring; alerts for low pressure | Fleet management, logistics companies | Vorteile: Convenient data tracking; Nachteile: Higher cost, reliance on technology |

| Tire Pressure Monitoring System (TPMS) | Integrated system alerting for low pressure; often built into the vehicle | OEM manufacturers, automotive suppliers | Vorteile: Automatic monitoring, enhances safety; Nachteile: Complex installation, potential for sensor failure |

Analog tire pressure gauges utilize a mechanical dial to display pressure readings, making them a reliable option for many automotive professionals. These gauges do not require batteries, which enhances their durability and ease of use in various environments. They are particularly suited for automotive repair shops and fleet maintenance operations where frequent tire checks are necessary. However, while they are robust, analog gauges may lack the precision of digital models, which can be a critical factor for buyers focused on accuracy.

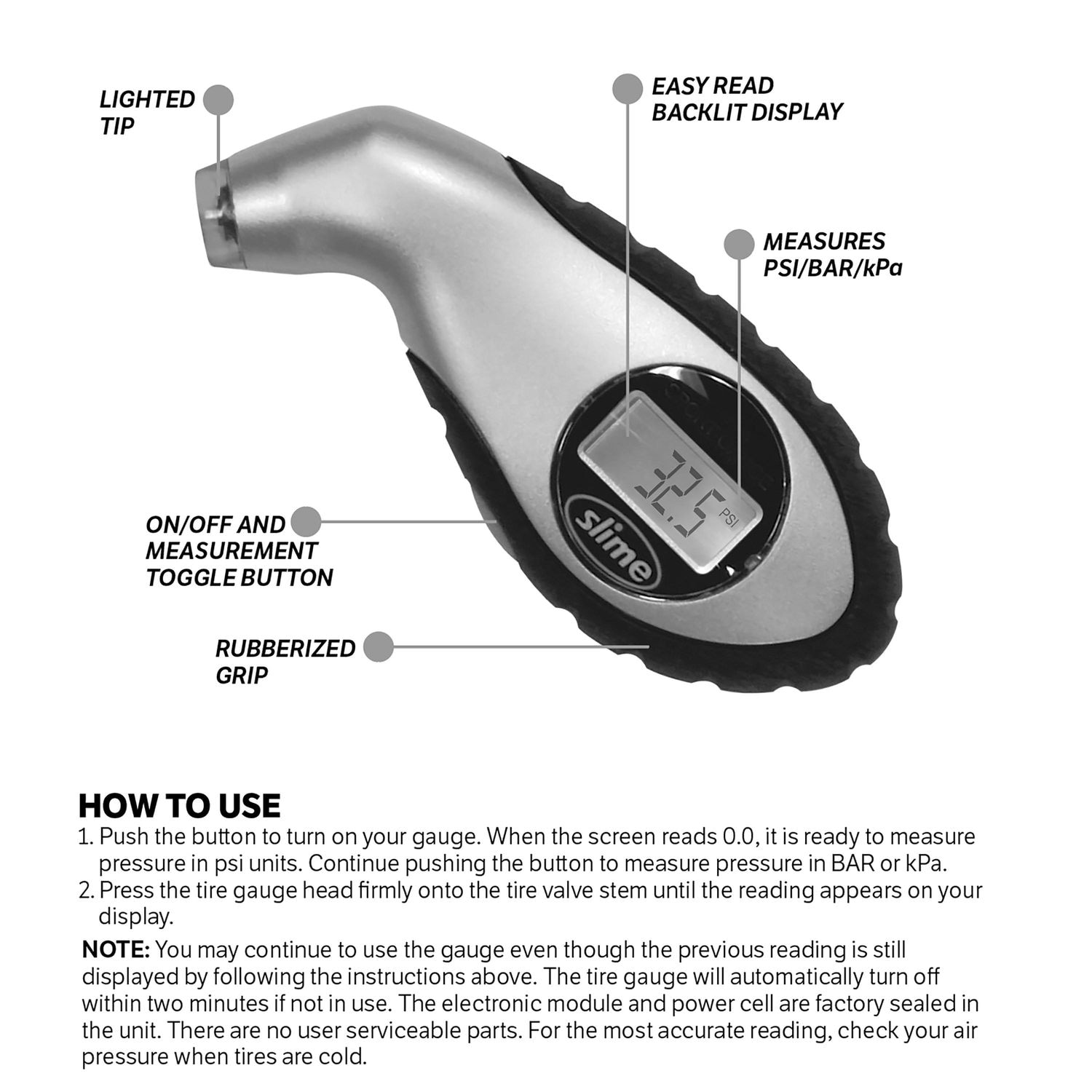

Digital tire pressure gauges provide precise readings with a clear digital display, often featuring backlighting for visibility in low-light conditions. These gauges are ideal for car dealerships and tire service centers where accuracy is paramount. Their ease of use and quick readings make them a favorite among professionals. However, they do require batteries, which can add to the long-term maintenance costs, and they are generally more expensive than their analog counterparts.

Stick tire pressure gauges are compact and highly portable, making them an excellent choice for mobile mechanics or personal use. Their simple design allows for straightforward pressure checks without complicated features. While they are cost-effective and lightweight, their limited visibility in dim lighting can be a drawback, potentially affecting usability in certain conditions. Buyers should consider their operational environment when opting for this gauge type.

Bluetooth tire pressure gauges offer the convenience of real-time monitoring by connecting to smartphones or tablets. This feature allows for alerts when tire pressure falls below safe levels, making them particularly beneficial for fleet management and logistics companies. While they provide advanced tracking capabilities, the reliance on technology and higher cost may deter some buyers. However, the benefits of convenience and safety often outweigh these concerns for businesses focused on efficiency.

TPMS is an integrated system that automatically monitors tire pressure and alerts drivers of any discrepancies. This system is essential for OEM manufacturers and automotive suppliers who prioritize safety in their vehicles. The convenience of automatic monitoring significantly enhances safety on the road, but it may involve complex installation and potential sensor failures. Businesses should weigh the long-term safety benefits against the initial installation complexities and costs.

| Industrie/Sektor | Specific Application of autozone tire pressure gauge | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automotive Repair & Maintenance | Routine tire pressure checks for vehicles | Enhances vehicle safety and extends tire lifespan, reducing costs | Reliability and accuracy of readings; compatibility with various vehicle types |

| Transport und Logistik | Fleet management and maintenance | Improves fuel efficiency and reduces breakdowns, optimizing operational costs | Durability for frequent use; ease of use and portability |

| Agricultural Equipment | Monitoring tire pressure on tractors and machinery | Ensures optimal performance and reduces soil compaction, enhancing productivity | Adaptability for different tire sizes; weather resistance |

| Construction & Heavy Machinery | Tire pressure checks on construction vehicles | Enhances safety and efficiency, minimizing downtime due to tire issues | Robust design for rugged environments; ease of calibration |

| Mining Operations | Tire pressure monitoring for heavy mining trucks | Increases tire life and reduces fuel consumption, leading to significant cost savings | High durability; ability to withstand harsh conditions |

In automotive repair and maintenance, the AutoZone tire pressure gauge is essential for ensuring that vehicles are operating safely and efficiently. Regular tire pressure checks help mechanics identify under-inflated or over-inflated tires that can lead to uneven wear, reduced fuel efficiency, and compromised vehicle handling. For B2B buyers in this sector, the gauge must provide reliable and accurate readings, especially in regions where temperature fluctuations are common, affecting tire pressure.

Illustrative image related to autozone tire pressure gauge

In the transportation and logistics industry, the AutoZone tire pressure gauge is crucial for fleet management. Regular monitoring of tire pressure across a fleet of vehicles enhances fuel efficiency, reduces the risk of tire blowouts, and minimizes maintenance costs. For international buyers, especially in regions like Africa and South America, sourcing gauges that are durable and easy to use is vital, as they may face challenging road conditions that demand reliable equipment.

Farmers and agricultural businesses use the AutoZone tire pressure gauge to monitor the tire pressure of tractors and other machinery. Maintaining optimal tire pressure is critical to achieving maximum traction and minimizing soil compaction, which can adversely affect crop yields. B2B buyers in this sector should consider gauges that are adaptable to various tire sizes and can withstand outdoor conditions, ensuring consistent performance in the field.

In the construction industry, the AutoZone tire pressure gauge is vital for checking the tire pressure of heavy machinery such as excavators and bulldozers. Proper tire pressure ensures that these machines operate efficiently, reducing the likelihood of tire-related issues that can lead to costly downtime. Buyers in this sector should prioritize gauges that are robust and designed for rugged environments, as well as those that are easy to calibrate for consistent accuracy.

Illustrative image related to autozone tire pressure gauge

Mining operations rely on the AutoZone tire pressure gauge to monitor the tire pressure of heavy trucks used in transporting materials. Maintaining proper tire pressure not only extends the life of the tires but also reduces fuel consumption, significantly impacting operational costs. For buyers in the mining sector, sourcing gauges that can withstand harsh conditions and provide quick, accurate readings is essential for maintaining productivity and safety on-site.

Das Problem: In regions like Africa and South America, where road conditions can vary significantly, maintaining the correct tire pressure in a fleet of vehicles is critical for safety and operational efficiency. B2B buyers managing fleets often face challenges with tire pressure gauges that provide inaccurate readings due to environmental factors such as humidity or temperature fluctuations. An inaccurate gauge can lead to under-inflation or over-inflation, resulting in increased tire wear, reduced fuel efficiency, and potential safety hazards.

Die Lösung: To ensure accurate tire pressure readings, B2B buyers should invest in high-quality AutoZone tire pressure gauges, specifically those with digital displays that provide precise readings. It’s essential to regularly calibrate these gauges according to manufacturer recommendations and to compare readings with a known accurate gauge periodically. Buyers should also train their staff on proper usage techniques, including how to ensure a tight seal when measuring pressure to prevent air leaks. Additionally, implementing a routine maintenance schedule that includes regular checks and calibrations will significantly enhance the reliability of tire pressure measurements across the fleet.

Das Problem: When sourcing tire pressure gauges, B2B buyers may encounter compatibility issues with different types of valve stems found on various vehicles. This is particularly common in regions like the Middle East and Europe, where a diverse range of vehicle makes and models are prevalent. Incompatibility can lead to frustration, wasted time, and even the need for additional purchases to ensure all vehicles can be serviced properly.

Illustrative image related to autozone tire pressure gauge

Die Lösung: To avoid compatibility issues, buyers should prioritize purchasing multi-purpose tire pressure gauges that come with various attachments or those specifically designed to work with a wide range of valve stems. AutoZone offers gauges that accommodate both Schrader and Presta valves, making them versatile for different vehicles. Furthermore, buyers should review their fleet’s vehicle specifications and ensure that the selected gauges meet these requirements. Investing in a few specialized gauges for unique vehicles can save time and ensure that all vehicles are properly maintained without the risk of missing critical tire pressure checks.

Das Problem: User errors during the tire pressure measurement process can lead to inconsistent results, especially in large operations where multiple personnel may be involved. This issue is prevalent in regions with high vehicle turnover, such as Nigeria and other emerging markets. Common mistakes include not placing the gauge correctly on the valve stem, misreading the gauge, or failing to account for changes in pressure due to temperature variations.

Die Lösung: To mitigate user error, B2B buyers should invest in training sessions for their employees focused on the correct usage of AutoZone tire pressure gauges. This training should cover best practices, such as the proper technique for attaching the gauge to the valve stem and understanding how temperature can affect tire pressure. Additionally, implementing a checklist for tire maintenance can help standardize the process and reduce errors. Buyers may also consider digital gauges with automatic shut-off features that minimize human error by providing clear, easy-to-read digital displays. Regular workshops or refreshers on tire maintenance practices can further enhance staff competency and ensure accurate tire pressure management across all vehicles.

When selecting materials for tire pressure gauges, several factors must be considered, including performance, durability, cost, and compliance with international standards. Below are analyses of four common materials used in the construction of AutoZone tire pressure gauges.

Plastic is frequently used in the casing and components of tire pressure gauges due to its lightweight and cost-effective nature. Key properties include good temperature resistance, typically up to 80°C (176°F), and decent impact resistance.

Vorteile: Plastic is generally low-cost, easy to mold, and lightweight, which makes it suitable for portable gauges. Its corrosion resistance is beneficial in humid or wet environments, common in many regions.

Nachteile: However, plastic may not withstand extreme temperatures or pressures as well as metals. Over time, exposure to UV light can degrade the material, leading to brittleness.

Illustrative image related to autozone tire pressure gauge

Auswirkungen auf die Anwendung: While plastic is compatible with air and nitrogen, it may not be suitable for gauges used in high-pressure environments, such as those found in industrial applications.

Überlegungen für internationale Käufer: Buyers in regions like Africa and South America should ensure that the plastic used complies with local environmental regulations. Standards such as ASTM D6400 for biodegradability may be relevant.

Aluminum is another common material used in tire pressure gauges, especially for the body and internal components. It offers excellent strength-to-weight ratio and good corrosion resistance.

Illustrative image related to autozone tire pressure gauge

Vorteile: Aluminum is durable and can withstand higher temperatures and pressures, making it suitable for both consumer and commercial applications. It also has a lower weight compared to steel, enhancing portability.

Nachteile: The primary disadvantage is cost; aluminum is generally more expensive than plastic. Additionally, while it resists corrosion, it can still oxidize if not properly coated.

Auswirkungen auf die Anwendung: Aluminum is compatible with various gases, including air and nitrogen, and is often preferred in environments where durability is critical.

Überlegungen für internationale Käufer: Buyers from Europe and the Middle East should look for aluminum products that meet EN standards for material quality and safety.

Steel, particularly stainless steel, is used in high-end tire pressure gauges due to its exceptional durability and pressure resistance.

Vorteile: Steel offers superior strength and can withstand extreme conditions, making it ideal for heavy-duty applications. It is also resistant to deformation under high pressure.

Nachteile: The main drawbacks are its weight and cost, which are higher than plastic and aluminum. Additionally, if not properly treated, steel can corrode over time, especially in humid environments.

Auswirkungen auf die Anwendung: Steel gauges are well-suited for industrial applications where high pressure is a norm, ensuring accurate readings under demanding conditions.

Überlegungen für internationale Käufer: Buyers in regions like Saudi Arabia should ensure that steel gauges comply with local standards, such as the Saudi Standards, Metrology and Quality Organization (SASO) regulations.

Rubber is often used in seals and gaskets within tire pressure gauges. Its flexibility and resilience make it an ideal choice for ensuring airtight seals.

Vorteile: Rubber is highly effective at preventing air leaks and can withstand a range of temperatures. It is also relatively inexpensive and easy to source.

Illustrative image related to autozone tire pressure gauge

Nachteile: However, rubber can degrade over time due to exposure to ozone, UV light, and extreme temperatures. This can lead to cracks and loss of sealing capability.

Auswirkungen auf die Anwendung: Rubber is compatible with air and nitrogen but may not be suitable for gauges that come into contact with oils or solvents.

Überlegungen für internationale Käufer: Buyers should ensure that the rubber used meets relevant international standards, such as ASTM D2000, to ensure quality and durability.

| Material | Typical Use Case for AutoZone Tire Pressure Gauge | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kunststoff | Casing and lightweight components | Leicht und kostengünstig | Limited temperature and pressure resistance | Niedrig |

| Aluminium | Body and internal components | Langlebig und korrosionsbeständig | Higher cost than plastic | Mittel |

| Stahl | Heavy-duty applications | Superior strength and pressure resistance | Heavier and can corrode | Hoch |

| Gummi | Seals and gaskets | Effective at preventing leaks | Degrades over time under harsh conditions | Niedrig |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, durability, and compliance with local standards.

The manufacturing process of tire pressure gauges, such as those provided by AutoZone, involves several key stages that ensure the product meets both quality and performance standards. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

The manufacturing journey begins with material selection. High-quality tire pressure gauges typically use robust materials like stainless steel for the body, rubber for the valve stem, and high-grade plastic for the gauge casing. These materials are chosen for their durability and resistance to environmental factors like moisture and temperature fluctuations.

Before production begins, these materials undergo thorough inspection and testing to confirm they meet industry standards. Suppliers often provide certificates of compliance to assure buyers of the material’s quality and origin.

The next stage is forming, where raw materials are shaped into the required components. This process may involve precision machining for metal parts, injection molding for plastic components, and rubber molding for seals and valve stems. Advanced techniques like CNC machining ensure high accuracy, which is crucial for the gauge’s performance.

Assembly involves fitting these components together, often using automated machinery to increase efficiency and consistency. Skilled workers may perform final assembly steps to ensure everything is fitted correctly, particularly the calibration of the gauge to ensure accurate readings.

Finishing processes are essential for enhancing the durability and aesthetics of tire pressure gauges. These processes may include surface treatments such as anodizing or powder coating for metal parts to prevent corrosion. Additionally, thorough cleaning and polishing of the gauge surfaces are conducted to ensure they are free from defects and contaminants.

Once the finishing touches are applied, the product undergoes a final inspection to ensure all components meet the required specifications. This stage is critical as it determines the overall quality and readiness of the product for market distribution.

Quality control (QC) is an integral part of the manufacturing process, ensuring that each tire pressure gauge meets international and industry-specific standards. For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding these QC measures is crucial.

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that the manufacturer has established processes to ensure consistent quality in their products.

Additional certifications may include CE marking for compliance with European health, safety, and environmental protection standards, and API (American Petroleum Institute) standards for gauges used in specific industrial applications. B2B buyers should look for these certifications when evaluating suppliers.

The QC process includes several checkpoints throughout the manufacturing journey:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint involves inspecting raw materials before they enter the production line. Suppliers must provide documentation proving that materials meet specified standards.

Prozessbegleitende Qualitätskontrolle (IPQC): During production, random samples are tested at various stages to ensure components are being manufactured correctly. This can include dimensional checks and functional tests.

Endgültige Qualitätskontrolle (FQC): After assembly, the final products undergo comprehensive testing to ensure they meet all performance standards. This often includes pressure testing, accuracy checks, and aesthetic inspections.

Several testing methods are employed to verify the accuracy and reliability of tire pressure gauges. Common tests include:

Calibration Tests: Ensuring the gauge reads accurately across the specified pressure range. This is often done using calibrated reference gauges.

Dauerhaftigkeitsprüfung: Simulating real-world conditions such as temperature fluctuations, humidity, and physical impacts to assess the gauge’s performance under stress.

Funktionsprüfung: Checking the gauge for leaks and ensuring that it maintains pressure over time without degradation in performance.

For international B2B buyers, particularly those from diverse regions, verifying the quality control measures of potential suppliers is vital. Here are actionable steps:

Request Documentation: Ask for quality certifications and inspection reports. Reliable suppliers should readily provide this information.

Conduct Audits: Arrange for on-site audits to assess the manufacturing processes and QC measures. This firsthand observation can provide invaluable insights into the supplier’s operational standards.

Utilize Third-Party Inspection Services: Engaging third-party inspection services can help verify that products meet specified standards before shipment, reducing the risk of receiving subpar goods.

Review Supplier Performance History: Evaluate the supplier’s track record regarding product recalls, customer complaints, and adherence to delivery schedules. This historical data can offer insights into the reliability of the supplier.

When sourcing tire pressure gauges, international buyers should be aware of potential certification nuances. For instance, products sold in the European Union must comply with CE marking, while those in other markets may require different certifications. Understanding these requirements can help buyers avoid compliance issues and ensure product acceptance in their respective markets.

Additionally, buyers should consider the implications of tariffs and import regulations that may affect the overall cost and feasibility of sourcing from specific regions. Staying informed about international trade agreements can also facilitate smoother transactions.

Illustrative image related to autozone tire pressure gauge

In-depth knowledge of the manufacturing processes and quality assurance measures for AutoZone tire pressure gauges enables B2B buyers to make informed decisions. By understanding material preparation, forming, assembly, finishing, and the critical role of quality control, buyers can assess suppliers effectively. Furthermore, awareness of international standards and testing methods aids in ensuring product reliability and compliance, ultimately contributing to successful procurement strategies in diverse markets.

In the competitive landscape of automotive parts procurement, sourcing a reliable tire pressure gauge, such as those offered by AutoZone, is crucial for maintaining vehicle safety and performance. This guide provides a step-by-step checklist to assist B2B buyers in evaluating and procuring tire pressure gauges effectively.

Understanding the technical specifications of the tire pressure gauge is essential. Determine the types of vehicles you are servicing and the required pressure range for each. Consider whether you need digital or analog gauges, as well as features such as automatic shutoff or backlighting, which can enhance usability in various conditions.

Illustrative image related to autozone tire pressure gauge

Conduct thorough research to identify suppliers with a solid reputation in the automotive parts market. Look for those who specialize in tire pressure gauges and have a proven track record. Evaluate their online presence, customer reviews, and industry affiliations to gauge reliability and service quality.

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence helps ensure that you are partnering with a supplier that meets your quality and service expectations.

Analyze the pricing structure of the tire pressure gauges and compare it with competitors. Ensure that the pricing aligns with your budget while considering the total cost of ownership, including shipping and potential import tariffs.

Illustrative image related to autozone tire pressure gauge

Before finalizing your order, request samples of the tire pressure gauges you are considering. Testing these samples can provide valuable insights into their accuracy, durability, and overall performance, which is vital for ensuring customer satisfaction.

Understanding the warranty and support policies offered by the supplier can save you significant time and money in the long run. A robust warranty indicates confidence in the product’s quality, while good customer support is essential for resolving any issues that may arise post-purchase.

Once you’ve selected a supplier and confirmed the specifications, finalize your order. Monitor the delivery process to ensure that the gauges arrive on time and in good condition, as delays can impact your operations.

By following this checklist, B2B buyers can make informed decisions when sourcing AutoZone tire pressure gauges, ultimately ensuring better service delivery and customer satisfaction in their automotive maintenance operations.

When sourcing tire pressure gauges from AutoZone, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materialien: The materials used in tire pressure gauges typically include plastic, metal, and rubber components. The choice of high-quality materials not only affects durability but also the accuracy of the gauge. For instance, brass fittings might be more expensive but offer better longevity compared to cheaper alternatives.

Arbeit: Labor costs can vary depending on the region and manufacturing standards. In regions with higher labor costs, such as Europe, the overall price might be elevated compared to areas with lower labor costs, like parts of South America or Africa.

Fertigungsgemeinkosten: This includes costs related to factory utilities, equipment maintenance, and administrative expenses. Efficient production processes can help keep these costs lower, which can be advantageous for bulk buyers.

Werkzeugbau: The initial investment in tooling for manufacturing gauges can be significant. This upfront cost is usually amortized over larger production runs, influencing the pricing for smaller orders.

Qualitätskontrolle (QC): Rigorous QC processes ensure that each gauge meets safety and performance standards. The costs associated with testing and compliance can impact the final price, particularly for international buyers who may require specific certifications.

Logistik: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, transportation method, and customs duties can significantly affect overall costs.

Marge: Suppliers typically include a profit margin in their pricing, which can vary based on market demand and competition. Understanding the typical margins in the industry can help buyers negotiate better terms.

Several factors influence the pricing of tire pressure gauges. Understanding these can help international buyers, especially from Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Volumen/MOQ (Mindestbestellmenge): Bulk orders often come with discounts. Buyers should evaluate their needs carefully and consider purchasing larger quantities to lower the per-unit cost.

Spezifikationen und Anpassungen: Custom specifications can increase costs. Buyers should determine whether standard models meet their needs or if customization is essential for their market.

Materialqualität und Zertifizierungen: Gauges with higher quality materials and certifications (e.g., ISO standards) generally command higher prices. Buyers should weigh the importance of these factors against their budget.

Lieferanten-Faktoren: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their quality assurance and after-sales support, which can be beneficial in the long run.

Incoterms: Understanding international shipping terms is crucial. Incoterms define the responsibilities of buyers and sellers in shipping, which can affect overall costs, including insurance, freight, and duties.

To maximize cost efficiency and ensure a favorable purchasing experience, B2B buyers should consider the following strategies:

Verhandlung: Engaging in negotiations can lead to better pricing, especially for larger orders. Buyers should be prepared to discuss volume commitments and payment terms.

Gesamtbetriebskosten (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, replacement costs, and potential savings from using high-quality gauges that reduce wear and tear on tires.

Nuancen in der Preisgestaltung für internationale Käufer: Be aware of currency fluctuations, import tariffs, and local market conditions that can impact pricing. Establishing relationships with local distributors can also provide insights into regional pricing trends.

Research and Comparison: Conduct thorough market research and compare prices from multiple suppliers. This practice helps in identifying the best value and ensures that the selected gauge meets the required specifications.

Stay Informed on Industry Trends: Keeping abreast of advancements in tire pressure technology and shifts in market demand can give buyers a competitive edge when sourcing products.

By understanding these cost structures and pricing influencers, international B2B buyers can make strategic sourcing decisions that align with their business objectives while ensuring quality and reliability in tire pressure gauges.

When it comes to maintaining optimal tire pressure, selecting the right tools is crucial for vehicle safety and efficiency. While the AutoZone tire pressure gauge is a popular choice among consumers, various alternative solutions exist that may better suit the specific needs of international B2B buyers. This analysis compares the AutoZone tire pressure gauge with two viable alternatives: digital tire pressure gauges and tire pressure monitoring systems (TPMS).

Illustrative image related to autozone tire pressure gauge

| Vergleich Aspekt | AutoZone Tire Pressure Gauge | Digital Tire Pressure Gauge | Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Leistung | Accurate readings; manual use | High precision; instant readouts | Continuous monitoring; alerts driver |

| Kosten | Low to moderate price | Moderate price | Higher initial investment |

| Leichte Implementierung | Simple; requires user input | User-friendly; easy to read | Requires installation; may need calibration |

| Wartung | Minimal; battery replacement if digital | Minimal; battery replacement | Periodic checks for sensor functionality |

| Bester Anwendungsfall | Quick checks; DIY maintenance | Frequent use; professional settings | Fleet management; long-term monitoring |

Digital Tire Pressure Gauge

Digital tire pressure gauges offer a modern twist on traditional gauges, providing high precision and instant readings. They are user-friendly and often feature backlit displays for easy reading in low-light conditions. However, they tend to be more expensive than manual gauges and require battery replacements. For businesses that prioritize accuracy and ease of use, a digital gauge can be an excellent choice, particularly in settings where tire pressure is frequently monitored.

Tire Pressure Monitoring System (TPMS)

TPMS represents a more advanced technology, continuously monitoring tire pressure and alerting the driver to any deviations from the recommended levels. This system is particularly beneficial for fleet management, where tire safety is crucial for operational efficiency. However, TPMS can involve a higher initial investment due to installation costs and may require periodic checks to ensure sensor functionality. For businesses operating large fleets or requiring ongoing monitoring, investing in a TPMS can provide significant long-term benefits.

Selecting the right tire pressure monitoring solution depends on the specific requirements of the business. For those needing quick, cost-effective checks, the AutoZone tire pressure gauge remains a solid option. However, if accuracy and ease of use are paramount, a digital tire pressure gauge may be more suitable. For organizations managing fleets or seeking continuous monitoring capabilities, a TPMS offers advanced features that can enhance safety and operational efficiency. Ultimately, B2B buyers should assess their unique needs, budget, and the scale of operations to make the most informed decision.

Understanding the essential technical properties of tire pressure gauges is crucial for B2B buyers, particularly in automotive markets across Africa, South America, the Middle East, and Europe. Here are several critical specifications:

Material Klasse: Tire pressure gauges are typically made from high-grade plastic or metal components. The choice of materials affects durability, accuracy, and resistance to environmental factors. For instance, a gauge made from stainless steel may offer better longevity and resistance to corrosion, which is vital in humid or salty climates.

Druckbereich: The typical pressure range for automotive tire gauges is between 0-60 PSI (pounds per square inch). Some gauges may extend up to 100 PSI for heavy-duty applications. Understanding the pressure range is essential for ensuring the gauge meets the specific needs of various vehicles, especially in regions where tire specifications can vary significantly.

Accuracy/Tolerance: Accuracy is critical in tire pressure gauges, typically measured within ±1 PSI. High accuracy helps in preventing over-inflation or under-inflation, which can lead to safety issues and increased tire wear. B2B buyers should prioritize gauges that provide reliable readings to maintain optimal vehicle performance and safety.

Display Type: Tire pressure gauges come with analog (dial) or digital displays. Digital gauges often offer easier readability and quicker response times, making them more user-friendly. For businesses that prioritize efficiency, investing in digital gauges may lead to improved service delivery in tire maintenance.

Calibration Standards: Calibration refers to the process of adjusting the gauge to ensure accurate readings. A gauge that complies with international calibration standards (like ISO 17025) is preferable for B2B transactions, as it assures buyers of its reliability and performance.

Größe und Tragbarkeit: Compact and lightweight designs are advantageous for mobile tire service providers. A gauge that is easy to carry can enhance service efficiency, especially in roadside assistance scenarios.

Familiarity with trade terminology can greatly enhance the purchasing process for B2B buyers. Here are some commonly used terms:

OEM (Original Equipment Manufacturer): This term refers to products made by the original manufacturer of the vehicle. Buying OEM tire pressure gauges ensures compatibility and performance standards, which is crucial for businesses looking to maintain quality.

MOQ (Mindestbestellmenge): MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ helps businesses plan their inventory and manage costs effectively, especially when sourcing from international suppliers.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to invite them to bid on providing specific products or services. In the context of tire pressure gauges, submitting an RFQ can help businesses compare prices and terms from multiple suppliers.

Incoterms (Internationale Handelsklauseln): These are standard trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers to understand shipping costs and liability.

Vorlaufzeit: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead time is crucial for inventory management and ensuring that tire maintenance operations run smoothly without delays.

Gewährleistungsfrist: The warranty period is the time frame during which a product is covered for defects or issues. A longer warranty period on tire pressure gauges can indicate a manufacturer’s confidence in their product and can be an important consideration for businesses looking to minimize long-term costs.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing tire pressure gauges, ensuring they select the right products for their operations.

The global tire pressure gauge market is experiencing notable growth driven by several factors. Firstly, increasing vehicle ownership, particularly in emerging markets in Africa, South America, and the Middle East, is leading to heightened demand for automotive maintenance tools. As consumers and businesses become more aware of the importance of tire maintenance for safety and fuel efficiency, the market for tire pressure gauges, including those offered by AutoZone, is expected to expand.

Technological advancements are also shaping the market dynamics. Digital tire pressure gauges are becoming increasingly popular due to their accuracy and ease of use. Furthermore, integration with mobile applications for real-time monitoring is emerging as a trend that appeals to tech-savvy consumers. B2B buyers should consider sourcing these advanced tools to meet the evolving demands of their customers.

Illustrative image related to autozone tire pressure gauge

Additionally, supply chain dynamics are shifting, with a focus on local sourcing and partnerships to mitigate risks associated with global supply chain disruptions. Buyers from regions like Nigeria and Saudi Arabia are encouraged to establish relationships with local distributors to ensure timely access to products. The growing emphasis on sustainability and eco-friendly products is also influencing sourcing decisions, with buyers seeking gauges that are made from recyclable materials or are produced using environmentally friendly processes.

Sustainability is becoming an essential consideration for B2B buyers in the auto parts sector. The environmental impact of automotive maintenance products, including tire pressure gauges, is significant, as manufacturing processes can contribute to pollution and waste. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices.

Ethical sourcing is equally crucial, as consumers worldwide are more inclined to support brands that align with their values. Companies that can provide certifications indicating responsible sourcing practices, such as ISO 14001 for environmental management or other ‘green’ certifications, will likely have a competitive edge in the market. B2B buyers should seek suppliers who implement ethical labor practices and maintain transparency in their supply chains, ensuring that products are produced in a socially responsible manner.

Furthermore, the use of eco-friendly materials in the production of tire pressure gauges is gaining traction. Products that incorporate recycled materials or are designed for longevity can attract environmentally conscious customers, providing B2B buyers with unique selling points in their offerings.

The tire pressure gauge has evolved significantly since its inception. Originally, these tools were purely mechanical, relying on analog dials for pressure readings. Over time, advancements in technology have led to the development of more precise digital gauges, enhancing usability and accuracy. AutoZone has been at the forefront of this evolution, offering a range of tire pressure gauges that cater to both consumer and professional markets.

The rise of the digital age has transformed how these tools are marketed and utilized. The integration of smart technologies, such as sensors linked to mobile apps, reflects changing consumer preferences toward convenience and real-time data. As this sector continues to evolve, B2B buyers must stay informed about new technologies and trends to remain competitive in the marketplace.

How do I ensure the accuracy of the AutoZone tire pressure gauge?

To guarantee the accuracy of your AutoZone tire pressure gauge, regularly calibrate it according to the manufacturer’s recommendations. Calibration can typically be performed by a professional service or according to specific guidelines provided with the gauge. Additionally, compare readings with a known accurate gauge to identify any discrepancies. Ensure that the gauge is free from dirt and debris, particularly around the valve stem connection, as this can affect the reading.

What is the best tire pressure gauge for commercial use?

For commercial applications, a digital tire pressure gauge is often the best choice due to its precision and ease of reading. Look for models that offer features like automatic shut-off, backlit displays for low-light conditions, and a wide pressure range suitable for various vehicle types. Brands like AutoZone often provide durable options that withstand heavy usage, making them ideal for businesses that require frequent tire pressure checks.

What are the minimum order quantities (MOQ) for purchasing tire pressure gauges from AutoZone?

Minimum order quantities can vary based on the supplier and the specific product line. For tire pressure gauges, inquire directly with AutoZone or authorized distributors to confirm their MOQ policies. Typically, bulk purchases may lead to better pricing and terms, so establishing a relationship with a supplier can also provide flexibility on MOQs.

What payment terms are commonly available for B2B buyers of tire pressure gauges?

Payment terms for B2B transactions can vary significantly. Common options include net 30, net 60, or net 90 days, depending on the supplier’s policies and the buyer’s creditworthiness. Some suppliers may also offer discounts for early payment or require a deposit for large orders. Always confirm terms before finalizing a purchase to ensure they align with your cash flow requirements.

How can I vet suppliers for tire pressure gauges effectively?

To vet suppliers for tire pressure gauges, start by checking their reputation through online reviews, references, and industry certifications. Assess their compliance with international quality standards, such as ISO certifications. Additionally, request product samples to evaluate quality firsthand and inquire about their manufacturing processes and sourcing of materials to ensure they meet your specifications.

What logistics considerations should I keep in mind when sourcing tire pressure gauges internationally?

When sourcing tire pressure gauges internationally, consider shipping costs, customs duties, and delivery timelines. Evaluate the supplier’s ability to manage logistics effectively, including their experience with international shipping and handling. Additionally, be aware of any regulations specific to your country regarding the importation of automotive tools and equipment to avoid delays or additional fees.

Can I customize the AutoZone tire pressure gauge for my brand?

Many suppliers, including AutoZone, offer customization options for bulk purchases. This can include branding the gauges with your company logo or specific color schemes that align with your brand identity. Discuss your customization needs with the supplier’s sales team to understand available options, associated costs, and lead times for customized orders.

What quality assurance measures should I expect from my tire pressure gauge supplier?

A reputable tire pressure gauge supplier should implement strict quality assurance measures, including regular product testing and adherence to industry standards. Request information on their quality control processes and any certifications they hold. It’s also beneficial to inquire about their return policy and warranty offerings, as these can indicate the supplier’s confidence in their product quality.

Could not verify enough suppliers for autozone tire pressure gauge to create a list at this time.

As the automotive industry continues to evolve, the importance of effective tire maintenance cannot be overstated. Sourcing high-quality tire pressure gauges, such as those offered by AutoZone, plays a crucial role in ensuring vehicle safety, enhancing fuel efficiency, and extending tire lifespan. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, aligning with reliable suppliers like AutoZone can lead to significant operational benefits.

Strategic sourcing of tire pressure gauges not only fosters better vehicle performance but also addresses the growing demand for safety and reliability in automotive maintenance. By investing in quality tools, businesses can reduce long-term costs associated with tire wear and vehicle repairs, thereby improving their bottom line.

Looking ahead, the automotive market will likely see increased emphasis on sustainability and efficiency, making it imperative for buyers to adopt proactive sourcing strategies. By prioritizing reputable suppliers and high-quality products, businesses can position themselves as leaders in automotive care. We encourage international buyers to explore AutoZone’s offerings and integrate these essential tools into their inventory to meet the demands of their markets effectively.

Illustrative image related to autozone tire pressure gauge

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.