In the competitive landscape of the global automotive market, sourcing a reliable central tire inflation system for 4×4 vehicles presents a significant challenge for international B2B buyers. With the increasing demand for off-road and utility vehicles in regions like Africa, South America, the Middle East, and Europe, businesses must ensure their fleets are equipped with efficient tire management solutions. This guide offers a comprehensive overview of central tire inflation systems, including various types, applications, and the benefits they provide in enhancing vehicle performance and safety.

Navigating this guide will empower you to make informed purchasing decisions by detailing key aspects such as supplier vetting processes, cost considerations, and installation requirements. You’ll learn about the advantages of different systems, from those designed for rugged terrains to more versatile options suitable for urban settings. Additionally, we will highlight the importance of after-sales support and warranty considerations, ensuring that your investment is protected.

Whether you are a fleet manager, a procurement specialist, or a business owner, this guide aims to equip you with the knowledge necessary to confidently source a central tire inflation system that meets your operational needs. By understanding the market dynamics and product specifications, you can optimize your fleet’s performance and reliability, ultimately driving greater efficiency and profitability for your business.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Onboard Systems | Integrated with vehicle air supply; allows simultaneous inflation/deflation. | Fleet management, off-road vehicle rentals | Vorteile: Efficient for fleet use; reduces downtime. Nachteile: Higher upfront costs. |

| Portable Systems | Standalone units; often battery-operated or air compressor-based. | Emergency services, remote area operations | Vorteile: Versatile; can be used anywhere. Nachteile: Limited power; slower inflation. |

| Manual Systems | Requires manual operation; typically involves hand pumps or valves. | Agricultural vehicles, utility trucks | Vorteile: Cost-effective; simple design. Nachteile: Labor-intensive; not suitable for rapid use. |

| Smart Tire Inflation Systems | Advanced technology; features automated pressure monitoring and adjustments. | High-end off-road vehicles, luxury fleets | Vorteile: Precision control; enhances safety. Nachteile: Complex installation; potential for higher maintenance. |

| Dual Source Systems | Can connect to both onboard compressors and portable pumps. | Versatile applications across various sectors | Vorteile: Flexibility in power sources; efficient. Nachteile: May require additional accessories. |

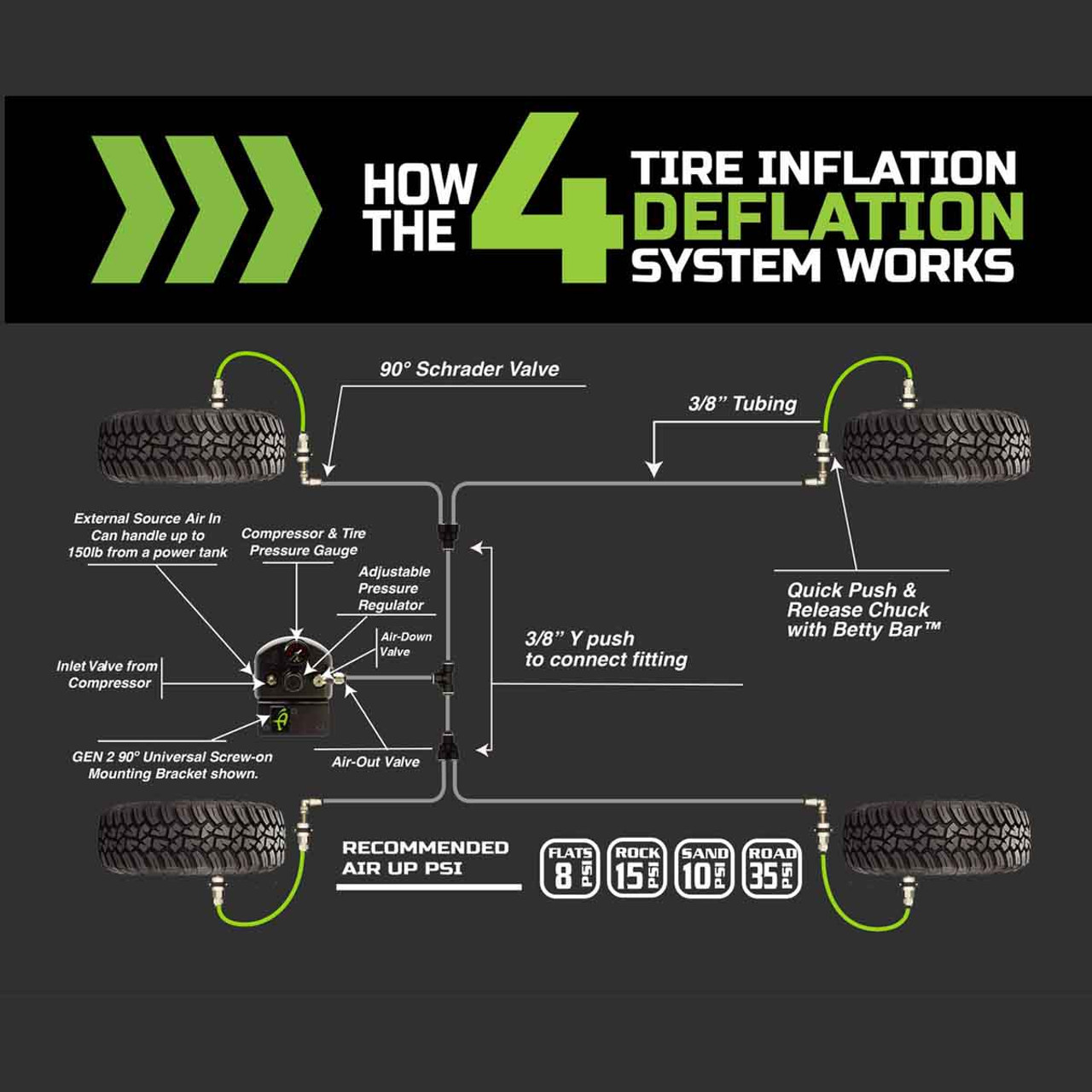

Onboard systems are integrated directly into the vehicle’s air supply, enabling the inflation and deflation of all tires simultaneously. This type is particularly beneficial for fleet management and off-road vehicle rentals, where time efficiency is critical. B2B buyers should consider the initial investment against the potential reduction in operational downtime, as these systems streamline tire maintenance.

Portable systems are standalone units that can be battery-operated or powered by an air compressor. They are ideal for emergency services and operations in remote areas where access to power is limited. Their versatility allows for use across various vehicles, making them a valuable investment. However, buyers should weigh the slower inflation speeds against their flexibility and ease of transport.

Manual systems rely on hand pumps or valves for operation and are often found in agricultural vehicles and utility trucks. These systems are cost-effective and straightforward, appealing to budget-conscious buyers. However, their labor-intensive nature may not suit operations requiring rapid tire adjustments, making them less ideal for fast-paced environments.

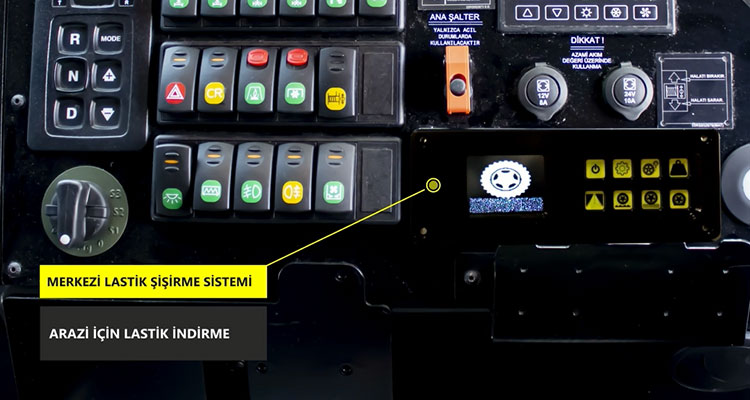

Smart tire inflation systems leverage advanced technology to monitor and adjust tire pressure automatically. These systems are commonly used in high-end off-road vehicles and luxury fleets, where precision and safety are paramount. While they provide significant advantages in tire management, buyers must consider the complexities of installation and the potential for increased maintenance costs.

Dual source systems can connect to both onboard compressors and portable pumps, providing flexibility for various applications. This versatility makes them suitable for a wide range of sectors, from logistics to construction. Buyers should evaluate the efficiency benefits against the need for additional accessories, which may increase overall costs.

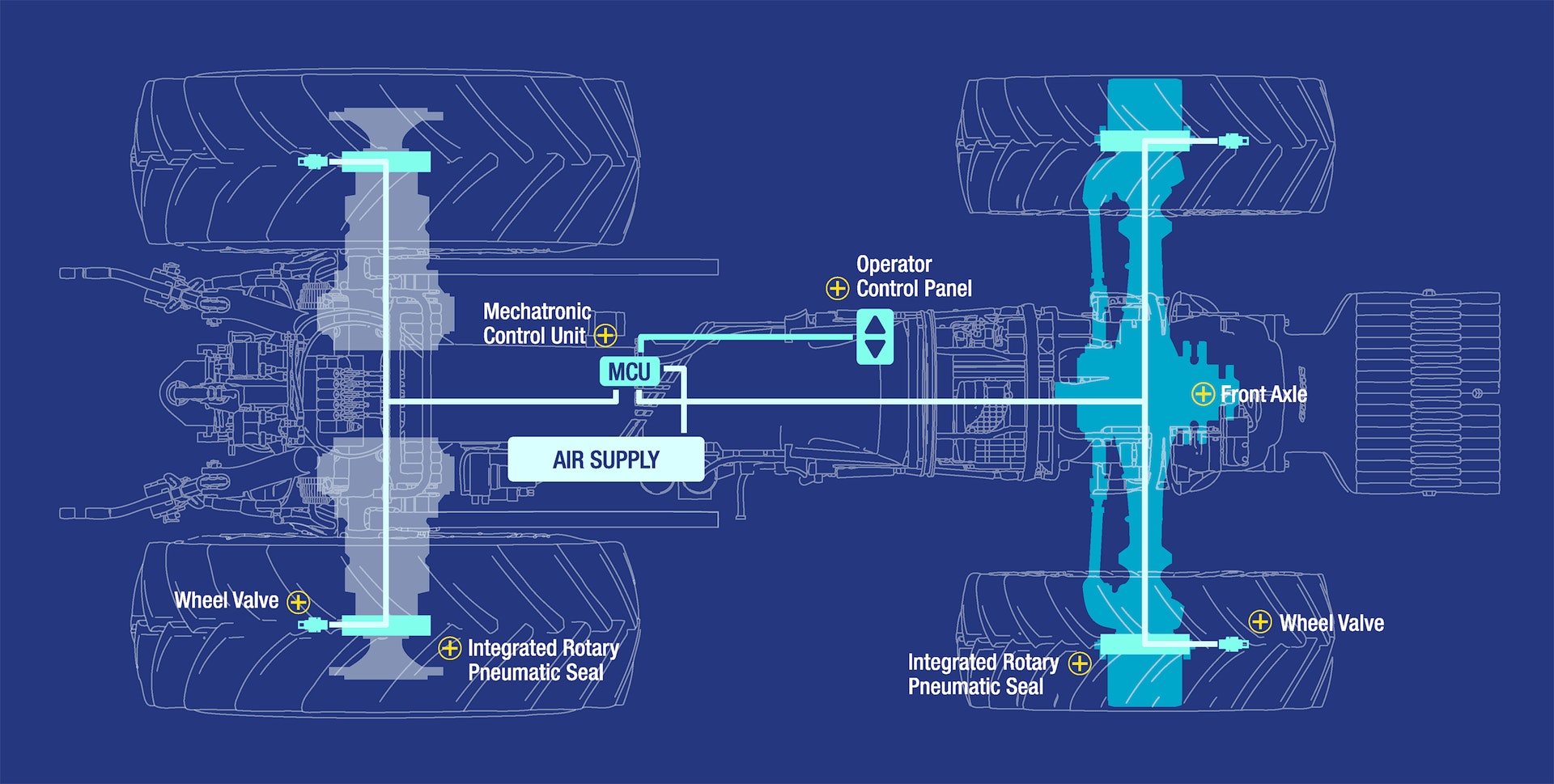

Illustrative image related to central tire inflation system 4×4

| Industrie/Sektor | Specific Application of central tire inflation system 4×4 | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Mining | Maintaining optimal tire pressure in off-road vehicles | Enhanced safety and reduced downtime due to tire failures | Durability in harsh environments and compatibility with existing equipment |

| Landwirtschaft | Adjusting tire pressure for varying terrain in farming equipment | Improved traction and reduced soil compaction | Versatility for different vehicle types and easy installation |

| Bauwesen | Tire pressure management for heavy-duty machinery | Increased efficiency and reduced operational costs | Robust design to withstand rugged conditions and easy maintenance |

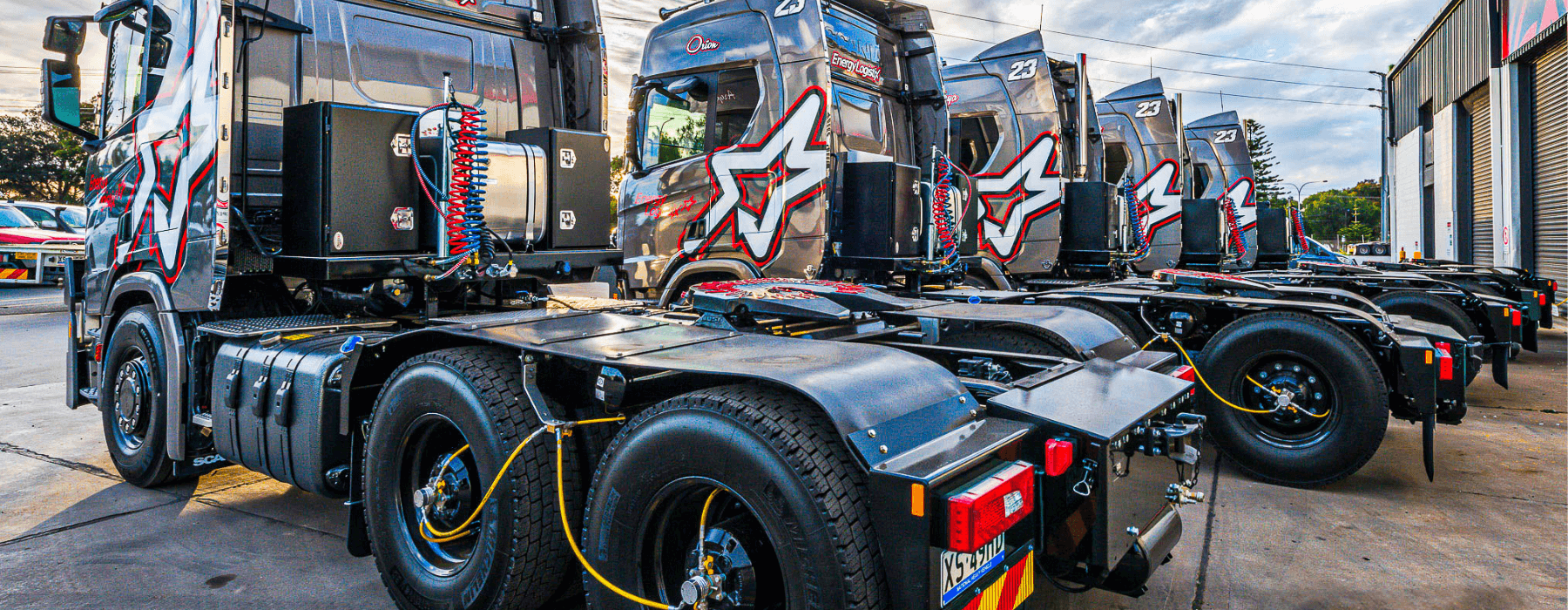

| Logistik und Verkehr | Simultaneous inflation/deflation of fleet vehicles | Time savings and improved fleet management | Compatibility with various vehicle models and reliable customer support |

| Notfalldienste | Quick tire adjustments for rescue vehicles | Enhanced responsiveness and operational readiness | Lightweight and portable options for rapid deployment |

In the mining industry, central tire inflation systems are essential for maintaining optimal tire pressure on off-road vehicles, which often navigate rough and uneven terrain. By allowing for quick adjustments to tire pressure, these systems help prevent tire blowouts and extend tire life, ultimately reducing downtime and maintenance costs. Buyers in this sector must consider the system’s durability to withstand extreme conditions and ensure compatibility with their existing fleet of vehicles.

Agricultural machinery frequently operates on varied terrains, necessitating adaptable tire pressure. Central tire inflation systems enable farmers to adjust tire pressure on-the-fly, enhancing traction on soft soil and minimizing compaction. This versatility leads to better crop yields and operational efficiency. For international buyers, especially in regions like Africa and South America, sourcing systems that are easy to install and compatible with diverse equipment types is crucial.

In construction, heavy-duty machinery often faces challenging conditions that require precise tire pressure management. A central tire inflation system enables operators to maintain optimal tire pressure, enhancing fuel efficiency and reducing wear and tear. This results in cost savings and improved productivity. Buyers should prioritize systems designed for rugged environments and easy maintenance to ensure long-term reliability.

Illustrative image related to central tire inflation system 4×4

Logistics companies benefit significantly from central tire inflation systems by enabling simultaneous inflation or deflation of multiple fleet vehicles. This capability saves time during vehicle preparation and enhances overall fleet management efficiency. For international B2B buyers, it is essential to choose systems that are compatible with various vehicle types and come with reliable customer support to ensure seamless integration into their operations.

Emergency services rely on quick tire adjustments to ensure their vehicles are always operationally ready. Central tire inflation systems allow for rapid inflation or deflation, enabling emergency responders to adapt to different terrains swiftly. This responsiveness can be critical in life-or-death situations. Buyers in this sector should consider lightweight, portable options that can be deployed quickly in emergency scenarios.

Das Problem: Many B2B buyers operating in regions with varying terrains, such as the rugged landscapes of South America or the sandy deserts of the Middle East, struggle with maintaining optimal tire pressure across different driving conditions. Incorrect tire pressure can lead to reduced traction, increased tire wear, and even vehicle breakdowns. This inconsistency can be particularly problematic for companies relying on 4×4 vehicles for logistics and transport in remote areas, where delays can significantly impact operations.

Die Lösung: To address this challenge, B2B buyers should invest in a central tire inflation system specifically designed for 4×4 applications that allows for real-time pressure adjustments based on terrain type. When sourcing a system, look for features such as dual air source compatibility, which enables connection to both onboard compressors and portable pumps. This flexibility allows users to adjust tire pressure quickly and efficiently, ensuring optimal traction for both off-road and on-road conditions. Consider systems that include a pressure regulator and blow-off valve for precise control and safety. Additionally, educating operators on how to utilize the system effectively will enhance performance and prolong tire life.

Das Problem: Buyers in industries such as mining, oil, and agriculture often operate in harsh environments that can cause wear and tear on equipment. Central tire inflation systems exposed to extreme temperatures, dust, or moisture can fail if they are not built with robust materials. This not only leads to costly repairs but can also cause downtime, affecting productivity and safety.

Die Lösung: Selecting a central tire inflation system that is designed for heavy-duty use is essential. Buyers should prioritize systems constructed with high-quality, durable materials that can withstand extreme conditions. Features such as DOT-approved hoses and fittings are critical for reliability. In addition, look for a manufacturer that offers a comprehensive warranty, ensuring that any defects or issues can be promptly addressed. Regular maintenance checks, including inspections of hoses and fittings for signs of wear, will help in prolonging the system’s lifespan and maintaining operational efficiency.

Das Problem: A common frustration for B2B buyers is the complexity involved in installing and using central tire inflation systems. Companies may lack the in-house expertise to install such systems, leading to delays and additional costs for professional installation. Moreover, if the system is not user-friendly, operators may struggle to achieve optimal tire pressure adjustments, undermining the system’s effectiveness.

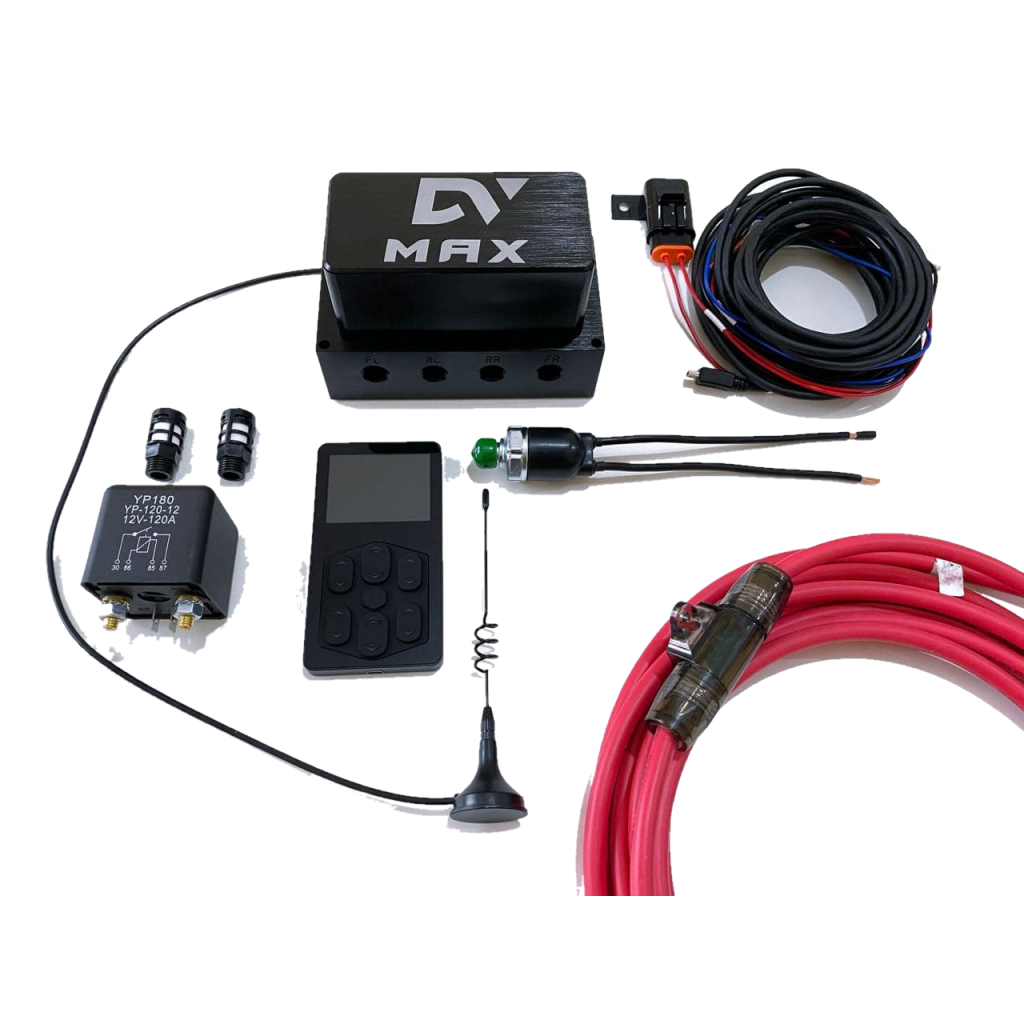

Die Lösung: When selecting a central tire inflation system, buyers should look for products that come with pre-cut, ready-to-install components and comprehensive installation guides. Systems that offer plug-and-play capabilities can significantly reduce installation time and complexity. Additionally, training sessions for operators on the system’s functionality can enhance user confidence and efficiency. Opting for systems with intuitive controls, such as an ADS controller box, can further simplify the operation, allowing for simultaneous inflation or deflation of all four tires with minimal effort. Investing in user-friendly technology not only saves time but also ensures that the system is used to its full potential, enhancing overall vehicle performance.

When selecting materials for central tire inflation systems (CTIS) in 4×4 vehicles, several factors must be considered, including performance characteristics, durability, cost, and compliance with international standards. Here, we analyze four common materials used in these systems: rubber, aluminum, stainless steel, and composite plastics.

Rubber is often used for hoses and seals in CTIS due to its excellent flexibility and ability to withstand high pressures. Key properties include a temperature rating typically between -40°C to 100°C and good resistance to abrasion and weathering.

Vorteile: Rubber is cost-effective and easy to manufacture, making it a popular choice for various applications. It provides a reliable seal, essential for maintaining air pressure in tires.

Nachteile: However, rubber can degrade over time when exposed to ozone or UV light, which may lead to failures in harsh environments. Its performance can also diminish at extreme temperatures.

Auswirkungen auf die Anwendung: Rubber is compatible with air and various gases, but care must be taken with oils and fuels.

Überlegungen für internationale Käufer: Buyers from regions like Africa and South America should ensure that the rubber meets local standards for temperature and pressure ratings, as well as compliance with ASTM or ISO standards.

Illustrative image related to central tire inflation system 4×4

Aluminum is frequently used for components like valves and fittings due to its lightweight and corrosion-resistant properties. It typically has a temperature rating of up to 150°C and offers good strength-to-weight ratios.

Vorteile: Aluminum is durable and can withstand harsh environmental conditions, making it suitable for off-road applications. Its lightweight nature contributes to overall vehicle efficiency.

Nachteile: The primary drawback is its higher cost compared to other materials like steel or rubber. Additionally, aluminum can be susceptible to galvanic corrosion when in contact with dissimilar metals.

Auswirkungen auf die Anwendung: Aluminum is compatible with air and most fluids used in tire inflation systems, but care must be taken to avoid contact with corrosive substances.

Überlegungen für internationale Käufer: Buyers should look for aluminum components that comply with international standards, ensuring they can withstand the specific environmental conditions in regions like the Middle East and Europe.

Stainless steel is often selected for its exceptional corrosion resistance and strength. It can handle high pressures and temperatures, with ratings typically reaching up to 300°C.

Vorteile: Stainless steel is highly durable and resistant to rust and corrosion, making it ideal for harsh environments. Its longevity can lead to lower maintenance costs over time.

Nachteile: However, stainless steel is heavier and more expensive than alternatives like aluminum or rubber. The manufacturing process can also be more complex, potentially leading to higher production costs.

Auswirkungen auf die Anwendung: Stainless steel is compatible with air and a wide range of fluids, providing versatility in various applications.

Illustrative image related to central tire inflation system 4×4

Überlegungen für internationale Käufer: Buyers should ensure compliance with international standards such as DIN or ASTM, particularly in regions with strict regulations on material quality.

Composite plastics are increasingly used in modern CTIS due to their lightweight and corrosion-resistant properties. They can withstand temperatures up to 120°C and provide good pressure ratings.

Vorteile: Composite plastics are often less expensive than metals and can be produced in various shapes, allowing for design flexibility. They are also resistant to corrosion and chemicals.

Nachteile: The main limitation is that composite materials may not be as strong as metals, potentially leading to durability issues in extreme conditions.

Auswirkungen auf die Anwendung: Composite plastics are typically compatible with air and various gases, making them suitable for tire inflation systems.

Überlegungen für internationale Käufer: Buyers should verify that composite materials meet local and international standards, particularly in regions like Brazil and Vietnam, where material quality can vary.

Illustrative image related to central tire inflation system 4×4

| Material | Typical Use Case for central tire inflation system 4×4 | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Schläuche und Dichtungen | Cost-effective and flexible | Degrades over time in harsh conditions | Niedrig |

| Aluminium | Valves and fittings | Leicht und korrosionsbeständig | Higher cost and potential for corrosion | Mittel |

| Rostfreier Stahl | High-pressure components | Außergewöhnliche Haltbarkeit und Korrosionsbeständigkeit | Schwerer und teurer | Hoch |

| Composite Plastics | Lightweight components | Design flexibility and chemical resistance | Less strength compared to metals | Mittel |

This material selection guide provides essential insights for B2B buyers in various international markets, helping them make informed decisions regarding the materials used in central tire inflation systems for 4×4 vehicles.

The manufacturing process of a central tire inflation system (CTIS) for 4×4 vehicles involves several critical stages that ensure the final product meets quality and performance standards. Here’s a breakdown of the main stages:

Vorbereitung des Materials

The manufacturing process begins with sourcing high-quality raw materials, such as durable rubber for hoses, metals for fittings, and plastics for control units. Suppliers are often vetted based on their adherence to international quality standards, ensuring that the materials can withstand rugged environments and harsh conditions typical for off-road applications.

Bildung von

In this stage, the raw materials are shaped into components. Techniques such as injection molding for plastic parts, extrusion for rubber hoses, and machining for metal fittings are commonly employed. Advanced technologies like CNC machining ensure precision in dimensions, which is crucial for the proper functioning of the CTIS.

Montage

The assembly process is where components come together to form the complete system. This stage often involves automated assembly lines for efficiency, supplemented by manual checks to ensure quality. Each unit typically includes the air delivery system, control box, hoses, and quick-connect fittings, which must be assembled to exact specifications.

Fertigstellung

Once assembled, the systems undergo finishing processes that may include surface treatment, coating, and packaging. These steps enhance durability and protect against corrosion, particularly important for systems expected to perform in challenging terrains.

Quality assurance (QA) is integral to the manufacturing process, ensuring that the central tire inflation systems meet the necessary standards for safety and performance. Here are some key aspects:

Illustrative image related to central tire inflation system 4×4

Einhaltung der internationalen Normen

Manufacturers often comply with international standards such as ISO 9001, which focuses on quality management systems. Compliance with industry-specific certifications like CE for European markets and API for oil and gas applications may also be required. These certifications ensure that products meet specific safety and environmental requirements.

Kontrollpunkte der Qualitätskontrolle

Various checkpoints are established throughout the manufacturing process:

– Eingehende Qualitätskontrolle (IQC): Raw materials are inspected upon arrival to verify they meet quality specifications.

– Prozessbegleitende Qualitätskontrolle (IPQC): Continuous checks are conducted during the manufacturing process to identify and rectify any issues immediately.

– Endgültige Qualitätskontrolle (FQC): After assembly, the complete system undergoes rigorous testing, including pressure tests and functional checks, to ensure it operates as intended.

Gängige Prüfmethoden

Various testing methods are employed to validate the performance and safety of the CTIS. These include:

– Pressure Testing: Ensures that the system can withstand operational pressures without leaks.

– Dauerhaftigkeitsprüfung: Simulates real-world conditions to assess how the system performs over time.

– Temperature and Environmental Testing: Evaluates the system’s performance in extreme conditions, ensuring reliability in diverse environments.

B2B buyers must conduct due diligence to ensure that their suppliers maintain high-quality standards. Here are effective strategies:

Lieferanten-Audits

Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Audits should review compliance with international standards and internal quality protocols.

Requesting Quality Assurance Reports

Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC. This information can help buyers assess the reliability of the manufacturer.

Beauftragung von Inspektoren von Drittanbietern

Utilizing independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. Inspectors can conduct on-site evaluations and testing, providing reports that highlight compliance with quality standards.

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control and certification:

Understanding Local Regulations

It is essential for buyers to be aware of local regulations and standards that may differ from international norms. This understanding helps in selecting suppliers who can meet both local and international requirements.

Navigating Trade Agreements

Buyers must consider trade agreements that might affect the import of products. Compliance with specific standards may be necessary to avoid tariffs or delays in customs clearance.

Cultural and Communication Considerations

Differences in business practices and communication styles can impact the quality assurance process. Establishing clear expectations and maintaining open lines of communication can mitigate misunderstandings and ensure that quality standards are met.

In conclusion, the manufacturing processes and quality assurance protocols for central tire inflation systems are critical for ensuring product reliability and performance. By understanding the manufacturing stages, implementing robust quality control measures, and conducting thorough supplier evaluations, B2B buyers can ensure they source high-quality systems that meet their operational needs. As markets continue to expand globally, these practices will become increasingly important in fostering long-term partnerships and ensuring customer satisfaction.

Illustrative image related to central tire inflation system 4×4

This guide serves as a practical checklist for B2B buyers looking to procure a central tire inflation system for 4×4 vehicles. The aim is to streamline your sourcing process, ensuring that you select a system that meets your operational needs while maintaining quality and reliability.

Start by clearly outlining the technical requirements for the central tire inflation system. Consider factors such as the type of vehicles you will be using it on, the desired inflation speed, and compatibility with existing air compressors. Having precise specifications will help you narrow down options and avoid systems that do not meet your needs.

Conduct thorough market research to identify the various central tire inflation systems available. Look for systems that offer simultaneous tire inflation and deflation, which is essential for efficiency. Pay attention to features such as dual air source compatibility and heavy-duty construction, ensuring they can withstand the rugged conditions typical in off-road environments.

Before making a commitment, vet potential suppliers carefully. Request detailed company profiles, product specifications, and case studies demonstrating their experience in your sector. It’s also beneficial to seek references from other businesses that have purchased similar systems, especially in regions like Africa or South America, where specific operational conditions may apply.

Ensure that the suppliers and their products comply with industry standards and regulations. Look for certifications that indicate quality and safety, such as DOT approval for hoses and fittings. Compliance is crucial not only for performance but also for liability and warranty considerations in your business operations.

Review the warranty terms offered by suppliers, as a robust warranty can be indicative of product quality and reliability. Additionally, evaluate the customer support services available, including installation assistance and after-sales support. A supplier that provides comprehensive support can significantly reduce downtime and maintenance issues.

Whenever possible, request samples or demonstrations of the central tire inflation systems. This will allow you to assess the product’s functionality firsthand. Pay attention to ease of installation, user-friendliness, and overall build quality during the demonstration.

Illustrative image related to central tire inflation system 4×4

Once you have selected a supplier, engage in negotiations to secure the best terms possible. Discuss pricing, delivery timelines, and payment options to ensure that they align with your budget and operational needs. Finalizing the purchase with clear agreements will help avoid misunderstandings later on.

Following this checklist will guide you through the procurement process, ensuring that you select a central tire inflation system that enhances your operational efficiency and meets the demands of your specific applications.

When sourcing central tire inflation systems for 4×4 vehicles, understanding the cost structure is crucial. The primary cost components include:

Materialien: The choice of materials directly impacts both the performance and cost of the system. High-quality hoses, fittings, and valves typically result in higher upfront costs but offer better durability and reliability. For example, DOT-approved components are often preferred for their compliance with safety standards.

Arbeit: Labor costs include both manufacturing and assembly processes. Skilled labor is required for precise installation and quality control, which may vary based on the region and local wage standards.

Fertigungsgemeinkosten: This encompasses indirect costs such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, ultimately affecting the final price.

Werkzeugbau: Initial investment in tooling for production can be significant, especially for custom designs. Sharing costs through larger production runs can help lower the per-unit cost.

Qualitätskontrolle (QC): Rigorous QC processes are essential to ensure product reliability and safety. The cost of implementing these procedures can influence the overall price but is critical for maintaining quality standards.

Logistik: Transportation costs, including shipping and handling, vary significantly based on the destination. B2B buyers must consider these costs, particularly when sourcing from overseas suppliers.

Marge: Supplier margins will vary based on market positioning and competition. Understanding the typical margins in the industry can help buyers gauge whether a price is fair.

Several factors can influence the pricing of central tire inflation systems:

Volumen und Mindestbestellmenge (MOQ): Suppliers often provide discounts for bulk purchases. Understanding MOQ requirements can help buyers negotiate better pricing structures.

Spezifikationen und Anpassungen: Custom systems tailored to specific vehicle requirements can incur additional costs. Buyers should assess whether the benefits of customization outweigh the price increase.

Materialien und Qualitätszertifikate: Higher-quality materials often come with a premium price. Systems with recognized certifications (e.g., ISO, DOT) may also be priced higher due to the assurance of quality and safety.

Lieferanten-Faktoren: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: The chosen Incoterms can significantly impact the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will help buyers evaluate the overall expense.

Negotiation Strategies: Engage in discussions to secure better pricing by highlighting potential long-term partnerships or bulk purchase intentions. Understanding the supplier’s cost structure can also provide leverage during negotiations.

Konzentration auf die Gesamtbetriebskosten (TCO): Assessing TCO, which includes installation, maintenance, and potential downtime, provides a more comprehensive view of expenses beyond the initial purchase price. A system that is more expensive upfront may save money in the long run if it requires less maintenance.

Nuancen in der Preisgestaltung für internationale Käufer: When sourcing from regions like Africa, South America, the Middle East, or Europe, consider currency fluctuations and import tariffs that may affect overall costs. Establishing clear communication regarding payment terms can mitigate financial risks.

Marktforschung: Conduct thorough market research to benchmark prices. Understanding the prevailing rates in different regions can empower buyers to negotiate effectively.

While this analysis provides a framework for understanding costs and pricing factors, actual prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotes to ensure competitive pricing.

In the realm of 4×4 vehicle management, the central tire inflation system (CTIS) stands out as a highly efficient solution for maintaining optimal tire pressure. However, various alternatives exist that can also fulfill the need for tire pressure management. This section will explore these alternatives, allowing B2B buyers to make informed decisions based on their specific operational requirements.

| Vergleich Aspekt | Central Tire Inflation System 4X4 | Tragbarer Luftkompressor | Manual Tire Inflation Kit |

|---|---|---|---|

| Leistung | Automates inflation/deflation of all tires simultaneously | Single tire inflation; slower process | Manual inflation; labor-intensive |

| Kosten | High initial investment (e.g., $300-$500) | Moderate ($50-$200) | Low ($20-$50) |

| Leichte Implementierung | Requires professional installation; complex system | Easy setup; user-friendly | Simple; no installation needed |

| Wartung | Low; occasional checks required | Moderate; regular checks for functionality | Low; minimal upkeep needed |

| Bester Anwendungsfall | Off-road and commercial applications needing quick adjustments | Personal use or light commercial | Emergency situations or basic maintenance |

Portable air compressors are a popular alternative to central tire inflation systems. They are compact and can easily be stored in a vehicle for on-the-go inflation. The primary advantages of this solution include its affordability and ease of use; operators can inflate tires individually without needing specialized installation. However, the performance is limited to one tire at a time, making it less efficient for scenarios requiring rapid tire pressure adjustments, such as off-road expeditions. Additionally, users must ensure that the compressor is charged and functional before trips, which adds a layer of responsibility.

Manual tire inflation kits consist of basic tools like a hand pump or a foot pump. They are the most cost-effective option, making them accessible for budget-conscious buyers. The simplicity of these kits allows for immediate use in emergencies, as no power source is required. However, the downside is that they are labor-intensive and time-consuming, requiring significant effort to inflate tires manually. This option is best suited for occasional use rather than regular maintenance, especially in commercial applications where efficiency is paramount.

Illustrative image related to central tire inflation system 4×4

When selecting the appropriate tire inflation solution, B2B buyers should carefully assess their specific operational needs and budget constraints. Central tire inflation systems provide unmatched performance and efficiency, making them ideal for commercial and off-road applications. In contrast, portable air compressors offer a balance of cost and convenience for personal use, while manual kits serve as a practical backup for emergency situations. By evaluating these aspects, buyers can choose a solution that aligns with their operational goals and enhances overall vehicle performance.

When considering a central tire inflation system (CTIS) for 4×4 vehicles, several technical properties are crucial for ensuring efficiency, reliability, and safety. Here are some key specifications that international B2B buyers should be aware of:

The construction materials used in a CTIS, such as hoses and fittings, should meet specific industry standards (e.g., DOT-approved materials). High-grade materials ensure durability and resistance to harsh environmental conditions, which is essential for off-road applications. This affects the longevity of the system and can significantly reduce maintenance costs over time.

Understanding the pressure ratings of the system components is vital. A typical CTIS should include components rated for at least 150 PSI to accommodate high-performance tires. This specification ensures that the system can effectively manage tire inflation and deflation without risk of failure, particularly in demanding terrains.

The flow rate, often measured in cubic feet per minute (CFM), determines how quickly air can be delivered to or removed from the tires. A higher flow rate allows for faster inflation or deflation, which is crucial for minimizing downtime during operations. For businesses that rely on efficiency, this property can lead to significant time savings.

Illustrative image related to central tire inflation system 4×4

A versatile CTIS should be compatible with various air sources, such as onboard compressors or portable pumps. This compatibility ensures that businesses can select the best air source for their specific needs, whether they are operating in remote locations or within urban settings. It also allows for flexibility in equipment procurement.

Systems that come pre-cut and ready to install with comprehensive installation guides reduce installation time and labor costs. Ease of installation is particularly important for B2B buyers who may not have specialized technical expertise. A user-friendly system can lead to quicker deployment and operational efficiency.

A robust warranty (typically around five years) reflects the manufacturer’s confidence in their product. A solid warranty not only protects the investment but also indicates the manufacturer’s commitment to customer service. For B2B buyers, this can translate into lower total cost of ownership and peace of mind.

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several key terms relevant to CTIS:

Illustrative image related to central tire inflation system 4×4

This term refers to companies that produce components or systems that are marketed by another manufacturer. In the context of CTIS, knowing the OEM can help buyers ensure compatibility with existing vehicle systems and make informed purchasing decisions.

MOQ is the smallest amount of product a supplier is willing to sell. This is critical for B2B buyers as it can impact inventory management and cash flow. Understanding MOQ helps businesses plan their purchases according to demand.

An RFQ is a formal process wherein a buyer solicits price quotes from suppliers for specific products or services. This is particularly relevant in B2B transactions, as it enables buyers to compare offers and negotiate better terms.

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers involved in cross-border trade, as they clarify shipping, insurance, and risk management.

Illustrative image related to central tire inflation system 4×4

Lead time refers to the amount of time from placing an order to receiving the product. For businesses, understanding lead times is essential for inventory planning and ensuring that operational schedules are met without delays.

This term refers to the services and parts available after the initial sale of a product. Strong aftermarket support is vital for B2B buyers, as it ensures the longevity and reliability of the CTIS over time, thereby protecting their investment.

By understanding these essential technical properties and industry terms, B2B buyers can make informed decisions when investing in central tire inflation systems for 4×4 vehicles, ultimately improving their operational efficiency and cost-effectiveness.

The central tire inflation system (CTIS) for 4×4 vehicles has witnessed significant growth, driven by the increasing demand for off-road capabilities and enhanced vehicle performance. This market is particularly dynamic in regions such as Africa, South America, the Middle East, and Europe, where rugged terrains necessitate advanced tire management solutions. Key trends include the integration of smart technology, enabling real-time monitoring and adjustment of tire pressure via mobile applications. This innovation not only enhances safety but also optimizes fuel efficiency and tire longevity.

Emerging B2B sourcing trends highlight a shift toward modular systems that can be customized based on vehicle type and usage scenarios. Buyers are increasingly looking for systems that are compatible with both onboard and portable air compressors, providing flexibility for various operational needs. Additionally, the adoption of lightweight materials and compact designs is gaining traction, catering to the growing demand for efficiency in both space and weight.

Furthermore, competitive pricing and reliable after-sales support are becoming crucial factors for international buyers. Companies that offer robust warranties and hassle-free return policies are likely to gain a competitive edge. As the market evolves, B2B buyers must stay informed about these dynamics to make strategic sourcing decisions.

Sustainability has emerged as a critical consideration for B2B buyers in the central tire inflation system sector. The environmental impact of manufacturing processes and the materials used in these systems is under scrutiny. Companies are increasingly expected to adopt sustainable practices, such as using recyclable materials and minimizing waste during production.

Ethical sourcing is equally important, as buyers prioritize suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential credentials that buyers look for when evaluating potential partners.

Illustrative image related to central tire inflation system 4×4

Moreover, there is a growing market for ‘green’ products that utilize eco-friendly materials, such as biodegradable hoses or energy-efficient compressors. This trend not only appeals to environmentally conscious consumers but also helps companies align with global sustainability goals. As regulations tighten around environmental standards, B2B buyers must prioritize suppliers who demonstrate a commitment to sustainable and ethical sourcing.

The evolution of central tire inflation systems can be traced back to the early 20th century, initially developed for military applications to enhance vehicle mobility in challenging terrains. As off-roading gained popularity, particularly in the 1970s and 1980s, manufacturers began to adapt these systems for civilian use, focusing on improving convenience and safety for recreational vehicles.

In recent years, advancements in technology have transformed CTIS into sophisticated systems that allow for real-time adjustments and monitoring. This evolution reflects the growing demand for performance and efficiency in off-road vehicles, positioning CTIS as a critical component for both commercial and recreational applications. Today, these systems are not only integral for enhancing vehicle capability but also for promoting sustainability and efficiency in tire management, catering to a diverse range of international markets.

How do I select the right central tire inflation system for my fleet?

When choosing a central tire inflation system for your fleet, consider compatibility with your vehicle types, ease of installation, and the ability to inflate or deflate tires simultaneously. Evaluate systems that offer robust features like dual air source compatibility and durable construction for off-road conditions. Additionally, assess the warranty and customer service support, as these can be critical for ongoing maintenance and reliability. It’s advisable to consult with suppliers about your specific needs to find a tailored solution that enhances your operational efficiency.

What are the key features to look for in a central tire inflation system?

Key features to prioritize include simultaneous tire inflation and deflation capabilities, compatibility with both onboard and portable air compressors, and quick connect fittings for ease of use. A robust pressure regulator and blow-off valve enhance safety and performance. Ensure the system is built from heavy-duty materials that can withstand harsh environments, particularly if used in off-road applications. Finally, check for comprehensive installation kits and support to facilitate a smooth setup process.

What are the typical payment terms for purchasing a central tire inflation system?

Payment terms can vary significantly by supplier and region. Common arrangements include upfront payments, partial payments with the balance due upon delivery, or net terms (e.g., net 30 or net 60 days). For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify the terms before finalizing the purchase to ensure they align with your cash flow and budgeting strategies.

What is the minimum order quantity (MOQ) for central tire inflation systems?

MOQs can vary widely depending on the manufacturer or supplier. Some may offer units for individual purchase, while others may require orders of several units to ensure cost-effectiveness. It’s beneficial to discuss your specific needs with suppliers to understand their MOQ policies. If your requirement is below the MOQ, inquire about potential exceptions or whether they can accommodate a smaller order at a higher price point.

How can I ensure the quality of the central tire inflation system I’m buying?

To ensure quality, source from reputable suppliers with established track records in the industry. Look for products that come with warranties, as these indicate manufacturer confidence in their quality. Request certifications or compliance with international standards (like ISO) to verify the system’s reliability and safety. Additionally, review customer testimonials and case studies to gain insights into the product’s performance in real-world applications.

What logistics considerations should I keep in mind for international shipping?

When planning for international shipping, consider the following logistics aspects: customs regulations in your country, shipping costs, and delivery times. Choose a reliable logistics partner experienced in handling automotive parts to streamline the process. Ensure that the supplier provides necessary documentation, including shipping manifests and certificates of origin. It’s also wise to account for potential delays and plan your inventory accordingly to avoid operational disruptions.

Can I customize the central tire inflation system for my specific vehicle requirements?

Many suppliers offer customization options to tailor the central tire inflation system to your specific vehicle needs. This may include variations in hose lengths, fitting types, or integration with existing onboard systems. Discuss your requirements with the supplier early in the procurement process to explore available options. Custom solutions can enhance compatibility and functionality, ensuring that the system meets the unique demands of your fleet.

What after-sales support is typically available for central tire inflation systems?

After-sales support can include installation assistance, troubleshooting, and maintenance guidance. Reputable suppliers often provide comprehensive customer service, including access to technical support teams who can assist with any issues that arise post-purchase. Additionally, inquire about available training resources for your team to maximize the system’s efficiency. Ensure that the warranty covers parts and potential repairs, which can help mitigate future costs associated with system maintenance.

Bereich: bronco6g.com

Registriert: 2015 (10 Jahre)

Einleitung: Central Tire Inflation System (CTIS) allows for inflating and deflating tires from the cabin. Users are seeking aftermarket systems for this technology, which is noted for being expensive and potentially unreliable over time. Some users suggest alternatives like ARB compressors for easier tire inflation. Discussion includes experiences with CTIS in vehicles like H1 Hummers and Mercedes G-Wagons, a…

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Central Tire Inflation System (CTIS) operates off pneumatic/pressurized air, allowing control over tire pressure independently or as a set. Benefits include improved performance on various surfaces, maintaining proper tire inflation for peak efficiency, and enhancing maneuverability. It can lower tire pressure for better traction on softer ground and temporarily counteract slow air leaks. Commonly…

Bereich: forum.expeditionportal.com

Registriert: 2004 (21 Jahre)

Einleitung: Centralised Tyre Inflation System (CTIS) manufactured by AIR CTI, located in Morwell, Victoria, Australia. Designed for convenience, safety, and comfort, it maintains constant air pressure regardless of tyre temperature. The system includes a hard pipe made from strong material sourced and manufactured in Australia, with a design life of 1,000,000 kilometres for the rotator and its seals. Suitable…

Bereich: parker.com

Registriert: 1995 (30 Jahre)

Einleitung: This company, Parker – Central Tire Inflation System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the rapidly evolving landscape of central tire inflation systems (CTIS) for 4×4 vehicles, strategic sourcing emerges as a pivotal strategy for international B2B buyers. By focusing on quality suppliers, businesses can ensure the reliability and durability of their tire inflation systems, which are essential for optimizing performance in diverse terrains. The ability to inflate or deflate all four tires simultaneously not only enhances efficiency but also significantly improves safety and fuel economy, a crucial consideration for fleet operators and off-road enthusiasts alike.

As demand for advanced CTIS technology grows, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should prioritize suppliers that offer innovative solutions and robust customer support. By leveraging comprehensive warranties and dedicated service, businesses can mitigate risks associated with product failures, thus safeguarding their investments.

Illustrative image related to central tire inflation system 4×4

Looking ahead, the integration of smart technologies into central tire inflation systems promises to revolutionize the industry. Buyers are encouraged to stay informed about these advancements and consider partnerships with suppliers who are at the forefront of innovation. As the market continues to expand, seizing these opportunities will not only enhance operational efficiency but also position businesses for long-term success in an increasingly competitive environment.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.