The challenge of maintaining optimal tire pressure is a critical concern for businesses operating in diverse sectors, from automotive repair shops to fleet management. Sourcing reliable air tire checkers is essential for ensuring safety, enhancing fuel efficiency, and prolonging tire lifespan. This comprehensive guide delves into the global market for air tire checkers, examining various types, applications, and advanced technologies available today.

International B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, will find valuable insights into supplier vetting processes, cost considerations, and industry trends. We will explore how digital air inflation machines can attract more customers to gas stations and convenience stores, improve service efficiency in tire shops, and ensure precise tire calibration for fleets and auto rentals.

By equipping decision-makers with knowledge about the latest innovations and best practices in tire pressure management, this guide empowers businesses to make informed purchasing decisions. Whether you are looking to enhance customer satisfaction, drive sales, or streamline operations, understanding the nuances of air tire checkers is key to navigating today’s competitive landscape. Prepare to elevate your business by leveraging the insights provided in this essential resource.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Digital Tire Inflators | Automated air inflation, user-friendly interfaces, data tracking | Gas stations, tire shops, car washes | Vorteile: High accuracy, ease of use, increased customer traffic. Nachteile: Higher initial investment. |

| Analog Tire Gauges | Mechanical design, manual reading, varying pressure ranges | Auto repair shops, fleet maintenance, personal use | Vorteile: Lower cost, no power requirements. Nachteile: Less accurate, slower to use. |

| Portable Tire Pumps | Compact, battery-operated or manual, versatile for various vehicles | Roadside assistance, personal vehicle maintenance | Vorteile: Convenience, mobility. Nachteile: Limited pressure capacity, may require frequent refills. |

| Fleet Management Systems | Integrated with telematics, real-time monitoring, predictive analytics | Fleet operators, logistics companies, rental services | Vorteile: Enhanced tire performance, fuel efficiency. Nachteile: Complexity, requires training. |

| Coin-Operated Air Machines | Self-service, revenue-generating, often located at gas stations | Convenience stores, car washes, public parking areas | Vorteile: Passive income, low maintenance. Nachteile: Limited features, reliance on foot traffic. |

Digital tire inflators are automated machines designed for precise air inflation, equipped with user-friendly interfaces that simplify the calibration process. These machines often feature data tracking capabilities, allowing businesses to monitor usage and performance metrics. Suitable for gas stations, tire shops, and car washes, digital inflators enhance customer satisfaction by providing quick and accurate services. For B2B buyers, investing in digital inflators can lead to increased customer traffic and loyalty, although the initial investment may be higher compared to traditional options.

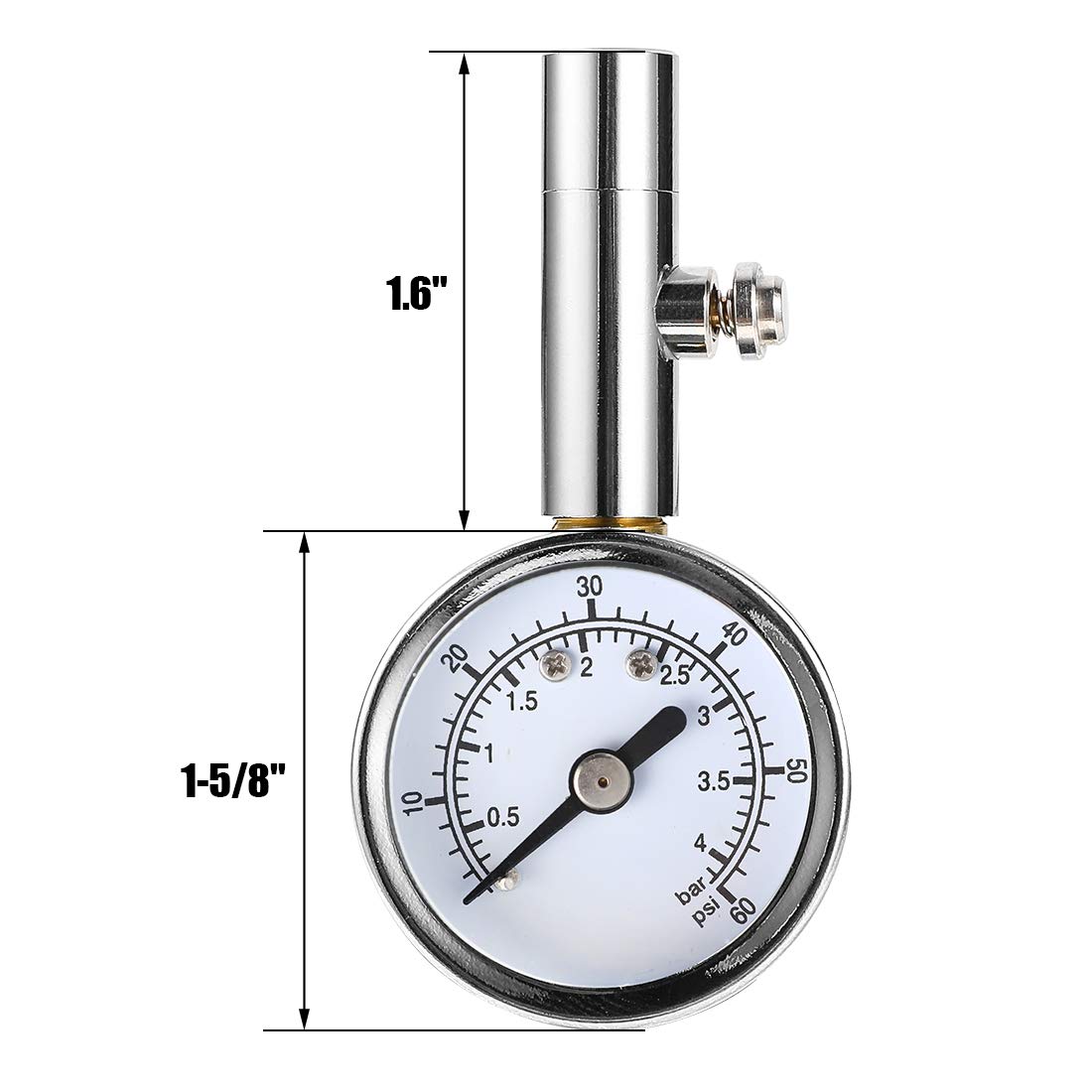

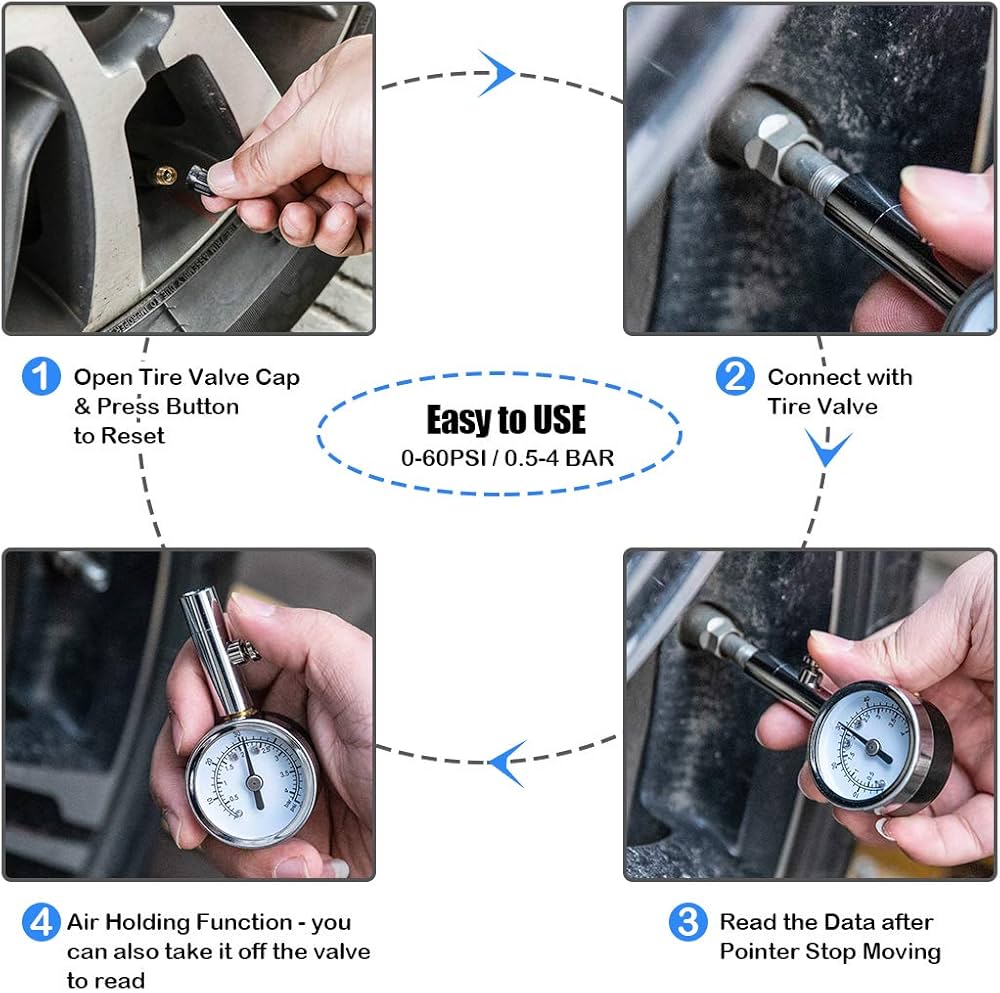

Analog tire gauges are mechanical devices that require manual operation and reading. They come in various pressure ranges and are often more affordable than digital counterparts. Commonly used in auto repair shops and fleet maintenance, analog gauges are reliable for basic tire pressure checks. However, they may be less accurate and slower to use, which can affect efficiency in high-volume settings. B2B buyers should weigh the cost benefits against the potential for reduced accuracy and speed.

Portable tire pumps are compact and can be battery-operated or manually driven, making them ideal for roadside assistance and personal vehicle maintenance. Their mobility allows businesses to provide on-the-go solutions, catering to customers who require immediate tire inflation. While portable pumps offer convenience, they may have limited pressure capacities and require frequent refills. B2B buyers should consider the trade-off between convenience and performance when selecting portable options.

Fleet management systems integrate tire monitoring with telematics, providing real-time data on tire pressure and performance. This technology is particularly beneficial for fleet operators and logistics companies, as it helps improve fuel efficiency and extend tire life through predictive analytics. While these systems can enhance operational efficiency, they may introduce complexity and require training for staff. B2B buyers should assess the long-term benefits of improved tire management against the initial setup and training costs.

Coin-operated air machines serve as self-service tire inflation solutions, commonly found at gas stations and convenience stores. They generate passive income while requiring minimal maintenance. These machines typically attract customers who may also purchase other services or products at the location. However, their limited features and reliance on foot traffic can be drawbacks. B2B buyers should evaluate the potential for consistent revenue generation against the operational limitations of coin-operated systems.

| Industrie/Sektor | Specific Application of air tire checker | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Gas Stations & Convenience Stores | Offering self-service air tire checking stations | Attracts more customers, increases sales, and enhances brand loyalty | Ensure ease of use, durability in various climates, and reliable service support |

| Automotive Repair Shops & Tire Shops | Streamlining tire inflation processes for customers | Improves technician productivity and customer satisfaction | Look for precision accuracy, quick inflation times, and ease of integration into existing workflows |

| Fuhrpark-Management | Regular tire pressure checks for vehicle fleets | Increases fuel efficiency and prolongs tire lifespan | Consider machines that can handle high usage and provide real-time data monitoring |

| Car Wash Facilities | Integrating air tire checkers into service offerings | Boosts customer loyalty and increases foot traffic | Choose user-friendly interfaces and machines that can withstand outdoor conditions |

| Auto Rentals & Dealerships | Providing tire checking as part of vehicle maintenance | Enhances customer experience and reduces maintenance costs | Select reliable machines that offer accurate readings and easy operation for users |

Gas stations and convenience stores utilize air tire checkers as self-service stations to provide customers with easy access to tire inflation. This convenience not only attracts more foot traffic but also boosts sales of other products and services offered in-store. For international buyers, particularly in regions like Africa and South America, sourcing durable machines that withstand local weather conditions and provide reliable service is crucial. Additionally, revenue-sharing models can be appealing, allowing for minimal upfront investment while generating passive income.

In automotive repair and tire shops, air tire checkers streamline the tire inflation process, allowing technicians to focus on more complex tasks. By providing precise tire pressure readings quickly, these machines enhance safety and improve customer satisfaction. For B2B buyers in Europe and the Middle East, it’s essential to consider the accuracy of the equipment, the speed of inflation, and compatibility with existing shop systems. Investing in high-quality air tire checkers can lead to significant time savings and improved operational efficiency.

Illustrative image related to air tire checker

Fleet management companies leverage air tire checkers to ensure that all vehicles maintain optimal tire pressure, which significantly affects fuel efficiency and tire longevity. By integrating these machines into their maintenance routines, fleets can reduce operational costs and enhance vehicle safety. Buyers in regions like Brazil and Vietnam should prioritize machines that offer high durability and real-time data monitoring capabilities to manage large fleets effectively. This proactive approach can lead to substantial savings over time.

Car wash facilities incorporate air tire checkers to provide additional services that enhance customer loyalty. Offering tire inflation as part of the car wash experience can draw in more customers and encourage repeat business. For B2B buyers in regions with diverse climates, selecting equipment that is weather-resistant and user-friendly is vital. Additionally, facilities should consider machines that can handle high traffic while maintaining accuracy and reliability.

In auto rentals and dealerships, air tire checkers are essential for maintaining vehicle safety and performance. By ensuring that rental vehicles are always at optimal tire pressure, businesses can enhance customer experience and reduce maintenance costs. Buyers in international markets should focus on sourcing machines that are easy to operate for customers and provide accurate readings. This not only improves service quality but also enhances the overall perception of the rental or dealership brand.

Das Problem: One common challenge B2B buyers face when sourcing air tire checkers is ensuring the accuracy of tire pressure measurements. In environments such as tire shops, auto repairs, or fleet management, even minor inaccuracies can lead to significant operational issues. Over-inflated or under-inflated tires can cause premature wear, reduced fuel efficiency, and compromised safety. Buyers may find that traditional gauges are prone to error, especially in high-demand settings, leading to frustration among technicians and dissatisfied customers.

Die Lösung: To overcome this challenge, B2B buyers should prioritize sourcing high-quality, digital air tire checkers that are designed for precision and reliability. Look for models that feature advanced calibration technology and are verified by industry standards. Regularly scheduled maintenance and calibration checks should be instituted to ensure ongoing accuracy. Additionally, training staff on the proper use of these digital devices can further minimize human error. By investing in these solutions, businesses can enhance their service quality, improve customer satisfaction, and reduce costs associated with tire maintenance.

Illustrative image related to air tire checker

Das Problem: Gas stations and convenience stores often struggle with customer satisfaction due to long wait times at air filling stations. Customers may become frustrated if the air machines are difficult to operate or malfunction frequently, leading to negative perceptions of the business. This can result in lost revenue, as customers might choose to go elsewhere for their air and tire needs, impacting overall foot traffic and sales in associated convenience store offerings.

Die Lösung: B2B buyers can address this pain point by investing in user-friendly, digital air tire checkers that offer intuitive interfaces and quick inflation times. These machines can be equipped with features such as touchscreens, multi-language support, and clear instructions to enhance usability. Implementing a revenue-sharing program with suppliers can alleviate upfront costs, allowing businesses to provide these services at no initial expense. Additionally, placing these machines in high-visibility areas can attract more customers and increase convenience store traffic, ultimately boosting sales.

Das Problem: Fleet managers and auto rental companies often face escalating operational costs due to inefficient tire maintenance practices. Regularly overlooked tire pressure checks can lead to decreased fuel efficiency and increased wear and tear, translating into higher maintenance expenses and reduced vehicle lifespan. Additionally, the time spent on manual tire pressure checks takes away from core business operations, leading to lost productivity.

Die Lösung: To combat these issues, fleet operators should implement automatic tire inflation systems paired with air tire checkers that provide real-time data analytics. These systems can automatically monitor and adjust tire pressure, ensuring optimal performance without manual intervention. Furthermore, investing in machines that offer remote monitoring capabilities can provide fleet managers with insights into tire performance across their entire fleet, allowing for proactive maintenance scheduling. This approach not only lowers operational costs but also enhances safety and extends the longevity of the fleet, ultimately leading to a more profitable business model.

When selecting materials for air tire checkers, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Below, we analyze four common materials used in the manufacturing of air tire checkers, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum is a lightweight and corrosion-resistant metal, making it a popular choice for air tire checkers. It typically has a temperature rating of up to 150°C and can withstand pressures of around 200 psi.

Vorteile: Its lightweight nature enhances portability, and its resistance to corrosion extends the product’s lifespan, especially in humid or saline environments. Additionally, aluminum is relatively easy to manufacture, allowing for intricate designs.

Nachteile: While durable, aluminum can be prone to scratches and dents. It is also more expensive than some alternatives, which may affect the overall cost of the tire checker.

Auswirkungen auf die Anwendung: Aluminum is compatible with various media, including air and nitrogen, making it suitable for both conventional and specialized tire inflation.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM and DIN is essential for aluminum products. Buyers in regions like Africa and South America should also consider the availability of aluminum recycling programs to ensure sustainability.

Illustrative image related to air tire checker

Stainless steel is known for its exceptional strength and corrosion resistance, making it ideal for air tire checkers exposed to harsh conditions. It can handle temperatures up to 300°C and pressures exceeding 300 psi.

Vorteile: The durability of stainless steel means it can withstand heavy use without significant wear. Its resistance to rust and corrosion makes it suitable for outdoor applications, particularly in regions with high humidity.

Nachteile: The primary drawback is its higher cost compared to aluminum and plastic alternatives. Additionally, stainless steel is heavier, which may affect portability.

Auswirkungen auf die Anwendung: Stainless steel is compatible with air and other gases, ensuring reliable performance across various environments.

Überlegungen für internationale Käufer: Buyers should ensure that the stainless steel used complies with international standards such as JIS or ASTM, particularly in markets like the Middle East and Europe, where quality control is stringent.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is increasingly used in air tire checkers due to its versatility. These materials can typically handle temperatures up to 80°C and pressures around 150 psi.

Vorteile: Plastic is lightweight and cost-effective, making it an attractive option for budget-conscious buyers. It is also resistant to corrosion and can be molded into complex shapes.

Nachteile: Plastic is generally less durable than metals, making it more susceptible to wear and tear over time. Moreover, its temperature and pressure limitations may restrict its use in high-performance applications.

Illustrative image related to air tire checker

Auswirkungen auf die Anwendung: Plastic is suitable for air and nitrogen but may not be ideal for applications involving chemicals or extreme temperatures.

Überlegungen für internationale Käufer: Buyers should verify that the plastic materials meet local and international safety standards, especially in regions like Africa and South America, where product quality may vary.

Rubber is often used in seals and gaskets within air tire checkers, providing essential flexibility and sealing properties. It can withstand temperatures up to 100°C and pressures of around 100 psi.

Vorteile: Rubber offers excellent elasticity and resilience, making it ideal for components that require a tight seal. It is also relatively inexpensive and easy to source.

Nachteile: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. Its lifespan may be shorter compared to metals and plastics.

Illustrative image related to air tire checker

Auswirkungen auf die Anwendung: Rubber is primarily used in conjunction with other materials to enhance sealing and pressure retention.

Überlegungen für internationale Käufer: Compliance with standards related to rubber quality is crucial, particularly in markets where product longevity is critical, such as in Europe and the Middle East.

| Material | Typical Use Case for air tire checker | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Body and housing components | Leicht und korrosionsbeständig | Prone to scratches and dents | Mittel |

| Rostfreier Stahl | Structural components | Exceptional strength and durability | Higher cost and heavier | Hoch |

| Kunststoff | Housing and non-critical components | Cost-effective and versatile | Less durable and temperature-sensitive | Niedrig |

| Gummi | Seals and gaskets | Excellent elasticity and sealing | Verschlechtert sich mit der Zeit | Niedrig |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

The manufacturing process of air tire checkers involves several key stages that ensure the final product meets the quality and performance standards expected by B2B buyers. These stages include material preparation, forming, assembly, and finishing.

The first step in manufacturing an air tire checker is the careful selection and preparation of materials. Common materials used in the construction of air tire checkers include durable metals such as stainless steel and aluminum, which provide strength and resistance to corrosion. Plastics may also be utilized for non-critical components to reduce weight and cost. Material quality is vital; hence, suppliers often conduct tests to ensure the materials meet specified standards, such as tensile strength and impact resistance.

Illustrative image related to air tire checker

Once the materials are prepared, they undergo forming processes. This may include cutting, bending, and machining to create the various components of the tire checker. Advanced techniques like CNC (Computer Numerical Control) machining ensure precision and consistency in the parts produced.

After forming, the assembly process begins. This typically involves integrating various components, such as sensors, gauges, and electronic displays. During assembly, manufacturers often employ automated systems to enhance efficiency and reduce human error. Quality checks at this stage ensure that all components fit correctly and function as intended.

Finishing processes are crucial in enhancing the durability and aesthetic appeal of air tire checkers. Common techniques include coating with protective finishes to prevent corrosion and improve wear resistance. Powder coating is a popular choice, as it provides a tough, attractive surface that can withstand harsh environmental conditions.

Additionally, manufacturers may conduct calibration and testing of the air tire checkers to ensure accuracy in pressure readings. This step is critical, as even minor inaccuracies can lead to significant performance issues.

Quality control (QC) is an integral part of the manufacturing process for air tire checkers. Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement.

In addition to general quality standards, industry-specific certifications may apply. For example, CE marking indicates compliance with European health, safety, and environmental protection standards, while API certifications may be relevant for products used in specific industrial applications.

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that the final product meets all required specifications. Key checkpoints typically include:

Eingehende Qualitätskontrolle (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

Prozessbegleitende Qualitätskontrolle (IPQC): During production, manufacturers conduct regular inspections and tests to monitor the quality of work-in-progress items. This helps identify any deviations from quality standards early in the process.

Endgültige Qualitätskontrolle (FQC): Once assembly is complete, a comprehensive inspection and testing of the finished air tire checker occur. This includes functional testing, calibration, and visual inspections for defects.

Various testing methods are employed to verify the performance and reliability of air tire checkers. Common tests include:

Illustrative image related to air tire checker

Druckprüfung: This ensures that the tire checker can accurately measure and maintain tire pressure within specified limits.

Dauerhaftigkeitsprüfung: Simulating real-world conditions helps assess the product’s resilience against wear and tear.

Umweltprüfungen: Subjecting the tire checker to extreme temperatures, humidity, and other environmental factors helps evaluate its operational limits.

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

Request Quality Certification Documentation: Buyers should ask for copies of certifications like ISO 9001 and any relevant industry-specific certifications. This documentation serves as evidence of the manufacturer’s commitment to quality.

Durchführung von Lieferantenaudits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can be done by the buyer’s quality assurance team or through third-party audit services.

Review Quality Control Reports: Manufacturers should provide detailed reports on their QC processes, including testing results and compliance with international standards. Buyers should review these reports to assess the reliability of the products.

Engage Third-Party Inspection Services: Utilizing independent inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes. This can be particularly valuable for international transactions where buyers may be unable to conduct on-site inspections.

For international buyers, understanding the nuances of quality control and certification is essential. Different regions may have varying standards and expectations regarding product quality and safety. For example, while CE marking is crucial for products sold in Europe, other regions may prioritize different certifications.

Buyers should familiarize themselves with local regulations and standards in their target markets. Additionally, engaging with suppliers who have experience exporting to their region can help navigate these complexities more effectively.

Illustrative image related to air tire checker

In conclusion, the manufacturing processes and quality assurance practices for air tire checkers play a significant role in ensuring that the products meet the high standards expected by B2B buyers. By understanding these processes and actively verifying supplier quality control, buyers can make informed decisions that enhance their operational efficiency and customer satisfaction.

When sourcing an air tire checker, especially for B2B purposes across diverse markets such as Africa, South America, the Middle East, and Europe, it’s essential to follow a systematic approach. This guide provides a comprehensive checklist to ensure you make informed purchasing decisions that align with your business objectives.

Before diving into the market, clearly outline what you need from the air tire checker. Consider factors such as:

– Druckbereich: Determine the psi range suitable for your applications, whether it’s for light vehicles or heavy-duty trucks.

– Type of Gauge: Decide between digital, analog, or mechanical gauges based on user preference and ease of use.

Illustrative image related to air tire checker

Clearly defined specifications will help you narrow down your options and ensure that the equipment meets your operational needs.

Understanding current trends in tire inflation technology is crucial. Stay informed about:

– Digital vs. Analog: Digital gauges often provide higher accuracy and easier readability.

– User Experience: Look for features that enhance customer interaction, such as easy-to-use interfaces and payment options (coin, cashless).

Researching these trends will help you choose a product that not only meets technical requirements but also aligns with customer expectations.

Before committing, thoroughly vet suppliers. Important aspects to consider include:

– Reputation: Look for reviews or testimonials from other businesses, particularly those in your industry.

– Product Range: Ensure the supplier offers a variety of models to meet different needs.

A reliable supplier can significantly impact your operational efficiency and customer satisfaction.

Ensure that potential suppliers comply with industry standards and regulations. Key certifications to look for include:

– ISO Certifications: Indicate quality management systems.

– Safety Standards: Compliance with safety regulations ensures the product’s reliability and safety.

Verification of certifications helps mitigate risks associated with product failures or non-compliance.

Consider the level of support you will receive after the purchase. Important points include:

– Warranty Terms: Understand what is covered and for how long.

– Customer Service: Assess the responsiveness and availability of support teams.

Strong after-sales support is crucial for minimizing downtime and maintaining operational efficiency.

Illustrative image related to air tire checker

Whenever possible, request samples or product demonstrations to evaluate the equipment firsthand. This step allows you to:

– Test Performance: Assess accuracy, ease of use, and durability.

– Gather User Feedback: Involve your team in the evaluation process to gather insights from those who will operate the equipment.

Experiencing the product before purchase helps ensure it meets your expectations and operational needs.

Once you’ve selected a supplier, it’s time to negotiate terms. Focus on:

– Pricing and Payment Terms: Ensure that the pricing structure aligns with your budget and cash flow.

– Delivery and Installation: Confirm delivery timelines and whether installation support is included.

Illustrative image related to air tire checker

Effective negotiation can lead to cost savings and smoother implementation of the air tire checker in your operations.

By following this checklist, B2B buyers can make informed decisions that enhance their service offerings and operational efficiency.

When considering the sourcing of air tire checkers, a comprehensive understanding of the cost structure is essential for B2B buyers. The primary cost components include:

Materialien: The quality and type of materials used in air tire checkers significantly impact the overall cost. Durable materials, such as stainless steel or high-grade plastics, increase initial expenses but enhance longevity and reliability.

Arbeit: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may provide more competitive pricing, but this could affect the quality of workmanship and the final product.

Fertigungsgemeinkosten: This encompasses the indirect costs of production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, thus reducing the overall price.

Werkzeugbau: Initial tooling costs for custom designs can be substantial. Buyers should consider the potential for amortizing these costs over larger production runs to achieve better pricing per unit.

Qualitätskontrolle (QC): Investing in stringent quality control measures ensures that the products meet safety and performance standards. However, this can add to the cost. Buyers should evaluate the balance between quality assurance and overall pricing.

Logistik: Shipping costs, including freight, customs duties, and insurance, can significantly affect the total expenditure. Understanding the logistics involved in transporting air tire checkers to your destination is crucial for accurate budgeting.

Marge: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition, brand reputation, and product exclusivity.

Several factors can influence the price of air tire checkers, particularly for international B2B buyers:

Volumen und Mindestbestellmenge (MOQ): Higher order volumes usually lead to discounted pricing. Buyers should negotiate MOQs to benefit from bulk pricing while ensuring they do not overstock.

Spezifikationen und Anpassungen: Customized air tire checkers with specific features or branding will generally cost more than standard models. Buyers should assess whether customization aligns with their market needs and budget.

Materialien und Qualitätszertifikate: Premium materials and certifications (such as ISO or CE) may increase costs but can enhance product value and marketability. Buyers should weigh the benefits of these certifications against their cost.

Lieferanten-Faktoren: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

Incoterms: Understanding the Incoterms agreed upon in the contract is vital. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect the total cost.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, effective negotiation can yield better pricing:

Research and Benchmarking: Conduct thorough market research to understand the pricing landscape. Comparing quotes from multiple suppliers can provide leverage during negotiations.

Gesamtbetriebskosten (TCO): Emphasize TCO rather than just the purchase price. Highlighting factors such as durability, maintenance costs, and operational efficiencies can justify a higher upfront price for better long-term value.

Flexibility in Order Quantities: Being open to flexible order sizes can help negotiate better terms. Suppliers may offer favorable pricing for larger orders or future commitments.

Long-term Partnerships: Building relationships with suppliers can lead to advantageous pricing over time. Consider establishing long-term contracts that ensure consistent supply and pricing stability.

International buyers must navigate specific pricing nuances:

Currency Fluctuations: Be aware of currency exchange rates, which can impact the final cost. Locking in pricing when the exchange rate is favorable can mitigate risks.

Tariffs and Duties: Understand the tariffs and import duties applicable to your region. These can significantly affect the landed cost of air tire checkers.

Logistische Herausforderungen: Consider the logistics involved in shipping across borders, including potential delays and additional costs related to customs clearance.

Prices for air tire checkers can vary widely based on the factors mentioned above. It is recommended to request detailed quotations and conduct thorough due diligence to understand the specific costs associated with your procurement needs.

In the realm of tire maintenance, air tire checkers play a vital role in ensuring optimal vehicle performance and safety. However, several alternative solutions also address tire pressure management. This analysis will compare air tire checkers against two viable alternatives: manual tire pressure gauges and digital tire inflators. Understanding the strengths and weaknesses of these options will empower B2B buyers to make informed decisions tailored to their operational needs.

Illustrative image related to air tire checker

| Vergleich Aspekt | Air Tire Checker | Manual Tire Pressure Gauge | Digital Tire Inflator |

|---|---|---|---|

| Leistung | High accuracy with automated calibration | Varies, often less accurate | High accuracy with automatic shut-off |

| Kosten | Moderate initial investment, potential for revenue sharing | Low cost, typically one-time purchase | Higher upfront cost, potential for long-term savings |

| Leichte Implementierung | Easy to install; minimal training required | Simple to use; no installation needed | Requires installation and user training |

| Wartung | Low maintenance with service options available | Minimal maintenance; replace as needed | Regular checks and occasional repairs required |

| Bester Anwendungsfall | High-traffic areas (gas stations, tire shops) | Personal or small business use | Commercial fleets, auto shops needing efficiency |

Manual tire pressure gauges are a traditional and cost-effective solution for checking tire pressure. They are portable, require no electricity, and can be used anywhere. However, their accuracy can vary significantly based on the gauge’s quality and user proficiency. Manual gauges demand a hands-on approach, which may lead to user error, especially in high-stress environments like auto repair shops. Additionally, they do not provide the convenience of automated features that can enhance user experience and efficiency.

Digital tire inflators represent a modern approach to tire pressure management. These devices offer high accuracy and often come with features like automatic shut-off once the desired pressure is reached. This can significantly reduce the risk of over-inflation and enhance safety. However, the initial investment is typically higher than that of manual gauges, and they require installation and occasional maintenance. Digital inflators are particularly advantageous for commercial use, such as in fleet operations or auto shops, where speed and accuracy are critical.

When selecting the appropriate tire maintenance solution, B2B buyers should consider their specific operational needs, budget constraints, and the environment in which the solution will be implemented. Air tire checkers are ideal for high-traffic locations seeking to enhance customer satisfaction and operational efficiency. In contrast, manual gauges may suit small businesses or personal use due to their affordability. Digital tire inflators, while more costly upfront, offer significant long-term benefits for commercial applications. By evaluating these factors, buyers can make strategic choices that align with their business goals and enhance tire management practices.

When evaluating air tire checkers, understanding their critical technical properties is essential for making informed purchasing decisions. Here are some key specifications to consider:

Material Klasse

The construction material of an air tire checker significantly impacts its durability and performance. Common materials include stainless steel, aluminum, and high-grade plastics. Stainless steel offers corrosion resistance and longevity, making it ideal for outdoor use, while aluminum is lightweight and easy to handle. Choosing the right material ensures that the equipment can withstand harsh weather conditions and frequent usage, reducing long-term replacement costs.

Druckbereich

The pressure range indicates the minimum and maximum tire pressure the checker can measure, typically expressed in pounds per square inch (psi). A broader pressure range allows for versatility across various vehicles, from passenger cars to heavy-duty trucks. This capability is crucial for businesses that serve diverse clientele, ensuring they can accommodate all types of vehicles effectively.

Accuracy and Tolerance

Accuracy refers to how close the tire checker’s readings are to the actual tire pressure, while tolerance denotes the acceptable deviation from the true value. High accuracy (±1 psi) is vital for proper tire maintenance, which can enhance fuel efficiency and prolong tire life. For businesses, investing in precise equipment can lead to improved customer satisfaction and reduced liability from inaccurate readings.

Ease of Use

User-friendly interfaces, such as digital displays and straightforward operation, enhance the efficiency of tire inflation and checking processes. Features like automatic shut-off and ergonomic designs can significantly improve the user experience. For B2B operations, simplifying the user experience can lead to higher productivity and reduce the likelihood of errors during tire checks.

Calibration and Maintenance Requirements

Regular calibration ensures that the tire checker maintains its accuracy over time. Equipment that requires frequent calibration can lead to increased maintenance costs and downtime. Understanding the calibration frequency and ease of maintenance is crucial for businesses, as it affects operational efficiency and the total cost of ownership.

Stromquelle

Air tire checkers can be powered by electricity, battery, or manual operation. Electric models typically offer more consistent performance, while battery-operated versions provide flexibility and portability. Assessing the power source is critical, especially for businesses operating in locations without easy access to electrical outlets.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of air tire checkers, understanding whether a product is OEM can help buyers ascertain quality and compatibility with existing equipment.

MOQ (Mindestbestellmenge)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ is essential for budgeting and inventory management, as it can impact cash flow and storage capabilities.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It’s an important step in the procurement process, enabling buyers to compare options and make informed purchasing decisions.

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps businesses manage logistics and mitigate risks associated with shipping and delivery.

Vorlaufzeit

Lead time is the time between the initiation of an order and its completion. For air tire checkers, shorter lead times can enhance operational efficiency and customer satisfaction, making it a critical factor in supplier selection.

Garantie

A warranty is a guarantee provided by the manufacturer regarding the condition and performance of the air tire checker. Understanding warranty terms can protect businesses from unexpected costs associated with equipment failure and ensure peace of mind regarding product reliability.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions when sourcing air tire checkers, ultimately leading to enhanced operational efficiency and customer satisfaction.

The air tire checker market is experiencing significant transformation driven by technological advancements and evolving consumer expectations. Global demand for precision and convenience in tire maintenance is a primary driver, as businesses aim to enhance customer satisfaction and operational efficiency. Digital air inflation systems are emerging as a preferred choice among gas stations, auto repair shops, and car washes due to their user-friendly interfaces and real-time monitoring capabilities. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, adopting these modern solutions can significantly boost service offerings and customer retention.

Emerging trends include the integration of smart technology into tire inflation systems, such as automated calibration and data analytics for monitoring tire health. This trend is particularly relevant for fleet operators and rental companies, where maintaining optimal tire pressure can lead to substantial fuel savings and extended tire lifespan. Moreover, the shift towards electric vehicles (EVs) is influencing sourcing decisions, as businesses seek air tire checkers that cater to the specific needs of EV maintenance. International buyers must stay abreast of these trends to align their sourcing strategies with market demands and technological innovations.

The importance of sustainability in the air tire checker sector cannot be overstated, particularly as global markets shift towards environmentally responsible practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their environmental impact. This includes sourcing materials that are recyclable and implementing manufacturing processes that minimize carbon emissions. The use of digital air machines, for instance, not only enhances efficiency but also reduces waste by ensuring precise inflation, which prolongs tire life and decreases the frequency of replacements.

Ethical sourcing is becoming a significant consideration for B2B buyers. Companies are encouraged to partner with manufacturers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. Buyers in Africa, South America, the Middle East, and Europe should actively seek suppliers that align with these values, as this can enhance their brand reputation and customer loyalty in an increasingly eco-conscious market.

The air tire checker sector has evolved significantly over the decades, transitioning from manual gauges to sophisticated digital systems. Historically, tire maintenance relied heavily on analog tools that required a degree of skill and experience to operate effectively. However, with the advent of digital technology in the late 20th century, tire inflation became more accessible and accurate, paving the way for innovations such as automated tire inflators.

In recent years, the sector has further adapted to changing consumer behaviors and technological advancements. The integration of data analytics and smart technology into tire checkers has enhanced their functionality, making them essential tools for businesses looking to improve service quality and operational efficiency. As the market continues to evolve, B2B buyers must remain vigilant and adaptable, ensuring their sourcing strategies reflect the latest trends and technologies in the air tire checker landscape.

Illustrative image related to air tire checker

1. How do I choose the right air tire checker for my business needs?

When selecting an air tire checker, consider factors such as accuracy, durability, ease of use, and the specific needs of your customer base. Look for digital options that provide precise tire pressure readings and are user-friendly, enhancing customer experience. Additionally, evaluate the machine’s maintenance requirements and the level of customer support provided by the supplier. Opt for brands with proven reliability and positive reviews from similar businesses in your industry.

2. What are the benefits of using a digital air tire checker?

Digital air tire checkers offer numerous advantages, including higher accuracy in tire pressure readings, faster inflation times, and an intuitive interface for users. They often come equipped with features like automatic shut-off and error notifications, which enhance safety and efficiency. Furthermore, digital models can improve customer satisfaction and retention, leading to increased traffic and sales for your business.

3. How can I ensure the quality of the air tire checker I purchase?

To ensure quality, vet suppliers by checking their certifications, customer testimonials, and product warranties. Request samples or demos to evaluate the performance and durability of the air tire checker before making a bulk purchase. Additionally, inquire about the supplier’s quality assurance processes and any testing standards they adhere to, which can provide insights into the product’s reliability.

4. What customization options are available for air tire checkers?

Many suppliers offer customization options for air tire checkers, including branding, colors, and additional features tailored to your business needs. Customization can enhance your brand visibility and create a more cohesive customer experience. Discuss your specific requirements with potential suppliers to explore available options, ensuring they align with your marketing strategy and operational requirements.

Illustrative image related to air tire checker

5. What is the typical minimum order quantity (MOQ) for air tire checkers?

The minimum order quantity (MOQ) for air tire checkers varies by supplier and product type. Some manufacturers may have an MOQ as low as 10 units, while others may require larger orders to achieve economies of scale. It’s essential to communicate with suppliers about your needs and negotiate terms that work for both parties, especially if you are considering a long-term partnership.

6. What payment terms should I expect when sourcing air tire checkers internationally?

Payment terms can differ significantly among suppliers. Common practices include upfront payments, partial deposits, or payment upon delivery. For international transactions, consider secure payment methods such as letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing your order to avoid misunderstandings and ensure a smooth transaction process.

7. How do I handle logistics and shipping for international orders of air tire checkers?

When ordering air tire checkers internationally, work with suppliers who have experience in logistics and shipping. Discuss shipping options, estimated delivery times, and associated costs upfront. Consider partnering with freight forwarders who can assist with customs clearance and ensure compliance with local regulations. Proper planning can help minimize delays and additional charges during the import process.

8. What should I know about after-sales support for air tire checkers?

After-sales support is crucial for the longevity and effective operation of your air tire checkers. Ensure that the supplier provides reliable customer service, including technical support, warranty services, and access to spare parts. Ask about the response times for service requests and any available training for your staff on using and maintaining the equipment. Strong after-sales support can significantly enhance your operational efficiency and customer satisfaction.

Bereich: exceltiregauge.com

Registriert: 2004 (21 Jahre)

Einleitung: High-Quality Air Machines & Tire Inflators from Excel Tire Gauge include: 1. SC09-SS Pay Air Machine 2. SC05-SS Free Air Machine 3. SC05-SS Kiosk Air Machine 4. SCWM-23 Wall Mount Air Machine 5. PNT PRO Automatic Tire Inflator 6. PNT 4 Automatic Tire Inflator. The products are designed for various industries including gas stations, car washes, tire shops, auto repair, quick lube, fleets, rental ca…

In today’s competitive landscape, strategic sourcing of air tire checkers is essential for businesses seeking to enhance operational efficiency and customer satisfaction. By investing in high-quality air tire checking solutions, companies can streamline their tire maintenance processes, reduce costs, and improve safety standards. Notably, the adoption of digital air machines not only increases customer traffic but also fosters brand loyalty through enhanced user experiences.

Moreover, the revenue-sharing models offered by leading suppliers present an attractive opportunity for gas stations, tire shops, and automotive services to enhance profitability without incurring upfront costs. As the demand for reliable tire maintenance solutions continues to grow globally—especially in emerging markets across Africa, South America, the Middle East, and Europe—businesses must prioritize partnerships with reputable suppliers to leverage innovative technologies and maximize their market potential.

Looking ahead, B2B buyers are encouraged to embrace these advancements in air tire checking technology. By doing so, they will not only improve their service offerings but also position themselves as leaders in customer satisfaction and operational excellence. Now is the time to act and secure a competitive edge in your market.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.