In the rapidly evolving landscape of automotive care, sourcing an automatic air inflator can pose significant challenges for international B2B buyers. The demand for efficient tire maintenance solutions is at an all-time high, particularly in regions like Africa, South America, the Middle East, and Europe. Businesses are seeking reliable products that not only enhance operational efficiency but also ensure safety and compliance with local standards. This guide serves as a comprehensive resource, covering various types of automatic air inflators, their applications across diverse industries, and key factors to consider when selecting suppliers.

From wall-mounted units to portable handheld inflators, understanding the nuances of each type can empower decision-makers to choose the right equipment for their unique needs. Additionally, we delve into supplier vetting processes, providing insights on how to evaluate quality, reliability, and service support. Cost analysis is also featured, equipping buyers with the necessary tools to negotiate effectively and make informed purchasing decisions.

By navigating the complexities of the automatic air inflator market, this guide aims to simplify the procurement process for businesses in Nigeria, Saudi Arabia, and beyond. With actionable insights and expert recommendations, buyers will be well-prepared to invest in solutions that enhance productivity and ensure the safety of their operations.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Wall-Mounted Tire Inflators | Fixed installation, automated pressure control | Automotive service stations, fleet maintenance | Vorteile: Space-saving, consistent performance. Nachteile: Limited mobility, requires installation. |

| Handheld Automatic Tire Inflators | Portable, battery-operated or plug-in options | Roadside assistance, small workshops | Vorteile: Versatile, easy to use. Nachteile: Limited power, may require frequent recharging. |

| Digital Inflators with Shutoff | Digital pressure gauges, automatic shutoff features | Tire retailers, rental services | Vorteile: High accuracy, user-friendly. Nachteile: Can be pricier, dependent on battery life. |

| Heavy-Duty Industrial Inflators | High PSI capabilities, robust construction | Construction sites, heavy machinery | Vorteile: Fast inflation, suitable for large tires. Nachteile: Bulky, higher initial investment. |

| Multi-Purpose Inflators | Includes additional adapters for various inflatables | Sports facilities, event organizers | Vorteile: Versatile for multiple applications. Nachteile: May lack specialized features for tires. |

Wall-mounted tire inflators are designed for fixed installations in service environments such as automotive service stations and fleet maintenance facilities. These units typically offer automated pressure control, allowing for consistent inflation without manual intervention. Their space-saving design makes them ideal for busy workshops. B2B buyers should consider installation requirements and ensure that the unit’s PSI capabilities meet their specific needs.

Handheld automatic tire inflators are portable devices that can be battery-operated or powered through a vehicle’s power outlet. These inflators are particularly useful for roadside assistance services and small workshops where mobility is essential. Their ease of use and versatility make them a practical choice for various applications. However, buyers should evaluate the battery life and power capabilities to ensure they can meet their operational demands.

Digital inflators equipped with shutoff features provide precise inflation through digital pressure gauges, automatically shutting off once the desired pressure is reached. These inflators are commonly used in tire retail and rental services, where accuracy and user-friendliness are paramount. While they tend to be more expensive than traditional models, the enhanced accuracy and ease of use can lead to long-term savings for B2B buyers.

Heavy-duty industrial inflators are built to handle high PSI requirements and are constructed for durability. They are well-suited for construction sites and heavy machinery, where quick and efficient tire inflation is critical. While these units may require a higher initial investment and can be bulkier than other options, their ability to inflate large tires quickly can significantly enhance operational efficiency.

Multi-purpose inflators come with various adapters, allowing them to inflate not just tires but also sports equipment and inflatable toys. They are particularly beneficial for sports facilities and event organizers who require versatile equipment. While they may not offer the specialized features of dedicated tire inflators, their adaptability can be a significant advantage for businesses looking to maximize their investment in inflation equipment.

Illustrative image related to automatic air inflator

| Industrie/Sektor | Specific Application of Automatic Air Inflator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparatur | Tire inflation in workshops | Increases efficiency and reduces labor costs during tire servicing | Reliability, compatibility with various tire types, and ease of use |

| Transportation | Fleet maintenance for commercial vehicles | Enhances vehicle safety and reduces downtime due to tire issues | Durability, serviceability, and ability to handle high-pressure tires |

| Bauwesen | Inflation of heavy machinery tires | Ensures operational readiness and minimizes equipment failure | Robustness, pressure range, and ability to inflate large tires |

| Sports and Recreation | Maintenance of inflatable sports equipment | Ensures safety and performance during sports events | Portability, ease of use, and quick inflation capabilities |

| Herstellung | Automated inflation of products requiring air pressure | Streamlines production processes and ensures quality control | Integration capabilities with existing systems and precision accuracy |

In automotive repair shops, automatic air inflators are essential for quickly inflating tires to the correct pressure. This not only speeds up the tire servicing process but also ensures that vehicles are safe for operation. By automating the inflation process, businesses can reduce labor costs and human error, leading to better service quality. Buyers in this sector should prioritize inflators that are reliable, easy to use, and compatible with a variety of tire types to meet diverse customer needs.

For transportation companies managing fleets, automatic air inflators are critical tools for maintaining tire pressure across numerous vehicles. Proper tire inflation enhances fuel efficiency and vehicle safety, reducing the likelihood of roadside breakdowns. Fleet managers should consider inflators with durability and high-pressure capabilities, as they often deal with larger vehicle tires. Ensuring that inflators are easy to operate and maintain will further improve operational efficiency in these businesses.

In the construction sector, heavy machinery often requires specific tire pressures to function optimally. Automatic air inflators can quickly inflate or deflate these tires, ensuring that equipment is ready for use without delays. This capability minimizes downtime and enhances productivity on job sites. Buyers should focus on inflators that are robust and can handle high-pressure requirements, as well as those that can operate in challenging environments typical of construction sites.

In the sports and recreation industry, automatic air inflators are used to maintain inflatable sports equipment, such as rafts and balls. Ensuring that this equipment is properly inflated is crucial for safety and performance during events. Buyers should look for portable inflators that offer quick inflation capabilities and ease of use, allowing for rapid setup and maintenance during events. This is particularly valuable in outdoor environments where time and convenience are critical.

Manufacturers often require precise air pressure for various products, making automatic air inflators vital in production lines. These devices can streamline the inflation process, ensuring that products meet quality control standards. For international buyers, especially those in regions with varying manufacturing standards, sourcing inflators that integrate seamlessly with existing systems and offer precision accuracy is essential. This not only improves production efficiency but also enhances product quality, leading to higher customer satisfaction.

Illustrative image related to automatic air inflator

Das Problem: Many B2B buyers, especially those in industries relying on fleet vehicles or heavy machinery, face significant challenges in achieving accurate tire pressure. Overinflation or underinflation can lead to reduced fuel efficiency, increased tire wear, and potential safety hazards. Buyers often struggle with inflators that provide inaccurate readings, leading to operational inefficiencies and increased costs. This issue is particularly pronounced in regions with varying temperature conditions, such as Africa and the Middle East, where tire pressure can fluctuate dramatically.

Die Lösung: To ensure accuracy in tire inflation, buyers should invest in automatic air inflators equipped with high-quality digital gauges that offer precise pressure readings. When sourcing these inflators, look for models that feature automatic shutoff capabilities, which stop the inflator once the desired pressure is reached. Additionally, consider inflators that allow for preset pressure settings to streamline the inflation process across various vehicles. Regular calibration and maintenance of the inflators can further enhance accuracy, ensuring that all tires are inflated to the correct specifications, thereby improving safety and reducing operational costs.

Das Problem: In fast-paced industries, such as logistics and transportation, time is of the essence. B2B buyers often find that manual tire inflation methods are time-consuming, leading to delays in vehicle readiness and reduced productivity. The challenge is compounded in regions where the workforce is limited or where downtime can significantly impact business operations. This inefficiency can result in increased labor costs and logistical challenges.

Die Lösung: To address time constraints, companies should consider investing in high-capacity automatic air inflators that can inflate multiple tires in quick succession. For instance, wall-mounted units that connect directly to an air compressor can provide rapid inflation without the need for manual intervention. When selecting an inflator, prioritize models with fast inflation rates and long hoses that can reach all tires without moving the vehicle. Training staff to efficiently use these inflators can further minimize downtime and ensure that tire maintenance becomes a seamless part of daily operations.

Das Problem: B2B buyers managing a fleet with diverse vehicle types, including cars, trucks, and heavy machinery, often encounter compatibility issues with tire inflators. Different tire types require varying pressure levels, and using a single inflator that does not cater to these variations can lead to improper inflation. This incompatibility not only affects vehicle performance but can also result in increased maintenance costs and safety risks.

Illustrative image related to automatic air inflator

Die Lösung: To overcome this challenge, buyers should opt for versatile automatic air inflators that are designed to handle a wide range of tire pressures and types. Look for inflators that offer adjustable pressure settings and come with multiple nozzle attachments for various applications, including high-pressure inflators suitable for trucks and lower-pressure options for passenger vehicles. Additionally, conducting a thorough analysis of the fleet’s tire requirements can help in specifying the right inflator. Collaborating with manufacturers that provide customizable options can also ensure that the inflators meet the specific needs of diverse vehicle types, ultimately enhancing operational efficiency and safety.

When selecting materials for automatic air inflators, it is crucial to consider their properties, advantages, and limitations. The right choice can significantly impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of automatic air inflators.

Aluminum is widely used in the manufacturing of automatic air inflators due to its excellent strength-to-weight ratio. It can withstand high pressures and has a temperature rating suitable for various climates. Aluminum is also resistant to corrosion, making it ideal for applications in humid or saline environments.

Profis: Lightweight, good corrosion resistance, and ease of machining make aluminum a preferred choice. It is also relatively cost-effective compared to other metals.

Nachteile: While durable, aluminum can be susceptible to scratches and dents, which may affect its long-term performance. Additionally, its manufacturing process can be more complex than plastic options.

Auswirkungen auf die Anwendung: Aluminum is compatible with various media, including air and nitrogen, making it versatile for different inflation needs.

Überlegungen für internationale Einkäufer: Buyers from regions like Africa and the Middle East should ensure compliance with local standards and regulations, such as ASTM or DIN, particularly concerning pressure ratings and safety guidelines.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is frequently used in the construction of housing and components for automatic air inflators. These materials are lightweight and can be molded into complex shapes, allowing for innovative designs.

Profis: Plastics are generally less expensive than metals and can be produced in various colors and finishes. They also offer good resistance to chemicals and moisture.

Nachteile: While they are resistant to corrosion, plastics can be less durable under extreme temperatures and pressures compared to metals. They may also degrade over time when exposed to UV light.

Auswirkungen auf die Anwendung: Plastic is suitable for non-structural components and can be used in conjunction with metal parts to optimize performance.

Überlegungen für internationale Einkäufer: Buyers should verify that the plastics used meet relevant safety and environmental regulations, especially in regions with strict compliance standards.

Steel, particularly stainless steel, is another common material used in automatic air inflators. It is known for its high strength and durability, making it suitable for high-pressure applications.

Profis: Steel offers excellent resistance to wear and tear and can withstand high temperatures and pressures. It also has a long service life, making it a cost-effective option over time.

Nachteile: The primary drawback of steel is its weight, which can be a disadvantage for portable inflators. Additionally, it is more susceptible to corrosion unless adequately treated or alloyed.

Auswirkungen auf die Anwendung: Steel is ideal for components that require high structural integrity, such as valves and fittings.

Überlegungen für internationale Einkäufer: Buyers should ensure that the steel used complies with international standards, such as JIS or ASTM, particularly regarding corrosion resistance in humid climates.

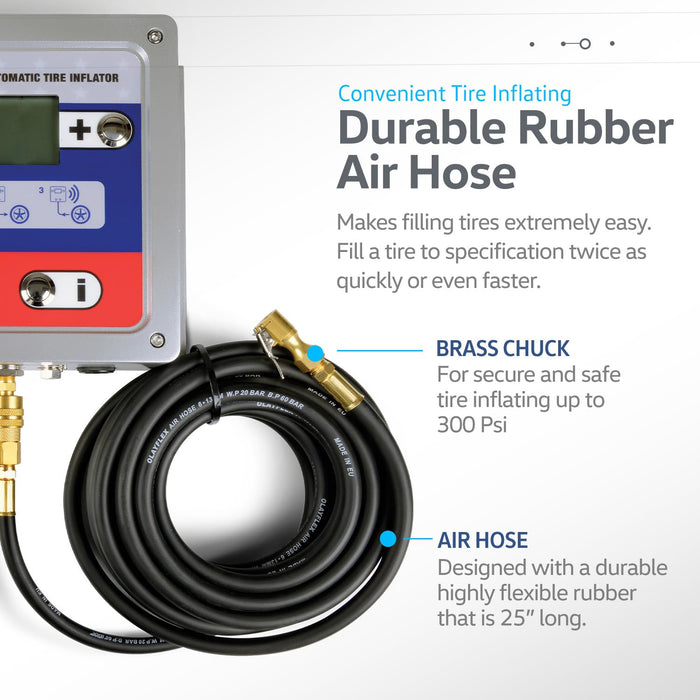

Rubber is primarily used in seals and hoses within automatic air inflators. Its elasticity and flexibility make it an excellent choice for components that require a tight seal.

Profis: Rubber is highly resistant to air leakage and provides excellent cushioning properties. It is also relatively inexpensive and easy to manufacture.

Illustrative image related to automatic air inflator

Nachteile: Rubber can degrade over time due to exposure to ozone and UV light, which may lead to failure in sealing capabilities. Its temperature resistance is also limited compared to metals.

Auswirkungen auf die Anwendung: Rubber is essential for ensuring airtight seals in inflators, which is critical for performance and safety.

Überlegungen für internationale Einkäufer: Buyers should check for compliance with material safety standards, especially in regions where extreme temperatures or environmental conditions are common.

| Material | Typical Use Case for automatic air inflator | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Body and structural components | Leicht und korrosionsbeständig | Susceptible to scratches | Mittel |

| Kunststoff | Housing and non-structural parts | Cost-effective and versatile | Weniger haltbar unter extremen Bedingungen | Niedrig |

| Stahl | Valves and high-pressure fittings | Hohe Festigkeit und Haltbarkeit | Schwerer und korrosionsanfälliger | Hoch |

| Gummi | Dichtungen und Schläuche | Ausgezeichnete Dichtungseigenschaften | Verschlechtert sich mit der Zeit | Niedrig |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in automatic air inflators, helping them make informed purchasing decisions tailored to their regional needs and compliance requirements.

The manufacturing process of automatic air inflators typically involves several critical stages, ensuring that the end product meets both functionality and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Vorbereitung des Materials: The first step involves sourcing high-quality materials such as durable plastics, metals, and electronic components. Manufacturers often conduct thorough inspections of incoming materials to ensure they meet specified standards. This stage may also involve cutting materials to the required dimensions and preparing electronic components for integration.

Bildung von: This stage includes molding and shaping the components of the inflator. Injection molding is commonly used for plastic parts, allowing for precise shapes and sizes. For metal components, processes such as stamping or CNC machining are employed to create the necessary pieces. The forming stage is crucial as it determines the structural integrity and durability of the inflator.

Montage: Once all components are formed, they are assembled into the final product. This can be done manually or through automated processes, depending on the scale of production. During assembly, careful attention is paid to the integration of electronic systems, such as pressure sensors and shutoff mechanisms, which are critical for the inflator’s functionality.

Fertigstellung: The final stage involves applying surface treatments, coatings, or finishes to enhance the product’s durability and aesthetic appeal. This may include powder coating for metal parts or UV treatments for plastics to resist degradation from sunlight. Quality checks are also conducted during this stage to ensure that the product meets visual and functional standards.

Quality assurance (QA) in the production of automatic air inflators is vital for ensuring reliability and performance. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for quality management systems. Additionally, industry-specific standards like CE marking (for European markets) and API certification (for specific equipment) may apply.

International and Industry-Specific Standards: Compliance with these standards guarantees that the inflators meet safety and performance criteria recognized globally. For instance, CE marking signifies that a product meets EU safety, health, and environmental protection requirements, while ISO 9001 ensures a consistent quality management system.

Kontrollpunkte der Qualitätskontrolle: Effective quality control is implemented at various checkpoints throughout the manufacturing process:

– Eingehende Qualitätskontrolle (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified quality standards.

– Prozessbegleitende Qualitätskontrolle (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards early. This includes checking dimensions, functionality, and assembly accuracy.

– Endgültige Qualitätskontrolle (FQC): Before products are packaged and shipped, they undergo rigorous testing to ensure they function correctly. This includes pressure tests, functionality tests, and checks for any cosmetic defects.

Gängige Prüfmethoden: Manufacturers use various testing methods to validate the performance of automatic air inflators. These include:

– Funktionelle Prüfung: Ensures that the inflator operates correctly and meets preset pressure levels.

– Dauerhaftigkeitsprüfung: Involves simulating real-world conditions to assess how the product performs under stress and over time.

– Sicherheitsprüfung: Verifies that the inflator complies with safety regulations, minimizing risks to users.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are some actionable steps:

Lieferanten-Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their production facilities, equipment, and quality management systems.

Qualitätsberichte: Request detailed quality control reports from suppliers. These reports should outline their QA processes, testing methods, and results from recent production batches. Consistency in these reports can indicate a reliable supplier.

Inspektionen durch Dritte: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices. These organizations can conduct inspections and testing to confirm compliance with international standards and specifications.

Certification Verification: Verify the authenticity of any certifications claimed by the supplier. This can often be done through official certification bodies or industry associations.

B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe must be aware of specific quality control nuances:

Illustrative image related to automatic air inflator

Einhaltung von Vorschriften: Different regions have varying regulatory requirements that impact product certification and safety standards. Understanding these regulations is essential for compliance and market entry.

Kulturelle Erwägungen: Cultural differences may influence communication and business practices. Establishing clear expectations regarding quality standards and delivery timelines can help mitigate misunderstandings.

Logistics and Supply Chain: International shipping and logistics can introduce risks related to product quality. It’s important for buyers to work closely with suppliers to ensure proper handling and storage of products during transit.

Post-Purchase Support: Consider suppliers that offer robust after-sales support, including warranty services and product recalls. This can be an indicator of a supplier’s commitment to quality and customer satisfaction.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing automatic air inflators, ensuring they select reliable suppliers that meet their quality expectations.

When sourcing automatic air inflators, it’s essential to take a structured approach to ensure that you select the best option for your business needs. This guide provides a comprehensive checklist designed for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Before you start evaluating options, clearly outline your technical requirements. Consider factors such as the maximum pressure range (psi), compatibility with nitrogen inflation, and whether you need a wall-mounted or portable unit. This step is crucial as it helps narrow down your choices to inflators that meet your specific operational needs.

Stay informed about the latest trends and technological advancements in automatic air inflators. Look for features like automatic shutoff, built-in digital gauges, and rapid inflation capabilities. Understanding current innovations can help you identify products that offer superior performance and efficiency, which can translate into cost savings and enhanced service delivery.

Illustrative image related to automatic air inflator

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product certifications, and references from other clients, especially those in similar industries or regions. A reputable supplier should have a solid track record and demonstrate compliance with international standards, which is particularly important for businesses operating in regulated markets.

Before making a bulk purchase, ask for samples of the inflators you are considering. Testing these units in real-world conditions will provide insights into their functionality, ease of use, and durability. Pay attention to how quickly they inflate tires and whether they accurately maintain set pressures, as these factors can significantly impact your operational efficiency.

While initial pricing is a critical factor, consider the total cost of ownership, which includes maintenance, warranty, and potential repair costs. Compare quotes from different suppliers and analyze the long-term value of each option. A slightly higher upfront cost might be justified if the unit offers better durability and lower maintenance expenses.

Evaluate the after-sales support offered by suppliers, including warranty terms, training for your staff, and availability of spare parts. Strong after-sales support can enhance your operational efficiency and reduce downtime, making it an essential consideration in your procurement process.

Once you’ve selected a supplier and product, ensure that the purchase agreement clearly outlines all terms, including delivery timelines, payment terms, and service commitments. A well-defined agreement will protect both parties and ensure a smooth transaction, helping to avoid potential disputes in the future.

Illustrative image related to automatic air inflator

By following this checklist, B2B buyers can make informed decisions when sourcing automatic air inflators, ensuring they choose products that align with their business needs and operational goals.

When sourcing automatic air inflators, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Materialien: The quality of components such as gauges, pumps, and housing materials can significantly impact costs. High-quality materials may increase the initial price but can lead to enhanced durability and performance.

Arbeit: Labor costs vary by region and skill level. Countries with lower labor costs may offer attractive pricing, but quality assurance is paramount.

Fertigungsgemeinkosten: This includes expenses related to utilities, rent, and administration. Efficient manufacturing processes can help minimize these costs.

Werkzeugbau: Investment in specialized tooling for production can be substantial, particularly for customized inflators. Buyers should consider whether the tooling cost is amortized over large production runs.

Qualitätskontrolle (QC): Implementing rigorous QC processes ensures that each unit meets safety and performance standards. This is crucial for compliance, especially in regulated markets.

Logistik: Shipping costs can vary widely depending on the destination and chosen transport method. Incoterms should be clearly defined to understand which party is responsible for shipping, insurance, and tariffs.

Marge: Supplier margins can vary based on market conditions, competition, and the supplier’s business model. Understanding these factors can help buyers negotiate better terms.

Several factors influence pricing and can significantly impact the overall cost of sourcing automatic air inflators:

Illustrative image related to automatic air inflator

Volumen und Mindestbestellmenge (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating favorable MOQ terms can lead to significant savings.

Spezifikationen und Anpassungen: Customized inflators tailored to specific needs can drive costs higher. Buyers should balance the necessity of customization with budget constraints.

Materialien und Qualitätszertifikate: The choice of materials affects not only price but also the inflator’s performance and lifespan. Additionally, certifications (e.g., ISO, CE) can add to costs but enhance marketability.

Lieferanten-Faktoren: Supplier reliability, reputation, and location can affect pricing. Establishing long-term relationships with reputable suppliers may yield better pricing and service.

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is crucial for calculating total landed costs, which include shipping, insurance, and tariffs.

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost-efficiency:

Negotiate Wisely: Leverage volume purchases and long-term contracts to negotiate better pricing. Being prepared with market intelligence can strengthen your position.

Berücksichtigen Sie die Gesamtbetriebskosten (Total Cost of Ownership, TCO): Evaluate not only the purchase price but also maintenance, warranty, and operational costs over the product’s lifespan. A lower upfront cost may lead to higher TCO if the product is less durable.

Nuancen der Preisgestaltung verstehen: Different regions may have varying pricing strategies due to local demand, currency fluctuations, and tariffs. Staying informed about these factors can help in making better sourcing decisions.

Evaluate Supplier Diversity: Consider sourcing from multiple suppliers to mitigate risks associated with supply chain disruptions. This strategy can also foster competitive pricing.

The prices referenced are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain quotes to ensure accurate pricing.

In the realm of tire maintenance and inflation, automatic air inflators are widely recognized for their efficiency and user-friendly features. However, B2B buyers should also consider alternative solutions that may better fit their operational needs and budget constraints. Below, we compare automatic air inflators with two viable alternatives: manual tire inflators and gas station air pumps.

| Vergleich Aspekt | Automatic Air Inflator | Manual Tire Inflator | Gas Station Air Pump |

|---|---|---|---|

| Leistung | High precision with digital gauges; quick inflation time | Varies; typically slower and less precise | Generally high pressure, but can be inconsistent |

| Kosten | Moderate initial investment; long-term savings through efficiency | Low initial cost; may require more time and labor | Low cost per use, but frequent expenses add up |

| Leichte Implementierung | Requires setup and potential training; easy to operate once installed | Simple to use; no installation needed | Readily available; no setup required, but may require transport |

| Wartung | Minimal maintenance; regular checks needed for accuracy | Low maintenance; occasional replacement of parts | Limited maintenance, but may require repairs if damaged |

| Bester Anwendungsfall | Ideal for businesses with high volume tire inflation needs | Suitable for low-volume, occasional use | Best for emergency or infrequent use |

Manual tire inflators offer a cost-effective alternative for businesses that do not require frequent tire inflation. Their simplicity allows for easy transport and use, making them ideal for small businesses or individual users. However, they can be time-consuming and labor-intensive, particularly when inflating multiple tires. Accuracy can also vary, leading to potential over-inflation or under-inflation, which can affect tire performance and safety.

Gas station air pumps are a convenient option for businesses that only occasionally need to inflate tires. They are widely accessible and generally inexpensive to use. However, the reliability of these pumps can be questionable, as they often lack the precision of automatic inflators and may deliver inconsistent air pressure. Additionally, businesses that rely on these pumps may face inconvenience due to travel time to the station and potential wait times during peak hours.

When selecting a tire inflation solution, B2B buyers should consider their specific operational needs, budget constraints, and the volume of tire maintenance required. Automatic air inflators are best suited for high-volume environments where accuracy and efficiency are critical. In contrast, manual inflators may serve well for lower-volume needs, while gas station air pumps can be a stop-gap solution for infrequent use. Ultimately, the decision should align with the business’s inflation frequency, cost considerations, and the level of precision required for optimal tire maintenance.

When evaluating automatic air inflators for B2B applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

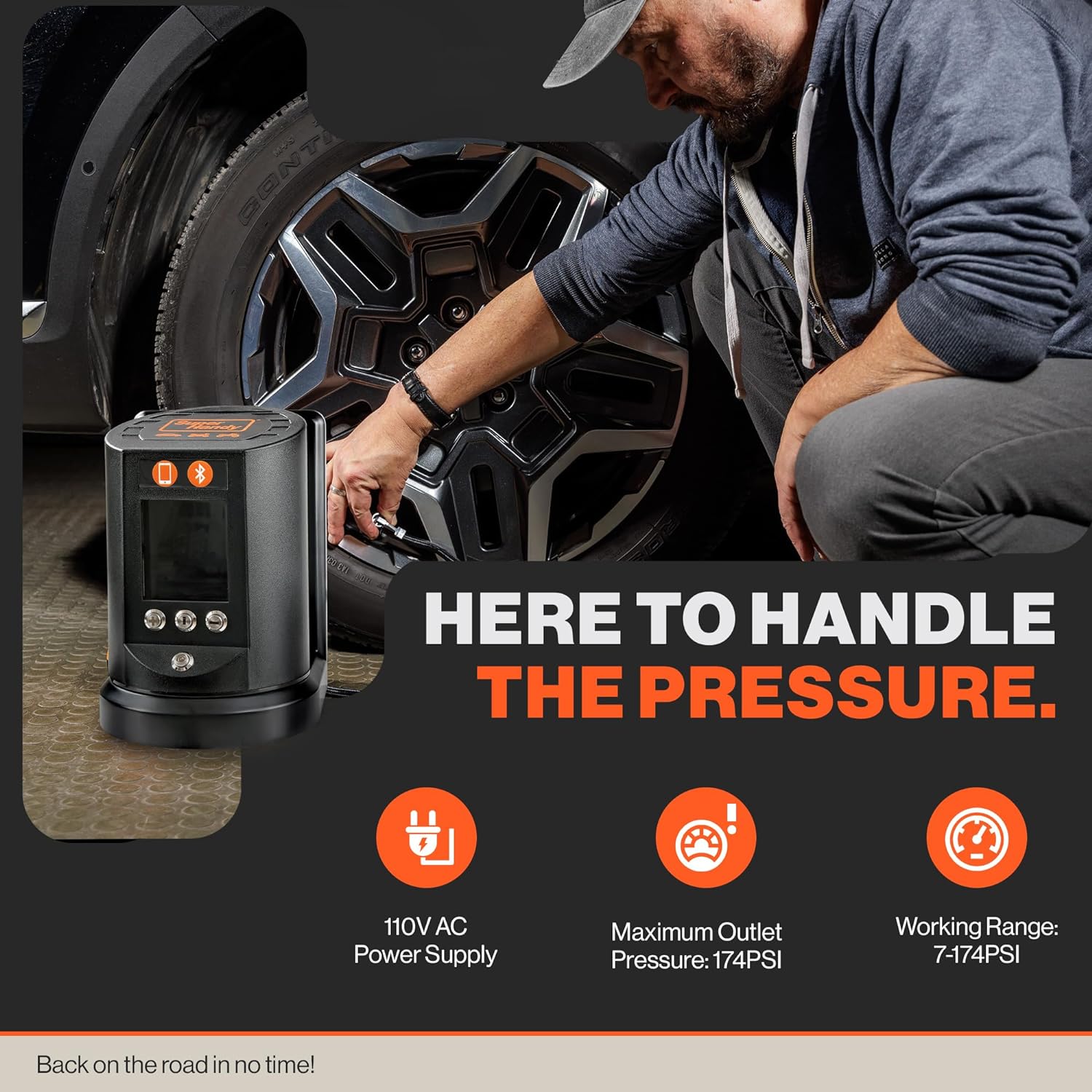

The maximum pressure rating indicates the highest pressure the inflator can achieve, measured in pounds per square inch (psi). Common ratings range from 100 psi to 175 psi. This specification is vital for ensuring the inflator can accommodate various tire types, especially for heavy-duty vehicles used in sectors such as logistics and transportation. A higher psi rating allows versatility in application, catering to both light and heavy vehicles.

Cubic feet per minute (CFM) measures the volume of air the inflator can deliver. A higher CFM means faster inflation times, which is essential for businesses aiming to maximize efficiency. Rapid inflation can reduce downtime, particularly in environments like automotive shops or fleet maintenance facilities where quick service is a priority.

Automatic air inflators can be powered by various sources, including battery, AC, or DC power. Understanding the power source is crucial for compatibility with existing equipment and operational environments. For instance, a battery-operated inflator may be more suitable for remote locations, while an AC-powered model might be ideal for fixed installations in workshops.

Illustrative image related to automatic air inflator

A digital pressure gauge enhances accuracy and ease of use by providing real-time pressure readings. This feature is particularly important for businesses that require precise tire pressure for safety and performance. Accurate readings help in avoiding overinflation or underinflation, which can lead to increased tire wear and potential safety hazards.

The materials used in constructing the inflator, such as high-grade plastics or metals, determine its durability and lifespan. For B2B applications, investing in a robust inflator can reduce replacement costs and downtime. Products designed for industrial use often feature reinforced components to withstand harsher conditions.

This feature allows the inflator to automatically stop when the desired pressure is reached. It not only saves time but also prevents overinflation, contributing to safer operations. Businesses can benefit from this feature by reducing the need for manual monitoring during inflation, thereby streamlining processes.

Illustrative image related to automatic air inflator

Understanding industry jargon can enhance communication and negotiation in B2B transactions. Here are key terms to be familiar with:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of air inflators, buyers may seek OEMs to ensure they receive high-quality components that meet specific standards.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management. It can also affect pricing, as larger orders often qualify for discounts.

An RFQ is a document sent to suppliers asking for pricing and availability of specific products. For buyers of automatic air inflators, issuing an RFQ can facilitate competitive bidding and help secure the best deal.

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing shipping costs, risks, and delivery timelines.

The warranty period is the duration during which the manufacturer guarantees the product against defects. Knowing the warranty terms can help buyers assess the long-term value and reliability of an automatic air inflator.

Certification standards indicate that a product meets specific safety and performance benchmarks. For air inflators, certifications such as CE, ISO, or UL can be critical for ensuring compliance with regional regulations and quality assurance.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing automatic air inflators, ensuring they meet their operational needs effectively.

Illustrative image related to automatic air inflator

The global market for automatic air inflators is experiencing robust growth, driven by several key factors. Increasing vehicle ownership, particularly in emerging markets across Africa, South America, and the Middle East, is elevating the demand for efficient tire maintenance solutions. The rise in e-commerce has also facilitated access to innovative inflator technologies, allowing international B2B buyers to source products that meet specific regional needs.

Emerging technologies in the sector include smart inflators equipped with digital pressure gauges and automatic shutoff features, which enhance user experience by preventing over-inflation. Additionally, portable and battery-operated inflators are gaining traction, particularly among consumers who require flexibility and ease of use. For B2B buyers, understanding these technological advancements is crucial for sourcing products that align with market demands and consumer preferences.

The competitive landscape is evolving, with manufacturers focusing on developing multi-functional inflators that cater to a broader range of applications, such as inflating sports equipment or recreational vehicles. This diversification not only meets various customer needs but also opens up new market segments for B2B suppliers. As sustainability becomes a priority, buyers are increasingly looking for suppliers who demonstrate a commitment to eco-friendly practices and products.

Illustrative image related to automatic air inflator

Sustainability is becoming a cornerstone of purchasing decisions in the automatic air inflator sector. The environmental impact of manufacturing processes and the materials used in production is under scrutiny, prompting B2B buyers to prioritize suppliers who embrace sustainable practices.

Ethical sourcing is essential for maintaining a positive brand reputation, especially in regions where consumers are becoming more environmentally conscious. Buyers should seek out manufacturers that adhere to recognized sustainability certifications, such as ISO 14001 for environmental management or products made from recycled materials.

Incorporating ‘green’ certifications into procurement strategies not only enhances the sustainability profile of a business but also appeals to a growing market segment that values eco-friendly products. As governments across Africa, South America, and Europe implement stricter regulations on environmental standards, B2B buyers must align their sourcing strategies accordingly to mitigate risks and ensure compliance.

The automatic air inflator has evolved significantly from its early mechanical predecessors. Initially, tire inflation was a manual task that required considerable time and effort. The introduction of electric inflators in the late 20th century marked a pivotal shift, offering convenience and efficiency.

As technology advanced, digital gauges and automatic shutoff features became standard, greatly improving the accuracy and safety of tire inflation. Today, the market is witnessing innovations that integrate smart technology, allowing for real-time pressure monitoring and mobile app connectivity. This evolution not only reflects the changing needs of consumers but also underscores the importance of adapting to technological advancements in the B2B landscape.

Illustrative image related to automatic air inflator

Understanding the historical context of automatic air inflators is vital for buyers, as it provides insights into product development trends and informs future purchasing decisions. By recognizing the trajectory of this sector, B2B buyers can make more informed choices that align with both current market demands and technological advancements.

How do I choose the right automatic air inflator for my business needs?

Selecting the right automatic air inflator hinges on understanding your specific requirements. Consider factors like the types of vehicles or equipment you will be servicing, the required psi range, and whether you need features like automatic shutoff or digital gauges. Additionally, evaluate the inflator’s compatibility with various inflation mediums, such as nitrogen. Reviewing supplier specifications and getting insights from existing users can help you make an informed decision.

What are the key features to look for in a high-quality automatic air inflator?

When sourcing an automatic air inflator, prioritize features such as preset pressure settings, automatic shutoff capabilities, and digital pressure gauges for accuracy. Durability and ease of use are also crucial; look for models constructed from robust materials that can withstand frequent use. Additional features like a flexible hose, multiple nozzle attachments, and portability can enhance functionality, making the inflator more versatile for your operations.

What is the typical lead time for ordering automatic air inflators from international suppliers?

Lead times can vary significantly based on the supplier’s location, production capacity, and shipping logistics. Generally, you can expect a lead time of 4 to 12 weeks for international orders. It’s essential to communicate with your supplier to confirm their production timelines and any potential delays due to customs or shipping challenges, especially when dealing with suppliers from regions like Africa or South America.

What are the minimum order quantities (MOQ) for automatic air inflators?

Minimum order quantities for automatic air inflators can range from a few units to several hundred, depending on the supplier and product type. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Some manufacturers may offer lower MOQs for new clients or bulk purchasing discounts, making it possible to start with a smaller order while establishing a relationship for future needs.

How can I ensure the quality of the automatic air inflators I purchase?

To ensure quality, conduct thorough research on potential suppliers, focusing on their reputation, certifications, and customer reviews. Request samples before placing a bulk order to evaluate the product’s performance firsthand. Additionally, inquire about their quality assurance processes, including testing standards and warranty policies. Establishing a clear communication channel with the supplier can also help address any quality concerns promptly.

What payment terms should I expect when sourcing automatic air inflators internationally?

Payment terms can vary widely, but common practices include a deposit upfront (typically 30-50%) with the balance due prior to shipping. Some suppliers may offer letters of credit or payment through escrow services to mitigate risk. It’s crucial to clarify payment methods and terms before finalizing the order, ensuring both parties are comfortable with the arrangement to avoid misunderstandings.

What are the best practices for logistics when importing automatic air inflators?

Effective logistics management involves selecting reliable freight forwarders and understanding customs regulations in your destination country. Ensure all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth customs clearance. Additionally, consider the shipping method that best balances cost and delivery speed, and monitor the shipment closely to address any potential delays or issues proactively.

Are there customization options available for automatic air inflators?

Many suppliers offer customization options to meet specific business needs, including branding, color preferences, and additional features. Discuss your requirements with potential manufacturers to explore available options. Keep in mind that customization may impact lead times and costs, so it’s wise to weigh the benefits against these factors when considering tailored solutions for your business.

Bereich: martinsindustries.com

Registriert: 2005 (20 Jahre)

Einleitung: Automatic Tire Inflators for Professionals, available in various models including handheld and wall-mounted options. Features include: digital gauge, nitrogen-inflation compatibility, and the ability to accurately inflate or deflate tires to desired pressure. Key products include: Handheld digital tire inflator – Flate Mate Handheld MH-30 ($107.72), Analog Handheld Tire Inflator – Flate Mate Analo…

Bereich: rapidairproducts.com

Registriert: 2007 (18 Jahre)

Einleitung: {“product_name”: “Automatic Shutoff Tire Inflator Gauge”, “brand”: “RapidAir”, “part_number”: “K3015”, “price”: {“original”: 261.12, “current”: 174.95}, “features”: [“Preset desired pressure”, “Automatic shutoff at preset pressure”, “Relieves air if overfilled”, “Handheld unit”, “Includes 7 AA batteries”, “6 ft filling cord”], “inflation_range”: “7 to 175 psi”, “compliance”: “Not intended for pota…

Bereich: safetykitsplus.com

Registriert: 2006 (19 Jahre)

Einleitung: {“product_name”: “AAA Digital Tire Air Inflator”, “description”: “Fast and Portable for On-the-Go Inflation. Designed with a powerful heavy-duty motor, this inflator can inflate a standard car tire in just 6 minutes. Compact and portable design for easy storage in your vehicle.”, “features”: {“fast_inflation”: “Inflates a standard car tire in 6 minutes”, “digital_display”: “Built-in digital pressu…

In conclusion, the strategic sourcing of automatic air inflators presents a compelling opportunity for international B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe. The growing demand for efficient tire maintenance solutions underscores the importance of selecting high-quality, reliable inflators that can enhance operational efficiency and customer satisfaction. Key takeaways include the necessity for accurate pressure gauges, automatic shutoff features, and compatibility with various air sources to meet diverse inflation needs.

Investing in strategic sourcing not only ensures access to superior products but also fosters long-term partnerships with manufacturers who prioritize innovation and quality. As the automotive and logistics industries continue to evolve, the role of automatic air inflators in maintaining vehicle performance will only become more critical.

Looking ahead, B2B buyers are encouraged to stay informed about the latest advancements in inflator technology and to engage with suppliers who can offer tailored solutions. By prioritizing strategic sourcing now, businesses can position themselves for success in a competitive landscape, ensuring they meet the demands of their customers and capitalize on market growth.

Illustrative image related to automatic air inflator

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.