In the ever-evolving landscape of motorcycle accessories, sourcing crash bar bags for Harley Davidson models poses a significant challenge for international B2B buyers. These essential storage solutions not only enhance the functionality of motorcycles but also ensure that riders have quick access to critical gear, particularly during long journeys or off-road adventures. This comprehensive guide aims to equip you with the knowledge necessary to navigate the diverse market for crash bar bags, covering various types, applications, and supplier vetting processes, as well as cost considerations.

As the global demand for motorcycle accessories continues to rise, especially in regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—understanding the nuances of product specifications and supplier reliability becomes paramount. This guide empowers B2B buyers by providing actionable insights into selecting high-quality crash bar bags that meet the unique needs of their clientele. By analyzing material durability, design features, and price points, you can make informed purchasing decisions that enhance your product offerings and satisfy customer expectations.

Whether you are a distributor, retailer, or an OEM looking to expand your portfolio, this guide will serve as your essential resource for successfully navigating the global market for crash bar bags tailored for Harley Davidson motorcycles.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Expedition Series Bags | Made from Cordura, 5L capacity, mud-resistant, anti-splash lock | Off-road motorcycle tours, adventure riding | Vorteile: Durable, quick access; Nachteile: Limited color options. |

| Motorschutzbügel-Taschen | Water-repellent, Teflon-coated, optimal weight distribution | Urban commuting, daily use | Vorteile: Excellent design for balance; Nachteile: May not fit all models. |

| Satteltaschenschutztaschen | Synthetic leather, dual zippered opening, internal pouch | Touring, long-distance rides | Vorteile: Stylish, organized storage; Nachteile: Less weatherproof. |

| Crash Bar Storage Bags | Ballistic nylon, storm-flapped zippers, reflective webbing | Trail riding, adventure touring | Vorteile: Rugged and weather-resistant; Nachteile: Mounting may require adjustment. |

| Custom Fit Bags | Tailored for specific Harley models, high-quality materials | Custom motorcycle builds, aftermarket sales | Vorteile: Perfect fit, enhanced aesthetics; Nachteile: Höherer Preispunkt. |

Expedition series bags are designed for rugged use, often crafted from durable Cordura fabric that is both mud-resistant and lightweight. With a capacity of around 5 liters, these bags allow riders to carry essential gear like gloves and raincoats while maintaining easy access during off-road adventures. B2B buyers focused on adventure tourism or motorcycle rentals will find these bags particularly beneficial due to their durability and quick-access features.

Engine protection bar bags are tailored to fit snugly on the motorcycle’s protective bars, providing an optimal center of gravity for balanced weight distribution. Made from water-repellent, Teflon-coated Cordura, these bags are ideal for urban commuting, allowing riders to store items like smartphones, tools, and documents within easy reach. B2B buyers in urban markets will appreciate their sleek design and functionality, which caters to everyday riders seeking convenience and style.

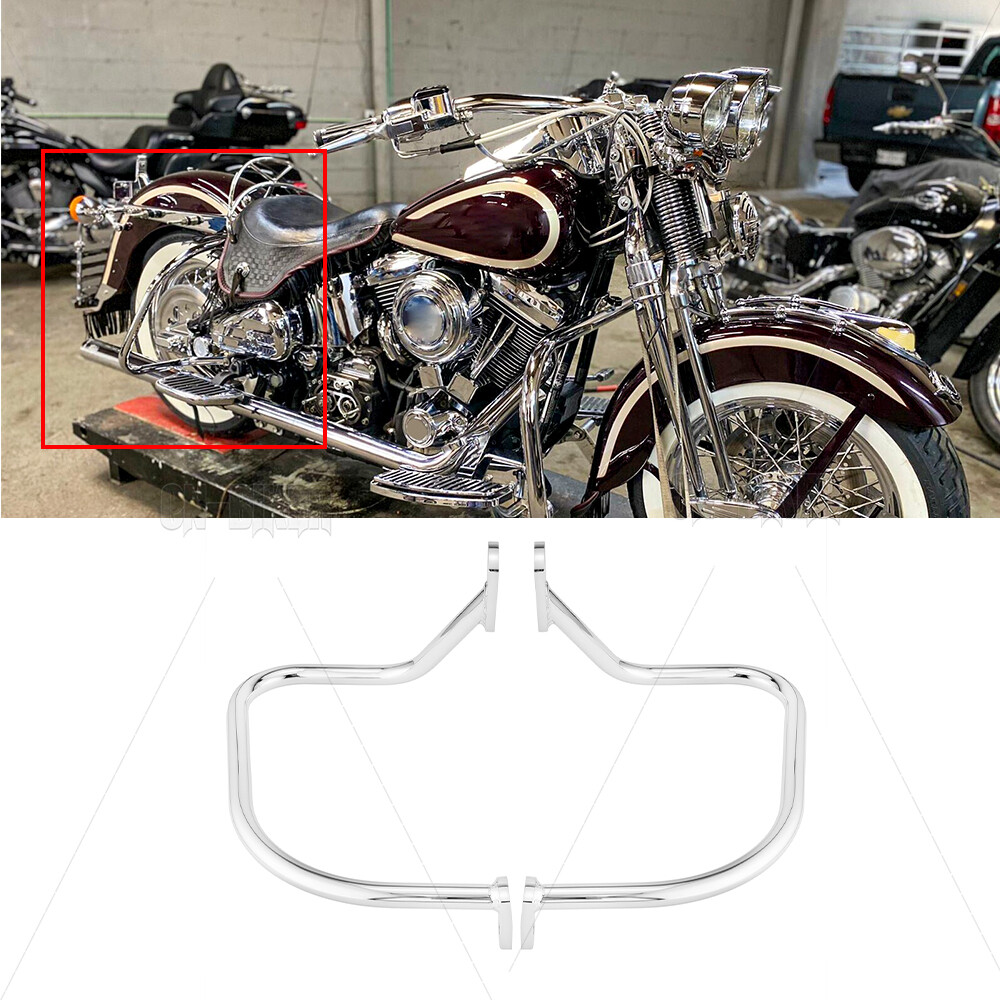

Illustrative image related to crash bar bags for harley davidson

Saddlebag guard bags are constructed from synthetic leather and feature dual zippered openings, making them perfect for long-distance touring. They provide organized storage for essentials while complementing the bike’s aesthetics with an embossed logo. B2B buyers targeting touring motorcycle enthusiasts can leverage these bags to offer stylish and functional accessories that enhance the riding experience, although they may not be as weatherproof as other options.

Crash bar storage bags are designed for versatility and ease of access, made from rugged ballistic nylon that is both abrasion and weather-resistant. They feature storm-flapped zippers and reflective webbing, making them suitable for trail riding and adventure touring. B2B buyers in the adventure motorcycle sector will find these bags appealing for their practical design and secure mounting system, although installation may require some adjustment.

Custom fit bags are designed specifically for certain Harley models, ensuring a perfect fit and seamless integration with the bike’s design. These bags are often made from high-quality materials, enhancing both functionality and aesthetics. B2B buyers in the custom motorcycle market can capitalize on the demand for personalized accessories that not only improve storage but also elevate the overall look of the motorcycle, although they may come with a higher price tag.

| Industrie/Sektor | Specific Application of crash bar bags for harley davidson | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Motorradtourismus | Storage for essentials during long-distance rides | Enhances rider convenience and safety by providing easy access to necessary items while riding. | Durability, weather resistance, and compatibility with various models. |

| Off-Road-Abenteuer | Carrying tools and emergency supplies | Facilitates quick access to tools and gear, improving safety and readiness during off-road excursions. | Rugged construction, secure mounting systems, and size specifications. |

| Motorradvermietung | Additional storage for rental bikes | Increases rental value by offering enhanced storage solutions, appealing to touring customers. | Cost-effectiveness, ease of installation, and aesthetic compatibility with different bike models. |

| Custom Motorcycle Shops | Customization options for client bikes | Offers clients personalized features that enhance functionality and aesthetics, driving sales and customer satisfaction. | Material quality, design options, and potential for branding. |

| Motorcycle Accessories Retail | Retailing as complementary products | Increases overall sales by bundling crash bar bags with other motorcycle accessories, creating a one-stop shop experience. | Supplier reliability, shipping logistics, and market demand analysis. |

In the motorcycle tourism sector, crash bar bags serve as essential storage solutions for riders embarking on long-distance journeys. These bags allow easy access to necessities such as maps, snacks, and personal items while keeping them secure and out of the way. For international buyers, especially from regions like Europe and South America, the focus should be on the durability of materials and weather resistance to ensure reliability in various climates and terrains.

For off-road enthusiasts, crash bar bags are invaluable for stashing tools, tire repair kits, and emergency supplies. Their strategic placement on the bike ensures that these items are easily accessible without compromising the rider’s balance or maneuverability. Buyers in Africa or the Middle East should prioritize rugged, weather-resistant options that can withstand rough terrains and varying weather conditions.

In the motorcycle rental industry, providing crash bar bags can significantly enhance the customer experience. These bags offer additional storage for renters who may be traveling with gear, thus increasing the appeal of rental services. B2B buyers in this sector should consider the cost-effectiveness and ease of installation of these bags to maximize profitability and customer satisfaction.

Custom motorcycle shops can leverage crash bar bags as a way to enhance their offerings. By providing customization options for these bags, shops can cater to client preferences, thus driving sales and improving customer satisfaction. Buyers should look for high-quality materials and design flexibility to meet diverse customer needs while maintaining the shop’s brand identity.

For motorcycle accessory retailers, crash bar bags represent a complementary product that can boost overall sales. By bundling these bags with other motorcycle accessories, retailers create a more appealing shopping experience for customers. When sourcing these products, considerations such as supplier reliability and market demand are crucial to ensure a steady inventory and maximize sales potential.

Das Problem: B2B buyers often encounter the challenge of balancing additional storage without compromising motorcycle performance. Crash bar bags, while providing extra space for essentials, can add weight and impact the center of gravity. This can affect the handling of heavier bikes, especially for long-distance or off-road rides. Retailers and distributors may struggle to find products that offer adequate storage while ensuring optimal bike performance, which is crucial for both rider safety and satisfaction.

Die Lösung: To address this issue, B2B buyers should focus on sourcing crash bar bags designed with lightweight materials and an optimized design that maintains the bike’s balance. Look for bags constructed from durable yet lightweight fabrics like Cordura 1000, which provide strength without unnecessary bulk. Ensure the bags have a compact design that fits snugly against the crash bars, minimizing wind resistance and weight distribution issues. Additionally, consider products that offer adjustable mounting systems to allow for customization according to the bike’s configuration and the rider’s needs. This approach not only enhances storage capacity but also preserves the motorcycle’s performance characteristics.

Das Problem: B2B buyers frequently report concerns about the accessibility of items stored in crash bar bags. Riders need to access tools, documents, or personal items quickly, especially during long trips or when navigating urban environments. However, poor bag design can lead to items falling out or being difficult to reach while on the move, creating safety hazards. Retailers must provide solutions that combine easy access with secure storage to meet customer expectations.

Die Lösung: To overcome this challenge, B2B buyers should prioritize crash bar bags that feature user-friendly designs, such as dual-zippered openings and secure Velcro fasteners. These features facilitate quick access while ensuring that the contents remain secure during rides. Additionally, consider bags with internal organization, such as separate compartments or pockets for small items, which can help riders keep essentials in place and easily retrievable. Providing detailed installation instructions and promoting bags with weather-resistant properties can further enhance the product’s appeal, ensuring that items are protected from the elements while remaining accessible.

Das Problem: Many B2B buyers struggle with the challenge of ensuring compatibility with various motorcycle models, particularly for brands like Harley-Davidson. The wide range of designs, from touring to off-road bikes, means that a one-size-fits-all solution is rarely effective. Retailers need to provide crash bar bags that are versatile enough to fit different models while also catering to the specific needs of various riding styles.

Die Lösung: To effectively address this compatibility issue, B2B buyers should seek out suppliers who offer crash bar bags specifically designed for a range of Harley-Davidson models, taking into account the unique dimensions and mounting points of each bike. It’s beneficial to source from manufacturers that provide clear fitment information and installation guides tailored to each motorcycle model. Additionally, consider products that feature adjustable mounting systems, allowing for modifications to accommodate different bike configurations. By offering a selection of crash bar bags with varied sizes and mounting options, retailers can cater to a broader audience, enhancing customer satisfaction and driving sales.

When selecting materials for crash bar bags designed for Harley Davidson motorcycles, it is crucial to consider various factors such as durability, weather resistance, and overall performance. Below, we analyze four common materials used in the manufacturing of these bags, providing insights tailored to international B2B buyers.

Cordura is a high-performance nylon fabric known for its durability and resistance to abrasion, tears, and scuffs. It typically has a temperature rating that can withstand a range of environmental conditions, making it suitable for outdoor applications.

Vorteile:

– Excellent durability and abrasion resistance.

– Water-repellent and UV-stable, preventing fading over time.

– Lightweight, which helps in maintaining the motorcycle’s balance.

Nachteile:

– Higher manufacturing costs compared to standard nylon.

– May require specialized sewing techniques, increasing production complexity.

Auswirkungen auf die Anwendung: Cordura is ideal for environments where exposure to moisture and dirt is common, ensuring that the contents of the bags remain protected.

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM for textile performance is essential. Buyers from regions like Europe may prefer Cordura due to its reputation for quality and durability.

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a stylish and functional option for crash bar bags.

Vorteile:

– Aesthetically pleasing with a premium look.

– Generally lower cost than high-end fabrics like Cordura.

– Easy to clean and maintain.

Nachteile:

– Less durable than Cordura, particularly in extreme weather conditions.

– Can be prone to cracking or peeling over time, especially in high-temperature environments.

Auswirkungen auf die Anwendung: Synthetic leather may not perform well in wet or humid conditions, making it less suitable for long-distance rides in unpredictable weather.

Überlegungen für internationale Käufer: Buyers in regions with high humidity, such as parts of South America and Africa, should consider the limitations of synthetic leather in terms of longevity and performance.

Ballistic nylon is a heavy-duty fabric originally developed for military applications, offering superior strength and resistance to wear and tear.

Vorteile:

– Exceptional durability and resistance to abrasions and punctures.

– Water-resistant properties make it suitable for various weather conditions.

– Retains shape well, even when empty.

Illustrative image related to crash bar bags for harley davidson

Nachteile:

– Heavier than other materials, which may affect motorcycle handling.

– Higher manufacturing costs due to the complexity of fabric production.

Auswirkungen auf die Anwendung: Ballistic nylon is particularly effective for off-road conditions, where durability is paramount.

Überlegungen für internationale Käufer: Buyers from the Middle East and Africa may find ballistic nylon appealing due to its ruggedness, which is ideal for varied terrains.

Teflon-coated fabrics offer a unique advantage by providing an additional layer of water and dirt resistance.

Illustrative image related to crash bar bags for harley davidson

Vorteile:

– Enhanced water-repellency and dirt resistance.

– Maintains a clean appearance over time.

– Durable and abrasion-resistant.

Nachteile:

– Can be more expensive due to the coating process.

– Limited breathability, which may lead to moisture retention inside the bag.

Auswirkungen auf die Anwendung: Teflon-coated fabrics are excellent for riders who frequently encounter wet conditions, ensuring that contents remain dry.

Illustrative image related to crash bar bags for harley davidson

Überlegungen für internationale Käufer: Compliance with environmental regulations regarding chemical coatings is essential, particularly in Europe, where sustainability is a priority.

| Material | Typical Use Case for crash bar bags for harley davidson | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Cordura | Off-road and long-distance touring | Excellent durability and weather resistance | Higher manufacturing costs | Hoch |

| Synthetisches Leder | Urban riding and aesthetic-focused applications | Aesthetic appeal and easy maintenance | Weniger haltbar unter extremen Bedingungen | Mittel |

| Ballistisches Nylon | Rugged off-road conditions | Superior strength and puncture resistance | Heavier, which may affect handling | Hoch |

| Teflon-Coated Fabric | Wet and dirty environments | Enhanced water and dirt resistance | Limited breathability | Mittel bis Hoch |

This strategic material selection guide provides essential insights for B2B buyers looking to source crash bar bags for Harley Davidson motorcycles, ensuring informed decisions that align with regional preferences and performance needs.

The manufacturing process of crash bar bags involves several critical stages, each contributing to the final product’s durability and functionality.

Illustrative image related to crash bar bags for harley davidson

The first stage in manufacturing crash bar bags is material selection and preparation. High-quality materials like Cordura nylon, ballistic nylon, and synthetic leather are commonly used due to their abrasion resistance, water repellency, and UV stability. Manufacturers typically source these materials from reputable suppliers who provide certifications to confirm the materials’ durability and performance characteristics.

Once materials are sourced, they undergo a quality check to ensure they meet specific criteria. This may include testing for tear strength, colorfastness, and water resistance. The preparation phase also involves cutting the materials into specific patterns and sizes tailored to fit various motorcycle models, such as the Harley Davidson Pan America.

The forming and assembly stage is where the actual construction of the bags takes place. Manufacturers utilize techniques like die-cutting for precise shapes and laser cutting for intricate designs. These processes ensure that every bag is consistent in size and shape, which is crucial for maintaining a proper fit on the motorcycle’s crash bars.

After cutting, the components are sewn together using heavy-duty stitching techniques to enhance durability. Some manufacturers employ reinforced stitching at stress points to prevent wear and tear, especially in high-use areas like zippers and seams.

Finishing processes for crash bar bags can include adding features such as waterproof coatings, Teflon treatments, or additional lining to improve durability and functionality. Zippers are often tested for smooth operation and water resistance. Aesthetic elements, such as brand logos and decorative stitching, may also be added at this stage.

Illustrative image related to crash bar bags for harley davidson

Before final packaging, bags undergo a visual inspection to check for defects, ensuring that only products meeting quality standards proceed to the next stage.

Quality assurance (QA) is vital in the manufacturing of crash bar bags, particularly for B2B buyers who demand high standards. Manufacturers generally adhere to international quality standards such as ISO 9001, which outlines a framework for quality management systems, ensuring consistent product quality.

In addition to ISO 9001, manufacturers may comply with industry-specific standards such as CE marking for products sold in Europe, ensuring they meet health, safety, and environmental protection requirements. For regions like Africa and South America, compliance with local regulations and standards is crucial, as these can vary significantly.

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process to ensure quality at every stage. Typical checkpoints include:

Manufacturers employ various testing methods to validate the quality of crash bar bags. Common tests include:

For B2B buyers, especially those operating internationally, verifying the quality control processes of suppliers is essential. Here are some actionable steps:

Durchführung von Lieferantenaudits: Regular audits allow buyers to assess the manufacturing processes and quality assurance protocols firsthand. This can be done by sending representatives or hiring third-party auditors.

Qualitätsberichte anfordern: Suppliers should provide documentation of quality checks, including results from IQC, IPQC, and FQC stages. This transparency builds trust and ensures accountability.

Inspektionen durch Dritte: Engaging third-party inspectors to conduct random checks can provide an unbiased assessment of product quality before shipment.

Certifications and Compliance Documents: Buyers should request copies of relevant certifications (ISO, CE, etc.) and compliance documents to ensure that the supplier meets both international and local standards.

International buyers must navigate various nuances when it comes to quality control. For instance, different regions may have distinct regulations regarding material safety and environmental impact.

In Europe, compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is mandatory for chemical substances used in manufacturing. In contrast, buyers from Africa may need to consider local standards that vary by country.

Illustrative image related to crash bar bags for harley davidson

Understanding these regional differences is crucial for B2B buyers to avoid potential legal issues and ensure that the products they import meet their market’s expectations.

In summary, the manufacturing and quality assurance processes for crash bar bags involve meticulous attention to detail at every stage. By understanding these processes and implementing robust verification methods, B2B buyers can confidently source high-quality products that meet international standards and specific market requirements.

In the competitive landscape of motorcycle accessories, particularly for Harley Davidson crash bar bags, sourcing the right products requires diligence and strategic planning. This guide provides a step-by-step checklist to assist B2B buyers in procuring high-quality crash bar bags that meet both functional and aesthetic needs.

Before beginning the sourcing process, clearly outline the technical specifications of the crash bar bags you require. Consider factors such as size, material (e.g., Cordura or ballistic nylon), weight capacity, and compatibility with specific Harley Davidson models. This step ensures that you have a concrete understanding of your product requirements, which is crucial for effective supplier communication.

Conduct thorough research to identify potential suppliers who specialize in motorcycle accessories. Look for companies with a strong reputation in the industry, proven experience, and positive customer reviews. Use online platforms, trade shows, and industry publications to compile a list of candidates that align with your quality expectations.

Once you have a shortlist of suppliers, evaluate the quality of their crash bar bags. Request samples to assess materials, stitching, and overall craftsmanship. Pay attention to features such as water-resistance, durability, and ease of installation. High-quality products not only enhance customer satisfaction but also reduce returns and complaints.

Before proceeding with any order, ensure that your chosen suppliers hold relevant certifications that demonstrate their adherence to industry standards. Look for certifications related to product safety, environmental impact, and quality management systems, such as ISO certifications. This verification process mitigates risks associated with non-compliance and enhances trust in your supply chain.

Engage with suppliers to understand their pricing structures and payment terms. Compare quotes from multiple suppliers to ensure competitive pricing without compromising on quality. Also, inquire about bulk order discounts and payment flexibility, which can significantly impact your overall procurement costs.

Investigate the shipping methods and delivery timelines offered by your suppliers. For international transactions, ensure that they are experienced in handling customs and can provide timely delivery to your region. Understanding logistics is critical, as delays can affect your inventory and sales.

Finally, set up a clear communication plan with your selected supplier. Ensure that you have direct contacts for inquiries, updates, and problem resolution. Regular communication helps build a strong relationship and facilitates smoother transactions throughout the procurement process.

By following this checklist, B2B buyers can confidently source high-quality crash bar bags for Harley Davidson motorcycles, ensuring both functionality and customer satisfaction in a competitive marketplace.

When analyzing the cost structure for crash bar bags designed for Harley Davidson motorcycles, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to crash bar bags for harley davidson

Materialien: The choice of materials significantly impacts the overall cost. High-quality fabrics like Cordura or ballistic nylon are preferred for their durability and weather resistance. Depending on the specification, the material cost can vary widely, typically ranging from €20 to €50 per unit.

Arbeit: Labor costs can fluctuate based on the manufacturing location. For example, production in regions with lower wage rates, such as certain countries in South America or Africa, may reduce costs. Labor costs are often estimated at 15-25% of the total production cost.

Fertigungsgemeinkosten: This includes utilities, rent, and administrative expenses associated with production facilities. Overhead can account for an additional 10-20% of total costs.

Werkzeugbau: Initial tooling costs for molds and dies can be significant, especially for custom designs. These costs are amortized over the production volume, impacting the pricing structure for smaller orders.

Qualitätskontrolle: Ensuring product quality through rigorous testing and inspections adds to the cost. Budgeting around 5-10% of the total production cost for QC can help maintain standards.

Logistik: Shipping and handling costs are particularly relevant for international buyers. Factors such as shipping methods, distances, and import duties will affect logistics costs, which can constitute 10-15% of the total price.

Marge: Manufacturers typically apply a profit margin of 20-40% on top of the total costs, influenced by market demand and competition.

Several factors can influence pricing for B2B buyers sourcing crash bar bags:

Volumen/MOQ: Purchasing in larger quantities often leads to better pricing. Minimum order quantities (MOQs) can vary, and negotiating these terms can yield significant savings.

Spezifikationen und Anpassungen: Custom designs or specific branding requirements will typically increase costs. However, they may also enhance perceived value, justifying a higher selling price.

Materialien und Qualitätszertifikate: Premium materials and certifications (like ISO standards) can elevate costs but may also enhance the product’s marketability and durability.

Lieferanten-Faktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their brand equity and assurance of quality.

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities for shipping and delivery costs, which can significantly affect the total landed cost.

When sourcing crash bar bags, international buyers should consider the following negotiation strategies:

Leverage Volume Discounts: Always inquire about discounts for bulk purchases. Suppliers may offer lower per-unit prices for larger orders.

Bewertung der Gesamtbetriebskosten (TCO): Beyond initial costs, consider the long-term value, including durability, warranty, and potential resale value, which can justify a higher upfront investment.

Understand Local Market Dynamics: Different regions may have varying pricing structures due to local demand and supply. Researching local competitors can provide leverage during negotiations.

Achten Sie auf preisliche Nuancen: Currency fluctuations, tariffs, and import duties can affect final costs. Buyers should account for these factors when comparing prices from different suppliers.

Beziehungen aufbauen: Establishing a good rapport with suppliers can lead to better terms, including favorable payment plans or exclusive deals.

Understanding the comprehensive cost structure and pricing dynamics for crash bar bags for Harley Davidson motorcycles can empower B2B buyers to make informed purchasing decisions. By considering cost components, price influencers, and effective negotiation strategies, buyers can optimize their sourcing processes and enhance their business outcomes. Always remember that indicative pricing may vary based on numerous factors, so thorough market research and supplier assessment are essential.

In the motorcycle accessories market, crash bar bags for Harley Davidson motorcycles offer a unique solution for additional storage while enhancing the safety and functionality of the bike. However, there are alternative solutions available that can also serve similar purposes. This section explores these alternatives in detail, providing a comprehensive comparison to assist B2B buyers in making informed decisions.

| Vergleich Aspekt | Crash Bar Bags For Harley Davidson | Satteltaschenschutztaschen | Rucksäcke |

|---|---|---|---|

| Leistung | Provides quick access and weight distribution; acts as a cushion in case of a tip-over. | Offers secure storage for essential items but less accessible while riding. | Excellent for long trips, but less accessible and can be cumbersome. |

| Kosten | Moderate, typically around €129-€150 for a set. | Generally lower, around $89.95 each. | Higher investment, ranging from $200 to $800 depending on brand and size. |

| Leichte Implementierung | Easy to install with Velcro or straps; requires minimal tools. | Simple installation on existing saddlebag guards; minimal effort required. | Installation can be more complex, often requiring additional brackets or modifications. |

| Wartung | Low maintenance; periodic cleaning recommended. | Low maintenance; may require occasional checks for attachment security. | Moderate maintenance; regular checks needed for wear and tear, especially on zippers. |

| Bester Anwendungsfall | Ideal for short trips and daily commutes where quick access is needed. | Best for organized storage of items that aren’t needed frequently. | Suitable for long-distance touring where significant storage is necessary. |

Saddlebag guard bags, such as those offered by Harley-Davidson, provide a practical alternative for riders looking for additional storage. These bags attach securely to the saddlebag guards, offering a compact storage solution. The primary advantage is their lower cost and ease of installation. However, they may lack the quick access feature that crash bar bags provide, which can be a drawback during rides when immediate access to items is needed.

Illustrative image related to crash bar bags for harley davidson

Panniers represent a more traditional and larger storage solution for motorcyclists. They are designed for longer trips, allowing riders to carry significant amounts of gear securely. While they offer ample storage space, the installation process can be more complicated and may require additional modifications to the bike. Additionally, accessing items within panniers can be less convenient during a ride, making them less suitable for quick stops.

When selecting the right storage solution for Harley Davidson motorcycles, B2B buyers should consider their specific use case and riding style. Crash bar bags excel in providing easy access and added safety, making them suitable for urban commuting and short trips. In contrast, saddlebag guard bags offer a more budget-friendly option with secure storage but less accessibility. Panniers are ideal for long-distance touring, providing ample storage but at a higher cost and complexity. By weighing these factors, buyers can make informed decisions that best align with their needs and those of their customers.

Crash bar bags designed for Harley Davidson motorcycles come with specific technical properties that ensure durability, functionality, and ease of use. Here are some critical specifications to consider:

Material Klasse: Most crash bar bags utilize high-grade materials like Cordura 1000 or ballistic nylon. These fabrics are known for their abrasion resistance, water repellency, and UV stability. In a B2B context, selecting bags made from superior materials can lead to reduced returns and increased customer satisfaction due to their longevity and reliability.

Volume Capacity: Crash bar bags typically range from 2 to 5 liters in capacity. This specification is crucial for B2B buyers as it determines how much gear can be stored, which directly impacts customer usability. Understanding the volume helps businesses cater to specific customer needs, whether for short trips or extended journeys.

Gewicht: The weight of the bags, often around 0.7 kg to 1 kg per pair, is essential for performance. Lighter bags contribute to better handling and maneuverability of the motorcycle. B2B buyers must consider weight specifications to ensure they are providing products that do not compromise the performance of the bikes.

Attachment Mechanism: The method of securing the bags to the crash bars is vital for ease of use and safety. Common systems include Velcro straps or quick-release buckles, which facilitate easy installation and removal. B2B purchasers should evaluate the attachment systems for ease of use, as complicated mechanisms can deter end-users.

Witterungsbeständigkeit: Many bags feature storm-flapped zippers and water-resistant materials, crucial for maintaining the integrity of stored items in various weather conditions. For B2B buyers, this property is a selling point, particularly in regions prone to rain or harsh weather.

Design Features: Additional features such as reflective strips for visibility, non-slip zippers, and padded interiors enhance the functionality of the bags. Including such features can differentiate products in a competitive market, appealing to buyers looking for added value.

Understanding industry-specific terminology is essential for navigating B2B transactions effectively. Here are some common trade terms relevant to crash bar bags:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that can be marketed under another brand name. For crash bar bags, OEM products are often preferred by buyers looking for compatibility and quality assurance.

MOQ (Mindestbestellmenge): This term defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and ensure that they are not overcommitting to stock that may not sell.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. For B2B buyers, issuing an RFQ allows for better comparison of prices and terms across different suppliers, facilitating informed purchasing decisions.

Incoterms (Internationale Handelsklauseln): These are international rules that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms is essential for international transactions, helping buyers understand shipping costs, risks, and delivery obligations.

SKU (Lagerhaltende Einheit): A unique identifier for each distinct product and service that can be purchased. Understanding SKU numbers is important for inventory management, as they streamline the tracking and ordering processes for B2B suppliers.

Vorlaufzeit: This refers to the amount of time between placing an order and receiving the goods. For B2B buyers, knowing the lead time helps in planning inventory and managing customer expectations effectively.

By grasping these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that align with their business needs and enhance customer satisfaction.

Illustrative image related to crash bar bags for harley davidson

The crash bar bags market for Harley Davidson is experiencing notable growth, driven by several global factors. Increased motorcycle tourism, particularly in regions such as Africa, South America, and Europe, is prompting riders to seek additional storage solutions that enhance their travel experience. International B2B buyers are particularly interested in products that offer convenience, durability, and protection, as riders often face varied terrains and weather conditions.

Emerging technologies and sourcing trends are also shaping the market. The rise of e-commerce platforms facilitates easier access to suppliers and manufacturers, allowing B2B buyers to source crash bar bags from global markets efficiently. Additionally, the use of advanced materials such as water-repellent Cordura and ballistic nylon enhances product durability and functionality, appealing to buyers focused on quality and performance. Moreover, manufacturers are adopting innovative designs that prioritize weight distribution and ease of access, catering to the practical needs of motorcyclists.

Market dynamics indicate a shift towards customization and personalization, with buyers increasingly looking for products that fit specific motorcycle models. This trend not only provides a competitive edge for manufacturers but also enhances customer satisfaction by ensuring optimal fit and performance. Overall, B2B buyers must stay attuned to these market shifts to capitalize on emerging opportunities in the crash bar bags segment.

Sustainability and ethical sourcing are becoming crucial considerations for B2B buyers in the crash bar bags market. As environmental awareness grows, manufacturers are increasingly pressured to adopt eco-friendly practices. This includes using materials that are not only durable but also have a lower environmental impact. For instance, sourcing recycled or sustainably produced fabrics can significantly enhance a product’s appeal to environmentally conscious buyers.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more inclined to partner with manufacturers who demonstrate a commitment to fair labor practices and transparency. This trend is particularly relevant in regions like Europe, where consumers are increasingly scrutinizing the origins of the products they purchase. Certifications such as ISO 14001 (environmental management) and Fair Trade can serve as valuable indicators of a company’s commitment to sustainability and ethical practices, making them attractive to B2B buyers.

Illustrative image related to crash bar bags for harley davidson

Furthermore, the demand for ‘green’ certifications is on the rise. Buyers are looking for suppliers that can provide proof of sustainable practices, which not only helps in marketing but also enhances brand loyalty. As the market evolves, integrating sustainability into product development and supply chain management will be vital for manufacturers aiming to compete effectively in the global marketplace.

The evolution of crash bar bags for Harley Davidson motorcycles reflects the broader trends in the motorcycle accessories market. Initially designed primarily for safety and protection, these bags have transformed into multifunctional storage solutions that cater to the needs of modern riders. Early iterations were often simple pouches, lacking in durability and design features. However, advancements in materials technology and consumer preferences have driven manufacturers to innovate.

Today, crash bar bags are crafted from high-performance materials such as Cordura and ballistic nylon, enhancing their resistance to wear and weather conditions. The focus has shifted towards not only providing additional storage but also improving the overall riding experience. Features such as ergonomic design, ease of access, and secure attachment systems are now standard, reflecting the evolving demands of the market. This evolution highlights the importance of understanding consumer needs and adapting products accordingly, a key consideration for B2B buyers in this sector.

How do I ensure the crash bar bags I source are compatible with different Harley-Davidson models?

To ensure compatibility with various Harley-Davidson models, request detailed specifications from suppliers, including dimensions and mounting mechanisms. It’s advisable to provide your suppliers with a list of the specific models you intend to cater to, such as the Pan America series. Additionally, consider samples or prototypes for testing fit and functionality before placing bulk orders. Suppliers with experience in motorcycle accessories often have comprehensive fitment guides that can help streamline this process.

What materials should I look for in crash bar bags to ensure durability?

For durability, prioritize crash bar bags made from high-quality materials such as Cordura or ballistic nylon, which are known for their abrasion and weather resistance. Check if the bags feature waterproof zippers and reinforced stitching, as these elements contribute to longevity. Request samples to assess material quality and performance under various weather conditions. Understanding the material specifications will also help in marketing these products effectively to your customers.

What is the best way to vet suppliers for crash bar bags?

Vetting suppliers involves several steps: first, check their industry experience and reputation by reviewing customer testimonials and case studies. Request references from existing clients and verify their manufacturing capabilities through audits or factory visits if possible. Additionally, assess their compliance with international quality standards and certifications, such as ISO. Conducting a small initial order can also serve as a practical test of their reliability and product quality.

How can I customize crash bar bags to meet specific market needs?

Customization options can include altering the size, color, and material of the crash bar bags to fit regional preferences. Work closely with your suppliers to discuss the feasibility of these customizations, keeping in mind their production capabilities. Consider incorporating branding elements like logos or unique designs that resonate with your target market. It may also be beneficial to gather feedback from potential customers to guide your customization efforts effectively.

What is the typical minimum order quantity (MOQ) for crash bar bags?

The MOQ for crash bar bags can vary significantly between suppliers, typically ranging from 100 to 500 units. Factors influencing MOQ include manufacturing processes, material availability, and customization requirements. Discussing your needs with potential suppliers can lead to flexible arrangements, especially if you are willing to place larger orders or establish a long-term partnership. Always clarify MOQ during initial negotiations to avoid any misunderstandings later.

Mit welchen Zahlungsbedingungen muss ich rechnen, wenn ich Sturzbügeltaschen international beschaffe?

Payment terms can differ based on supplier policies and your negotiating power. Common terms include a 30% deposit upfront with the balance due upon shipment or delivery. For new relationships, suppliers may request more favorable terms for themselves, such as partial prepayment or letters of credit. Ensure to clarify all terms, including any potential discounts for bulk orders, before finalizing contracts to protect your financial interests.

How can I ensure quality assurance for crash bar bags sourced internationally?

Quality assurance can be established through a combination of pre-production samples, in-process inspections, and final product audits. Requesting quality certifications from suppliers and specifying your quality standards in the contract can also mitigate risks. Consider hiring third-party inspection services to verify compliance with your quality requirements before shipment. Establishing clear communication channels with suppliers for ongoing quality feedback is crucial for long-term success.

Welche logistischen Überlegungen sollte ich bei der Einfuhr von Sturzbügelsäcken anstellen?

When importing crash bar bags, consider shipping methods, tariffs, and customs regulations specific to your destination country. Evaluate the total landed cost, including shipping, duties, and taxes, to understand the financial implications of your order. Partnering with a reliable freight forwarder can streamline the logistics process. Additionally, plan for potential delays in customs clearance and ensure proper documentation is in place to facilitate smooth transport.

Bereich: deemeed.com

Registriert: 2003 (22 Jahre)

Einleitung: {“product_name”: “Crash Guard Bags Expedition to HD Pan America (Set of 2)”, “product_code”: “DBGPA_SET L/R_XPED”, “warranty”: “2 years”, “price”: “129,00 €”, “series”: “Expedition series”, “shipment_time”: “24h”, “capacity”: “5 liters”, “design_material”: “Cordura”, “dimensions”: {“height”: “30 cm / 11.8 inch”, “width”: “15 cm / 5.9 inch”, “depth”: “10 cm / 3.9 inch”}, “weight”: “0.7 kg”, “featur…

Bereich: wunderlichamerica.com

Registriert: 2008 (17 Jahre)

Einleitung: Wunderlich Engine Protection Bar Bags Set, Black

– Part #: 90470000

– Price: $225.95

– Install Time: 20 minutes*

– In Stock: Yes

– Material: Cordura 1000 fabric, high-strength, water-repellent, Teflon-coated, dirt-repellent, abrasion-resistant, UV-stable

– Dimensions: Width 180mm (7.08in), Height 330mm (12.99in), Depth 55mm (2.16in)

– Volume: Approximately 2 liters per side

– Color: Black

– Featur…

Bereich: harley-davidson.de

Registriert: 1994 (31 Jahre)

Einleitung: {"Name": "Right Saddlebag Guard Bag", "price": "$89.95", "part_number": "93300062", "description": "Halten Sie Ihre wichtigsten Utensilien immer griffbereit. Die Taschen sind aus robustem Kunstleder gefertigt, mit Klettverschlussabdeckungen und einer Öffnung mit zwei Reißverschlüssen, die einen einfachen Zugang zum Innenraum ermöglicht.", "fitment": "Passend für Touring-Modelle ab '93 (außer FLTRXRRSE ab '25), die mit Satteltaschenschutz ausgestattet sind.", "feat...

Bereich: originalgaragemoto.com

Registriert: 2017 (8 Jahre)

Einleitung: {“name”: “OG Rear Crash Bar for Harley-Davidson Bagger”, “SKU”: “C-CB-12-BK-BK”, “price”: {“base”: “$649.95”, “variants”: [{“color”: “Black / Black”, “price”: “$649.95”}, {“color”: “Black / Aluminium Finish”, “price”: “$649.95”}, {“color”: “Black / Chrome”, “price”: “$659.95”}, {“color”: “Black / Gold”, “price”: “$649.95”}, {“color”: “Black / Red”, “price”: “$649.95”}, {“color”: “Black / Blue”, “p…

Bereich: vikingbags.com

Registriert: 2006 (19 Jahre)

Einleitung: Motorcycle crash bars are designed to protect vital components of motorcycles while enhancing their aesthetic appeal. Key features include:

– Made from high-quality steel rods, forming a rigid perimeter around the engine, fuel tank, and radiator.

– Angular seven-sided open shape for added leg room and protection.

– Tube diameter of 1.25 inches with a glossy black stainless steel finish.

– Rust…

Bereich: obradvgear.com

Registriert: 2014 (11 Jahre)

Einleitung: Crash Bar Storage Bags – Low-Mounted Motorcycle Storage

SKU: OBR7010

Regular price: $89.99 USD

Sold as a pair

Rugged ballistic nylon construction: abrasion and water-resistant

Heavy-duty #10 coil zippers with storm flaps for added weather protection

Secure Velcro mounting system: wraps tight to your crash bars

Spacious compartments: 6″ x 10″ x 3″

Reflective webbing for increased visibility in low …

Bereich: foreverrad.com

Registriert: 2021 (4 Jahre)

Einleitung: Elevate your Harley Davidson Touring experience with the exclusive “Harley Davidson Touring Crash/Bag Guards” collection from Forever Rad. This selection is meticulously engineered for riders who prioritize both safety and style on their touring adventures. Key Features of the Collection: Designed for Touring Models: Each crash and bag guard in this collection is tailored to fit Harley Davidson To…

Bereich: leatherboundonline.com

Registriert: 2004 (21 Jahre)

Einleitung: Product: Motorcycle Crash Bar Bags

Features:

– Easy Access: Keep essentials within arm’s reach

– Versatile Mounting: Compatible with most crash bars for a universal fit

– Spacious Storage: Roomy compartments for tools, snacks, and more

– Weather-Resistant: Built to withstand the elements, keeping gear dry

– Quick Release: Easily detach when it’s time to fuel up or head inside

Price Range: $24.99 …

The strategic sourcing of crash bar bags for Harley-Davidson motorcycles presents a unique opportunity for international B2B buyers to enhance their product offerings. With the increasing popularity of adventure touring and off-road riding, these accessories serve a dual purpose: they not only provide essential storage solutions but also enhance rider safety by acting as protective gear during tip-overs. Buyers should prioritize sourcing products made from high-quality materials, such as Cordura and ballistic nylon, which offer durability and weather resistance.

Moreover, understanding regional market preferences is crucial. For instance, European buyers may favor products with superior craftsmanship and eco-friendly materials, while buyers in Africa and South America may seek cost-effective solutions that do not compromise on quality. By strategically selecting suppliers that align with these regional preferences, businesses can optimize their inventory and meet diverse customer needs.

Looking ahead, the demand for crash bar bags is set to grow as more riders seek versatility and convenience on their journeys. Now is the time for B2B buyers to engage with manufacturers who can provide innovative designs and reliable products. Establishing strong partnerships in this niche market will not only enhance your product portfolio but also position your business for sustained growth in the evolving motorcycle accessory landscape.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.