Navigating the global market for cycle air pumps can be a daunting task for B2B buyers, especially when sourcing reliable suppliers and ensuring product quality. Whether you are looking for high-performance pumps for commercial cycling operations or durable models for retail, the need to find the right “cycle air pump near me” is critical. This guide is designed to provide a comprehensive overview of the various types of cycle air pumps available, their applications across different markets, and essential criteria for vetting suppliers.

In this guide, we will delve into the specifications of different pump types, including floor pumps, hand pumps, and electric inflators, while also addressing their unique features and advantages. Understanding the cost implications associated with each type will empower you to make informed purchasing decisions that align with your budget and operational needs.

Moreover, we will explore supplier vetting processes, ensuring that you can confidently establish partnerships with manufacturers and distributors who meet your quality standards. This resource is particularly valuable for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Nigeria, who are looking to optimize their procurement strategies. By leveraging the insights provided in this guide, you will be well-equipped to navigate the complexities of the cycle air pump market and enhance your business operations.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Floor Pumps | High volume, foot-operated, often with pressure gauges | Bike shops, rental services | Vorteile: Fast inflation, stable; Nachteile: Bulky, requires floor space. |

| Handpumpen | Compact, portable, manually operated | Mobile bike repair, individual cyclists | Vorteile: Lightweight, easy to carry; Nachteile: Arbeitsintensiv, langsamere Inflation. |

| CO2 Inflators | Verwendet CO2-Patronen für schnelles Aufblasen | Emergency kits, racing teams | Vorteile: Quick and convenient; Nachteile: Ongoing cost for cartridges, limited usage. |

| Electric Pumps | Battery or plug-in powered, automatic inflation | Bike rental companies, workshops | Vorteile: Effortless operation, consistent pressure; Nachteile: Requires power source, heavier. |

| Mini Pumps | Small, lightweight, designed for portability | Individual cyclists, emergency kits | Vorteile: Extremely portable; Nachteile: Limited pressure capacity, slower inflation. |

Floor pumps are characterized by their high-volume output and foot-operated design, making them ideal for quick inflation of multiple tires. They often come equipped with built-in pressure gauges, allowing for precise inflation. For B2B buyers, such as bike shops or rental services, floor pumps are essential for efficiently servicing multiple bicycles. While they offer rapid inflation, their bulkiness requires designated space in retail or workshop environments.

Hand pumps are compact and manually operated, making them a staple for mobile bicycle repair services and individual cyclists. Their lightweight design allows for easy transport, which is crucial for on-the-go repairs. However, the manual operation can be labor-intensive and slower compared to other types. B2B buyers should consider their target market’s needs, as hand pumps are ideal for those who prioritize portability over speed.

CO2 inflators are favored for their speed and convenience, utilizing CO2 cartridges for quick tire inflation. This makes them particularly useful for racing teams and emergency repair kits, where time is of the essence. B2B buyers should be aware of the ongoing costs associated with CO2 cartridges, which can add up over time. While they provide a fast solution, their limited use capacity may not suit all cycling environments.

Electric pumps offer effortless operation and consistent tire pressure, making them suitable for bike rental companies and workshops. These pumps can quickly service multiple bicycles, enhancing customer satisfaction. However, they require a power source and are typically heavier than manual options. B2B buyers should evaluate the trade-off between convenience and the need for electrical infrastructure when considering electric pumps.

Mini pumps are designed for portability, making them an excellent choice for individual cyclists and emergency kits. Their small size allows them to be easily stored in a bike bag or pocket. However, they usually have limited pressure capacity and can be slower to inflate tires compared to larger pumps. B2B buyers should assess whether their customers value portability over speed and capacity when selecting mini pumps for retail.

| Industrie/Sektor | Specific Application of cycle air pump near me | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Bicycle Retailers | Providing accessible tire inflation stations | Attracts customers, enhances service | Proximity to cycling routes, pump durability, maintenance support |

| Urban Mobility Solutions | Integration into public bike-sharing programs | Promotes cycling, reduces congestion | Compatibility with existing infrastructure, ease of use |

| Erholung im Freien | Installation in parks and recreational areas | Encourages outdoor activities, increases foot traffic | Weather resistance, user-friendly design |

| Logistik und Lieferung | Use in delivery fleet maintenance | Ensures timely deliveries, reduces downtime | Portable options, pressure accuracy, service agreements |

| Event Management | Setup at cycling events and races | Enhances participant experience, boosts brand visibility | Quick setup, mobility, partnership with local suppliers |

Bicycle retailers leverage cycle air pumps to offer free tire inflation services, enhancing customer satisfaction and encouraging repeat visits. By providing accessible inflation stations, these businesses can attract cyclists who may need quick repairs or maintenance. Retailers should consider the pump’s durability and ease of maintenance, ensuring they can withstand high usage, especially in areas with heavy cycling traffic.

Cycle air pumps are integral to urban mobility initiatives, particularly in bike-sharing programs. By installing these pumps at docking stations, cities can promote cycling as a sustainable transport option, reducing urban congestion and pollution. For international buyers, especially in developing regions, sourcing pumps that are easy to operate and maintain is crucial to ensure they meet the needs of a diverse user base.

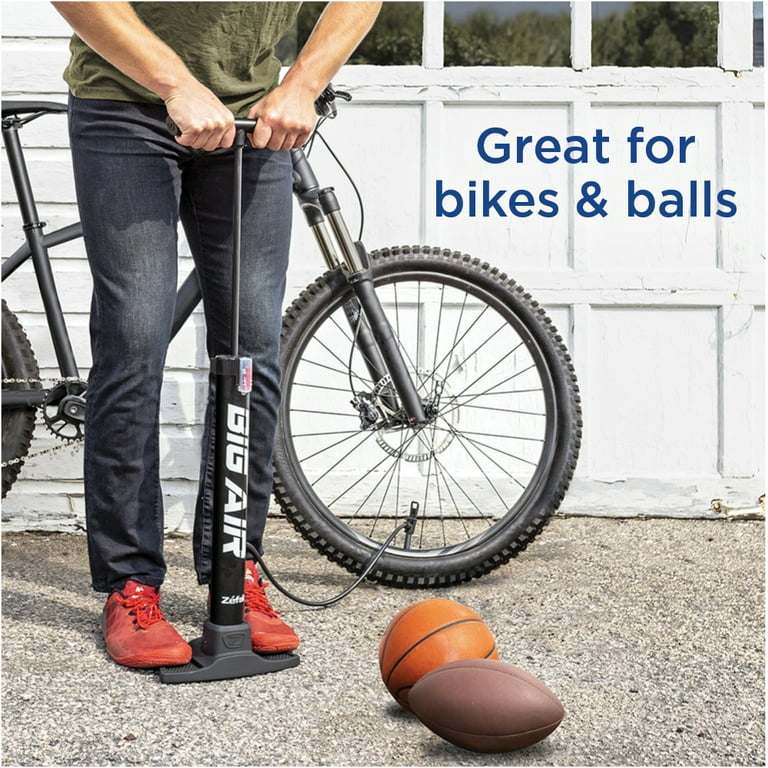

Illustrative image related to cycle air pump near me

In parks and recreational zones, cycle air pumps serve as essential amenities that encourage cycling and outdoor activities. By providing convenient access to tire inflation, these pumps can increase foot traffic and enhance the overall visitor experience. Buyers in this sector should focus on weather-resistant models that can endure outdoor conditions while remaining user-friendly for all cyclists.

Delivery services utilize cycle air pumps to maintain their fleet of bicycles, ensuring that they operate efficiently and reduce downtime caused by flat tires. This proactive maintenance approach is vital for timely deliveries. For B2B buyers, sourcing portable and accurate air pumps can significantly improve operational efficiency, making it essential to evaluate the reliability and service agreements with suppliers.

At cycling events and races, having cycle air pumps readily available can greatly enhance the participant experience by providing quick tire inflation solutions. This convenience not only supports cyclists but also increases brand visibility for sponsors and event organizers. Buyers should consider pumps that are easy to transport and set up, as well as potential partnerships with local suppliers to ensure a smooth operation during events.

Das Problem: B2B buyers, especially those operating bike rental services or delivery companies using bicycles, often face the challenge of finding accessible and reliable air pump stations. In many regions, particularly in developing markets across Africa and South America, public air pump stations may be scarce or poorly maintained. This not only leads to inconvenience for cyclists but can also hinder business operations, causing delays and increasing maintenance costs. When cyclists cannot find a reliable source to inflate tires, it can lead to downtime and dissatisfaction among customers.

Die Lösung: To overcome this challenge, B2B buyers should develop partnerships with local businesses such as gas stations, bike shops, and community centers that can provide or sponsor air pump stations. Establishing a network of reliable air pump locations will ensure that customers can easily access inflation services. Additionally, leveraging technology to map out these locations can provide cyclists with real-time updates on the nearest available stations. This can be achieved through a mobile app or website, where users can report the operational status of these pumps, thereby creating a community-driven resource that enhances accessibility and reliability.

Illustrative image related to cycle air pump near me

Das Problem: Many B2B buyers struggle to find high-quality cycle air pumps that meet the specific needs of their operations. Whether it’s for a bike-sharing service, a delivery fleet, or a retail shop, the lack of access to durable and efficient air pumps can lead to frequent breakdowns and increased operational costs. Buyers may encounter inferior products that fail to deliver the required performance, leading to dissatisfaction among users and potential damage to the business’s reputation.

Die Lösung: Buyers should prioritize sourcing air pumps from reputable manufacturers and suppliers who specialize in bicycle accessories. Conducting thorough research, including reading reviews and seeking recommendations from industry peers, can help identify trusted brands. Additionally, buyers should consider the specific needs of their target market, such as portability, pump type (e.g., floor pumps vs. hand pumps), and ease of use. Establishing relationships with suppliers who offer warranties and customer support can also provide peace of mind and ensure that any issues with the products can be resolved quickly.

Das Problem: Maintaining consistent tire pressure is crucial for the safety and performance of bicycles. However, B2B buyers often find that their users may not have the knowledge or tools to check and maintain proper tire pressure. This can lead to flat tires, accidents, and a negative cycling experience. In regions with varying climate conditions, tire pressure can fluctuate significantly, compounding the issue and posing safety risks.

Die Lösung: To address this pain point, B2B buyers can implement educational initiatives that inform users about the importance of maintaining proper tire pressure and how to do it effectively. This could include workshops, instructional videos, or informative brochures distributed alongside air pumps. Furthermore, integrating pressure gauges into the air pumps can provide users with instant feedback on their tire inflation status. Establishing a routine check system, possibly through partnerships with local bike shops, can also help ensure that bicycles remain safe and operational, ultimately enhancing user experience and trust in the brand.

When selecting materials for cycle air pumps, it’s crucial to consider the performance characteristics, durability, and cost-effectiveness of each option. The following analysis explores four common materials used in the construction of cycle air pumps, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum is widely used in cycle air pumps due to its excellent strength-to-weight ratio. It typically has a temperature rating of up to 150°C and can withstand pressures of around 200 psi, making it suitable for various pumping applications.

Vorteile: Aluminum is lightweight, which enhances portability and ease of use. Additionally, it offers good corrosion resistance, particularly when anodized, and is relatively easy to manufacture.

Nachteile: While durable, aluminum can be prone to dents and scratches, which may affect its aesthetic appeal. It is also more expensive than some alternatives, such as plastic.

Auswirkungen auf die Anwendung: Aluminum is compatible with a wide range of media, including air and various gases, making it a versatile choice for cycle air pumps.

Illustrative image related to cycle air pump near me

Überlegungen für internationale Käufer: Compliance with standards such as ASTM and DIN is essential, particularly in regions like Europe and the Middle East. Buyers should also consider the availability of aluminum in their local markets, as sourcing can vary.

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are commonly used in budget-friendly cycle air pumps. These plastics can handle moderate pressures, typically up to 100 psi, and are resistant to a range of chemicals.

Vorteile: The primary advantage of plastic is its low cost and lightweight nature, making it an attractive option for budget-conscious consumers. Additionally, plastics are resistant to corrosion and can be molded into complex shapes.

Nachteile: Plastic materials may not be as durable as metals, particularly under high-stress conditions. They can also become brittle over time, especially when exposed to UV light.

Auswirkungen auf die Anwendung: While suitable for air, some plastics may not be compatible with certain gases or chemicals, which could limit their use in specific applications.

Überlegungen für internationale Käufer: Buyers should ensure that the plastics used comply with local regulations regarding material safety and environmental impact, especially in regions like Africa and South America.

Steel, particularly stainless steel, is another common material used in cycle air pumps. It provides excellent strength and can withstand high pressures, often exceeding 300 psi, making it suitable for heavy-duty applications.

Vorteile: Steel is incredibly durable and resistant to wear and tear. Stainless steel offers additional corrosion resistance, making it suitable for various environments.

Nachteile: The main downside is the weight; steel pumps can be significantly heavier than their aluminum or plastic counterparts. Additionally, steel can be more expensive to manufacture and transport.

Illustrative image related to cycle air pump near me

Auswirkungen auf die Anwendung: Steel is compatible with air and gases, but its weight may be a disadvantage for portable applications.

Überlegungen für internationale Käufer: Compliance with international standards is crucial, especially in Europe and the Middle East, where regulations may be stricter. Buyers should also consider the logistics of transporting heavier products.

Rubber is primarily used in seals and hoses within cycle air pumps. It can withstand moderate pressures and offers excellent flexibility and resilience.

Vorteile: Rubber provides a good seal, preventing air leaks and enhancing pump efficiency. It is also highly flexible, allowing for easy manipulation during use.

Nachteile: Rubber can degrade over time due to exposure to UV light and ozone, which may lead to failure in sealing performance. It is also less effective at high temperatures.

Auswirkungen auf die Anwendung: Rubber is suitable for air applications but may not be ideal for high-pressure scenarios.

Überlegungen für internationale Käufer: Buyers should consider the quality of rubber used, as lower-grade materials may not meet performance expectations. Compliance with local standards is also important.

| Material | Typical Use Case for cycle air pump near me | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Portable cycle air pumps | Leicht und korrosionsbeständig | Anfällig für Dellen und Kratzer | Mittel |

| Kunststoff | Budget-friendly cycle air pumps | Low cost and lightweight | Less durable under stress | Niedrig |

| Stahl | Heavy-duty cycle air pumps | Extremely durable and high pressure | Schwerer und teurer | Hoch |

| Gummi | Seals and hoses in pumps | Excellent sealing and flexibility | Degrades over time and less effective at high temps | Mittel |

This material selection guide provides valuable insights for international B2B buyers in selecting the most appropriate materials for cycle air pumps, considering performance, cost, and compliance with regional standards.

Illustrative image related to cycle air pump near me

The manufacturing of cycle air pumps involves several critical stages, ensuring that the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Vorbereitung des Materials: This initial stage involves selecting the right materials, typically high-grade plastics, metals, and rubber. Suppliers must ensure that materials are sourced from reputable vendors who comply with international quality standards. This step may involve various processes such as cutting, molding, and surface treatment to prepare materials for further processing.

Bildung von: In this stage, the prepared materials are shaped into specific components of the air pump. Techniques such as injection molding for plastic parts and stamping for metal components are commonly employed. This is where precision is critical, as any deviation can affect the pump’s functionality and durability.

Montage: Once the components are formed, they are assembled into the final product. This may involve manual or automated processes, depending on the scale of production. Key considerations during assembly include ensuring proper alignment of parts and the application of seals to prevent air leakage.

Fertigstellung: The final stage involves applying protective coatings, branding, and packaging. This not only enhances the aesthetic appeal of the product but also provides corrosion resistance and durability. Quality checks are conducted during this stage to ensure that the pumps meet the specified standards before they are shipped out.

Quality assurance (QA) is crucial in the manufacturing of cycle air pumps to ensure that products are safe, reliable, and meet customer expectations. Various international and industry-specific standards guide these practices.

Internationale Normen: Compliance with ISO 9001 is fundamental for manufacturers aiming to establish a quality management system. This standard emphasizes a process-oriented approach and continual improvement, which is vital for maintaining product quality.

Industry-Specific Certifications: Depending on the market, additional certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be necessary. These certifications verify that products meet specific safety and performance criteria, which can significantly enhance a supplier’s credibility in the international market.

Qualitätskontrollpunkte: The manufacturing process typically includes several quality control (QC) checkpoints:

– Eingehende Qualitätskontrolle (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– Prozessbegleitende Qualitätskontrolle (IPQC): Throughout the manufacturing process, inspections are conducted to identify any deviations or defects early on.

– Endgültige Qualitätskontrolle (FQC): Before products are packaged and shipped, a thorough inspection is performed to ensure that they meet all quality specifications.

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are several strategies to ensure that suppliers adhere to rigorous QC standards.

Illustrative image related to cycle air pump near me

Lieferanten-Audits: Conducting regular audits of potential suppliers is an effective way to assess their manufacturing processes and quality assurance practices. These audits can help buyers evaluate the supplier’s compliance with international standards and their internal QC measures.

Qualitätsberichte: Requesting detailed quality reports from suppliers can provide insights into their QA processes. These reports should outline inspection results, defect rates, and corrective actions taken. Transparency in reporting is a good indicator of a supplier’s commitment to quality.

Inspektionen durch Dritte: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These inspections can be conducted at various stages of the manufacturing process, providing peace of mind to buyers.

Testing is a critical component of the quality assurance process for cycle air pumps. Various methods are employed to ensure that the pumps perform as expected under different conditions.

Pressure Testing: This involves subjecting the pump to high-pressure conditions to ensure it can withstand the pressure without leaking. It is essential for validating the integrity and safety of the pump.

Dauerhaftigkeitsprüfung: Cycle air pumps are often tested for durability by simulating long-term use. This may involve repeated inflation cycles to assess wear and tear on the components.

Performance Testing: This testing checks the pump’s efficiency in inflating a tire to the specified pressure within a certain timeframe. Performance metrics are crucial for buyers looking for reliable and efficient products.

International B2B buyers must navigate specific nuances in quality control that can vary by region and industry. Understanding these nuances is key to establishing successful supplier relationships.

Regionale Normen: Different regions may have distinct quality standards and regulations. For instance, CE marking is mandatory in Europe, while other regions may follow different guidelines. Buyers should familiarize themselves with the regulatory landscape in their target markets.

Kulturelle Erwägungen: When dealing with suppliers from different countries, cultural differences can impact communication and business practices. Understanding these nuances can help build stronger relationships and facilitate smoother transactions.

Risk Management: Buyers should develop a risk management strategy that accounts for potential supply chain disruptions, quality issues, and compliance challenges. This may involve diversifying suppliers or conducting more frequent audits to ensure consistent quality.

By understanding the manufacturing processes and quality assurance practices for cycle air pumps, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring they receive high-quality products that meet their needs.

This practical sourcing guide is designed to assist B2B buyers in procuring cycle air pumps efficiently. As demand for cycling products continues to grow globally, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the sourcing process for cycle air pumps is essential. This checklist will help you navigate the procurement journey, ensuring you make informed decisions while optimizing costs.

Understanding the exact type of cycle air pump required is the foundation of your sourcing journey. Determine whether you need portable hand pumps, floor pumps, or electric inflators based on your target market’s preferences. Consider factors such as pump size, inflation speed, and compatibility with various tire types.

Finding dependable suppliers is crucial for ensuring product quality and timely delivery. Utilize online platforms, industry trade shows, and local bicycle shops to gather a list of potential suppliers.

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region to verify their reliability.

Understanding pricing structures and payment terms is vital for budget management. Request detailed quotes from multiple suppliers to compare costs effectively.

Before placing a large order, request samples of the cycle air pumps. Testing the quality of the products firsthand allows you to assess durability and performance.

Once you’ve selected a supplier, negotiate contracts to secure favorable terms. This includes delivery schedules, warranty agreements, and after-sales support.

Finally, strategize your logistics and distribution plan. Consider how the cycle air pumps will be transported and stored after procurement.

By following this checklist, B2B buyers can streamline their sourcing process for cycle air pumps, ensuring a successful procurement experience that meets market needs.

When sourcing cycle air pumps, understanding the cost components is essential for effective budgeting and pricing strategies. The primary cost elements include:

Materialien: The choice of materials significantly impacts costs. Common materials include high-density plastic, aluminum, and rubber for hoses. Higher-quality materials may increase initial costs but can enhance durability and customer satisfaction.

Arbeit: Labor costs vary by region and can be influenced by local wage standards. In countries with lower labor costs, like Vietnam or Nigeria, manufacturing might be more cost-effective. However, labor skills and expertise also play a critical role in ensuring quality.

Fertigungsgemeinkosten: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient overhead management can lead to significant savings.

Werkzeugbau: Initial setup costs for molds and machinery can be substantial, especially for custom designs. Investing in high-quality tooling is crucial for maintaining consistency in production.

Qualitätskontrolle (QC): Implementing rigorous QC processes ensures that the products meet specified standards. While this adds to costs, it can prevent costly returns and enhance brand reputation.

Logistik: Transportation and warehousing costs can vary greatly depending on the supplier’s location and the buyer’s destination. International shipping may introduce tariffs and customs fees that need to be factored into the total cost.

Marge: Suppliers typically apply a markup to cover their costs and ensure profitability. Understanding industry standards for margins can aid in negotiating fair prices.

Several factors influence the pricing of cycle air pumps, especially for international B2B buyers:

Volumen/MOQ (Mindestbestellmenge): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate bulk pricing and reduce per-unit costs.

Spezifikationen und Anpassungen: Custom features, such as branding or unique designs, can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

Materialien und Qualitätszertifikate: Pumps made from premium materials or certified for specific quality standards (e.g., ISO) may command higher prices. Buyers should assess whether these certifications align with their market needs.

Lieferanten-Faktoren: Established suppliers with a track record of reliability may charge more due to perceived quality and service. Evaluating multiple suppliers can uncover competitive pricing.

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. For instance, Ex Works (EXW) places minimal responsibility on the seller, which could lower purchase prices but increase buyer logistics costs.

To optimize sourcing decisions, international B2B buyers should consider the following strategies:

Negotiation Tactics: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a good relationship may lead to discounts or favorable payment terms.

Gesamtbetriebskosten (TCO): Beyond initial purchase price, evaluate the TCO, which includes maintenance, durability, and logistics costs. A cheaper pump may incur higher costs over time due to repairs or replacements.

Nuancen in der Preisgestaltung für internationale Käufer: Currency fluctuations can impact pricing, so consider locking in exchange rates or negotiating prices in a stable currency. Additionally, be aware of local taxes and tariffs that may affect final costs.

Supplier Assessment: Conduct thorough research on potential suppliers, including their financial stability, production capacity, and past performance. This can mitigate risks associated with quality and delivery timelines.

Market Trends: Stay informed about industry trends and competitor pricing. This knowledge can provide leverage during negotiations and help buyers identify value-added opportunities.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers in cycle air pump sourcing can empower international B2B buyers to make informed decisions. By focusing on cost components, negotiating effectively, and considering the total cost of ownership, buyers can achieve a competitive edge in their markets. While indicative prices may vary, thorough research and strategic procurement practices will ensure that sourcing decisions yield optimal results.

In the realm of cycling, maintaining optimal tire pressure is crucial for performance and safety. While the option of using a “cycle air pump near me” is popular among cyclists, several alternative solutions exist that may better suit different needs. This section explores these alternatives, providing a comparative analysis to help B2B buyers make informed decisions.

| Vergleich Aspekt | Cycle Air Pump Near Me | Tragbarer Luftkompressor | Free Air Stations |

|---|---|---|---|

| Leistung | Efficient for quick inflation on-the-go | High pressure, suitable for various tire types | Limited to availability; may vary in performance |

| Kosten | Often free or low-cost | Medium to high initial investment | Free or minimal cost, dependent on location |

| Leichte Implementierung | Requires manual effort; accessible in public spaces | Easy to use; needs power source | No setup needed, but dependent on location |

| Wartung | Minimal; usually requires no upkeep | Requires regular checks and battery maintenance | No maintenance; reliant on community upkeep |

| Bester Anwendungsfall | Ideal for cyclists needing quick access | Best for those who require a reliable, high-capacity pump | Suitable for casual cyclists or those on a budget |

Tragbarer Luftkompressor

Portable air compressors are a robust alternative to traditional cycle air pumps. These devices offer high pressure and can inflate various types of tires, making them versatile. However, they typically require a power source, which can limit their use in remote areas. The initial cost can be higher than standard pumps, but they provide consistent performance and convenience, especially for businesses that manage a fleet of bicycles or offer cycling tours.

Free Air Stations

Free air stations are often found at gas stations or community bike repair hubs, offering no-cost inflation options. This makes them an attractive choice for budget-conscious cyclists. However, their availability can be inconsistent, and the quality of the pumps may vary. For businesses, relying solely on free air stations can pose a risk of downtime if a nearby station is out of service, which can affect customer satisfaction and operational efficiency.

Illustrative image related to cycle air pump near me

When choosing the right solution for tire inflation, B2B buyers should consider their specific needs, including the frequency of use, budget constraints, and the operational environment. For businesses managing cycling fleets, a portable air compressor may provide the reliability needed for consistent performance. Conversely, for casual cyclists or those operating in urban areas, utilizing cycle air pumps and free air stations could be cost-effective and convenient. Ultimately, the best solution will align with the organization’s operational goals and customer expectations, ensuring that cyclists can maintain optimal tire pressure efficiently.

When sourcing cycle air pumps, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

Material Klasse

The material used in the construction of a cycle air pump significantly affects its durability and performance. Common materials include aluminum, plastic, and rubber. Aluminum pumps are lightweight and sturdy, making them ideal for portability, while rubber components ensure a good seal and prevent air leaks. Selecting the right material can impact the pump’s lifespan, especially in varied climatic conditions.

Maximum Pressure Rating

This specification indicates the maximum air pressure the pump can generate, typically measured in PSI (pounds per square inch). For road bikes, a higher pressure rating (up to 130 PSI) is essential, while mountain bikes may require lower pressures (around 30-50 PSI). Understanding the pressure rating helps buyers match the pump to the specific needs of different bicycle types, ensuring optimal performance and safety.

Volume per Stroke

This refers to the amount of air the pump can deliver with each stroke. Measured in cubic centimeters (cc), a higher volume per stroke means quicker inflation times. For B2B buyers, this specification is vital for efficiency, especially in commercial settings where time is of the essence. Pumps with larger volumes are preferable for larger tire sizes, while smaller volumes may be sufficient for standard bikes.

Gewicht und Tragbarkeit

The weight of the pump affects its ease of transport. Lightweight models are preferable for cyclists who need to carry their pump on rides. B2B buyers should assess the balance between durability and weight, as overly heavy pumps may deter users from carrying them. Portable options that can easily fit in a backpack or attach to a bike frame are often more appealing.

Gauge Accuracy

An integrated pressure gauge allows users to monitor tire pressure accurately. The accuracy of the gauge is critical for maintaining optimal tire pressure, which impacts cycling performance and safety. B2B buyers should prioritize pumps with reliable gauges, as inaccurate readings can lead to under- or over-inflation, affecting the longevity of tires.

Understanding industry jargon can streamline the procurement process and ensure effective communication with suppliers. Here are several common trade terms relevant to cycle air pumps:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of cycle air pumps, OEM suppliers may provide components that brands use to assemble their final products. Understanding OEM relationships can help buyers identify quality manufacturers and maintain consistency in product quality.

MOQ (Mindestbestellmenge)

MOQ is the smallest number of units a supplier is willing to sell in a single order. This term is critical for B2B buyers as it impacts inventory management and cash flow. Understanding MOQ helps businesses plan purchases effectively, especially when negotiating with suppliers to meet their needs without overcommitting resources.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. It is a key step in the sourcing process, allowing buyers to compare costs and terms. B2B buyers should prepare detailed RFQs to ensure they receive accurate and comprehensive quotes, facilitating better decision-making.

Incoterms (Internationale Handelsklauseln)

These are standardized trade terms used in international transactions to clarify the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B buyers engaged in cross-border purchasing, as they define who is responsible for shipping, insurance, and tariffs, thereby minimizing potential disputes.

Vorlaufzeit

Lead time refers to the duration between placing an order and receiving the product. It is a critical consideration for B2B buyers as it affects inventory levels and customer satisfaction. Understanding lead times helps businesses plan their stock and manage customer expectations effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing cycle air pumps, ensuring they meet their specific needs and operational requirements.

The cycle air pump sector is experiencing notable transformations driven by several global factors. Firstly, the growing popularity of cycling as a sustainable mode of transport is pushing demand for high-quality, accessible inflation solutions. Urbanization, particularly in regions like Africa and South America, is leading to increased cycling infrastructure, making it imperative for businesses to adapt to this changing landscape. Additionally, the rise of e-commerce platforms has revolutionized the sourcing of cycling accessories, including air pumps, providing international B2B buyers with a wider array of options.

Illustrative image related to cycle air pump near me

Emerging technologies, such as mobile applications that locate nearby bike pumps, are enhancing customer convenience and influencing purchasing decisions. For instance, platforms that map public bike pump stations are becoming increasingly popular, enabling cyclists to quickly find nearby resources. Furthermore, the integration of smart technology in air pumps, such as automatic pressure gauges and portable battery-operated models, is becoming a key trend. International buyers should also be aware of regional variations in consumer preferences, as markets in Europe may prioritize advanced features while those in developing regions may focus on affordability and accessibility.

Sustainability has become a critical consideration for B2B buyers in the cycle air pump market. The environmental impact of production processes and materials used in manufacturing air pumps is under scrutiny, prompting businesses to seek suppliers who prioritize eco-friendly practices. Ethical sourcing is increasingly important, as buyers look for manufacturers that adhere to sustainable supply chain principles, ensuring minimal waste and responsible sourcing of raw materials.

Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. Moreover, the use of recycled materials in the production of cycle air pumps is gaining traction, appealing to environmentally conscious consumers and businesses alike. By aligning with suppliers who prioritize sustainability, B2B buyers can enhance their brand reputation while contributing positively to the environment, thereby meeting the growing demand for ‘green’ products in the cycling industry.

The cycle air pump market has evolved significantly over the years, transitioning from basic hand pumps to more sophisticated, portable, and user-friendly designs. Initially, most air pumps were manual, requiring significant effort from users. However, advancements in technology have introduced electric pumps and compact, battery-operated models, catering to a wider range of consumer needs.

The rise of cycling culture in urban areas and the increased focus on sustainability have further shaped the market. As more individuals turn to cycling for commuting and leisure, the demand for convenient and efficient air inflation solutions has surged. Today, B2B buyers can choose from a diverse range of products tailored to various cycling preferences, including floor pumps, mini pumps, and electric inflators. This evolution underscores the importance of staying attuned to consumer trends and technological advancements when sourcing cycle air pumps.

How do I choose the right cycle air pump for my business needs?

Selecting the right cycle air pump involves assessing your target market’s preferences, the types of bicycles being used, and the pump’s features. Look for pumps that offer versatility, such as compatibility with different valve types (Schrader and Presta) and various inflation pressures. Consider the durability of materials and ease of use, as these factors can significantly influence customer satisfaction. Additionally, evaluate the pump’s size and portability if you plan to cater to cyclists who travel frequently.

What is the best cycle air pump for commercial use?

For commercial use, a high-quality floor pump with a large capacity and a stable base is recommended. Brands like Topeak and Lezyne offer models that can quickly inflate tires to the desired pressure while accommodating various valve types. Look for pumps with integrated pressure gauges for accuracy and those made from durable materials to withstand frequent use. If you cater to a specific market, consider pumps designed for electric bikes, which may require higher pressure levels.

What are the key factors to consider when vetting suppliers for cycle air pumps?

When vetting suppliers, focus on their reputation, production capabilities, and compliance with international quality standards. Request samples to evaluate product quality and ensure they can meet your specific needs regarding customization, such as branding or features. Investigate their delivery timelines and logistics capabilities, especially if you’re sourcing from overseas. Additionally, check for certifications like ISO or CE, which indicate adherence to safety and quality protocols.

What are typical minimum order quantities (MOQs) for cycle air pumps?

Minimum order quantities for cycle air pumps can vary significantly based on the supplier and the pump type. Generally, MOQs range from 100 to 1,000 units. For custom or branded products, MOQs may be higher due to the added costs of production and setup. Always clarify MOQs with potential suppliers and consider negotiating terms that align with your business strategy, especially if you’re testing a new product in your market.

What payment terms should I expect when sourcing cycle air pumps internationally?

Payment terms can differ based on the supplier’s policies and your negotiation leverage. Common terms include a 30% deposit upfront with the balance due before shipment or upon delivery. Some suppliers may offer more flexible terms, such as letters of credit or payment upon delivery, especially for established relationships. Always ensure that payment methods are secure and consider the potential for currency fluctuations in your financial planning.

How can I ensure quality assurance (QA) when purchasing cycle air pumps?

To ensure quality assurance, request detailed product specifications and quality certifications from suppliers. Implement a systematic quality control process, including pre-shipment inspections and third-party audits, to verify that products meet your standards. Establish clear communication regarding your quality expectations and consider building long-term relationships with suppliers who consistently deliver high-quality products. Regular feedback and collaboration can also foster continuous improvement.

What logistics considerations should I keep in mind when importing cycle air pumps?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose between air freight for speed and sea freight for cost-effectiveness based on your urgency and budget. Be aware of import duties and taxes that may affect overall costs. Work with reliable freight forwarders who can navigate customs and provide updates on shipment status. Proper planning ensures that products arrive on time and in good condition, minimizing disruptions to your business operations.

How can I customize cycle air pumps to meet my brand’s needs?

Customizing cycle air pumps can involve branding (logos and colors), design modifications, or specific features that cater to your target market. Discuss customization options with your supplier and provide clear specifications regarding your desired changes. Be prepared for potential adjustments in MOQs or pricing based on the complexity of the customization. Additionally, consider the lead time for custom orders, as these may require more extensive production processes.

Bereich: freeairpump.com

Registriert: 2012 (13 Jahre)

Einleitung: FreeAirPump.com provides a crowdsourced map of locations that offer free air for tires, including gas stations and bike repair stations. Users can add locations and report errors. The site also offers a guide to portable air compressors for those who can’t find free air. In Connecticut, free air is available at gas stations, while in California, it is required for paying customers. The site encour…

Bereich: yelp.com

Registriert: 2003 (22 Jahre)

Einleitung: This company, Yelp – Best Bike Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: bike-pump.com

Registered: 2025 (0 years)

Einleitung: Find bike pump stations and motorcycle tire inflation stations worldwide using an interactive map. The service allows users to locate free bike pump stations near them, ensuring they never get stranded with a flat tire. The platform is community-powered, with data that is constantly updated for accuracy. Users can enable location services to view available pump stations, get directions, and access…

Bereich: ziel.de

Registriert: 1997 (28 Jahre)

Einleitung: This company, Target – Top-Rated Cycle Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Places to fill up air in bike tires in Jersey City include bike shops, specifically mentioned is a bike shop on Central Avenue. Users suggest that bike shops typically have a pump available for public use. One user also offers their personal bike pump for use near Washington Park.

In the evolving landscape of cycling accessories, strategic sourcing of cycle air pumps can significantly enhance your supply chain efficiency and market competitiveness. Key takeaways from this guide emphasize the importance of understanding local demand and leveraging community-driven resources, such as free air stations and public pump locations, to meet customer needs effectively. By integrating these insights, B2B buyers can optimize their inventory strategies and establish strong relationships with suppliers who can provide high-quality products tailored to their market.

Furthermore, as cycling continues to gain traction as a sustainable transportation option, there is a growing demand for reliable air pump solutions. International buyers from regions such as Africa, South America, the Middle East, and Europe should focus on sourcing innovative and eco-friendly products that resonate with the values of their customer base.

As you consider your next steps, think about how you can leverage these insights to improve your sourcing strategy and capitalize on emerging trends in the cycling market. Engage with local suppliers and explore community resources to enhance your offerings and ensure your customers never face the frustration of a flat tire again.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.