In today’s competitive landscape, sourcing reliable air compressors for vehicles poses a significant challenge for international B2B buyers. Whether you are operating in the rugged terrains of Africa or the bustling markets of Europe, understanding the nuances of the air compressor market is crucial for ensuring operational efficiency and vehicle performance. This comprehensive guide delves into the various types of air compressors, from portable models to onboard systems, and explores their diverse applications, including tire inflation, powering air tools, and enhancing off-road capabilities.

Moreover, we will provide insights into supplier vetting processes, helping you identify trustworthy manufacturers and distributors that meet your specific requirements. Cost considerations will also be addressed, ensuring you are equipped to make informed purchasing decisions that align with your budget and operational needs. This guide aims to empower B2B buyers from regions such as Nigeria, Saudi Arabia, and South America by offering actionable insights and expert advice tailored to the unique challenges and opportunities within their respective markets.

By leveraging the knowledge contained within this guide, you will be better positioned to navigate the complexities of the air compressor market, ultimately driving efficiency and enhancing the overall performance of your vehicle fleet.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Onboard Air Compressors | Mounted within the vehicle, often with high PSI capability | Off-road vehicles, air suspension systems, RVs | Vorteile: Reliable, space-efficient, versatile. Nachteile: Installation complexity, higher initial cost. |

| Portable Air Compressors | Lightweight, easy to transport, lower PSI | Emergency tire inflation, recreational vehicles | Vorteile: Highly portable, easy to use. Nachteile: Limited power output, not suitable for heavy-duty tasks. |

| Dual Motor Compressors | Equipped with two motors for enhanced performance | Heavy-duty applications, frequent tire inflation | Vorteile: Faster inflation, increased durability. Nachteile: More expensive, requires more space. |

| Brushless Air Compressors | Utilize brushless motor technology for efficiency | Performance-oriented vehicles, air tools | Vorteile: Longer lifespan, quieter operation. Nachteile: Higher cost, may require specific mounting solutions. |

| High-Pressure Air Compressors | Capable of reaching high PSI levels, often for specialized tasks | Industrial applications, heavy machinery | Vorteile: Suitable for demanding tasks, robust construction. Nachteile: Bulkier, requires more maintenance. |

Onboard air compressors are integrated directly into vehicles, providing a constant source of compressed air for various applications. These compressors are particularly advantageous for off-road enthusiasts and those with air suspension systems, as they can adjust tire pressure on-the-go, enhancing traction and performance. When purchasing, consider factors such as PSI ratings, duty cycles, and compatibility with existing vehicle systems to ensure optimal performance.

Portable air compressors are designed for mobility and ease of use, making them ideal for emergency situations or light-duty applications. These compressors are particularly useful for businesses involved in recreation, such as camping or off-roading, allowing for quick tire inflation and tool operation without the need for a fixed installation. Buyers should evaluate the compressor’s CFM (cubic feet per minute) output and battery life to ensure it meets their specific operational needs.

Dual motor compressors feature two motors that significantly increase their air output and efficiency. This makes them an excellent choice for businesses that require rapid tire inflation or frequent use in demanding environments. While they can be more expensive and require more installation space, their performance benefits often justify the investment, especially for commercial fleets or off-road vehicles that operate under challenging conditions.

Illustrative image related to air compressor in vehicle

Brushless air compressors leverage advanced motor technology to provide efficient and quiet operation, making them suitable for performance-oriented vehicles and air tools. Their durability and reduced maintenance needs make them appealing for businesses seeking long-term reliability. When considering a purchase, assess the compressor’s power requirements and installation flexibility to ensure compatibility with your vehicle’s layout.

High-pressure air compressors are engineered to deliver substantial air pressure, making them vital for industrial applications and heavy machinery. These compressors are built for robustness and can handle demanding tasks such as powering pneumatic tools or inflating large tires. Buyers should focus on the compressor’s construction quality, maintenance needs, and overall pressure capabilities to ensure it aligns with their operational requirements.

| Industrie/Sektor | Specific Application of air compressor in vehicle | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automotive Service Centers | Tire inflation and maintenance for customer vehicles | Enhances customer satisfaction and loyalty | Durability, ease of use, and service support |

| Off-Road and Adventure Sports | Onboard air systems for tire pressure adjustment | Improves vehicle performance and safety | Compact design, high pressure capabilities, reliability |

| Construction and Heavy Equipment | Powering pneumatic tools and equipment in the field | Increases operational efficiency and productivity | Duty cycle rating, portability, and maintenance options |

| Logistics and Fleet Management | Maintaining optimal tire pressure for fuel efficiency | Reduces operational costs and extends tire life | Compatibility with various vehicle types, cost-effectiveness |

| Landwirtschaft und Landbau | Inflating agricultural vehicle tires and tools | Enhances productivity and reduces downtime | Ruggedness, ease of transport, and performance in harsh conditions |

In automotive service centers, air compressors are essential for tire inflation and maintenance. By providing quick and efficient tire inflation, these compressors enhance customer satisfaction, leading to higher retention rates. Service centers require compressors that are durable and easy to operate, ensuring minimal downtime during busy periods. For international buyers, particularly in regions like Africa and South America, sourcing compressors that can withstand diverse environmental conditions is critical.

In the off-road and adventure sports sector, onboard air systems are pivotal for adjusting tire pressure to match varying terrains. This capability significantly improves vehicle performance and safety during challenging expeditions. Buyers in this industry should prioritize compact and reliable compressors that can deliver high pressure, as these features are essential for effective use in remote locations. The ability to perform under extreme conditions is also a key factor for international buyers in regions like the Middle East, where terrain can be unpredictable.

Air compressors are widely utilized in construction for powering pneumatic tools and equipment, enhancing operational efficiency on job sites. The ability to quickly inflate tires and provide air for tools reduces downtime and increases productivity. Businesses in this sector should consider compressors with a high duty cycle rating and portability to ensure they can handle demanding tasks. For buyers in Europe, where regulatory standards may vary, ensuring compliance with local safety and environmental regulations is essential.

In logistics and fleet management, maintaining optimal tire pressure is crucial for fuel efficiency and reducing operational costs. Air compressors facilitate regular tire maintenance, helping to extend tire life and improve vehicle safety. Fleet managers should seek compressors that are compatible with various vehicle types and offer cost-effective solutions for their operations. For international buyers, especially in Africa, understanding local fuel prices and operational challenges can guide their compressor selection process.

In agriculture, air compressors are used for inflating tires on agricultural vehicles and tools, which enhances productivity and reduces downtime. Reliable compressors can withstand the rugged conditions often found on farms, making them a valuable investment for farmers. Buyers should focus on the ruggedness and ease of transport of these compressors, ensuring they can effectively operate in diverse agricultural environments. For buyers in regions like South America, where farming practices can vary widely, versatility in compressor applications is a significant advantage.

Das Problem: B2B buyers often face challenges in sourcing air compressors that meet the specific needs of various vehicles and applications. In regions like Africa and the Middle East, where off-roading and rugged terrain are common, buyers require durable and high-performance compressors. However, many products in the market do not provide clear specifications on their performance under extreme conditions, leading to uncertainty about their reliability and longevity. This can result in costly downtime if the equipment fails when it is needed the most.

Die Lösung: To effectively source reliable air compressors, B2B buyers should focus on established brands known for their performance in tough environments. Look for products that have undergone rigorous testing for durability and efficiency, such as those with a high duty cycle rating (e.g., 100% duty cycle at 200 PSI). Additionally, consider investing in compressors that are versatile enough to handle multiple tasks, such as inflating tires and powering air tools. To ensure compatibility with various vehicle types, consult with manufacturers about universal mounting kits and accessories. Always ask for customer testimonials and case studies that demonstrate the compressor’s performance in real-world scenarios, particularly in similar geographic conditions.

Das Problem: Another common pain point for B2B buyers is the maintenance and longevity of onboard air compressors. Many companies in sectors like logistics or construction rely heavily on these systems, and any malfunction can lead to operational delays. Buyers often worry about the availability of spare parts and the ease of conducting repairs. In regions where service centers may be sparse, the inability to quickly maintain equipment can significantly impact business operations.

Die Lösung: To mitigate maintenance concerns, buyers should prioritize compressors that are designed for easy serviceability and have readily available spare parts. Brands that offer comprehensive warranties and support services can provide peace of mind regarding long-term investments. Regular maintenance practices, such as checking air hoses for wear and tear and ensuring accurate pressure gauges, should be established. Additionally, investing in training for staff on basic maintenance procedures can enhance the longevity of the equipment. Consider creating a partnership with local distributors for ongoing support and prompt access to parts, which is especially crucial in remote areas.

Das Problem: For businesses operating fleets, such as delivery services or transportation companies, inefficient tire inflation processes can lead to increased fuel costs and compromised safety. Manual inflation methods can be time-consuming and often result in inconsistent tire pressure, which negatively affects vehicle performance and longevity. This is particularly problematic in regions with varying terrains, where quick adjustments are necessary for optimal driving conditions.

Die Lösung: To streamline tire inflation processes, B2B buyers should invest in high-performance onboard air compressors that can provide quick and accurate inflation for multiple tires simultaneously. Look for systems that feature automatic shut-off capabilities and digital pressure gauges to enhance accuracy. Implementing a proactive maintenance schedule that includes regular checks on tire pressure can help prevent under-inflation and over-inflation issues. Additionally, consider integrating these compressors with a centralized air system for fleet vehicles, allowing for real-time monitoring and adjustments based on driving conditions. Training drivers on the importance of maintaining optimal tire pressure can also contribute to overall fleet efficiency and safety.

When selecting materials for air compressors in vehicles, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Here, we analyze four common materials: aluminum, steel, plastic, and brass. Each material has unique characteristics that can significantly impact the performance and suitability of air compressors in various applications.

Aluminum is widely used in air compressor manufacturing due to its lightweight nature and excellent corrosion resistance. With a high strength-to-weight ratio, aluminum can withstand considerable pressure and temperature fluctuations, making it suitable for both portable and onboard compressors.

Illustrative image related to air compressor in vehicle

Vorteile: The lightweight property of aluminum enhances fuel efficiency in vehicles, while its corrosion resistance prolongs the lifespan of the compressor. Additionally, aluminum is relatively easy to machine, allowing for complex designs.

Nachteile: However, aluminum can be more expensive than other materials like steel, and it may not be as durable under extreme conditions. In high-stress applications, aluminum components can be prone to fatigue.

Auswirkungen auf die Anwendung: Aluminum compressors are ideal for applications requiring frequent mobility, such as off-road vehicles or portable units.

Überlegungen für internationale Käufer: Buyers from regions like Africa and the Middle East should ensure that aluminum components meet local standards for pressure vessels, such as ASTM or JIS, to ensure safety and compliance.

Illustrative image related to air compressor in vehicle

Steel is another common material used in air compressors, particularly for components that require high strength and durability. It is often used in the construction of compressor housings and tanks due to its robustness.

Vorteile: Steel’s high tensile strength allows it to withstand high pressures, making it suitable for heavy-duty applications. It is also cost-effective compared to aluminum.

Nachteile: The main drawback of steel is its susceptibility to corrosion, which can lead to premature failure if not properly coated or treated. Additionally, steel components are heavier, which may affect vehicle performance.

Auswirkungen auf die Anwendung: Steel is suitable for stationary compressors or applications where weight is less of a concern, such as in industrial vehicles.

Illustrative image related to air compressor in vehicle

Überlegungen für internationale Käufer: Buyers should be aware of the need for corrosion-resistant coatings, especially in humid or coastal regions, and ensure compliance with local manufacturing standards.

Plastic is increasingly being utilized in air compressor manufacturing, particularly for non-structural components like housings and fittings.

Vorteile: The primary advantages of plastic include its lightweight nature and resistance to corrosion. Plastic components are also less expensive to produce, which can lower overall manufacturing costs.

Nachteile: However, plastics generally have lower strength and temperature resistance compared to metals, which can limit their use in high-pressure applications. They may also degrade over time when exposed to UV light or extreme temperatures.

Auswirkungen auf die Anwendung: Plastic is suitable for low-pressure applications and can be effectively used in portable compressors where weight savings are critical.

Illustrative image related to air compressor in vehicle

Überlegungen für internationale Käufer: Buyers should check for compliance with international safety standards, as some plastics may not meet the required specifications for pressure vessels.

Brass is often used for fittings and connectors in air compressors due to its excellent corrosion resistance and machinability.

Vorteile: The main advantage of brass is its ability to withstand high pressures while offering good thermal conductivity. This makes it ideal for fittings that require precise connections.

Nachteile: Brass is generally more expensive than steel and can be heavy, which may not be suitable for all applications.

Auswirkungen auf die Anwendung: Brass components are particularly useful in applications involving air tools or where reliable connections are critical.

Illustrative image related to air compressor in vehicle

Überlegungen für internationale Käufer: Buyers should ensure that brass components meet international standards for safety and performance, especially in regions with stringent regulations.

| Material | Typical Use Case for air compressor in vehicle | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Portable and onboard compressors | Leicht und korrosionsbeständig | Prone to fatigue under high stress | Mittel |

| Stahl | Heavy-duty stationary compressors | High tensile strength | Susceptible to corrosion | Niedrig |

| Kunststoff | Non-structural components in low-pressure applications | Leicht und kostengünstig | Lower strength and temperature resistance | Niedrig |

| Brass | Fittings and connectors | Excellent corrosion resistance | More expensive and heavier | Mittel |

This guide provides a comprehensive overview of the materials commonly used in air compressors for vehicles, aiding B2B buyers in making informed decisions that align with their operational needs and regional standards.

The manufacturing process for air compressors designed for vehicles encompasses several critical stages that ensure product reliability and performance.

Illustrative image related to air compressor in vehicle

The process begins with material preparation, where raw materials such as aluminum, steel, and high-grade plastics are sourced. Aluminum is often favored for its lightweight properties and resistance to corrosion, which is vital for portable and mounted air compressors. Steel components are typically used in parts that require durability, such as the housing and motor components. Quality assurance starts here; suppliers must provide certifications to confirm material standards and specifications.

The next step involves forming, where these materials are shaped into the necessary components through techniques like casting, machining, and stamping. Advanced CNC (Computer Numerical Control) machinery is often employed to ensure precision in creating parts such as cylinder heads and pistons. This stage is crucial for maintaining tight tolerances and ensuring that each component fits perfectly during assembly.

Following forming, the assembly stage involves bringing together all components, including motors, valves, and control systems. Automated assembly lines are commonly used to streamline this process, which may include robotic arms for precision placement. Each compressor is then fitted with essential components such as gauges, switches, and hoses. During assembly, adherence to standard operating procedures (SOPs) is essential to minimize human error and ensure consistency.

The finishing stage includes surface treatments, painting, and final inspections. Components may undergo anodizing or powder coating to enhance corrosion resistance and aesthetic appeal. The final products are subjected to rigorous testing before packaging to verify their operational performance and compliance with design specifications.

Quality assurance is paramount in the manufacturing of air compressors, particularly for international B2B buyers who require assurance of product quality and compliance with global standards.

International standards such as ISO 9001 are critical benchmarks for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established a robust quality management framework, ensuring continuous improvement and customer satisfaction. Additionally, certifications like CE mark and API standards may be relevant, depending on the application of the air compressors.

Quality control (QC) checkpoints are integral throughout the manufacturing process. Key checkpoints include:

Eingehende Qualitätskontrolle (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Suppliers must provide documentation proving material quality.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, regular inspections are conducted to monitor production quality. This may include dimensional checks and functionality tests of components.

Endgültige Qualitätskontrolle (FQC): The final product is subjected to comprehensive testing, which may involve pressure tests, flow rate assessments, and operational simulations to ensure it meets performance specifications.

Several testing methods are employed to validate the performance and reliability of air compressors. These include:

Pressure Testing: Ensures that the compressor can handle specified pressures without leaking.

Flow Rate Testing: Measures the volume of air produced to verify that it meets the manufacturer’s specifications.

Dauerhaftigkeitsprüfung: Involves running the compressor for extended periods under various conditions to ensure long-term performance.

Vibration and Noise Testing: Assesses the operational sound levels and vibrations to ensure compliance with industry standards.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is essential for mitigating risks associated with poor-quality products.

Durchführung von Audits: Regular audits of suppliers can help ensure that manufacturing processes comply with international standards. Buyers can request access to audit reports and certifications.

Dokumentation anfordern: Suppliers should provide detailed documentation of their quality control processes, including inspection reports, test results, and compliance certificates.

Beauftragung von Drittinspektoren: Utilizing third-party inspection services can add an additional layer of verification, ensuring that products meet the required specifications before shipment.

International B2B buyers must navigate various quality control and certification nuances. For example, regulations may differ significantly between regions. Buyers from Africa and South America may encounter unique challenges related to import standards and local compliance requirements. Understanding these nuances is crucial for making informed purchasing decisions.

Research Local Regulations: Familiarize yourself with local standards and regulations that may apply to imported air compressors, such as safety and environmental regulations.

Leverage Local Expertise: Engaging local consultants or experts can provide valuable insights into navigating compliance and quality standards specific to each region.

Establish Clear Communication: Maintain open lines of communication with suppliers to ensure they are aware of your quality expectations and compliance needs.

By understanding the manufacturing processes and quality assurance measures in place for air compressors, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Sourcing an air compressor for vehicles is a critical decision for B2B buyers in various sectors, including automotive, manufacturing, and construction. This guide provides a structured checklist to streamline the procurement process, ensuring that your choice aligns with operational needs, budget constraints, and regional requirements.

Before reaching out to suppliers, it’s essential to determine the specific requirements for the air compressor. Consider factors such as the intended use (e.g., inflating tires, powering tools), required pressure levels, and flow rates. This clarity will help you filter options effectively and avoid overspending on unnecessary features.

Understanding the types of air compressors available is crucial. Options include portable, onboard, and stationary models, each with distinct advantages. For instance, portable compressors are ideal for mobility, while onboard systems provide convenience for off-road vehicles. Evaluating the types will ensure you select a compressor suited to your operational context.

Prioritize suppliers who possess relevant certifications and industry standards, such as ISO or CE markings. These certifications indicate compliance with safety and quality regulations, which is especially important in regions with strict import standards. Additionally, verify if the supplier has experience in your specific market.

Investigate the performance metrics of the compressors you’re considering. Look for specifications such as duty cycle, PSI ratings, and motor types. Reliable compressors, like those with a 100% duty cycle, can withstand continuous operation without overheating, which is vital for demanding tasks.

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, warranty terms, and delivery options. Comparing these quotes will help you identify the best value for your investment. Pay attention to the total cost of ownership, factoring in maintenance and potential spare parts availability.

Before finalizing your purchase, seek feedback from previous customers. Look for reviews that discuss the product’s performance, durability, and customer service experiences. Additionally, ask suppliers for references in your industry or region to validate their reputation.

Finally, ensure that the supplier offers robust after-sales support and clear warranty terms. A reliable warranty and accessible customer service can significantly reduce downtime in case of equipment failure. Clarifying these aspects upfront can save your business from future complications.

By following this checklist, B2B buyers can make informed decisions when sourcing air compressors for vehicles, ensuring they meet their operational needs while adhering to budgetary constraints.

When sourcing air compressors for vehicles, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis provides insights into the various cost components, pricing influencers, and practical tips for negotiating favorable terms.

Illustrative image related to air compressor in vehicle

Materialien: The primary cost driver in air compressor manufacturing is the materials used, which include metals, plastics, and electrical components. High-quality materials enhance durability and performance but may increase upfront costs.

Arbeit: Labor costs vary by region and can significantly impact pricing. In regions with higher wages, such as parts of Europe, labor costs may account for a larger portion of the total price.

Fertigungsgemeinkosten: This includes costs associated with factory operations, utilities, and maintenance. Efficient manufacturing processes can minimize overhead costs, thereby affecting the final pricing.

Werkzeugbau: Custom tooling for specific designs can be a significant investment. If a buyer requires specialized features, this could lead to higher costs.

Illustrative image related to air compressor in vehicle

Qualitätskontrolle (QC): Rigorous QC processes ensure that products meet required standards. Implementing strict quality measures may lead to increased costs but results in higher reliability and satisfaction.

Logistik: Transportation and warehousing costs are critical, particularly for international shipments. Factors like shipping distance, mode of transport, and import tariffs can influence total costs.

Marge: Suppliers typically add a margin to cover their costs and profit. Understanding the competitive landscape can help buyers gauge whether the margin is reasonable.

Volumen und Mindestbestellmenge (MOQ): Purchasing in larger volumes often leads to lower per-unit costs. Suppliers may offer discounts for bulk orders, which is a significant consideration for B2B buyers.

Illustrative image related to air compressor in vehicle

Spezifikationen und Anpassungen: Custom features can increase both the complexity and cost of air compressors. Buyers should clearly define their specifications to avoid unexpected expenses.

Material Choices: The choice of materials impacts both performance and price. For example, compressors made from high-grade steel may offer better longevity but come at a premium.

Quality Certifications: Products that meet international quality standards (e.g., ISO certifications) may command higher prices due to the assurance of quality and reliability.

Lieferanten-Faktoren: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge more for their proven track record and after-sales support.

Incoterms: Understanding shipping terms is essential for calculating total costs. Different Incoterms can affect who bears responsibility for shipping costs, insurance, and tariffs, impacting the final price.

Illustrative image related to air compressor in vehicle

Negotiation Strategies: Engage suppliers in negotiations to explore flexible pricing structures, especially for larger orders. Highlighting long-term partnerships may yield better terms.

Gesamtbetriebskosten (TCO): Consider not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. A higher-quality compressor may result in lower TCO over its lifespan.

Nuancen in der Preisgestaltung für internationale Käufer: Buyers in regions like Africa and South America should be aware of local economic conditions, currency fluctuations, and import regulations that can affect pricing. Establishing relationships with local suppliers may also yield better deals.

Haftungsausschluss für indikative Preise: The prices provided by manufacturers can fluctuate based on market conditions and individual supplier practices. Buyers should seek updated quotes and consider all cost components before making purchasing decisions.

Illustrative image related to air compressor in vehicle

In summary, a comprehensive understanding of cost structures and pricing dynamics will empower international B2B buyers to make informed decisions when sourcing air compressors for vehicles. By evaluating all cost components and considering the various influencing factors, buyers can optimize their procurement strategies and achieve favorable outcomes.

As businesses and industries evolve, the need for efficient and effective solutions to power tools, inflate tires, and support various operational tasks grows. While air compressors in vehicles provide a reliable source of compressed air, it’s essential to explore alternative solutions that might better suit specific needs, particularly for international B2B buyers in diverse markets. This analysis compares vehicle-mounted air compressors with two viable alternatives: portable air compressors and onboard air systems. Each option has distinct advantages and limitations, which can significantly impact purchasing decisions.

| Vergleich Aspekt | Air Compressor In Vehicle | Tragbarer Luftkompressor | Onboard Air System |

|---|---|---|---|

| Leistung | High, consistent output for vehicle use | Moderate, dependent on model | High, designed for demanding tasks |

| Kosten | Moderate to high ($324 – $1,379) | Low to moderate ($187 – $300) | Moderate to high ($382 – $840) |

| Leichte Implementierung | Requires installation | Plug-and-play, user-friendly | Requires installation, may need modifications |

| Wartung | Regular checks needed, parts available | Low, easy to maintain | Moderate, requires periodic checks |

| Bester Anwendungsfall | Off-road and heavy-duty applications | General use, emergencies, and travel | Professional applications, heavy-duty vehicles |

Portable air compressors are designed for ease of use and mobility. They can be easily transported and connected to various power sources, making them ideal for users who require flexibility. With a lower cost compared to vehicle-mounted compressors, they are often favored by individual consumers and small businesses. However, their performance may vary significantly depending on the model, with some units providing insufficient power for larger tasks. Moreover, they may not be suitable for heavy-duty applications, limiting their utility for businesses engaged in demanding operations.

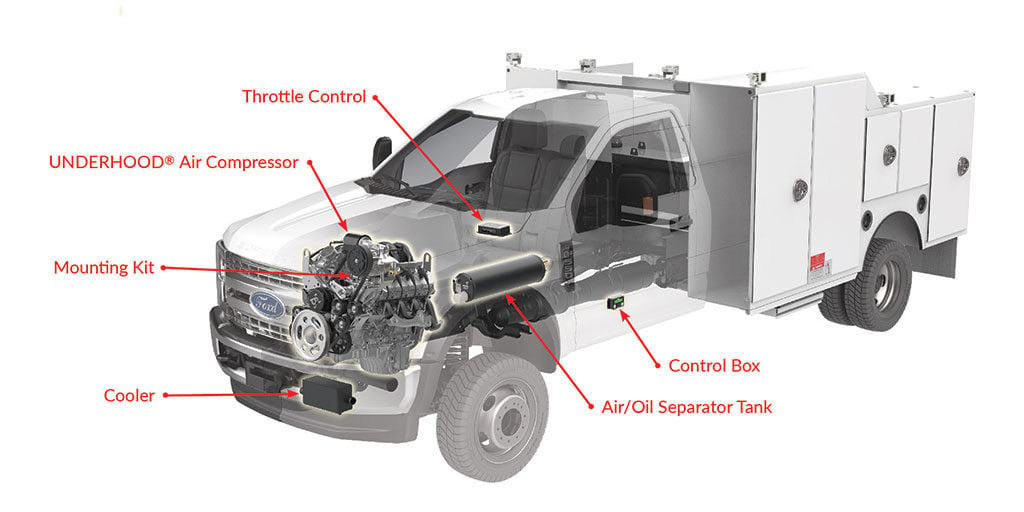

Onboard air systems are engineered for high performance, often featuring dual compressors that can handle more extensive applications such as air suspension systems, powering air tools, and inflating tires quickly. They are designed to be permanently mounted, ensuring that businesses have a ready source of compressed air for various tasks. However, the installation process can be more complex and may require specific vehicle modifications, which can add to overall costs. Maintenance is moderate, as users need to ensure that the system is functioning correctly to avoid downtime.

When selecting between an air compressor in a vehicle, a portable air compressor, or an onboard air system, B2B buyers must consider their unique operational needs, budget constraints, and the specific applications they intend to support. For businesses that prioritize mobility and flexibility, portable air compressors may be the best fit. Conversely, companies requiring consistent and high-performance air solutions for demanding tasks may find onboard air systems more beneficial. Ultimately, understanding the advantages and limitations of each option will enable buyers to make informed decisions that align with their operational goals and budgetary constraints.

When evaluating air compressors for vehicles, several technical specifications are critical for ensuring optimal performance, reliability, and compatibility with various applications. Here are the essential properties to consider:

The pressure rating, typically measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. For vehicle applications, compressors with a rating of 100 PSI or higher are common, enabling them to effectively inflate tires and operate pneumatic tools. Understanding this specification is vital for B2B buyers, as it impacts the compressor’s suitability for specific tasks, such as off-roading or heavy-duty applications.

Duty cycle refers to the percentage of time a compressor can operate continuously without overheating. For instance, a compressor rated for a 100% duty cycle can run indefinitely, while one rated at 50% may require cooling periods. This property is crucial for B2B buyers, particularly those in industries where prolonged use is common, as it affects productivity and equipment longevity.

Measured in cubic feet per minute (CFM), the airflow rate indicates how much air the compressor can deliver. Higher CFM ratings are essential for applications requiring quick inflation or powering multiple air tools simultaneously. Buyers should assess their operational needs to choose a compressor that meets the necessary airflow requirements.

The materials used in the compressor’s construction directly affect its durability and performance. High-grade aluminum or stainless steel is often preferred for components exposed to high pressure and heat. B2B buyers should prioritize compressors with robust construction to ensure longevity and reliability in demanding environments.

Air compressors can be powered by various sources, including 12V DC or 24V systems. Understanding the power requirements is essential for ensuring compatibility with the vehicle’s electrical system. This specification is particularly relevant for buyers looking for onboard solutions that integrate seamlessly into their fleet operations.

The physical dimensions and weight of the compressor are critical for mobile applications. Buyers should consider the space available in the vehicle and whether portability is a requirement. Compact and lightweight designs can enhance usability without compromising performance.

Understanding industry jargon can streamline the procurement process and enhance communication with suppliers. Here are several key terms:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of air compressors, buyers may choose OEM parts for reliable quality and compatibility with existing systems.

Illustrative image related to air compressor in vehicle

MOQ is the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of MOQs to manage inventory effectively and avoid overcommitting resources to unneeded stock.

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. Including detailed specifications in an RFQ ensures that the quotes received are tailored to the buyer’s specific requirements, facilitating informed decision-making.

International Commercial Terms (Incoterms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks involved in the procurement of air compressors.

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to plan their operations and ensure that they have the necessary equipment when needed.

Warranty terms and the availability of after-sales support are crucial factors for B2B buyers. A strong warranty and responsive support can significantly impact the long-term value and operational efficiency of the air compressor.

By considering these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiencies.

The air compressor market for vehicles is witnessing significant evolution driven by technological advancements and changing consumer demands. One of the key global drivers is the increasing adoption of air compressors in off-road and heavy-duty vehicles, particularly in regions like Africa, South America, and the Middle East, where rugged terrains necessitate reliable equipment. Additionally, rising urbanization and the expansion of the automotive sector in emerging markets are contributing to a growing demand for onboard air compressor systems.

Current trends indicate a shift towards portable and multi-functional compressors that cater to various applications, from tire inflation to powering air tools. B2B buyers are increasingly seeking compressors that offer high performance, durability, and ease of use. For instance, systems that can maintain high-pressure outputs under continuous operation are becoming popular among commercial fleets and off-road vehicle manufacturers.

Moreover, technological innovations such as brushless motor designs and smart pressure gauges are enhancing user experience, making air compressors more efficient and reliable. As international B2B buyers navigate this evolving landscape, understanding regional preferences and the specific needs of their target markets is crucial. Suppliers that can offer customization, robust after-sales support, and competitive pricing will have a distinct advantage in attracting buyers from diverse regions, including Nigeria and Saudi Arabia.

Sustainability is increasingly becoming a priority for B2B buyers in the air compressor sector. Environmental concerns regarding emissions and energy consumption are driving manufacturers to adopt eco-friendly practices. Air compressors that utilize energy-efficient technologies not only reduce operational costs but also minimize environmental impact, aligning with global sustainability goals.

Ethical sourcing is equally important, as buyers are becoming more conscious of the materials used in compressor manufacturing. Sourcing components from suppliers that adhere to stringent environmental standards and provide certifications such as ISO 14001 can enhance a company’s reputation and appeal to eco-conscious consumers. Moreover, the use of recycled materials in compressor production is gaining traction, presenting an opportunity for businesses to differentiate themselves in a competitive market.

For international buyers, particularly in developing regions, establishing relationships with manufacturers committed to sustainability and ethical practices can lead to long-term benefits. This includes improved supply chain resilience and the ability to meet regulatory requirements that are increasingly focused on environmental sustainability.

The evolution of air compressors in vehicles dates back to the early 20th century, where they were primarily utilized in industrial applications. The automotive industry began to adopt these technologies for tire inflation and air suspension systems in the mid-1900s, enhancing vehicle performance and safety. As off-road and utility vehicles became more popular, the demand for portable and reliable air compressors surged.

Throughout the decades, advancements in technology have transformed air compressors, making them more compact, efficient, and user-friendly. The introduction of onboard air systems in the late 20th century revolutionized how vehicles operated in challenging environments, allowing drivers to adjust tire pressure on-the-go. Today, the focus is on integrating advanced features such as digital controls and enhanced durability, catering to the needs of both consumers and businesses in a competitive market landscape.

This historical context provides valuable insights for B2B buyers looking to understand the trajectory of air compressor technology and its implications for future sourcing strategies. Recognizing the past enables businesses to make informed decisions about the products they choose to invest in, ensuring alignment with market trends and customer expectations.

How do I choose the right air compressor for my vehicle?

Choosing the right air compressor involves considering several factors, including the intended use, power requirements, and portability. For off-road adventures, look for a compressor with a high duty cycle and PSI rating, such as those from reputable brands like ARB or VIAIR. Evaluate whether you need a portable model for versatility or a mounted system for ease of use. Additionally, assess the compressor’s output capacity to ensure it meets your tire inflation and tool powering needs.

What is the best onboard air compressor for off-road vehicles?

The best onboard air compressors for off-road vehicles typically feature high PSI ratings and robust construction. Brands like VIAIR and ARB offer models that are specifically designed for demanding conditions, ensuring reliability and performance. Look for features such as dual motors for faster inflation, a high-duty cycle, and compatibility with various accessories, including air tools and suspension systems. Customer reviews and expert recommendations can also guide you to the most suitable option.

What are the common issues with air compressors in vehicles, and how can I prevent them?

Common issues with vehicle air compressors include overheating, air leaks, and insufficient pressure. To prevent these problems, ensure proper installation and regular maintenance, such as checking for leaks and cleaning filters. Monitoring the compressor’s duty cycle is crucial; avoid running it for extended periods without breaks. Additionally, using the right power source can prevent electrical issues, and investing in quality components can enhance durability and performance.

What payment terms should I consider when sourcing air compressors internationally?

When sourcing air compressors internationally, consider payment terms that protect both parties. Common options include letters of credit, advance payments, or payment upon delivery, each with distinct advantages. Ensure you discuss terms such as currency, payment methods (e.g., wire transfers or PayPal), and potential deposits or installments. It’s essential to establish clear agreements to mitigate risks associated with international transactions and ensure timely delivery of goods.

How can I vet suppliers for air compressors in the international market?

To vet suppliers, conduct thorough research on their business credentials, including certifications, production capabilities, and customer reviews. Request references from previous clients to assess reliability and service quality. Additionally, consider visiting the supplier’s facility, if feasible, to evaluate production processes and quality control measures. Engaging with trade associations and utilizing platforms like Alibaba or Global Sources can also help identify reputable manufacturers.

What is the minimum order quantity (MOQ) for air compressors, and how does it vary by supplier?

Minimum order quantities (MOQs) for air compressors can vary significantly based on the supplier and the specific product. Some manufacturers may have MOQs as low as 10 units, while others may require larger orders to justify production costs. It’s essential to discuss MOQs upfront during negotiations and evaluate whether they align with your purchasing needs. If the MOQ is higher than desired, inquire about potential alternatives, such as consolidating orders with other buyers.

What quality assurance measures should I expect from air compressor suppliers?

Expect suppliers to implement rigorous quality assurance (QA) measures, including testing for performance, durability, and safety compliance. Look for manufacturers that adhere to international standards, such as ISO certifications. Suppliers should provide documentation, such as inspection reports and warranty information, to validate the quality of their products. Regular audits and customer feedback mechanisms can further enhance the QA process, ensuring consistent product reliability.

What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Select a reliable freight forwarder experienced in handling heavy machinery and ensure compliance with local regulations in your country. Calculate total landed costs, including shipping, insurance, and tariffs, to avoid unexpected expenses. Additionally, establish clear communication with your supplier regarding packaging and labeling requirements to facilitate a smooth customs clearance process.

Bereich: store.arbusa.com

Registriert: 1998 (27 Jahre)

Einleitung: Portable & Vehicle Mounted Air Compressor Systems | ARB 4×4 USA. Key products include: 1. Twin Motor Onboard 12V Air Compressor CKMTA12 – $593.95 (was $659.95) 2. Single Motor Onboard 12V Air Compressor CKMA12 – $323.95 (was $359.95) 3. Single Motor Portable 12V Air Compressor CKMP12V2 – $449.95 (was $499.95) 4. Twin Motor Portable 12V Air Compressor CKMTP12 – $953.95 (was $1,059.95) 5. Brushless …

Bereich: overlandvehiclesystems.com

Registriert: 2018 (7 Jahre)

Einleitung: Portable Air Compressor by Up Down Air designed for off-road use. Suitable for bikes, boats, trailers, and RV tires. Offers high output for various inflation needs. Comes with a warranty and free shipping in the Continental 48 States. Customer service available M-F 8am-6pm PT. Multiple models available including EGOI Portable Air Compressor System (5.6 CFM), Quick Flate Tire Inflation/Deflation Sy…

Bereich: compressedairsystems.com

Registriert: 1999 (26 Jahre)

Einleitung: Engine Mounted Air Compressors for Trucks in Clearwater, Tampa, Plant City, Kissimmee, Orlando, and Beyond. Designed for service trucks and personal ATVs, these compressors provide reliable compressed air on the go. They draw power directly from the vehicle’s engine, ensuring sufficient power for various applications. Available models include VMAC Underhood compressors, VMAC Predatair compressors,…

In the rapidly evolving landscape of automotive technology, strategic sourcing of air compressors for vehicles is essential for international B2B buyers. Investing in high-performance air compressor systems, whether portable or onboard, ensures reliability and versatility, particularly for industries operating in diverse terrains such as those found in Africa, South America, the Middle East, and Europe. The ability to efficiently manage tire pressures and power air tools enhances operational efficiency and safety, making these systems indispensable for both commercial and recreational applications.

Key considerations for B2B buyers include assessing product durability, ease of maintenance, and compatibility with various vehicle models. Engaging with reputable suppliers that offer robust warranties and customer support can significantly impact long-term satisfaction and performance.

As global demand for efficient automotive solutions continues to rise, now is the time to invest in quality air compressor systems that meet your specific operational needs. By prioritizing strategic sourcing, businesses can secure a competitive edge in their respective markets. Take the next step: explore partnerships with leading manufacturers and distributors to ensure your fleet is equipped with the best air compressor technology available.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.