When it comes to addressing the persistent issue of bike tires not inflating, international B2B buyers face a significant challenge that can hinder operational efficiency. This guide offers a thorough exploration of the myriad factors contributing to tire inflation failures, from valve types to compatibility with various pumps. Understanding these intricacies is essential for sourcing reliable products that meet specific market needs, particularly for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany.

Throughout this comprehensive guide, we will delve into different types of bike tires and their applications, alongside practical solutions for common inflation problems. The guide will also cover essential aspects of supplier vetting, including quality assurance and cost considerations, ensuring that buyers can make informed purchasing decisions. By equipping B2B buyers with the necessary insights and strategies, we empower them to navigate the complexities of the global market effectively. This resource aims to enhance operational capabilities and streamline the procurement process, ultimately contributing to improved customer satisfaction and business growth. With the right knowledge at hand, companies can confidently address tire inflation challenges and optimize their product offerings in an increasingly competitive landscape.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Valve Malfunction | Issues with valve cores or seals that prevent air intake. | Bicycle repair shops, OEM parts suppliers | Vorteile: Often easy to fix; Nachteile: May require specific parts for replacement. |

| Tube Damage | Punctures or tears in the inner tube causing air loss. | Bicycle manufacturers, retailers, repair shops | Vorteile: Replacement tubes are widely available; Nachteile: Frequent replacements may be needed. |

| Pump Compatibility Issues | Incompatibility between pump types (e.g., Presta vs. Schrader). | Retailers, bike rental services | Vorteile: Clear guidelines for pump selection; Nachteile: Miscommunication can lead to customer frustration. |

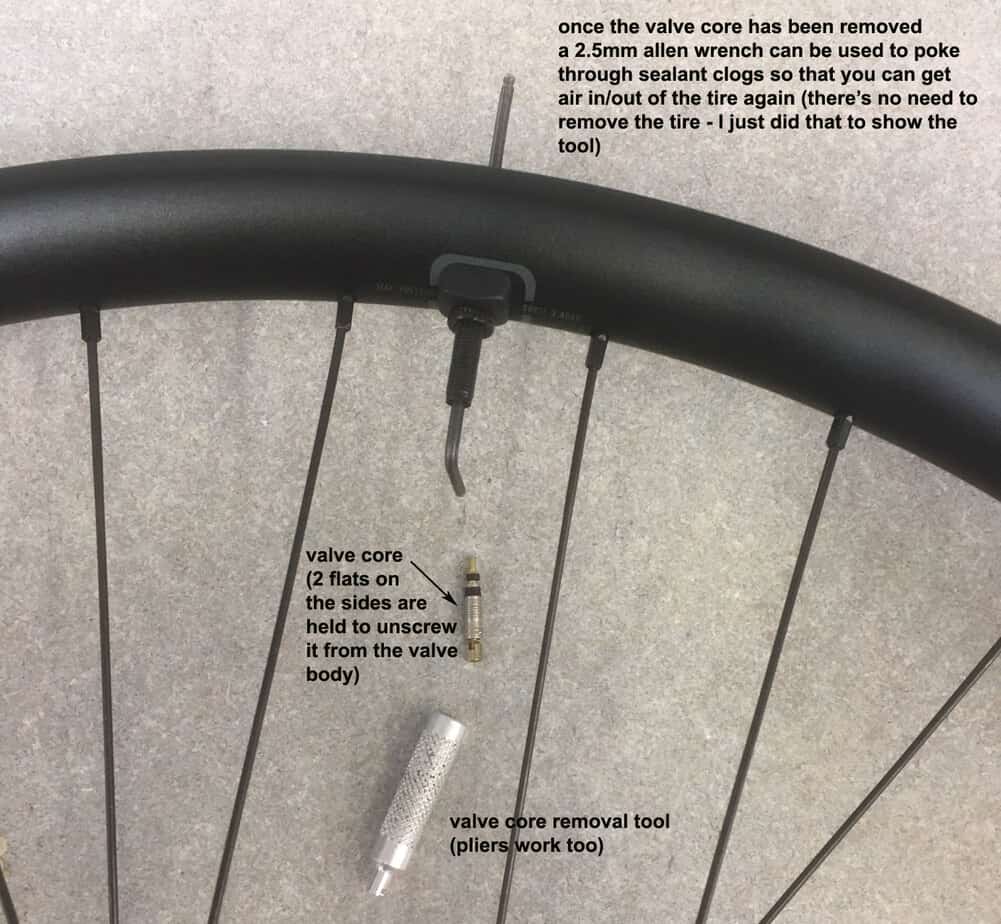

| Sealant Blockage | Tubeless systems where sealant clogs the valve or core. | Tubeless tire manufacturers, bike shops | Vorteile: Long-lasting solutions; Nachteile: Maintenance required to prevent issues. |

| Poor Connection | Inadequate sealing between pump and valve during inflation. | Bicycle repair services, pump manufacturers | Vorteile: Simple adjustments can resolve issues; Nachteile: Often overlooked, leading to wasted effort. |

Valve malfunctions are a common issue encountered in bike tire inflation. They often arise from damaged or clogged valve cores, which can prevent air from entering the tire. For B2B buyers, understanding the types of valves (Presta vs. Schrader) is crucial, as compatibility can affect sales and service. Suppliers should stock a range of valve cores and tools to facilitate quick repairs, as these parts are often needed by bicycle repair shops and manufacturers.

Tube damage, such as punctures or tears, is another significant reason for tires not inflating. This issue can arise from normal wear and tear or from external factors like sharp objects on the road. B2B buyers should consider the durability and quality of tubes when sourcing products, as high-quality tubes can reduce the frequency of replacements. Retailers and repair shops should keep a variety of tube sizes and types in stock to cater to diverse customer needs.

Pump compatibility issues can hinder the inflation process, especially when using pumps designed for different valve types. B2B buyers, particularly retailers and rental services, must ensure that they provide compatible pumps and educate customers on their use. Clear labeling and instructions can help minimize confusion, thus enhancing customer satisfaction and reducing return rates.

Sealant blockage is a concern for tubeless tire systems, where sealant can gum up valves and cores, preventing air intake. B2B suppliers should offer sealants that are less prone to clogging and provide maintenance products to keep systems functioning optimally. This is particularly important for bike shops that service a high volume of tubeless setups, as they can offer added value through expert advice and maintenance services.

Illustrative image related to bike tire not inflating

Poor connection between the pump and valve often leads to ineffective inflation efforts, resulting in frustration for cyclists. This issue is typically easy to resolve by ensuring proper alignment and sealing. B2B buyers should focus on providing high-quality pumps and training for their staff on proper inflation techniques. By addressing this common issue, retailers and service providers can enhance the overall customer experience, leading to increased loyalty and repeat business.

| Industrie/Sektor | Specific Application of bike tire not inflating | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Bicycle Manufacturing | Quality control in tire production | Ensures product reliability and customer satisfaction | Sourcing materials that meet durability and safety standards. |

| Transport und Logistik | Fleet maintenance for delivery bikes | Reduces downtime and increases operational efficiency | Availability of replacement parts and repair services. |

| Recreational Services | Rental bike operations | Enhances customer experience and safety | Need for robust tire management systems and training for staff. |

| Sports and Fitness | Cycling events and competitions | Guarantees participant safety and performance | High-quality equipment and support for emergency repairs. |

| Urban Planning & Development | Public bike-sharing programs | Promotes sustainable transport solutions | Partnerships with local bike shops for maintenance support. |

In the bicycle manufacturing industry, issues related to bike tires not inflating can significantly affect quality control processes. Manufacturers must ensure that tires are produced with reliable valves and materials to prevent inflation failures. This directly impacts customer satisfaction and brand reputation. Buyers in this sector need to source high-quality rubber compounds and valve systems that adhere to international safety standards, particularly when exporting to markets in Africa, South America, and Europe.

For businesses operating fleets of delivery bikes, the ability to effectively manage tire inflation is critical. When tires fail to inflate, it leads to increased downtime and operational inefficiencies. This can affect delivery timelines and customer satisfaction. Fleet managers should focus on sourcing reliable tire and valve systems, as well as establishing efficient maintenance protocols to ensure quick repairs. This is especially important in regions with varying climates, such as the Middle East and South America, where tire performance can be unpredictable.

In the recreational services sector, particularly in bike rental operations, the inability of tires to hold air can detract from the customer experience. Ensuring that all rental bikes are in good working order is essential for safety and satisfaction. Businesses in this space should implement regular maintenance checks and invest in quality tire management systems. Additionally, training staff to identify and fix common inflation issues can enhance service delivery, which is crucial in competitive markets across Europe and Africa.

In sports and fitness, particularly during cycling events, the failure of tires to inflate can pose serious safety risks to participants. Event organizers must ensure that all equipment is thoroughly checked and maintained before the event. This requires sourcing high-quality tires and having emergency repair kits on hand. For international competitions, adherence to specific regulations regarding equipment safety is paramount, making it vital for organizers to collaborate with trusted suppliers.

In urban planning, particularly with public bike-sharing programs, ensuring that bikes are always operational is essential for promoting sustainable transport solutions. A bike that cannot inflate is not only an inconvenience but can also deter users from utilizing the service. City planners must establish partnerships with local bike shops to facilitate regular maintenance and quick repairs. This is especially important in diverse urban environments across Europe and South America, where bike-sharing initiatives are becoming increasingly popular.

Das Problem:

A common issue faced by B2B buyers, particularly those managing bike fleets or retail operations, is the inability to inflate tires due to improper sealing between the pump and the valve. This can lead to a frustrating experience where the pump makes a hissing sound, indicating air is escaping rather than entering the tire. This scenario often arises with aging bikes or when using unfamiliar pumps that may not fit properly with the type of valve (Schrader or Presta) present on the tires. The challenge is not only time-consuming but can also result in operational delays, impacting customer satisfaction in a retail environment or hindering logistics for bike rental services.

Die Lösung:

To overcome this problem, it is essential to ensure that the pump’s head is compatible with the type of valve being used. Retailers should stock a variety of pumps that accommodate different valve types, including adapters for Presta valves, to enhance customer experience. When inflating a tire, users should first clean the valve stem to remove any debris and ensure a solid connection. Wetting the valve lightly can also help the pump head achieve a better seal. Additionally, providing staff training on proper inflation techniques and the importance of checking the pump fit can reduce issues significantly. For B2B buyers, investing in high-quality pumps with a universal fit and promoting their correct usage can streamline operations and improve service efficiency.

Das Problem:

B2B buyers managing bike maintenance or repair services often encounter scenarios where bike tires fail to inflate due to faulty valve cores. This issue can occur when the valve core becomes stuck or damaged, preventing air from entering the tire while still allowing air to escape. Such a situation can be particularly detrimental for businesses that rely on quick turnaround times, as it may require the replacement of parts or additional troubleshooting that delays service.

Die Lösung:

To address this issue, it is recommended that businesses maintain a stock of replacement valve cores and the necessary tools for their installation. Educating staff about identifying faulty valve cores—such as looking for signs of wear or testing by attempting to inflate the tire—can expedite repairs. When a valve core is suspected to be faulty, the first step is to unscrew it using a specialized valve core tool. Once removed, replacing it with a new core can often resolve the inflation issue immediately. Additionally, offering a service where customers can have their valve cores checked and replaced during routine maintenance can enhance customer trust and satisfaction.

Das Problem:

Another significant pain point for B2B buyers, especially in the bike rental or retail sectors, is dealing with damaged or leaking inner tubes that prevent proper inflation. This situation can arise from punctures, wear and tear, or age, leading to air escaping as quickly as it is pumped in. For businesses, this can result in an increased number of service calls, customer complaints, and a negative impact on operational efficiency.

Illustrative image related to bike tire not inflating

Die Lösung:

To mitigate this issue, B2B buyers should prioritize the regular inspection and maintenance of bike tubes. Implementing a proactive maintenance schedule can help identify tubes that are nearing the end of their lifecycle. For immediate solutions, training staff to perform quick diagnostic checks—such as submerging the inflated tube in water to find leaks—can save time. When leaks are found, replacing the tube should be prioritized to ensure safety and usability. Additionally, offering customers the option of upgraded puncture-resistant tubes can reduce future occurrences of this issue. Educating customers about proper tire care and inflation techniques can also enhance their experience and reduce the likelihood of damage.

In the context of bike tires that fail to inflate, several materials play a crucial role in both the tire construction and the associated components like valves and pumps. Understanding these materials can help B2B buyers make informed decisions when sourcing products that ensure reliability and performance.

Wichtige Eigenschaften: Rubber is flexible and resilient, with excellent pressure retention capabilities. It can withstand a wide range of temperatures and has inherent resistance to wear and tear.

Pro und Kontra: The durability of rubber makes it suitable for various terrains, but its performance can degrade under extreme temperatures or prolonged exposure to UV light. While rubber is relatively low-cost, high-performance variants can be more expensive and complex to manufacture.

Auswirkungen auf die Anwendung: Rubber tires are compatible with various media, including air and sealants used in tubeless systems. However, improper sealing can lead to air loss, making material quality critical.

Überlegungen für internationale Käufer: Compliance with local standards (such as ASTM in the U.S. or DIN in Germany) is essential. Buyers in regions with extreme climates, like Africa and the Middle East, should consider rubber formulations that maintain integrity under high temperatures.

Wichtige Eigenschaften: Metals used in valves (like brass or aluminum) offer high strength and corrosion resistance. They can handle high pressure and have a long lifespan when properly maintained.

Pro und Kontra: Metal components are durable and reliable, but they can add weight to the bike and may require additional treatments to prevent corrosion, particularly in humid environments. The manufacturing process for metal parts can be more complex and costly compared to plastics.

Auswirkungen auf die Anwendung: Metal valves are essential for maintaining air pressure in tires. If a valve fails, it can lead to significant air loss, making the choice of material critical for performance.

Überlegungen für internationale Käufer: Buyers should ensure that metal components meet international standards for pressure ratings and corrosion resistance, especially in coastal regions where saltwater can accelerate degradation.

Wichtige Eigenschaften: Plastics like polycarbonate or nylon are lightweight and resistant to corrosion. They can withstand moderate pressure and are often used in pump housings and valve caps.

Pro und Kontra: The lightweight nature of plastic makes it a popular choice for portable pumps. However, plastics may not perform well under extreme temperatures and can be less durable than metals or rubber. Manufacturing processes for high-quality plastics can also be complex.

Illustrative image related to bike tire not inflating

Auswirkungen auf die Anwendung: While suitable for low-pressure applications, plastic components may fail under high-stress conditions, potentially leading to inflation issues.

Überlegungen für internationale Käufer: Compliance with environmental regulations is crucial, particularly in Europe, where plastic use is heavily regulated. Buyers should also consider the recyclability of plastic components.

Wichtige Eigenschaften: Composite materials, such as reinforced rubber or hybrid plastics, combine the benefits of multiple materials, offering enhanced strength, flexibility, and resistance to wear.

Illustrative image related to bike tire not inflating

Pro und Kontra: While more expensive than traditional materials, composites can significantly improve performance and durability. However, their complex manufacturing processes can lead to higher costs.

Auswirkungen auf die Anwendung: Composites can effectively seal and retain air, reducing the chances of inflation issues. They are particularly useful in high-performance or specialized bike tires.

Überlegungen für internationale Käufer: Buyers should ensure that composite materials meet relevant performance standards and consider the long-term cost benefits versus initial investment.

| Material | Typical Use Case for bike tire not inflating | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Tire construction | Excellent flexibility and pressure retention | Degrades under extreme conditions | Niedrig |

| Metall | Valves and pump components | Hohe Festigkeit und Haltbarkeit | Heavier and potentially more costly | Med |

| Kunststoff | Pump housings and valve caps | Leicht und korrosionsbeständig | Weniger haltbar unter extremen Bedingungen | Niedrig |

| Komposit | High-performance tire applications | Enhanced strength and flexibility | Higher manufacturing costs | Hoch |

This analysis provides B2B buyers with insights into the materials that influence bike tire inflation issues, enabling them to make informed decisions based on performance, cost, and regional considerations.

The manufacturing of bike tires involves several crucial stages, each designed to ensure durability, performance, and safety. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

The first step in manufacturing bike tires is material preparation. Typically, tires are made from a combination of rubber compounds, fabric (such as polyester or nylon), and wire. The rubber provides elasticity and grip, while the fabric adds strength and stability. The wire is used for the bead, which helps the tire maintain its shape and fit securely on the rim.

Illustrative image related to bike tire not inflating

During this stage, suppliers often source materials from various vendors. It’s vital for B2B buyers to inquire about the quality and origin of these materials, as they directly impact the final product’s performance.

Once the materials are prepared, the next stage is forming. This involves mixing the rubber compounds with additives to enhance properties like weather resistance and flexibility. The mixture is then shaped into tire components, including the tread, sidewalls, and inner linings, using specialized machinery.

Molding is a critical step where the tire’s design is finalized. Manufacturers use precision molds to ensure that each tire has consistent dimensions and tread patterns. Buyers should look for suppliers who use advanced molding techniques that reduce defects and enhance the tire’s performance.

Illustrative image related to bike tire not inflating

After the components are formed, they are assembled into complete tires. This process usually involves layering the rubber and fabric to create the tire’s structure. The bead wires are inserted, and the components are then bonded together under heat and pressure.

Quality at this stage is essential, as improper assembly can lead to issues such as air leaks or tire blowouts. B2B buyers should assess whether the supplier has robust assembly protocols and whether they utilize automated systems to minimize human error.

The finishing stage includes several steps, such as trimming excess material, applying protective coatings, and conducting final inspections. This stage ensures that the tires meet aesthetic and functional standards before they are packaged and shipped.

Buyers should inquire about the finishing processes used by suppliers to ensure that all tires are visually appealing and free from defects. Additionally, it is crucial to understand how the supplier handles any post-production quality issues.

Quality assurance is integral to the manufacturing process of bike tires. Several international and industry-specific standards ensure that products meet safety and performance benchmarks.

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Manufacturers certified under ISO 9001 demonstrate their commitment to quality and continuous improvement. B2B buyers should prioritize suppliers with this certification, as it indicates a structured approach to quality management.

In addition to ISO 9001, other relevant certifications may include CE marking for compliance with European safety standards and API specifications for performance standards. Understanding these certifications can help buyers assess the credibility of their suppliers.

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process. These typically include:

Illustrative image related to bike tire not inflating

B2B buyers should ask suppliers about their specific QC processes and the frequency of inspections at each stage.

Verifying a supplier’s QC measures is crucial for ensuring that the products meet the required standards. Here are some methods buyers can use:

Regular audits are an effective way to assess a supplier’s quality management practices. Buyers should establish a schedule for audits and ensure that they cover all aspects of the manufacturing process. During these audits, buyers can review documentation, observe production processes, and conduct random product sampling.

Requesting quality control reports and testing data from suppliers can provide valuable insights into their manufacturing practices. Buyers should look for detailed reports that outline the results of various tests, such as tensile strength, puncture resistance, and air retention. This information can help buyers make informed decisions about supplier reliability.

Illustrative image related to bike tire not inflating

Engaging third-party inspection services can add an extra layer of assurance. These independent entities conduct thorough inspections and testing, ensuring that suppliers adhere to international standards. Buyers should consider partnering with accredited inspection agencies to verify the quality of their suppliers’ products.

When dealing with international suppliers, particularly from regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality control nuances.

Cultural attitudes toward quality can vary significantly across regions. In some areas, there may be a greater emphasis on quality, while in others, cost-saving measures might take precedence. B2B buyers should understand these cultural differences and consider them when evaluating potential suppliers.

Illustrative image related to bike tire not inflating

Additionally, regulatory environments differ from one country to another. Buyers should ensure that their suppliers comply with local regulations and international standards, particularly regarding safety and environmental impact.

Finally, logistics can affect the quality of bike tires during transportation. It’s important for buyers to ensure that their suppliers have robust logistics systems in place to minimize damage during shipping. Understanding the entire supply chain will enable buyers to make better decisions regarding supplier reliability.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures in bike tire production will empower B2B buyers to make informed decisions when selecting suppliers. By focusing on these critical areas, buyers can ensure they receive high-quality, reliable products that meet their specific needs.

This practical sourcing guide aims to equip B2B buyers with the essential steps to address the issue of bike tires that won’t inflate. This situation can be a significant barrier to sales and customer satisfaction, particularly in regions where cycling is a popular mode of transport. Following this checklist will help you identify reliable suppliers and solutions, ensuring you can meet your customers’ needs effectively.

Understanding the typical reasons for bike tires not inflating is crucial. Common issues include faulty valves, damaged tubes, or inadequate connections between the pump and the tire valve. By diagnosing these problems, you can specify the right products and solutions to your suppliers.

Illustrative image related to bike tire not inflating

Before sourcing, clearly define the technical specifications for the tires and pumps you need. This includes the size, valve type, and material requirements.

Diligently research potential suppliers who specialize in bike tires and accessories. Assess their reputation within the industry and their ability to deliver quality products.

Before making bulk purchases, request samples of the tires and pumps from potential suppliers. Testing these products in real-world scenarios will help you assess their performance and durability.

After-sales support is vital for resolving issues related to inflation and product failures. Ensure your suppliers offer reliable customer service and warranty options.

Develop a logistics plan for the timely delivery of your bike tire inventory. Efficient logistics will prevent stockouts and ensure you can address customer needs promptly.

Illustrative image related to bike tire not inflating

Stay informed about industry trends and gather customer feedback on the products you source. This ongoing research will help you adjust your offerings based on market demands.

By following these steps, B2B buyers can ensure they are well-prepared to source effective solutions for bike tires that won’t inflate, ultimately enhancing customer satisfaction and loyalty.

When analyzing the cost structure for sourcing solutions related to bike tires that won’t inflate, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materialien: The type of materials used in tire manufacturing can greatly influence costs. For instance, high-quality rubber compounds designed to prevent punctures or improve durability will be more expensive than standard materials. Additionally, the choice between tubeless and traditional tires also affects material costs.

Arbeit: Labor costs vary significantly based on geographic location. In regions like Africa and South America, labor may be less expensive compared to Europe, which can impact overall pricing strategies. Skilled labor for specialized manufacturing processes, such as producing tubeless tires or custom valve systems, can also add to costs.

Fertigungsgemeinkosten: This includes indirect costs associated with production, such as utilities, facility rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs, thereby lowering the final price.

Werkzeugbau: The initial investment in tooling is crucial, especially for customized solutions. High-quality molds and production tools can be costly but are essential for ensuring precision and consistency in tire production.

Qualitätskontrolle (QC): Implementing stringent quality control measures is vital to ensure product reliability. This includes testing for inflation capabilities and durability, which can add to the overall cost but is necessary to maintain customer satisfaction and minimize returns.

Logistik: Shipping and handling costs can fluctuate based on the distance between the supplier and buyer, as well as the chosen Incoterms. For international buyers, understanding these logistics costs is essential for accurate budgeting.

Marge: Suppliers typically apply a margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions, competition, and the perceived value of the product.

Several factors can influence pricing beyond the basic cost structure. These include volume or minimum order quantities (MOQ), specifications and customization options, material choices, quality certifications, supplier factors, and Incoterms.

Volumen/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for favorable pricing structures that account for higher volumes, especially if they anticipate ongoing demand.

Spezifikationen/Anpassung: Custom solutions tailored to specific market needs may incur additional costs. Buyers should assess whether the benefits of customization outweigh the extra expenses.

Materialien: The choice of materials can significantly impact pricing. Eco-friendly materials or advanced rubber compounds may cost more but can lead to increased sales due to market demand for sustainable products.

Quality/Certifications: Products that meet international quality standards or possess certifications (such as ISO or CE) can command higher prices. Buyers should consider the long-term benefits of investing in higher-quality products.

Lieferanten-Faktoren: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with proven track records may charge a premium but can provide better assurance of quality and timely delivery.

Incoterms: Understanding the implications of Incoterms on shipping costs and responsibilities is essential for international buyers. Choosing the right terms can lead to cost savings and clearer expectations regarding logistics.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and understanding pricing nuances are critical.

Verhandlung: Engage suppliers in discussions about pricing, focusing on long-term relationships that can lead to better terms. Highlighting potential for repeat business can be a powerful negotiation tool.

Kosteneffizienz: Assess the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, durability, and potential return on investment. This holistic view can justify higher upfront costs for better products.

Nuancen in der Preisgestaltung: Be aware of regional market dynamics that may affect pricing. For example, tariffs, import duties, and local competition can influence the final cost of sourcing products.

Haftungsausschluss für Richtpreise: Prices can fluctuate based on market conditions, so it is advisable to obtain formal quotes and verify costs before making purchasing decisions. Always factor in potential currency exchange impacts when dealing with international suppliers.

By understanding these components and tips, buyers can make informed decisions that enhance their sourcing strategy and ultimately lead to better product performance in the marketplace.

In the realm of cycling, encountering a bike tire that won’t inflate can be frustrating and time-consuming, especially for businesses involved in the sale, maintenance, or rental of bicycles. Understanding viable alternatives to address this issue can enhance operational efficiency and customer satisfaction. Below, we compare the scenario of a bike tire not inflating with two alternative solutions: using tubeless tires and employing portable electric pumps.

| Vergleich Aspekt | Bike Tire Not Inflating | Tubeless Tires | Portable Electric Pumps |

|---|---|---|---|

| Leistung | Limited to manual inflation; may lead to inconsistent pressure | Consistent pressure; reduces pinch flats | Quick inflation; can achieve desired pressure efficiently |

| Kosten | Low initial investment; but may incur costs for repairs | Higher upfront cost; potential savings on tube replacements | Moderate cost; varies by brand and features |

| Leichte Implementierung | Requires manual effort and knowledge of tire mechanics | Installation may require expertise; can be DIY | Easy to use; plug-and-play design suitable for all users |

| Wartung | Regular checks required; may need tube replacements | Minimal maintenance; occasional sealant replenishment needed | Requires battery charging; some models need regular cleaning |

| Bester Anwendungsfall | Suitable for basic cycling needs; ideal for casual riders | Best for serious cyclists; ideal for off-road and long-distance rides | Excellent for quick fixes; perfect for emergencies and convenience |

Tubeless Tires

Tubeless tires eliminate the need for inner tubes, which can reduce the incidence of punctures and pinch flats. They offer the advantage of maintaining consistent tire pressure, which enhances performance and ride quality. However, the initial investment is higher compared to traditional tires, and installation may require specific tools or expertise. Tubeless systems also necessitate occasional maintenance, such as adding sealant, which can be a barrier for some users. Nevertheless, for businesses targeting performance-driven cyclists, tubeless tires provide a compelling solution.

Portable Electric Pumps

Portable electric pumps represent a convenient alternative for inflating bike tires. They are easy to use, allowing cyclists to achieve the desired tire pressure quickly without manual pumping effort. These pumps typically feature built-in pressure gauges, ensuring accuracy and reducing the chances of over-inflation. However, the cost of these pumps can vary widely, and they may require regular charging or battery replacement. For B2B buyers, investing in portable electric pumps can enhance customer experience, particularly in rental or repair services, by providing a reliable solution for on-the-go inflation.

Illustrative image related to bike tire not inflating

When evaluating solutions for the common issue of bike tires not inflating, B2B buyers should consider their specific operational needs and customer demographics. For businesses focused on high-performance cycling, tubeless tires may offer significant advantages, despite higher initial costs. Conversely, if convenience and quick service are priorities, portable electric pumps can enhance customer satisfaction and operational efficiency. Ultimately, the right choice will depend on balancing cost, performance, and the unique needs of your target market.

When addressing the issue of bike tires not inflating, understanding the technical properties involved is crucial for B2B buyers. Here are several critical specifications:

Valve Type and Compatibility

Bike tires are equipped with different valve types, primarily Schrader and Presta. Schrader valves are wider and resemble car tire valves, while Presta valves are narrower and commonly found on high-performance bikes. Understanding the compatibility of pumps with these valves is essential to ensure successful inflation. B2B buyers should consider stocking pumps that accommodate both types to meet diverse customer needs.

Material Klasse

The rubber compound used in the tire tube significantly impacts its durability and air retention capabilities. Higher-grade materials can withstand punctures and provide better sealing, reducing the likelihood of leaks. B2B suppliers should focus on sourcing tires made from high-quality materials to ensure customer satisfaction and minimize returns due to inflation issues.

Pressure Tolerance

Each bike tire has a specified pressure range, typically measured in PSI (pounds per square inch). Understanding the pressure tolerance is vital for ensuring optimal performance and safety. If a tire is inflated beyond its tolerance, it can lead to blowouts. B2B buyers must ensure that the tires they offer meet the pressure requirements for the intended bike type and usage.

Seal Integrity

The ability of the tire tube to hold air is heavily influenced by the integrity of its seals. Imperfections in the manufacturing process or wear over time can compromise the seal, leading to rapid air loss. B2B suppliers should prioritize products with stringent quality control measures to enhance seal integrity and reduce customer complaints regarding inflating issues.

Tubeless Technology

Tubeless tires offer the advantage of eliminating the inner tube, thus reducing the risk of pinch flats and allowing for lower pressure riding. However, they require a specific setup, including sealants and compatible rims. B2B buyers should be aware of the growing trend towards tubeless systems and consider offering related products and services to meet market demands.

Weight Considerations

The weight of the tire affects the overall performance of the bicycle. Lighter tires can improve speed and handling, but may sacrifice durability. B2B buyers should assess the balance between weight and durability when selecting products, ensuring they cater to different customer preferences.

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some key terms relevant to bike tire inflation:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bike tires, sourcing OEM products ensures that the tires meet specific performance standards and are compatible with various bike models.

MOQ (Mindestbestellmenge)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ helps in inventory planning and managing costs, especially when dealing with niche products like specialized bike tires.

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. When dealing with bike tires, submitting an RFQ can help buyers compare prices and terms from multiple suppliers, ensuring they get the best deal.

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers involved in importing bike tires to ensure clarity on shipping costs, risks, and delivery responsibilities.

Vorlaufzeit

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For bike tires, understanding lead times can help businesses manage inventory effectively and meet customer demands without delays.

Warranty and Guarantee

Warranty refers to a manufacturer’s promise to repair or replace a product if necessary within a specified period. Offering warranties on bike tires can enhance buyer confidence and reduce the perceived risk of purchasing, making it an important consideration for B2B suppliers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operations and meet customer needs effectively.

The bike tire not inflating sector is witnessing significant shifts driven by various global factors. The increasing popularity of cycling as a sustainable transport option, alongside a growing emphasis on outdoor recreational activities, is fueling demand for high-quality bike tires. In regions like Africa and South America, where cycling is becoming a preferred mode of transport due to economic constraints, suppliers are seeing an opportunity to cater to a burgeoning market. In Europe, particularly in Germany, the trend towards e-bikes is influencing tire specifications, requiring innovations in valve technology and puncture resistance.

Illustrative image related to bike tire not inflating

Emerging technologies in tire manufacturing are also reshaping the landscape. The adoption of advanced materials that enhance durability and reduce weight is a key trend. B2B buyers are increasingly seeking suppliers who leverage these technologies to provide reliable products that meet the demands of both casual cyclists and professional riders. Furthermore, the rise of digital platforms for sourcing and distribution is changing how businesses interact with suppliers, enabling more efficient procurement processes and better visibility into product offerings.

Sustainability has become a pivotal concern for B2B buyers in the bike tire sector. Environmental impacts associated with tire production, such as carbon emissions and waste generation, are prompting businesses to seek eco-friendly alternatives. Buyers are increasingly looking for suppliers who prioritize sustainable practices, such as using recycled materials and minimizing chemical usage in tire manufacturing. This shift is particularly relevant for international buyers from regions like Europe, where stringent regulations on environmental standards are being implemented.

Ethical sourcing is equally important. Ensuring that supply chains are transparent and uphold labor rights is vital for maintaining brand integrity. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are becoming critical factors in supplier selection. B2B buyers are encouraged to seek partnerships with manufacturers who have these certifications, as they not only ensure compliance but also resonate with consumers who are increasingly aware of the ethical implications of their purchases.

The bike tire industry has evolved significantly over the past century, transitioning from solid rubber tires to the modern pneumatic designs we see today. Initially, the focus was solely on functionality, with little regard for factors such as weight or performance. However, with the rise of competitive cycling in the 20th century, manufacturers began to innovate, leading to the introduction of lighter materials and better inflation technologies.

In recent decades, the advent of tubeless tires and advancements in valve systems have revolutionized the market. These innovations not only improve performance but also address common issues such as air retention and puncture resistance, directly impacting the bike tire not inflating problem. As B2B buyers navigate this historical landscape, understanding these advancements can inform better sourcing decisions and highlight the importance of selecting suppliers who are at the forefront of technological innovation.

Navigating the complexities of the bike tire not inflating sector requires a comprehensive understanding of market dynamics, sustainability trends, and the historical context of product evolution. By leveraging insights into these areas, international B2B buyers can make informed decisions that align with both their operational needs and the growing expectations of environmentally-conscious consumers. As the sector continues to evolve, staying ahead of these trends will be key to maintaining a competitive edge in the marketplace.

How do I solve the issue of bike tires not inflating?

To address bike tires that won’t inflate, first check the valve type (Schrader or Presta) and ensure the pump is compatible. Inspect the valve for blockages or damage; a faulty valve core can prevent air from entering. Additionally, verify that the pump head is securely attached to the valve to avoid leaks. If the tire remains unresponsive, inspect for punctures or leaks in the inner tube, which may require replacement. Regular maintenance and carrying spare tubes can also help mitigate inflation issues.

What is the best pump for inflating bike tires?

The ideal pump for bike tires depends on the valve type and intended use. Floor pumps are excellent for home use due to their efficiency and speed, while mini or hand pumps are suitable for on-the-go repairs. Look for pumps with dual-head designs that accommodate both Schrader and Presta valves. Brands like Topeak, Lezyne, and Blackburn are known for their reliability. Additionally, consider pumps with built-in pressure gauges for accurate inflation, which is particularly beneficial for high-performance tires.

How can I evaluate the quality of bike tires from suppliers?

To assess the quality of bike tires, request samples from potential suppliers and conduct a thorough inspection. Check for manufacturing defects, material quality, and tread design. Inquire about the tire’s performance metrics, such as puncture resistance and durability. Additionally, review supplier certifications and compliance with international quality standards. Customer feedback and reviews can also provide insights into tire performance in various conditions, helping you make an informed purchasing decision.

What are common issues with bike tire valves?

Bike tire valves can experience several issues, including blockages, damaged cores, or improper sealing. For Presta valves, ensure the tip is unscrewed and not stuck, as this can prevent air from entering. In Schrader valves, debris can obstruct airflow. Regular maintenance, including cleaning the valve area and checking for wear, is essential. Consider carrying spare valve cores, particularly for tubeless systems, to quickly resolve valve-related problems while on the road.

What is the minimum order quantity (MOQ) for bike tires?

Minimum order quantities for bike tires can vary significantly by supplier and region. Typically, MOQs range from 50 to 500 units, depending on the manufacturer’s production capacity and the tire type. It’s advisable to discuss your specific needs with suppliers, as some may offer flexible terms for new customers or larger orders. Additionally, consider consolidating orders with other products to meet MOQ requirements while optimizing shipping costs.

How do I ensure timely logistics for international tire shipments?

To secure timely logistics for international shipments of bike tires, partner with reliable freight forwarders experienced in handling bicycle components. Confirm shipping terms, including Incoterms, to understand responsibilities for customs clearance and delivery. It’s beneficial to track shipments using online tools provided by logistics partners. Plan for potential delays by accounting for customs processing times and seasonal fluctuations in shipping demand, especially during peak cycling seasons.

What payment terms should I negotiate with tire suppliers?

When negotiating payment terms with tire suppliers, consider options such as net 30, net 60, or even letter of credit for larger orders. Establishing a clear payment schedule can enhance cash flow management while building a trustworthy relationship with suppliers. Be aware of any upfront deposits or fees associated with custom orders. It’s also wise to inquire about discounts for early payments or bulk orders, which can improve your overall procurement costs.

How can I vet suppliers for bike tires effectively?

Effective vetting of bike tire suppliers involves a multi-faceted approach. Start by reviewing their company history, product range, and customer testimonials. Request references from other businesses that have sourced tires from them. Assess their manufacturing capabilities and compliance with international quality standards. Conduct on-site visits if possible, and consider using third-party inspection services to verify quality before placing significant orders. Building a strong relationship with trustworthy suppliers is crucial for long-term success.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: The user is experiencing an issue with a flat front tire on their bicycle, where air is not pumping into the tire. The valve is described as loose and moves up and down easily, unlike the back tire which is functioning properly. The user is uncertain whether the tire has a tube or is tubeless and has received suggestions that the problem may be related to the tube or the valve. They are seeking ad…

Bereich: bicycles.stackexchange.com

Registriert: 2009 (16 Jahre)

Einleitung: The bike has Schrader valves and the pump works for any type of valve. The pump may have a faulty piston seal or may not be making a good seal with the valve stem. Possible solutions include testing the pump with a different tube, ensuring a good connection between the pump and valve, and checking for leaks.

Bereich: roadbikerider.com

Registriert: 2001 (24 Jahre)

Einleitung: Park Tool’s VC-1 valve-core removal tool; Presta valve cores (universal fitting); spare tubes with replaceable valve cores; 2.5mm allen wrench for clearing sealant plugs.

Bereich: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, Facebook – Bike Repair Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: bikeforums.net

Registriert: 2001 (24 Jahre)

Einleitung: Airtool Sport Floor Pump, $45, designed for high-pressure tires, includes a pressure gauge, compatible with Presta valves.

The challenges associated with bike tires not inflating highlight the importance of strategic sourcing for B2B buyers in the cycling industry. Understanding the root causes—such as faulty valves, poor seals, or damaged pumps—enables suppliers to identify and offer high-quality components and solutions that address these common issues. By investing in reliable products, businesses can enhance customer satisfaction and reduce the frequency of returns due to tire inflation problems.

As international buyers from diverse regions like Africa, South America, the Middle East, and Europe seek to optimize their supply chains, it is crucial to prioritize partnerships with manufacturers who emphasize quality and durability in their offerings. This proactive approach not only mitigates operational challenges but also positions businesses to capitalize on emerging market trends, ultimately leading to increased profitability.

Looking ahead, it is vital for B2B buyers to stay informed about innovations in tire technology and inflation mechanisms. By fostering relationships with forward-thinking suppliers, businesses can ensure they are equipped to meet consumer demands and enhance their competitive edge in the market. Embrace the opportunity to refine your sourcing strategies and secure your place in the evolving landscape of the cycling industry.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.