In today’s competitive landscape, effectively sourcing Black and Decker tire inflator parts can pose significant challenges for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe—including key markets like Germany and Nigeria—finding reliable suppliers who offer authentic parts at competitive prices is essential for maintaining operational efficiency. This guide is designed to navigate the complexities of the global market for Black and Decker tire inflator parts, ensuring that you can make informed purchasing decisions.

Within this comprehensive resource, we delve into various aspects of tire inflator parts, including their types, applications, and the importance of using genuine components for optimal performance. We also explore effective strategies for vetting suppliers, assessing costs, and understanding shipping logistics tailored to your region. By equipping you with actionable insights and a clear framework for sourcing, this guide empowers you to enhance your procurement process and mitigate risks associated with counterfeit or subpar products.

Ultimately, our goal is to help you streamline your supply chain, reduce downtime, and ensure that your operations are supported by high-quality inflator parts. With the right knowledge at your fingertips, you can confidently navigate the global marketplace and secure the components necessary for your business success.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Air Hose End | Connects inflator to tire; often includes quick-release. | Automotive repair shops, tire service centers. | Vorteile: Essential for tire inflation; easy to replace. Nachteile: May wear out over time, requiring frequent replacements. |

| Regulator Repair Kit | Contains components to fix air pressure regulation issues. | Maintenance services for inflators/compressors. | Vorteile: Restores functionality; cost-effective solution. Nachteile: Requires technical knowledge for installation. |

| Gaskets and Seals | Prevent air leaks; critical for maintaining pressure. | Manufacturing, automotive, and repair industries. | Vorteile: Improves efficiency; essential for safety. Nachteile: May degrade over time; regular checks needed. |

| Drain Valve | Allows moisture removal from compressor tanks. | Industrial applications, automotive maintenance. | Vorteile: Prevents rust; extends equipment life. Nachteile: Can clog if not maintained; may need periodic replacement. |

| Pump Assembly | Core component for air compression; includes motor and piston. | Heavy-duty tire shops, commercial automotive service. | Vorteile: Central to inflator function; durable. Nachteile: Higher replacement cost; requires professional installation. |

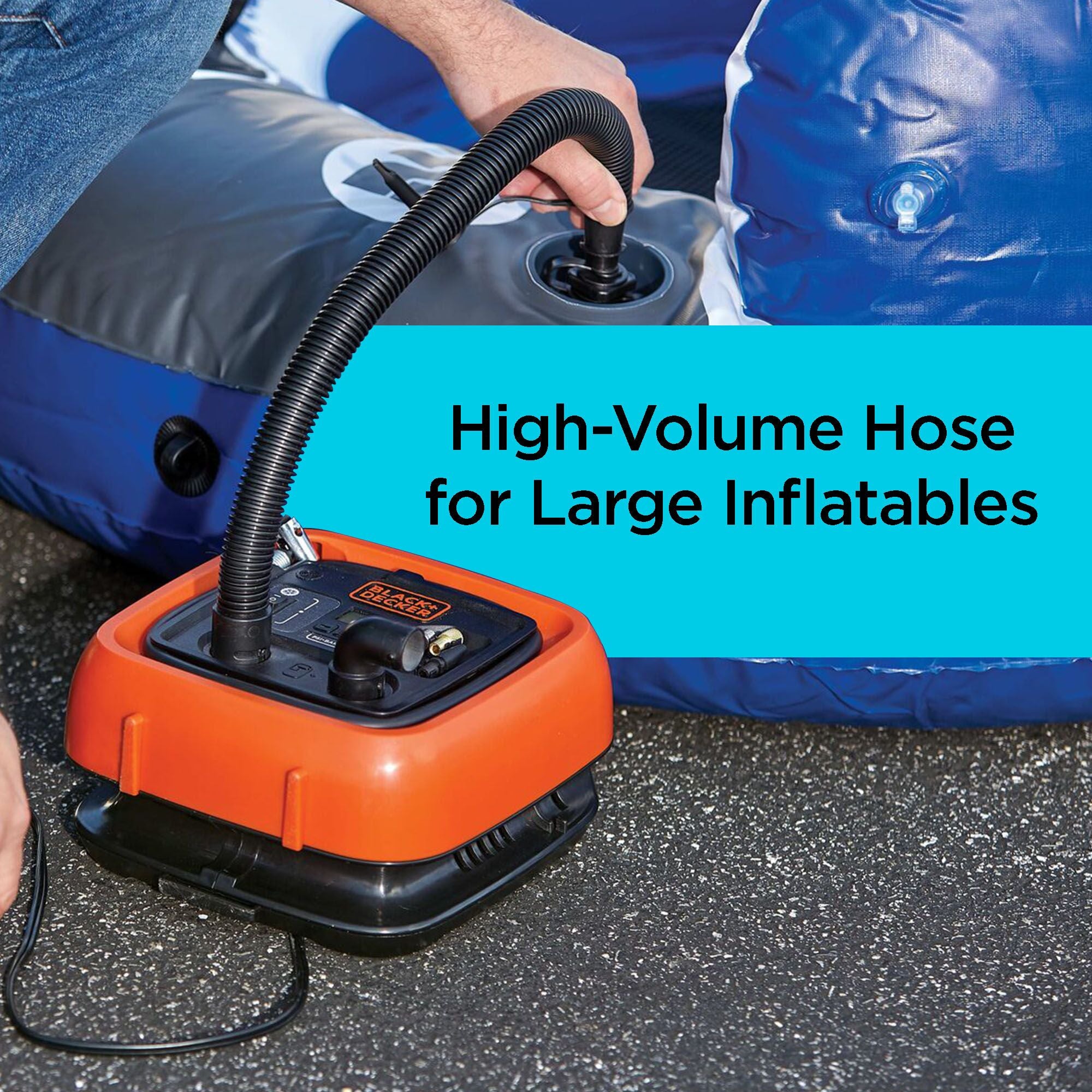

The air hose end is a crucial part of Black and Decker tire inflators, designed to connect the inflator to the tire valve. Typically featuring a quick-release mechanism, it ensures a secure and efficient air transfer process. In B2B applications, particularly in automotive repair shops and tire service centers, having reliable air hose ends is essential for maintaining operational efficiency. Buyers should consider the durability and compatibility of these parts with various tire inflator models, as wear and tear can lead to frequent replacements.

A regulator repair kit is vital for addressing air pressure regulation issues in Black and Decker tire inflators. This kit includes various components that restore the inflator’s ability to maintain consistent air pressure, which is critical for tire inflation accuracy. B2B buyers, particularly those in maintenance services, should evaluate the ease of installation and the technical expertise required. Investing in a regulator repair kit can be a cost-effective way to prolong the life of inflators, ensuring they remain efficient and reliable.

Gaskets and seals are integral to the functionality of Black and Decker tire inflators, as they prevent air leaks and maintain pressure. In industries such as manufacturing and automotive repair, the efficiency of inflators directly impacts productivity. B2B purchasers should prioritize the quality and compatibility of gaskets and seals, as degraded parts can lead to performance issues. Regular inspections and replacements are necessary to ensure safety and operational effectiveness.

Illustrative image related to black and decker tire inflator parts

The drain valve is a component that allows for the removal of moisture from compressor tanks, which is essential for preventing rust and corrosion. In industrial applications and automotive maintenance, a functioning drain valve is crucial for extending the life of equipment. Buyers must consider the maintenance requirements of drain valves, as they can clog if not regularly cleaned. Investing in high-quality drain valves can help organizations avoid costly equipment failures and ensure consistent performance.

The pump assembly is the heart of Black and Decker tire inflators, comprising the motor and piston that facilitate air compression. This component is critical in heavy-duty tire shops and commercial automotive services, where reliable and efficient tire inflation is paramount. Buyers should evaluate the durability and serviceability of pump assemblies, as they represent a significant investment. While they are designed for longevity, professional installation may be necessary, particularly for complex or high-capacity models.

| Industrie/Sektor | Specific Application of black and decker tire inflator parts | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparatur | Tire inflation and maintenance for vehicles | Ensures safety and performance of vehicles, reducing breakdowns. | Reliability of parts, availability of OEM vs. aftermarket options. |

| Logistik und Verkehr | Fleet tire management and servicing | Minimizes downtime and enhances operational efficiency. | Bulk purchasing options, compatibility with various vehicle models. |

| Bauwesen | Inflation of pneumatic tools and equipment | Increases productivity by ensuring tools are always operational. | Durability of parts, ease of maintenance and replacement. |

| Landwirtschaft | Inflation of agricultural vehicle tires | Enhances performance and reduces tire-related accidents on farms. | Weather resistance, and adaptability to different soil conditions. |

| Retail Automotive Parts | Retail and distribution of tire inflator parts | Expands product offerings, attracting more customers. | Demand forecasting, inventory management, and supplier reliability. |

In the automotive repair industry, Black and Decker tire inflator parts are crucial for maintaining tire pressure and ensuring vehicle safety. These parts facilitate quick and efficient tire inflation, which is essential for avoiding potential accidents due to under-inflated tires. Repair shops often require reliable inflator components to minimize customer wait times and enhance service quality. International buyers, particularly in regions like Africa and South America, should focus on sourcing durable parts that can withstand varying climate conditions.

In logistics and transport, maintaining fleet tire pressure is vital for operational efficiency. Black and Decker tire inflator parts are used to service multiple vehicles, ensuring they are roadworthy and reducing the risk of breakdowns. This proactive maintenance approach can significantly cut down on downtime, leading to cost savings for companies. Buyers in Europe and the Middle East should consider bulk purchasing to ensure they have a consistent supply of parts that are compatible with a diverse fleet.

In the construction sector, Black and Decker tire inflator parts are employed to inflate pneumatic tools and heavy machinery tires. This ensures that equipment operates at optimal performance levels, thereby increasing productivity on job sites. Given the demanding environments in which construction equipment operates, buyers should prioritize sourcing high-quality, robust parts that can endure wear and tear. Additionally, ease of maintenance is a critical factor for international buyers to consider.

Illustrative image related to black and decker tire inflator parts

Agricultural vehicles rely heavily on properly inflated tires for effective operation across various terrains. Black and Decker tire inflator parts help farmers maintain tire pressure, reducing the likelihood of accidents and improving overall vehicle performance. This is particularly important in regions like Africa, where agricultural machinery plays a key role in food production. Buyers should look for parts that offer weather resistance and adaptability to different soil conditions to ensure longevity and reliability.

Retail automotive parts businesses can expand their product offerings by including Black and Decker tire inflator parts. This diversification not only attracts a broader customer base but also meets the growing demand for reliable tire maintenance solutions. Retailers should focus on demand forecasting and effective inventory management to ensure they can meet customer needs promptly. Sourcing from reputable suppliers that guarantee quality can enhance customer satisfaction and loyalty, especially in competitive markets across Europe and South America.

Das Problem: B2B buyers often face challenges in sourcing genuine Black and Decker tire inflator parts due to the proliferation of counterfeit products in the market. This issue is particularly prominent in regions where brand recognition is low, leading to the purchase of substandard parts that do not meet performance expectations. For companies relying on these inflators for operations—such as tire repair services or automotive maintenance—using counterfeit parts can result in frequent breakdowns, increased maintenance costs, and potential safety hazards.

Die Lösung: To ensure you are purchasing genuine Black and Decker parts, always source from authorized distributors or the official Black and Decker website. Establish a relationship with reputable suppliers who have a proven track record of providing OEM (Original Equipment Manufacturer) parts. Additionally, consider implementing a verification process for any parts received, such as checking part numbers against manufacturer specifications. Training your procurement team to identify genuine parts can also mitigate risks associated with counterfeit products, ensuring operational efficiency and safety.

Illustrative image related to black and decker tire inflator parts

Das Problem: Another common pain point for B2B buyers is the incompatibility of replacement parts with existing tire inflator models. Many businesses operate a mixed fleet of inflators, and ordering parts without confirming compatibility can lead to wasted resources and downtime. This issue is especially critical in industries where time is of the essence, such as automotive service centers that require quick turnaround times for tire changes.

Die Lösung: To avoid compatibility issues, maintain an updated inventory of inflator models and their corresponding part numbers. When ordering parts, always cross-reference the model number of your inflator with the part specifications provided by suppliers. Utilize online databases or catalogs from Black and Decker that allow for easy searching based on model numbers. Additionally, consider investing in a parts management system that integrates with your inventory software to streamline the ordering process and ensure that the correct parts are always sourced.

Das Problem: B2B buyers often struggle with a lack of technical support when it comes to installing or troubleshooting Black and Decker tire inflator parts. This gap can lead to improper installations, which can compromise the functionality of the inflators and lead to costly repairs. Businesses, especially those in remote areas, may find it difficult to access immediate assistance, resulting in prolonged downtime.

Illustrative image related to black and decker tire inflator parts

Die Lösung: To enhance support, invest in training sessions for your technical team, focusing on the specific models and parts of Black and Decker inflators. Many manufacturers, including Black and Decker, provide online resources such as installation videos, manuals, and FAQs. Encourage your team to utilize these resources and consider establishing a partnership with local service providers who can offer on-site support for complex installations. Additionally, joining online forums or professional networks can provide valuable insights and troubleshooting tips from other industry professionals who have faced similar challenges.

When selecting materials for Black and Decker tire inflator parts, it is essential to consider the specific properties that will affect performance, durability, and cost. Below, we analyze four common materials used in these parts, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is frequently used in the housing and components of tire inflators.

Illustrative image related to black and decker tire inflator parts

Rubber is commonly used for seals, gaskets, and hoses in tire inflators due to its flexibility and sealing properties.

Metals, such as aluminum and stainless steel, are often used in structural components and high-stress areas of tire inflators.

Composite materials, which combine plastics and fibers, are increasingly used in tire inflator components.

| Material | Typical Use Case for black and decker tire inflator parts | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kunststoff | Gehäuse und nicht-strukturelle Komponenten | Leicht und kostengünstig | Less durable under high stress | Niedrig |

| Gummi | Seals, gaskets, and hoses | Ausgezeichnete Dichtungseigenschaften | Susceptible to wear and UV damage | Mittel |

| Metall | Structural components and high-stress areas | Hohe Festigkeit und Haltbarkeit | Höhere Kosten und komplexere Herstellung | Hoch |

| Komposit | Portable inflator components | Hohes Verhältnis von Festigkeit zu Gewicht | Teurer und komplexer in der Herstellung | Mittel |

This strategic material selection guide provides B2B buyers with insights into the materials used in Black and Decker tire inflator parts, enabling informed decisions tailored to their regional requirements and applications.

Illustrative image related to black and decker tire inflator parts

The manufacturing of Black & Decker tire inflator parts involves a series of well-defined stages to ensure that the components meet high standards of quality and performance. The primary stages include:

Vorbereitung des Materials: This initial phase involves sourcing high-quality raw materials, such as metals and plastics, which are essential for the durability and functionality of inflator parts. Suppliers are often vetted based on their ability to provide materials that comply with international standards, ensuring reliability and performance.

Bildung von: In this stage, the prepared materials undergo various forming processes. Techniques such as injection molding for plastics and stamping for metals are commonly employed. These methods allow for precise shaping and dimensional accuracy, which are crucial for the parts to fit and function correctly.

Montage: After forming, the individual components are assembled. This process can involve manual labor or automated systems, depending on the complexity of the parts. For tire inflators, components like valves, hoses, and electronic assemblies must be carefully integrated to ensure the final product operates efficiently.

Fertigstellung: The final stage involves surface treatments and coatings that enhance the aesthetic appeal and resistance to wear and corrosion. Techniques such as painting, powder coating, or anodizing are applied. This not only improves the product’s longevity but also complies with regulatory requirements regarding safety and environmental impact.

Quality assurance is critical in maintaining the integrity and reliability of Black & Decker tire inflator parts. Several international and industry-specific standards guide these processes:

ISO 9001-Zertifizierung: This standard emphasizes a process-based approach to quality management. Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Compliance with ISO 9001 is a strong indicator of a supplier’s commitment to quality.

CE-Kennzeichnung: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards. This is particularly important for inflator parts that may be subject to rigorous testing before entering the European market.

API-Normen: For components used in more technical applications, adherence to American Petroleum Institute (API) standards may be necessary. These standards ensure that parts can withstand specific operational conditions, particularly for inflators used in industrial or heavy-duty contexts.

To uphold quality standards, manufacturers implement several checkpoints throughout the production process:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint involves inspecting raw materials before they enter the manufacturing process. This ensures that only materials meeting specified standards are used, reducing defects in the final product.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, IPQC measures are taken to monitor production and identify any deviations from quality standards. This can include regular inspections and tests of components at various stages of manufacturing.

Endgültige Qualitätskontrolle (FQC): The final inspection ensures that the assembled product meets all design specifications and quality standards before shipping. This includes testing for functionality, durability, and safety.

Various testing methods are employed to verify the quality and performance of tire inflator parts:

Funktionelle Prüfung: This involves checking if the inflator operates as intended. It includes testing the pressure output, flow rate, and safety features.

Dauerhaftigkeitsprüfung: Parts are subjected to stress tests to simulate long-term use. This helps identify potential failure points and ensures that the product can withstand everyday wear and tear.

Sicherheitsprüfung: Compliance with safety standards is verified through rigorous testing to ensure that all components are safe for consumer use. This includes electrical safety tests for any electronic components.

B2B buyers need to ensure that their suppliers adhere to stringent quality control measures. Here are practical steps they can take:

Illustrative image related to black and decker tire inflator parts

Lieferanten-Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This allows buyers to assess compliance with international standards.

Anforderung von Qualitätsberichten: Buyers should request quality assurance documentation, including ISO certifications and quality control reports. This helps verify that the supplier meets the required standards.

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct checks at various stages of production, offering additional assurance to buyers.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding quality control nuances is vital:

Einhaltung von Vorschriften: Buyers must be aware of different regulatory requirements in their regions. For instance, compliance with CE marking is essential for European buyers, while other regions may have distinct safety standards.

Kulturelle Erwägungen: Different regions may have varying expectations regarding quality and service. Buyers should consider these cultural differences when evaluating suppliers and negotiating terms.

Logistics and Supply Chain: The complexities of international shipping can affect product quality. Buyers should ensure that suppliers have robust logistics and handling processes to mitigate risks during transportation.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing Black & Decker tire inflator parts, ensuring they receive high-quality products that meet their operational needs.

Sourcing Black & Decker tire inflator parts requires a strategic approach to ensure quality, compatibility, and timely delivery. This practical checklist will guide B2B buyers through the essential steps to effectively procure these parts, catering to diverse international markets including Africa, South America, the Middle East, and Europe.

Illustrative image related to black and decker tire inflator parts

Before initiating the sourcing process, clearly outline the technical specifications of the parts you need. This includes identifying the model numbers and specific components required for the inflators you are servicing. A precise specification helps in avoiding compatibility issues and ensures that you receive the correct parts.

Conduct thorough research to identify suppliers with a proven track record in providing Black & Decker parts. Look for suppliers that specialize in power tool components and have a solid reputation in your target regions.

Before finalizing any order, request samples of the tire inflator parts to evaluate their quality and compatibility. This is a critical step to ensure that the products meet your standards and specifications.

Ensure that your chosen suppliers have the necessary certifications and comply with industry standards. This is particularly important for quality assurance and regulatory compliance in your region.

Engage in discussions with suppliers to negotiate favorable terms, including pricing, payment methods, and delivery timelines. Effective negotiation can lead to better pricing structures and stronger partnerships.

Illustrative image related to black and decker tire inflator parts

Setting up clear lines of communication with your suppliers is essential for a smooth procurement process. Establishing these channels helps in addressing any issues promptly and ensures transparency.

After successfully sourcing the parts, ensure that you have a plan for after-sales support. This includes understanding warranty policies, return processes, and technical support availability.

By following this checklist, B2B buyers can effectively navigate the sourcing process for Black & Decker tire inflator parts, ensuring a successful procurement that meets their operational needs.

Illustrative image related to black and decker tire inflator parts

When sourcing Black & Decker tire inflator parts, understanding the cost structure is crucial. The primary cost components include:

Materialien: The quality and type of materials used significantly influence the cost. For tire inflators, durable plastics, metals, and rubber components are common. Sourcing high-grade materials can increase initial costs but may reduce long-term failures and replacements.

Arbeit: Labor costs can vary based on the region and the complexity of assembly. Countries with lower labor costs may provide competitive pricing, but quality and expertise in handling specific parts should be considered.

Fertigungsgemeinkosten: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

Werkzeugbau: Initial setup for production, including molds and specific machinery for inflator parts, can be a significant upfront cost. However, these costs are amortized over production volume.

Qualitätskontrolle (QC): Implementing robust QC measures ensures that parts meet the required specifications. While this adds to the cost, it helps in minimizing defects and improving customer satisfaction.

Logistik: Transportation costs can vary based on the distance and mode of transport. International shipping, customs duties, and handling fees must be factored into the overall cost.

Marge: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the supplier’s margin can aid in negotiation.

Several factors influence pricing when sourcing Black & Decker tire inflator parts:

Volumen/MOQ (Mindestbestellmenge): Suppliers often provide discounts for larger orders. Understanding the volume requirements can lead to significant cost savings.

Spezifikationen und Anpassungen: Custom parts or modifications can increase costs due to the need for specialized tooling or materials. Clearly defining specifications upfront can streamline the process and control costs.

Materials Quality and Certifications: High-quality materials and certifications (like ISO standards) can increase costs but may be necessary for specific markets, especially in Europe.

Lieferanten-Faktoren: The reliability, reputation, and production capacity of suppliers can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

Incoterms: The choice of Incoterms affects logistics costs and risk. For instance, FOB (Free on Board) may shift some costs to the buyer, while DDP (Delivered Duty Paid) includes shipping and customs in the seller’s price, simplifying budgeting.

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should adopt strategic approaches to negotiation:

Verstehen der Gesamtbetriebskosten (TCO): Look beyond the initial purchase price. Consider long-term costs such as maintenance, failure rates, and warranty support. A slightly higher upfront cost may lead to lower TCO.

Be Transparent in Negotiations: Share your sourcing goals and constraints with suppliers. This openness can foster trust and encourage suppliers to offer competitive pricing.

Leverage Market Knowledge: Research current market trends and pricing for similar parts. Knowledge of competitor pricing can provide leverage in negotiations.

Lokale Zulieferer berücksichtigen: Sourcing from local suppliers may reduce logistics costs and lead times. This can be particularly advantageous for urgent repairs or replacements.

Negotiate Payment Terms: Discuss payment options that can ease cash flow, such as extended payment terms or installment payments, especially for larger orders.

Navigating the complexities of cost and pricing for Black & Decker tire inflator parts is essential for international B2B buyers. A thorough understanding of cost components and pricing influencers enables informed sourcing decisions, ultimately leading to better profitability and efficiency. Always consider local market dynamics and supplier capabilities to optimize your sourcing strategy.

Illustrative image related to black and decker tire inflator parts

Haftungsausschluss: Prices mentioned are indicative and can fluctuate based on market conditions, exchange rates, and supplier negotiations. Always verify with suppliers for the most accurate pricing.

In the competitive landscape of tire inflators, understanding alternative solutions is crucial for B2B buyers seeking efficiency, cost-effectiveness, and reliability. While Black and Decker tire inflator parts are well-regarded, evaluating other options can lead to better purchasing decisions tailored to specific operational needs.

| Vergleich Aspekt | Black And Decker Tire Inflator Parts | Portable Battery-Powered Inflator | Heavy-Duty Air Compressor |

|---|---|---|---|

| Leistung | Reliable for standard tire inflation | Quick inflation for small tires | High volume, multi-use capability |

| Kosten | Moderate pricing | Im Allgemeinen niedrigere Kosten | Higher initial investment |

| Leichte Implementierung | User-friendly, minimal setup | Extremely portable, easy to use | Requires installation and setup |

| Wartung | Low, with readily available parts | Low maintenance, but limited durability | Higher maintenance due to complexity |

| Bester Anwendungsfall | Personal and light commercial use | Ideal for emergency situations | Suitable for workshops and heavy-duty applications |

1. Portable Battery-Powered Inflator

Portable battery-powered inflators are compact and designed for quick, on-the-go tire inflation. Their primary advantage lies in their ease of use and portability, making them ideal for emergency situations, especially for travelers or those in remote areas. However, they often lack the power required for larger tires or heavy-duty applications, making them less suitable for commercial use. The cost is generally lower than that of Black and Decker parts, but the trade-off is often a shorter lifespan and reduced reliability over time.

Illustrative image related to black and decker tire inflator parts

2. Heavy-Duty Air Compressor

Heavy-duty air compressors provide substantial power and versatility, suitable for a range of applications beyond tire inflation, such as powering pneumatic tools. Their performance is unmatched, handling high-volume tasks efficiently. However, these compressors come with a higher initial investment and require more complex setup and maintenance. They are best suited for workshops or businesses that need to manage multiple tasks with substantial air demand. While they represent a higher cost, their durability and performance can justify the investment for businesses focused on heavy-duty applications.

Selecting the right tire inflator parts or alternative solutions hinges on understanding specific business needs and operational contexts. For routine tire maintenance in personal or light commercial settings, Black and Decker parts may provide the reliability and ease of use necessary. Conversely, if your operations demand quick, portable solutions or robust, heavy-duty capabilities, considering alternatives such as portable battery-powered inflators or heavy-duty air compressors may yield better results. Ultimately, B2B buyers should evaluate their unique requirements—performance needs, budget constraints, and maintenance capabilities—before making a decision.

Understanding the essential technical properties of Black and Decker tire inflator parts is critical for B2B buyers looking to make informed purchasing decisions. Here are several key specifications that should be taken into account:

Material Klasse

The material grade of inflator parts, such as plastic, rubber, and metal components, significantly affects durability and performance. For example, high-grade ABS plastic is commonly used for housings due to its impact resistance, while rubber is essential for seals to prevent air leaks. B2B buyers should consider the material grade to ensure longevity and reliability in demanding environments.

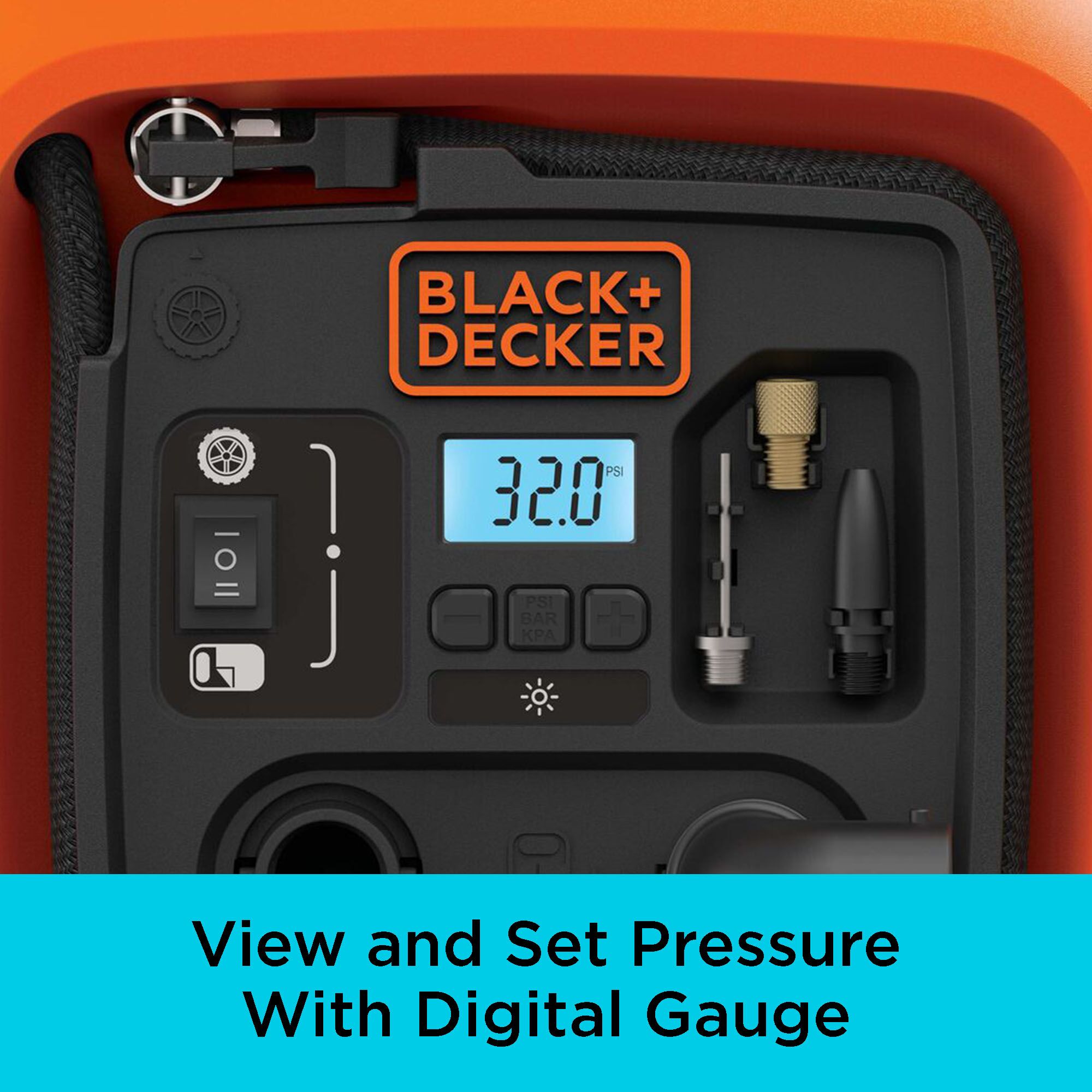

Pressure Rating

Tire inflators typically operate within specific pressure ranges, measured in PSI (pounds per square inch). Understanding the pressure rating of parts like valves and hoses is vital, as components must withstand the operational pressures without failing. Buyers should match the inflator’s pressure rating with the intended application, especially in industrial or heavy-use scenarios.

Tolerance Levels

Tolerance refers to the acceptable deviation in dimensions during manufacturing. In tire inflator parts, precise tolerances are crucial for ensuring proper fit and function, particularly in components like pistons and seals. A high tolerance level minimizes the risk of air leaks and inefficiencies, which can lead to operational failures.

Compatibility Standards

Compatibility with existing systems and components is essential for seamless integration. B2B buyers should verify that the inflator parts meet standard compatibility requirements, such as voltage ratings for electric inflators or specific connector types for hoses. This reduces the risk of additional costs or complications during installation.

Durability Ratings

Durability ratings provide insight into how well parts can withstand wear and tear over time. This includes resistance to temperature fluctuations, corrosion, and mechanical stress. Buyers should prioritize parts with high durability ratings to ensure the inflator can operate effectively under various conditions, reducing the need for frequent replacements.

Navigating the procurement of tire inflator parts involves familiarizing oneself with industry jargon. Here are some essential trade terms every B2B buyer should know:

OEM (Original Equipment Manufacturer)

OEM parts are components made by the original manufacturer of the inflator. These parts are designed to meet specific quality and performance standards. Buyers often prefer OEM parts for their reliability and compatibility with existing equipment.

MOQ (Mindestbestellmenge)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their purchasing capabilities while ensuring sufficient stock levels.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific parts. This process allows buyers to compare offers and make cost-effective decisions. A well-prepared RFQ can streamline procurement and lead to better pricing negotiations.

Incoterms

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms helps clarify costs, risks, and obligations during transportation, which is vital for international transactions.

Vorlaufzeit

Lead time is the time taken from placing an order to receiving the goods. In industries where inflator parts are essential for operations, understanding lead times can help businesses plan maintenance schedules and manage inventory effectively.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Black and Decker tire inflator parts, ultimately leading to more successful procurement outcomes.

Illustrative image related to black and decker tire inflator parts

The global market for tire inflator parts, particularly for established brands like Black & Decker, is witnessing significant growth driven by several key factors. The increasing prevalence of vehicle ownership in emerging markets, particularly in Africa and South America, is fueling demand for reliable tire maintenance solutions. Additionally, the rise in e-commerce platforms is transforming how businesses source parts, allowing international buyers to access a broader inventory of components directly from manufacturers or authorized distributors.

Technological advancements are also shaping the sector. The integration of IoT (Internet of Things) technology into tire inflators is enhancing user experience and operational efficiency, prompting buyers to seek compatible replacement parts that support these innovations. Furthermore, sustainability is becoming a pivotal consideration in sourcing decisions, with buyers increasingly favoring suppliers who prioritize eco-friendly materials and practices.

Emerging trends include the growing preference for modularity and compatibility in parts, which allows for easier repairs and upgrades, thereby extending the product lifecycle. International buyers, especially from regions like Europe and the Middle East, are increasingly looking for suppliers that offer comprehensive support, including parts catalogs, maintenance guides, and warranty assurances.

Sustainability is no longer just a buzzword but a critical factor influencing sourcing decisions in the B2B landscape. The environmental impact of production processes and material sourcing is under scrutiny, pushing companies to adopt greener practices. For Black & Decker tire inflator parts, this means prioritizing components manufactured with recyclable materials and minimizing waste during production.

Ethical sourcing practices are also gaining traction. International buyers are increasingly demanding transparency in supply chains to ensure that the materials used are sourced responsibly. Certifications like ISO 14001 for environmental management and the use of recycled content can enhance a supplier’s reputation and appeal in the global market.

Furthermore, the importance of lifecycle assessments is becoming apparent, with B2B buyers looking for parts that not only meet performance requirements but also have lower environmental footprints over their entire lifespan. Suppliers that can demonstrate adherence to sustainable practices and offer eco-friendly alternatives will likely gain a competitive edge in this evolving market landscape.

The history of Black & Decker in the tire inflator sector mirrors the brand’s broader commitment to innovation and quality. Founded in 1910, Black & Decker has evolved from a small machine shop to a leading global manufacturer of power tools and home improvement products. The introduction of portable tire inflators in the 1990s marked a significant milestone, catering to the increasing need for convenience in vehicle maintenance.

Over the years, Black & Decker has consistently integrated technological advancements into its inflator products, leading to the development of more efficient, user-friendly designs. The brand’s commitment to quality has fostered a loyal customer base, and as a result, the demand for genuine replacement parts has remained strong. This evolution not only underscores Black & Decker’s role as a market leader but also highlights the importance of maintaining a robust supply chain for aftermarket parts, ensuring that international buyers have access to the components necessary for optimal product performance.

How do I solve compatibility issues with Black & Decker tire inflator parts?

To resolve compatibility issues, first, verify the model number of your tire inflator. Each model may require specific parts, and using the wrong components can lead to malfunctions. Consult the manufacturer’s website or authorized distributors for a detailed parts list and compatibility information. Ensure that the parts you order are OEM (Original Equipment Manufacturer) to guarantee proper fit and functionality, especially when sourcing from international suppliers.

What is the best source for Black & Decker tire inflator parts in my region?

The best sources for Black & Decker tire inflator parts vary by region. For buyers in Africa, South America, the Middle East, and Europe, consider authorized distributors or reputable online platforms specializing in power tool parts. Look for suppliers that provide OEM parts to ensure quality and compatibility. Additionally, check for local retailers who may have established supply chains for faster shipping and reduced customs complications.

What are the minimum order quantities (MOQ) for Black & Decker inflator parts?

Minimum order quantities can vary significantly based on the supplier and the specific parts being ordered. Generally, B2B suppliers may set MOQs to ensure profitability on bulk orders. It’s advisable to discuss your specific needs with potential suppliers and inquire about their MOQ policies. Some suppliers may offer flexibility based on your purchasing history or the urgency of your order.

What payment terms should I expect when sourcing Black & Decker parts internationally?

Payment terms can differ widely among suppliers. Common practices include upfront payment, net 30 or net 60 terms, and letter of credit arrangements for larger transactions. Ensure you discuss and clarify payment options before finalizing orders. It’s also beneficial to establish trust with the supplier by reviewing their payment history and terms with other clients, especially in your region.

How can I vet suppliers for Black & Decker tire inflator parts?

Vetting suppliers involves a thorough evaluation of their business credentials, customer reviews, and service history. Request references from other businesses that have sourced similar parts. Evaluate their response times and customer service quality. Additionally, consider suppliers who provide OEM parts and have a transparent return policy, ensuring you receive genuine components and can easily address any issues.

What quality assurance measures should I look for when purchasing inflator parts?

When sourcing inflator parts, prioritize suppliers who adhere to recognized quality standards, such as ISO certifications. Look for parts that come with warranties or guarantees, as this indicates the manufacturer’s confidence in their product quality. Request detailed product specifications and certifications to ensure compliance with international safety and performance standards, especially when importing goods.

How do logistics and shipping affect the procurement of inflator parts?

Logistics and shipping play a crucial role in the procurement process. Consider the supplier’s ability to ship internationally and their experience with customs regulations in your region. Shipping times can vary, so confirm estimated delivery dates and costs upfront. Additionally, inquire about tracking options and policies for lost or damaged goods during transit to ensure a smooth supply chain.

Can I customize Black & Decker tire inflator parts for my business needs?

Customization options depend on the supplier and the specific parts required. Some manufacturers may offer tailored solutions, such as branding or modifications to existing parts. Discuss your requirements with potential suppliers and assess their capacity for customization. Keep in mind that custom orders may have longer lead times and higher costs, so plan accordingly in your procurement strategy.

Bereich: powertoolreplacementparts.com

Registriert: 2016 (9 Jahre)

Einleitung: This company, Black & Decker – Inflator Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: blackanddecker.com

Registriert: 1995 (30 Jahre)

Einleitung: Accessories + Parts for BLACK+DECKER appliances and tools include sanding discs, string trimmer line, circular saw parts, reciprocating saw attachments, blades, drills, and bits. Replacement or supplemental chargers, wall plugs, base charging units, and batteries of various sizes (20V, 40V, 60V) are available. The POWERSERIES branded products feature interchangeable batteries and chargers.

Bereich: ereplacementparts.com

Registriert: 2004 (21 Jahre)

Einleitung: Black and Decker Compressor Parts include various genuine OEM parts such as:

1. Drain Valve N286039 – $6.15

2. Tube Seal N044359 – $6.15

3. Regulator Repair Kit N008792 – $35.60

4. Belt N011005 – $36.12

5. Hose Clamp CAC-1206-1 – $6.15

6. Valve Plate With Lower Gasket N017592SV – $15.23

7. Head Gasket Z-D24819 – $18.31

8. Gasket 5140118-80 – $6.00 (min quantity of 2 required)

9. Torx Scre…

Bereich: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Einleitung: This company, Black & Decker – Air Compressor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: partswarehouse.com

Registriert: 1997 (28 Jahre)

Einleitung: Model: Black & Decker 9527 Inflator 120 Volt (Type 1)

Bereich: ifixit.com

Registriert: 2001 (24 Jahre)

Einleitung: Black and Decker Air Station, 160 psi air compressor, designed for inflating household items, electric air pump, suitable for car tires, approximately 20 years old, requires a new valve due to dry-rotted rubber, replacement parts available at local hardware stores or Grainger.

In today’s competitive landscape, strategic sourcing for BLACK+DECKER tire inflator parts is paramount for international B2B buyers aiming to optimize their supply chains. By leveraging a diverse supplier base and maintaining an inventory of essential components, businesses can enhance operational efficiency and minimize downtime. The availability of OEM parts ensures quality and compatibility, crucial for maintaining the reliability of inflator products.

Additionally, focusing on suppliers that offer comprehensive maintenance kits and replacement parts can significantly reduce long-term costs and improve customer satisfaction. As market demands evolve, buyers should prioritize partnerships with suppliers that are agile and responsive to changing needs, particularly in regions such as Africa, South America, the Middle East, and Europe.

Looking ahead, the potential for growth in the tire inflator market remains strong. By adopting a proactive sourcing strategy, businesses can position themselves to capitalize on emerging opportunities. Engage with trusted suppliers today to secure your supply chain and ensure your product offerings remain competitive. Embrace the future of tire inflator parts sourcing and unlock new avenues for success in your business operations.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

Illustrative image related to black and decker tire inflator parts

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.