In today’s competitive landscape, sourcing efficient tire pressure fillers is crucial for businesses looking to maintain optimal vehicle performance and safety. With the rising costs of fuel and the increasing importance of sustainability, international B2B buyers are tasked with finding reliable solutions that enhance tire efficiency while minimizing operational expenses. This comprehensive guide delves into the various types of tire pressure fillers available in the global market, from portable electric inflators to heavy-duty compressors, ensuring that you can identify the right product for your needs.

Throughout this guide, we will explore key applications, supplier vetting processes, and cost considerations, providing a holistic view that empowers informed purchasing decisions. Special attention is given to the unique challenges faced by businesses in Africa, South America, the Middle East, and Europe, including market trends and regional regulations that may influence your sourcing strategy.

By leveraging the insights and actionable strategies presented here, B2B buyers can navigate the complexities of the tire pressure filler market with confidence, ensuring they choose products that not only meet their operational requirements but also contribute to long-term cost savings and sustainability goals. This guide serves as a vital resource, equipping you with the knowledge necessary to make strategic investments in tire pressure management solutions.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Portable Electric Inflators | Compact, battery-operated, fast inflation speeds | Automotive repair shops, logistics | Vorteile: Easy to use, portable, quick inflation. Nachteile: Limited battery life, may require frequent charging. |

| Heavy-Duty Air Compressors | High PSI capacity, suitable for larger vehicles | Construction, fleet maintenance | Vorteile: Durable, can inflate multiple tires quickly. Nachteile: Bulkier, requires a power source. |

| Manual Pumps | Hand-operated, no electricity needed | Emergency kits, remote locations | Vorteile: Reliable, lightweight, no power needed. Nachteile: Labor-intensive, slower inflation rates. |

| Smart Tire Inflators | Integrated digital gauges, auto-stop features | Fleet management, automotive services | Vorteile: Accurate pressure readings, user-friendly. Nachteile: Higher upfront cost, reliance on technology. |

| Multi-Function Inflators | Combines tire inflation with other tools (e.g., vacuum) | Automotive service centers | Vorteile: Versatile, saves space and cost. Nachteile: May compromise on specific inflation capabilities. |

Portable electric inflators are designed for convenience and speed, making them ideal for businesses requiring quick tire pressure adjustments. These devices typically operate on rechargeable batteries, offering mobility without the need for a power outlet. Their compact size allows easy storage in vehicles or workshops. When selecting a portable inflator, businesses should consider battery life, inflation speed, and compatibility with various tire types, as these factors directly impact operational efficiency.

Heavy-duty air compressors are robust machines capable of inflating larger tires, such as those found on trucks and construction vehicles. They often feature high PSI capabilities, allowing for quick inflation of multiple tires in a short time. B2B buyers in construction or fleet maintenance should prioritize durability and power source options when purchasing. While these compressors are efficient, they can be bulkier and may require dedicated space in workshops or garages.

Manual pumps are a reliable option for businesses that operate in remote areas without access to electricity. These hand-operated devices are lightweight and easy to transport, making them suitable for emergency kits or outdoor applications. However, they require physical effort and may take longer to inflate tires compared to electric options. B2B buyers should evaluate the trade-off between reliability and the labor intensity of manual pumps, especially in high-demand environments.

Smart tire inflators come equipped with advanced features such as integrated digital gauges and auto-stop capabilities, ensuring precise inflation without user intervention. These devices are particularly beneficial for fleet management and automotive service centers, where maintaining accurate tire pressure is crucial for safety and efficiency. When considering a smart inflator, businesses should assess the device’s accuracy, ease of use, and overall cost-effectiveness, as these features can enhance operational workflows.

Multi-function inflators combine tire inflation capabilities with additional features, such as vacuuming or lighting, catering to the diverse needs of automotive service centers. This versatility can save space and reduce costs for businesses looking to maximize their equipment’s utility. However, B2B buyers should ensure that these multi-function devices do not compromise on the core inflation capabilities, as the primary goal remains efficient tire maintenance.

| Industrie/Sektor | Specific Application of Tire Pressure Filler | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automotive Manufacturing | Assembly line tire pressure filling | Ensures optimal tire performance and safety | Compatibility with various tire types and sizes |

| Logistics & Transportation | Fleet maintenance for trucks and buses | Reduces downtime and increases fuel efficiency | Portability and battery life for remote locations |

| Landwirtschaft | Tire inflation for agricultural machinery | Enhances productivity and reduces tire wear | Durability and resistance to harsh environments |

| Bauwesen | Tire inflation for heavy machinery | Improves operational efficiency and safety | Ability to handle high-pressure requirements |

| Sports & Recreation | Inflation of sports equipment and recreational vehicles | Ensures safety and performance in activities | Versatility to accommodate different types of inflatables |

In automotive manufacturing, tire pressure fillers are essential during the assembly process. They ensure that tires are inflated to the correct specifications before vehicles leave the factory, which is crucial for optimal performance and safety. This application helps avoid costly recalls and enhances customer satisfaction. Buyers in this sector should consider inflators that are compatible with a range of tire sizes and types to accommodate diverse vehicle models.

For logistics and transportation companies, maintaining optimal tire pressure is vital for fleet efficiency. Tire pressure fillers are used to quickly inflate tires on trucks and buses, minimizing downtime and maximizing fuel efficiency. This is particularly important in regions with vast distances between service stations. Buyers should look for portable inflators with long battery life and fast inflation capabilities to cater to remote locations and ensure quick service.

In the agriculture sector, tire pressure fillers are utilized for inflating tires on tractors and other heavy machinery. Proper tire inflation is crucial for enhancing productivity, ensuring safety, and reducing tire wear in rugged terrains. Buyers in this industry should seek durable inflators that can withstand harsh environmental conditions and provide reliable performance over extended periods, as agricultural operations often occur in remote areas with limited access to power sources.

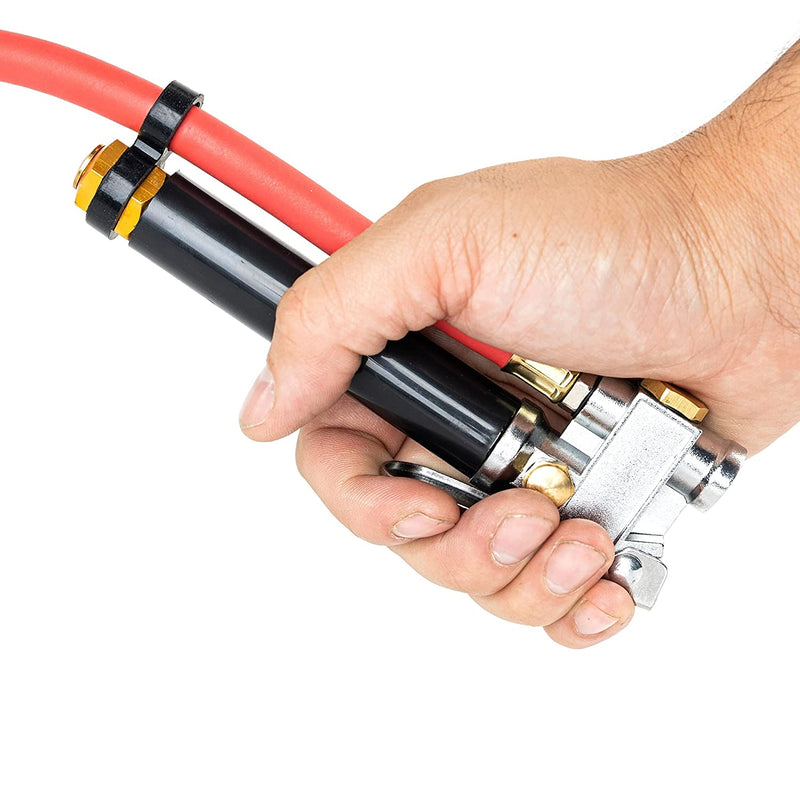

Construction sites rely heavily on heavy machinery, which requires proper tire inflation for safe and efficient operation. Tire pressure fillers are used to maintain the correct pressure in equipment like excavators and bulldozers, which can lead to improved operational efficiency and reduced risk of accidents. When sourcing inflators for construction, businesses should prioritize models that can handle high-pressure requirements and are rugged enough to endure demanding site conditions.

In the sports and recreation industry, tire pressure fillers are essential for inflating tires on bicycles, motorcycles, and recreational vehicles. Ensuring proper tire pressure is crucial for safety and performance during activities. Buyers should look for versatile inflators that can accommodate various types of inflatables, including sports balls and air mattresses, to maximize their utility across different recreational applications.

Illustrative image related to tire pressure filler

Das Problem: B2B buyers managing fleets of vehicles often encounter the challenge of inconsistent tire pressure, which can lead to increased fuel consumption, tire wear, and safety issues. In regions like Africa or South America, where road conditions can vary significantly, maintaining uniform tire pressure across a diverse fleet is essential yet difficult. Fleet managers may struggle with the time-consuming process of checking and inflating tires regularly, especially when vehicles are frequently on the move or dispersed over large geographical areas.

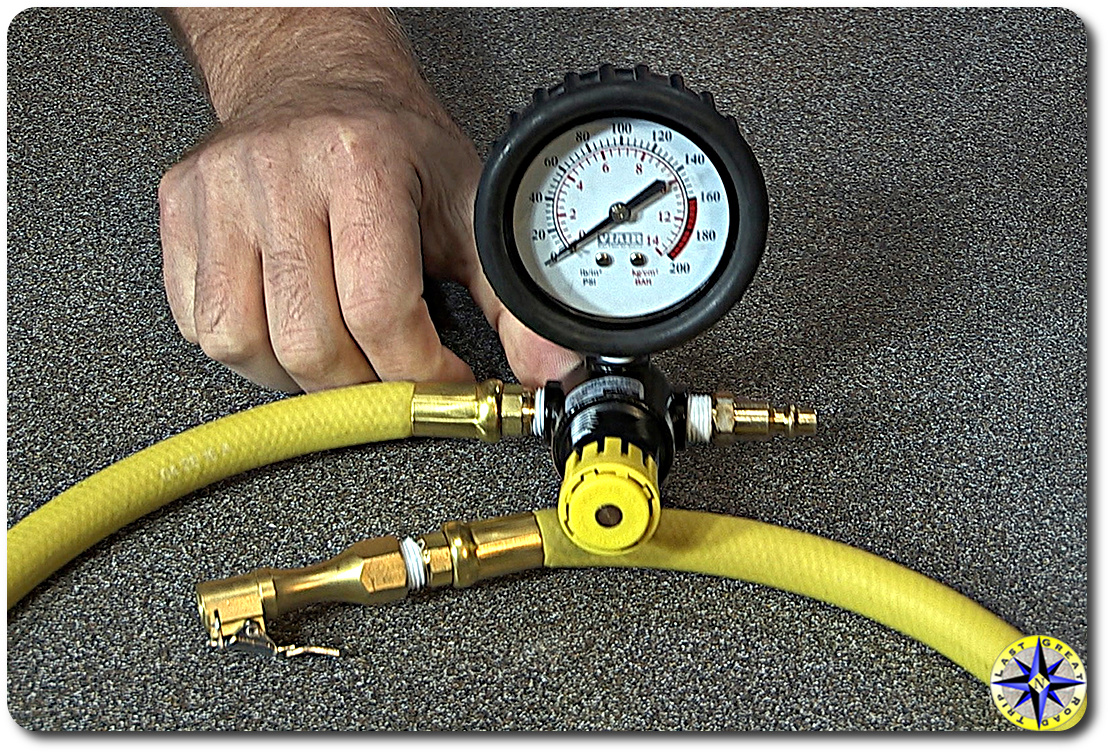

Die Lösung: Implementing a proactive tire maintenance program is key to addressing this issue. B2B buyers should consider investing in high-quality, portable tire pressure fillers that feature built-in pressure gauges and programmable settings for automatic shut-off at desired PSI levels. This allows for quick and efficient inflation without the need for constant monitoring. Additionally, integrating a tire pressure monitoring system (TPMS) can provide real-time data on tire pressure across the fleet, enabling managers to identify under-inflated tires promptly. Buyers should also establish a routine schedule for tire maintenance checks, combining both manual and automated processes to ensure optimal performance and safety.

Das Problem: Many B2B buyers face the challenge of sourcing tire pressure fillers that meet their specific operational needs. Whether it’s for a transportation company in Europe or a service provider in the Middle East, buyers may find that many available products do not align with their performance requirements, such as inflation speed, portability, or compatibility with various tire types, including heavy-duty vehicles or electric cars.

Die Lösung: To effectively navigate this sourcing challenge, B2B buyers should conduct thorough market research to identify manufacturers that specialize in tire inflators tailored to their industry. Engaging with suppliers who provide detailed specifications, user reviews, and product comparisons can help in making informed decisions. Additionally, leveraging local distributors can facilitate quicker access to parts and maintenance support, especially in regions with limited infrastructure. Buyers should also consider trialing different models to evaluate their performance in real-world conditions before making bulk purchases, ensuring that the selected tire pressure fillers enhance operational efficiency.

Das Problem: User error is a common issue that can significantly impede the efficiency of tire inflation processes. For businesses that rely on multiple operators to handle tire maintenance, varying levels of experience and knowledge can lead to inconsistent inflation practices, resulting in improperly inflated tires. This not only affects vehicle performance but also poses safety risks, particularly in high-pressure environments like trucking or logistics.

Die Lösung: To mitigate the impact of user error, B2B buyers should invest in tire pressure fillers that offer user-friendly features, such as clear digital displays, automatic shut-off functions, and preset inflation modes for different tire types. Providing comprehensive training programs for employees can also enhance understanding of proper tire maintenance techniques. Additionally, establishing standard operating procedures (SOPs) that include step-by-step guides for using the inflation equipment can help standardize practices across the workforce. Regularly scheduled training refreshers can further ensure that all operators are up-to-date on best practices, reducing the likelihood of user error and promoting overall safety and efficiency.

When selecting materials for tire pressure fillers, it is crucial to consider their properties, advantages, and limitations. This guide examines four common materials used in tire pressure filler applications, focusing on their performance characteristics and implications for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Rubber is a widely used material in tire pressure fillers due to its elasticity and resilience. It typically has a temperature rating of -40°C to 100°C and can withstand moderate pressures. The primary advantage of rubber is its excellent sealing properties, which prevent air leaks effectively. However, it is susceptible to degradation from UV light and ozone, which can limit its lifespan.

For B2B buyers, rubber’s cost-effectiveness makes it an attractive option. However, compliance with international standards such as ASTM and ISO is essential, especially in regions like Brazil and Nigeria, where local regulations may dictate specific material requirements.

Illustrative image related to tire pressure filler

Aluminum is another common material, particularly for the structural components of tire inflators. It offers a high strength-to-weight ratio and excellent corrosion resistance, making it suitable for outdoor use. Aluminum can handle higher pressures, typically up to 150 PSI, and operates effectively in a wide temperature range (-50°C to 150°C).

The main advantage of aluminum is its durability and lightweight nature, which enhances portability. However, it can be more expensive than rubber and may require more complex manufacturing processes. Buyers in the Middle East and Africa should consider the availability of aluminum and its cost implications in their regions.

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is frequently used in tire pressure fillers due to its lightweight and resistance to chemicals. Plastics can handle temperatures ranging from -20°C to 80°C and pressures up to 100 PSI. The primary advantage of plastic is its low cost and ease of manufacturing, making it suitable for high-volume production.

However, plastics can be less durable than rubber or aluminum, especially under extreme conditions. For international buyers, understanding the specific grades of plastic that comply with local standards is crucial, as some regions may have preferences for certain types of plastics.

Steel is often used for high-pressure applications due to its exceptional strength and durability. It can withstand pressures exceeding 200 PSI and operates effectively in extreme temperatures. The primary advantage of steel is its robustness, making it ideal for heavy-duty applications.

On the downside, steel is heavier and more prone to corrosion if not properly treated. This can lead to higher maintenance costs. B2B buyers should be aware of the need for protective coatings and the implications of weight in terms of transport and handling, particularly in regions with less developed infrastructure.

| Material | Typical Use Case for Tire Pressure Filler | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Seals and hoses in inflators | Ausgezeichnete Dichtungseigenschaften | Susceptible to UV and ozone degradation | Niedrig |

| Aluminium | Structural components of inflators | High strength-to-weight ratio, corrosion-resistant | More expensive, complex manufacturing | Med |

| Kunststoff | Lightweight components, housing | Low cost, easy to manufacture | Weniger haltbar unter extremen Bedingungen | Niedrig |

| Stahl | High-pressure applications | Exceptional strength and durability | Heavier, prone to corrosion | Med |

This analysis provides a comprehensive overview of the materials commonly used in tire pressure fillers, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

The manufacturing of tire pressure fillers, also known as tire inflators, involves several critical stages, each designed to ensure that the final product meets high standards of performance and reliability. Understanding these stages is essential for B2B buyers looking to source high-quality products.

The first step in manufacturing tire pressure fillers involves sourcing and preparing materials. Common materials include high-strength plastics for the housing, metals such as aluminum or steel for the internal components, and rubber for seals and hoses. These materials are selected based on their durability, resistance to wear, and ability to withstand high pressure.

Before fabrication, materials undergo quality checks to ensure they meet specified standards. This includes checking for defects, measuring dimensions, and verifying material properties. Suppliers often provide certificates of compliance, which are crucial for B2B buyers to validate the quality of the materials used.

The forming stage involves shaping the prepared materials into the components of the tire pressure filler. Key techniques include:

Illustrative image related to tire pressure filler

Each of these techniques plays a vital role in ensuring that the components fit together seamlessly, which is critical for the overall performance of the tire inflator.

Once the individual components are formed, they move to the assembly stage. This process typically involves:

During assembly, careful attention is given to the integration of electronic components, such as pressure sensors and displays. These elements are crucial for the functionality of modern tire inflators, which often feature digital readouts and preset pressure settings.

The finishing stage is where the tire pressure fillers are prepared for packaging and shipping. This may include:

Products that pass these checks are then packaged for distribution. Packaging is designed to protect the product during transport while providing essential information to the end user.

Illustrative image related to tire pressure filler

Quality assurance is a critical aspect of the manufacturing process, ensuring that tire pressure fillers meet international standards and customer expectations. B2B buyers should be familiar with the key practices and standards that govern quality assurance in this industry.

Manufacturers of tire pressure fillers often adhere to various international standards to ensure quality and safety. Key certifications include:

B2B buyers should request documentation of these certifications to ensure compliance with relevant standards.

Quality control in tire pressure filler manufacturing typically involves multiple checkpoints:

These checkpoints help minimize defects and ensure that only high-quality products reach the market.

Manufacturers employ various testing methods to validate the performance and safety of tire pressure fillers, including:

These tests are crucial for ensuring that the final product is reliable and meets customer expectations.

For B2B buyers, verifying the quality control practices of potential suppliers is essential to ensure that they receive high-quality products. Here are several strategies to consider:

Conducting supplier audits can provide valuable insights into a manufacturer’s quality control processes. Buyers should look for:

Buyers should request detailed quality control reports, including:

Having access to this documentation allows buyers to make informed decisions about their suppliers.

Engaging third-party inspection services can provide an additional layer of assurance. Independent inspectors can conduct audits and tests on behalf of the buyer, ensuring that the supplier’s practices align with industry standards and buyer expectations. This is particularly beneficial for international buyers, as it helps mitigate risks associated with sourcing from unfamiliar markets.

Illustrative image related to tire pressure filler

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for tire pressure fillers is crucial. By being informed about the stages of production, relevant standards, and verification methods, buyers can make educated decisions, ensuring that they source reliable, high-quality products that meet their operational needs.

To successfully procure a tire pressure filler, particularly in diverse international markets, B2B buyers must follow a structured approach to ensure they make informed decisions. This guide outlines essential steps to streamline the sourcing process and optimize procurement outcomes.

Begin by clearly outlining the technical specifications required for the tire pressure filler. Consider factors such as the desired PSI range, portability, power source (cordless vs. corded), and additional features like built-in pressure gauges or automatic shut-off functions. Establishing these parameters will help narrow down options that meet your operational needs.

Illustrative image related to tire pressure filler

Stay informed about the latest trends in tire inflators and pressure fillers within your target regions, such as Africa, South America, the Middle East, and Europe. Understanding local preferences and compliance standards is crucial, as markets may have different requirements based on vehicle types and inflation standards. Utilize industry reports and market analyses to gain insights into popular models and features that resonate with buyers in these areas.

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, including their manufacturing capabilities, quality control processes, and experience in your target market. It’s advisable to ask for references from other businesses in similar industries or regions to gauge supplier reliability and product performance.

Obtain quotes from multiple suppliers to compare pricing structures. Consider the total cost of ownership, including shipping fees, import duties, and potential maintenance costs. Analyze payment terms and negotiate for favorable conditions, such as extended payment periods or bulk order discounts, which can significantly impact your cash flow.

Before finalizing an order, request samples of the tire pressure fillers to evaluate their performance firsthand. Testing the products will allow you to assess their ease of use, inflation speed, accuracy, and durability. This step is vital to ensure that the product meets your expectations and operational needs.

Illustrative image related to tire pressure filler

Once you have selected a supplier, draft a comprehensive contract that outlines all agreed-upon terms, including pricing, delivery timelines, and quality standards. Ensure that the contract also includes provisions for handling potential disputes or quality issues that may arise after purchase. Having a clear agreement protects your interests and fosters a professional relationship with the supplier.

Develop a logistics plan to manage the distribution of tire pressure fillers within your operations. Consider factors such as warehousing, transportation methods, and inventory management. A well-organized logistics strategy will help ensure timely delivery and availability of products to meet market demand.

By following these steps, B2B buyers can streamline their procurement process for tire pressure fillers, ensuring that they make informed decisions that align with their operational goals and market requirements.

When sourcing tire pressure fillers, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. This section delves into the key components of costs, the influencers on pricing, and provides actionable insights for negotiating favorable terms.

The cost structure for tire pressure fillers encompasses several critical components:

Materialien: The primary materials used in tire inflators typically include durable plastics, metals, and electronic components. The quality and source of these materials can significantly influence the overall cost. For instance, sourcing high-grade materials may increase initial expenses but can enhance product longevity and reliability.

Arbeit: Labor costs vary depending on the region of production. Manufacturers in regions with higher labor costs may reflect this in the pricing, making it essential for buyers to consider the labor market when selecting suppliers.

Fertigungsgemeinkosten: This includes expenses related to factory operations such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

Werkzeugbau: Custom tooling for specific designs or features adds to the upfront costs. Buyers seeking customized products should factor in these additional expenses and evaluate whether the enhancements justify the investment.

Qualitätskontrolle (QC): Implementing stringent QC measures ensures product reliability and safety. While this may raise costs, it can prevent costly returns and enhance brand reputation.

Logistik: Shipping and handling costs can vary widely based on distance, shipping method, and the volume of goods. International buyers should account for tariffs, import duties, and insurance, which can significantly affect the total landed cost.

Marge: Supplier profit margins vary, influenced by market demand and competition. Understanding the margin expectations can aid in negotiations.

Several factors influence the pricing of tire pressure fillers:

Volumen/MOQ (Mindestbestellmenge): Suppliers often offer better pricing for larger orders. Buyers should assess their needs against potential savings from bulk purchasing.

Spezifikationen und Anpassungen: Custom features or specific performance standards can lead to higher costs. Buyers must balance the need for customization with budget constraints.

Materialien und Qualitätszertifikate: Premium materials and certifications (like ISO or CE) can enhance product value but may also increase costs. Buyers should weigh the benefits of certifications against their budget.

Lieferanten-Faktoren: Reputation, reliability, and location of suppliers can affect pricing. Established suppliers with proven track records may command higher prices but offer better assurance of quality and service.

Incoterms: Understanding Incoterms is crucial as they define the responsibilities of buyers and sellers regarding shipping, risk, and costs. Choosing the right Incoterms can help optimize logistics costs.

To achieve optimal pricing and cost-efficiency in sourcing tire pressure fillers, consider the following strategies:

Verhandlung: Engage suppliers in discussions about pricing, especially for larger orders. Highlighting your potential for ongoing business can motivate suppliers to offer better terms.

Gesamtbetriebskosten (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and potential returns. This holistic view can lead to smarter purchasing decisions.

Nuancen in der Preisgestaltung für internationale Käufer: Be aware of fluctuations in currency exchange rates, which can affect costs. Additionally, understand regional market dynamics that may impact pricing and availability.

Supplier Diversification: Establish relationships with multiple suppliers to mitigate risks associated with supply chain disruptions and to leverage competitive pricing.

Marktforschung: Stay informed about market trends and competitors’ offerings. This knowledge can empower you to negotiate better deals and make informed sourcing decisions.

In summary, a comprehensive understanding of the cost structure and pricing dynamics for tire pressure fillers is crucial for international B2B buyers. By focusing on material quality, labor costs, and strategic negotiation tactics, businesses can optimize their sourcing processes and enhance their overall cost-efficiency. Always remember to consider the total cost of ownership when making purchasing decisions to ensure long-term value.

When considering tire maintenance solutions, the tire pressure filler stands out as a popular choice among businesses. However, it’s essential to evaluate alternative methods that may offer unique advantages depending on specific needs and operational contexts. This section provides a comparative analysis of tire pressure fillers against other viable solutions, enabling buyers to make informed decisions.

Illustrative image related to tire pressure filler

| Vergleich Aspekt | Tire Pressure Filler | Electric Tire Inflators | Manuelle Reifenpumpen |

|---|---|---|---|

| Leistung | Quick inflation with precision | High-speed inflation, usually cordless | Slower, manual inflation |

| Kosten | Moderate initial investment | Varies widely; generally higher than manual | Low-cost option |

| Leichte Implementierung | Easy to use, minimal setup required | Simple, but may require battery charging | Requires physical effort |

| Wartung | Low; occasional checks needed | Moderate; battery maintenance required | Very low; minimal upkeep |

| Bester Anwendungsfall | Regular maintenance for vehicles | Emergency inflation for various vehicles | Occasional use, especially for bikes or sports equipment |

Electric tire inflators are often favored for their speed and efficiency. They can inflate tires quickly, making them ideal for emergency situations or when time is of the essence. Many models are cordless, enhancing portability and ease of use. However, they typically come at a higher price point and require periodic battery maintenance, which can add to operational costs. These inflators are best suited for businesses that need rapid, frequent tire inflation and are willing to invest in reliable technology.

Manual tire pumps are the most economical option available. They require no electricity or batteries, making them a reliable choice in remote areas or during power outages. While they are lightweight and easy to transport, the primary drawback is the physical effort required to operate them, which can be a disadvantage for larger fleets or in high-volume operations. Manual pumps are best for occasional use or as a backup solution when other options are unavailable.

In selecting the appropriate tire inflation solution, B2B buyers should carefully consider their operational needs, budget constraints, and the specific contexts in which they will use these tools. For companies requiring quick, reliable inflation capabilities, electric tire inflators may offer the best return on investment despite their higher costs. Conversely, for those focused on minimizing expenses or requiring a simple, low-maintenance solution, manual tire pumps could suffice. Ultimately, the right choice depends on balancing performance needs with budgetary limitations while considering the frequency of use and maintenance capacity.

When considering tire pressure fillers, understanding their technical specifications is crucial for B2B buyers. Here are some essential properties that influence performance and usability:

Illustrative image related to tire pressure filler

The inflation pressure range indicates the minimum and maximum pressure the inflator can achieve, typically measured in PSI (pounds per square inch) or BAR. For example, a unit that inflates from 0 to 150 PSI is suitable for various vehicles, including cars and trucks. Understanding this range ensures that the selected inflator meets the requirements for diverse applications, reducing the risk of under-inflation or over-inflation, which can lead to tire damage.

Tire inflators may be powered by electricity, battery, or a vehicle’s 12V outlet. Battery-powered models offer portability, ideal for roadside emergencies, while electric models provide consistent power for frequent use. The power source affects the inflator’s efficiency and suitability for different environments, making it essential for buyers to match the inflator’s capabilities with their operational needs.

The flow rate, measured in liters per minute (L/min), indicates how quickly the inflator can pump air into a tire. A higher flow rate translates to faster inflation times, which is particularly important for commercial operations where time efficiency is critical. Buyers should consider the flow rate based on the typical tire size they will be inflating to optimize productivity.

Portability is a significant factor for businesses that require tire inflators to be mobile, such as roadside assistance services or fleet management. The weight and design of the inflator should facilitate easy transport and storage. Compact, lightweight models are often favored in these scenarios, as they can be easily stored in vehicles without taking up excessive space.

The materials used in the construction of tire pressure fillers influence their durability and lifespan. High-grade plastics, metal casings, and robust hoses can withstand heavy use and adverse conditions. For B2B buyers, investing in durable equipment minimizes replacement costs and downtime, enhancing overall operational efficiency.

Familiarity with industry jargon is essential for effective communication and negotiation. Here are several common terms relevant to tire pressure fillers:

OEM refers to companies that manufacture parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, buyers may seek OEM products to ensure compatibility and quality assurance, especially for fleet maintenance.

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to assess whether the supplier’s terms align with their purchasing needs, especially when considering large-scale operations or budget constraints.

Illustrative image related to tire pressure filler

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. This term is critical in B2B transactions as it allows buyers to compare offerings and negotiate better terms based on their requirements.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with these terms helps B2B buyers understand shipping costs, risk transfers, and delivery responsibilities, which are crucial for international trade, particularly in regions like Africa and South America.

The warranty period specifies the time frame in which the manufacturer guarantees the product’s performance. Understanding warranty terms is essential for B2B buyers as it reflects the manufacturer’s confidence in their product and provides a safety net for repairs or replacements.

Illustrative image related to tire pressure filler

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing tire pressure fillers, ensuring they select products that meet their operational needs while navigating the complexities of international trade.

The tire pressure filler market is experiencing a significant transformation driven by technological advancements, rising safety awareness, and the increasing adoption of electric vehicles (EVs). Global demand for efficient tire inflation solutions is rising, particularly in regions like Africa, South America, the Middle East, and Europe, where vehicle ownership is expanding. International buyers are increasingly looking for products that combine convenience, speed, and accuracy, as evidenced by the rising popularity of portable and battery-operated inflators. These devices offer features such as auto-stop functions, built-in pressure gauges, and multiple inflation modes, catering to diverse user needs.

Emerging trends in B2B sourcing include a focus on multifunctionality and compact design, which align with the growing trend of urbanization and space constraints in cities. Additionally, partnerships between manufacturers and technology firms are leading to innovations that improve user experience, such as mobile app integration and real-time pressure monitoring. For B2B buyers, understanding these trends is crucial for making informed purchasing decisions and staying ahead in a competitive market.

Sustainability is increasingly becoming a focal point in the tire pressure filler sector. As consumers and businesses alike prioritize environmental responsibility, manufacturers are under pressure to adopt ethical sourcing practices. This includes using sustainable materials and minimizing waste throughout the product lifecycle. B2B buyers are advised to look for suppliers who prioritize green certifications, such as ISO 14001, which indicates adherence to environmental management standards.

Moreover, the use of eco-friendly materials, such as recycled plastics or biodegradable components in tire inflators, is gaining traction. This shift not only helps reduce the environmental impact but also appeals to consumers who are more inclined to support brands that demonstrate commitment to sustainability. For international buyers, ensuring that their sourcing aligns with ethical standards can enhance brand reputation and customer loyalty, particularly in regions where environmental concerns are paramount.

Illustrative image related to tire pressure filler

The tire pressure filler market has evolved significantly over the past few decades. Initially dominated by manual pumps, the sector saw a shift towards electric and portable inflators as technology advanced. The introduction of battery-operated models has revolutionized the market, providing consumers with greater convenience and efficiency.

In recent years, the proliferation of smart technology has further transformed the landscape, with features like automatic pressure adjustment and mobile connectivity becoming commonplace. This evolution reflects broader trends in consumer expectations for ease of use and multifunctionality in everyday products. As the market continues to innovate, B2B buyers must stay informed about emerging technologies to ensure they are selecting the best solutions for their needs.

How do I ensure the tire pressure filler I choose is suitable for various vehicle types?

To ensure that the tire pressure filler you select meets the diverse needs of different vehicle types, review the specifications and capabilities of each model. Look for inflators that offer adjustable pressure settings and are compatible with various inflation requirements, such as those for cars, motorcycles, and electric vehicles. Additionally, consider models with automatic shut-off features that allow you to set the desired pressure, ensuring optimal performance across different applications.

What is the best tire pressure filler for heavy-duty vehicles like trucks and SUVs?

For heavy-duty vehicles such as trucks and SUVs, look for tire pressure fillers that can achieve high PSI levels, typically up to 80 PSI or more. Models like high-capacity inflators with robust motors and extended hoses are ideal. It’s crucial to select inflators that have been tested for speed and accuracy, ensuring they can quickly inflate larger tires without compromising performance. Additionally, consider portability and ease of use, especially for on-the-road applications.

What should I consider when vetting suppliers for tire pressure fillers?

When vetting suppliers for tire pressure fillers, assess their reputation, production capabilities, and compliance with international quality standards. Request references or case studies from previous clients to gauge reliability. It’s also essential to inquire about their certifications, warranty policies, and after-sales support. Finally, evaluate their responsiveness to inquiries and ability to meet your specific customization needs, as this can indicate their commitment to customer satisfaction.

What customization options are typically available for tire pressure fillers?

Many manufacturers offer customization options for tire pressure fillers, including branding, color choices, and specialized features such as built-in digital displays or multiple inflation modes. Depending on your needs, you may also request specific adapters for different valve types or additional functionality like integrated power banks. Discuss these options with your supplier to ensure that the final product aligns with your brand and operational requirements.

What is the minimum order quantity (MOQ) for tire pressure fillers?

The minimum order quantity (MOQ) for tire pressure fillers can vary widely depending on the supplier and the specific model. Generally, MOQs can range from a few dozen units to several hundred. When negotiating with suppliers, clarify the MOQ and discuss potential discounts for larger orders. Understanding the MOQ is essential for managing your inventory and ensuring you can meet customer demand without overcommitting resources.

What payment terms are standard for international purchases of tire pressure fillers?

Standard payment terms for international purchases typically include options such as a letter of credit, advance payment, or partial payment upon order confirmation. Many suppliers may also accept payment through secure platforms like PayPal or bank transfers. It’s crucial to negotiate terms that protect your interests while ensuring timely delivery. Always review the terms thoroughly and consider working with suppliers who offer favorable payment plans to help manage cash flow.

How can I ensure quality assurance (QA) for the tire pressure fillers I purchase?

To ensure quality assurance for tire pressure fillers, request detailed specifications and testing certifications from your supplier. Many manufacturers will conduct factory inspections and provide samples before the full order is produced. Consider implementing a third-party inspection service to verify product quality before shipment. Establish clear QA protocols, including performance benchmarks and compliance with relevant international standards, to ensure the products meet your expectations.

What logistics considerations should I keep in mind when importing tire pressure fillers?

When importing tire pressure fillers, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder who understands the complexities of international shipping and can assist with documentation and customs clearance. Additionally, assess the total landed cost, including shipping, taxes, and duties, to ensure accurate budgeting. Establishing clear communication with your supplier regarding shipping schedules and any potential delays is also essential to maintain supply chain efficiency.

Bereich: fanttik.com

Registered: 2020 (5 years)

Einleitung: 2X Faster Electric Tire Inflators, Various Models: X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Prices range from $48.99 to $199.97 with discounts up to 50%. Features include upgraded versions and deluxe packages. Ratings around 4.8/5 for several models.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: 1. Ryobi inflator: Good for topping off motorcycle and car tires, priced around $25. Digital display may not be very accurate. Lacks trigger hold function. Suitable for tires up to 36 psi. 2. Viair 88p: Recommended by users for its performance. 3. Ridgid inflator: $70 kit from Home Depot includes battery and charger, can connect to 12v car outlet, features automatic setting for specific PSI with a…

As the global market for tire pressure fillers continues to evolve, strategic sourcing emerges as a crucial component for B2B buyers aiming to enhance their procurement processes. By understanding the latest advancements in tire inflator technology, including high-speed electric models and compact designs, businesses can optimize their inventory while meeting diverse customer needs.

Moreover, prioritizing suppliers that emphasize quality, efficiency, and after-sales support can significantly impact operational success. Buyers in regions like Africa, South America, the Middle East, and Europe should leverage their unique market insights to negotiate favorable terms and establish lasting partnerships with reliable manufacturers.

In an increasingly competitive landscape, the ability to source innovative tire pressure fillers not only improves service delivery but also positions businesses for sustainable growth. As we look to the future, it is essential for international buyers to remain proactive, adapting to emerging trends and consumer demands. Equip your business with the right tools and partnerships today to ensure you stay ahead in the tire inflator market. Engage with trusted suppliers and explore the latest product offerings to enhance your operational efficiency and customer satisfaction.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Illustrative image related to tire pressure filler