In today’s competitive landscape, sourcing high-quality air tires presents a significant challenge for international B2B buyers. Whether you operate in the bustling markets of Africa, the resource-rich landscapes of South America, or the dynamic economies of the Middle East and Europe, navigating the complexities of tire procurement is crucial for maintaining operational efficiency and safety. This guide serves as a comprehensive resource on air tires, addressing key considerations such as types, applications, supplier vetting, and cost analysis.

Understanding the nuances of air tire options—from traditional air-filled tires to the growing trend of nitrogen inflation—can empower your purchasing decisions. Each section of this guide is designed to equip you with actionable insights, enabling you to assess suppliers effectively and make informed choices that align with your business objectives. We delve into the implications of tire performance on fuel efficiency and vehicle longevity, ensuring that you can optimize your fleet’s operational costs.

With a focus on the unique needs of international markets, particularly in regions like Brazil and Vietnam, this guide aims to demystify the air tire sourcing process. By the end, you will be well-prepared to navigate the global tire market, ensuring that your investment leads to enhanced performance and reliability for your vehicles.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Air Tires | Filled with regular atmospheric air, widely available. | Passenger vehicles, light trucks. | Vorteile: Cost-effective, easy to find air sources. Nachteile: Pressure loss over time, may require frequent maintenance. |

| Nitrogen-Filled Tires | Filled with nitrogen gas, retains pressure longer. | Commercial fleets, performance vehicles. | Vorteile: Improved fuel efficiency, reduced temperature fluctuations. Nachteile: Higher initial cost, limited availability in some regions. |

| Run-Flat Tires | Designed to be driven on even when deflated. | Emergency vehicles, long-distance travel. | Vorteile: Enhanced safety, no immediate need for roadside assistance. Nachteile: Higher purchase price, potential for a harsher ride. |

| All-Season Tires | Versatile design suitable for various weather conditions. | General consumer vehicles, delivery vans. | Vorteile: Year-round usability, reduced inventory costs. Nachteile: Compromise on performance in extreme conditions. |

| Performance Tires | Optimized for speed and handling, softer rubber compounds. | Sports cars, racing applications. | Vorteile: Superior grip and responsiveness, enhanced driving experience. Nachteile: Shorter lifespan, may require specialized maintenance. |

Standard air tires are the most commonly used type, filled with atmospheric air. They are readily available and can be inflated at numerous locations, including gas stations and tire shops. Their affordability makes them a popular choice for passenger vehicles and light trucks. However, businesses should consider that these tires can lose air pressure over time, necessitating regular maintenance to ensure optimal performance and safety.

Nitrogen-filled tires are increasingly favored in commercial applications due to their ability to maintain tire pressure longer than standard air. This characteristic can lead to improved fuel efficiency and enhanced safety, making them ideal for commercial fleets and performance vehicles. However, businesses must weigh the higher initial costs and the availability of nitrogen filling stations, particularly in less urbanized areas.

Run-flat tires are engineered to allow continued driving even after a puncture, providing an essential safety feature for emergency vehicles and long-distance travel. This capability eliminates the immediate need for roadside assistance, giving drivers peace of mind. On the downside, run-flat tires often come with a higher price tag and may provide a stiffer ride, which can be a consideration for businesses focused on comfort.

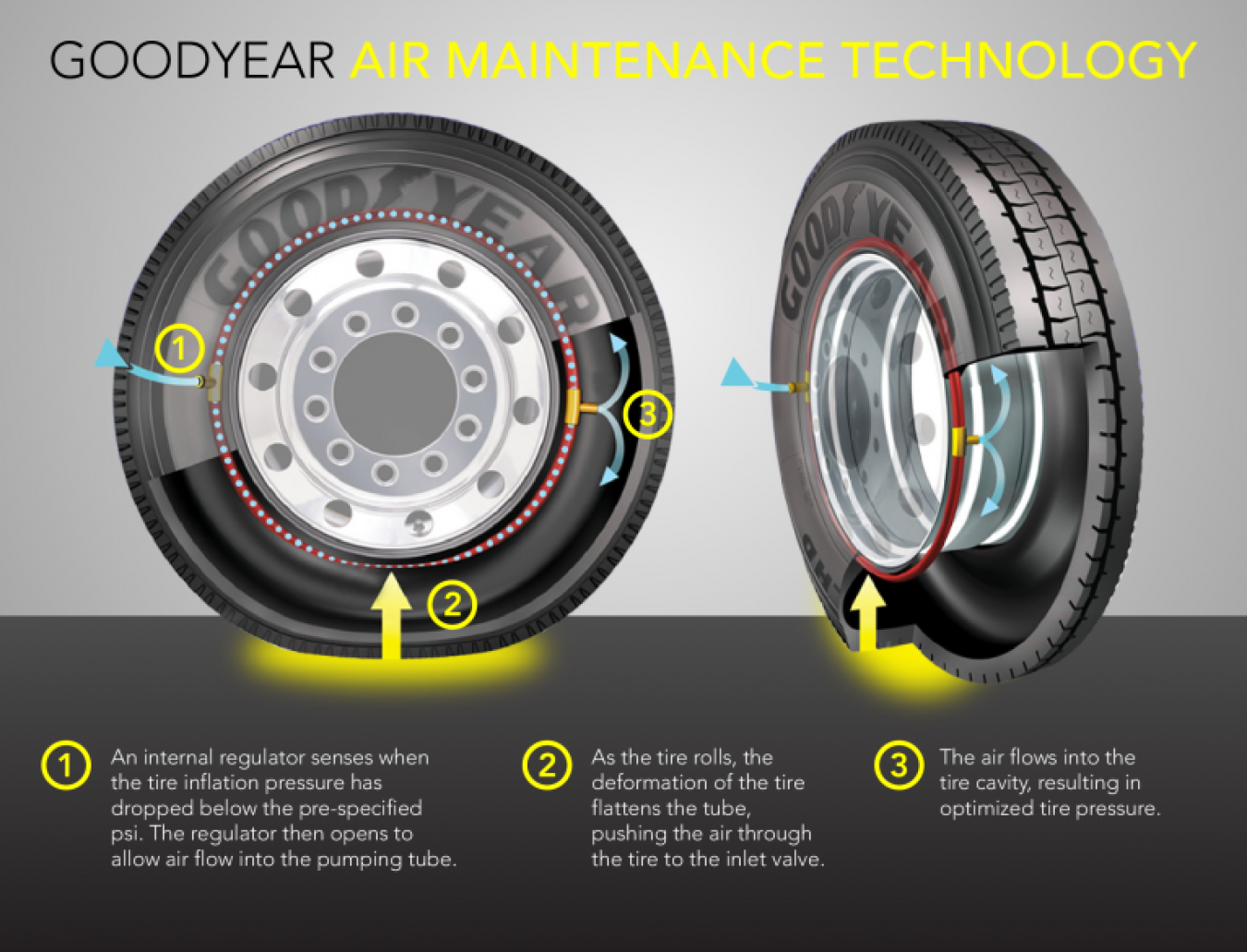

Illustrative image related to air tires

All-season tires offer versatility, making them suitable for various weather conditions, which is advantageous for general consumer vehicles and delivery vans. By reducing the need for seasonal tire changes, businesses can lower inventory and maintenance costs. However, the trade-off may be compromised performance in extreme weather, which is a critical factor for companies operating in regions with harsh conditions.

Performance tires are designed with softer rubber compounds to optimize speed and handling, making them essential for sports cars and racing applications. These tires provide superior grip and responsiveness, enhancing the overall driving experience. However, businesses should consider that performance tires typically have a shorter lifespan and may require specialized maintenance, which can impact long-term operational costs.

| Industrie/Sektor | Specific Application of air tires | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automotive Manufacturing | Production line vehicles using air tires | Enhanced mobility and efficiency in manufacturing processes | Quality assurance, compatibility with machinery, cost-effectiveness |

| Transport und Logistik | Delivery trucks and freight carriers | Improved fuel efficiency and reduced maintenance costs | Reliability of supply, tire pressure management systems, local service availability |

| Landwirtschaft | Agricultural vehicles (tractors, harvesters) | Better traction and stability on uneven terrain | Durability under heavy loads, resistance to punctures, sourcing local suppliers for replacement |

| Bauwesen | Heavy machinery and earth-moving equipment | Increased safety and performance on job sites | Compliance with safety standards, availability of specialized tire types, local regulations |

| Aviation | Ground support vehicles for airports | Enhanced safety and operational efficiency | Certification standards, sourcing from specialized manufacturers, availability of repair services |

In automotive manufacturing, air tires are essential for production line vehicles, including forklifts and assembly line transporters. These vehicles require reliable mobility to transport components efficiently throughout the production process. By using air tires, manufacturers can enhance operational efficiency and reduce downtime caused by tire-related issues. B2B buyers in this sector should prioritize quality assurance and compatibility with existing machinery to ensure seamless integration.

Air tires are crucial for delivery trucks and freight carriers, where they contribute significantly to fuel efficiency and overall vehicle performance. Properly inflated tires reduce rolling resistance, leading to lower fuel consumption and decreased maintenance costs. International buyers, particularly from regions like Africa and South America, should consider sourcing tires that allow for easy pressure management and local service support to mitigate any logistical challenges.

In the agricultural sector, vehicles like tractors and harvesters rely on air tires for optimal performance on varied terrains. The ability of air tires to provide better traction and stability is crucial for ensuring safety and efficiency during operations. Buyers in this sector must focus on durability and puncture resistance, as agricultural environments can be harsh. Establishing relationships with local suppliers for timely replacements can further enhance operational reliability.

Heavy machinery and earth-moving equipment in construction heavily depend on air tires for safe and effective operation. These tires provide the necessary grip and stability required on uneven job sites, significantly reducing the risk of accidents. B2B buyers should ensure compliance with local safety standards and seek specialized tire types that can withstand the demanding conditions of construction sites. The availability of repair services is also a key consideration to minimize downtime.

In aviation, ground support vehicles utilize air tires to ensure safety and operational efficiency at airports. These vehicles, which include baggage carts and fuel trucks, require reliable tire performance to handle the fast-paced airport environment. Buyers in this sector must focus on sourcing tires that meet rigorous certification standards and are backed by manufacturers that offer comprehensive repair services, ensuring minimal disruption to airport operations.

Das Problem:

Many B2B buyers, particularly those managing fleets or logistics operations, face challenges with maintaining consistent tire pressure across multiple vehicles. Inconsistent tire pressure can lead to increased fuel consumption, decreased safety, and uneven tire wear, ultimately affecting the bottom line. For businesses operating in regions with varying temperatures, such as Africa and South America, the challenge is amplified, as fluctuations in temperature can further affect tire pressure. Buyers often find it cumbersome to manually check each tire, leading to oversight and potential operational inefficiencies.

Illustrative image related to air tires

Die Lösung:

Investing in a centralized tire pressure monitoring system (TPMS) can drastically improve consistency and efficiency. These systems provide real-time data on tire pressure, allowing fleet managers to monitor conditions remotely. When sourcing TPMS, look for systems that offer integration with existing fleet management software to streamline operations. Additionally, consider systems that provide alerts for low pressure, enabling proactive management. Training staff to understand the importance of tire pressure maintenance and how to interpret TPMS data can further enhance operational efficiency. This proactive approach not only ensures safety but also extends the lifespan of the tires, ultimately saving costs.

Das Problem:

B2B buyers often struggle with the limited availability of air sources for inflating tires, especially in remote areas or regions where access to service stations is scarce. This can be particularly problematic for businesses involved in transportation or agriculture, where downtime due to flat tires can lead to significant financial losses. Buyers may find themselves in situations where they cannot quickly inflate a tire, leading to delays in deliveries or operational disruptions.

Die Lösung:

To mitigate this issue, businesses should consider investing in portable air compressors or tire inflators. These devices are compact and can easily fit into the trunk of a vehicle or be stored in a service vehicle. When selecting a portable compressor, prioritize models that can deliver sufficient pressure and have a quick inflation time. Additionally, establishing partnerships with local tire shops or service stations that offer air could be beneficial. Consider creating a directory of these locations for employees to access easily. This proactive approach ensures that teams can quickly address tire issues, reducing downtime and maintaining operational continuity.

Das Problem:

Many B2B buyers are uncertain about whether to fill tires with nitrogen or regular air. This confusion can lead to improper tire maintenance, affecting performance, fuel efficiency, and safety. In markets where nitrogen filling stations are not widely available, such as certain areas in Africa and the Middle East, buyers may struggle with the decision of whether to invest in nitrogen systems or stick with air, which is more readily available.

Illustrative image related to air tires

Die Lösung:

To make an informed decision, buyers should assess the specific needs of their fleet or equipment. For high-performance vehicles or heavy machinery that operates in extreme conditions, nitrogen may offer advantages such as longer retention of tire pressure and reduced moisture. However, for standard vehicles or operations with limited access to nitrogen, sticking with regular air may be more practical. Buyers should also consider the costs associated with both options, including the availability of nitrogen filling stations in their area. Providing staff with training on the benefits and drawbacks of each option will empower them to make informed choices. Implementing a regular tire maintenance schedule that includes pressure checks, regardless of the filling gas, will help ensure optimal performance and safety.

When selecting materials for air tires, it is essential to consider their properties and how they impact performance, durability, and cost. The following analysis focuses on four common materials used in the manufacturing of air tires: rubber, nylon, polyester, and steel. Each material has unique characteristics that influence its suitability for various applications.

Rubber is the primary material used in tire manufacturing due to its excellent elasticity and resilience. It can withstand a wide range of temperatures, typically rated from -40°F to 140°F (-40°C to 60°C), making it suitable for diverse climates. Rubber also exhibits good abrasion resistance, which is crucial for tires that encounter rough surfaces.

Vorteile: Rubber provides superior grip and traction, enhancing vehicle safety and performance. It is relatively inexpensive and widely available, making it a cost-effective choice for manufacturers.

Nachteile: While durable, rubber can degrade over time due to exposure to UV light and ozone, necessitating regular maintenance and replacement. Additionally, its performance can diminish in extreme temperatures, affecting tire longevity.

Internationale Erwägungen: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding rubber quality and environmental impact. Standards such as ASTM and ISO can guide material selection.

Nylon is commonly used in the tire’s inner layers, providing strength and flexibility. It has a high tensile strength, enabling it to withstand significant pressure, typically rated for 40-50 psi (pounds per square inch) in passenger tires.

Illustrative image related to air tires

Vorteile: Nylon’s lightweight nature contributes to improved fuel efficiency. Its resistance to punctures and tears enhances tire durability, making it suitable for off-road applications.

Nachteile: The primary limitation of nylon is its susceptibility to heat buildup, which can lead to tire failure if not managed properly. Additionally, nylon tires may not perform as well in wet conditions compared to rubber.

Internationale Erwägungen: Buyers should be aware of varying nylon quality standards across regions. Compliance with local manufacturing regulations and testing protocols is crucial for maintaining product integrity.

Polyester is often used in the tire’s carcass, providing structural support and stability. It has a lower density than nylon, which helps reduce overall tire weight while maintaining strength.

Illustrative image related to air tires

Vorteile: Polyester tires offer excellent resistance to environmental factors, including moisture and chemicals. They also provide a smoother ride due to their flexibility.

Nachteile: Polyester’s lower tensile strength compared to nylon means it may not be suitable for high-performance applications. Additionally, it can be more expensive than other materials.

Internationale Erwägungen: Buyers in Europe and the Middle East should consider compliance with EU regulations regarding material safety and performance standards. Familiarity with DIN standards can also aid in ensuring product quality.

Steel is primarily used in the belts and beads of tires, providing strength and stability. Steel belts help maintain tire shape and improve handling, while steel beads ensure a secure fit on the rim.

Vorteile: Steel enhances tire durability and performance, particularly under heavy loads. Its high resistance to deformation under pressure makes it ideal for commercial and industrial applications.

Nachteile: The main disadvantage of steel is its weight, which can negatively impact fuel efficiency. Additionally, steel can be prone to corrosion if not adequately treated.

Internationale Erwägungen: Buyers should be aware of different corrosion resistance standards in various regions. Compliance with JIS standards in Japan or ASTM standards in the U.S. is essential for maintaining quality.

Illustrative image related to air tires

| Material | Typical Use Case for air tires | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Tread and sidewall | Excellent grip and traction | Verschlechtert sich mit der Zeit | Niedrig |

| Nylon | Inner layers | High tensile strength | Susceptible to heat buildup | Mittel |

| Polyester | Carcass | Good moisture and chemical resistance | Lower tensile strength | Mittel |

| Stahl | Belts and beads | Enhanced durability and performance | Heavier, prone to corrosion | Hoch |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, helping them make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing of air tires involves a series of meticulously coordinated processes designed to ensure high-quality end products. Understanding these stages is crucial for B2B buyers seeking reliable suppliers.

The first stage in tire manufacturing is material preparation. This involves sourcing and mixing various raw materials, including natural and synthetic rubber, fabric, and steel. The rubber is blended with additives such as carbon black, sulfur, and accelerators to enhance durability, traction, and weather resistance. The quality of these materials is paramount; therefore, suppliers often perform rigorous testing to ensure they meet specific standards before proceeding to the next stage.

Once materials are prepared, the next step is forming. This involves several key techniques:

Each component is carefully aligned to ensure the tire’s structural integrity, which is crucial for performance and safety.

The assembly of air tires involves placing the green tire onto a mold for curing. This process, known as vulcanization, uses heat and pressure to bond the materials and shape the tire. The curing time and temperature are closely monitored to ensure optimal results.

Illustrative image related to air tires

During assembly, manufacturers conduct regular inspections to identify any defects early in the process. This includes visual inspections and measurements to ensure that all components meet predefined specifications.

After curing, tires undergo several finishing techniques, including trimming and painting. Trimming removes excess rubber, ensuring a smooth surface. Painting may also include branding or marking for identification.

Additionally, a final inspection is performed, often involving testing for uniformity, balance, and overall aesthetic quality. This stage is critical for ensuring that the tire meets both performance and aesthetic standards before it is shipped to customers.

Quality assurance (QA) is integral to the tire manufacturing process, ensuring that every tire meets international safety and performance standards.

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001, which outlines quality management systems, and specific industry standards like the European CE marking and American API certifications. These standards ensure that tires are manufactured with a focus on quality, safety, and environmental impact.

Quality control (QC) checkpoints are critical throughout the manufacturing process. Common checkpoints include:

Each checkpoint aims to catch defects early, thereby reducing waste and ensuring customer satisfaction.

Illustrative image related to air tires

B2B buyers must adopt a proactive approach when selecting suppliers to ensure they meet quality standards. Here are several methods to verify supplier QC:

Tire manufacturers employ various testing methods to ensure their products meet rigorous standards. Common tests include:

These tests provide vital data that can help manufacturers improve their products and reassure buyers of their reliability.

For international B2B buyers, understanding the nuances of quality control is essential. Different regions may have varying regulations and standards, which can impact tire performance and safety. For example, tires sold in Europe may be subject to stricter environmental regulations compared to those in South America or Africa.

Additionally, cultural factors can influence quality perceptions. B2B buyers should consider these aspects when assessing suppliers and seek partners who are familiar with the specific requirements of their target markets.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for air tires is crucial. By familiarizing themselves with the stages of production, international standards, and verification methods, buyers can make informed decisions that enhance their supply chain reliability and overall business success. Prioritizing quality assurance not only mitigates risks but also fosters long-term partnerships with reputable suppliers.

In the competitive landscape of tire procurement, especially for international B2B buyers, understanding the nuances of sourcing air tires is critical. This guide provides a clear, actionable checklist to streamline your purchasing process, ensuring you acquire high-quality products that meet your operational needs.

Before diving into the procurement process, it’s essential to establish your technical specifications for air tires. Consider factors such as tire size, load capacity, and intended use (e.g., passenger vehicles, commercial trucks). Defining these parameters helps narrow down your options and ensures compatibility with your vehicles.

Thoroughly vet potential suppliers to ensure they meet industry standards. Look for certifications such as ISO 9001 or relevant local certifications that demonstrate a commitment to quality. Additionally, evaluate their production capabilities and track record within the tire industry to gauge reliability and experience.

Quality should be a top priority in your sourcing strategy. Request samples or product specifications to assess the materials and construction of the tires. Ensure that the products comply with local regulations and international safety standards, which can vary significantly across regions like Africa, South America, and Europe.

Understanding the pricing structure is vital for budget management. Request detailed quotations from multiple suppliers, including unit prices, bulk discounts, and shipping costs. Additionally, clarify payment terms to avoid unexpected expenses, ensuring they align with your financial capabilities.

A reliable after-sales support system can greatly influence your purchasing decision. Inquire about warranty terms and conditions, as well as the availability of technical support. A robust support framework not only protects your investment but also ensures that any issues with the tires can be swiftly addressed.

Logistics play a crucial role in the timely delivery of your air tires. Discuss shipping methods, lead times, and tracking options with potential suppliers. Ensure that they can accommodate your delivery requirements, especially if you are sourcing from international markets where transit times may vary.

Illustrative image related to air tires

Before finalizing a supplier, seek references from other B2B buyers who have previously worked with them. Gathering feedback about their experiences can provide valuable insights into the supplier’s reliability, product quality, and customer service. This step helps mitigate risks associated with procurement decisions.

By following this checklist, you can effectively navigate the complexities of sourcing air tires, ensuring that you make informed decisions that align with your business needs and operational goals.

Understanding the cost structure of air tires is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materialien: The quality of rubber, synthetic fibers, and other components significantly impacts the final cost. Premium materials may increase durability and performance, which can justify higher pricing.

Arbeit: Skilled labor is essential in the manufacturing process, particularly in regions where labor costs may vary significantly. Countries with lower labor costs can produce tires at a reduced rate, but this may come at the expense of quality.

Fertigungsgemeinkosten: This includes costs related to machinery, utilities, and facility maintenance. Efficient manufacturing processes can help reduce overhead costs, ultimately affecting pricing.

Werkzeugbau: Custom molds and equipment for tire production can be a substantial upfront investment. Buyers should consider whether they require standard or custom tooling based on their specifications.

Qualitätskontrolle (QC): Rigorous QC processes ensure product reliability and safety, impacting both cost and pricing. Certifications (e.g., ISO, DOT) may also add to costs but are often necessary for compliance in various markets.

Logistik: Transportation and warehousing costs play a significant role in the overall pricing structure. Buyers should account for the distance from suppliers, which can affect shipping times and costs.

Marge: Suppliers typically add a margin to cover their costs and risks. This margin can vary based on market conditions and competition.

Several factors can influence pricing, especially for B2B buyers.

Volumen/MOQ (Mindestbestellmenge): Higher order volumes can lead to lower per-unit costs. Negotiating favorable terms based on projected purchase volumes can yield significant savings.

Spezifikationen und Anpassungen: Custom features, such as tread patterns or sizes, can increase costs. Buyers should assess whether customization is necessary or if standard options suffice.

Materialien: The choice between natural and synthetic rubber, as well as additives for specific performance characteristics, can significantly affect pricing.

Qualität und Zertifizierungen: Tires that meet specific safety and performance standards may command higher prices. Buyers should weigh the benefits of certified products against their budget constraints.

Lieferanten-Faktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge premium prices due to perceived quality and service levels.

Incoterms: Understanding the Incoterms agreed upon in contracts is essential. They define responsibilities for shipping, insurance, and tariffs, impacting the total landed cost of tires.

B2B buyers should adopt strategic approaches to enhance their negotiation power and ensure cost-efficiency.

Hebelwirkung auf die Gesamtbetriebskosten (TCO): Assessing the TCO, which includes maintenance, fuel efficiency, and lifecycle costs, can help justify a higher initial investment in quality tires.

Forschung Markttrends: Keeping abreast of market conditions, such as raw material prices and supply chain disruptions, can provide leverage during negotiations.

Build Long-term Relationships: Establishing strong relationships with suppliers can lead to better pricing, favorable terms, and improved service.

Be Clear on Specifications: Clearly define specifications and requirements upfront to avoid misunderstandings that could lead to additional costs.

Consider Alternative Suppliers: Diversifying suppliers across different regions can create competitive pricing and reduce dependency on a single source.

While sourcing air tires involves various cost components and pricing influencers, understanding these elements can lead to more informed purchasing decisions. B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, should approach their sourcing strategy with a comprehensive understanding of costs, negotiation tactics, and market dynamics. Always consider indicative pricing, as actual costs may vary based on specific circumstances and supplier negotiations.

When evaluating tire solutions for various applications, businesses must consider alternatives to traditional air-filled tires. The decision often hinges on performance, cost, ease of implementation, and maintenance requirements. Below, we compare air tires with two viable alternatives: solid tires and nitrogen-filled tires, offering insights to facilitate informed purchasing decisions.

| Vergleich Aspekt | Air Tires | Solid Tires | Nitrogen-Filled Tires |

|---|---|---|---|

| Leistung | Good traction and comfort, but susceptible to punctures | Excellent durability, no risk of punctures, but can be less comfortable | Maintains pressure longer, potentially improves fuel efficiency |

| Kosten | Generally low initial cost; ongoing maintenance required | Higher upfront cost; lower long-term maintenance costs | Moderate cost; requires specialized filling equipment |

| Leichte Implementierung | Widely available and easy to install | Heavier and requires specialized equipment for installation | Available at select service stations; easy to fill but less common |

| Wartung | Requires regular pressure checks; prone to wear and tear | Minimal maintenance; can last longer due to durability | Less frequent pressure checks needed; however, can be inconvenient to refill |

| Bester Anwendungsfall | Ideal for personal vehicles and light-duty applications | Suitable for heavy machinery and industrial applications | Best for performance vehicles and racing contexts |

Solid tires are a robust alternative that eliminates the risk of punctures, making them ideal for industrial and heavy-duty applications. Their durability allows them to withstand rough terrains without the need for frequent replacements. However, solid tires tend to be heavier and can offer a harsher ride compared to air-filled options, potentially affecting operator comfort. Additionally, the upfront cost is generally higher, which may deter some businesses from adopting this solution for lighter applications.

Nitrogen-filled tires are gaining popularity due to their ability to maintain tire pressure longer than traditional air. This can lead to improved fuel efficiency and enhanced vehicle handling. However, businesses must consider the availability of nitrogen filling stations, which may not be as widespread as conventional air pumps. The cost of nitrogen filling can also be higher than standard air, making it a less attractive option for budget-conscious buyers. Despite these factors, nitrogen is often preferred in performance settings, such as racing, where tire pressure stability is crucial.

Choosing the right tire solution depends on the specific needs of your operations. For businesses focused on cost-effectiveness and ease of access, traditional air tires may be the most suitable option. However, if durability and reduced maintenance are priorities, solid tires could be the better investment. For those in performance-oriented sectors, nitrogen-filled tires offer unique advantages that may justify their higher costs. Ultimately, evaluating the operational requirements and long-term goals will guide B2B buyers in selecting the optimal tire solution.

Illustrative image related to air tires

Understanding the essential technical properties of air tires is crucial for B2B buyers, as these specifications can significantly impact performance, safety, and cost-effectiveness. Here are some critical specifications to consider:

Materialzusammensetzung

The primary materials used in air tires include natural rubber, synthetic rubber, and various reinforcing agents like steel and polyester. The material grade directly affects durability, flexibility, and resistance to wear. For instance, high-grade rubber compounds enhance traction and longevity, which are essential for commercial vehicles operating in diverse conditions.

Tread Depth

Tread depth is a vital measurement that affects a tire’s grip on the road, water drainage, and overall performance. Standard depths typically range from 6 to 12 mm for commercial tires. A deeper tread can enhance traction, particularly in adverse weather conditions, making it a critical specification for buyers in regions prone to heavy rainfall or off-road conditions.

Load Index

The load index indicates the maximum weight a tire can support when properly inflated. This index is crucial for B2B buyers, especially those in logistics or transportation sectors, as it determines the suitability of a tire for specific vehicles. Selecting a tire with an appropriate load index ensures safety and efficiency in transporting goods.

Inflation Pressure

Proper inflation pressure is essential for optimal tire performance, fuel efficiency, and safety. Most manufacturers provide recommended pressure levels, which can vary based on vehicle type and load. For B2B buyers, maintaining correct inflation is vital for reducing operational costs and extending tire life.

Rolling Resistance

Rolling resistance refers to the energy lost as a tire rolls under load. Lower rolling resistance translates to better fuel efficiency, which is a significant cost consideration for businesses operating fleets. Buyers should look for tires specifically designed to minimize rolling resistance without compromising safety and performance.

Familiarity with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the tire industry, OEM tires are those made specifically for vehicle manufacturers. Understanding OEM specifications is crucial for ensuring compatibility and performance, especially when replacing tires for fleet vehicles.

MOQ (Mindestbestellmenge)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. It can also influence negotiation strategies when sourcing tires for large fleets.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers should provide detailed specifications when issuing RFQs for tires to ensure accurate pricing and suitability for their needs.

Incoterms (Internationale Handelsklauseln)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, as they help mitigate risks and clarify logistics responsibilities.

Treadwear Rating

This rating assesses how quickly a tire wears down under normal use. It is vital for B2B buyers to evaluate the long-term cost implications of different tire options. A higher treadwear rating indicates a longer-lasting tire, which can contribute to overall savings in maintenance and replacement costs.

Warranty Coverage

Warranty coverage specifies the terms under which a tire may be replaced or repaired if it fails. Understanding warranty terms is essential for B2B buyers to evaluate the risk associated with tire purchases and to ensure that they receive adequate support in case of defects or performance issues.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring air tires, ultimately leading to improved operational efficiency and cost savings.

Illustrative image related to air tires

The air tires market is experiencing notable transformations driven by several global factors. Increasing vehicle ownership in emerging markets, particularly in regions like Africa and South America, is propelling demand. As urbanization accelerates, the need for reliable transportation solutions is paramount. Furthermore, innovations in tire technology, such as improved materials and manufacturing processes, are enhancing performance and durability. International B2B buyers should be aware of the growing trend toward digital sourcing platforms that facilitate efficient procurement processes. These platforms enable buyers to compare suppliers, access real-time pricing, and streamline their supply chain operations.

Additionally, the shift towards electric vehicles (EVs) is influencing tire design, with a focus on lightweight and low rolling resistance tires that can optimize battery life. B2B buyers need to consider suppliers who are adapting to these changes, ensuring their tire offerings are aligned with the latest technological advancements. The integration of smart technology in tires, such as sensors for real-time pressure monitoring, is also gaining traction, offering buyers new opportunities for operational efficiency.

Sustainability is becoming a critical factor in the air tires market, with environmental impacts prompting B2B buyers to prioritize ethical sourcing practices. The production of tires has significant ecological ramifications, including resource extraction and waste generation. Buyers are increasingly seeking suppliers who adhere to sustainable manufacturing processes, such as using recycled materials or bio-based compounds in tire production.

Certifications like ISO 14001 (Environmental Management) and the Global Recycled Standard are gaining importance, as they indicate a commitment to sustainable practices. Furthermore, the push for circular economy models encourages tire manufacturers to develop tires that can be recycled or repurposed at the end of their lifecycle, reducing landfill contributions. B2B buyers should actively inquire about suppliers’ sustainability initiatives and certifications to ensure compliance with global environmental standards and to enhance their own corporate responsibility profiles.

The evolution of air tires dates back to the late 19th century, with significant advancements shaping today’s market. The introduction of pneumatic tires revolutionized transportation, providing improved comfort and performance. Over the decades, innovations such as radial tire technology have further enhanced tire durability and fuel efficiency, making them indispensable for modern vehicles.

For B2B buyers, understanding this historical context is crucial as it highlights the ongoing innovation within the sector. Suppliers that leverage historical advancements to inform their product development are more likely to provide high-quality, reliable products. Additionally, recognizing the trajectory of tire technology can help buyers anticipate future trends and align their sourcing strategies accordingly. As the market evolves, staying informed about both historical and current advancements will empower B2B buyers to make informed decisions that enhance their operational efficiency and competitiveness.

How do I solve quality issues with air tires from international suppliers?

To address quality issues with air tires sourced from international suppliers, start by conducting thorough vetting of potential suppliers. Request samples to assess the tire’s performance and durability. Implement a quality assurance (QA) process that includes regular inspections and testing upon receipt. Additionally, establish clear communication regarding quality standards in your contracts. Engaging a third-party inspection service can also help ensure compliance with specifications before shipment, reducing the risk of receiving defective products.

What is the best way to evaluate air tire suppliers in different regions?

Evaluating air tire suppliers effectively requires a multi-faceted approach. Begin by checking their industry certifications and customer reviews to gauge reliability. Conduct site visits if feasible, or utilize virtual tours to assess production capabilities. Request references from other international buyers, particularly those in your region, to understand their experiences. Finally, consider suppliers who demonstrate knowledge of local regulations and customs practices, as this can streamline logistics and compliance.

What are the typical minimum order quantities (MOQs) for air tires?

Minimum order quantities for air tires can vary significantly depending on the supplier and the type of tire. Generally, MOQs range from 100 to 1,000 units for standard products. For customized or specialty tires, the MOQ may be higher due to the additional costs associated with production changes. It’s essential to clarify MOQs during initial negotiations, as some suppliers may be willing to accommodate smaller orders for first-time buyers or long-term partnerships.

What payment terms should I expect when sourcing air tires internationally?

Payment terms for international air tire transactions often depend on the supplier’s policies and the buyer’s negotiation power. Common arrangements include letters of credit, advance payments, or net 30-90 days after shipment. It’s advisable to negotiate terms that minimize risk while maintaining a good relationship with your supplier. Ensure that all payment terms are clearly outlined in the contract to avoid misunderstandings, and consider using escrow services for larger transactions to protect both parties.

How can I customize air tires to meet specific needs?

Customizing air tires involves collaborating closely with your supplier to discuss your specific requirements. This may include modifications to tread patterns, rubber compounds, or tire sizes. Provide detailed specifications and performance criteria to ensure the supplier understands your needs. Be aware that customization may lead to increased MOQs and longer lead times. Always request prototypes before finalizing your order to verify that the customized product meets your expectations.

What logistics considerations should I keep in mind when importing air tires?

When importing air tires, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable logistics partner familiar with international shipping and the specific requirements for transporting tires. Additionally, account for potential delays at customs by ensuring all documentation is complete and compliant. It’s also wise to factor in insurance for high-value shipments to protect against loss or damage during transit.

What certifications should I look for in air tires?

Look for certifications that indicate compliance with international safety and quality standards. Common certifications include ISO 9001 for quality management, DOT (Department of Transportation) approval in the U.S., and ECE (Economic Commission for Europe) certification for the European market. These certifications can assure you that the tires meet rigorous safety and performance criteria. Additionally, inquire about any eco-labels that indicate environmentally friendly manufacturing practices, which can be a selling point in your market.

How can I ensure timely delivery of air tires from suppliers?

To ensure timely delivery of air tires, maintain open lines of communication with your supplier throughout the production and shipping processes. Set clear deadlines and confirm the supplier’s ability to meet them before placing your order. Utilize tracking systems to monitor shipment progress and establish contingency plans for potential delays. It’s also beneficial to build a buffer into your inventory management to accommodate unexpected shipping issues, ensuring that your operations remain uninterrupted.

Bereich: freeairpump.com

Registriert: 2012 (13 Jahre)

Einleitung: Map of places that provide free air for tires; over 12k locations in the U.S.; user-generated database; ability to submit new locations; search by device location or address; indicates bike repair stations and free air for autos; suggests portable air compressors as an alternative; mentions common locations offering free air: tire shops, car repair stations, bike shops, and specific gas station ch…

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Electric tire pump, approximately $35; tire pressure gauge; tire pressure sticker location (door jamb of driver’s door); typical tire pressure around 30 pounds; digital tire pumps with preset pressure settings; battery-operated pumps; basic electric tire pump recommended for regular use.

Bereich: principlevolvocarssanantonio.com

Registriert: 2017 (8 Jahre)

Einleitung: Nitrogen-filled tires can hold their pressure longer, potentially improving comfort and fuel economy. Filling tires with air is less expensive and more commonly available. Both nitrogen and air can effectively fill tires, but nitrogen is preferred in heavy-duty applications and racing due to its larger molecule size, which reduces air loss. However, nitrogen is more costly and less accessible than…

Bereich: continentaltire.com

Registriert: 1996 (29 Jahre)

Einleitung: Nitrogen is offered as an alternative to air for tire inflation. It is an inert gas that does not support moisture or combustion, making it suitable for specialized tire service applications like aircraft, mining, and professional auto racing. While nitrogen can marginally reduce tire inflation loss by permeation, it does not prevent loss from punctures or leaks. Regular tire inflation pressure ma…

Bereich: goodyearautoservice.com

Registriert: 2006 (19 Jahre)

Einleitung: Proper tire inflation is critical for tire care, extending tire life, improving vehicle performance, and enhancing safety. Recommended air pressure is specified by the vehicle’s manufacturer and can be found in various locations such as the vehicle door edge, door jamb, glove box door, or fuel door. It is important to check tire pressure when the tires are cool and to visually inspect tires for an…

As the global market for air tires continues to evolve, strategic sourcing remains a critical factor for international B2B buyers. Companies must prioritize partnerships with reliable suppliers who can provide high-quality products, competitive pricing, and timely delivery. Understanding the regional dynamics in Africa, South America, the Middle East, and Europe is essential, as local preferences and regulations can significantly impact sourcing decisions.

Moreover, the choice between traditional air and nitrogen-filled tires presents an opportunity for buyers to differentiate their offerings. While nitrogen can enhance tire performance and longevity, accessibility and cost should be considered, especially in emerging markets.

In conclusion, the strategic sourcing of air tires is not just about procurement; it’s about building relationships that foster innovation and sustainability. International buyers are encouraged to leverage market insights, explore new technologies, and remain adaptable to changing demands. By doing so, they can position themselves for success in a competitive landscape. Embrace the journey of sourcing air tires as a pathway to growth and operational excellence in your business.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Illustrative image related to air tires