In the competitive landscape of international trade, sourcing quality inflate tires presents a significant challenge for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The necessity for reliable tire inflation solutions transcends geographical boundaries, with companies facing pressure to enhance operational efficiency, reduce costs, and ensure safety across their fleets. This comprehensive guide serves as a vital resource for buyers looking to navigate the complexities of the global tire inflation market.

Within this guide, you will find in-depth insights into various types of inflate tires, their applications across different industries, and the critical factors to consider when vetting suppliers. Additionally, we will explore cost analysis and the latest innovations in tire inflation technology, including the benefits of nitrogen inflation and the use of portable compressors. By empowering B2B buyers with actionable knowledge and best practices, this guide aims to facilitate informed purchasing decisions that align with their strategic goals.

Whether you are sourcing tires for commercial vehicles, industrial machinery, or personal transport, understanding the intricacies of tire inflation is essential for optimizing performance and safety. Dive into this guide to unlock the potential of your procurement strategy and secure the best tire solutions for your operational needs.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Air Inflation | Utilizes compressed air, widely available and easy to use. | Automotive service stations, fleet management | Vorteile: Cost-effective, widely accessible. Nachteile: Air can leak faster than nitrogen. |

| Nitrogen Inflation | Tires are inflated with nitrogen gas, reducing air loss and maintaining pressure longer. | Racing teams, luxury vehicle services | Vorteile: Improved tire longevity, better fuel efficiency. Nachteile: Higher initial cost, limited availability. |

| Portable Air Compressors | Compact devices for inflation, often used for emergency situations or personal vehicles. | Small businesses, roadside assistance | Vorteile: Convenient, portable. Nachteile: Requires power source, may be slower than commercial inflators. |

| Tire Pressure Monitoring Systems (TPMS) | Integrated systems that automatically monitor tire pressure and alert drivers. | Fleet vehicles, logistics companies | Vorteile: Enhances safety, reduces maintenance costs. Nachteile: Initial setup cost, potential for sensor malfunctions. |

| Manual Tire Inflators | Hand-operated devices that require physical effort to inflate tires. | Small automotive shops, DIY enthusiasts | Vorteile: Low cost, no power needed. Nachteile: Labor-intensive, less efficient for multiple tires. |

Standard air inflation is the most common method for inflating tires, utilizing compressed air from gas stations or service centers. This method is highly accessible and cost-effective, making it suitable for a wide range of B2B applications, including automotive service stations and fleet management. However, a significant drawback is that tires inflated with regular air can lose pressure more quickly than those inflated with nitrogen, necessitating more frequent checks and maintenance.

Nitrogen inflation involves filling tires with nitrogen gas, which has larger molecules compared to air, resulting in reduced air loss and prolonged tire pressure maintenance. This method is particularly advantageous for racing teams and luxury vehicle services that prioritize performance and efficiency. While the initial investment may be higher, the long-term benefits include enhanced tire longevity and improved fuel efficiency, making it a worthwhile consideration for businesses focused on operational cost savings.

Portable air compressors are compact devices designed for tire inflation in emergency situations or for personal vehicles. They are particularly useful for small businesses and roadside assistance services that may encounter flat tires. The convenience and portability of these compressors make them an essential tool; however, they require a power source and may inflate tires more slowly than commercial-grade inflators, which can impact service speed.

Tire Pressure Monitoring Systems (TPMS) are integrated technologies that automatically monitor tire pressure and alert drivers when levels fall below recommended thresholds. These systems are particularly beneficial for fleet vehicles and logistics companies, as they enhance safety and can reduce maintenance costs by preventing tire-related issues. However, the initial setup costs and potential for sensor malfunctions may deter some buyers.

Manual tire inflators are hand-operated devices that do not require a power source for operation. They are often used by small automotive shops and DIY enthusiasts due to their low cost and simplicity. While they offer the advantage of being usable in remote areas without electricity, they can be labor-intensive and less efficient for inflating multiple tires, making them less suitable for larger-scale operations.

| Industrie/Sektor | Specific Application of Inflate Tires | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Transport und Logistik | Fuhrpark-Management | Enhances fuel efficiency and extends tire lifespan. | Ensure compatibility with various vehicle types. |

| Landwirtschaft | Agricultural Machinery | Optimizes performance of tractors and harvesters. | Look for durable tires suitable for rugged terrains. |

| Bauwesen | Heavy Equipment | Reduces downtime due to tire failures. | Prioritize tires with high load capacities and durability. |

| Automotive Services | Tire Retail and Service Stations | Increases customer satisfaction through improved safety. | Source high-quality inflation equipment and gauges. |

| Mining | Off-Road Vehicle Tires | Improves safety and reduces the risk of tire blowouts. | Consider specialized tires designed for extreme conditions. |

In the transportation and logistics sector, properly inflated tires are crucial for fleet management. Companies often invest in tire inflation systems to maintain optimal pressure, which directly influences fuel efficiency and tire longevity. For international buyers, especially in regions like Africa and South America where road conditions may vary, sourcing reliable inflation equipment and understanding local regulations becomes essential. Ensuring compatibility with a diverse fleet can also enhance operational efficiency.

Agricultural machinery relies heavily on tire performance to navigate uneven terrains and support heavy loads. Proper inflation is vital to optimize the performance of tractors and harvesters, minimizing soil compaction and maximizing traction. Buyers in agricultural sectors must consider sourcing durable tires that can withstand rigorous conditions, particularly in regions like the Middle East where heat and rough terrains are prevalent. Understanding the specific requirements for tire inflation in agricultural contexts can significantly impact productivity.

Illustrative image related to inflate tires

In the construction industry, the use of heavy equipment necessitates the need for reliable tire inflation practices. Properly inflated tires reduce the risk of blowouts, thereby minimizing downtime and enhancing safety on job sites. For B2B buyers, sourcing high-quality tires that can support heavy loads and endure harsh conditions is critical. Buyers should prioritize suppliers that offer robust inflation solutions and consider regional factors such as climate and terrain to ensure optimal performance.

Tire retail and service stations benefit from offering tire inflation services as a value-added offering. Proper tire inflation not only enhances vehicle safety but also improves customer satisfaction by reducing the likelihood of tire-related issues. For businesses in this sector, sourcing high-quality inflation equipment and gauges is vital. International buyers should seek suppliers with a reputation for reliability and accuracy to ensure the best service for their customers.

In the mining sector, the safety of off-road vehicles is paramount, making proper tire inflation critical. Correctly inflated tires reduce the risk of blowouts and improve traction on uneven surfaces, which is essential in mining environments. B2B buyers must consider specialized tires designed for extreme conditions and source inflation systems that can withstand rugged use. Understanding the unique demands of mining operations will help in selecting the right tire solutions to enhance safety and efficiency.

Illustrative image related to inflate tires

Das Problem: B2B buyers operating in regions with extreme temperature fluctuations—such as parts of Africa and the Middle East—often struggle with maintaining the proper tire pressure for their fleets. High temperatures can lead to overinflation, while colder temperatures can cause underinflation. This inconsistency can lead to increased tire wear, higher fuel consumption, and ultimately, safety hazards on the road. Buyers may find it challenging to ensure that their drivers are regularly checking tire pressures, especially in remote locations where access to air pumps and tire gauges may be limited.

Die Lösung: To address this challenge, B2B buyers should implement a structured tire maintenance program that includes regular training for drivers on the importance of checking tire pressure, especially before long trips. Investing in portable tire inflators with built-in pressure gauges can empower drivers to adjust tire pressure on-site, mitigating issues related to temperature variations. Additionally, establishing a partnership with local tire service providers can facilitate scheduled checks and maintenance, ensuring that tire pressure remains consistent regardless of climate changes. This proactive approach not only enhances safety but also optimizes fuel efficiency and extends tire lifespan.

Das Problem: Companies managing logistics and transport fleets often overlook the critical balance of tire inflation, leading to either overinflation or underinflation. Overinflated tires wear out more quickly in the center, compromising grip, especially in wet conditions. Conversely, underinflated tires lead to excessive rolling resistance, increasing fuel consumption and risking tire blowouts. This dual problem can significantly impact operational costs and road safety, creating a pressing concern for fleet managers.

Die Lösung: To mitigate these risks, B2B buyers should adopt an automated tire pressure monitoring system (TPMS) that alerts drivers in real-time about tire pressure changes. This technology can provide immediate feedback, allowing for prompt adjustments before problems escalate. Additionally, conducting routine training sessions that emphasize the effects of improper tire inflation can enhance awareness among drivers. Pairing this education with easy access to tire pressure gauges and inflation tools ensures that drivers can make necessary adjustments quickly, fostering a culture of safety and efficiency within the organization.

Das Problem: International B2B buyers, particularly those in regions with developing infrastructure, may face challenges sourcing reliable tire inflation equipment. Poor-quality inflators can lead to inaccurate readings, resulting in either overinflation or underinflation. This situation is exacerbated in remote areas where access to maintenance and support is limited. Buyers often find themselves with equipment that fails to meet their operational needs, leading to increased downtime and operational inefficiencies.

Illustrative image related to inflate tires

Die Lösung: To overcome this sourcing challenge, B2B buyers should conduct thorough research to identify reputable suppliers of tire inflation equipment. Establishing relationships with trusted manufacturers or distributors can ensure access to high-quality, calibrated inflators that meet industry standards. Buyers should also consider bulk purchasing agreements to reduce costs while securing reliable equipment. Furthermore, providing ongoing training for employees on how to effectively use and maintain these tools can enhance their longevity and reliability. By investing in quality equipment and training, businesses can ensure that their tire inflation processes are efficient, safe, and cost-effective.

When selecting materials for inflating tires, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Rubber is the most common material used in tire manufacturing, particularly for the inner linings that hold air. Its key properties include excellent elasticity, temperature resistance (typically between -40°C to 100°C), and good pressure retention capabilities. Rubber also exhibits inherent corrosion resistance, making it suitable for various environmental conditions.

Pro und Kontra:

The primary advantage of rubber is its durability and flexibility, allowing it to withstand the stresses of inflation and deflation cycles. However, rubber can degrade over time due to UV exposure and ozone, leading to potential leaks. Manufacturing complexity is moderate, as rubber requires specialized processes for molding and curing.

Illustrative image related to inflate tires

Auswirkungen auf die Anwendung:

Rubber is compatible with air and nitrogen inflation, making it versatile for different tire types. However, international buyers must consider local climatic conditions that may affect rubber longevity.

Steel is often used in tire construction, particularly in belts and beads, to provide structural integrity and strength. Key properties of steel include high tensile strength, temperature resilience, and corrosion resistance, particularly when treated or coated.

Pro und Kontra:

The inclusion of steel enhances durability and puncture resistance, leading to longer tire life. However, steel can increase the overall weight of the tire, potentially affecting fuel efficiency. The manufacturing complexity is high, as it involves precise engineering to integrate steel components with rubber.

Illustrative image related to inflate tires

Auswirkungen auf die Anwendung:

Steel-reinforced tires are essential for heavy-duty applications, especially in regions with rough terrains, such as parts of Africa and South America. Compliance with international standards like ASTM and DIN is crucial for ensuring safety and performance.

Nylon is frequently used in tire manufacturing, particularly in the casing and inner linings. Its key properties include high tensile strength, flexibility, and resistance to wear and tear. Nylon can also withstand a wide range of temperatures, making it suitable for various climates.

Pro und Kontra:

Nylon’s primary advantage is its lightweight nature, which can improve fuel efficiency and handling. However, it may not offer the same level of puncture resistance as steel. The manufacturing complexity is moderate, as nylon requires specific treatments to enhance its properties.

Illustrative image related to inflate tires

Auswirkungen auf die Anwendung:

Nylon is particularly beneficial in passenger vehicle tires, which are common in urban environments across Europe and the Middle East. Buyers should ensure that the nylon used meets local standards to avoid performance issues.

Polyurethane is emerging as an alternative material for tire linings and inflation systems. Its key properties include excellent abrasion resistance, flexibility, and a wide temperature range (from -30°C to 80°C).

Pro und Kontra:

The advantages of polyurethane include its resistance to wear and tear, making it suitable for high-performance applications. However, it can be more expensive than traditional materials, and its long-term durability in extreme conditions is still under evaluation. Manufacturing complexity can be high due to the need for specialized processes.

Auswirkungen auf die Anwendung:

Polyurethane is gaining traction in specialized applications, such as off-road and performance tires. International buyers should consider the availability of polyurethane options in their regions and ensure compliance with relevant standards.

| Material | Typical Use Case for inflate tires | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Standard passenger and light truck tires | Excellent elasticity and durability | Degrades over time due to UV exposure | Mittel |

| Stahl | Heavy-duty and performance tires | High tensile strength and puncture resistance | Increases tire weight | Hoch |

| Nylon | Passenger vehicle tires | Lightweight, improving fuel efficiency | Lower puncture resistance than steel | Mittel |

| Polyurethane | High-performance and specialized tires | Excellent abrasion resistance | Higher cost and uncertain long-term durability | Hoch |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make informed decisions that align with their specific needs and regional conditions.

The manufacturing process for inflate tires involves several critical stages, each essential to producing a high-quality product. These stages include material preparation, forming, assembly, and finishing.

Material preparation is the foundational step in tire manufacturing. It involves sourcing raw materials such as natural and synthetic rubber, fabric, and steel. Each of these materials must meet specific quality standards to ensure the tire’s performance and longevity. For instance, rubber compounds are formulated to achieve the desired balance of durability, flexibility, and heat resistance.

Once the materials are sourced, they undergo rigorous testing and quality checks. This includes assessing the physical properties of the rubber, ensuring it can withstand the stresses of inflation and road conditions. Suppliers must provide certificates of analysis (COAs) to verify material quality, which is crucial for B2B buyers aiming to ensure compliance with international standards.

The forming stage involves shaping the prepared materials into tire components. This process typically employs advanced machinery to ensure precision and consistency. Key techniques include:

B2B buyers should inquire about the machinery and technology used in these processes, as well as any innovations that may improve efficiency or product quality.

Illustrative image related to inflate tires

The assembly stage is where the individual components come together to form the complete tire. This process requires precision and attention to detail to ensure that each tire meets safety and performance standards.

Typically, assembly includes the following steps:

Finishing processes are crucial in ensuring that tires are ready for market. This stage includes:

Quality assurance (QA) is integral to tire manufacturing, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these practices is essential for making informed purchasing decisions.

International standards such as ISO 9001 play a significant role in tire manufacturing quality assurance. This standard focuses on quality management systems and processes, ensuring that manufacturers consistently meet customer and regulatory requirements.

Illustrative image related to inflate tires

In addition to ISO standards, various industry-specific certifications are critical, including:

Quality control checkpoints are established throughout the manufacturing process to maintain product integrity. These include:

For B2B buyers, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

International buyers face unique challenges regarding quality control, particularly when sourcing from regions with varying regulatory environments. Understanding these nuances is essential for mitigating risks:

Illustrative image related to inflate tires

Understanding the manufacturing processes and quality assurance practices for inflate tires is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as adhering to international quality standards and implementing robust quality control measures, buyers can ensure they source high-quality products that meet their operational needs. Engaging in thorough verification processes, including audits and third-party inspections, further enhances confidence in supplier capabilities, especially in diverse markets across Africa, South America, the Middle East, and Europe.

This guide provides a practical checklist for B2B buyers looking to procure tire inflation solutions, ensuring optimal performance and safety across various vehicle types. Proper tire inflation is essential for efficiency, safety, and longevity of tires, making it a critical area for procurement.

Understanding the specific requirements for tire inflation is crucial. Consider the types of vehicles in your fleet, the average tire sizes, and the environments in which these vehicles operate. Assess whether you need portable compressors for remote locations or stationary inflators for service stations.

Explore the different tire inflation technologies available in the market. Options range from traditional air compressors to advanced nitrogen inflation systems. Each technology has unique benefits, such as nitrogen’s ability to maintain pressure longer, which could lead to reduced maintenance costs and improved tire longevity.

Illustrative image related to inflate tires

Thoroughly vet potential suppliers for their ability to meet your specific tire inflation needs. Request detailed company profiles, including their experience in the industry, client portfolios, and case studies. Look for suppliers who can demonstrate successful implementations in similar markets or with comparable vehicle types.

Ensure that suppliers adhere to international standards and local regulations related to tire inflation equipment. Certifications such as ISO 9001 or specific automotive industry standards can indicate a supplier’s commitment to quality and safety. This step is vital to mitigate risks associated with non-compliance, which can lead to operational disruptions.

Before finalizing a purchase, ask suppliers to provide demonstrations or trial periods for their tire inflation solutions. This allows you to assess performance, ease of use, and compatibility with your existing systems. Observing the equipment in action can also help identify potential issues before committing to a larger order.

Evaluate not only the upfront costs but also the total cost of ownership for the tire inflation solutions you are considering. Include factors such as maintenance costs, energy consumption, and the longevity of the equipment. A lower initial price may not be advantageous if the long-term costs outweigh the benefits.

Illustrative image related to inflate tires

After procurement, develop a structured maintenance plan to ensure the longevity and reliability of your tire inflation equipment. Regular inspections and servicing can prevent breakdowns and ensure optimal performance. Additionally, consider training staff on proper usage and maintenance to maximize efficiency and safety.

By following this checklist, B2B buyers can make informed decisions when sourcing tire inflation solutions, ensuring safety, efficiency, and cost-effectiveness in their operations.

When sourcing inflate tires, understanding the cost structure is critical for B2B buyers. The primary cost components include:

Materialien: The primary materials used in tire manufacturing include rubber, steel, and textiles. The quality and source of these materials significantly influence costs. For instance, natural rubber sourced from sustainable plantations may be more expensive than synthetic alternatives but offers enhanced performance and environmental benefits.

Arbeit: Labor costs vary by region and are influenced by local wage standards, skill levels, and labor laws. Countries with a skilled workforce may offer higher-quality products but at a premium price.

Fertigungsgemeinkosten: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, impacting the overall pricing strategy.

Werkzeugbau: The initial investment in molds and machinery is a significant expense, especially for customized tire designs. Buyers should consider the tooling costs when assessing the total price of custom tires.

Qualitätskontrolle (QC): Ensuring product quality requires investment in QC processes. Certifications, such as ISO or local standards, not only assure quality but can also influence pricing. Tires that meet higher standards typically command higher prices.

Logistik: Transportation and warehousing costs are critical, particularly for international buyers. Shipping methods, distances, and regional regulations can all affect the final cost of tires.

Marge: Suppliers will include a profit margin in their pricing, which can vary based on market conditions, competition, and perceived value.

Several factors influence the pricing of inflate tires, particularly for international B2B buyers:

Volumen/MOQ (Mindestbestellmenge): Larger orders often lead to reduced per-unit costs. Buyers should negotiate favorable terms based on anticipated demand to secure better pricing.

Spezifikationen und Anpassungen: Custom tire specifications can significantly affect costs. Specialized tires may require unique materials or manufacturing processes, increasing the price. Standardized products generally offer better pricing.

Materialqualität und Zertifizierungen: Higher quality materials and certifications can raise costs but may lead to lower Total Cost of Ownership (TCO) through improved durability and performance. Buyers should weigh the long-term benefits against the initial price.

Lieferanten-Faktoren: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer higher prices but provide assurances of quality and timely delivery, reducing risk for buyers.

Incoterms: The choice of Incoterms (International Commercial Terms) determines who is responsible for shipping, insurance, and tariffs, affecting overall costs. Clear understanding of these terms is essential for budgeting.

To enhance cost-efficiency and secure favorable pricing, B2B buyers should consider the following strategies:

Illustrative image related to inflate tires

Verhandlung: Engage in discussions with suppliers to explore bulk discounts, payment terms, and potential rebates. Building a long-term relationship can also lead to better pricing over time.

Kosteneffizienz: Analyze the Total Cost of Ownership, not just the purchase price. Consider factors such as longevity, maintenance costs, and fuel efficiency associated with the tires to make informed decisions.

Nuancen der Preisgestaltung verstehen: International buyers should be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. Being informed can help buyers negotiate better terms and avoid unexpected costs.

Local Market Insights: For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics, including demand trends and competition, can provide leverage in negotiations.

Pricing for inflate tires can vary widely based on the factors mentioned above. The figures provided in this analysis are indicative and should be validated with suppliers for precise quotes tailored to specific requirements. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to ensure competitive pricing and quality assurance.

When it comes to maintaining tire performance, proper inflation is critical. However, various alternatives and complementary methods exist that can enhance tire longevity, performance, and safety. Understanding these options allows B2B buyers to make informed decisions that align with their operational needs and business objectives.

| Vergleich Aspekt | Inflate Tires | Nitrogen Inflation | Tire Sealant |

|---|---|---|---|

| Leistung | Optimal fuel efficiency, safety | Maintains pressure longer, reduces heat build-up | Provides a temporary fix for leaks |

| Kosten | Low (cost of air) | Higher initial cost, service fees | Moderate cost, one-time purchase |

| Leichte Implementierung | Simple and accessible | Requires specialized service | Easy to apply, DIY-friendly |

| Wartung | Regular checks needed | Minimal (check nitrogen levels) | Reapplication needed periodically |

| Bester Anwendungsfall | General use across vehicles | Performance vehicles, long-haul transportation | Off-road vehicles, emergency situations |

Nitrogen inflation involves filling tires with nitrogen gas instead of regular air. This method offers several advantages, including a slower rate of pressure loss and reduced oxidation, which can enhance tire longevity. The larger nitrogen molecules reduce air seepage through the tire walls, making it particularly beneficial for high-performance and long-haul vehicles that require consistent pressure. However, the initial cost can be higher due to the need for specialized equipment and service, which may not be justifiable for every business.

Tire sealants are liquid products that can be applied to tires to seal punctures and leaks. This solution is particularly useful for off-road vehicles or in industries where tires are subject to rough conditions, as it offers a temporary fix that can keep vehicles operational without immediate tire replacement. The ease of application makes it a viable option for businesses looking for a fast solution. However, tire sealants do not address the root cause of pressure loss and may require reapplication over time.

Selecting the appropriate tire maintenance solution depends on various factors, including the specific requirements of your vehicles, operational conditions, and budget constraints. For companies prioritizing performance and longevity, nitrogen inflation may offer significant benefits. Conversely, businesses that frequently encounter punctures in challenging terrains might find tire sealants to be a practical choice. Regular tire inflation remains essential for all methods, as maintaining proper tire pressure is critical for safety, performance, and cost-effectiveness. B2B buyers should evaluate their operational needs, weigh the pros and cons of each option, and choose the solution that best aligns with their business objectives and vehicle usage patterns.

Illustrative image related to inflate tires

When engaging in the tire inflation process, understanding the critical technical properties is essential for ensuring performance, safety, and cost-effectiveness. Here are several key specifications that B2B buyers should be familiar with:

The tire pressure rating, typically expressed in pounds per square inch (PSI) or bar, indicates the optimal air pressure required for safe operation. Maintaining the correct pressure is vital, as underinflation can lead to increased tire wear, reduced fuel efficiency, and a higher risk of blowouts. For B2B operations, adherence to these specifications can significantly affect operational costs and safety standards.

The load index is a numerical code that indicates the maximum load a tire can support at its specified pressure. This specification is crucial for businesses that rely on transporting goods, as it ensures that the tires can handle the weight of the load without compromising performance. Choosing tires with the appropriate load index is essential to avoid excess wear and potential accidents.

Speed ratings indicate the maximum speed at which a tire can safely operate. This is denoted by a letter (e.g., H for 130 mph, V for 149 mph). For B2B buyers, selecting tires with the appropriate speed rating is critical for ensuring safety during transportation, especially in industries where time-sensitive deliveries are essential.

The material composition of tires, including the rubber grade and the presence of reinforcing materials like steel belts, affects durability and performance. Higher-grade materials can improve wear resistance and reduce the likelihood of punctures. B2B buyers should consider these factors when sourcing tires, as they directly impact the longevity and reliability of the products.

The tread pattern influences traction, handling, and braking performance. Tread depth is equally important, as tires with insufficient tread can lead to unsafe driving conditions, particularly in wet or slippery conditions. For businesses, selecting the right tread design can enhance operational efficiency and safety, reducing the likelihood of accidents.

Temperature resistance refers to a tire’s ability to withstand heat generated during operation. This property is critical, especially in regions with extreme weather conditions. Ensuring that tires can handle high temperatures helps prevent blowouts and extends tire life, which is essential for maintaining fleet performance.

Understanding trade terminology is equally important for effective communication and decision-making in the tire industry. Here are several common terms that B2B buyers should know:

OEM refers to the company that originally manufactures the tires or vehicles. When sourcing tires, buyers often seek OEM products to ensure compatibility and quality. Utilizing OEM parts can lead to better performance and longer-lasting products.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B transactions, as it affects inventory management and budgeting. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or shortages.

An RFQ is a document that solicits pricing and terms from suppliers for specific products. This term is vital for B2B buyers looking to compare costs and negotiate favorable terms. A well-structured RFQ can streamline the procurement process and enhance supplier relationships.

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify aspects such as shipping, insurance, and risk transfer. Understanding Incoterms helps B2B buyers navigate global supply chains more effectively, reducing the risk of disputes.

TPMS is a technology that monitors tire pressure and alerts drivers when levels fall below the recommended threshold. For businesses, integrating TPMS in vehicles can enhance safety and reduce maintenance costs by ensuring optimal tire performance.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency, safety, and cost-effectiveness in tire management and inflation processes.

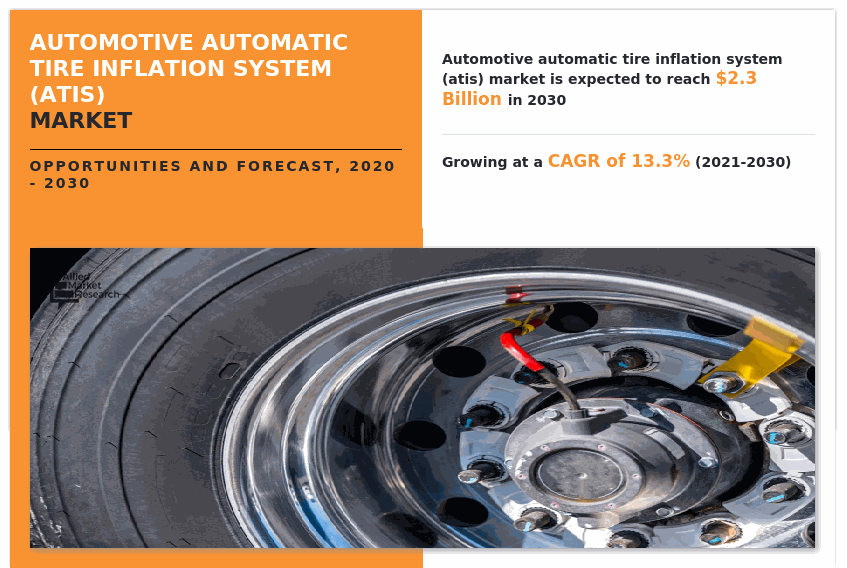

The inflate tires market is experiencing notable growth, driven by several global factors. Firstly, the increasing vehicle ownership in emerging markets like Africa and South America is leading to higher demand for tires. Additionally, the rising awareness of vehicle safety and fuel efficiency is prompting buyers to prioritize proper tire inflation, thus driving sales of inflation products and services. Furthermore, technological advancements in tire pressure monitoring systems (TPMS) and inflation technology are streamlining the tire maintenance process, making it easier for businesses to ensure optimal performance.

Emerging B2B technology trends include the integration of IoT devices that provide real-time tire pressure data, allowing for proactive maintenance and reduced downtime. This is particularly relevant for fleet operators in regions such as the Middle East, where harsh driving conditions can lead to rapid tire wear. Moreover, e-commerce platforms are increasingly becoming vital sourcing channels, enabling international buyers to access a wider range of tire products and services with greater convenience.

Sustainability is becoming an essential consideration in the inflate tires market. The environmental impact of tire production and disposal is significant, with improper management contributing to pollution and waste. As a result, B2B buyers are increasingly seeking suppliers who adhere to sustainable practices. This includes sourcing materials responsibly and utilizing recycled rubber in tire manufacturing. The demand for ‘green’ certifications is rising, with buyers looking for products that meet international environmental standards.

Ethical sourcing is equally important, as businesses aim to ensure their supply chains are free from exploitation and harmful labor practices. Companies that prioritize ethical sourcing often gain a competitive edge, as they can appeal to environmentally conscious consumers and businesses. Suppliers that can demonstrate their commitment to sustainability and ethical practices are likely to build stronger relationships with B2B buyers, particularly in regions where regulations and consumer expectations are evolving rapidly.

Illustrative image related to inflate tires

The evolution of tire inflation technology reflects the broader advancements in automotive engineering. Initially, tire inflation was a manual process, often neglected by vehicle owners, leading to safety hazards and reduced tire life. Over the decades, innovations such as TPMS have revolutionized how tire pressure is monitored, allowing drivers to receive real-time alerts when tire pressure falls below optimal levels.

The introduction of portable tire inflators and nitrogen inflation services has further enhanced the user experience, providing more efficient and effective ways to maintain tire pressure. Today’s B2B buyers are increasingly interested in these technologies, which not only improve safety but also contribute to fuel efficiency and lower operational costs. As the market continues to evolve, integrating smart technologies and sustainable practices will be crucial for suppliers aiming to meet the demands of modern buyers.

How do I ensure my tire supply meets international quality standards?

When sourcing tires for international distribution, ensure that your suppliers comply with recognized quality standards such as ISO 9001 or specific regional certifications. Request documentation that verifies compliance and conduct regular audits. Additionally, consider third-party quality assurance inspections before shipment. Establishing partnerships with reputable manufacturers known for their commitment to quality can significantly enhance your supply chain reliability.

What is the best tire inflation method for different climates?

The optimal tire inflation method can vary based on climate. In hotter regions, consider nitrogen inflation as it reduces pressure loss and maintains tire performance. In colder areas, using compressed air is common; however, be aware that tire pressure can drop with temperature changes. Always check the manufacturer’s recommendations for pressure adjustments based on regional climate conditions to ensure safety and efficiency.

What are the advantages of using nitrogen for tire inflation?

Nitrogen inflation offers several advantages, including reduced pressure loss, improved fuel efficiency, and enhanced tire lifespan. Nitrogen molecules are larger than those in regular air, leading to less permeation through the tire walls. This is particularly beneficial for businesses operating in extreme temperature conditions, as nitrogen maintains more stable pressure levels compared to air, reducing the frequency of inflation checks.

How can I vet suppliers for tire inflation equipment?

Vetting suppliers for tire inflation equipment requires a thorough evaluation process. Start by assessing their industry reputation through reviews and references. Check for certifications that demonstrate compliance with international safety and quality standards. Additionally, request product samples and performance data, and evaluate their customer service response times to ensure they are reliable partners.

What are typical payment terms when sourcing tires internationally?

Payment terms in international tire sourcing can vary widely but typically include options like letter of credit, advance payment, or open account terms. It’s crucial to negotiate terms that protect your interests while also being feasible for the supplier. Establishing clear conditions regarding payment timelines, penalties for late payments, and acceptable currencies will help avoid misunderstandings.

What is the minimum order quantity (MOQ) for tire inflators?

The MOQ for tire inflators can differ depending on the supplier and the product specifications. Generally, MOQs range from 50 to 500 units. It is advisable to discuss your needs directly with potential suppliers to negotiate favorable terms. If your order volume is lower than the MOQ, consider pooling orders with other businesses to meet the supplier’s minimum requirements.

How should I handle logistics when importing tires?

Effective logistics management when importing tires involves selecting reliable freight forwarders familiar with international regulations and customs procedures. Ensure you have the necessary documentation, such as bills of lading and import permits, to facilitate smooth customs clearance. Plan for potential delays by allowing extra time in your supply chain and consider using warehousing solutions to manage inventory levels efficiently.

What quality assurance measures should I implement for tire products?

Implementing robust quality assurance measures includes conducting regular inspections at the manufacturing site, testing tire performance under various conditions, and ensuring compliance with safety standards. Establish a clear return policy for defective products and maintain ongoing communication with suppliers for continuous improvement. Utilizing third-party testing services can also provide an unbiased assessment of tire quality before distribution.

Bereich: michelinman.com

Registriert: 2001 (24 Jahre)

Einleitung: Michelin offers a complete range of tires for various mobility needs, including passenger cars, SUVs, light commercial vehicles, and electric/hybrid cars. Their tire families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy™, Latitude Sport, Pilot Alpin, and Premier. Michelin also provides tires for motorcycles, bicycles, and classic cars, along with accessories such as inn…

Bereich: goodyear.com

Registered: 1992 (33 years)

Einleitung: Proper tire inflation is crucial for safety, performance, and tire longevity. The right air pressure is specified by the vehicle manufacturer and can be found on the door edge, door jamb, glove box door, or fuel door, as well as in the owner’s manual. Tires should be checked when cool, and the following steps should be followed: unscrew the valve cap, connect a tire gauge, add air to reach the rec…

Bereich: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, Facebook – Social Networking Platform, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic sourcing in the tire inflation sector is crucial for optimizing both operational efficiency and sustainability. By understanding the importance of maintaining proper tire pressure, businesses can significantly reduce fuel consumption, enhance tire lifespan, and improve safety on the roads. The strategic sourcing of high-quality inflation equipment, such as calibrated gauges and portable compressors, ensures that companies can uphold these standards consistently.

For B2B buyers across Africa, South America, the Middle East, and Europe, investing in reliable tire inflation solutions not only promotes environmental responsibility but also aligns with cost-saving initiatives. As the global market evolves, the demand for innovative tire management solutions will continue to grow, paving the way for new partnerships and technologies.

Moving forward, it is essential for businesses to prioritize strategic sourcing as a means to elevate their operational standards. Engage with reputable suppliers who understand local market nuances and can provide tailored solutions that meet specific regional needs. By doing so, you will not only enhance your business’s performance but also contribute to a more sustainable and efficient future in tire management.

Illustrative image related to inflate tires

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.