In the dynamic landscape of international commerce, the question of whether you can inflate a car tire with a bicycle pump emerges as a practical concern for businesses reliant on vehicle maintenance. Understanding the feasibility and efficiency of using a bicycle pump for car tires can significantly impact operational costs and logistics, particularly in regions where access to traditional air compressors may be limited. This guide delves into the nuances of this topic, offering insights into various types of pumps, their applications, and how they can serve different market needs.

As we explore the mechanics behind tire inflation, we will provide a comprehensive overview tailored for B2B buyers from Africa, South America, the Middle East, and Europe, such as those in Nigeria and Vietnam. The guide covers critical aspects including supplier vetting, cost considerations, and best practices for maintenance and repair. By equipping businesses with the knowledge to make informed purchasing decisions, we aim to enhance operational efficiency and reduce downtime.

Navigating the complexities of tire inflation tools not only addresses immediate logistical challenges but also empowers buyers to source the right equipment that meets their specific needs. This guide is your go-to resource for understanding the practicalities and implications of using bicycle pumps for car tires, ensuring that your business stays ahead in a competitive global market.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Traditional Hand Pump | Compact design, manual operation, lightweight | Emergency tire inflation, small fleets | Vorteile: Cost-effective, portable. Nachteile: Labor-intensive, slow inflation rate. |

| Track Pump | High volume, foot-operated, designed for higher pressure | Workshops, bike shops, automotive services | Vorteile: Efficient for larger volumes, easy to use. Nachteile: Less portable, requires space. |

| Foot Pump | Uses body weight for operation, dual-barrel designs | Mobile tire repair, roadside assistance | Vorteile: Requires less physical effort, good for multiple tires. Nachteile: Bulky, may not fit all tire sizes. |

| Electric Bike Pump | Battery-operated, quick inflation, digital pressure gauge | Automotive service centers, fleet management | Vorteile: Fast and convenient, precise pressure control. Nachteile: Higher cost, reliance on battery. |

| Compressor-Powered Pump | Uses electricity or vehicle battery, high PSI capability | Heavy-duty vehicles, commercial fleets | Vorteile: Rapid inflation, suitable for large tires. Nachteile: Erfordert eine Stromquelle, weniger tragbar. |

Traditional hand pumps are manual devices designed for portability and ease of use. They are typically lightweight and compact, making them suitable for emergency situations, especially in regions where access to service stations is limited. However, their labor-intensive nature and slower inflation rate can be a drawback for businesses that require quick turnaround times for vehicle maintenance. B2B buyers should consider the balance between cost and efficiency, especially for small fleets or emergency kits.

Track pumps are designed for higher volume and pressure, making them more efficient for inflating car tires compared to traditional hand pumps. They often feature a foot-operated mechanism, allowing users to apply more force without excessive physical strain. This type of pump is ideal for workshops and bike shops where multiple tires need to be inflated quickly. B2B buyers should assess their space availability and the volume of tire inflation required to determine if a track pump meets their operational needs.

Foot pumps utilize body weight to operate, often featuring dual-barrel designs that can inflate tires more efficiently than standard hand pumps. They are particularly useful for mobile tire repair services or roadside assistance, allowing users to inflate multiple tires with less physical effort. However, their bulkiness may pose challenges for transport and storage. B2B buyers should evaluate the trade-offs between portability and efficiency when considering foot pumps for their operations.

Electric bike pumps are battery-operated devices that provide rapid inflation and often come with digital pressure gauges for precise measurements. They are ideal for automotive service centers and fleet management where speed and accuracy are critical. Although they come at a higher initial cost and require a reliable battery, their convenience can significantly enhance service efficiency. B2B buyers should weigh the benefits of speed against the investment in electric pumps for their tire maintenance needs.

Compressor-powered pumps are designed for high-pressure inflation, making them suitable for heavy-duty vehicles and commercial fleets. They can quickly inflate large tires, which is essential for businesses that rely on heavy machinery or transportation. However, these pumps require a power source, which can limit portability. B2B buyers should consider the operational environment and the need for rapid inflation when deciding on compressor-powered solutions for their tire maintenance strategies.

| Industrie/Sektor | Specific Application of can you inflate a car tire with a bicycle pump | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Emergency tire inflation for low-pressure situations | Provides a quick and cost-effective solution for minor tire issues | Durability and compatibility with various tire valves are crucial. |

| Logistics and Transportation | Routine maintenance for fleet vehicles | Enhances vehicle uptime by allowing quick fixes during operations | Pumps must be high volume and capable of handling different tire sizes. |

| Outdoor Equipment Rental | Supporting customers with tire inflation for rental vehicles | Increases customer satisfaction by offering convenient solutions | Must be portable and easy to use for customers of varying skill levels. |

| Agricultural Sector | Tire maintenance for farm vehicles and machinery | Reduces downtime and improves productivity in agricultural operations | Pumps should be robust and able to handle high-pressure requirements. |

| Recreational Services | Tire inflation for RVs and campers | Enhances customer experience by ensuring safe and functional vehicles | Lightweight and compact options are preferred for easy transport. |

In automotive repair shops, bicycle pumps can serve as an emergency solution for inflating car tires with low pressure. This is particularly beneficial for minor tire issues, allowing mechanics to quickly address customer concerns without the need for elaborate equipment. The key for buyers in this sector is to ensure that the pumps are durable and compatible with various tire valves, enabling efficient service without delays.

For logistics and transportation companies, maintaining fleet vehicles is crucial to ensure smooth operations. A bicycle pump can be an effective tool for routine tire maintenance, allowing drivers to quickly inflate tires during their routes. This practice enhances vehicle uptime and prevents delays. Buyers should consider pumps with high volume capabilities that can accommodate different tire sizes, ensuring versatility across their fleet.

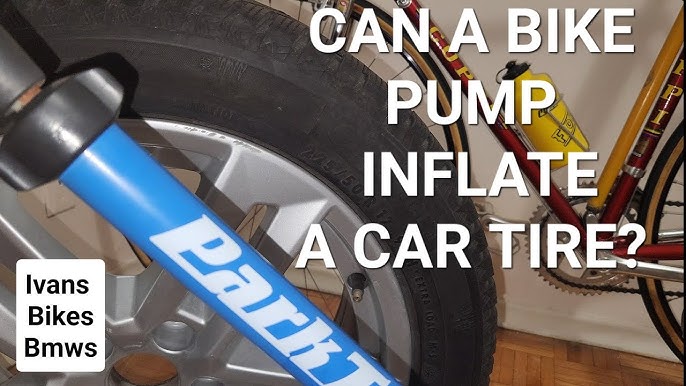

Illustrative image related to can you inflate a car tire with a bicycle pump

Outdoor equipment rental services can leverage bicycle pumps for tire inflation on rental vehicles, such as ATVs or bicycles. Providing this service enhances customer satisfaction by addressing tire issues on the spot, which is vital for maintaining a good reputation. It’s important for rental businesses to source pumps that are portable and easy to use, catering to customers with varying levels of mechanical skill.

In the agricultural sector, maintaining tire pressure in farm vehicles and machinery is essential for productivity. Using a bicycle pump for tire inflation can minimize downtime, allowing farmers to quickly address tire issues in the field. Buyers in this industry should prioritize robust pumps that can handle high-pressure requirements, ensuring they can effectively service larger agricultural tires.

Recreational services, such as RV and camper rentals, can use bicycle pumps to ensure that tires are properly inflated before customers embark on their journeys. This practice not only enhances the safety of the vehicles but also improves the overall customer experience. Lightweight and compact options are preferred, as they are easy to transport and store, making them ideal for recreational use.

Das Problem: A common challenge faced by B2B buyers, particularly those in logistics and transport, is ensuring that vehicle tires are adequately inflated to maintain safety and efficiency. Many operators may find themselves in remote locations without access to traditional air compressors or gas stations. Using a bicycle pump can seem like a feasible alternative, but the sheer volume of air needed to inflate car tires can make this method frustrating and labor-intensive, leading to employee dissatisfaction and potential delays in operations.

Die Lösung: To effectively utilize a bicycle pump for inflating car tires, businesses should invest in high-quality, high-volume bicycle pumps designed for both bikes and cars. These pumps often have larger barrels and can provide more air per stroke, significantly reducing the effort and time required. Additionally, operators should ensure that they have the right attachments for the valve types found on car tires, which may differ from those on bicycles. Training staff on efficient pumping techniques, such as using body weight and leg strength rather than just arm strength, can further enhance the process. Regularly checking tire pressure and maintaining an emergency inflation kit in each vehicle can also prevent issues from arising in the first place.

Das Problem: In fast-paced business environments, time is of the essence. When a vehicle’s tire pressure is low, the need for quick inflation becomes critical to avoid delays. However, using a bicycle pump to inflate a car tire can be a time-consuming process, especially when operators are unfamiliar with the volume of air required or the number of pumps necessary to reach the desired pressure. This can lead to frustration, increased downtime, and a potential loss of productivity.

Die Lösung: To streamline the inflation process, companies should implement a proactive maintenance schedule that includes regular tire pressure checks and inflation as part of routine vehicle inspections. Providing employees with a well-designed, dual-function bicycle pump that can handle both bike and car tires will make the process smoother and more efficient. Additionally, creating a standardized checklist for tire maintenance can help employees quickly assess tire conditions and inflate them as needed, making it easier to manage time effectively. For urgent situations, consider pairing bicycle pumps with portable electric inflators that can be powered through the vehicle’s lighter socket, offering a faster alternative in emergencies.

Das Problem: Many B2B buyers may underestimate the capability of bicycle pumps when it comes to inflating car tires due to a lack of awareness or experience. This can lead to hesitation in utilizing bicycle pumps as a viable option, resulting in reliance on less accessible solutions like compressors or gas station air pumps. Such misconceptions may prevent businesses from effectively managing tire inflation, particularly in regions where access to air supply is limited.

Die Lösung: Education and training are essential to building confidence among employees regarding the use of bicycle pumps for car tires. Companies can conduct workshops or distribute instructional materials that explain the principles of tire inflation, the differences in pressure and volume between bicycle and car tires, and the practical steps for effective pumping. Highlighting success stories and testimonials from other businesses that have successfully adopted this practice can also motivate employees to embrace this method. Additionally, providing a selection of pumps that are easy to use and come with clear instructions will further empower employees to tackle tire inflation confidently and efficiently.

When considering the use of bicycle pumps for inflating car tires, the materials involved in the pump’s construction play a crucial role in determining performance and usability. Here, we analyze four common materials—aluminum, plastic, rubber, and steel—focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum is a popular choice for bicycle pumps due to its lightweight nature and strength. It typically has a high-temperature rating, making it suitable for various environments. Aluminum pumps can withstand moderate pressure levels, generally around 100 psi, which is adequate for most car tires.

Profis: Aluminum is durable and resistant to corrosion, ensuring longevity. It is also relatively easy to manufacture, which can lower production costs.

Nachteile: While aluminum is strong, it can be prone to dents and scratches, which may affect aesthetics and functionality over time. Additionally, aluminum pumps can be more expensive than plastic alternatives.

Illustrative image related to can you inflate a car tire with a bicycle pump

Auswirkungen auf die Anwendung: Aluminum’s compatibility with air and resistance to corrosion make it ideal for tire inflation. However, care must be taken to avoid mechanical damage.

Überlegungen für internationale Einkäufer: Buyers from regions like Africa and South America should ensure compliance with local standards for pressure ratings and material safety, as aluminum quality can vary significantly.

Plastic is often used in the construction of bicycle pumps, particularly for the housing and some internal components. It is lightweight and can be molded into various shapes, allowing for innovative designs.

Profis: Plastic is cost-effective and can be manufactured in various colors and styles. It is also resistant to corrosion and can withstand a range of temperatures.

Nachteile: Plastic may not endure high pressures as well as metal options, leading to potential failure under stress. It is also less durable than aluminum or steel, making it more susceptible to wear and tear.

Auswirkungen auf die Anwendung: Plastic pumps may be suitable for occasional use, but their limitations in pressure handling make them less ideal for regular car tire inflation.

Überlegungen für internationale Einkäufer: Buyers should verify that the plastic materials used comply with local safety standards, especially in regions with extreme temperatures.

Rubber is primarily used in seals and gaskets within bicycle pumps. Its elasticity allows for a tight seal, preventing air leaks during the inflation process.

Profis: Rubber is highly durable and can withstand a wide range of temperatures. It also provides excellent resistance to wear and tear.

Nachteile: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures, which may lead to failure in sealing.

Illustrative image related to can you inflate a car tire with a bicycle pump

Auswirkungen auf die Anwendung: The effectiveness of rubber components is critical for maintaining air pressure in tires. Proper maintenance and replacement of rubber parts are essential for optimal performance.

Überlegungen für internationale Einkäufer: Buyers should consider the sourcing of rubber materials, ensuring they meet international standards like ASTM or JIS, particularly in regions with varying climate conditions.

Steel is often used for the pump’s barrel and other structural components due to its strength and ability to handle high pressures.

Profis: Steel is incredibly durable and can withstand high pressures, making it suitable for both bicycle and car tire inflation. Its longevity is a significant advantage.

Illustrative image related to can you inflate a car tire with a bicycle pump

Nachteile: Steel is heavier than aluminum or plastic, which may affect portability. It is also prone to rust if not properly treated.

Auswirkungen auf die Anwendung: Steel pumps are ideal for heavy-duty use and can handle high-volume air delivery, making them effective for inflating car tires.

Überlegungen für internationale Einkäufer: Buyers should ensure that steel components are treated for corrosion resistance, particularly in humid or coastal regions.

| Material | Typical Use Case for can you inflate a car tire with a bicycle pump | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Lightweight bicycle pumps for car tire inflation | Langlebig und korrosionsbeständig | Anfällig für Dellen und Kratzer | Mittel |

| Kunststoff | Budget-friendly pumps for occasional use | Cost-effective and versatile | Limited pressure handling | Niedrig |

| Gummi | Seals and gaskets in pumps | Excellent durability and elasticity | Zersetzt sich mit der Zeit durch UV-Einwirkung | Mittel |

| Stahl | Heavy-duty pumps for high-pressure applications | Extremely durable and high-pressure capable | Schwerer und anfällig für Rost | Mittel bis Hoch |

This analysis highlights the importance of material selection in the performance of bicycle pumps used for inflating car tires, offering valuable insights for B2B buyers navigating the international market.

Illustrative image related to can you inflate a car tire with a bicycle pump

When considering the manufacturing processes of bicycle pumps designed for inflating car tires, several critical stages are involved. The process typically encompasses material preparation, forming, assembly, and finishing.

The initial step involves selecting high-quality materials that ensure durability and efficiency. Commonly used materials include aluminum or steel for the pump body, high-density rubber for seals, and plastic or composite materials for the handles and base. Each material is chosen for its ability to withstand high pressure and frequent use. B2B buyers should verify that suppliers source materials that comply with international standards, ensuring longevity and safety.

In the forming stage, raw materials undergo processes like extrusion and machining to create the pump body and components. Advanced techniques, such as CNC machining, ensure precision in the dimensions, which is critical for maintaining the pump’s efficiency. This stage also includes the molding of rubber seals and other fittings, ensuring they fit snugly to prevent air leaks. Buyers should inquire about the forming techniques used to ensure they meet the necessary performance specifications.

Illustrative image related to can you inflate a car tire with a bicycle pump

The assembly process combines all components into a fully functioning unit. This includes installing the piston, connecting the handle, and affixing the valve. Manufacturers often utilize automated assembly lines for efficiency, but manual checks are essential for ensuring quality. It’s advisable for B2B buyers to ask suppliers about their assembly methods and the extent of automation used, as this can impact the consistency of the final product.

Finishing involves painting, coating, or polishing the pump to enhance its aesthetic appeal and protect it from corrosion. This stage may also include rigorous cleaning processes to remove any manufacturing residues. Quality assurance checks at this stage ensure that the bicycle pumps meet both aesthetic and functional standards. Buyers should consider suppliers that implement comprehensive finishing processes to guarantee a superior final product.

Quality assurance is crucial in the manufacturing of bicycle pumps, especially when they are intended for inflating car tires. Adhering to international standards ensures that products are reliable and safe for consumers.

International standards such as ISO 9001 play a vital role in ensuring quality management systems are in place. This standard focuses on meeting customer expectations and delivering consistent quality. Additionally, compliance with specific industry standards, such as CE marking in Europe, ensures that products meet safety and environmental requirements. B2B buyers should prioritize suppliers that can provide certifications and documentation proving compliance with these standards.

Quality control (QC) is integrated throughout the manufacturing process and typically includes several checkpoints:

Eingehende Qualitätskontrolle (IQC): This step involves inspecting raw materials before production begins to ensure they meet specified standards.

Prozessbegleitende Qualitätskontrolle (IPQC): During manufacturing, continuous checks are conducted to monitor the production process. This includes measuring dimensions and testing components for defects.

Endgültige Qualitätskontrolle (FQC): Once assembly is complete, the final product undergoes thorough testing for functionality, pressure capacity, and overall performance.

B2B buyers should verify that suppliers have robust QC protocols in place, ensuring that products are thoroughly tested and meet the required specifications.

Common testing methods for bicycle pumps include:

Druckprüfung: Ensures that the pump can withstand and operate at the required pressure levels without failure.

Dichtheitsprüfung: Determines if there are any air leaks in the pump, which can affect its performance.

Dauerhaftigkeitsprüfung: Evaluates the pump’s ability to withstand repeated use without degradation.

Buyers should inquire about the specific testing methods employed by suppliers, as this can provide insight into the reliability of the final product.

B2B buyers can take several steps to verify the quality control processes of their suppliers, ensuring they receive a reliable product.

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. This can involve on-site visits to observe manufacturing operations, review QC documentation, and check for compliance with international standards. Buyers should prepare a checklist to ensure all aspects of the manufacturing and QC processes are covered during the audit.

Requesting detailed reports from suppliers, including QC records, test results, and certifications, is essential. These documents provide transparency and allow buyers to verify that the products meet the required quality standards. It’s beneficial to ask for historical data on product performance and any corrective actions taken in response to past quality issues.

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct audits, inspections, and testing to validate that the manufacturer adheres to quality standards. This is particularly important for international B2B buyers from regions such as Africa, South America, and the Middle East, where local regulations may vary.

For international B2B buyers, understanding the nuances of quality control in different regions is crucial. Variations in regulations, standards, and manufacturing practices can impact product quality.

Illustrative image related to can you inflate a car tire with a bicycle pump

Different regions may have specific requirements and standards that manufacturers must comply with. For instance, while CE marking is essential in Europe, other regions may have their own certifications. Buyers should familiarize themselves with these regional standards and ensure that their suppliers are compliant.

Challenges such as language barriers, cultural differences, and varying expectations can complicate international sourcing. It’s essential for buyers to establish clear communication with suppliers and consider employing local representatives who understand the market dynamics.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for bicycle pumps designed for inflating car tires is essential for B2B buyers. By focusing on quality materials, effective manufacturing techniques, and stringent QC processes, buyers can ensure they procure reliable products that meet their operational needs.

This guide serves as a practical checklist for B2B buyers interested in the feasibility and logistics of using bicycle pumps for inflating car tires. Understanding the nuances of this process can help suppliers and businesses in various regions, including Africa, South America, the Middle East, and Europe, make informed decisions regarding product offerings and customer support.

Illustrative image related to can you inflate a car tire with a bicycle pump

Identify the pump specifications that match your needs. Not all bicycle pumps are created equal; some are designed for high volume, while others focus on high pressure. Look for pumps that offer compatibility with car tire valves and can handle the required PSI levels for vehicles.

Understand the pump’s air volume output per stroke. Car tires require significantly more air volume than bicycle tires, meaning that a bicycle pump must be capable of delivering a sufficient amount of air with each stroke.

Conduct thorough research to find reliable suppliers. Look for companies that specialize in bicycle pumps with a proven track record in the automotive sector.

Ensure that potential suppliers meet necessary certifications. Quality assurance is crucial when selecting suppliers, particularly for products intended for consumer safety, like tire inflators.

Evaluate the pricing structure of different suppliers. Cost is an essential factor in procurement, but it should be balanced with quality and performance.

Examine the customer support services offered by suppliers. Good customer service can be invaluable, especially when dealing with technical products.

Conduct practical tests with potential products. If possible, arrange for a demonstration or trial period to assess the pump’s performance in real-world conditions.

By following this structured approach, B2B buyers can make informed decisions when considering bicycle pumps for inflating car tires, ensuring they choose the right products for their needs.

When evaluating the costs associated with sourcing bicycle pumps that can inflate car tires, several key components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

Materialien: The quality of materials used in the construction of the pumps significantly impacts the cost. High-grade plastics or metals that withstand wear and tear typically command higher prices. Furthermore, if the pumps are designed to handle higher pressures, the materials must be robust, increasing the overall cost.

Arbeit: Labor costs vary based on geographic location and labor market conditions. In regions like Africa and South America, labor costs may be lower compared to Europe, which can affect the pricing structure. However, this can also lead to variability in the craftsmanship and durability of the pumps.

Fertigungsgemeinkosten: This includes costs associated with factory operations, such as utilities, rent, and salaries of administrative staff. Companies with more automated processes may have lower overhead costs, which can translate into competitive pricing.

Werkzeugbau: The initial investment in tooling for manufacturing can be substantial, especially if custom designs or specific features are required. This cost is often amortized over the production volume, meaning larger orders could lead to lower per-unit costs.

Qualitätskontrolle (QC): Implementing rigorous QC processes ensures that the pumps meet safety and performance standards. While this incurs additional costs, it is crucial for maintaining a reputation in the market, particularly when catering to international buyers who may prioritize product quality.

Logistik: Shipping costs can fluctuate based on the origin of the pumps and the target market. Factors such as distance, shipping method, and customs duties significantly influence overall logistics costs.

Marge: Suppliers typically add a profit margin to cover their operational expenses and generate profit. This margin can vary based on competitive positioning and market demand.

Several factors influence the pricing of bicycle pumps capable of inflating car tires. Understanding these can help buyers negotiate better deals and optimize their sourcing strategies.

Volumen/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Higher volumes often yield better pricing due to economies of scale, allowing suppliers to reduce their per-unit costs.

Spezifikationen/Anpassung: Pumps designed with specific features or certifications may cost more. Buyers should determine if these additional features are necessary for their target market to avoid overspending.

Materialien: The choice of materials directly affects the durability and performance of the pumps. Buyers should assess whether the added costs of premium materials justify the potential for higher customer satisfaction and fewer returns.

Quality/Certifications: Pumps that comply with international safety and performance standards may command higher prices. However, these certifications can enhance marketability and consumer trust, making them a worthy investment.

Lieferanten-Faktoren: The reliability and reputation of suppliers can influence pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better support and assurance.

Incoterms: Understanding international commercial terms (Incoterms) is crucial for calculating total landed costs. These terms dictate responsibilities for shipping, insurance, and tariffs, which can impact the final price significantly.

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are several strategic approaches to enhance cost efficiency:

Illustrative image related to can you inflate a car tire with a bicycle pump

Verhandlung: Always approach negotiations with a clear understanding of your cost structure and the supplier’s pricing model. Leverage the potential for larger orders to negotiate better terms.

Kosteneffizienz: Consider the total cost of ownership rather than just the purchase price. This includes logistics, potential repairs, and replacement costs, which can vary significantly between suppliers.

Nuancen in der Preisgestaltung: Be aware of regional pricing differences and market conditions. Prices may fluctuate based on local demand, currency exchange rates, and economic stability, so timing your purchase can yield savings.

Beziehungen zu den Lieferanten: Building long-term relationships with suppliers can lead to better pricing, priority during shortages, and improved service.

Marktforschung: Conduct thorough market research to understand competitive pricing and product specifications. This knowledge empowers buyers during negotiations and ensures they make informed purchasing decisions.

Pricing for bicycle pumps that can inflate car tires can vary widely based on the factors discussed above. It is recommended that buyers conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing aligned with their specific needs and market conditions.

When considering the practicality of inflating car tires, it’s essential to evaluate various methods beyond the conventional bicycle pump. This analysis highlights the effectiveness of using a bicycle pump compared to other viable alternatives such as electric tire inflators and foot pumps. By understanding the strengths and weaknesses of each method, B2B buyers can make informed decisions based on their specific operational needs.

| Vergleich Aspekt | Can You Inflate A Car Tire With A Bicycle Pump | Electric Tire Inflator | Foot Pump |

|---|---|---|---|

| Leistung | Moderate; slow due to high volume requirement | High; quick and efficient | Moderate; effective but slower than electric |

| Kosten | Low; generally inexpensive | Moderate; varies widely | Low; generally affordable |

| Leichte Implementierung | Requires effort and physical strength | User-friendly; minimal effort | Simple; requires manual effort |

| Wartung | Minimal; occasional checking needed | Moderate; requires care for electrical components | Low; generally durable |

| Bester Anwendungsfall | Emergency situations, small adjustments | Routine tire maintenance and emergencies | Occasional use, especially in remote areas |

Electric tire inflators are designed for quick and efficient inflation, making them ideal for routine tire maintenance and emergencies. They offer high performance, capable of inflating tires rapidly without significant physical effort. However, the cost can be moderate, and they require electrical power or a vehicle battery, limiting their usability in remote areas without power sources. Maintenance is also necessary to ensure the electrical components remain functional, which can be a downside for some users.

Foot pumps present a manual alternative that can be effective for inflating car tires. They are generally low-cost and durable, making them a reliable choice for occasional use. The ease of use is reasonable, but it still requires physical effort, which may be a drawback for some users. While foot pumps can perform adequately, their inflation speed is slower than that of electric inflators, making them less suitable for quick adjustments or emergencies.

Using a bicycle pump to inflate car tires is a viable option, especially in emergency situations. It is a low-cost solution that requires minimal maintenance. However, the performance is moderate due to the high volume of air required to fill a car tire, resulting in a slower inflation process. While it is possible to inflate car tires with a bicycle pump, it may not be practical for routine use, especially for those unfamiliar with the physical exertion required.

B2B buyers should consider their operational needs, including the frequency of tire inflation, the environments in which they operate, and the physical capabilities of their personnel. For businesses requiring quick and efficient tire maintenance, electric tire inflators may be the best choice despite their higher cost and maintenance needs. In contrast, companies operating in remote areas might benefit from the reliability and affordability of foot pumps or bicycle pumps. Ultimately, understanding the specific use case and balancing performance with cost will guide buyers toward the most suitable tire inflation solution.

When considering the feasibility of using a bicycle pump to inflate a car tire, several technical properties come into play. Understanding these properties is crucial for B2B buyers, especially when sourcing pumps for various applications.

Druckstufe (PSI): The pressure rating, typically measured in pounds per square inch (PSI), is critical. Car tires generally require a pressure of 30-35 PSI, while bicycle tires may range from 30 to 120 PSI. A bicycle pump must be capable of achieving these pressures efficiently. For B2B buyers, selecting a pump with a suitable PSI rating ensures compatibility with the intended application.

Volume Output per Stroke: The volume of air delivered with each stroke is another essential property. Car tires have a significantly larger volume than bicycle tires. A bicycle pump typically has a smaller cylinder, resulting in lower volume output per stroke. Buyers should consider this metric, as a pump that delivers insufficient volume will require excessive pumping, leading to inefficiency and potential fatigue.

Material Klasse: The materials used in the construction of the pump affect durability and performance. High-grade plastics or metals can enhance longevity and resistance to wear and tear. For B2B buyers, understanding material specifications can inform purchasing decisions, ensuring that the pump will withstand regular use and environmental factors, especially in diverse markets like Africa and South America.

Connector Type: The connector type must be compatible with the valve of the tire being inflated. Bicycle pumps may come with a Schrader or Presta valve connector, which may not fit standard car tire valves without an adapter. Buyers must ensure that the pump they select can accommodate the specific type of valve prevalent in their target market.

Gewicht und Tragbarkeit: The weight of the pump is also an important consideration, particularly for emergency use. A lightweight, portable pump can be easily stored in a vehicle and accessed when needed. B2B buyers should assess the balance between weight and performance to meet customer expectations for convenience.

When navigating the procurement process for bicycle pumps, it’s essential to be familiar with industry terminology that can impact purchasing decisions.

Illustrative image related to can you inflate a car tire with a bicycle pump

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality products and establish reliable supply chains.

MOQ (Mindestbestellmenge): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to determine if a supplier’s terms align with their purchasing needs and inventory management strategies.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process helps buyers gather competitive pricing and understand supplier capabilities before making purchasing decisions.

Incoterms (Internationale Handelsklauseln): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management.

Vorlaufzeit: This term refers to the time taken from placing an order to receiving the product. Understanding lead time is crucial for inventory planning and ensuring that operations run smoothly without delays.

Warranty Terms: Warranty terms specify the conditions under which a product will be repaired or replaced. Buyers should be well-versed in warranty policies to safeguard their investments and ensure long-term satisfaction with the product.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when considering the practicality of using a bicycle pump for inflating car tires, ensuring that their procurement aligns with operational needs and market demands.

The market dynamics surrounding the use of bicycle pumps to inflate car tires are influenced by several global drivers. Increasing awareness of vehicle maintenance, especially in emerging markets in Africa, South America, and parts of the Middle East and Europe, has led to a surge in DIY solutions. As inflation rates and fuel prices rise, more consumers are looking for cost-effective alternatives for tire maintenance, making bicycle pumps an attractive option.

Technological advancements in pump design have made high-volume bicycle pumps more efficient, enabling them to handle higher pressures typically required for car tires. Additionally, the integration of digital pressure gauges in some modern bicycle pumps enhances user experience by ensuring accurate inflation. The growing trend of sustainability also plays a role; consumers are increasingly inclined to opt for manual solutions that minimize reliance on electric compressors, which consume more energy and have a higher environmental footprint.

For international B2B buyers, sourcing trends indicate a shift towards multi-functional tools that cater to both bicycles and cars, allowing for greater versatility. Suppliers who can offer durable, lightweight, and ergonomically designed pumps stand to gain a competitive edge. As the market evolves, understanding local consumer behavior and preferences will be crucial for success in these diverse regions.

The environmental impact of manufacturing and using bicycle pumps cannot be overlooked. As global awareness of climate change rises, businesses are increasingly held accountable for their supply chains. Ethical sourcing of materials—such as recycled plastics and sustainable metals—has become a priority. B2B buyers should seek suppliers who can demonstrate a commitment to sustainable practices through certifications like ISO 14001 or the Global Recycled Standard.

Moreover, the trend towards eco-friendly products is gaining traction. Bicycle pumps that incorporate ‘green’ materials not only appeal to environmentally-conscious consumers but can also enhance brand reputation. This is particularly relevant in regions such as Europe, where consumers are more likely to prioritize sustainability in their purchasing decisions.

By investing in sustainable products, businesses can also mitigate risks associated with resource scarcity and fluctuating material costs. As a result, fostering relationships with suppliers who prioritize ethical sourcing will not only align with corporate social responsibility (CSR) goals but also provide long-term economic benefits.

Historically, the use of bicycle pumps for car tires dates back to when manual inflation was the norm. In the mid-20th century, bicycle pumps were commonly utilized for both bicycles and light vehicles due to their simplicity and availability. The design of these pumps evolved to accommodate various tire pressures, with foot pumps and dual-barrel options becoming popular for car tires.

Illustrative image related to can you inflate a car tire with a bicycle pump

As automotive technology advanced, dedicated tire inflators became prevalent, leading to a decline in the use of bicycle pumps for this purpose. However, the recent resurgence of interest in DIY vehicle maintenance and the push for sustainable practices have revitalized the bicycle pump’s role in tire inflation. Today, they serve as a practical solution for emergency situations, especially in regions with limited access to conventional air compressors.

Understanding this historical context allows B2B buyers to appreciate the adaptability of bicycle pumps and their potential for multi-purpose use in both personal and commercial applications.

How can I effectively use a bicycle pump to inflate a car tire?

Using a bicycle pump to inflate a car tire is feasible but requires effort and patience. First, ensure that the pump is compatible with the car tire valve (Schrader valves are common for cars). Connect the pump securely to the valve and begin pumping. Keep in mind that car tires have a larger volume than bike tires; therefore, it may take significantly more strokes to achieve the desired pressure, which typically ranges from 30 to 35 psi. Consider using a high-volume or foot pump to ease the process.

What are the limitations of using a bicycle pump for car tires?

While a bicycle pump can inflate a car tire, it has limitations primarily due to volume and efficiency. Car tires require a larger volume of air to achieve adequate pressure, meaning that using a traditional hand pump can be labor-intensive and time-consuming. Additionally, the pump may overheat with prolonged use, necessitating breaks. For emergency situations, a bicycle pump can suffice, but for regular maintenance, a dedicated air compressor or a foot pump is advisable.

What should I consider when sourcing bicycle pumps for international trade?

When sourcing bicycle pumps for international trade, prioritize factors such as compatibility with various valve types, pump volume capacity, and durability. Assess the supplier’s reputation, product certifications, and compliance with international standards. Additionally, consider logistical aspects like shipping costs, lead times, and customs regulations, particularly in regions like Africa, South America, and the Middle East, where these factors can significantly impact your supply chain.

How can I vet suppliers for bicycle pumps in the B2B market?

To vet suppliers, begin by researching their market presence and customer reviews. Request product samples to evaluate quality and performance. Investigate their manufacturing processes to ensure adherence to safety and quality standards. It’s also beneficial to ask for references from previous clients. Engaging in direct communication regarding their capacity for customization, MOQ (Minimum Order Quantity), and delivery terms will further clarify their suitability for your needs.

What are the common payment terms in international trade for bicycle pumps?

Common payment terms in international trade often include options like Letters of Credit (LC), advance payments, and payment upon delivery. It’s crucial to negotiate terms that provide security for both parties. For larger orders, consider using escrow services to mitigate risks. Always ensure clarity regarding payment methods and timelines, as these can vary significantly based on the supplier’s location and your business’s financial policies.

Can I customize bicycle pumps to meet specific market needs?

Yes, many manufacturers offer customization options for bicycle pumps. You can request alterations in design, color, branding, and even functionality to cater to specific market demands. Discuss your requirements during the supplier vetting process and inquire about any additional costs or minimum order quantities associated with customization. Customization can enhance brand recognition and cater to unique customer preferences, particularly in diverse markets across Africa and South America.

What quality assurance measures should I implement when purchasing bicycle pumps?

Implementing quality assurance measures involves setting clear specifications and standards before procurement. Request certifications that validate the product’s quality, such as ISO or CE marks. Conduct factory audits if possible, and establish a testing process for the pumps upon arrival. Consider implementing a return policy for defective products and maintain open communication with suppliers for continual improvement based on customer feedback.

How can logistics impact the sourcing of bicycle pumps internationally?

Logistics play a critical role in international sourcing, influencing costs and delivery times. Evaluate shipping options, including air freight for speed or sea freight for cost-effectiveness, while considering the geographic location of suppliers. Ensure that your logistics partner understands customs regulations in your target markets, as delays can occur due to documentation errors or tariffs. Establishing a reliable logistics strategy will help maintain inventory levels and meet customer demand efficiently.

Bereich: mechanics.stackexchange.com

Registriert: 2009 (16 Jahre)

Einleitung: Hand pumps for car tires exist but are not commonly used due to the higher volume and pressure requirements compared to bicycle tires. Users report that hand pumping car tires is significantly more labor-intensive and time-consuming than pumping bicycle tires. High-quality, high-volume bike pumps can be used for car tires, but they may not be practical for everyone. Foot pumps are also an option, …

Bereich: gotire.com

Registriert: 2005 (20 Jahre)

Einleitung: You can use a bike pump to add air to your car’s tires. Ensure the pump fits the car valve; most cars use Shrader valves, while some bikes may have Presta valves that require an adapter. Pumping a car tire with a bike pump typically takes 15-20 minutes, but it can take longer if the tire is significantly deflated. Recommended tire pressure for most passenger cars is between 32 and 35 psi when cold…

Bereich: wikihow.com

Registriert: 2004 (21 Jahre)

Einleitung: This article provides a step-by-step guide on how to inflate a car tire using a bike pump, specifically one equipped with a Schrader valve. It emphasizes the importance of proper tire inflation for fuel economy and tire longevity. Key steps include parking on a flat surface, removing valve caps, determining the optimal tire pressure (usually found on a sticker inside the driver’s door or in the ca…

In conclusion, while inflating a car tire with a bicycle pump is technically feasible, it is often impractical due to the significant differences in volume and pressure requirements. B2B buyers should recognize the importance of understanding the limitations of various inflation methods, particularly in regions where access to specialized tools may be limited. Strategic sourcing of reliable tire inflation solutions—whether through high-capacity pumps or compressors—can enhance operational efficiency and reduce downtime.

For businesses in Africa, South America, the Middle East, and Europe, investing in quality inflating equipment is vital. It not only ensures the safety and performance of vehicles but also supports sustainable practices by minimizing reliance on external services. As the market evolves, companies should stay informed about innovations in tire maintenance technology that can streamline operations and reduce costs.

Illustrative image related to can you inflate a car tire with a bicycle pump

We encourage international B2B buyers to explore partnerships with suppliers who prioritize quality and reliability in their product offerings. By doing so, you will position your business for success in an increasingly competitive landscape, ensuring that you are equipped to handle all tire inflation needs effectively.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.