In the fast-paced world of automotive maintenance, sourcing a good tire inflator can pose a significant challenge for B2B buyers. Whether you’re managing a fleet of vehicles in Africa or supplying automotive tools in Europe, the ability to choose an efficient, reliable, and cost-effective tire inflator is crucial. This guide offers a comprehensive exploration of various tire inflator types, their applications across different vehicle categories, and essential supplier vetting processes. By highlighting key features such as inflation speed, portability, and pressure capabilities, we aim to simplify the decision-making process.

Understanding the diverse needs of international markets—from the robust demands in South America to the high standards in Germany and Saudi Arabia—this guide is tailored to empower B2B buyers. With insights into pricing structures, performance benchmarks, and market trends, we provide the knowledge necessary to make informed purchasing decisions. Each section is designed to equip you with actionable insights, ensuring you select a tire inflator that meets your operational requirements and enhances your service offerings. By navigating the complexities of the global market effectively, you can streamline your procurement process and foster long-term partnerships with reliable suppliers.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Schnurlose Reifenfüller | Battery-operated, portable, often compact design | Autowerkstätten, Pannenhilfe | Vorteile: High portability, ease of use. Nachteile: Limited battery life, may require recharging. |

| 12V Tire Inflators | Plugs into vehicle’s 12V outlet, often compact | Fleet maintenance, personal vehicle upkeep | Vorteile: Convenient for vehicles, generally affordable. Nachteile: Limited range without vehicle access. |

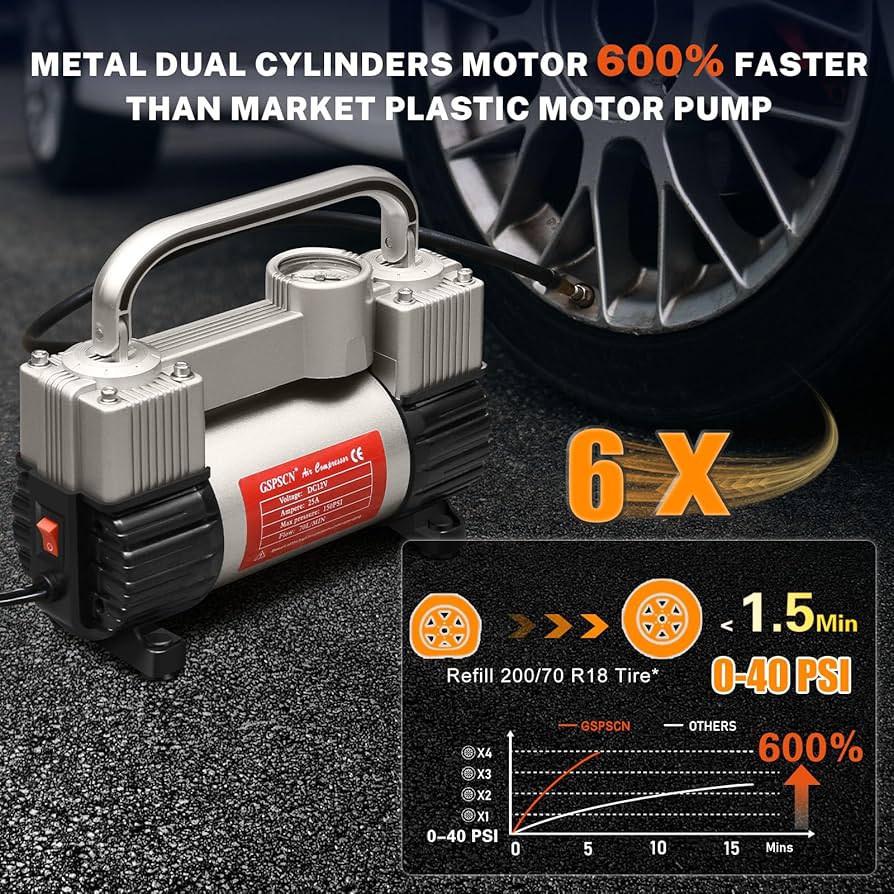

| Schwerlast-Reifenfüller | High PSI capability, often battery-clamp powered | Off-road vehicle maintenance, commercial trucking | Vorteile: Fast inflation, suitable for larger tires. Nachteile: Bulkier design, requires direct battery connection. |

| Digital Tire Inflators | Features digital pressure gauges, preset functions | Automotive service centers, tire shops | Vorteile: Accurate readings, user-friendly. Nachteile: Potentially higher cost, reliance on electronic components. |

| Ultra-Compact Tire Inflators | Small, lightweight, often USB rechargeable | Motorcycles, bicycles, emergency kits | Vorteile: Extremely portable, versatile use. Nachteile: Limited power for larger tires, slower inflation rate. |

Cordless tire inflators are battery-operated devices that offer high portability and convenience. Ideal for automotive repair shops and roadside assistance services, these inflators are designed for quick inflation of tires without needing an external power source. Buyers should consider the battery life and charging time, as these factors can influence operational efficiency, especially in high-demand environments.

12V tire inflators are powered through a vehicle’s 12V outlet, making them a practical choice for fleet maintenance and personal vehicle upkeep. Their compact design allows for easy storage in vehicles, ensuring they are readily available when needed. However, buyers should be aware that these inflators depend on the vehicle for power, limiting their use in scenarios where the vehicle is not accessible.

Illustrative image related to good tire inflator

Heavy-duty tire inflators are characterized by their ability to achieve high PSI levels, making them suitable for off-road vehicles and commercial trucking applications. These inflators often require a direct battery connection, which can be intimidating for inexperienced users. Nonetheless, their rapid inflation capabilities are crucial for businesses that need to maintain large vehicles efficiently.

Digital tire inflators come equipped with features such as digital pressure gauges and preset inflation functions, enhancing user experience and accuracy. These inflators are particularly beneficial for automotive service centers and tire shops that require precise tire pressure management. While they may come with a higher price tag, the added accuracy and ease of use can justify the investment for businesses focused on quality service.

Ultra-compact tire inflators are lightweight, often USB rechargeable, and designed for versatility across various applications, including motorcycles and bicycles. Their small size makes them ideal for emergency kits, allowing users to carry them easily. However, buyers should consider their limited power capacity for larger tires and slower inflation rates, which may not meet the demands of heavier vehicles or high-volume operations.

Illustrative image related to good tire inflator

| Industrie/Sektor | Specific Application of good tire inflator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparatur | Tire maintenance and emergency repair services | Reduces downtime and enhances customer satisfaction | Reliability, portability, and ease of use are essential features. |

| Transport und Logistik | Fleet tire management and emergency roadside assistance | Minimizes operational disruptions and costs associated with tire failures | High PSI capabilities and durable construction for heavy-duty use. |

| Bauwesen | Equipment tire inflation for heavy machinery | Ensures safety and efficiency on job sites | Compatibility with various machinery and robust performance under pressure. |

| Agricultural | Inflation of agricultural vehicle tires | Enhances productivity and reduces risk of accidents | Weather resistance and ability to handle high-volume inflation. |

| Recreational Vehicles | Tire inflation for RVs and trailers | Supports leisure activities by ensuring vehicle readiness | Compact design for portability and multi-functionality for various inflatables. |

In the automotive repair sector, a good tire inflator is essential for regular tire maintenance and emergency repairs. Service centers utilize these inflators to check and adjust tire pressures, ensuring vehicles operate safely and efficiently. The ability to quickly inflate tires can significantly reduce customer wait times, enhancing satisfaction. Buyers should prioritize inflators that are reliable and easy to use, as well as those that come with built-in pressure gauges for accuracy.

In transportation and logistics, maintaining a fleet of vehicles requires efficient tire management. A good tire inflator is crucial for performing pre-trip inspections and emergency roadside assistance. By ensuring that tires are properly inflated, companies can minimize the risk of blowouts and other costly operational disruptions. Buyers in this sector should look for inflators capable of high PSI levels and those designed for heavy-duty use, as this ensures reliability under demanding conditions.

In the construction industry, a good tire inflator is vital for inflating tires on heavy machinery and equipment. Properly inflated tires are essential for safety and operational efficiency on job sites. An inflator that can handle high-pressure requirements and is durable enough for rugged environments is necessary. Buyers should consider inflators that offer portability and quick inflation times, as these features can significantly enhance productivity during tight project timelines.

Illustrative image related to good tire inflator

For agricultural operations, tire inflators are used to maintain the tires of various vehicles, including tractors and harvesters. Proper tire inflation is critical for optimizing performance and reducing the risk of accidents due to tire failures in challenging terrains. Buyers should seek inflators that can withstand harsh weather conditions and provide high-volume inflation capabilities, ensuring that agricultural vehicles remain operational during peak seasons.

In the recreational vehicle sector, a good tire inflator is indispensable for ensuring that RVs and trailers are road-ready. These inflators help maintain tire pressure, which is crucial for safe travel and fuel efficiency. Compact and portable inflators are particularly valuable, as they can easily be stored in RVs for on-the-go use. Buyers should look for inflators that offer versatility, such as the ability to inflate various types of inflatables beyond just tires, enhancing their utility.

Das Problem: B2B buyers in industries such as transportation or logistics often require tire inflators that can handle larger tires, such as those found on trucks and SUVs. A common frustration arises when standard inflators are unable to inflate these larger tires quickly or effectively, leading to downtime that can impact operations and increase costs. Additionally, many inflators may not reach the necessary PSI levels for heavy-duty applications, leaving users stranded or forced to seek alternative solutions.

Die Lösung: When sourcing a tire inflator for larger vehicles, prioritize models specifically designed for high-capacity inflation, such as the Viair 88P. Look for inflators that can reach a minimum of 120 PSI and have a robust duty cycle. It’s also vital to consider the inflator’s power source; those that connect directly to the vehicle’s battery often provide the best performance. For effective usage, train staff on the proper connection techniques to ensure safety and efficiency. Encourage users to familiarize themselves with the inflator’s features, such as automatic shut-off capabilities, to prevent over-inflation. Investing in high-quality, heavy-duty inflators will ultimately reduce downtime and enhance operational efficiency.

Das Problem: Accurate tire pressure is crucial for safety and efficiency, yet many B2B buyers encounter inflators with unreliable pressure gauges. This leads to under-inflation or over-inflation, which can cause uneven tire wear, reduced fuel efficiency, and even accidents. Buyers often struggle to find inflators that provide consistent and precise readings, leaving them second-guessing the condition of their tires.

Die Lösung: When selecting a tire inflator, prioritize models that feature digital pressure gauges over analog ones. Digital gauges tend to provide more accurate and easy-to-read results. Additionally, consider inflators with preset pressure settings, allowing users to select the desired PSI for various tire types automatically. This feature minimizes the risk of human error during inflation. It’s also wise to periodically calibrate the inflator’s gauge against a reliable standalone pressure gauge to ensure ongoing accuracy. Encouraging staff to adopt a routine check of tire pressures using the inflator can enhance safety and vehicle performance over time.

Das Problem: Many B2B buyers in sectors such as construction or emergency services face challenges with the portability of tire inflators. Heavy, bulky models are not practical for field operations, where space is limited and mobility is essential. This can lead to delays in addressing tire issues on-site, impacting productivity and safety.

Die Lösung: For buyers seeking portable tire inflators, consider investing in ultra-compact models like the Craftsman 12V Max Portable Air Inflator. Look for inflators that are lightweight and come with convenient carrying cases, making them easy to transport and store. Evaluate battery life and charging options; models with rechargeable batteries and additional power sources, like 12-volt adapters, can provide flexibility in various environments. To maximize portability, implement a system where inflators are stored in vehicles or equipment trailers, ensuring they are always accessible for quick use. Training staff to efficiently use these compact inflators will enhance their ability to respond to tire emergencies promptly, thereby minimizing downtime on projects.

Illustrative image related to good tire inflator

When selecting materials for tire inflators, it’s essential to consider their properties, performance, and suitability for various applications. Here, we analyze four common materials used in tire inflators: plastic, aluminum, steel, and rubber.

Plastic is frequently used in the housing and components of tire inflators due to its lightweight and corrosion-resistant properties. Common types include high-density polyethylene (HDPE) and polycarbonate. These plastics can withstand moderate pressure and temperature variations, making them suitable for inflators that operate under typical automotive conditions.

Vorteile: Plastic is cost-effective, lightweight, and resistant to corrosion, which enhances the durability of the inflator. It can also be molded into complex shapes, allowing for innovative designs.

Illustrative image related to good tire inflator

Nachteile: While plastic is durable, it may not withstand extreme temperatures or high-pressure environments as well as metals. Over time, exposure to UV light can degrade some plastics, leading to brittleness.

Auswirkungen auf die Anwendung: Plastic is suitable for components that do not experience extreme stress or high temperatures. However, buyers should ensure that the specific type of plastic used complies with international standards such as ASTM for safety.

Aluminum is another popular choice for tire inflators, particularly for the body and internal components. It offers excellent strength-to-weight ratio and good corrosion resistance, making it ideal for portable devices.

Vorteile: Aluminum is lightweight yet strong, allowing for a compact design. It also has good thermal conductivity, which helps dissipate heat generated during operation.

Nachteile: While aluminum is resistant to corrosion, it can be more expensive than plastic and may require additional coatings for enhanced durability. It is also less impact-resistant compared to some plastics.

Illustrative image related to good tire inflator

Auswirkungen auf die Anwendung: Aluminum is suitable for inflators that require a balance between weight and strength. International buyers should consider the alloy grades used, ensuring compliance with regional standards, especially in harsh environments like those found in the Middle East and Africa.

Steel is often used in tire inflators for components that need to withstand high pressures, such as the pump and fittings. Stainless steel is particularly favored for its corrosion resistance and strength.

Vorteile: Steel offers high durability and can handle significant pressure without deforming. It is also resistant to wear and tear, making it suitable for heavy-duty applications.

Nachteile: Steel is heavier and more expensive than both plastic and aluminum. It can also be prone to rust if not properly coated or treated.

Auswirkungen auf die Anwendung: Steel is ideal for inflators designed for heavy vehicles or extreme conditions. Buyers from regions with high humidity or salt exposure, like coastal areas in South America, should prioritize stainless steel options to prevent corrosion.

Rubber is primarily used for seals, hoses, and other flexible components in tire inflators. Its elasticity and resilience make it an excellent choice for maintaining airtight seals.

Vorteile: Rubber is highly flexible and can withstand a wide range of temperatures. It provides excellent sealing capabilities, which is crucial for maintaining pressure in inflators.

Illustrative image related to good tire inflator

Nachteile: Rubber can degrade over time due to ozone exposure and may require regular replacement. It is also less effective in high-temperature applications compared to other materials.

Auswirkungen auf die Anwendung: Rubber is essential for components that require flexibility and sealing. International buyers should ensure that the rubber used meets relevant standards for durability and performance, especially in regions with extreme weather conditions.

| Material | Typical Use Case for good tire inflator | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kunststoff | Housing and non-pressurized components | Leicht und korrosionsbeständig | Limited temperature and pressure tolerance | Niedrig |

| Aluminium | Body and internal components | Strong yet lightweight | Higher cost and less impact resistance | Mittel |

| Stahl | High-pressure components like pumps | High durability and pressure resistance | Schwerer und anfällig für Rost | Hoch |

| Gummi | Seals and flexible hoses | Excellent sealing and flexibility | Degrades over time and less effective at high temperatures | Niedrig |

This analysis provides B2B buyers with actionable insights into the materials used in tire inflators, helping them make informed decisions based on performance, cost, and regional compliance requirements.

The manufacturing process of a tire inflator involves several critical stages that ensure the final product is reliable, efficient, and meets international standards. Understanding these stages can help B2B buyers make informed decisions when sourcing from suppliers.

Illustrative image related to good tire inflator

The first step in manufacturing a tire inflator is the preparation of raw materials. Common materials include high-strength plastics, metals such as aluminum or steel for structural components, and rubber for seals and hoses. Selecting the right materials is crucial for durability and performance. Suppliers often source materials from certified vendors to ensure quality, while also considering factors like weight, resistance to wear, and temperature stability.

Once materials are prepared, the next step is forming. This can involve several processes, including:

These techniques ensure that components meet the design specifications necessary for optimal performance.

Illustrative image related to good tire inflator

The assembly phase is where individual components come together to form the complete tire inflator. This process may include:

Automation plays a significant role in assembly, particularly in high-volume production, helping to enhance efficiency and reduce human error.

The finishing stage involves applying coatings or treatments to enhance the product’s appearance and protect it from environmental factors. This can include:

Illustrative image related to good tire inflator

Quality assurance is a vital aspect of the manufacturing process, ensuring that tire inflators meet industry standards and customer expectations. For B2B buyers, understanding these measures can help in selecting reliable suppliers.

B2B buyers should ensure that suppliers adhere to international quality standards such as ISO 9001. This standard focuses on quality management systems, promoting consistent quality and customer satisfaction. Other relevant certifications include:

These certifications provide assurance that the manufacturer follows best practices in production and quality control.

Quality control (QC) checkpoints are critical in maintaining the integrity of the manufacturing process. Key checkpoints typically include:

Illustrative image related to good tire inflator

These checkpoints help to identify and rectify issues early in the production process, minimizing defects in the final product.

Testing methods for tire inflators vary but commonly include:

By implementing these testing methods, manufacturers can ensure that their products meet both safety and performance criteria.

For B2B buyers, verifying a supplier’s quality control processes is essential in mitigating risks associated with product defects. Here are effective strategies to ensure supplier reliability:

Buyers should conduct audits of potential suppliers to assess their quality control practices. This includes reviewing their manufacturing processes, quality assurance documentation, and compliance with international standards. Buyers can request:

Illustrative image related to good tire inflator

International buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality certification and compliance. For instance:

By being proactive in verifying supplier quality control processes, B2B buyers can build strong partnerships and ensure the reliability of the tire inflators they procure.

This guide aims to assist B2B buyers in sourcing high-quality tire inflators, ensuring you select a product that meets your operational needs and budget constraints. A well-chosen tire inflator can enhance vehicle maintenance efficiency, reduce downtime, and improve safety for your fleet or business. Below is a step-by-step checklist designed to streamline your procurement process.

Understanding your specific needs is the first step in sourcing a tire inflator. Consider the types of vehicles you will be servicing—passenger cars, trucks, or heavy-duty vehicles—as this will dictate the required pressure capabilities and inflator size.

– Druckbereich: Look for inflators that can handle at least 80 psi for larger vehicles.

– Stromquelle: Decide whether you need a cordless model for portability or a corded version for continuous use.

Illustrative image related to good tire inflator

Investigate potential suppliers to ensure they have a solid reputation within the industry. Reliable suppliers should have a history of providing quality products and excellent customer service.

– Customer Reviews: Check online reviews and ratings from other businesses to gauge reliability.

– Industry Experience: Look for suppliers with experience in your specific market segment, particularly in regions like Africa, South America, or Europe.

Assess the features of the tire inflators on your shortlist. Innovative features can significantly enhance usability and efficiency, so ensure the models you’re considering meet essential criteria.

– Built-in Pressure Gauge: An accurate gauge is crucial for monitoring tire pressure effectively.

– Zusätzliche Merkmale: Consider inflators with built-in lights, USB charging ports, or adapters for various applications to increase versatility.

Ensure that the inflators meet industry standards and regulations, particularly if you are importing products. Compliance with safety and quality standards can prevent future liabilities.

– Certifications: Look for certifications such as CE, ISO, or other relevant standards that validate the product’s quality.

– Garantie und Support: A good warranty indicates the manufacturer’s confidence in their product and provides you with peace of mind.

Before making a bulk purchase, request samples to evaluate performance in real-world conditions. Testing can reveal potential issues not apparent from specifications alone.

– Performance Metrics: Check the inflator’s speed, noise level, and ease of use during the testing phase.

– Durability Tests: Ensure the inflator can withstand typical working conditions, particularly if used in rugged environments.

Once you have selected a preferred supplier, it’s time to negotiate pricing and terms. Effective negotiation can lead to significant savings and better contract conditions.

– Bulk Discounts: Inquire about discounts for larger orders, which can lower your overall costs.

– Payment Terms: Establish favorable payment terms that align with your cash flow needs.

After agreeing on terms, finalize your order and consider logistics for delivery and storage. Ensure that the supply chain is optimized for timely delivery to avoid operational disruptions.

– Shipping Options: Discuss shipping methods and times to ensure timely arrival.

– Storage Solutions: Plan for adequate storage space to accommodate the inflators upon arrival, ensuring they remain in optimal condition.

By following this checklist, B2B buyers can make informed decisions when sourcing tire inflators, ultimately enhancing their operational efficiency and reliability in vehicle maintenance.

In the competitive landscape of tire inflators, understanding the cost structure and pricing strategies is essential for international B2B buyers. This knowledge not only aids in effective sourcing but also ensures that companies can negotiate favorable terms and secure quality products that meet their needs.

The cost structure of a tire inflator encompasses several components:

Materialien: The type and quality of materials significantly affect pricing. For instance, high-quality plastics and durable metals used in the inflator’s casing and internal mechanisms will increase costs but contribute to longevity and reliability.

Arbeit: Manufacturing labor costs vary by region. In countries with higher labor costs, such as Germany, the overall production cost of tire inflators may be higher compared to regions in Africa or South America where labor is more affordable.

Fertigungsgemeinkosten: This includes expenses related to factory operations, such as utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help minimize these overhead costs.

Werkzeugbau: The initial investment in molds and specialized tools for production can be substantial, particularly for customized inflators. This cost is typically amortized over larger production runs.

Qualitätskontrolle (QC): Implementing rigorous QC processes ensures that each inflator meets industry standards, which can incur additional costs. However, this investment pays off by reducing returns and enhancing brand reputation.

Logistik: Transportation and storage costs must also be factored in, especially for international shipments. Factors like distance, shipping methods, and local tariffs will influence the final price.

Marge: Manufacturers and suppliers will add a profit margin to their costs, which varies based on market dynamics and competition.

Several factors can influence the pricing of tire inflators:

Volumen/MOQ (Mindestbestellmenge): Suppliers often offer better pricing for bulk orders. Understanding the required MOQ can help buyers negotiate more effectively.

Spezifikationen und Anpassungen: Custom features, such as built-in digital gauges or additional accessories, can drive up costs. Buyers should carefully assess which specifications are essential for their market needs.

Materialqualität und Zertifizierungen: Products certified to specific industry standards may have higher price points. Buyers should weigh the importance of certifications against their budget constraints.

Lieferanten-Faktoren: The reputation and reliability of the supplier can affect pricing. Established brands with a history of quality may charge more but can offer peace of mind through consistent performance.

Incoterms: The terms of shipping and delivery (such as FOB or CIF) will impact overall costs. Buyers should consider these terms during negotiations to avoid unexpected expenses.

When sourcing tire inflators, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, consider these strategies:

Verstehen der Gesamtbetriebskosten (TCO): Look beyond the initial purchase price. Factor in logistics, potential maintenance costs, and the product’s lifespan to assess the true value of the inflator.

Beziehungen nutzen: Building strong relationships with suppliers can lead to better pricing, favorable terms, and priority service during peak seasons.

Request Quotes from Multiple Suppliers: This not only gives leverage in negotiations but also helps in comparing product offerings and quality.

Be Prepared to Walk Away: If the pricing does not align with your budget or quality expectations, be willing to explore other options. This mindset can often lead to more competitive offers from suppliers.

Yes, regional market dynamics can significantly influence pricing. For instance, in Europe, strict regulations may necessitate higher production standards, thus increasing costs. In contrast, suppliers in regions with less stringent regulations may offer lower prices but could compromise on quality. Understanding these nuances can assist buyers in making informed decisions that align with their market requirements and customer expectations.

Prices for tire inflators can fluctuate based on market conditions, material costs, and supplier pricing strategies. It is advisable for buyers to conduct thorough market research and obtain current quotes to ensure they are making informed purchasing decisions.

Illustrative image related to good tire inflator

In the world of tire maintenance, tire inflators are essential tools for ensuring optimal vehicle performance and safety. However, there are various alternatives that businesses can consider, each with its unique advantages and disadvantages. This section will compare a good tire inflator against other viable solutions, enabling B2B buyers to make informed decisions tailored to their specific operational needs.

| Vergleich Aspekt | Good Tire Inflator | Tragbarer Luftkompressor | Manual Tire Pump |

|---|---|---|---|

| Leistung | Quickly inflates tires to high PSI; automatic shut-off features | High PSI output; can run continuously | Labor-intensive; slower inflation |

| Kosten | $40 – $90, depending on features | $100 – $300, higher upfront cost | $20 – $50, budget-friendly |

| Leichte Implementierung | Plug-and-play; user-friendly controls | Requires setup and power source | Requires physical effort; no power needed |

| Wartung | Low maintenance; occasional battery checks | Moderate; regular oil changes and filter replacements | Very low; minimal parts to maintain |

| Bester Anwendungsfall | Ideal for personal vehicles and light trucks | Suitable for workshops and heavy-duty vehicles | Best for emergencies or light use |

A portable air compressor is a powerful alternative to a traditional tire inflator. It provides high PSI output and can run continuously, making it suitable for workshops or environments where multiple vehicles need to be serviced. However, it typically comes with a higher upfront cost and requires a power source, which may not be readily available in all situations. Maintenance can also be a consideration, as air compressors often require regular oil changes and filter replacements to operate efficiently.

A manual tire pump offers a budget-friendly solution for tire inflation. It is lightweight and portable, making it easy to store in a vehicle. However, the performance of a manual pump is significantly lower compared to a good tire inflator. It requires physical effort to operate, resulting in slower inflation times and potential user fatigue. While it may be sufficient for emergencies or occasional use, it is not ideal for regular maintenance of multiple vehicles or larger tires.

When selecting the right tire inflation solution, B2B buyers should consider their specific operational needs, budget constraints, and the typical use case of the equipment. A good tire inflator is ideal for quick, efficient inflation of personal vehicles and light-duty applications. In contrast, a portable air compressor is better suited for workshops or heavy-duty applications, while a manual tire pump serves as an economical option for emergencies or infrequent use. By evaluating these factors, businesses can make informed decisions that enhance their vehicle maintenance capabilities.

When selecting a tire inflator, understanding its technical specifications is crucial for ensuring reliability and performance, particularly in diverse markets. Below are essential technical properties to consider:

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates how much air pressure the inflator can deliver. For most passenger vehicles, a range of 30-35 PSI is standard, while larger vehicles may require inflators capable of reaching up to 80 PSI or more. B2B buyers must prioritize this specification to ensure compatibility with their fleet requirements, especially in regions with varying vehicle types.

Duty cycle refers to the duration an inflator can operate continuously before requiring a cooldown period. It is often expressed in minutes. For example, a duty cycle of 20 minutes means the inflator can run for 20 minutes before needing a rest. This specification is critical for B2B buyers managing multiple vehicles or high-frequency tire inflation tasks, as it ensures efficiency and minimizes downtime.

Tire inflators can be powered by various sources, including battery, 12-volt outlet, or AC power. Understanding the power source is essential for determining the inflator’s portability and usability. For instance, cordless models offer greater convenience for on-the-go applications, while corded models may be more suitable for garage settings. B2B buyers should consider the operational environment when selecting an inflator.

The hose length impacts the inflator’s reach and usability. A longer hose allows for easier access to all tires without needing to reposition the inflator frequently. In B2B scenarios, especially in workshops or service stations, an adequate hose length can enhance workflow efficiency and reduce labor time.

The type of pressure gauge—digital or analog—affects the accuracy and ease of use when monitoring tire pressure. Digital gauges are generally more precise and easier to read, which can lead to better tire maintenance. B2B buyers should ensure that the inflator they choose has a gauge that meets their accuracy requirements, as this can significantly influence tire longevity and fuel efficiency.

Illustrative image related to good tire inflator

Familiarity with industry terminology is vital for effective communication and negotiation in the B2B space. Here are some essential terms:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the tire inflator market, understanding whether a product is OEM can help buyers assess quality and compatibility with existing equipment.

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps B2B buyers budget and plan their inventory effectively. It also affects pricing structures, as larger orders may yield better per-unit costs.

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specified products. Utilizing RFQs can streamline the purchasing process for tire inflators, ensuring that buyers receive competitive quotes from multiple suppliers.

Illustrative image related to good tire inflator

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, risk management, and cost allocation.

The warranty period is the timeframe during which the manufacturer guarantees that the product will function as specified. This term is essential for B2B buyers, as it reflects the manufacturer’s confidence in their product and provides assurance against defects.

By understanding these technical specifications and trade terms, B2B buyers can make informed decisions when selecting tire inflators, ensuring they choose products that meet their operational needs and align with their business objectives.

The global tire inflator market is experiencing robust growth, propelled by increasing vehicle ownership, rising demand for road safety, and heightened consumer awareness regarding tire maintenance. With the global automotive sector on an upward trajectory, particularly in emerging markets across Africa and South America, the need for reliable tire inflators has surged. Buyers are now prioritizing products that combine efficiency, portability, and advanced features such as digital pressure gauges and automatic shutoff mechanisms.

A significant trend influencing the market is the shift towards cordless and compact inflators, which cater to the growing preference for convenience among consumers. B2B buyers are particularly interested in products that can easily fit in vehicles and provide quick inflation, reducing downtime on the road. Additionally, tech advancements such as smart inflators that connect via smartphone applications are gaining traction, appealing to the tech-savvy demographic in Europe and the Middle East.

Moreover, supply chain dynamics are evolving, with buyers increasingly looking for local suppliers to mitigate risks associated with global logistics disruptions. This is particularly relevant in regions like the Middle East and Africa, where local sourcing can lead to more reliable delivery times and reduced transportation costs. International B2B buyers must remain vigilant about these market dynamics to make informed sourcing decisions that align with their operational needs.

In today’s market, sustainability and ethical sourcing are paramount considerations for B2B buyers in the tire inflator sector. As environmental concerns grow, manufacturers are increasingly pressured to minimize their ecological footprint. This includes adopting eco-friendly materials in the production of tire inflators, such as recyclable plastics and sustainable packaging solutions.

Buyers are also gravitating towards companies that demonstrate a commitment to ethical supply chains, which can enhance brand reputation and consumer trust. Certifications like ISO 14001 for environmental management and other green certifications are becoming essential for manufacturers aiming to differentiate their products in a competitive market. Such certifications not only signify compliance with environmental standards but also reassure buyers of the product’s sustainability.

Illustrative image related to good tire inflator

Furthermore, the push for energy-efficient inflators that consume less power during operation aligns with global initiatives to reduce carbon emissions. B2B buyers should prioritize suppliers that integrate these sustainability practices into their operations, as this can lead to long-term cost savings and improved market positioning.

The tire inflator market has undergone significant evolution since its inception. Initially, inflators were manual pumps requiring physical effort to operate, which posed challenges for users. With advancements in technology, electric and battery-operated inflators have transformed the landscape, providing users with ease and efficiency.

The introduction of portable models has also changed consumer expectations, making inflators a staple in emergency roadside kits. As vehicle technology advanced, so too did the features of tire inflators, incorporating digital displays, preset pressure settings, and even smartphone connectivity in some high-end models. This evolution reflects a broader trend towards convenience and technological integration in automotive accessories, catering to a modern consumer base that values efficiency and ease of use.

In summary, understanding these market dynamics, sustainability considerations, and historical context can empower international B2B buyers to make strategic sourcing decisions in the tire inflator sector.

Wie wähle ich den richtigen Reifenfüller für meine geschäftlichen Anforderungen?

Selecting the right tire inflator involves assessing your specific requirements, such as the types of vehicles in your fleet and the typical tire sizes you deal with. Consider factors like maximum pressure, inflation speed, power source (cordless or corded), and additional features like built-in pressure gauges and portability. Evaluate the durability and warranty offered by suppliers, as these can significantly impact long-term usability and maintenance costs.

What is the best tire inflator for commercial use?

For commercial applications, the AstroAI Cordless Tire Inflator is highly recommended due to its quick inflation capabilities and versatility. It can efficiently inflate multiple tires on a single charge, making it ideal for businesses with varied vehicle types. However, for larger vehicles like trucks and SUVs, the Viair 88P may be more suitable due to its high-pressure capacity and speed, despite being bulkier. Assess your specific usage scenarios to determine the best fit.

What are the key features to look for in a tire inflator for international markets?

When sourcing tire inflators for international markets, prioritize features such as multi-voltage compatibility to accommodate different power outlets, robust construction to withstand varied environments, and ease of use. Additionally, consider inflation speed, maximum pressure capabilities, and built-in safety features. Customization options may also be valuable for branding or specific regional requirements.

How can I vet suppliers for tire inflators?

To vet suppliers, conduct thorough research by checking their business credentials, customer reviews, and industry certifications. Request samples to evaluate product quality and performance firsthand. Additionally, consider their manufacturing processes, adherence to international quality standards, and ability to provide after-sales support. Engaging with previous clients can provide insights into the supplier’s reliability and service quality.

What are the minimum order quantities (MOQs) for tire inflators?

Minimum order quantities for tire inflators can vary significantly between suppliers. Typically, MOQs range from a few dozen to several hundred units, depending on the manufacturer and the product type. Discuss your purchasing needs with potential suppliers, as many are willing to negotiate MOQs, especially for first-time orders or long-term partnerships.

What payment terms are commonly offered for international purchases?

Common payment terms for international purchases often include options like letters of credit, bank transfers, or payment through platforms like PayPal. Many suppliers may require a deposit upfront, with the balance due upon shipment or delivery. It’s essential to clarify these terms before finalizing any agreements to ensure that they align with your cash flow and risk management strategies.

How do I ensure quality assurance (QA) for tire inflators?

To ensure quality assurance, request certifications that demonstrate compliance with international standards such as ISO or CE. Implement a quality control process, including pre-shipment inspections and third-party testing, to verify that the inflators meet your specifications. Establish clear communication with suppliers regarding your quality expectations and consider building a long-term relationship to foster mutual accountability.

What are the logistics considerations when sourcing tire inflators internationally?

Logistics considerations include understanding shipping costs, transit times, and customs regulations in both the exporting and importing countries. Evaluate the reliability of the chosen shipping method, whether air or sea, and consider potential tariffs or duties that may apply. Collaborating with a logistics partner experienced in international trade can streamline the process and help mitigate risks associated with customs delays and shipping damages.

We are currently compiling a detailed list of top good tire inflator suppliers. Please check back later.

In the competitive landscape of tire inflators, strategic sourcing emerges as a critical component for B2B buyers looking to enhance their operational efficiency and customer satisfaction. By prioritizing quality, performance, and features such as portability and accuracy, businesses can ensure they select inflators that not only meet their immediate needs but also contribute to long-term savings on maintenance and operational costs.

The recent evaluations have highlighted top products like the AstroAI Cordless Tire Inflator for its versatility and efficiency, while the Viair 88P stands out for those requiring robust performance for larger vehicles. These insights allow international buyers—especially from regions such as Africa, South America, the Middle East, and Europe—to make informed decisions that align with their specific market demands.

As you move forward in your sourcing strategy, consider the unique requirements of your customer base and the environments in which these inflators will be used. Embrace innovation and reliability in your procurement processes, and position your business to thrive in an evolving market. Engage with suppliers who understand your regional challenges and can provide tailored solutions, ensuring that you stay ahead of the competition.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.