In today’s dynamic global marketplace, sourcing the right Milton inflator gauge can be a daunting task for international B2B buyers. With varying standards, quality expectations, and supply chain challenges across regions such as Africa, South America, the Middle East, and Europe, making informed purchasing decisions is crucial. This comprehensive guide addresses these challenges by exploring the diverse types of Milton inflator gauges available, their specific applications across various industries, and essential supplier vetting criteria.

Buyers will gain insights into cost considerations, ensuring that they not only find the right products but also secure competitive pricing. Understanding the nuances of product specifications and regional requirements will empower businesses to select inflator gauges that align with their operational needs while maintaining compliance with local regulations.

By navigating the complexities of sourcing Milton inflator gauges with this guide, international buyers can streamline their procurement processes, mitigate risks associated with subpar products, and ultimately enhance operational efficiency. This resource serves as a vital tool, equipping stakeholders with the knowledge necessary to make strategic purchasing decisions that drive profitability and success in their respective markets.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Milton S986 Service Gauge | Straight foot design, dual scale (PSI and BAR) | Automotive service, tire repair shops | Vorteile: Easy to read; durable. Nachteile: Limited to specific pressure ranges. |

| Milton S506 Full Swivel Inflator | 15-inch length, full swivel head for maneuverability | Heavy equipment maintenance, fleet services | Vorteile: Enhanced reach; versatile. Nachteile: Higher initial investment. |

| Milton Digital Tire Gauge DTG108 | Digital readout, includes tread depth measurement | Automotive inspections, tire retailers | Vorteile: Accurate readings; easy to use. Nachteile: Battery-dependent; may require calibration. |

| Milton S934 Dial Type Tire Gauge | Mechanical dial, 0-120 PSI range, includes tread depth gauge | General automotive, DIY tire maintenance | Vorteile: No batteries needed; reliable. Nachteile: Slightly less accurate than digital options. |

| Milton Combination Tool M-443 | Multi-functional: core extractor, installer, inflator | Tire shops, automotive service centers | Vorteile: Space-saving; multifunctional. Nachteile: Learning curve for new users. |

The Milton S986 Service Gauge features a straight foot design with dual measurement scales (PSI and BAR), making it suitable for various tire pressure applications. Its robust construction ensures durability in demanding environments like automotive service centers and tire repair shops. B2B buyers should consider its ease of use and readability, but note that it may have limitations in pressure range compared to other models.

Illustrative image related to milton inflator gauge

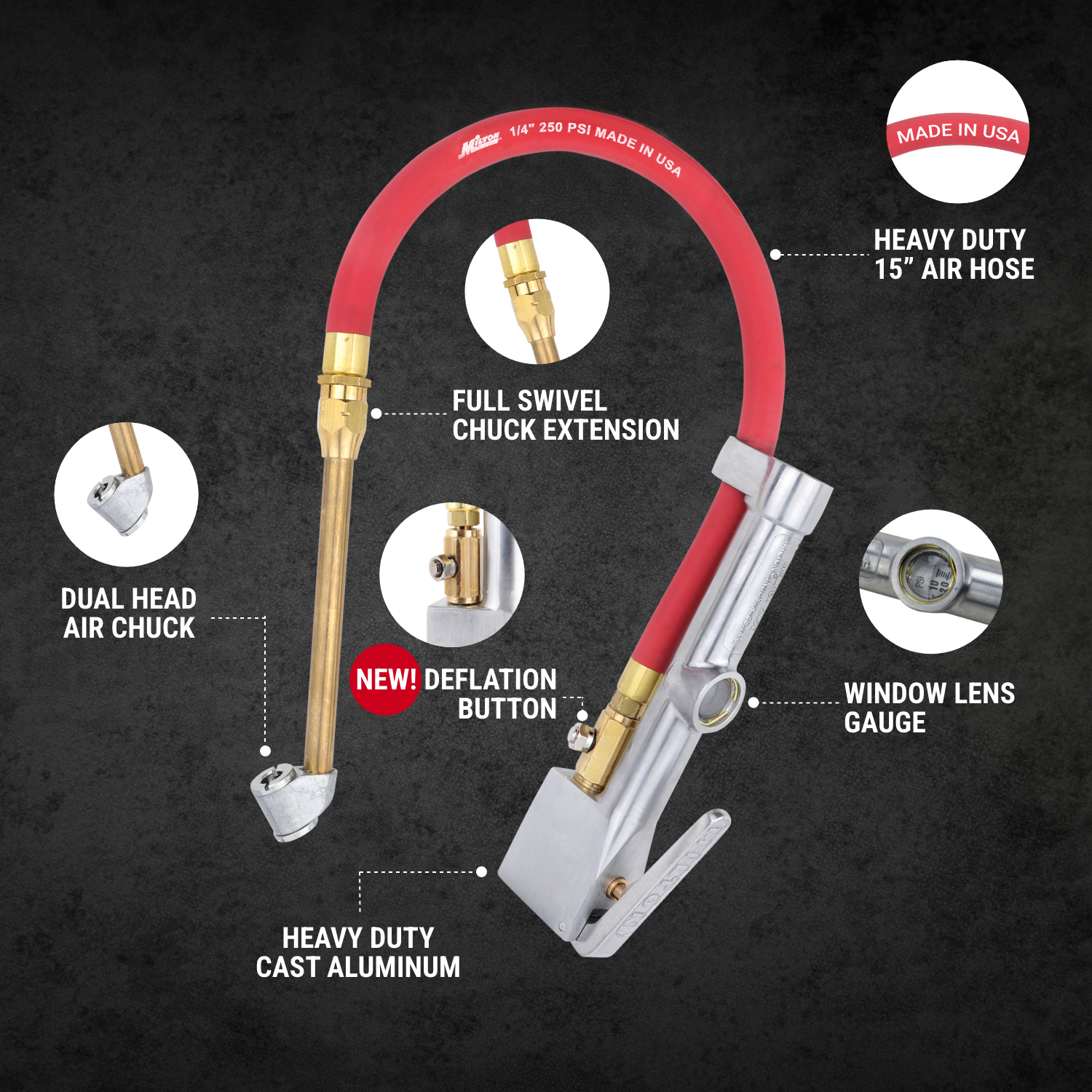

The Milton S506 Full Swivel Inflator is designed for enhanced maneuverability, featuring a 15-inch length and a full swivel head. This design is particularly beneficial in heavy equipment maintenance and fleet services, where access to tight spaces is crucial. While it offers versatility and improved reach, buyers should be aware of the higher initial investment compared to standard gauges.

The Milton Digital Tire Gauge DTG108 stands out for its digital readout and integrated tread depth measurement, providing precise and user-friendly readings. This gauge is ideal for automotive inspections and tire retailers who require accuracy and efficiency. However, it is battery-dependent and may necessitate occasional calibration, which could be a consideration for B2B buyers focusing on long-term reliability.

The Milton S934 Dial Type Tire Gauge features a mechanical dial with a pressure range of 0-120 PSI and includes a tread depth gauge. Its mechanical nature means it doesn’t rely on batteries, making it a reliable choice for general automotive and DIY tire maintenance. While it is dependable, it might not offer the same level of precision as digital gauges, which is something buyers should consider based on their specific needs.

The Milton Combination Tool M-443 is a versatile solution that combines a valve core extractor, installer, and inflator in one compact tool. This multifunctionality is particularly advantageous for tire shops and automotive service centers, where space and efficiency are paramount. While it saves space and offers multiple functions, new users may face a learning curve to master its use effectively.

| Industrie/Sektor | Specific Application of milton inflator gauge | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparatur | Tire inflation and pressure monitoring | Ensures vehicle safety and optimal performance | Calibration accuracy, durability, and ease of use |

| Landwirtschaft | Tire maintenance for tractors and farm equipment | Reduces downtime and enhances equipment reliability | Compatibility with various tire types and sizes |

| Transport und Logistik | Fleet vehicle maintenance and tire pressure checks | Increases fuel efficiency and extends tire lifespan | Robustness, portability, and quick response time |

| Bauwesen | Inflation of heavy machinery tires | Minimizes operational delays and improves safety | Pressure range, ruggedness, and weather resistance |

| Herstellung | Pressure testing of pneumatic tools and equipment | Improves operational efficiency and safety compliance | Precision, ease of calibration, and service support |

In the automotive repair sector, the Milton inflator gauge is essential for tire inflation and pressure monitoring. Accurate tire pressure is crucial for vehicle safety and performance. By utilizing this gauge, repair shops can ensure that vehicles are operating within manufacturer specifications, reducing the risk of blowouts and improving fuel efficiency. International buyers should prioritize gauges with high calibration accuracy and durability to withstand frequent use in high-volume environments.

In agriculture, the Milton inflator gauge is vital for maintaining the tires of tractors and other farming equipment. Proper tire inflation is necessary to enhance traction and reduce soil compaction, which can affect crop yields. By utilizing this tool, farmers can minimize downtime caused by tire issues and ensure that their equipment operates reliably. Buyers should consider compatibility with various tire sizes and types, as well as the gauge’s ability to perform in rugged outdoor conditions.

For the transportation and logistics industry, regular tire pressure checks using the Milton inflator gauge are critical for fleet maintenance. Properly inflated tires improve fuel efficiency and extend tire lifespan, which directly impacts operational costs. Fleet managers should look for gauges that offer portability and quick response times, enabling them to perform checks efficiently during routine inspections or roadside emergencies. Durability is also a key consideration due to the demanding nature of this sector.

In the construction industry, the Milton inflator gauge is used to inflate tires on heavy machinery such as bulldozers and excavators. Maintaining the correct tire pressure is crucial to prevent operational delays and enhance safety on job sites. This gauge can help construction companies avoid costly downtime due to tire-related issues. Buyers should ensure the gauge can handle a wide pressure range and is rugged enough to withstand harsh working environments.

In manufacturing, the Milton inflator gauge is employed for pressure testing pneumatic tools and equipment. Ensuring that these tools operate within safe pressure ranges is essential for maintaining operational efficiency and safety compliance. Businesses in this sector should focus on precision and ease of calibration when sourcing inflator gauges, as these factors contribute to the overall effectiveness of their maintenance programs. Additionally, reliable service support is a valuable consideration for ongoing operational needs.

Das Problem: B2B buyers often face issues with inflator gauges that provide inconsistent pressure readings. This can lead to significant safety risks, particularly in industries relying on heavy machinery or commercial vehicles. For example, a fleet manager in the transportation sector may experience discrepancies in tire pressure due to faulty gauges, resulting in tire blowouts or decreased fuel efficiency. Such incidents can lead to costly downtime and even accidents, impacting operational efficiency and safety.

Illustrative image related to milton inflator gauge

Die Lösung: To mitigate this issue, it is essential to invest in high-quality Milton inflator gauges known for their accuracy and reliability. Buyers should consider sourcing models like the Milton S506, which features a full swivel design for ease of use and improved accuracy. It’s advisable to regularly calibrate the gauges and adhere to manufacturer guidelines for maintenance. Establishing a routine for checking and calibrating the inflator gauges can significantly enhance their reliability, ensuring that tire pressures are consistently monitored and maintained at optimal levels.

Das Problem: Another common challenge faced by B2B buyers is the difficulty of accessing tire valves in tight spaces, particularly in larger vehicles or machinery. For instance, a construction company might struggle to inflate the tires of heavy equipment due to awkward valve placements. This can lead to time-consuming workarounds, increasing labor costs and project delays.

Die Lösung: To address this issue, buyers should consider investing in inflator gauges with specialized designs, such as the Milton M-504, which features a straight head air chuck that can easily access tight valve placements. Additionally, using a flexible hose or an extension can improve reach and maneuverability. Training staff on effective techniques for using these tools can further streamline the inflation process, reducing downtime and ensuring that equipment is ready for immediate use.

Das Problem: Frequent wear and tear on inflator gauges can be a significant pain point for B2B buyers, particularly in environments where tools are used extensively. For example, a tire service company may find that their inflator gauges need constant replacement due to rugged usage, leading to increased costs and operational inefficiencies. This not only affects the bottom line but can also frustrate workers who rely on these tools for daily operations.

Die Lösung: To combat wear and tear, it is crucial to select Milton inflator gauges designed for durability and longevity. Models like the Milton S934, which includes a robust dial-type gauge, can withstand harsher conditions better than standard models. Buyers should also consider implementing a routine inspection and maintenance schedule for their inflator gauges to identify signs of wear early on. Investing in protective cases or storage solutions can also help extend the life of the tools. Furthermore, providing training for employees on proper handling and usage can significantly reduce the risk of damage, ultimately saving costs in the long run.

When selecting materials for Milton inflator gauges, it’s crucial to consider their properties, advantages, and limitations. The right material not only influences the performance of the gauge but also impacts its longevity and suitability for specific applications. Below, we analyze four common materials used in Milton inflator gauges: brass, stainless steel, rubber, and plastic.

Brass is a popular choice for components in inflator gauges due to its excellent machinability and corrosion resistance. It typically has a temperature rating of up to 200°C and can withstand moderate pressures, making it suitable for various applications.

Vorteile: Brass is durable and resistant to rust, which is essential for gauges exposed to moisture. Its relatively low cost and ease of manufacturing make it an economical choice for mass production.

Illustrative image related to milton inflator gauge

Nachteile: However, brass can be susceptible to dezincification in certain environments, which may compromise its integrity over time. Additionally, while it is cost-effective, it may not be the best choice for high-pressure applications.

Auswirkungen auf die Anwendung: Brass is compatible with air and non-corrosive gases, making it ideal for standard inflator gauges.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM B16 and DIN 17660 is essential for brass components. Buyers in regions like Africa and the Middle East should also consider the local availability of brass and its pricing fluctuations.

Stainless steel is often utilized for inflator gauge components that require enhanced durability and corrosion resistance. It can withstand higher temperatures (up to 400°C) and pressures, making it suitable for more demanding applications.

Vorteile: The primary advantage of stainless steel is its exceptional resistance to corrosion and staining, which extends the lifespan of the product. It also has a modern aesthetic appeal, which can be important in consumer-facing applications.

Nachteile: On the downside, stainless steel is generally more expensive than brass and can be more challenging to machine, potentially increasing manufacturing complexity.

Auswirkungen auf die Anwendung: Stainless steel is compatible with a wider range of media, including corrosive gases, making it a versatile choice for various inflator gauge applications.

Überlegungen für internationale Käufer: Buyers should ensure compliance with international standards such as ASTM A276 and JIS G4303. The higher cost may be a consideration for buyers in developing regions.

Rubber and plastic are often used for seals, grips, and protective components in inflator gauges. Rubber typically has a temperature rating of around -40°C to 100°C, while plastics can vary significantly depending on the type.

Vorteile: Rubber provides excellent sealing capabilities and flexibility, while plastic is lightweight and can be manufactured in various colors and shapes, enhancing the product’s usability and aesthetics.

Nachteile: However, rubber can degrade over time when exposed to certain chemicals or UV light, while plastic may not withstand high temperatures or pressures as effectively as metals.

Auswirkungen auf die Anwendung: Rubber seals are crucial for maintaining pressure integrity, while plastic components can be used for lightweight applications where high strength is not a priority.

Illustrative image related to milton inflator gauge

Überlegungen für internationale Käufer: Compliance with material safety standards such as ASTM D2000 for rubber and ISO 11469 for plastics is essential. Buyers should also consider the environmental impact and recyclability of these materials, especially in regions with stringent regulations.

| Material | Typical Use Case for milton inflator gauge | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Brass | Gauge fittings and connectors | Langlebig und korrosionsbeständig | Susceptible to dezincification | Niedrig |

| Rostfreier Stahl | High-pressure gauge components | Excellent corrosion resistance | Höhere Kosten und komplexere Herstellung | Hoch |

| Gummi | Dichtungen und Griffe | Excellent sealing and flexibility | Degrades with chemicals and UV exposure | Mittel |

| Kunststoff | Lightweight components and protective parts | Leicht und vielseitig | Limited high-temperature/pressure use | Niedrig |

This material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on performance, cost, and regional compliance.

The manufacturing process for Milton inflator gauges involves several critical stages that ensure product quality and reliability. The main stages include material preparation, forming, assembly, and finishing.

Material preparation begins with the selection of high-quality raw materials, such as brass, stainless steel, and durable plastics. These materials are sourced from reputable suppliers to meet industry standards. The preparation phase may involve cutting, machining, or treating materials to achieve the desired specifications. For instance, brass components are often treated for corrosion resistance, ensuring longevity and performance in various environments.

Forming techniques play a pivotal role in shaping the raw materials into functional components. Common techniques include stamping, casting, and extrusion. For Milton inflator gauges, precision machining is frequently used to create intricate parts such as valve seats and pressure measurement mechanisms. This precision is vital as it directly impacts the accuracy and reliability of the gauge readings.

The assembly of Milton inflator gauges is a meticulous process that combines various components into a final product. Skilled technicians follow detailed assembly protocols, which may include:

Finishing processes for Milton inflator gauges involve several techniques aimed at enhancing appearance and functionality. These may include:

Quality assurance in the manufacturing of Milton inflator gauges is governed by various international standards. The ISO 9001 standard is central, focusing on maintaining a quality management system that enhances customer satisfaction through consistent product quality.

In addition to ISO 9001, industry-specific certifications such as CE marking and API standards may apply, depending on the target market. CE marking indicates compliance with European health, safety, and environmental protection standards, while API standards may be relevant for gauges used in oil and gas applications.

Illustrative image related to milton inflator gauge

Quality control (QC) is an integral part of the manufacturing process for Milton inflator gauges, involving multiple checkpoints:

Eingehende Qualitätskontrolle (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified requirements. Any non-conforming materials are rejected or returned to suppliers.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing stages, continuous monitoring takes place. Technicians conduct tests at various points to identify any deviations from quality standards early in the process.

Endgültige Qualitätskontrolle (FQC): Once assembly is complete, the final products undergo rigorous testing. This includes functional tests, pressure tests, and calibration checks to confirm that each inflator gauge performs to specification.

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are several strategies:

Lieferanten-Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, QC measures, and adherence to international standards firsthand. This can build trust and ensure that the supplier meets quality expectations.

Anforderung von Qualitätsberichten: Suppliers should provide detailed quality reports, including test results and compliance certificates. These documents help buyers assess the reliability and performance of the inflator gauges.

Inspektionen durch Dritte: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing and QC processes. These agencies can verify compliance with international standards and provide additional assurance to buyers.

International B2B buyers need to be aware of specific nuances in quality control when sourcing products like Milton inflator gauges. Different regions may have varying standards and regulations. For example, products exported to the European market must comply with CE marking requirements, while buyers in the Middle East may need to consider GSO standards.

Additionally, understanding the local market dynamics, including import regulations and quality expectations, is essential. Buyers should engage with suppliers who demonstrate a clear understanding of these requirements and have robust quality assurance processes in place.

The manufacturing processes and quality assurance measures for Milton inflator gauges are critical in ensuring that these tools meet the demands of international markets. By understanding the various stages of manufacturing and the associated quality control checkpoints, B2B buyers can make informed decisions when sourcing these essential tools. Implementing thorough verification processes will not only mitigate risks but also foster long-term partnerships with reliable suppliers.

Illustrative image related to milton inflator gauge

When sourcing Milton inflator gauges, a structured approach can significantly streamline the procurement process, ensuring you secure high-quality products that meet your operational needs. This guide serves as a comprehensive checklist to help B2B buyers, particularly from international markets, navigate the complexities of sourcing inflator gauges effectively.

Before initiating the sourcing process, clearly define the technical specifications required for the Milton inflator gauge. Consider factors such as pressure range, accuracy, and compatibility with existing equipment. This step ensures that you target products that meet your exact needs, reducing the risk of purchasing unsuitable items.

Identifying reputable suppliers is critical to ensuring product quality and reliability. Research various suppliers of Milton inflator gauges and look for established companies with a proven track record in the industry. Reviews and testimonials from previous clients can provide valuable insights into their reliability and customer service.

Before finalizing a supplier, it is essential to verify their certifications and compliance with international standards. Certifications such as ISO 9001 can indicate that the supplier adheres to quality management principles, which is crucial for maintaining product quality and safety.

Once you have narrowed down your options, request samples of the Milton inflator gauges you are considering. Testing samples allows you to evaluate the quality, performance, and ease of use of the products before making a bulk purchase.

Price is a significant factor in the sourcing process, but it should not be the only consideration. Compare pricing among different suppliers while also evaluating their terms of sale, including payment options, lead times, and return policies. This comprehensive assessment will help you find the best value for your investment.

Effective communication with your chosen supplier is vital for a smooth procurement process. Establish clear lines of communication regarding expectations, timelines, and any specific requirements you may have. This step helps prevent misunderstandings and ensures that both parties are aligned.

After selecting a supplier and agreeing on terms, finalize your purchase and monitor the delivery process closely. Ensure that you have a tracking system in place to stay informed about shipment progress and address any issues that may arise promptly.

When evaluating the cost structure for sourcing Milton inflator gauges, several components come into play. Materialien typically account for a significant portion of the overall cost, including the quality of metals, plastics, and other components used in the gauge production. Arbeit costs are influenced by the skill level required for assembly and calibration, especially if the gauges are manufactured in regions with varying wage rates.

Fertigungsgemeinkosten includes expenses related to facilities, utilities, and equipment maintenance. Tooling costs can be substantial if custom molds or specific production tools are needed, particularly for specialized gauges. Additionally, quality control (QC) processes are essential to ensure that the inflator gauges meet industry standards, which may add to the overall cost. Finally, Logistik expenses, encompassing shipping, warehousing, and handling, must also be factored in, particularly for international shipments.

Several factors can influence the pricing of Milton inflator gauges, most notably volume and minimum order quantities (MOQ). Larger orders often lead to reduced per-unit costs due to economies of scale. Specifications and customization requests can significantly impact pricing, as tailored solutions typically require additional resources and adjustments in production.

The quality of Materialien used in the manufacturing process also plays a critical role. High-grade materials that offer durability and reliability can elevate the price point. Certifications and compliance with international standards can further influence costs, as these requirements might necessitate additional testing and validation.

Illustrative image related to milton inflator gauge

Lieferantenfaktoren such as reputation, reliability, and location can also affect pricing. Suppliers based in regions with higher operational costs may charge more. Finally, understanding Incoterms is crucial for international buyers, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact the total cost.

For B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe, effective negotiation strategies are essential for securing favorable pricing on Milton inflator gauges. One effective tactic is to build long-term relationships with suppliers, as loyalty can often lead to better pricing and terms.

Das Verständnis der Gesamtbetriebskosten (TCO) is also vital. This approach considers not just the initial purchase price but also maintenance costs, potential downtime, and the lifespan of the product. By presenting a comprehensive TCO analysis during negotiations, buyers can justify their budget and push for more favorable terms.

It’s also wise to remain flexible on order quantities. If a supplier is unwilling to adjust prices, consider negotiating for better payment terms or additional services such as extended warranties or free shipping. Additionally, being aware of Preisnuancen in different regions can help buyers negotiate more effectively, as market conditions may vary significantly across continents.

When assessing indicative prices for Milton inflator gauges, buyers should exercise caution. Prices can fluctuate based on market demand, raw material costs, and geopolitical factors that may affect supply chains. It’s crucial for international buyers to request detailed quotes that break down all associated costs, including shipping and import duties, to avoid unexpected expenses.

Illustrative image related to milton inflator gauge

By understanding the complete cost structure and being aware of the various factors influencing pricing, B2B buyers can make informed decisions when sourcing Milton inflator gauges, ensuring they achieve the best value for their investment.

In the competitive landscape of tire inflation solutions, the Milton Inflator Gauge stands out for its reliability and accuracy. However, various alternatives exist that may better suit specific needs or preferences. This analysis will compare the Milton Inflator Gauge with two notable alternatives: the digital tire inflator and the manual tire pressure gauge. By examining performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their operational requirements.

| Vergleich Aspekt | Milton Inflator Gauge | Digital Tire Inflator | Manual Tire Pressure Gauge |

|---|---|---|---|

| Leistung | Accurate, reliable readings | Quick inflation and deflation | Basic pressure measurement |

| Kosten | $26.75 – $50.73 | $30 – $100 | $10 – $25 |

| Leichte Implementierung | Simple to use | Requires power source | Very user-friendly |

| Wartung | Minimal | Moderate, battery replacement | Low, no moving parts |

| Bester Anwendungsfall | Commercial tire shops | Mobile service providers | Personal or light-duty use |

Digital tire inflators offer a modern solution for tire pressure management. They typically feature digital displays for precise readings and often come with built-in LED lights for visibility in low-light conditions. The quick inflation feature can save time, especially in high-volume operations. However, the reliance on batteries or a power source can be a disadvantage, particularly in remote areas where electricity may not be available. Additionally, digital inflators can be more expensive than traditional options, making them less appealing for budget-conscious buyers.

Manual tire pressure gauges are straightforward tools that provide an easy way to check tire pressure without the need for a power source. They are usually compact and portable, making them ideal for personal use or light-duty applications. The low cost and minimal maintenance requirements make them an attractive option for individual consumers or small businesses. However, they may lack the advanced features of digital inflators and can be less accurate if not calibrated properly. For organizations that need to monitor tire pressure frequently and accurately, manual gauges may not meet their needs.

When selecting the right tire inflation solution, B2B buyers should consider their specific operational requirements, budget constraints, and the environment in which they operate. The Milton Inflator Gauge excels in commercial settings where reliability and accuracy are paramount, while digital inflators may be ideal for those who prioritize speed and convenience. On the other hand, manual gauges could be sufficient for smaller-scale operations with less frequent use. By assessing the unique demands of their business, buyers can choose the most suitable solution that aligns with their goals and operational efficiency.

Understanding the technical specifications of the Milton inflator gauge is essential for B2B buyers looking to invest in reliable equipment. Here are some critical properties to consider:

Material Klasse

The Milton inflator gauge is typically constructed from high-grade materials such as brass and stainless steel. These materials are chosen for their durability and resistance to corrosion, which is vital for tools exposed to various environmental conditions. High-quality materials ensure longevity and reliability, reducing the need for frequent replacements, which can be a significant cost consideration for businesses.

Druckbereich

Most Milton inflator gauges offer a pressure range of up to 120 PSI, making them suitable for various applications, from automotive to industrial. Understanding the appropriate pressure range is crucial for businesses to ensure the gauge meets their operational requirements. An inadequate pressure range could lead to inaccurate readings or inadequate inflation, potentially impacting productivity and safety.

Calibration Tolerance

Calibration tolerance indicates the accuracy of the gauge’s measurements, typically within ±1 PSI. This level of precision is critical for applications where exact tire pressure is necessary for safety and performance. Businesses should prioritize gauges with a low tolerance level to ensure they are making informed decisions based on accurate data.

Gauge Type

Milton offers different types of gauges, including analog and digital options. Analog gauges provide a straightforward, mechanical readout, while digital gauges often feature enhanced readability and additional functionalities such as backlighting. The choice between these types can depend on the specific needs of the business, including user preference and operational conditions.

Connection Type

The inflator gauge typically features a 1/4” NPT (National Pipe Thread) connection, which is standard in the industry. This specification is important for compatibility with various air hoses and systems. Businesses should ensure that the inflator gauge they choose can easily integrate with their existing equipment to avoid additional costs related to adapters or modifications.

Length and Swivel Features

Many models come with a swivel feature and various lengths, like the 15″ full swivel design. These attributes enhance ease of use, allowing operators to access hard-to-reach valves without hassle. Choosing a gauge with the right length and flexibility can improve efficiency during operations, especially in confined spaces.

Navigating the purchasing process for inflator gauges requires familiarity with industry jargon. Here are some essential terms to know:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for businesses looking to source high-quality components that guarantee compatibility and reliability.

MOQ (Mindestbestellmenge)

MOQ is the smallest number of units a supplier is willing to sell. This metric is essential for budgeting and inventory management, as it can impact the total cost of procurement. B2B buyers should negotiate MOQs that align with their operational needs without incurring excess inventory costs.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on specific products or services. It typically includes details about quantities, specifications, and delivery timelines. Crafting a comprehensive RFQ can help businesses obtain competitive pricing and ensure they receive exactly what they need.

Incoterms (Internationale Handelsklauseln)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly affect the total cost of acquisition. Familiarity with Incoterms helps businesses avoid unexpected expenses and logistical issues.

Vorlaufzeit

Lead time refers to the duration from placing an order to receiving the goods. Understanding lead times is crucial for effective supply chain management, especially for businesses with tight project timelines. Knowing this information allows for better planning and inventory control.

Gewährleistungsfrist

The warranty period indicates the timeframe during which the manufacturer guarantees the product against defects. A robust warranty can provide peace of mind and protect against potential losses, making it an essential consideration for B2B buyers focused on long-term investments.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions regarding the procurement of Milton inflator gauges, ultimately enhancing operational efficiency and product reliability.

The global market for inflator gauges, particularly Milton products, is experiencing substantial growth driven by the rising demand for efficient tire management solutions. With increasing vehicle ownership across emerging markets in Africa, South America, and the Middle East, the need for reliable inflator gauges has surged. As businesses focus on enhancing operational efficiency, innovations in B2B technology—such as digital inflator gauges and integrated pressure monitoring systems—are gaining traction. These technologies not only improve accuracy but also offer data analytics capabilities that can help businesses optimize their tire maintenance processes.

Additionally, the emphasis on safety and compliance with automotive regulations is shaping the market. Companies are increasingly prioritizing high-quality tools that can withstand rigorous use while adhering to international safety standards. In regions like Europe and the Middle East, the demand for premium products such as the Milton S506 Full Swivel Inflator Gauge reflects a trend toward investing in durable and efficient equipment. Furthermore, the rise of e-commerce platforms is facilitating easier access to Milton inflator gauges, enabling international buyers to source products quickly and efficiently.

Sustainability is becoming a pivotal concern in the inflator gauge sector, influencing procurement strategies for B2B buyers. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny. As a result, businesses are increasingly seeking suppliers who prioritize ethical sourcing and sustainable practices. This shift is particularly relevant in regions where environmental regulations are tightening, pushing companies to adopt greener alternatives.

Milton products, known for their durability, are often made from materials that can be recycled or reused, aligning with the growing demand for eco-friendly options. Buyers are encouraged to look for certifications such as ISO 14001, which signifies adherence to environmental management standards. Additionally, sourcing from suppliers committed to sustainable practices not only enhances a company’s brand image but also mitigates risks associated with unethical labor practices in the supply chain. By prioritizing sustainability, businesses can contribute to a healthier planet while ensuring compliance with evolving regulations.

Milton has a rich history in the inflator gauge market, established over decades as a trusted name synonymous with quality and reliability. The brand’s commitment to innovation has allowed it to adapt to changing market demands, maintaining relevance in an ever-evolving landscape. Initially focused on basic inflator gauges, Milton has expanded its product line to include advanced digital gauges and multifunctional tools, catering to a diverse clientele.

This evolution reflects broader trends in the automotive and industrial sectors, where precision and efficiency are paramount. For international B2B buyers, understanding the historical context of Milton products provides insight into their long-standing reputation and reliability. As the market continues to evolve, Milton’s legacy of quality ensures that their inflator gauges remain a preferred choice for businesses looking to enhance their tire management solutions.

How do I choose the right Milton inflator gauge for my needs?

Selecting the right Milton inflator gauge depends on your specific application and requirements. Consider factors such as the pressure range, accuracy, ease of use, and whether you need additional features like a tread depth gauge. For heavy-duty applications, gauges with durable materials and high-pressure ratings are advisable. Additionally, check compatibility with existing equipment, ensuring that the gauge can connect seamlessly to your air supply system. Consulting with suppliers about your intended use can also provide valuable insights to make an informed choice.

What are the key features to look for in a Milton inflator gauge?

When evaluating Milton inflator gauges, focus on features such as measurement accuracy, durability, and ease of reading. Look for gauges that offer both analog and digital displays, as digital gauges often provide more precise readings. Other essential features include a swivel head for easier access in tight spaces, a built-in pressure relief valve, and compatibility with various tire valves. Assessing the gauge’s material quality is crucial; brass and stainless steel components typically offer superior longevity and resistance to wear.

What are the typical payment terms for purchasing Milton inflator gauges in bulk?

Payment terms can vary by supplier and region, but many B2B transactions involve options such as net 30, net 60, or prepayment. It’s common to negotiate terms based on order size, especially for bulk purchases. Some suppliers may offer discounts for early payments or larger quantities. Always clarify payment methods accepted, including bank transfers, letters of credit, or online payment platforms. Ensure that the terms are documented in the purchase agreement to avoid any misunderstandings.

What is the minimum order quantity (MOQ) for Milton inflator gauges?

The minimum order quantity for Milton inflator gauges often depends on the supplier’s policies and your specific needs. Many suppliers set an MOQ to cover production and shipping costs efficiently. Typically, MOQs can range from a few dozen to several hundred units. It’s beneficial to inquire directly with potential suppliers about their MOQs and explore whether they offer flexibility for smaller orders, especially for new customers or trial purchases.

How can I ensure the quality of Milton inflator gauges before placing a bulk order?

To ensure the quality of Milton inflator gauges, request samples before committing to a bulk order. Evaluate the gauges for accuracy, durability, and ease of use. Additionally, research the supplier’s reputation through customer reviews and industry references. Consider requesting certifications that verify compliance with relevant industry standards. Engaging in third-party quality assessments or audits can also provide peace of mind regarding the product’s reliability.

What logistics considerations should I keep in mind when importing Milton inflator gauges?

When importing Milton inflator gauges, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Evaluate whether air freight or sea freight is more economical based on urgency and cost. Understanding your country’s import duties and taxes is crucial to avoid unexpected expenses. Collaborating with a freight forwarder can streamline the logistics process, ensuring compliance with all regulations and timely delivery of your order.

Can I customize Milton inflator gauges for my branding needs?

Many suppliers offer customization options for Milton inflator gauges, including branding with your company logo or specific color schemes. Customization typically requires a minimum order quantity and may involve additional costs. Discuss your branding requirements with potential suppliers to understand their capabilities and lead times for customized orders. Custom gauges can enhance brand visibility and create a unique selling proposition in your market.

What should I do if my Milton inflator gauge arrives damaged or defective?

If your Milton inflator gauge arrives damaged or defective, promptly contact the supplier to report the issue. Document the damage with photos and provide a detailed description of the problem. Most suppliers have return policies that allow for exchanges or refunds, especially if the issue is reported within a specified timeframe. Review the supplier’s warranty and return policy beforehand to understand your rights and ensure a smooth resolution.

Bereich: miltonbrands.com

Registered: 2023 (2 years)

Einleitung: This company, Milton – 3-in-1 Pro Analog Tire Inflator/Deflator Kit, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: alltiresupply.com

Registriert: 2001 (24 Jahre)

Einleitung: Milton collection includes a variety of high-quality products such as:

– Milton M-S986 Service Gauge (Straight Foot Dual) – Price: $26.75

– Milton M-S1173 Mini Inline Air Dryer – Price: $32.75

– Milton M-731 Quick-Fill Valve Plug For Car and LT – Price: $3.50

– Milton M-1654-9-EA Brass Hose Ferrules – Price: From $1.25

– Milton M-435 Hex Head Chrome Valve Cap (50/Box) – Price: $32.11

– Milton M-S4…

Bereich: steckmfg.com

Registriert: 1998 (27 Jahre)

Einleitung: Milton® Inflator Gauge Cartridge Repair Kit 506-79A

In conclusion, the strategic sourcing of Milton inflator gauges presents a compelling opportunity for international B2B buyers seeking reliable, high-quality tire maintenance solutions. The diverse product range, including the M-S506 Full Swivel Inflator Gauge and the M-S934 Dial Type Tire Gauge, showcases Milton’s commitment to precision and durability, essential for various applications across different industries.

By prioritizing strategic sourcing, businesses can ensure they are procuring products that not only meet operational needs but also enhance safety and efficiency. The competitive pricing and availability of Milton inflator gauges across global markets make them an attractive choice for buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia.

As the demand for reliable tire maintenance tools continues to rise, now is the time to invest in Milton products. By aligning with a reputable supplier, businesses can strengthen their supply chains and contribute to improved operational performance. Explore the full range of Milton inflator gauges today, and position your business for success in a dynamic market landscape.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Illustrative image related to milton inflator gauge