In the competitive landscape of the global market, sourcing a reliable snap-on air gauge can pose significant challenges for B2B buyers. With the growing demand for precision in tire pressure management across various industries, understanding the nuances of these tools is crucial. This comprehensive guide aims to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—with the knowledge needed to make informed purchasing decisions.

Throughout this guide, we will delve into various types of snap-on air gauges, their diverse applications, and the critical factors to consider when selecting a supplier. From assessing quality and reliability to navigating pricing structures, we will provide actionable insights that can streamline your procurement process. Moreover, we will explore how to effectively vet suppliers to ensure that you are partnering with reputable manufacturers who meet your operational needs.

By empowering you with the essential information and strategies, this guide serves as a valuable resource to enhance your purchasing strategy in the global market. Whether you are looking to optimize your fleet’s performance or ensure compliance with safety standards, understanding the intricacies of snap-on air gauges will position you to make decisions that drive efficiency and profitability in your operations.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Digital Tire Inflator | Digital display, automatic shut-off, backlit screen | Automotive workshops, tire retailers | Vorteile: Easy to read, accurate; Nachteile: Higher initial cost compared to analog. |

| Analog Tire Pressure Gauge | Mechanical dial, no batteries required | Fleet maintenance, agricultural equipment | Vorteile: Durable, no power needed; Nachteile: Less precise than digital versions. |

| Heavy-Duty Air Gauge | Robust construction, high PSI range | Industrial applications, construction | Vorteile: Built to last, handles high pressures; Nachteile: Bulkier and heavier. |

| Compact Air Gauge | Portable design, lightweight | Mobile mechanics, emergency services | Vorteile: Easy to carry, quick to use; Nachteile: Limited features compared to larger models. |

| Bluetooth Tire Pressure Gauge | Syncs with mobile devices, data tracking capabilities | Fleet management, logistics | Vorteile: Provides historical data, convenient; Nachteile: Requires compatible devices. |

The Digital Tire Inflator is characterized by its advanced digital display, which provides precise readings of tire pressure. Its automatic shut-off feature prevents over-inflation, making it particularly suitable for automotive workshops and tire retailers where accuracy is paramount. B2B buyers should consider the initial investment, as it is typically higher than analog models, but the long-term benefits in efficiency and reliability often justify the cost.

The Analog Tire Pressure Gauge operates through a mechanical dial and does not require batteries, making it a reliable choice for fleet maintenance and agricultural applications. Its durability and simplicity are key advantages, especially in rugged environments. However, B2B buyers should note that while it is cost-effective, it may not provide the same level of precision as digital gauges, which could be a consideration for businesses prioritizing accuracy.

Designed for industrial applications, the Heavy-Duty Air Gauge features robust construction and a high PSI range, allowing it to withstand demanding environments such as construction sites. Its durability is a significant selling point for B2B buyers in sectors where equipment is exposed to harsh conditions. However, its bulkier design may be less convenient for mobile use, which is a consideration for businesses with diverse operational needs.

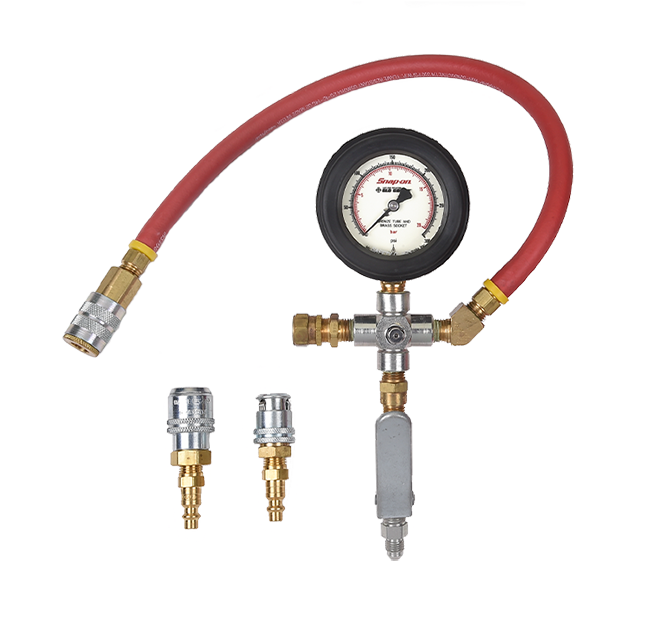

Illustrative image related to snap on air gauge

The Compact Air Gauge is lightweight and portable, making it ideal for mobile mechanics and emergency services. Its design allows for quick and easy use, which is crucial in time-sensitive situations. While it may lack some advanced features found in larger models, its practicality and ease of transport are compelling reasons for B2B buyers who require a reliable tool on the go.

Bluetooth Tire Pressure Gauges offer modern conveniences such as syncing with mobile devices and data tracking capabilities. This is particularly advantageous for fleet management and logistics companies that need to monitor tire pressure over time. While the ability to provide historical data enhances operational efficiency, B2B buyers should ensure compatibility with existing devices, as this could limit functionality.

| Industrie/Sektor | Specific Application of snap on air gauge | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparatur | Tire pressure measurement and adjustment | Enhances vehicle safety and performance, reduces tire wear | Calibration accuracy, durability, ease of use |

| Herstellung | Pneumatic system pressure monitoring | Optimizes machinery efficiency, reduces downtime | Compatibility with existing systems, pressure range |

| Aviation | Aircraft tire pressure checks | Ensures safety and compliance with aviation standards | Lightweight design, precise measurement capabilities |

| Landwirtschaft | Monitoring air pressure in agricultural tools | Increases efficiency of equipment, improves crop yield | Resistance to environmental conditions, portability |

| Bauwesen | Pressure checks for pneumatic tools | Enhances tool performance, ensures safety on site | Robustness, ease of calibration, range of measurements |

In the automotive repair sector, the snap on air gauge is primarily utilized for measuring and adjusting tire pressure. Accurate tire pressure is crucial for vehicle safety, fuel efficiency, and prolonging tire life. By employing this tool, automotive technicians can swiftly identify under-inflation or over-inflation issues, which can lead to hazardous driving conditions. For B2B buyers in regions like Africa and South America, sourcing a reliable air gauge that offers calibration accuracy and durability is essential to maintain service quality and customer satisfaction.

Illustrative image related to snap on air gauge

In manufacturing, the snap on air gauge serves as a vital instrument for monitoring air pressure in pneumatic systems. Maintaining the correct pressure is essential for the optimal functioning of machinery, as it minimizes the risk of equipment failure and production downtime. For international buyers, particularly from Europe, it is important to consider compatibility with existing systems and the pressure range required for specific applications. Investing in high-quality gauges can lead to significant operational efficiencies and cost savings.

The aviation industry employs snap on air gauges for critical tire pressure checks on aircraft. Given the stringent safety regulations in aviation, accurate pressure measurement is non-negotiable. These gauges help ensure compliance with safety standards and enhance overall aircraft performance. For buyers in regions such as the Middle East, where aviation is rapidly expanding, sourcing lightweight and precise measuring tools can contribute to safer operations and better fleet management.

Agricultural operations utilize snap on air gauges to monitor air pressure in various pneumatic tools and equipment, such as seeders and sprayers. Proper air pressure is vital for the efficient functioning of these tools, directly impacting crop yield and operational efficiency. For B2B buyers in the agricultural sector, especially in emerging markets, the ability to source gauges that can withstand harsh environmental conditions while providing accurate measurements is critical for enhancing productivity.

In construction, snap on air gauges are essential for checking the pressure of pneumatic tools, such as nail guns and air compressors. Ensuring the correct air pressure optimizes tool performance and enhances safety on job sites. Buyers in this industry should prioritize sourcing robust gauges that are easy to calibrate and offer a wide range of measurements, as these features contribute to reliable tool operation and worker safety.

Das Problem: B2B buyers often face the challenge of inaccurate tire pressure readings when using air gauges, which can lead to severe operational inefficiencies. In industries like transportation and logistics, where vehicle safety and performance are paramount, even a slight deviation in tire pressure can result in increased fuel consumption, tire wear, and ultimately, costly repairs. A buyer in a fleet management company might find that their Snap-on air gauge consistently provides readings that differ from expected values, leading to confusion and potential safety risks.

Die Lösung: To address this issue, buyers should ensure that they are calibrating their Snap-on air gauges regularly. Snap-on provides guidelines on how to calibrate these tools effectively, which involves checking the gauge against a known standard before use. Additionally, investing in digital gauges that offer features like automatic calibration reminders can enhance accuracy. Buyers should also consider training staff on proper usage techniques, including understanding how environmental factors such as temperature can affect readings. By prioritizing calibration and staff training, businesses can significantly reduce the risk of inaccuracies and improve operational efficiency.

Das Problem: Another common pain point for B2B buyers is the difficulty in integrating Snap-on air gauges with existing equipment, such as compressors or tire inflators. For businesses operating in automotive maintenance or tire service, having tools that seamlessly work together is crucial for optimizing workflow. A buyer in an auto repair shop might find that their Snap-on gauge doesn’t fit well with their current inflators, causing delays and frustration during service.

Die Lösung: To mitigate this issue, buyers should conduct thorough compatibility assessments before purchasing Snap-on air gauges. This involves checking specifications for fittings and adapters to ensure they match the existing equipment. Snap-on offers a range of accessories that can facilitate integration; thus, buyers should explore these options. Additionally, consulting with Snap-on’s customer service or technical support can provide insights into the best configurations for their specific setups. By taking these proactive steps, businesses can ensure that their tools work harmoniously, thus enhancing productivity and service quality.

Illustrative image related to snap on air gauge

Das Problem: A prevalent issue among B2B buyers is the lack of proper user training, which can lead to misuse of Snap-on air gauges. In environments where multiple employees operate these tools, inconsistent usage can result in varying levels of accuracy and reliability. For instance, a maintenance manager might notice discrepancies in tire pressure readings due to different technicians using the gauge without standardized procedures.

Die Lösung: To combat this challenge, companies should implement a structured training program focused on the correct usage of Snap-on air gauges. This program should cover essential topics such as reading the gauge accurately, understanding the importance of pressure settings, and recognizing common errors. Incorporating hands-on training sessions and easy-to-follow reference materials can significantly enhance user competence. Additionally, establishing a system for regular audits of tool usage can help reinforce best practices. By prioritizing training and standardization, businesses can improve the reliability of their tire pressure management processes, leading to better overall performance and safety.

When selecting materials for snap-on air gauges, it’s essential to consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of common materials used in the production of these gauges, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically withstands temperatures up to 150°C and pressures of around 300 psi, making it suitable for air gauge applications.

Illustrative image related to snap on air gauge

Profis: Aluminum is durable and resistant to rust, which is crucial in humid environments often found in Africa and South America. Its lightweight nature reduces shipping costs and makes handling easier.

Nachteile: While aluminum is generally cost-effective, it can be more expensive than plastic options. Additionally, it may not withstand extreme temperatures as well as some other metals, which could limit its use in high-temperature environments.

Auswirkungen auf die Anwendung: Aluminum is compatible with most gases and is particularly effective in automotive applications where weight savings are critical.

Überlegungen für internationale Einkäufer: Buyers from regions like Europe may prefer aluminum due to its compliance with EU regulations on material safety and environmental impact. Understanding local standards such as DIN for material properties is also essential.

Brass, an alloy of copper and zinc, offers excellent corrosion resistance and is particularly effective in applications involving air and gas. It can handle temperatures up to 200°C and pressures exceeding 300 psi.

Illustrative image related to snap on air gauge

Profis: Brass is known for its durability and resistance to corrosion, making it ideal for environments with varying humidity levels. Its aesthetic appeal also adds value in consumer-facing applications.

Nachteile: The primary drawback of brass is its higher cost compared to aluminum and plastic. Additionally, brass can be subject to dezincification, which may affect long-term performance if not properly treated.

Auswirkungen auf die Anwendung: Brass is highly compatible with various gases, making it a preferred choice for air gauges in industrial applications.

Überlegungen für internationale Einkäufer: Buyers in the Middle East may need to consider local regulations regarding the use of copper alloys, as some regions have restrictions due to health concerns. Compliance with ASTM standards is also crucial for quality assurance.

Illustrative image related to snap on air gauge

Plastic materials, such as ABS (Acrylonitrile Butadiene Styrene), are commonly used in air gauges due to their lightweight and cost-effectiveness. They can typically withstand temperatures up to 80°C and pressures around 150 psi.

Profis: Plastic is significantly cheaper than metals and offers excellent resistance to corrosion and chemicals. This makes it suitable for various applications, especially in environments where moisture is a concern.

Nachteile: The main limitation of plastic is its lower durability compared to metals, which can lead to a shorter lifespan in demanding applications. Additionally, plastics may not perform well under extreme temperatures or pressures.

Illustrative image related to snap on air gauge

Auswirkungen auf die Anwendung: Plastic is ideal for low-pressure applications and is often used in consumer-grade air gauges.

Überlegungen für internationale Einkäufer: Buyers should ensure that the plastics used comply with regulations in their regions, such as REACH in Europe, which governs the use of chemicals in manufacturing.

Stainless steel is renowned for its exceptional strength, corrosion resistance, and ability to withstand high temperatures (up to 800°C) and pressures (over 500 psi).

Profis: The durability of stainless steel makes it suitable for high-performance applications, and its resistance to rust ensures longevity even in harsh environments.

Nachteile: The primary downside is the higher cost associated with stainless steel compared to other materials. Additionally, manufacturing processes can be more complex, which may increase lead times.

Auswirkungen auf die Anwendung: Stainless steel is ideal for industrial applications requiring high precision and reliability, such as in aerospace or automotive sectors.

Überlegungen für internationale Einkäufer: Buyers in regions like Germany may prioritize stainless steel due to stringent quality standards, including compliance with DIN specifications. Understanding local sourcing regulations is also vital.

| Material | Typical Use Case for snap on air gauge | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Automotive air gauges | Leicht und korrosionsbeständig | Limited high-temperature performance | Mittel |

| Brass | Industrial air gauges | Excellent corrosion resistance | Higher cost and dezincification risk | Hoch |

| Kunststoff | Consumer-grade air gauges | Kostengünstig und leicht | Lower durability under stress | Niedrig |

| Rostfreier Stahl | High-performance industrial gauges | Exceptional strength and durability | Höhere Kosten und komplexe Herstellung | Hoch |

This guide provides insights into material selection for snap-on air gauges, enabling B2B buyers to make informed decisions that align with their operational needs and regional compliance requirements.

The manufacturing process of Snap-On air gauges involves several critical stages, each designed to ensure precision and reliability. Understanding these stages is essential for B2B buyers looking to source high-quality tools.

Illustrative image related to snap on air gauge

The first stage involves sourcing high-quality materials, typically aluminum and stainless steel, known for their durability and resistance to corrosion. Suppliers must adhere to stringent specifications to ensure that the materials meet industry standards. Once sourced, materials undergo initial processing, which includes cutting and shaping using advanced CNC (Computer Numerical Control) machines. This level of automation helps achieve the exact tolerances required for accurate measurement.

After material preparation, the forming stage employs techniques such as stamping and extrusion. These methods are vital for creating the gauge’s body and internal components. Stamping allows for precise shapes and sizes, while extrusion can create continuous profiles that are essential for the gauge’s internal mechanisms. The use of high-quality dies and molds ensures consistency and quality across production batches.

The assembly process is where all components come together. This stage includes the installation of the internal pressure sensors, display units, and other electronic components. Workers follow detailed assembly instructions to ensure that each air gauge functions correctly. Automation plays a role here, but skilled labor is crucial for quality assurance, particularly in tasks that require precise alignment and calibration.

Finishing processes, such as anodizing and painting, enhance the durability and aesthetic appeal of the air gauges. Anodizing increases corrosion resistance, while painting provides a protective layer and branding opportunities. Finally, each gauge undergoes a thorough cleaning process to remove any contaminants that may have accumulated during manufacturing.

Quality assurance (QA) is a cornerstone of Snap-On’s manufacturing philosophy. B2B buyers must understand the various QA measures in place to ensure product reliability and compliance with international standards.

Snap-On air gauges are produced in compliance with ISO 9001, a globally recognized standard that outlines effective quality management systems. This certification ensures that manufacturing processes are consistently monitored and improved. In addition to ISO standards, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may also apply, depending on the intended market and application.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint involves inspecting raw materials before they enter the production line. It ensures that only materials meeting the required specifications are used.

Prozessbegleitende Qualitätskontrolle (IPQC): During assembly, IPQC monitors the production process to identify defects early. This includes checking alignment, calibration, and functionality of components as they are assembled.

Endgültige Qualitätskontrolle (FQC): Once assembly is complete, FQC involves rigorous testing of the finished product. Each air gauge is calibrated and tested for accuracy under various pressure conditions to ensure reliable performance.

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are several methods to consider:

Conducting supplier audits is one of the most effective ways to assess quality control measures. Buyers should request access to the supplier’s quality management documentation, including ISO certifications and internal audit reports. On-site visits can provide further insights into the manufacturing environment and processes.

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform checks at various stages of production, providing unbiased reports on quality standards and compliance. This is particularly important for buyers in regions with varying quality assurance practices.

Buyers should request detailed documentation that outlines the QC processes, including inspection reports, testing results, and compliance certificates. This information can help verify that the supplier adheres to both international standards and industry-specific requirements.

Illustrative image related to snap on air gauge

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Each region may have different regulatory requirements and market expectations. For example:

Africa: Buyers should be aware of local regulations that may affect the import of tools and equipment. Certifications from recognized bodies can facilitate smoother transactions.

South America: The presence of regional quality standards can impact the choice of suppliers. Understanding these standards can aid in selecting suppliers that align with local regulations.

Middle East: Compliance with GCC (Gulf Cooperation Council) standards is crucial for suppliers targeting this market. Buyers should ensure that suppliers have the necessary certifications.

Europe: European buyers often prioritize CE marking as a sign of compliance with EU safety and environmental standards. Suppliers must be prepared to provide documentation proving compliance.

In conclusion, understanding the manufacturing processes and quality assurance measures for Snap-On air gauges is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can make informed decisions and ensure they source reliable products that meet their specific needs.

To assist international B2B buyers in procuring a Snap-on air gauge, this practical sourcing guide provides a comprehensive checklist. Each step is designed to help you navigate the complexities of sourcing high-quality equipment that meets your specific needs.

Before initiating the procurement process, it’s essential to have a clear understanding of your technical requirements. Consider factors such as the gauge’s pressure range, accuracy, and compatibility with existing equipment. Documenting these specifications will streamline the selection process and ensure you choose a product that meets your operational needs.

Identifying reliable suppliers is critical for ensuring the quality of your purchase. Look for suppliers with a strong reputation in the industry, especially those who specialize in automotive tools and gauges. Utilize online platforms, industry directories, and trade shows to compile a list of potential suppliers for comparison.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their track record in fulfilling orders, customer service responsiveness, and any warranties or guarantees they offer. This due diligence helps mitigate risks associated with procurement.

Illustrative image related to snap on air gauge

Once you’ve narrowed down your list, request samples of the Snap-on air gauges. Testing these samples in real-world applications will provide insights into their performance and reliability. Pay attention to factors such as ease of use, durability, and measurement accuracy during your evaluation.

Ensure that the Snap-on air gauge complies with international standards and certifications relevant to your region. Check for ISO certifications, CE markings, or any other local regulatory requirements. Compliance not only assures quality but also protects your business from potential legal issues.

Engage in discussions with your shortlisted suppliers regarding pricing, payment terms, and delivery schedules. Be prepared to negotiate based on volume purchases or long-term commitments. Clear communication on these aspects can lead to better pricing and favorable terms that benefit your organization.

Once you’ve selected a supplier and agreed on terms, it’s time to finalize the purchase agreement. Ensure that the contract includes all pertinent details such as product specifications, delivery timelines, payment methods, and after-sales support. A well-documented agreement protects both parties and lays the groundwork for a successful business relationship.

By following this step-by-step checklist, you can confidently source a Snap-on air gauge that meets your operational requirements while fostering a reliable partnership with your suppliers.

When sourcing Snap-On air gauges, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materialien: The quality of materials used in manufacturing Snap-On air gauges significantly impacts the overall cost. Higher-grade materials, such as durable plastics and precision metals, enhance performance but also raise costs. Buyers should evaluate the trade-off between cost and the longevity of materials.

Arbeit: Labor costs can vary based on the region of production. In countries with higher wage standards, such as Germany, labor costs may be substantial. Conversely, sourcing from regions with lower labor costs, like parts of South America or Vietnam, may yield savings but could affect quality.

Fertigungsgemeinkosten: This includes costs related to production facilities, utilities, and equipment maintenance. Efficient production processes can help keep overhead low, which is crucial for competitive pricing.

Werkzeugbau: The initial investment in tooling for manufacturing Snap-On air gauges can be significant. Custom tooling for specialized designs or features may lead to higher upfront costs but can result in better precision and quality in the long run.

Qualitätskontrolle (QC): Ensuring high quality is paramount in the automotive industry. QC processes add to the cost but are necessary to prevent defects that could lead to costly recalls or warranty claims.

Logistik: Shipping costs play a critical role in the total cost structure. International logistics can be complex, and factors such as distance, shipping methods, and tariffs can affect pricing.

Marge: Suppliers typically add a profit margin to cover their costs and risks. Understanding the standard margins in the industry can help buyers negotiate better pricing.

Several factors influence the pricing of Snap-On air gauges, which buyers should consider when sourcing:

Volumen/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Higher order volumes often lead to discounts, enabling buyers to lower their per-unit costs.

Spezifikationen und Anpassungen: Custom features or specifications can increase costs. It’s essential for buyers to clearly define their requirements upfront to avoid unexpected expenses.

Materialien und Qualitätszertifikate: Gauges that meet specific quality standards or certifications may have higher costs due to the stringent manufacturing processes required.

Lieferanten-Faktoren: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may charge more but offer better quality assurance and service.

Incoterms: Understanding Incoterms is vital for determining who bears the cost and risk at various stages of shipping and delivery. This knowledge can help buyers negotiate better terms and avoid unexpected costs.

B2B buyers should adopt strategic approaches when negotiating prices for Snap-On air gauges:

Leverage Volume Discounts: If planning to purchase in bulk, use this as a negotiating tool to secure lower prices.

Konzentration auf die Gesamtbetriebskosten (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. A slightly higher upfront cost may be justified by lower long-term expenses.

Forschung Markttrends: Being informed about current market prices and trends can empower buyers during negotiations. Understanding competitor pricing can also provide leverage.

Aufbau von Beziehungen zu Zulieferern: Establishing a good rapport with suppliers may lead to better pricing and terms in the long run. Long-term partnerships often yield mutual benefits.

Achten Sie auf preisliche Nuancen: International buyers should consider currency fluctuations, import tariffs, and regional pricing differences. These factors can significantly impact the final cost.

Prices for Snap-On air gauges can vary widely based on the aforementioned factors and market conditions. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing and favorable terms tailored to their specific needs.

Illustrative image related to snap on air gauge

In the competitive landscape of tire pressure measurement tools, the Snap On Air Gauge stands out for its reliability and precision. However, potential buyers should consider various alternatives that may better suit specific operational needs or budget constraints. Below, we compare the Snap On Air Gauge with two viable alternatives: the Digital Tire Inflator and Manual Tire Pressure Gauge.

| Vergleich Aspekt | Snap On Air Gauge | Digital Tire Inflator | Manual Tire Pressure Gauge |

|---|---|---|---|

| Leistung | High accuracy with digital readout | Quick inflation and deflation; accuracy may vary | Reliable but dependent on user technique |

| Kosten | Premium pricing | Mid-range pricing | Low-cost option |

| Leichte Implementierung | User-friendly with straightforward controls | Simple plug-and-play operation | Requires user skill for proper use |

| Wartung | Low maintenance; battery replacement only | Minimal maintenance needed; check for leaks | Regular calibration may be required |

| Bester Anwendungsfall | Professional settings requiring precision | Quick service in busy environments | Basic personal use or occasional checks |

The Digital Tire Inflator is a robust alternative that offers quick inflation and deflation, making it ideal for high-volume settings like automotive service stations. Its ease of use is a significant advantage, as operators can connect it to the tire valve and achieve desired pressure levels rapidly. However, its accuracy may not match that of the Snap On Air Gauge, particularly in critical applications where precise readings are necessary. Additionally, while it generally falls within a mid-range pricing category, its reliance on electricity or battery power may pose limitations in remote areas.

Manual Tire Pressure Gauges are a classic choice for those seeking a low-cost option. These gauges can be quite accurate, provided users are skilled in their operation. They do not require power, making them suitable for diverse environments, including remote locations. However, the effectiveness of a manual gauge heavily relies on user technique and understanding of the proper measurement process. Regular calibration may also be necessary to ensure accuracy, which could add to the long-term operational costs for businesses that rely on precise tire pressure measurements.

When selecting between the Snap On Air Gauge and its alternatives, B2B buyers should evaluate their specific needs and operational context. For businesses operating in high-demand environments requiring accuracy, the Snap On Air Gauge may be the best fit despite its premium cost. Conversely, for businesses focused on quick turnaround times or those with budget constraints, the Digital Tire Inflator or Manual Tire Pressure Gauge may offer sufficient performance without the higher investment. Ultimately, understanding the operational environment, required precision, and budgetary limitations will guide buyers to the most suitable tire pressure measurement solution.

When selecting a snap-on air gauge, it’s essential to understand several critical specifications that define its performance and reliability. Here are some key technical properties:

Material Klasse

The material composition of an air gauge significantly impacts its durability and accuracy. Common materials include high-grade aluminum or stainless steel, which provide resistance to corrosion and wear. For B2B buyers, choosing gauges made from robust materials ensures longevity, especially in demanding industrial environments, reducing the need for frequent replacements.

Druckbereich

The pressure range indicates the minimum and maximum pressure the gauge can accurately measure. Snap-on air gauges typically offer a range from 0 to 150 PSI or higher. Understanding this range is crucial for businesses that require precise pressure measurements for various applications, such as tire inflation or pneumatic systems, ensuring operational efficiency and safety.

Accuracy and Tolerance

Accuracy is vital for any measurement tool, and snap-on air gauges often boast an accuracy of ±1 PSI. Tolerance refers to the acceptable deviation from the standard measurement. High accuracy and low tolerance are essential for industries where precision is critical, such as automotive and aerospace sectors, where even minor discrepancies can lead to safety hazards or operational failures.

Digital vs. Analog Display

Snap-on air gauges come in both digital and analog formats. Digital gauges provide clear, easy-to-read measurements and often include features like backlighting and automatic shut-off. Analog gauges may be preferred for their simplicity and reliability in harsh environments. The choice between digital and analog can influence user experience and operational efficiency, making it vital for buyers to assess their specific needs.

Calibration Certification

Calibration certification guarantees that the gauge has been tested against recognized standards. Snap-on air gauges often come with calibration certificates, ensuring that they meet industry specifications. For B2B buyers, this certification is crucial for compliance with safety regulations and quality assurance, particularly in sectors where precise measurements are mandated.

Ergonomics and Design

The design and ergonomics of an air gauge affect usability and comfort during operation. Features such as a non-slip grip, lightweight construction, and intuitive controls can enhance user experience, particularly in high-volume environments. B2B buyers should consider how the design impacts daily operations, especially for teams that require frequent use of these tools.

Understanding industry terminology is crucial for effective communication and decision-making in B2B environments. Here are some common terms related to snap-on air gauges:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of snap-on air gauges, knowing whether the product is OEM can assure buyers of its quality and compatibility with existing systems.

MOQ (Mindestbestellmenge)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B transactions, as it affects purchasing decisions and inventory management. Understanding MOQ helps businesses optimize their procurement strategies and avoid excess stock.

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. For snap-on air gauges, submitting an RFQ can lead to competitive pricing and better terms, allowing businesses to make informed purchasing decisions.

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping and delivery. Familiarity with Incoterms helps B2B buyers manage logistics and reduce risks associated with cross-border purchases.

Warranty and Service Agreements

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. Service agreements may include maintenance or repair services. Understanding warranty terms and service options for snap-on air gauges is essential for B2B buyers to ensure long-term reliability and support.

Vorlaufzeit

Lead time is the duration from placing an order to receiving the product. For businesses relying on snap-on air gauges for operational continuity, understanding lead times helps in planning and inventory management, ensuring that they are not left without critical tools.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure compliance with industry standards.

The global market for snap-on air gauges is currently influenced by several key drivers. The increasing demand for precision tools in automotive and industrial applications is a significant factor. As industries evolve, the need for reliable and accurate pressure measurements has surged, especially in regions like Africa and South America, where automotive sectors are rapidly expanding. Additionally, technological advancements in digital measurement tools are enhancing product offerings, making gauges more user-friendly and precise. B2B buyers in Europe and the Middle East are particularly interested in these innovations, as they seek to improve operational efficiency and reduce downtime.

Emerging trends indicate a growing preference for digital tire inflators and gauges, which offer features such as automatic shut-off and real-time pressure readings. This shift towards digital solutions is being driven by the need for accuracy and ease of use. Furthermore, the integration of IoT (Internet of Things) technology is on the rise, allowing for remote monitoring and data collection, which appeals to international buyers looking for more efficient inventory and maintenance management. Understanding these trends is crucial for B2B buyers to make informed sourcing decisions that align with their operational needs.

Sustainability has become a pivotal consideration for B2B buyers in the snap-on air gauge sector. The environmental impact of manufacturing processes and product life cycles is under increasing scrutiny. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as reducing waste, utilizing eco-friendly materials, and adopting energy-efficient manufacturing processes.

Illustrative image related to snap on air gauge

Ethical sourcing is also gaining traction, with a focus on transparency throughout the supply chain. Buyers are encouraged to seek manufacturers who adhere to stringent labor practices and environmental regulations. Certifications like ISO 14001 for environmental management systems and Fair Trade certification can serve as indicators of a supplier’s commitment to sustainability. By choosing suppliers with these credentials, international buyers can not only meet their corporate social responsibility goals but also strengthen their brand reputation in markets that value sustainability.

The evolution of snap-on air gauges can be traced back to the early 20th century when precision measurement tools began to gain prominence in the automotive industry. Initially, these gauges were analog devices, requiring manual readings and calibration. Over the decades, advancements in technology led to the introduction of digital gauges, which significantly improved accuracy and ease of use.

Today, snap-on air gauges are not just tools but integral components of modern automotive service and maintenance. They reflect a blend of innovation and practicality, catering to the needs of a diverse range of industries. For B2B buyers, understanding this evolution is crucial as it highlights the importance of investing in reliable and technologically advanced tools that can enhance productivity and efficiency in their operations.

Illustrative image related to snap on air gauge

How do I solve issues with inaccurate readings on my Snap-on air gauge?

Inaccurate readings can stem from several factors, including improper calibration, dirt or debris on the gauge, or damage to the device. To address this, first ensure the gauge is clean and free from any obstructions. Regular calibration is essential; refer to the manufacturer’s guidelines for calibration procedures. If the problem persists, consider contacting your supplier for further assistance or potential warranty service. Ensuring the gauge is well-maintained will lead to more reliable performance.

What is the best Snap-on air gauge for high-volume tire service?

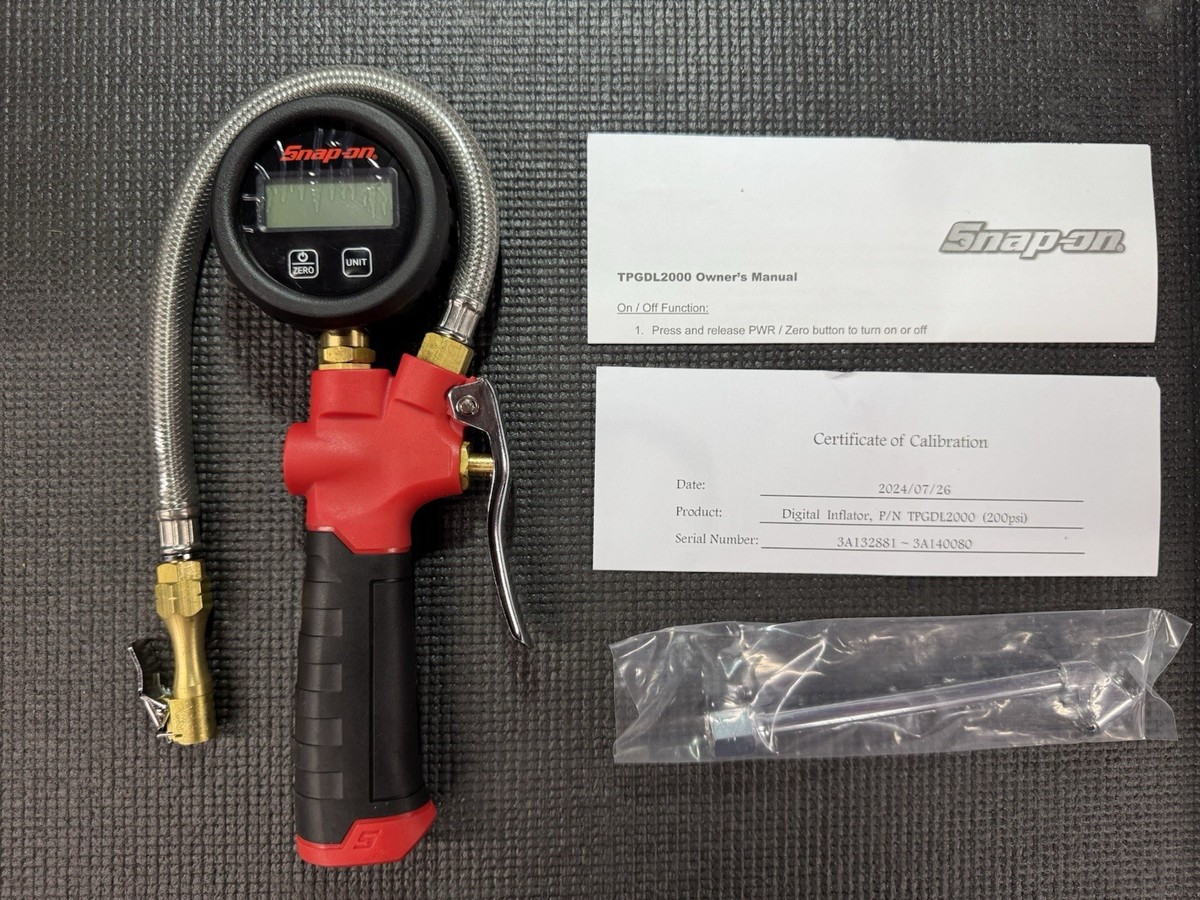

For high-volume tire service, the Snap-on Digital Tire Inflator (model TPGDL2000) is highly recommended. It offers rapid inflation and deflation capabilities, along with a digital display for precise readings. This model is designed for durability and efficiency, making it suitable for busy automotive shops. Additionally, it features programmable settings for different tire pressures, which can streamline the service process significantly. Evaluate your specific needs and volume to determine the best fit.

What should I consider when vetting suppliers for Snap-on air gauges?

When vetting suppliers, focus on their reputation, reliability, and after-sales support. Check for certifications and compliance with international standards to ensure product quality. Request references from other B2B clients to gauge their experience with the supplier. Additionally, evaluate their logistics capabilities, including shipping times and customs handling, especially for international transactions. A supplier with strong customer service and transparent communication is crucial for a smooth procurement process.

Are there customization options available for Snap-on air gauges?

Many suppliers offer customization options for Snap-on air gauges, including branding, specific pressure settings, and packaging solutions. If you require a unique feature or modification, it’s best to discuss your needs directly with the supplier. Be prepared to provide details on the intended application and any regulatory requirements. Customization can enhance brand visibility and better serve your specific market demands.

What is the minimum order quantity (MOQ) for purchasing Snap-on air gauges?

The minimum order quantity (MOQ) for Snap-on air gauges can vary based on the supplier and the specific model. Typically, MOQs range from 10 to 50 units for bulk orders, depending on the distributor’s policies. For smaller businesses, inquire if the supplier can accommodate smaller orders or offer a trial purchase. Understanding the MOQ is essential for budgeting and inventory management, especially for international buyers.

What payment terms are typically offered for Snap-on air gauge purchases?

Payment terms for Snap-on air gauge purchases can vary widely depending on the supplier and the buyer’s location. Common terms include net 30, net 60, or payment in advance. Some suppliers may offer letter of credit options for international buyers, which can provide security for both parties. It’s advisable to clarify payment terms upfront to avoid any misunderstandings and ensure smooth transactions.

How can I ensure quality assurance (QA) for my Snap-on air gauge orders?

To ensure quality assurance, request a detailed QA process from your supplier, including inspection protocols and certifications. Establishing a quality control plan prior to placing your order can help maintain standards. Additionally, consider requesting samples before committing to a larger order to evaluate product performance. Regular communication with your supplier regarding any quality concerns can also help address issues proactively.

What logistics considerations should I be aware of when importing Snap-on air gauges?

When importing Snap-on air gauges, it’s crucial to understand the logistics process, including shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who is familiar with international shipping to help navigate these complexities. Additionally, verify that the supplier can provide necessary documentation, such as invoices and certificates of origin, to facilitate customs clearance. Planning ahead can help minimize delays and ensure timely delivery of your order.

Bereich: shop.snapon.com

Registriert: 1995 (30 Jahre)

Einleitung: Digital Tire Inflator, Model: TPGDL2000, features a digital display for accurate tire pressure readings, designed for ease of use, suitable for both professional and personal use, provides quick inflation and deflation, built with durable materials for longevity.

Bereich: snapon.com

Registriert: 1995 (30 Jahre)

Einleitung: Tire Gauges from Snap-on are designed for accurate measurement and inflation of aircraft tires and struts, which is crucial for aviation safety. The digital gauges provide a pressure measurement range of up to 300 psi with an accuracy of plus or minus 0.25% of full scale. Features include a backlit display for low light conditions, multiple pressure unit displays (PSI, Bar, KPa), and the ability t…

Bereich: ebay.de

Registriert: 1995 (30 Jahre)

Einleitung: Snap-On Tire Gauge available in various models including digital and dial types. Prices range from $16.50 to $249.99. Condition options include new and used. Free shipping and returns are offered on many listings. Popular models include TPGDL2000ORG, TPGDL2000, and TDG2. Items are located in the United States with delivery options within 2-4 days.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Brass Tire pressure gauge and maple box for $96

In the evolving landscape of the automotive industry, the Snap-on air gauge stands out as an essential tool for precision and efficiency. Key takeaways for B2B buyers include the importance of investing in high-quality, reliable equipment that enhances productivity and minimizes errors. The Snap-on air gauge not only offers superior accuracy but also durability, making it a cost-effective choice for businesses focused on long-term performance.

Strategic sourcing plays a critical role in optimizing supply chains, particularly for international buyers in regions like Africa, South America, the Middle East, and Europe. By leveraging partnerships with trusted manufacturers like Snap-on, companies can ensure they acquire tools that meet rigorous industry standards while also benefiting from competitive pricing and support services.

Looking ahead, it is imperative for B2B buyers to stay informed about innovations in automotive tools and technologies. By prioritizing strategic sourcing and selecting partners who prioritize quality, businesses can position themselves for success in a competitive market. Engage with Snap-on to explore how their air gauges can elevate your operational efficiency and drive business growth.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to snap on air gauge

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.