In today’s competitive landscape, sourcing reliable solutions for inflating bike tires presents a significant challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. The importance of well-inflated tires cannot be overstated; they directly impact ride quality, safety, and overall customer satisfaction. This comprehensive guide aims to equip international buyers with the essential knowledge needed to navigate the complexities of tire inflation solutions.

Within this guide, we delve into the various types of pumps available, including track pumps, mini pumps, and CO2 inflators, each tailored for specific applications and user needs. Additionally, we explore the nuances of valve types, optimal tire pressures, and best practices for maintenance. Understanding supplier vetting processes and cost considerations will further empower businesses to make informed purchasing decisions.

By addressing the intricacies of inflating bike tires, this guide serves as a vital resource for B2B buyers, helping them to streamline their operations and enhance their product offerings. Whether you’re a distributor, retailer, or service provider, the insights provided will enable you to optimize your supply chain and meet the diverse needs of your clientele effectively.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Track Pump | Large, stable design; pressure gauge; suitable for home use | Bike shops, rental services, cycling clubs | Vorteile: Quick inflation, accurate pressure readings. Nachteile: Bulky; not portable. |

| Mini Pump | Compact, lightweight; designed for portability | Retailers, distributors, mobile repair services | Vorteile: Easy to carry, versatile for emergencies. Nachteile: Slower inflation, less accurate. |

| CO2-Inflator | Uses compressed CO2 cartridges; rapid inflation | Emergency kits, racing teams, bike tours | Vorteile: Fast inflation, lightweight. Nachteile: Limited use; cartridges may expire. |

| Electric Pump | Automated inflation; often rechargeable or plug-in | Large retailers, bike manufacturers | Vorteile: Effortless operation, consistent pressure. Nachteile: Higher cost, reliance on power. |

| Tubeless Setup | Direct attachment to rim; no inner tube; requires specific valve | High-end bike shops, performance cycling | Vorteile: Reduced puncture risk, improved performance. Nachteile: Complex setup, requires maintenance. |

Track Pump

Track pumps are designed for home use, featuring a large base for stability and a pressure gauge for accurate inflation. They are ideal for bike shops and rental services where efficiency is paramount. B2B buyers should consider the pump’s compatibility with valve types and its durability, as frequent use in high-traffic areas may lead to wear and tear.

Mini Pump

Mini pumps are compact and lightweight, making them perfect for cyclists who need a portable solution. These pumps are commonly used by retailers and mobile repair services. B2B buyers should evaluate the pump’s inflation speed and ease of use, as some models come with a hose attachment that minimizes stress on the valve, enhancing durability.

CO2-Inflator

CO2 inflators utilize compressed gas cartridges for rapid tire inflation, making them a favorite among racing teams and emergency kits. B2B buyers should assess the availability of cartridges and the cost-effectiveness of this solution, as while it offers quick inflation, the cartridges can be a recurring expense and may not be ideal for long-term use.

Electric Pump

Electric pumps automate the inflation process, providing consistent pressure with minimal effort. They are suitable for large retailers and bike manufacturers looking to offer convenience to customers. Buyers should consider the pump’s power source and portability, as these factors can influence the pump’s usability in various settings.

Tubeless Setup

Tubeless setups eliminate the inner tube, attaching directly to the rim and requiring specific valves. This option is increasingly popular in high-end bike shops and among performance cyclists due to its reduced puncture risk. B2B buyers should weigh the complexity of setup and maintenance against the long-term performance benefits, as they may require specialized knowledge and tools for installation.

| Industrie/Sektor | Specific Application of inflate a bike tire | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Logistik und Lieferung | Maintaining delivery bikes’ tyre pressure | Ensures efficient operations and minimizes breakdowns during deliveries | Reliability of pumps, compatibility with various valve types, and ease of use. |

| Bike Rental Services | Regular inflation of rental bikes | Enhances customer experience by providing well-maintained bikes | Volume purchasing of pumps, durability, and maintenance support. |

| Sports and Recreation | Inflate bicycles used in competitive events | Optimizes performance and safety of athletes | Precision in pressure gauges, lightweight portable options, and training on use. |

| Manufacturing and Assembly | Inflating tires on production lines for electric bikes | Streamlines production processes and ensures quality control | Automation compatibility, bulk purchase options, and service agreements. |

| Tourismus und Abenteuer | Pre-ride checks and inflation for guided bike tours | Increases safety and enjoyment for tourists | Robustness of equipment, local service availability, and training for guides. |

In the logistics and delivery sector, maintaining the correct tyre pressure in delivery bikes is crucial for operational efficiency. Regular inflation prevents flat tires, which can lead to delays and increased operational costs. Businesses need reliable pumps that can handle different valve types, ensuring that their fleet remains on the road. For international buyers, particularly in regions like Africa and South America, sourcing durable and easy-to-use inflation equipment is vital, as it minimizes downtime and enhances delivery reliability.

Bike rental services rely on the regular inflation of rental bikes to ensure a positive customer experience. Properly inflated tires enhance safety and ride quality, which is essential for customer satisfaction and repeat business. B2B buyers in this sector should consider bulk purchasing options for pumps and accessories to keep operational costs low. Additionally, they should look for durable equipment that can withstand frequent use, especially in high-demand tourist areas in Europe and the Middle East.

In the sports and recreation industry, especially during competitive events, the inflation of bicycles is critical for optimizing athlete performance and safety. Proper tire pressure can significantly affect speed, control, and comfort during races. Buyers in this sector need precise and portable inflation solutions, such as mini pumps with accurate pressure gauges. International buyers, particularly those in regions with fluctuating climates, should prioritize equipment that can maintain consistent performance under various conditions.

Illustrative image related to inflate a bike tire

In the manufacturing and assembly of electric bikes, inflating tires during production is essential for quality control and efficiency. Automated systems may require specific types of pumps that can integrate seamlessly into existing assembly lines. Bulk purchasing agreements and service contracts are crucial for international B2B buyers, ensuring a steady supply of reliable inflation equipment. Additionally, manufacturers must consider the compatibility of pumps with various tire valves to streamline operations.

For tourism and adventure companies offering guided bike tours, pre-ride checks, including tire inflation, are essential for safety and customer enjoyment. Properly inflated tires ensure a smooth ride over varying terrains, enhancing the overall experience for tourists. Buyers in this sector should focus on robust and portable inflation solutions, as well as local service availability for maintenance. Training for tour guides on proper inflation techniques can also improve service quality and safety for adventure seekers.

Das Problem: In the B2B bicycle retail sector, buyers often encounter challenges when sourcing pumps that are compatible with various valve types, such as Presta and Schrader. This is particularly pertinent in regions like Africa and South America, where bicycle models may vary significantly. Retailers may stock a wide range of bicycles, but if they do not have the right pumps to accommodate the specific valve types of those bikes, it can lead to lost sales and frustrated customers.

Die Lösung: To address this issue, B2B buyers should prioritize sourcing versatile pumps that feature dual compatibility for both Presta and Schrader valves. When selecting pumps, ensure they include an adjustable chuck or multiple fittings to cater to a broader range of bicycle types. Additionally, providing clear labeling and specifications on the pump packaging can help retailers and customers easily identify compatibility. Training staff to educate consumers about valve types and pump compatibility can further enhance customer satisfaction and reduce the likelihood of returns. By stocking a well-rounded selection of pumps, businesses can ensure they meet the diverse needs of their clientele.

Das Problem: Many B2B buyers in the cycling industry face the challenge of inconsistent tire pressure across their inventory, which can lead to suboptimal riding experiences and increased risk of punctures. This is especially problematic for businesses that offer rental services or organize cycling tours, as customers may receive bikes that are not properly inflated, resulting in complaints and a negative reputation.

Illustrative image related to inflate a bike tire

Die Lösung: Implementing a standardized tire pressure check protocol before bikes are rented or sold can drastically improve performance. Buyers should invest in high-quality pressure gauges and ensure that staff are trained to check and adjust tire pressure according to manufacturer specifications. Establishing a routine maintenance schedule can also help ensure that all bikes remain in optimal condition. Additionally, providing educational materials or workshops for customers on the importance of proper tire inflation can enhance their understanding and encourage them to check tire pressures regularly. This proactive approach not only improves customer satisfaction but also extends the lifespan of the bicycles in inventory.

Das Problem: B2B buyers often struggle with the challenge of understanding and communicating the correct tire pressure specifications to their customers. This is particularly critical for businesses that cater to performance cyclists who demand precise tire pressures for different riding conditions. In regions with diverse terrains, such as the Middle East and Europe, the need for tailored pressure guidance can make or break the riding experience.

Die Lösung: To overcome this knowledge gap, businesses should consider developing comprehensive informational resources that detail the optimal tire pressures for various bike types and riding conditions. This could include creating easy-to-understand charts or infographics that can be displayed in-store or shared digitally. Additionally, staff training programs can help ensure that employees are well-versed in tire pressure specifications and can confidently advise customers. Collaborating with local cycling experts or organizations to host workshops can also provide valuable insights and foster community engagement. By equipping both staff and customers with the right information, B2B buyers can enhance their service offerings and build a loyal customer base.

When selecting materials for inflating bike tires, it is essential to consider the properties, advantages, and limitations of various materials. This analysis focuses on common materials used in pumps, valves, and inner tubes, providing insights for international B2B buyers.

Rubber is a fundamental material in the construction of inner tubes and tire surfaces. Its key properties include excellent elasticity, temperature resistance, and the ability to withstand varying pressures. Rubber can typically handle pressures up to 120 psi, making it suitable for most cycling applications.

Vorteile: Rubber is durable and provides a good seal against air leaks. It is also relatively inexpensive, making it a cost-effective choice for manufacturers.

Illustrative image related to inflate a bike tire

Nachteile: However, rubber can degrade over time due to UV exposure and ozone, leading to potential failures. Additionally, its manufacturing process can be complex, requiring careful formulation to achieve the desired performance characteristics.

Auswirkungen auf die Anwendung: Rubber’s compatibility with air makes it ideal for tire inflation. However, buyers should ensure that the rubber used meets international standards for durability and safety, particularly in regions with extreme weather conditions.

Metal components, particularly brass and aluminum, are commonly used in valve construction for bike tires. These materials exhibit high strength and corrosion resistance, essential for maintaining the integrity of the valve under pressure.

Illustrative image related to inflate a bike tire

Vorteile: Metal valves provide a reliable seal and can withstand high temperatures and pressures, enhancing overall safety and performance.

Nachteile: The main drawback is the higher cost compared to plastic alternatives. Additionally, metal can be heavier, which may not appeal to performance-oriented cyclists.

Auswirkungen auf die Anwendung: The choice of metal affects the compatibility of the valve with different tire types. For international buyers, compliance with standards such as ASTM or DIN is crucial to ensure product reliability.

Plastic is often used in the construction of pump bodies and heads due to its lightweight nature and resistance to corrosion. Common types include polypropylene and polycarbonate, which can withstand moderate pressures and temperatures.

Vorteile: The lightweight characteristic of plastic makes it easy to transport, and its resistance to corrosion enhances longevity.

Nachteile: On the downside, plastic may not withstand high pressures as effectively as metal, leading to potential failures in high-performance applications. Moreover, the manufacturing process can lead to variability in quality.

Auswirkungen auf die Anwendung: For B2B buyers, selecting high-quality plastic that meets international standards is essential, especially in regions with varying environmental conditions.

Composite materials, which combine rubber with other substances like textiles or polymers, are increasingly used in advanced tire designs. These materials can enhance performance characteristics, such as puncture resistance and flexibility.

Vorteile: Composites can significantly improve durability and performance, making them suitable for high-end bicycles.

Nachteile: However, they are typically more expensive and may require specialized manufacturing techniques, which can complicate production.

Auswirkungen auf die Anwendung: Buyers should consider the specific performance requirements of their target markets, as the benefits of composites may justify their cost in high-performance segments.

| Material | Typical Use Case for inflate a bike tire | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Inner tubes and tire surfaces | Excellent elasticity and air retention | Degrades over time due to UV exposure | Niedrig |

| Metall | Valves (brass, aluminum) | Hohe Festigkeit und Korrosionsbeständigkeit | Higher cost and potential weight issues | Med |

| Kunststoff | Pump bodies and heads | Leicht und korrosionsbeständig | Limited pressure handling capabilities | Niedrig |

| Komposit | Advanced tire designs | Enhanced durability and performance | Höhere Kosten und komplexe Herstellung | Hoch |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their product offerings in the bike tire inflation market. Understanding the properties, advantages, and limitations of these materials will help in making informed purchasing decisions tailored to specific regional requirements and standards.

The manufacturing process for equipment used to inflate bike tires involves several crucial stages: material preparation, forming, assembly, and finishing. Each stage plays a pivotal role in ensuring that the final product meets the necessary performance and safety standards.

The primary materials involved in the production of bike tire inflation equipment include rubber, metal, and plastic. The rubber is typically sourced from natural or synthetic sources and is essential for creating durable and flexible components, such as hoses and seals. Metals like aluminum or steel are commonly used for the pump body and internal mechanisms due to their strength and resistance to wear. Plastics are often utilized for pump handles and other non-load-bearing components, offering lightweight and cost-effective solutions.

Before manufacturing begins, these materials undergo a rigorous selection process to ensure they meet specific quality criteria, including tensile strength, elasticity, and resistance to environmental factors like moisture and UV exposure.

Illustrative image related to inflate a bike tire

The forming process involves shaping the prepared materials into their desired forms. This may include molding rubber components, machining metal parts, and extruding plastic elements. Advanced techniques such as injection molding for plastic parts and die-casting for metal components are commonly employed to achieve precise dimensions and high-quality finishes.

Following the forming stage, assembly takes place. This process includes the integration of various components, such as the pump head, valve systems, and pressure gauges. Automated assembly lines are often used to enhance efficiency, although manual assembly may be employed for more complex or delicate components.

Finishing processes are critical for enhancing the aesthetic and functional properties of the inflation equipment. Techniques such as surface treatment, powder coating, and anodizing are often applied to metal parts to improve corrosion resistance and durability. Rubber components may be treated with additives to enhance their lifespan and performance.

Quality checks during the finishing stage ensure that the equipment meets specific design and performance specifications. This includes visual inspections for surface defects and functional tests to confirm that all components work harmoniously.

Illustrative image related to inflate a bike tire

Quality assurance is a critical component in the manufacturing of bike tire inflation equipment. International standards like ISO 9001 are widely recognized, focusing on quality management systems and ensuring that manufacturers consistently meet customer and regulatory requirements. Compliance with these standards is essential for B2B buyers who seek reliable suppliers.

In addition to general ISO certifications, industry-specific standards may apply. For example, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. For manufacturers targeting markets in South America, compliance with local regulations and certifications, such as INMETRO in Brazil, may also be necessary.

Quality control (QC) is integrated throughout the manufacturing process, encompassing several checkpoints:

Eingehende Qualitätskontrolle (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide documentation verifying compliance with quality standards, including material certifications.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, continuous monitoring is conducted to ensure that production parameters remain within specified limits. This includes regular checks on machinery calibration and component dimensions.

Endgültige Qualitätskontrolle (FQC): Before products are shipped, a comprehensive assessment is performed. This includes functional testing of the inflation equipment, pressure tests, and visual inspections to identify any defects.

Various testing methods are utilized to verify the quality and functionality of bike tire inflation equipment. Common methods include:

B2B buyers can take several steps to ensure that their suppliers adhere to high-quality standards:

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of regional regulations and standards that may influence quality assurance practices. For instance, understanding local certification requirements is essential for avoiding potential compliance issues.

Moreover, cultural differences in business practices can affect communication and expectations regarding quality. Establishing clear agreements and maintaining open lines of communication can help mitigate misunderstandings and ensure that both parties are aligned on quality standards.

The manufacturing processes and quality assurance measures for bike tire inflation equipment are critical for ensuring safety and performance. By understanding the stages of manufacturing, international standards, and quality control checkpoints, B2B buyers can make informed decisions when sourcing equipment. Engaging in thorough supplier evaluations and maintaining awareness of regional compliance requirements will further enhance the reliability of their procurement processes.

This guide serves as a comprehensive checklist for B2B buyers looking to procure the necessary tools and equipment for inflating bike tires effectively. Understanding the various components involved in the inflation process is essential for ensuring quality and performance in cycling products.

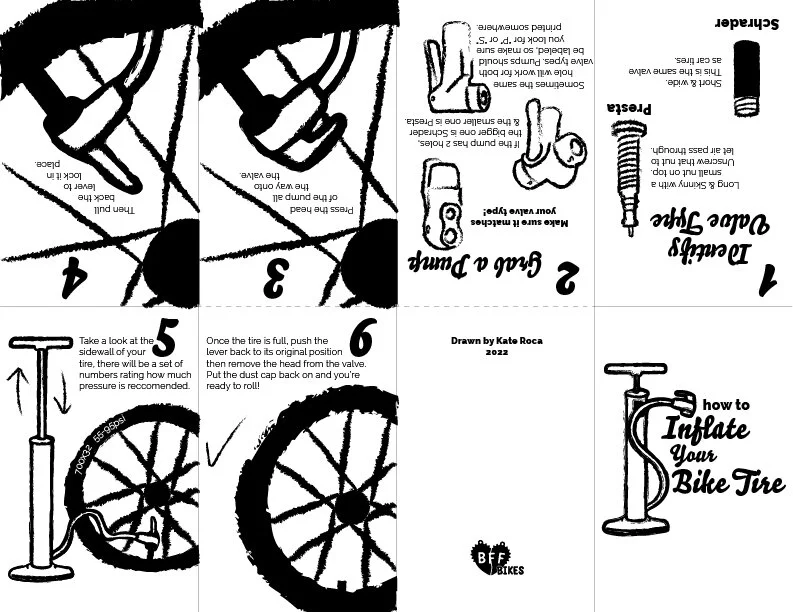

Understanding the types of valves—Schrader, Presta, and Dunlop/Woods—is crucial for selecting compatible pumps and accessories. Ensure that your suppliers can provide pumps that cater to both Schrader and Presta valves, as this will maximize your customer base. Additionally, consider sourcing adaptors for less common valve types to meet diverse market needs.

Select the right type of pump based on your business model and customer requirements. Track pumps are ideal for retail settings or workshops due to their efficiency, while mini-pumps are essential for portable solutions. Evaluate the design and durability of the pumps, ensuring they can withstand regular use without compromising performance.

Understanding the appropriate tire pressure for different bike types is essential for customer satisfaction. Provide clear guidelines on the ideal pressure range for various bicycles, as this will help users optimize their riding experience. Suppliers should be able to offer products that facilitate easy adjustments to tire pressure.

Before engaging with potential suppliers, ensure they hold relevant certifications that guarantee product quality and safety. Certifications such as ISO or CE can provide assurance that the products meet international standards. This step is vital in maintaining trust and reliability in your supply chain.

Evaluate the supplier’s logistics capabilities to ensure timely delivery and availability of products. Consider their ability to handle varying order sizes and their shipping policies, especially if you’re operating in regions with specific logistical challenges. A reliable supplier can significantly impact your business’s operational efficiency.

Illustrative image related to inflate a bike tire

Before finalizing any agreements, request samples of pumps and accessories to assess their quality firsthand. This step allows you to evaluate the design, functionality, and overall user experience. Testing products also gives you valuable insights into how they will perform in real-world conditions.

Once you have evaluated potential suppliers and products, engage in negotiations to secure favorable terms and pricing. Consider factors such as bulk discounts, payment terms, and warranty options. Establishing a mutually beneficial agreement can enhance your profitability and foster a long-term partnership.

By following this checklist, B2B buyers can make informed decisions when sourcing tools and equipment for inflating bike tires, ultimately enhancing their product offerings and customer satisfaction.

When sourcing bike tire inflation solutions, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Materialien: The quality and type of materials used for pumps, valves, and hoses significantly influence costs. For example, high-quality rubber and durable plastics may raise material costs but enhance performance and longevity.

Arbeit: Labor costs vary by region and can be influenced by local wage standards. Countries with lower labor costs may offer more competitive pricing, but it’s essential to assess the skill level of the workforce, as this affects product quality.

Fertigungsgemeinkosten: This encompasses utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, making it vital for buyers to evaluate suppliers’ operational efficiencies.

Werkzeugbau: Initial setup costs for specialized tools or molds can be substantial, particularly for customized pumps or valves. Buyers should consider these costs in relation to their specific requirements.

Qualitätskontrolle (QC): Implementing rigorous QC processes ensures product reliability. While this adds to costs, it ultimately protects buyers from expenses related to defects and returns.

Logistik: Shipping, handling, and storage costs fluctuate based on the supplier’s location and the buyer’s destination. Understanding Incoterms is crucial for clarifying responsibilities for these costs.

Marge: Suppliers will add a margin to their cost base, which can vary significantly based on market competition and perceived value. Negotiating this margin is often key to achieving a favorable price.

Several factors can influence the pricing of bike tire inflation solutions:

Volumen und Mindestbestellmenge (MOQ): Bulk purchases typically allow buyers to negotiate lower prices. Suppliers often have MOQs that can affect pricing; thus, understanding these thresholds can lead to better deals.

Spezifikationen und Anpassungen: Customized products may incur additional costs due to unique tooling or materials. Buyers should weigh the benefits of customization against the potential for increased expenses.

Materialien: The choice between standard and premium materials can lead to significant price differences. Buyers should assess their needs to determine the best material balance for cost and performance.

Qualität und Zertifizierungen: Products that meet international quality standards or certifications may command higher prices. However, these certifications can also be vital for market access, especially in regulated regions.

Lieferanten-Faktoren: A supplier’s reputation, reliability, and service can impact pricing. Established suppliers might charge more but can offer better quality assurance and customer service.

Incoterms: Understanding Incoterms can help buyers manage logistics costs and responsibilities more effectively, ensuring that they are not caught off-guard by unexpected charges.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

Illustrative image related to inflate a bike tire

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and competitor offerings. This knowledge equips buyers with leverage during negotiations.

Gesamtbetriebskosten (TCO): Consider the TCO, which includes purchase price, maintenance, and operational costs. A higher initial investment in quality products may yield lower long-term costs.

Be Flexible with Specifications: If customization is not essential, opting for standard products can lead to lower prices. Suppliers often have existing inventory that can be sold at a discount.

Beziehungen aufbauen: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Loyalty often translates into favorable conditions.

Understand Cultural Nuances: Different regions may have unique negotiation styles. Understanding these cultural nuances can enhance communication and lead to successful outcomes.

Prices in the bike tire inflation market are subject to fluctuations based on market demand, material costs, and geopolitical factors. It is advisable for buyers to obtain quotes from multiple suppliers and factor in all costs when making purchasing decisions. Always verify current prices and terms before proceeding with any agreements.

When it comes to maintaining optimal performance in cycling, keeping bike tires properly inflated is crucial. While traditional methods of inflating tires using pumps are widely recognized, there are alternative solutions available that can meet the needs of B2B buyers. In this section, we will compare the conventional method of inflating bike tires with two other viable alternatives: CO2 inflators and electric tire pumps. This analysis will help businesses make informed decisions on the best solution for their specific requirements.

| Vergleich Aspekt | Inflate A Bike Tire | CO2-Inflator | Electric Tire Pump |

|---|---|---|---|

| Leistung | Reliable and efficient for regular use; requires physical effort | Quick inflation, but limited to single-use cartridges | High efficiency; can inflate multiple tires without manual effort |

| Kosten | Varies (manual pumps $20-$100) | Low cost per cartridge; initial purchase around $10-$50 | Higher initial investment ($50-$150), but may save costs over time |

| Leichte Implementierung | Requires physical effort and knowledge of valve types | Simple to use; requires no setup, just attach and inflate | Plug-and-play design; easy to use, often with automatic shut-off |

| Wartung | Minimal; occasional checks needed for wear | Low; cartridges are disposable | Moderate; requires battery maintenance or charging |

| Bester Anwendungsfall | Ideal for regular cyclists needing consistent tire pressure | Best for emergency situations and on-the-go repairs | Suitable for frequent riders and businesses managing multiple bikes |

CO2 inflators offer a rapid solution for inflating bike tires, making them particularly useful for cyclists who may experience a flat tire while on the road. They are compact and lightweight, making them easy to carry in a jersey pocket or attached to the bike frame. However, the main drawback is that they rely on disposable cartridges, which can become costly over time if used frequently. Additionally, CO2 can leak from the tire more quickly than air, which means it’s not a long-term solution for maintaining tire pressure.

Electric tire pumps represent a modern solution to inflating bike tires with minimal physical effort. They are particularly advantageous for users who may have difficulty using manual pumps due to physical limitations. These pumps can quickly inflate multiple tires and often come with features like automatic shut-off and built-in pressure gauges for accurate inflation. However, the initial investment is higher than manual pumps or CO2 inflators, and they require charging or battery maintenance, which may be a consideration for businesses operating in remote areas without consistent power sources.

Illustrative image related to inflate a bike tire

Selecting the most appropriate tire inflation solution depends on several factors, including the frequency of use, the number of bikes to maintain, and budget constraints. For businesses in regions with limited access to repair shops or inconsistent power supply, a combination of methods may be the most effective strategy. Understanding the pros and cons of each alternative will empower B2B buyers to make informed decisions that align with their operational needs and enhance the cycling experience for their customers.

When considering the inflation of bike tires in a B2B context, understanding the essential technical properties is crucial. Here are several critical specifications to keep in mind:

Material Klasse

The inner tube of a bike tire is typically made from rubber or latex. The material grade affects durability, puncture resistance, and elasticity. For B2B buyers, selecting high-grade materials ensures a longer product lifespan, reducing the frequency of replacements and enhancing customer satisfaction.

Pressure Tolerance

Each tire has a specified pressure range, usually measured in PSI (pounds per square inch). Understanding the correct pressure tolerance is vital to prevent blowouts or under-inflation, which can lead to poor performance and increased wear. B2B buyers should prioritize products that meet or exceed manufacturer specifications to ensure safety and reliability.

Valve Type Compatibility

The compatibility of the pump with valve types (Schrader, Presta, or Dunlop) is an essential consideration. Different markets may favor specific valve types based on regional preferences. For international buyers, ensuring that pumps can accommodate a range of valve types can facilitate broader market access and customer satisfaction.

Size Specifications

The dimensions of the tire, including width and diameter, directly impact the inflation process. Tires come in various sizes, and it’s critical to match the pump and inflation system to these specifications. Buyers should ensure that their product offerings can cater to the most common sizes in their target markets to maximize sales potential.

Pressure Gauge Accuracy

A built-in pressure gauge provides real-time feedback on tire pressure during inflation. Accurate gauges help prevent over-inflation or under-inflation, both of which can negatively impact performance and safety. B2B buyers should look for pumps with reliable gauge technology to enhance user experience and maintain brand reputation.

Langlebigkeit und Design

The design of the pump (manual, electric, or CO2 inflator) influences durability and ease of use. Pumps designed for frequent use should be robust and user-friendly. For B2B suppliers, offering a variety of pump designs can cater to different customer needs, from casual riders to professional cyclists.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company. In the context of bike tires and pumps, OEM partnerships can help businesses secure high-quality components tailored to their needs.

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to assess inventory needs and manage cash flow. This term is particularly relevant in international trade, where bulk purchasing may lead to cost savings.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process helps businesses compare prices and terms from different vendors, facilitating informed purchasing decisions.

Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like delivery, risk, and insurance. Familiarity with these terms is vital for B2B buyers to understand shipping costs and liabilities.

SKU (Lagerhaltende Einheit)

An SKU is a unique identifier for each distinct product and service that can be purchased. For businesses, SKUs help manage inventory and streamline order processing, ensuring that the right products are available when needed.

Vorlaufzeit

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management and customer satisfaction, particularly in markets with high demand or limited supply chains.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that they select the right products for their markets and enhance operational efficiency.

The global bike tire inflation market is witnessing significant growth, driven by the increasing popularity of cycling as a sustainable mode of transportation and recreational activity. Urbanization and a push for eco-friendly commuting options are propelling demand, particularly in regions like Africa and South America, where cycling infrastructure is expanding. In Europe and the Middle East, the trend is supported by government initiatives promoting cycling to reduce carbon emissions.

Emerging B2B technologies such as smart tire pressure monitoring systems (TPMS) and automated inflation devices are revolutionizing the market. These innovations not only enhance user experience but also reduce the risk of tire-related accidents, making them attractive to B2B buyers. Additionally, the rise of e-commerce platforms has facilitated easier sourcing of tire inflation products, allowing international buyers to access a broader range of suppliers and competitive pricing.

Market dynamics are also influenced by fluctuating raw material costs, particularly rubber and synthetic compounds, which can affect pricing strategies. Buyers must remain vigilant about market shifts and consider establishing long-term supplier relationships to mitigate risks associated with supply chain disruptions.

Sustainability is becoming a crucial consideration for B2B buyers in the inflate a bike tire sector. The environmental impact of tire production and disposal is significant, leading to increased scrutiny on supply chains. Ethical sourcing practices, which prioritize environmental stewardship and social responsibility, are gaining traction. This shift is particularly important for buyers from regions like Africa and South America, where sustainability initiatives can align with local development goals.

The use of eco-friendly materials, such as biodegradable rubber and recycled plastics, is emerging as a key trend. Buyers are increasingly seeking suppliers that offer green certifications, such as ISO 14001 for environmental management, to ensure compliance with sustainability standards. Investing in products that meet these criteria not only enhances brand reputation but also attracts environmentally conscious consumers.

Moreover, adopting sustainable practices can lead to cost savings over time. For example, efficient manufacturing processes that minimize waste can lower production costs, making it an attractive proposition for international buyers. Establishing partnerships with suppliers committed to sustainability can enhance supply chain resilience and foster innovation in product development.

The evolution of bike tire inflation technology has significantly influenced the cycling experience. Initially, bicycles were equipped with solid rubber tires, which provided a harsh ride. The introduction of pneumatic tires in the late 19th century revolutionized cycling, offering better comfort and traction due to the air-filled inner tubes.

As cycling gained popularity, so did the need for effective inflation solutions. The development of manual pumps, such as floor pumps and mini-pumps, made tire inflation accessible to everyday cyclists. The advent of CO2 inflators further enhanced the convenience of maintaining tire pressure during rides, particularly for competitive cyclists.

In recent years, technological advancements have ushered in smart solutions, such as digital pressure gauges and automated inflation systems. These innovations not only simplify the inflation process but also enhance safety and performance, catering to a growing market of tech-savvy cyclists. As the industry continues to evolve, B2B buyers must stay informed about these advancements to leverage new opportunities in the bike tire inflation market.

How do I solve compatibility issues with bike tire pumps?

To address compatibility issues, first identify the type of valve your bikes utilize—typically either Schrader or Presta. Ensure that the pump you select can accommodate both types, as many modern pumps are designed for versatility. If a pump is not compatible, consider purchasing an adapter that can easily thread onto the pump head. This adaptability is crucial for international buyers who may encounter various bike models and valve types in different markets.

What is the best type of pump for inflating bike tires in diverse environments?

The best type of pump depends on your specific needs. A track pump is ideal for high-volume inflation at a fixed location, while a mini-pump is essential for on-the-go repairs. If you frequently encounter punctures, consider a CO2 inflator for quick fixes. For international buyers, ensure that the pump’s valve compatibility aligns with local bike standards to avoid operational issues in different regions.

How can I verify the quality of bike tire pumps before purchasing?

To verify the quality of bike tire pumps, conduct thorough supplier vetting by checking certifications and customer reviews. Request samples to assess the durability and functionality of the pump. Additionally, inquire about the materials used in construction, as high-quality pumps typically feature robust materials that ensure longevity. Engaging with suppliers who offer warranties can also provide peace of mind regarding product quality.

What minimum order quantities (MOQ) should I expect when sourcing bike tire pumps?

Minimum order quantities (MOQ) can vary significantly between suppliers, often ranging from 100 to 1,000 units. It’s advisable to communicate your specific needs and negotiate terms based on your market demand. Some suppliers may offer flexible MOQs for new buyers or bulk orders, particularly if you are a startup or entering a new market. Understanding the MOQ helps in budgeting and inventory management for your business.

What payment terms are common in international B2B transactions for bike accessories?

Common payment terms in international B2B transactions include advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit (usually 30-50%) upfront, with the balance paid before shipping. It’s essential to establish clear payment terms during negotiations to avoid misunderstandings. Additionally, consider using secure payment platforms that offer buyer protection to mitigate financial risks.

How do I ensure quality assurance (QA) for bike tire pumps sourced internationally?

To ensure quality assurance for bike tire pumps, implement a comprehensive QA process that includes supplier audits, product inspections, and adherence to international standards. Consider working with third-party inspection services to verify product quality before shipment. Additionally, ask suppliers for quality certifications, such as ISO, to guarantee that their products meet industry standards. Establishing clear quality criteria in your purchase agreement can also help maintain product integrity.

What logistical considerations should I keep in mind when importing bike tire pumps?

When importing bike tire pumps, consider factors such as shipping methods, customs regulations, and lead times. Choose reliable logistics partners who are experienced in handling international shipments to ensure timely delivery. Be aware of potential tariffs and duties that may apply in your target market, as these can affect overall costs. Additionally, plan for storage and distribution upon arrival to streamline your supply chain operations.

How often should I restock bike tire pumps to meet demand in my market?

Restocking frequency for bike tire pumps should be based on market demand, seasonal trends, and sales forecasts. Analyze historical sales data to identify peak periods and adjust inventory levels accordingly. Implementing a just-in-time inventory system can help minimize excess stock while ensuring that you meet customer needs. Regular communication with suppliers about lead times can also aid in timely restocking and maintaining optimal inventory levels.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Presta valve, bike pump, adapter for Presta valve, air, sealant, inner tube.

Bereich: bicycles.stackexchange.com

Registriert: 2009 (16 Jahre)

Einleitung: The tire has a Schrader Valve. The user mentions using an old pump. The discussion includes methods for inflating a completely flat tire, checking for damage in the tube, and ensuring the valve is not stuck.

Bereich: schwinnbikes.com

Registriert: 2003 (22 Jahre)

Einleitung: The guide provides tips for properly pumping bicycle tires, emphasizing three basic steps: 1) Locate the recommended inflation pressure (PSI) on the tire, 2) Identify the valve type (Presta or Schrader), and 3) Use a suitable pump for inflation. It mentions that different bike tires have varying PSI requirements and warns against riding with incorrect tire pressure. It also highlights the importan…

Bereich: fahrrad.de

Registriert: 1999 (26 Jahre)

Einleitung: 1. **Tire Pressure Ranges:**

– Road Tires: 65 to 95 psi

– Mountain Bike Tires: 15 to 25 psi

– Gravel Tires: 25 to 40 psi

2. **Recommended Tools:**

– Zipp Tire Pressure Calculator

– Silca Tire Pressure Calculator

3. **Pump Recommendations:**

– Lezyne Pressure Over Drive: $160

– Specialized Air Tool Pro: $130 (now $97)

– Silca Gravelero Mini Pump: $75

…

In the competitive landscape of the cycling industry, effective strategic sourcing is essential for ensuring the availability of quality bike tire inflation solutions. By understanding the various valve types and pump mechanisms, international B2B buyers can make informed purchasing decisions that enhance customer satisfaction and operational efficiency. Sourcing high-quality pumps that accommodate both Presta and Schrader valves, for instance, can significantly reduce friction in supply chains and improve product accessibility.

Illustrative image related to inflate a bike tire

Moreover, establishing relationships with reliable suppliers can streamline inventory management and ensure timely delivery of essential products. This is particularly crucial for markets in Africa, South America, the Middle East, and Europe, where diverse consumer preferences and varying road conditions necessitate tailored solutions.

As we move forward, the emphasis should be on leveraging technology and data analytics to optimize sourcing strategies. By investing in innovative pumping solutions and fostering partnerships with manufacturers who prioritize quality and sustainability, businesses can position themselves competitively in the evolving marketplace. Embrace this opportunity to enhance your sourcing strategy today and meet the growing demand for efficient bike tire inflation solutions across diverse global markets.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.