In an increasingly competitive global market, sourcing the right solutions for tire inflation presents a significant challenge for B2B buyers across various sectors. Whether you are managing a fleet in Africa, overseeing logistics in South America, or running a retail operation in Europe, ensuring optimal tire performance is crucial for operational efficiency and safety. This guide delves into the intricacies of the tire inflation market, offering insights into various types of inflating equipment, applications tailored to different vehicle types, and best practices for supplier vetting.

Through this comprehensive resource, international buyers will gain a deeper understanding of cost considerations, potential suppliers, and the latest technological advancements in tire inflation. We aim to empower businesses from diverse regions, including Brazil and Vietnam, by equipping them with the knowledge needed to make informed purchasing decisions. By addressing key challenges such as maintaining tire integrity, optimizing fuel efficiency, and enhancing safety, this guide serves as a vital tool for businesses looking to navigate the complexities of tire inflation effectively. With informed choices, organizations can not only improve their bottom line but also contribute to sustainable practices in their operations.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Air Inflation | Uses compressed air; widely available and cost-effective. | Automotive repair shops, fleet services. | Vorteile: Low cost, easy access. Nachteile: Higher rate of air loss over time. |

| Nitrogen Inflation | Uses nitrogen gas; reduces air loss and improves tire longevity. | High-performance vehicles, aviation. | Vorteile: Maintains pressure longer, better fuel efficiency. Nachteile: Higher initial cost, limited availability. |

| Portable Tire Inflators | Compact devices for on-the-go inflation; often battery-operated. | Individual consumers, roadside assistance. | Vorteile: Convenient, easy to use. Nachteile: Möglicherweise fehlt es an Leistung für größere Reifen. |

| Electric Tire Pumps | Electric-powered devices that quickly inflate tires. | Fleet operators, logistics companies. | Vorteile: Fast inflation, consistent pressure. Nachteile: Requires power source, may be bulkier. |

| Manual Hand Pumps | Hand-operated pumps; typically used for bicycles and small vehicles. | Small businesses, bike shops. | Vorteile: No power needed, lightweight. Nachteile: Arbeitsintensiv, langsamere Inflation. |

Standard air inflation is the most common method for inflating tires, utilizing compressed air available at most service stations. This method is cost-effective and widely accessible, making it suitable for automotive repair shops and fleet services. Businesses can easily maintain tire pressure, but they should be aware that tires inflated with air tend to lose pressure more quickly than those inflated with nitrogen. It is essential for B2B buyers to ensure regular checks and maintenance to avoid safety hazards and increased operational costs.

Nitrogen inflation involves filling tires with nitrogen gas, which has larger molecules than air, leading to reduced air loss and prolonged tire life. This method is particularly advantageous for high-performance vehicles and aviation, where tire reliability is crucial. Although the initial cost is higher, the long-term benefits, including improved fuel efficiency and reduced downtime due to tire failure, make it a worthwhile investment for businesses. B2B buyers should consider the availability of nitrogen inflation services in their region when making purchasing decisions.

Portable tire inflators are compact devices that allow users to inflate tires anywhere, making them ideal for individual consumers and roadside assistance services. These inflators are typically battery-operated and provide convenience for quick tire inflation. While they are easy to use, buyers should consider their limitations in terms of power and inflation speed for larger tires. For businesses that require mobility and quick responses, investing in portable inflators can enhance service efficiency.

Electric tire pumps are designed for quick and efficient tire inflation, making them particularly beneficial for fleet operators and logistics companies. These devices provide consistent pressure and faster inflation times compared to manual methods, improving operational efficiency. However, they require a power source, which can be a drawback in certain situations. B2B buyers in logistics and transportation should evaluate their operational needs to determine if the benefits of electric tire pumps align with their requirements.

Manual hand pumps are traditional devices used primarily for inflating bicycle tires and small vehicles. While they require physical effort and are slower than other methods, they are lightweight and do not depend on a power source. This makes them suitable for small businesses, such as bike shops or outdoor retailers. B2B buyers should assess the demand for manual inflation methods in their market and consider hand pumps as a cost-effective solution for specific applications.

| Industrie/Sektor | Specific Application of Inflate Tire | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | Regular tire maintenance for fleet vehicles | Enhances fuel efficiency, extends tire lifespan, and improves safety | Reliable tire inflation equipment and services; local regulations |

| Landwirtschaft | Inflation of agricultural machinery tires | Increases equipment reliability and reduces downtime | Access to specialized inflation equipment for large tires |

| Logistics and Transportation | Tire pressure management for delivery trucks | Reduces fuel costs and enhances vehicle safety | Calibration of inflation tools; availability of nitrogen options |

| Bauwesen | Inflation of heavy machinery tires | Ensures optimal performance and safety on job sites | Durable inflation systems; compliance with safety standards |

| Public Transportation | Regular tire checks for buses and coaches | Improves passenger safety and operational efficiency | Sourcing from certified tire service providers; maintenance contracts |

In the automotive industry, particularly for fleet management, regular tire inflation is crucial. Properly inflated tires enhance fuel efficiency, which is vital for cost control in transportation. Underinflated tires can lead to increased fuel consumption and reduced lifespan, resulting in higher operational costs. International B2B buyers should focus on sourcing reliable tire inflation equipment and services that comply with local regulations to ensure safety and efficiency across their fleets.

In agriculture, the inflation of machinery tires is essential for maintaining equipment reliability. Proper tire pressure ensures that tractors and other agricultural vehicles operate efficiently, minimizing downtime during critical planting and harvesting seasons. Buyers in this sector should consider specialized inflation equipment capable of handling larger tires and rugged conditions, ensuring that their machinery remains operational under various agricultural environments.

For logistics and transportation companies, effective tire pressure management is key to reducing fuel costs and enhancing vehicle safety. Delivery trucks often operate under varying loads, making it imperative to maintain optimal tire pressure for performance. Buyers should prioritize sourcing calibrated inflation tools and consider nitrogen inflation options, as these can significantly reduce air loss and extend tire life, ultimately leading to lower operational costs.

In the construction industry, the inflation of heavy machinery tires is crucial for optimal performance and safety on job sites. Properly inflated tires help prevent accidents and equipment failures, which can result in costly delays. B2B buyers should focus on acquiring durable inflation systems that comply with safety standards, ensuring that their machinery is well-maintained and ready for demanding construction tasks.

Regular tire checks and inflation for buses and coaches are vital for improving passenger safety and operational efficiency. Well-maintained tires contribute to better road handling and braking distances, which are critical in public transport. Buyers in this sector should source from certified tire service providers and consider maintenance contracts to ensure ongoing compliance with safety regulations and operational standards.

Das Problem: Many B2B buyers managing vehicle fleets face the challenge of underinflated tires, which can lead to increased operational costs. Underinflation not only reduces fuel efficiency but also accelerates tire wear, leading to more frequent replacements. This is particularly critical in regions with high fuel prices and limited tire availability, as it can significantly impact the bottom line. Fleet managers may struggle with keeping track of tire pressures, especially when vehicles are used extensively across diverse terrains.

Die Lösung: To effectively manage tire inflation, fleet managers should implement a systematic approach to monitor and maintain tire pressures. One actionable strategy is to invest in a centralized tire pressure monitoring system (TPMS) that provides real-time data on each vehicle’s tire pressure. This technology alerts managers to underinflation before it becomes a costly issue. Additionally, establishing a regular maintenance schedule that includes tire pressure checks can mitigate risks. Training drivers to recognize the signs of underinflation and ensuring that they have access to portable tire inflators can further enhance proactive measures. By prioritizing tire health, fleet managers can optimize fuel efficiency and extend tire life, ultimately reducing operational costs.

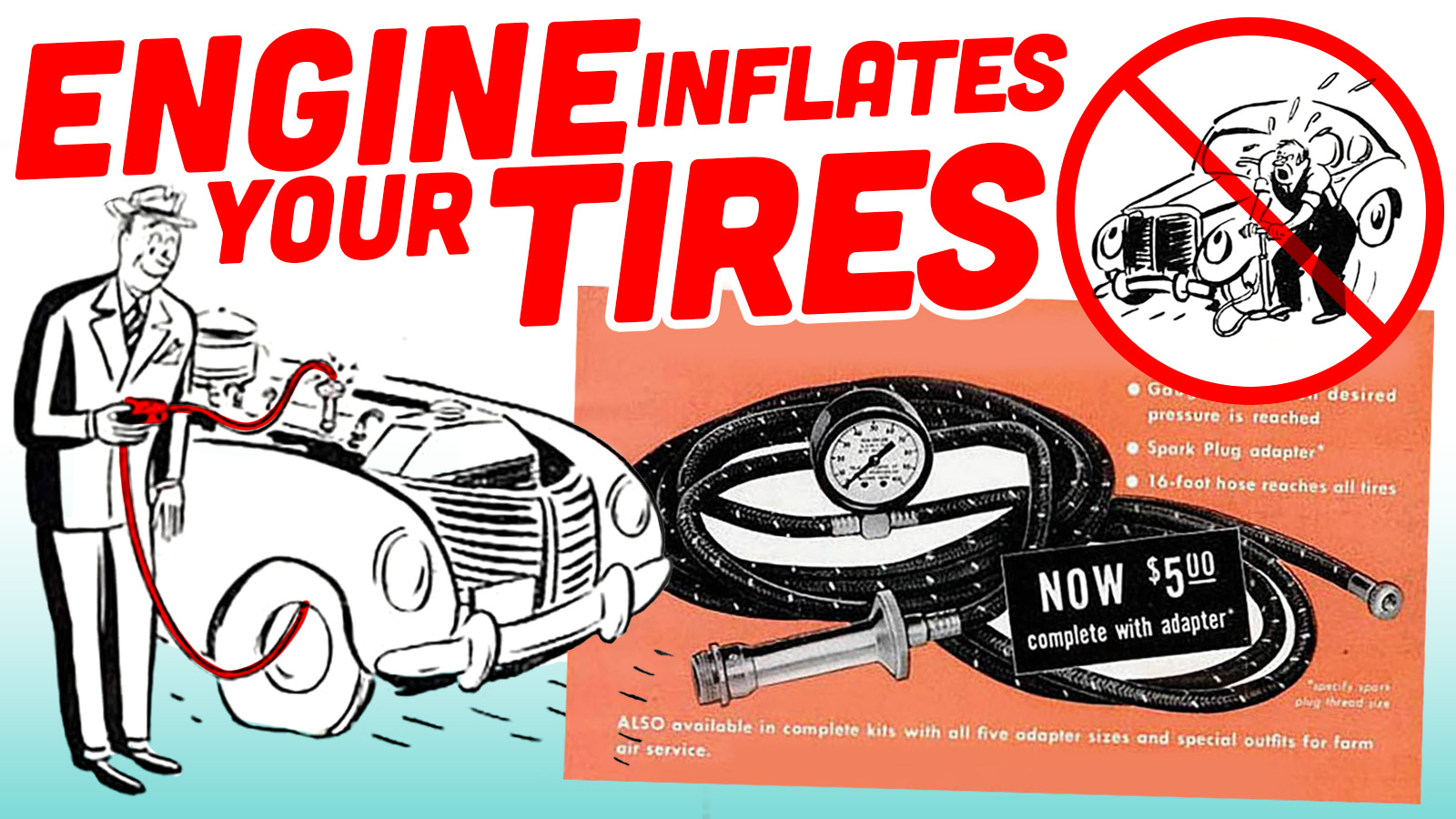

Illustrative image related to inflate tire

Das Problem: For B2B buyers operating in remote areas, finding reliable access to tire inflation services can be a significant hurdle. Inconsistent tire pressure can lead to dangerous driving conditions, particularly in regions where road infrastructure is poor. Buyers may experience frustrations when employees are stranded due to flat tires or improper inflation, leading to lost time and productivity.

Die Lösung: One effective solution is to equip vehicles with portable tire inflators that can be easily stored in the trunk. These devices are particularly useful in remote locations where service stations may be scarce. When sourcing portable inflators, businesses should consider models with built-in pressure gauges and automatic shut-off features to prevent over-inflation. Additionally, training employees on how to properly use these inflators can empower them to address tire issues independently, ensuring that they remain safe and operational even in the most isolated environments. Partnering with local tire suppliers to establish a network for tire maintenance services can also provide an added layer of support.

Das Problem: Seasonal changes can significantly affect tire pressure, leading to challenges for B2B buyers who operate in regions with extreme temperature fluctuations. For instance, cold weather can cause tire pressure to drop, while heat can lead to overinflation. This inconsistency can compromise safety, fuel efficiency, and tire longevity, creating a pressing concern for businesses that rely on transportation.

Illustrative image related to inflate tire

Die Lösung: To mitigate the risks associated with seasonal tire pressure changes, businesses should implement a proactive tire maintenance plan that includes monthly pressure checks and adjustments. Educating employees about the importance of checking tire pressure during seasonal transitions is crucial. Buyers can also invest in nitrogen tire inflation, as nitrogen is less affected by temperature changes compared to regular air. This can help maintain more stable tire pressures throughout varying climates. Additionally, providing employees with training on how to read tire pressure gauges and recognize when adjustments are necessary will foster a culture of safety and responsibility. By taking these steps, businesses can ensure that their vehicles are equipped to handle seasonal challenges while maintaining optimal performance.

When selecting materials for tire inflation systems, B2B buyers must consider various factors that influence performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

Rubber is the most widely used material in tire manufacturing due to its excellent elasticity and ability to withstand high pressure and temperature variations. It offers good corrosion resistance against various environmental factors, including moisture and UV light. Rubber can typically handle pressures up to 44 psi, depending on the specific formulation used.

Pro und Kontra:

– Vorteile: Durable, flexible, and cost-effective. Rubber also provides excellent sealing properties, which is critical for maintaining tire pressure.

– Nachteile: Over time, rubber can degrade due to ozone exposure and temperature fluctuations, leading to potential failure in tire inflation systems.

Illustrative image related to inflate tire

Auswirkungen auf die Anwendung:

Rubber is compatible with air and nitrogen, making it suitable for most tire inflation applications. However, buyers should consider the specific rubber compounds used, as some may not perform well in extreme temperatures.

Überlegungen für internationale Käufer:

Compliance with local standards like ASTM and DIN is essential. Buyers in regions like Africa and South America should also consider the availability of quality rubber suppliers to ensure consistent performance.

Aluminum is often used in tire inflation valves and fittings due to its lightweight nature and excellent corrosion resistance. It can withstand high-pressure environments, making it suitable for both passenger and commercial vehicle applications.

Pro und Kontra:

– Vorteile: Lightweight, resistant to corrosion, and provides a good strength-to-weight ratio. Aluminum components can enhance the overall efficiency of tire inflation systems.

– Nachteile: More expensive than traditional steel options and can be prone to deformation under extreme pressure if not properly designed.

Auswirkungen auf die Anwendung:

Aluminum is ideal for high-performance applications, particularly in racing or heavy-duty vehicles where weight savings are crucial. However, it may not be suitable for all environments, especially those with high levels of abrasive materials.

Überlegungen für internationale Käufer:

Buyers should ensure that aluminum components meet international standards for pressure ratings. In regions like the Middle East, where high temperatures are common, selecting aluminum with appropriate thermal properties is vital.

Steel is commonly used for tire rims and some inflation components due to its high strength and durability. It can handle high-pressure applications effectively and is often used in commercial vehicles.

Pro und Kontra:

– Vorteile: Very strong and durable, making it suitable for heavy-duty applications. Steel components can also be manufactured at a relatively low cost.

– Nachteile: Heavier than aluminum, which can impact vehicle performance. Steel is also susceptible to rust and corrosion if not properly treated.

Illustrative image related to inflate tire

Auswirkungen auf die Anwendung:

Steel’s robustness makes it ideal for commercial tire inflation systems, but its weight can be a disadvantage in performance-oriented applications.

Überlegungen für internationale Käufer:

Buyers should look for steel components that comply with relevant international standards to ensure safety and reliability. In humid regions, corrosion-resistant treatments are essential.

Composite materials, often a combination of plastic and rubber, are increasingly used in tire inflation systems due to their lightweight and flexible properties. They can be engineered to provide specific performance characteristics, such as enhanced resistance to temperature fluctuations.

Illustrative image related to inflate tire

Pro und Kontra:

– Vorteile: Lightweight, flexible, and can be designed for specific applications. Composites can also be resistant to various chemicals.

– Nachteile: Generally more expensive to manufacture and may not offer the same durability as metal options.

Auswirkungen auf die Anwendung:

Composites are suitable for lightweight applications and can be used in environments where chemical exposure is a concern. However, their long-term durability under high pressure may not match that of metals.

Überlegungen für internationale Käufer:

When sourcing composite materials, buyers should ensure that they meet local standards for pressure and temperature ratings. In developing markets, the availability of composite materials may vary, influencing procurement strategies.

Illustrative image related to inflate tire

| Material | Typical Use Case for inflate tire | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Tire manufacturing | Excellent elasticity and sealing | Verschlechtert sich mit der Zeit | Niedrig |

| Aluminium | Valves and fittings | Leicht und korrosionsbeständig | Higher cost than steel | Med |

| Stahl | Rims and heavy-duty components | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Rost | Niedrig |

| Komposit | Lightweight applications | Flexible and resistant to chemicals | More expensive and less durable | Hoch |

This guide provides a comprehensive overview of material options for tire inflation systems, helping international B2B buyers make informed decisions based on performance, cost, and regional considerations.

Manufacturing inflate tires involves several critical stages that ensure quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

The first step in the manufacturing process is material preparation, which begins with the selection of high-quality raw materials. Typically, this includes rubber compounds, textiles, and steel wires. The rubber is mixed with various additives, such as carbon black and sulfur, to enhance durability and performance. The blending process is meticulously controlled to achieve the desired properties, including tensile strength and flexibility.

Once the rubber is mixed, it is shaped into sheets and prepared for the next stage. This preparation often involves cutting the rubber into specific dimensions, which are crucial for ensuring that the final product meets industry standards.

In the forming stage, the prepared materials are shaped into the various components of the tire, such as the tread, sidewalls, and inner linings. This is typically accomplished through processes like extrusion and molding.

Extrusion: This technique involves forcing the rubber through a die to create long strips that will become the tire’s components. For example, the tread is often extruded into a specific shape and size that aligns with design specifications.

Molding: The extruded rubber strips are then placed into molds where heat and pressure are applied to cure the rubber, solidifying its shape and enhancing its properties. This stage is crucial, as it determines the tire’s performance characteristics, including traction and wear resistance.

Following the forming stage, the assembly process begins. This involves combining all the components, including the tread, sidewalls, and steel belts. The assembly is typically performed on specialized machinery designed to ensure precise alignment and bonding of the materials.

During this stage, the tire’s inner lining is attached to the outer components, and steel belts may be added to enhance structural integrity. This is a critical phase, as improper assembly can lead to defects that affect tire performance and safety.

The final stage of manufacturing involves finishing processes that ensure the tire meets all aesthetic and functional requirements. This includes trimming excess rubber, inspecting for defects, and applying markings such as brand names and size specifications.

Additionally, tires undergo a final curing process, where they are subjected to heat for a set period to ensure proper bonding and durability. Quality checks are performed at this stage to confirm that the tires meet specified standards before they are packaged for distribution.

Quality assurance (QA) is integral to the tire manufacturing process, ensuring that each product meets international and industry-specific standards.

Tire manufacturers are often required to comply with various international standards, such as ISO 9001, which focuses on effective quality management systems. This standard helps ensure that manufacturers consistently produce products that meet customer and regulatory requirements.

In addition to ISO 9001, other certifications may be relevant depending on the market. For instance, the European market requires compliance with CE marking, indicating conformity with health, safety, and environmental protection standards. Similarly, the American Petroleum Institute (API) standards may apply to certain specialty tires.

Illustrative image related to inflate tire

Quality control (QC) checkpoints are established at various stages of the manufacturing process to identify and rectify defects. Key checkpoints include:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process, ensuring that only high-quality materials are used.

Prozessbegleitende Qualitätskontrolle (IPQC): Conducted during the manufacturing stages, IPQC involves real-time monitoring and testing of the product at various stages to catch defects early.

Endgültige Qualitätskontrolle (FQC): This final assessment is conducted before tires are packaged and shipped. FQC includes rigorous testing of tire performance characteristics such as pressure retention, durability, and visual inspections for defects.

Tires undergo several testing methods to verify their quality, including:

Treadwear Testing: Evaluates how quickly the tire wears under standard driving conditions.

Road Hazard Testing: Simulates real-world driving scenarios to assess tire durability against punctures and other road hazards.

Pressure Testing: Ensures that tires can maintain the required air pressure over time.

These tests help manufacturers ensure that their products meet or exceed industry standards, providing B2B buyers with confidence in their quality.

B2B buyers must conduct due diligence to ensure that their tire suppliers maintain high-quality standards. Here are actionable strategies:

Lieferanten-Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their quality control practices. These audits should assess compliance with international standards and the efficiency of their QC processes.

Anforderung von Qualitätsberichten: Buyers should request detailed QC reports from suppliers, including results from IQC, IPQC, and FQC. These reports should outline the testing methods used and any corrective actions taken in response to identified issues.

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes. This can be particularly valuable when dealing with suppliers in regions with varying compliance levels, such as Africa, South America, or the Middle East.

International buyers should be aware of specific nuances related to quality control in different regions. For example, some countries may have unique regulatory requirements that impact tire manufacturing. Understanding these differences is crucial for ensuring compliance and avoiding costly delays or penalties.

In regions like Africa and South America, where supply chains may be less standardized, buyers should emphasize the importance of robust quality control practices. This includes ensuring that suppliers have the necessary certifications and are willing to undergo audits to verify compliance.

Illustrative image related to inflate tire

The manufacturing processes and quality assurance measures for inflate tires are critical to ensuring that B2B buyers receive high-quality products that meet their needs. By understanding the stages of manufacturing and the importance of quality control, buyers can make informed decisions when selecting suppliers, ultimately leading to better performance and safety for their customers.

To assist B2B buyers in effectively procuring tire inflation solutions, this guide outlines a systematic approach to ensure the selection of high-quality products and reliable suppliers. Properly inflated tires are crucial for safety, efficiency, and environmental responsibility, making this checklist an essential tool for organizations in various regions, including Africa, South America, the Middle East, and Europe.

Understanding your specific requirements is the foundation of effective procurement. Consider the types of vehicles in your fleet, the average mileage, and the environmental conditions they operate under. This will help you determine the necessary tire pressure ranges and whether you need manual or automatic inflation solutions.

Illustrative image related to inflate tire

Explore the various tire inflation technologies available in the market, such as portable air compressors, nitrogen inflation systems, and centralized inflation systems. Each technology has its advantages:

– Portable Air Compressors: Ideal for flexibility and convenience, allowing for tire inflation on-site.

– Nitrogen Inflation Systems: Offer longer-lasting pressure retention and improved tire longevity, particularly beneficial for high-performance vehicles.

Before engaging with suppliers, verify their certifications and adherence to quality standards. Look for ISO certifications or specific regional compliance that demonstrates reliability and product quality. This step is crucial in ensuring that the products meet safety and performance benchmarks.

Gather quotes from several suppliers to compare pricing, delivery times, and after-sales services. Ensure that the quotes include:

– Bulk Purchase Discounts: Often available for larger orders.

– Warranty Terms: Understand the warranty coverage for potential defects or failures.

A supplier’s ability to provide ongoing support is critical to long-term satisfaction. Inquire about:

– Availability of Technical Support: Ensure they offer assistance for installation and maintenance.

– Training Programs: Some suppliers provide training for staff on using tire inflation equipment effectively, which can enhance operational efficiency.

Confirm the supplier’s ability to deliver to your location, especially if you operate in remote areas. Local suppliers may offer better logistics and quicker response times. Additionally, assess their inventory levels to ensure they can meet your demand without delays.

Illustrative image related to inflate tire

Before making a large purchase, consider conducting a trial run with the tire inflation equipment. This allows you to evaluate performance, ease of use, and integration with existing systems. Gather feedback from your team on the equipment’s functionality to ensure it meets your operational needs.

By following this structured checklist, B2B buyers can make informed decisions when sourcing tire inflation solutions, ensuring they select products that enhance safety, efficiency, and overall operational effectiveness.

When sourcing inflate tires, understanding the cost structure is critical for B2B buyers. The primary cost components include:

Materialien: The quality of rubber, steel belts, and other materials significantly influences tire pricing. Sourcing high-grade materials enhances durability but may increase costs. Buyers should assess local suppliers for availability and potential cost savings.

Arbeit: Labor costs vary by region, influenced by local wage rates and labor laws. Countries in Africa and South America may have lower labor costs, which can positively impact the overall pricing of tires. However, it is essential to ensure that labor practices meet international standards to avoid supply chain disruptions.

Fertigungsgemeinkosten: This encompasses the costs associated with running a factory, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, thus affecting the final price of the tires.

Werkzeugbau: Custom molds and production tools are necessary for producing specific tire designs or sizes. The initial investment in tooling can be substantial, especially for custom orders, impacting pricing based on the volume of production.

Qualitätskontrolle (QC): Rigorous QC processes are essential to ensure tire safety and performance. Investments in testing and certification can increase costs but are crucial for maintaining quality standards and complying with international regulations.

Logistik: Transportation costs can vary widely based on the location of the supplier and the destination market. International shipping, tariffs, and customs duties should be factored into the total cost. Efficient logistics management can help mitigate these expenses.

Marge: Suppliers typically include a profit margin in their pricing, which can vary significantly based on market demand and competition. Understanding the competitive landscape can help buyers negotiate better terms.

Several factors influence the pricing of inflate tires, which can impact your sourcing strategy:

Volumen und Mindestbestellmenge (MOQ): Larger orders typically result in lower per-unit costs. Buyers should negotiate favorable terms based on their expected volume to maximize savings.

Spezifikationen und Anpassungen: Custom tires tailored to specific applications or vehicles often come at a premium. Buyers should weigh the benefits of customization against potential cost increases.

Materialqualität und Zertifizierungen: Tires that meet higher quality standards or certifications (such as ISO or local safety regulations) may command higher prices. However, investing in quality can lead to lower Total Cost of Ownership (TCO) through reduced failure rates and longer life spans.

Lieferanten-Faktoren: Supplier reliability, reputation, and geographical location can significantly affect pricing. Engaging with reputable suppliers who have a proven track record can mitigate risks associated with quality and delivery.

Incoterms: Understanding the terms of delivery (Incoterms) is crucial for pricing clarity. Different Incoterms can shift responsibilities and costs between buyers and sellers, impacting the overall pricing structure.

To navigate the complexities of tire sourcing and achieve cost efficiency, consider the following strategies:

Führen Sie gründliche Marktforschung durch: Understand the average market prices for the specifications you need. This knowledge can empower your negotiation process.

Negotiate for Volume Discounts: Leverage your purchasing power by negotiating discounts based on order size. Suppliers may be more flexible on pricing for larger commitments.

Assess Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term costs associated with tire performance, including fuel efficiency and maintenance. A higher initial investment in quality tires may yield savings over time.

Stay Informed About Pricing Nuances: Be aware of regional pricing trends and factors that may affect costs in your target markets, such as currency fluctuations and import tariffs.

Build Strong Supplier Relationships: Establishing long-term partnerships with suppliers can lead to better pricing, improved service, and access to exclusive offers or early insights into new products.

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other external factors. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

In the realm of tire maintenance, ensuring optimal tire pressure is crucial for vehicle performance, safety, and longevity. While traditional tire inflation is a common practice, there are several alternative solutions available that may better suit specific needs for B2B buyers across various regions. This analysis will compare the conventional tire inflation method with two viable alternatives: nitrogen tire inflation and the use of portable air compressors.

| Vergleich Aspekt | Inflate Tire | Nitrogen Tire Inflation | Tragbarer Luftkompressor |

|---|---|---|---|

| Leistung | Standard air inflation, effective but can lose pressure quickly. | Maintains pressure longer due to larger nitrogen molecules. | Provides on-demand inflation, variable performance based on power source. |

| Kosten | Low initial cost, often free at gas stations. | Higher initial cost; may incur service fees. | Moderate one-time purchase cost; no ongoing fees. |

| Leichte Implementierung | Simple; can be done at gas stations or service centers. | Requires specialized equipment and service centers. | User-friendly; can be used at home or on-the-go. |

| Wartung | Minimal; requires regular pressure checks. | Low; tires still need pressure checks, but less frequent. | Requires occasional maintenance and battery checks (if applicable). |

| Bester Anwendungsfall | General use for personal and commercial vehicles. | Ideal for high-performance vehicles and fleet operations. | Great for remote locations or frequent travelers needing convenience. |

Nitrogen tire inflation involves filling tires with nitrogen gas instead of regular air. The primary advantage is that nitrogen molecules are larger, which reduces the rate of air loss and helps maintain tire pressure over time. This can lead to improved fuel efficiency, longer tire life, and enhanced safety. However, the service is typically more expensive than conventional inflation and may require access to specialized service centers, which may not be readily available in all regions.

Illustrative image related to inflate tire

Portable air compressors offer a convenient solution for tire inflation, allowing users to inflate tires at home or while traveling. They are easy to operate and provide immediate access to air, which is especially beneficial in remote areas or for businesses with mobile operations. However, the performance can vary based on the model and power source (battery vs. AC). Additionally, a one-time purchase cost is required, which may not be appealing for businesses seeking low upfront expenses.

For B2B buyers looking to optimize tire maintenance, the choice between traditional inflation, nitrogen inflation, and portable compressors will depend on specific operational needs and budget constraints. If cost-effectiveness and accessibility are priorities, conventional tire inflation may suffice. However, for businesses focused on performance and safety, nitrogen inflation could offer significant long-term benefits. Meanwhile, for those requiring flexibility and convenience, a portable air compressor might be the best investment. Evaluating these factors will enable buyers to select the solution that best aligns with their operational goals and regional availability.

Understanding the critical technical properties of inflatable tires is essential for B2B buyers to make informed purchasing decisions. Here are several key specifications that should be considered:

Illustrative image related to inflate tire

The primary materials used in tire manufacturing include rubber compounds, fabric layers, and steel belts. The choice of rubber affects durability, traction, and resistance to wear. For B2B buyers, selecting the right material composition can lead to longer-lasting tires, reduced operational costs, and improved vehicle performance, which is crucial for industries relying on transportation.

Tire pressure ratings are expressed in pounds per square inch (PSI) or bar and are critical for ensuring optimal performance. Each tire has a recommended pressure range, which must be adhered to for safety and efficiency. Proper tire pressure enhances fuel economy and minimizes uneven wear, thereby extending the tire’s lifespan. Understanding these ratings helps B2B buyers ensure compliance with safety regulations and operational efficiency.

The load index indicates the maximum weight a tire can safely carry, while the speed rating denotes the maximum speed the tire can sustain. Both metrics are vital for buyers in logistics and transportation sectors, as choosing tires with appropriate load and speed capabilities directly influences vehicle safety and efficiency under varying conditions.

Tread depth and pattern are essential for traction and handling. Different tread designs cater to specific driving conditions, such as off-road or wet surfaces. A minimum tread depth is required for safe operation, and understanding these specifications allows B2B buyers to select tires that align with their operational needs and environmental conditions.

Tires are often rated for durability, which includes resistance to punctures, cuts, and abrasions. A higher durability rating translates to lower maintenance costs and fewer replacements. For businesses, investing in tires with superior durability can significantly reduce downtime and enhance overall productivity.

Familiarity with industry-specific terminology is crucial for effective communication and negotiation in the tire market. Here are several common terms:

OEM refers to companies that manufacture products that are used as components in the products of another company. In the tire industry, OEM tires are those supplied by tire manufacturers to vehicle manufacturers. Understanding OEM specifications ensures compatibility and quality assurance in tire selection.

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and purchasing strategies. Knowing the MOQ helps businesses avoid excess inventory costs or stock shortages.

Illustrative image related to inflate tire

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for a specific product or service. In the tire industry, issuing an RFQ allows buyers to compare pricing, specifications, and delivery terms from multiple suppliers, facilitating informed decision-making.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is vital for B2B transactions, as they clarify who is responsible for costs and risks at various points in the supply chain.

Tire rotation is the practice of changing the position of each tire on a vehicle to promote even tire wear. This term is essential for maintenance discussions and can significantly affect the longevity of tires, making it a critical consideration for fleet management.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the tire market more effectively, ensuring they make informed and strategic purchasing decisions.

The inflate tire sector is experiencing transformative dynamics driven by several global factors. The rise of electric vehicles (EVs) and the demand for sustainable transportation solutions are reshaping tire design and functionality. As consumers and governments prioritize fuel efficiency and reduced carbon footprints, manufacturers are innovating to produce tires that minimize rolling resistance and enhance fuel economy. This shift is particularly relevant for international B2B buyers in emerging markets like Africa and South America, where fuel costs directly impact operational expenses.

Technological advancements are also playing a pivotal role in this sector. The integration of smart tire technology, including real-time pressure monitoring systems and predictive analytics, is gaining traction. These innovations allow businesses to optimize tire performance, reduce maintenance costs, and improve safety standards. For buyers in Europe and the Middle East, such technologies not only enhance operational efficiency but also align with regulatory requirements for vehicle safety and emissions.

Another significant trend is the increasing adoption of online sourcing platforms and digital marketplaces. These platforms provide B2B buyers with access to a wider range of suppliers and competitive pricing. The ability to compare products and services online facilitates informed purchasing decisions, particularly for buyers in regions like Brazil and Vietnam, where traditional supply chains may be less established.

Sustainability is becoming a cornerstone of the inflate tire sector, as both consumers and businesses recognize the environmental impacts associated with tire production and disposal. The production of tires often involves the use of non-renewable resources and generates significant waste. Consequently, B2B buyers are increasingly seeking suppliers who prioritize sustainable practices, such as utilizing eco-friendly materials and implementing recycling programs.

Ethical sourcing is also gaining importance in the supply chain. Buyers are now more vigilant about the labor practices of their suppliers, demanding transparency and accountability. Certifications such as the Global Organic Textile Standard (GOTS) or the Forest Stewardship Council (FSC) are valuable indicators of a supplier’s commitment to sustainable and ethical practices. In the inflate tire sector, using renewable materials, such as natural rubber from certified plantations, can significantly reduce environmental impact and appeal to eco-conscious consumers.

Moreover, sustainable tire technologies—such as those that incorporate bio-based materials and reduce CO2 emissions during production—are becoming essential. Buyers can leverage these innovations not only to enhance their brand reputation but also to meet regulatory requirements across various international markets.

The inflate tire sector has evolved significantly since its inception in the late 19th century. Initially, tires were made from solid rubber, which provided limited performance. The introduction of inflatable tires revolutionized the automotive industry by improving ride comfort and vehicle handling. Over the decades, technological advancements have led to the development of specialized tires for various applications, including heavy-duty and off-road vehicles.

In recent years, the focus has shifted towards enhancing tire longevity and performance, driven by consumer demand for efficiency and safety. As international trade has expanded, so too has the complexity of the tire supply chain, with raw materials sourced globally. Understanding this historical context is crucial for B2B buyers, as it informs current sourcing strategies and highlights the importance of partnering with suppliers who can adapt to evolving market trends and consumer expectations.

In conclusion, navigating the inflate tire sector requires an awareness of market dynamics, a commitment to sustainability, and an understanding of the historical context that shapes today’s industry landscape. By leveraging these insights, international B2B buyers can make informed decisions that enhance operational efficiency and drive sustainable growth.

Illustrative image related to inflate tire

How do I solve tire inflation issues for my fleet?

To address tire inflation issues, conduct regular pressure checks using a calibrated gauge, ideally once a month or before long trips. Consider implementing a tire monitoring system that alerts you to low pressure. Providing training for your drivers on the importance of proper tire inflation can also enhance safety and reduce costs. Additionally, partnering with local tire service providers for regular maintenance can help ensure your fleet remains in optimal condition, reducing downtime and improving fuel efficiency.

What is the best tire inflation solution for commercial vehicles?

The best tire inflation solution for commercial vehicles often includes a combination of nitrogen inflation and portable air compressors. Nitrogen maintains tire pressure longer and can enhance fuel efficiency. For convenience, investing in portable air compressors allows for quick inflation on-site, reducing reliance on service stations. Additionally, consider integrating tire pressure monitoring systems (TPMS) to provide real-time data, ensuring that tires are always within the optimal pressure range for safety and performance.

What are the minimum order quantities (MOQ) for tire inflation products?

Minimum order quantities (MOQ) for tire inflation products can vary widely based on suppliers and product types. Generally, for bulk purchases, MOQs range from 100 to 500 units, depending on the specific product and supplier capabilities. It’s advisable to negotiate with suppliers to find a quantity that meets your needs while also taking advantage of bulk pricing. Always inquire about lead times and potential discounts for larger orders to maximize your investment.

How can I vet suppliers for tire inflation equipment?

To effectively vet suppliers for tire inflation equipment, start by reviewing their certifications and industry reputation. Check for customer testimonials and case studies to gauge reliability and service quality. Request samples of their products to evaluate performance and durability. Additionally, consider visiting their facilities or arranging virtual meetings to discuss their manufacturing processes and quality control measures. Engaging in industry forums and trade shows can also provide insights into reputable suppliers.

What payment terms should I expect when sourcing tire inflation products internationally?

When sourcing tire inflation products internationally, payment terms can vary, but common practices include letters of credit, wire transfers, and payment upon delivery. Many suppliers may require a deposit (20-30%) upfront, with the balance due upon shipment or delivery. It’s crucial to clarify terms before finalizing orders to avoid misunderstandings. Additionally, consider using escrow services for large transactions to ensure both parties fulfill their obligations.

How can I customize tire inflation solutions for my business?

Customization options for tire inflation solutions may include branding, specific pressure settings, and tailored features based on your operational needs. Discuss your requirements directly with suppliers, as many are willing to work on custom solutions to meet unique business demands. Additionally, inquire about the possibility of integrating technology such as mobile app connectivity for monitoring and managing tire pressure remotely, which can enhance operational efficiency.

What quality assurance measures should I look for in tire inflation products?

Quality assurance measures for tire inflation products should include adherence to international standards such as ISO certifications. Ensure that suppliers conduct regular testing for their equipment, including durability and performance assessments. Request documentation of their quality control processes and any relevant test results. Additionally, inquire about warranty terms, as a strong warranty can indicate the manufacturer’s confidence in their product’s quality.

What logistics considerations should I keep in mind when importing tire inflation equipment?

When importing tire inflation equipment, consider shipping methods, customs regulations, and potential tariffs that may apply to your products. It’s essential to work with a reliable logistics partner familiar with international shipping processes to avoid delays. Additionally, ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared accurately. Finally, factor in lead times for customs clearance to align your inventory needs with delivery schedules.

Bereich: michelinman.com

Registriert: 2001 (24 Jahre)

Einleitung: Michelin offers a complete range of tires for various mobility needs, including passenger cars, SUVs, light commercial vehicles, and electric/hybrid vehicles. Their tire families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy, Latitude Sport, Pilot Alpin, and Premier. Michelin also provides specialized tires for classic cars, motorsport, motorcycles, and bicycles, with op…

Bereich: freeairpump.com

Registriert: 2012 (13 Jahre)

Einleitung: Map of places that provide free air for tires; Database of over 12k locations in the U.S.; User-generated map; Ability to submit new free air spots; Search functionality by device location or address; Indicates bike repair stations and free air for autos; Suggested locations include tire shops, car repair stations, bike shops, and specific gas station chains (e.g., Co-op, Family Express, Getgo, Hy…

Bereich: goodyearautoservice.com

Registriert: 2006 (19 Jahre)

Einleitung: Proper tire inflation is critical for tire care, extending tire life, improving vehicle performance, and enhancing safety. Recommended air pressure is specified by the vehicle’s manufacturer and can be found on the vehicle door edge, door jamb, glove box door, or fuel door, as well as in the owner’s manual. It is important to check tire pressure when tires are cool, and to visually inspect tires f…

Bereich: mastercrafttires.com

Registriert: 1997 (28 Jahre)

Einleitung: Recommended inflation pressures for tires are specified in pounds per square inch (psi) or kilopascals (kPa) as indicated on the vehicle’s tire placard, certification label, or in the owner’s manual. Underinflation causes excessive heat buildup and internal structural damage, leading to tire failure. Overinflated tires are more likely to be damaged by impacts. Proper inflation is critical for tire…

As the tire industry evolves, the importance of strategic sourcing for tire inflation solutions cannot be overstated. Proper tire inflation not only enhances vehicle safety and performance but also significantly reduces operational costs for businesses. International buyers should prioritize partnerships with reliable suppliers who offer high-quality tire inflation products, such as portable compressors and nitrogen inflation services. By ensuring that tires are inflated to the manufacturer’s recommended levels, companies can extend tire lifespan, improve fuel efficiency, and minimize CO2 emissions—key factors that resonate with sustainability goals.

Moreover, the accessibility of inflation resources, including free air services and professional tire shops, can further streamline operations and reduce costs. As markets in Africa, South America, the Middle East, and Europe continue to grow, buyers should leverage local and global sourcing opportunities to optimize their supply chains.

Looking ahead, the integration of advanced technologies in tire maintenance, such as digital pressure monitoring systems, will shape the future of tire inflation. Now is the time for businesses to invest in these innovations and establish robust sourcing strategies that ensure optimal tire performance. Engage with suppliers who understand your regional needs and can provide tailored solutions to enhance your fleet’s efficiency and safety.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.