In today’s competitive landscape, sourcing reliable automotive tools, such as the Ryobi car tire inflator, can present significant challenges for international B2B buyers. With the growing demand for efficient tire maintenance solutions across various markets—including Africa, South America, the Middle East, and Europe—businesses must navigate a complex array of products, supplier options, and pricing strategies. This guide is designed to empower buyers with comprehensive insights into the Ryobi car tire inflator, exploring its diverse applications, key features, and the advantages it offers for both personal and commercial use.

Throughout this guide, we will delve into the different types of Ryobi inflators available, their specific functionalities, and how they cater to various consumer needs, from automotive care to sports equipment. We will also cover critical aspects of supplier vetting, ensuring that you can identify reputable manufacturers and distributors in your region. Additionally, understanding cost considerations will be essential, as we analyze price points and potential savings when purchasing in bulk.

By equipping B2B buyers with actionable insights and data-driven recommendations, this guide aims to facilitate informed purchasing decisions, ultimately enhancing operational efficiency and customer satisfaction. As you explore the global market for Ryobi car tire inflators, you’ll gain the confidence to select the best products that meet your business needs while maximizing value in your procurement processes.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| 18V ONE+ Cordless High Pressure Inflator | Cordless, precise filling up to 160 PSI, auto shut-off | Automotive repair shops, fleet maintenance | Vorteile: Portability, ease of use; Nachteile: Battery not included in tool-only option. |

| 18V ONE+ High Pressure Digital Inflator Kit | Digital pressure gauge, on-board accessory storage | Tire shops, sports facilities | Vorteile: Accurate readings, versatile; Nachteile: Requires battery for operation. |

| 18V ONE+ Dual Function Digital Inflator/Deflator | Inflates and deflates, digital gauge, compact design | Automotive service centers, recreational vehicle maintenance | Vorteile: Dual functionality, space-saving; Nachteile: Möglicherweise fehlt es an Leistung für größere Reifen. |

| 18V ONE+ Whisper Series High Volume Inflator | Quiet operation, high volume output, lightweight | Landscaping, construction sites | Vorteile: Low noise, efficient; Nachteile: May not reach high pressure for heavy-duty tasks. |

| 18V ONE+ High Volume Inflator | High airflow rate, quick inflation, robust design | Emergency services, outdoor events | Vorteile: Fast inflation, durable; Nachteile: Less precision compared to digital models. |

The 18V ONE+ Cordless High Pressure Inflator is designed for portability and convenience. It operates on an 18V battery, making it ideal for mobile applications. Its ability to fill tires up to 160 PSI with an auto shut-off feature ensures precise inflation, which is crucial for automotive businesses that prioritize tire safety. B2B buyers should consider the availability of compatible batteries and whether they require a standalone tool or a kit that includes a battery.

This model features a digital pressure gauge that allows for accurate inflation, along with on-board accessory storage for added convenience. It is particularly suited for tire shops and sports facilities where precision and efficiency are paramount. When purchasing, businesses should evaluate the kit’s battery life and compatibility with existing RYOBI tools, as this can impact overall operational efficiency.

The Dual Function Inflator/Deflator is a versatile tool that serves both inflation and deflation needs, making it suitable for various applications, including automotive service centers and RV maintenance. Its compact design allows for easy storage and transport. B2B buyers should assess the inflator’s power and speed for their specific requirements, especially if they deal with larger tires or inflatables.

The Whisper Series Inflator is engineered for quiet operation while providing high volume output, making it an excellent choice for landscaping and construction sites where noise regulations may apply. While its lightweight design enhances portability, businesses should weigh its lower pressure capabilities against their operational needs, particularly for heavy-duty applications.

This inflator is designed for high airflow rates and quick inflation, making it ideal for emergency services and outdoor events where time is of the essence. Its robust design ensures durability, but B2B buyers should consider that it may lack the precision of digital models. Evaluating the specific inflation needs and the types of tires or equipment used will help determine if this model fits their operational demands.

| Industrie/Sektor | Specific Application of ryobi car tire inflator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automotive Services | Quick tire inflation for service stations | Verbessert den Kundenservice durch kürzere Wartezeiten | Reliability, ease of use, and compatibility with various tire types |

| Logistik und Verkehr | On-site tire maintenance for delivery fleets | Minimizes downtime and maximizes operational efficiency | Portability, battery life, and pressure accuracy |

| Sports and Recreation | Inflating sports equipment for teams and facilities | Ensures readiness for events, improving performance | Versatility in inflating various sports equipment |

| Construction and Heavy Machinery | Tire maintenance for construction vehicles | Reduces the risk of tire-related accidents and downtime | Durability, high PSI capability, and ease of transport |

| Retail and Wholesale | Resale of inflators in automotive accessory shops | Expands product offerings and attracts more customers | Cost-effectiveness, warranty options, and branding |

In automotive service stations, the RYOBI car tire inflator is utilized for quick and efficient tire inflation. Service centers can significantly enhance customer satisfaction by reducing wait times, as the inflator can fill tires up to 160 PSI with precision. This is crucial in regions where tire maintenance is often overlooked, leading to safety hazards. Buyers in this sector should prioritize reliability and ease of use, ensuring that the inflator can handle various tire sizes and types.

For logistics and transport companies, maintaining the proper tire pressure of delivery fleets is vital for operational efficiency. The RYOBI tire inflator allows for on-site tire maintenance, reducing vehicle downtime caused by flat tires. This is particularly important in regions with challenging road conditions, where tire issues are common. Buyers should consider factors such as portability, battery life, and pressure accuracy to ensure that the inflator meets their operational needs.

In the sports and recreation industry, the RYOBI car tire inflator is essential for inflating a variety of sports equipment, including balls and inflatable gear. Teams and facilities can ensure that they are always prepared for games and events, enhancing overall performance. This is especially relevant in regions with active sports cultures, where timely preparation can impact outcomes. Buyers should look for versatility in inflating different types of equipment and ease of transport to various locations.

In construction, tire maintenance for heavy machinery is critical to reduce the risk of accidents caused by tire failures. The RYOBI car tire inflator provides a reliable solution for ensuring that construction vehicles are always roadworthy. This is particularly important in emerging markets where construction activities are booming. Buyers in this sector should focus on the inflator’s durability, high PSI capability, and ease of transport to job sites.

Illustrative image related to ryobi car tire inflator

Retail and wholesale businesses can capitalize on the growing demand for automotive accessories by offering the RYOBI car tire inflator. This product can enhance their inventory and attract more customers looking for reliable tire maintenance solutions. Retailers should consider cost-effectiveness, warranty options, and branding when sourcing these inflators to ensure they meet customer expectations and drive sales.

Das Problem: A common challenge for B2B buyers, particularly those managing fleets or commercial vehicles, is the inconsistency in inflation performance when using the Ryobi car tire inflator on various tire types. For instance, larger truck tires may require higher pressure than standard car tires, leading to complications if the inflator struggles to adapt. This inconsistency can result in under-inflated tires, affecting vehicle performance, safety, and overall operational efficiency.

Die Lösung: To mitigate this issue, buyers should consider the specifications of the Ryobi inflator, which can inflate up to 160 PSI, making it suitable for a range of tire types. For optimal results, it’s essential to familiarize yourself with the inflator’s digital pressure gauge and auto shut-off feature. Buyers should ensure that their teams are trained to set the desired PSI accurately for each tire type before use. Additionally, investing in a multi-functional inflator that supports both high-pressure and low-pressure applications will provide the versatility needed for diverse fleet requirements. Regular maintenance and calibration of the inflator can also enhance its performance, ensuring reliable operation across all tire types.

Das Problem: In high-demand environments, such as roadside assistance or busy automotive workshops, the battery life of the Ryobi inflator can become a significant pain point. Users may find themselves in situations where they need to inflate multiple tires rapidly, only to discover that the battery depletes quicker than expected. This situation not only delays service but can also frustrate customers waiting for assistance.

Die Lösung: To address battery life concerns, B2B buyers should consider acquiring additional Ryobi ONE+ batteries to ensure uninterrupted use during peak periods. The Ryobi system allows for interchangeable batteries across over 300 tools, which maximizes efficiency. Implementing a battery management strategy, such as rotating batteries and maintaining a charging schedule, can keep inflators powered and ready for use. It may also be beneficial to evaluate the inflator’s power consumption during use and communicate these insights to staff, so they can manage expectations and plan accordingly during high-demand situations.

Illustrative image related to ryobi car tire inflator

Das Problem: For businesses that operate in mobile environments—like tire repair services or outdoor events—having a compact, portable inflator is crucial. However, users often face challenges with the size and accessibility of their inflator, making it cumbersome to transport and use in various locations. This can lead to inefficiencies, especially when time is of the essence.

Die Lösung: The Ryobi car tire inflator is designed with portability in mind, but optimizing its use involves strategic planning. Buyers should consider investing in protective carrying cases that allow for easy transport and organization of the inflator and its accessories. Additionally, leveraging the inflator’s on-board accessory storage can streamline operations, ensuring that necessary attachments are always at hand. Encouraging teams to practice quick setup and breakdown procedures will also enhance efficiency on the job. Lastly, assessing the specific needs of the mobile operation can help buyers determine if additional accessories, such as longer hoses or specialized attachments, are necessary for particular tasks, ultimately increasing the inflator’s usability in various scenarios.

When selecting materials for the RYOBI car tire inflator, it is crucial to consider the performance characteristics, cost implications, and regional compliance standards. Below is a detailed analysis of four common materials used in the construction of tire inflators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Kunststoff is often used in the housing and components of tire inflators due to its lightweight nature and versatility. Common plastics include ABS (Acrylonitrile Butadiene Styrene) and Polypropylene.

Metals, particularly aluminum and steel, are commonly used for components that require higher strength and durability.

Gummi is primarily used for seals and hoses in tire inflators, providing flexibility and airtight performance.

Verbundwerkstoffe, such as fiberglass-reinforced plastics, are increasingly used in advanced inflator designs for their strength and lightweight properties.

| Material | Typical Use Case for ryobi car tire inflator | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kunststoff | Housing and external components | Leicht und kostengünstig | Limited pressure handling | Niedrig |

| Metal (Aluminum) | Pressure chambers and fittings | Hohe Festigkeit und Korrosionsbeständigkeit | Schwerer und teurer | Med |

| Gummi | Dichtungen und Schläuche | Ausgezeichnete Dichtungseigenschaften | Verschlechtert sich mit der Zeit | Niedrig |

| Verbundwerkstoffe | Advanced designs for lightweight inflators | Hohes Verhältnis von Festigkeit zu Gewicht | Höhere Fertigungskomplexität | Hoch |

This material selection guide provides essential insights for B2B buyers in diverse markets, helping them make informed decisions that align with performance needs and regulatory requirements.

The manufacturing process for the Ryobi car tire inflator involves several critical stages, each designed to ensure quality and performance.

The first stage is material preparation, where raw materials such as high-quality plastics, metals, and electronic components are sourced. Suppliers must meet strict specifications to ensure durability and performance. Materials are often tested for strength, resistance to wear, and compatibility with the inflator’s design. For international B2B buyers, it’s essential to verify that suppliers adhere to relevant material standards, such as RoHS compliance for electronics, to ensure safety and environmental responsibility.

Next, the forming stage encompasses processes like injection molding for plastic components and machining for metal parts. Advanced techniques, including CNC machining, are often employed to create precise components that fit together seamlessly. This stage is critical as it directly impacts the inflator’s reliability and efficiency. Buyers should inquire about the technologies used in forming processes, as modern machinery can significantly enhance the precision and consistency of production.

Illustrative image related to ryobi car tire inflator

The assembly phase is where individual components are brought together. Automated assembly lines are commonly used to enhance efficiency and reduce human error. This stage often involves the integration of electronic systems, such as the digital pressure gauge and auto shut-off features, which are vital for the inflator’s functionality. B2B buyers should assess whether the assembly process includes rigorous checks at various points to prevent defects from reaching the final product.

Finally, the finishing stage involves quality checks, surface treatment, and packaging. Surface treatments may include painting or coating to enhance aesthetics and protect against corrosion. This stage also involves final inspections where the product is tested for functionality, including pressure tests to ensure the inflator can achieve its rated PSI. Buyers should ensure that the manufacturer provides comprehensive documentation of the finishing processes and the tests conducted.

Quality assurance is a cornerstone of the manufacturing process, ensuring that every Ryobi car tire inflator meets both international standards and customer expectations.

Manufacturers typically adhere to several international quality standards, such as ISO 9001, which focuses on quality management systems. This certification assures buyers that the manufacturer has implemented effective processes to maintain quality throughout production. Additionally, product-specific certifications like CE marking in Europe and compliance with UL standards in the U.S. demonstrate adherence to safety and performance requirements.

Quality control (QC) is divided into several checkpoints throughout the manufacturing process:

Eingehende Qualitätskontrolle (IQC): This is the initial stage where raw materials are inspected upon arrival. Suppliers are evaluated based on their quality records, and materials that do not meet specifications are rejected.

Prozessbegleitende Qualitätskontrolle (IPQC): During manufacturing, continuous monitoring occurs at various stages. This includes checking tolerances and ensuring that assembly procedures are followed correctly. Automated systems may be used to track performance metrics in real-time.

Endgültige Qualitätskontrolle (FQC): Before packaging, the final product undergoes rigorous testing. This includes pressure tests, functionality assessments, and visual inspections. Only products that pass all tests are approved for shipment.

Several testing methods are employed to ensure the inflators meet safety and performance standards:

Funktionsprüfung: Each inflator is tested for its ability to reach the specified PSI and ensure the auto shut-off feature operates correctly.

Dauerhaftigkeitsprüfung: Products are subjected to extended use scenarios to evaluate their performance over time. This might include thermal cycling tests to simulate extreme temperature changes.

Sicherheitsprüfung: Compliance with electrical safety standards is verified through insulation resistance tests and leakage current tests.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

Conducting supplier audits is one effective method. Buyers should request to see the manufacturer’s certifications and audit reports to confirm compliance with international standards. It’s also beneficial to arrange for third-party inspections where an independent entity evaluates the manufacturing processes and quality control measures.

Buyers can ask for regular quality reports that detail inspection results, testing outcomes, and any corrective actions taken. This documentation provides insight into the manufacturer’s commitment to quality and areas for improvement.

Illustrative image related to ryobi car tire inflator

International buyers should be aware of specific nuances in quality control that can impact their purchasing decisions.

In regions such as Africa and South America, logistical challenges can arise that affect the supply chain and product availability. Ensuring that manufacturers have contingency plans and robust quality assurance practices can mitigate these risks.

Language and cultural differences can complicate communication regarding quality standards. Buyers should consider working with local representatives or consultants who understand both the regional market and the manufacturer’s practices to facilitate clearer communication.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing Ryobi car tire inflators, ensuring they select a supplier that meets their quality expectations and operational needs.

Sourcing a reliable and efficient Ryobi car tire inflator can significantly enhance your operations, particularly in the automotive and retail sectors. This practical guide outlines essential steps to ensure that you procure the right product for your needs while establishing a robust relationship with suppliers. By following this checklist, B2B buyers can confidently navigate the procurement process and make informed decisions.

Before initiating the procurement process, it is vital to clearly define your technical specifications. Consider the inflator’s maximum pressure, power source (e.g., battery voltage), and additional features like auto shut-off and digital pressure gauges. Understanding these specifications will help you align your requirements with the capabilities of the inflator, ensuring it meets your operational needs.

Conduct thorough research to identify potential suppliers of Ryobi inflators. Utilize online platforms, industry trade shows, and professional networks to gather a list of reputable suppliers. Look for companies that specialize in power tools and automotive accessories, as they will likely have a deeper understanding of your requirements and offer competitive pricing.

It is essential to verify that your chosen suppliers meet industry standards and certifications. Check for compliance with local regulations, quality management systems (like ISO certifications), and safety standards. Suppliers with recognized certifications can provide assurance of product quality and reliability, minimizing risks in your procurement process.

Before finalizing a purchase, request product samples and relevant technical documentation from potential suppliers. This allows you to evaluate the inflator’s performance and ensure it aligns with your specifications. Additionally, reviewing technical documentation, such as user manuals and warranty information, will help you understand the product’s features and maintenance requirements.

Illustrative image related to ryobi car tire inflator

Compare pricing from different suppliers while considering the total cost of ownership, including shipping and handling. Assess payment terms to determine if they align with your budgetary constraints. Negotiating favorable terms can enhance your cash flow management and ensure that you receive the best value for your investment.

After-sales support is crucial for any B2B purchase. Inquire about the warranty options and after-sales services offered by suppliers. Understanding the support provided can help you resolve any potential issues efficiently and ensure that your investment remains protected.

Once you have completed your evaluations and negotiations, finalize the purchase agreement with the chosen supplier. Ensure that all terms, including delivery timelines, pricing, and warranty conditions, are clearly outlined in the contract. This step is essential for establishing a mutual understanding and safeguarding your interests throughout the procurement process.

By following this checklist, B2B buyers can effectively source Ryobi car tire inflators, ensuring that they meet their operational needs while fostering strong supplier relationships.

When evaluating the cost structure of sourcing a RYOBI car tire inflator, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Materialien: The primary materials used in inflator production typically involve high-quality plastics, metals, and electronic components. The selection of materials can significantly impact the durability and functionality of the inflator, influencing overall costs.

Arbeit: Labor costs vary depending on the region and the complexity of the assembly process. In countries with lower labor costs, such as Vietnam and Brazil, sourcing can be more economical, but quality control must be emphasized to ensure product reliability.

Fertigungsgemeinkosten: This includes utilities, facility maintenance, and administrative expenses. Efficient manufacturing practices can help lower these overhead costs, ultimately benefiting buyers.

Werkzeugbau: The initial setup for production, including molds and specialized machinery, can represent a significant upfront investment. Buyers may need to consider these costs when negotiating contracts, especially for custom inflator designs.

Qualitätskontrolle (QC): Ensuring product quality is essential, particularly for safety equipment like tire inflators. Implementing rigorous QC protocols may increase costs but can save buyers from potential liabilities and warranty claims.

Logistik: Transportation costs can vary widely based on the shipping methods chosen and the distances involved. Understanding the Incoterms can help buyers manage these costs effectively.

Marge: Supplier margins can fluctuate based on the supplier’s market position and product demand. Understanding these margins can empower buyers during negotiations.

Several factors influence the pricing of RYOBI car tire inflators, which international B2B buyers should consider:

Illustrative image related to ryobi car tire inflator

Volumen und Mindestbestellmenge (MOQ): Pricing often decreases with higher order volumes. Buyers should assess their inventory needs and aim for bulk purchasing to achieve better pricing.

Spezifikationen und Anpassungen: Custom features can elevate costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

Materialien und Qualitätszertifikate: Sourcing higher-grade materials and certified products often incurs higher costs. Buyers need to balance quality with budget constraints, especially in competitive markets.

Lieferanten-Faktoren: The reputation and reliability of suppliers can affect pricing. Established suppliers might offer better warranties and support, justifying higher costs.

Incoterms: Understanding shipping terms is crucial for calculating the total landed cost. Buyers should negotiate terms that minimize risk and costs, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight).

International B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing RYOBI car tire inflators:

Negotiation Skills: Building strong relationships with suppliers can lead to better pricing and terms. Engage in transparent negotiations to understand potential discounts for larger orders or long-term contracts.

Gesamtbetriebskosten (TCO): Assess the TCO, which includes purchase price, maintenance, warranty, and potential resale value. This holistic approach can help buyers make informed decisions beyond just the initial cost.

Nuancen der Preisgestaltung für internationale Märkte: Understand regional market dynamics. For instance, buyers in Africa and South America may face different import duties and taxes compared to European buyers, influencing the final price.

Marktforschung: Conducting thorough market research can reveal competitive pricing and help identify potential alternative suppliers. This knowledge can empower buyers during negotiations and sourcing decisions.

In summary, understanding the intricate cost structure and pricing influencers of RYOBI car tire inflators can help international B2B buyers make informed and strategic sourcing decisions. By leveraging negotiation skills and considering the total cost of ownership, buyers can achieve greater cost efficiency and value in their procurement processes.

In the automotive maintenance sector, choosing the right tire inflator can significantly impact operational efficiency and customer satisfaction. While the RYOBI Car Tire Inflator is a popular choice for its versatility and performance, several alternative solutions exist that may better serve specific business needs. This analysis provides a comparative overview of the RYOBI inflator against two viable alternatives: a traditional air compressor and a portable battery-operated inflator.

| Vergleich Aspekt | Ryobi Car Tire Inflator | Traditional Air Compressor | Portable Battery-Operated Inflator |

|---|---|---|---|

| Leistung | Up to 160 PSI with auto shut-off | High PSI, consistent output | Varies, generally lower than Ryobi |

| Kosten | Moderate ($64.97 – $89.97) | Higher initial investment ($150 – $300) | Lower cost ($30 – $70) |

| Leichte Implementierung | User-friendly with onboard storage | Requires setup and space | Extremely portable, easy to use |

| Wartung | Low, minimal upkeep | Moderate, oil changes and filter checks | Low, typically requires battery checks |

| Bester Anwendungsfall | Ideal for automotive and sports equipment | Best for heavy-duty, continuous use | Suitable for light, on-the-go tasks |

Traditional air compressors are robust machines often used in workshops and garages. They provide a high volume of air at a consistent pressure, making them ideal for commercial applications where multiple tires need inflating quickly. However, they require a larger space for setup and may involve higher costs, both in terms of initial purchase and ongoing maintenance. Additionally, they are less portable, making them impractical for roadside assistance.

Portable battery-operated inflators are lightweight and designed for convenience. They are an excellent option for quick fixes and emergencies, especially in remote areas where access to power is limited. While they are typically less powerful than the RYOBI inflator, they excel in portability and ease of use. However, the battery life may limit their effectiveness for larger tasks, and they may not reach the higher PSI levels needed for all vehicles.

When selecting the appropriate tire inflation solution, B2B buyers should consider factors such as performance requirements, cost constraints, and ease of use. The RYOBI Car Tire Inflator stands out for its high performance and user-friendly design, making it ideal for businesses that need reliable and precise inflation for various applications. However, if the operation demands heavy-duty performance or extreme portability, traditional air compressors or battery-operated inflators might be more suitable. Ultimately, understanding the specific needs of your business will guide you in making the best choice for tire inflation solutions.

Understanding the technical specifications of the Ryobi car tire inflator is crucial for B2B buyers looking to make informed purchasing decisions. Here are some key properties:

Druckstufe (PSI)

The inflator can reach up to 160 PSI, making it suitable for various applications beyond just car tires, including bicycles and sports equipment. This versatility is essential for businesses that require a single tool for multiple inflation tasks, reducing the need for various devices.

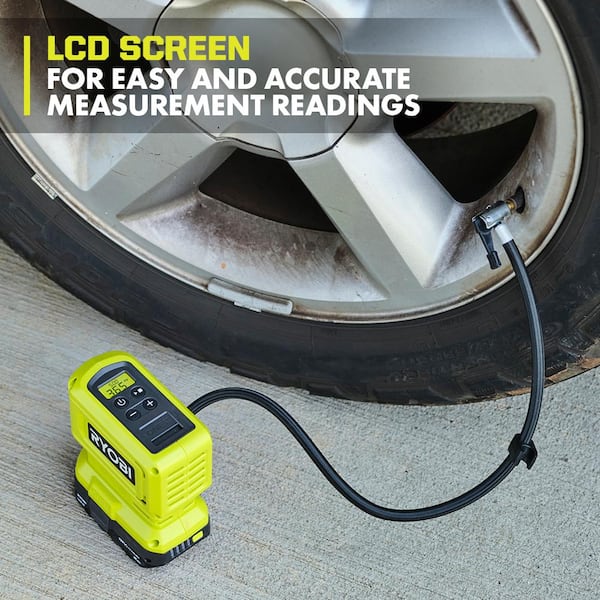

Digital Pressure Gauge

Equipped with an LCD screen, the digital pressure gauge provides accurate readings, ensuring that users can achieve precise inflation. This feature minimizes the risk of over-inflation, which can lead to safety hazards, thus appealing to companies focused on compliance and safety standards.

Auto Shut-off Feature

This inflator automatically shuts off when the desired pressure is reached. This not only enhances user convenience but also prevents damage to the tire or object being inflated, making it a reliable option for businesses that prioritize efficiency and safety.

Battery Compatibility (RYOBI ONE+ System)

The inflator operates on an 18V battery compatible with over 300 other Ryobi tools, promoting flexibility and reducing the need for multiple battery types. This is particularly beneficial for businesses that already utilize Ryobi tools, allowing for streamlined operations and cost savings.

On-board Accessory Storage

The design includes storage for essential accessories, such as nozzles and hoses, ensuring that users have everything they need at hand. This feature is vital for operational efficiency, particularly in mobile applications or for businesses that require quick setups.

Gewicht und Tragbarkeit

Weighing in at a manageable level, the inflator is designed for easy transport. For B2B buyers, the lightweight and portable nature of the tool means it can be used in various locations, enhancing its practicality for service providers and contractors.

Familiarity with industry terminology can enhance communication and negotiation in the B2B space. Here are some key terms:

Illustrative image related to ryobi car tire inflator

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to ensure quality and compatibility with existing products.

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ can help businesses manage inventory and budget effectively, ensuring they do not overcommit financially.

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. This process is essential for comparing prices and ensuring competitive sourcing, particularly for bulk purchases.

Incoterms (Internationale Handelsklauseln)

These are a set of predefined commercial terms published by the International Chamber of Commerce, which are widely used in international transactions. Understanding Incoterms can help B2B buyers clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

Vorlaufzeit

This term refers to the time it takes from placing an order to receiving the product. For businesses, understanding lead times is critical for planning and inventory management, ensuring that they can meet customer demands without delay.

Garantie

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the promise to repair or replace it if necessary. Knowing the warranty terms can significantly affect purchasing decisions, as it reflects the manufacturer’s confidence in their product quality.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing the Ryobi car tire inflator, ultimately leading to better procurement strategies and operational efficiencies.

The global market for tire inflators, particularly in the context of Ryobi’s offerings, is experiencing notable growth driven by increased consumer demand for portable and efficient solutions for tire maintenance. Key trends influencing this sector include the rise of cordless technology, as evidenced by the popularity of Ryobi’s 18V ONE+ system, which provides versatility across multiple tools with a single battery platform. Additionally, an increasing focus on smart technology is shaping product features, with digital pressure gauges and auto shut-off mechanisms becoming standard to enhance user experience and safety.

International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should be aware of regional market dynamics that impact sourcing strategies. For instance, the growing automotive sector in Brazil and Vietnam is fueling demand for reliable tire maintenance tools. Furthermore, the emphasis on e-commerce in these regions is reshaping procurement processes, making it essential for buyers to consider suppliers who can offer robust online platforms and efficient logistics to meet rapid delivery expectations.

Sustainability is increasingly becoming a critical factor for B2B buyers in the tire inflator market. Environmental concerns surrounding plastic waste and energy consumption are pushing companies to seek products that minimize their ecological footprint. Ryobi, being a part of the larger tool ecosystem, is expected to adhere to sustainable practices, which includes using recycled materials and reducing harmful emissions during production.

Ethical sourcing is another imperative for international buyers, particularly those aiming to enhance their corporate social responsibility (CSR) profiles. Suppliers must demonstrate compliance with ethical labor practices and environmental standards. Certifications like ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. For buyers in emerging markets, aligning with suppliers who prioritize ‘green’ certifications and materials not only enhances brand reputation but can also open new market opportunities as consumers increasingly favor eco-friendly products.

Illustrative image related to ryobi car tire inflator

Ryobi has established itself as a trusted name in the power tools and outdoor equipment sectors since its inception in 1943. Initially focusing on manufacturing die-cast products, the company evolved to include power tools in the 1960s. The introduction of the Ryobi ONE+ system marked a significant milestone, allowing users to operate multiple tools with a single battery platform, which has become a cornerstone of their product offerings, including car tire inflators.

The evolution of tire inflators within the Ryobi range reflects broader industry advancements, such as the shift toward cordless and portable solutions that cater to the needs of modern consumers. As the market continues to evolve, Ryobi’s commitment to innovation positions it well to meet the demands of B2B buyers seeking reliable, efficient, and sustainable tire maintenance solutions.

How do I solve issues with my RYOBI tire inflator not reaching the desired PSI?

If your RYOBI tire inflator isn’t reaching the desired PSI, first ensure that the nozzle is properly attached to the tire valve. Check for any air leaks in the connections or the hose. If the inflator has a digital pressure gauge, verify that it is functioning correctly. In some cases, recalibrating the gauge may be necessary. Ensure that the battery is fully charged, as low power can affect performance. If problems persist, consult the user manual for troubleshooting tips or contact customer support for assistance.

What is the best tire inflator for international shipping and usage?

The RYOBI 18V ONE+ High Pressure Inflator is an excellent choice for international buyers due to its compact design and dual functionality. It inflates up to 160 PSI, making it versatile for various applications, including car tires, bike tires, and sports equipment. Its cordless feature ensures ease of use in different environments without the need for a power outlet. Additionally, the availability of battery packs across global markets makes it convenient for users in regions like Africa, South America, and Europe.

What are the minimum order quantities (MOQ) for purchasing RYOBI inflators in bulk?

MOQs for RYOBI inflators can vary by supplier and region. Generally, distributors may require a minimum order of 10 to 50 units for bulk purchases. It’s advisable to contact your chosen supplier directly to inquire about specific MOQs, as they might offer flexibility based on your business needs or potential for future orders. Establishing a solid relationship with your supplier can also help negotiate better terms.

What payment terms should I expect when sourcing RYOBI inflators?

Payment terms can vary significantly depending on the supplier and your negotiation. Common terms include a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers might offer credit terms based on your business’s creditworthiness. Always ensure that payment terms are clearly outlined in your purchase agreement to avoid misunderstandings. It’s also advisable to use secure payment methods to mitigate risks.

How can I ensure quality assurance for RYOBI tire inflators?

To ensure quality assurance, request certifications and quality control reports from your supplier. Many manufacturers adhere to international standards, which can include ISO certifications. Additionally, consider asking for product samples before placing a bulk order to verify quality firsthand. Establishing a clear communication channel with your supplier for ongoing quality checks can help maintain high standards throughout your procurement process.

What logistics considerations should I keep in mind when importing RYOBI inflators?

When importing RYOBI inflators, consider shipping costs, lead times, and customs regulations in your destination country. Ensure you have a reliable freight forwarder who can handle international shipping and customs clearance. It’s essential to understand any import duties or taxes that may apply to your shipment. Additionally, plan for potential delays in shipping and customs processing, especially during peak seasons.

Are there customization options available for RYOBI tire inflators?

Customization options for RYOBI tire inflators may be limited, but some suppliers may offer branding or packaging modifications for bulk orders. If you require specific features or adaptations, discuss these needs with your supplier during the negotiation phase. Be clear about your requirements, as custom orders may impact lead times and costs. Always confirm the feasibility of customization before finalizing your order.

What should I look for when vetting suppliers for RYOBI inflators?

When vetting suppliers, consider their reputation, years in business, and customer reviews. Look for suppliers with a proven track record in handling RYOBI products or similar tools. Request references from past clients and verify their ability to meet your quality, pricing, and delivery expectations. It’s also beneficial to check if the supplier is authorized by RYOBI, as this can ensure authenticity and support in case of warranty claims or product issues.

Bereich: ryobitools.com

Registriert: 1999 (26 Jahre)

Einleitung: {“Product Name”: “18V ONE+ High Pressure Digital Inflator Kit”, “Model”: “PCL001K1”, “Price”: “$64.97 (originally $89.97)”, “Max Pressure”: “160 PSI”, “Features”: [“Digital pressure gauge for accurate filling”, “Auto shut-off when desired PSI is reached”, “On-board accessory storage”, “Hands-free use”], “Ideal For”: [“Filling car tires”, “Bike tires”, “Sports balls”]}

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: The Ryobi inflator is part of the ONE+ battery system, making it convenient for users who already own Ryobi batteries. It has dual functionality for high pressure and high volume applications. Users have noted that while it is easy to use and portable, it may be slower compared to larger compressors, especially for tasks like airing up tires after off-roading. The P737D model is a generic design w…

The RYOBI car tire inflator represents a significant opportunity for B2B buyers seeking reliable and efficient inflation solutions. Its features, such as the ability to inflate up to 160 PSI and an auto shut-off function, cater to diverse markets, from automotive industries to sports equipment retailers. The versatility of the RYOBI 18V ONE+ platform, which supports over 300 tools, enhances its appeal, offering businesses a cohesive ecosystem that can streamline operations and reduce costs.

Strategic sourcing of the RYOBI inflator enables businesses to secure high-quality products at competitive prices, fostering long-term relationships with suppliers. By investing in this innovative inflator, companies can improve service offerings, meet customer demands for convenience, and enhance operational efficiency.

Illustrative image related to ryobi car tire inflator

Looking ahead, as global markets continue to evolve, the demand for portable and versatile tools like the RYOBI inflator is expected to grow. International B2B buyers from Africa, South America, the Middle East, and Europe should act now to integrate this product into their offerings, positioning themselves at the forefront of a rapidly advancing market. Embrace this opportunity to enhance your product lineup and cater to the needs of your customers effectively.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.