In today’s dynamic automotive landscape, sourcing reliable tire gauges from AutoZone presents a significant challenge for international B2B buyers. Ensuring proper tire pressure is essential not only for vehicle performance but also for safety and fuel efficiency, making the selection of an appropriate tire gauge critical. This comprehensive guide delves into the diverse types of tire gauges available, their applications across various vehicle types, and the importance of supplier vetting to ensure quality and reliability.

As the global market for automotive supplies continues to expand, B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—face unique considerations. This guide is designed to empower these buyers by providing actionable insights into pricing strategies, cost-effectiveness, and the latest technological advancements in tire gauge design.

By navigating through this detailed resource, you will be equipped to make informed purchasing decisions that align with your operational needs. Whether you’re looking to enhance your fleet’s maintenance capabilities or seeking to expand your product offerings, understanding the nuances of tire gauges can significantly impact your bottom line and customer satisfaction. With the right information, you can confidently approach suppliers and secure the best products for your business.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Analog Tire Pressure Gauge | Mechanical dial or stick for reading pressure; no batteries required | Automotive repair shops, fleet maintenance | Vorteile: Simple to use, no power source needed. Nachteile: Can be less precise than digital gauges. |

| Digital Tire Pressure Gauge | Electronic display with precise readings; may include backlighting | Automotive services, tire retailers | Vorteile: High accuracy, easy to read, often includes multiple units. Nachteile: Requires batteries, can be more expensive. |

| Digital Tire Inflator | Combines inflation and pressure measurement; often includes a display | Tire service centers, roadside assistance | Vorteile: Multi-functional, quick inflation, user-friendly. Nachteile: Bulkier than standalone gauges, may require more maintenance. |

| Tire Pressure Monitoring System (TPMS) | Integrated system in vehicles that alerts for low pressure | Automotive manufacturers, fleet management | Vorteile: Continuous monitoring, alerts drivers automatically. Nachteile: May not provide precise pressure readings, can be expensive to replace. |

| Portable Tire Gauge | Compact, handheld device for easy transport; often includes a clip | Mobile mechanics, DIY automotive enthusiasts | Vorteile: Highly portable, affordable, easy to store. Nachteile: May lack advanced features, can be less durable. |

Analog tire pressure gauges utilize a mechanical dial or stick to indicate tire pressure. They do not require batteries, making them a reliable choice for automotive repair shops and fleet maintenance operations. While they are simple to use, their accuracy can vary, which is a critical consideration for businesses that depend on precise tire pressure readings. Buyers should weigh the benefits of low cost and ease of use against potential inaccuracies in tire pressure readings, particularly in high-stakes environments.

Digital tire pressure gauges offer enhanced precision with electronic displays that provide clear readings, often with backlighting for visibility in low-light conditions. These gauges are ideal for automotive services and tire retailers, where accuracy is paramount. While they tend to be more expensive and require batteries, the investment often pays off in terms of reliability and ease of use. B2B buyers should consider the frequency of use and the importance of accuracy when evaluating digital gauges.

Digital tire inflators combine the functions of inflating tires and measuring pressure, making them invaluable in tire service centers and roadside assistance operations. They feature user-friendly interfaces and can quickly inflate tires while providing accurate pressure readings. However, their bulkier design and maintenance requirements may deter some buyers. Businesses should assess their operational needs and space constraints when considering these multi-functional tools.

TPMS are integrated systems that continuously monitor tire pressure and alert drivers when levels drop below recommended thresholds. They are increasingly common in new vehicles and serve automotive manufacturers and fleet management companies well. While they provide real-time monitoring and enhance safety, replacement costs can be high, and they may not deliver precise readings. Businesses must evaluate the long-term benefits of safety and convenience against the investment required for these systems.

Portable tire gauges are compact, handheld devices that are easy to transport, making them perfect for mobile mechanics and DIY automotive enthusiasts. Their affordability and convenience are significant advantages, but they may lack the advanced features found in larger models. B2B buyers should consider how often they will use these gauges and whether the simplicity outweighs the need for more precise or multifunctional options.

| Industrie/Sektor | Specific Application of tire gauge autozone | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Routine tire pressure checks for customer vehicles | Ensures vehicle safety, enhances customer satisfaction, and prolongs tire life | Bulk purchasing options, reliability of product accuracy, and after-sales support |

| Logistics and Transportation | Regular tire maintenance for fleet vehicles | Reduces operational costs through improved fuel efficiency and tire longevity | Compatibility with various vehicle types, ease of use, and durability in harsh conditions |

| Manufacturing and Heavy Industry | Maintenance of industrial vehicles and equipment | Enhances safety and efficiency, reduces downtime due to tire issues | Precision measurement features, resistance to wear and tear, and availability of various pressure units |

| Agricultural Sector | Checking tire pressure on farm machinery | Increases productivity and reduces fuel consumption for agricultural operations | Adaptability to different tire types, ease of handling, and local availability of service support |

| Construction and Mining | Tire pressure monitoring for heavy machinery | Prevents accidents, reduces maintenance costs, and ensures optimal equipment performance | Robust construction, accuracy under extreme conditions, and support for international standards |

In automotive repair shops, tire gauges from AutoZone are essential for conducting routine tire pressure checks on customer vehicles. Regular checks help ensure that tires are inflated to the recommended pressure, which is critical for vehicle safety and performance. By maintaining proper tire pressure, repair shops can enhance customer satisfaction through improved vehicle handling and safety, while also prolonging the life of the tires. International buyers should consider sourcing gauges that offer reliability and accuracy, as well as bulk purchasing options to manage inventory effectively.

For logistics and transportation companies, maintaining tire pressure in fleet vehicles is crucial for operational efficiency. Accurate tire gauges help monitor and adjust tire pressure, leading to reduced rolling resistance and improved fuel efficiency. This not only lowers operational costs but also extends tire life, minimizing downtime for maintenance. Buyers in this sector should prioritize gauges that are easy to use, compatible with various vehicle types, and durable enough to withstand the demands of frequent use in diverse environments.

In manufacturing and heavy industries, tire gauges are vital for maintaining the safety and efficiency of industrial vehicles and equipment. Regular tire pressure checks can prevent accidents and equipment malfunctions, thereby reducing downtime and maintenance costs. For international buyers, sourcing gauges that provide precise measurements and are resistant to wear and tear is essential, especially in environments where machinery operates under extreme conditions.

In the agricultural sector, checking tire pressure on farm machinery can significantly impact productivity. Properly inflated tires ensure optimal performance and reduce fuel consumption, which is crucial for the cost-sensitive agricultural industry. Buyers should look for gauges that are adaptable to various tire types and easy to handle, as well as those that provide local service support for maintenance and calibration.

For construction and mining operations, tire pressure monitoring is critical for the safety and performance of heavy machinery. Using tire gauges helps prevent accidents caused by blowouts or tire failures, while also ensuring that equipment operates efficiently. Buyers in these industries should focus on robust gauges that can deliver accurate readings under extreme conditions, as well as those that comply with international safety standards to ensure reliability across different regions.

Das Problem: B2B buyers managing fleets often encounter challenges with inconsistent tire pressure monitoring across multiple vehicles. Each vehicle may have different tire pressure specifications, leading to confusion and potential safety risks. In addition, fluctuating weather conditions can cause pressure variations that are difficult to track, resulting in increased tire wear, reduced fuel efficiency, and potential breakdowns. This inconsistency can lead to higher operational costs and negatively impact overall fleet performance.

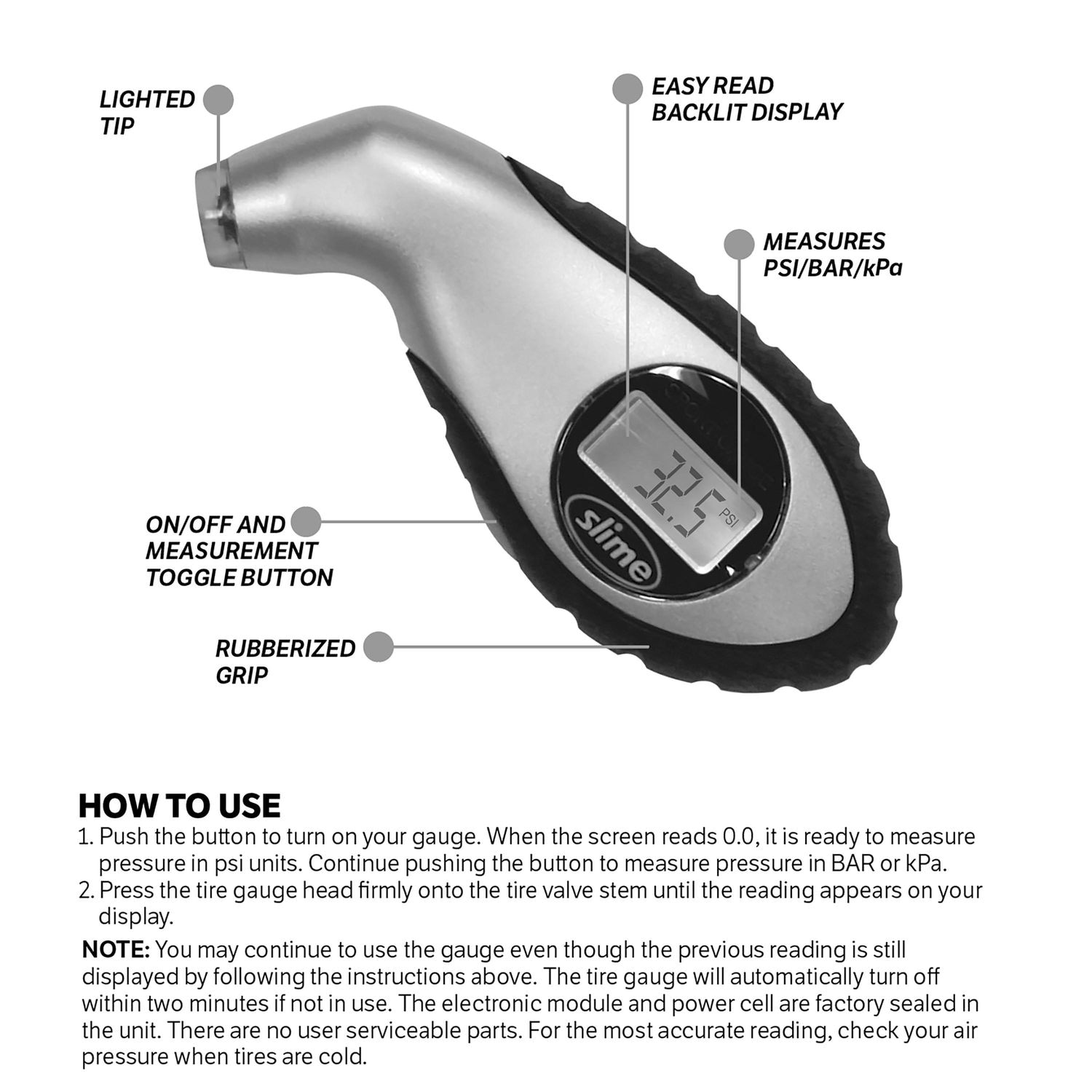

Die Lösung: To address this issue, B2B buyers should invest in high-quality tire pressure gauges from AutoZone, such as digital inflators that offer multiple pressure unit options (PSI, bar, kPa). Implement a standardized tire pressure management system across the fleet that includes regular checks—ideally weekly or before long trips. Establish protocols for drivers to check tire pressures at the start of their shifts, using easy-to-read gauges that minimize errors. Additionally, consider integrating a centralized monitoring system that alerts fleet managers to any deviations from recommended pressures. By prioritizing regular maintenance and utilizing precise tire pressure gauges, companies can enhance safety and reduce costs associated with tire wear and fuel inefficiency.

Das Problem: In organizations with multiple teams responsible for vehicle maintenance, miscommunication regarding the correct tire pressure specifications can lead to errors. Different team members may have varying levels of experience or access to information about specific vehicle models, resulting in incorrect tire inflation. This lack of clarity can lead to inconsistent tire performance, which may cause safety hazards and increase the likelihood of accidents or breakdowns.

Illustrative image related to tire gauge autozone

Die Lösung: To mitigate this challenge, B2B buyers should create a comprehensive tire maintenance manual tailored to their fleet, including detailed tire pressure specifications for each vehicle model. This manual should be easily accessible and regularly updated. When sourcing tire pressure gauges from AutoZone, choose models that provide clear and immediate readings to minimize the chance of misinterpretation. Additionally, training sessions for maintenance personnel can ensure that everyone understands how to check and adjust tire pressures accurately. By fostering a culture of communication and knowledge sharing, companies can ensure that all team members are aligned on tire specifications, thus improving vehicle safety and performance.

Das Problem: B2B buyers often struggle to find reliable and durable tire pressure gauges that can withstand heavy use in workshops or service stations. Many gauges available in the market may be inaccurate or fail to deliver consistent results, leading to frustration and potential safety risks. Inadequate tools can compromise the quality of maintenance services offered, affecting customer trust and satisfaction.

Die Lösung: To overcome sourcing challenges, B2B buyers should look for professional-grade tire pressure gauges available at AutoZone, such as the Vaper digital tire inflator. These gauges are designed for durability and accuracy, featuring a backlit display for easy readings in various lighting conditions. When purchasing, consider the gauge’s maximum pressure capacity and versatility (inflation, deflation, and pressure measurement) to ensure it meets the diverse needs of your operations. Additionally, establish a routine for calibrating gauges to maintain their accuracy over time. By investing in high-quality tools and ensuring they are well-maintained, businesses can enhance their service offerings and build stronger relationships with clients.

When selecting materials for tire gauges, it’s essential to consider various factors that impact performance, durability, and cost-effectiveness. The following analysis focuses on four common materials used in tire gauge construction: plastic, aluminum, stainless steel, and rubber. Each material has its unique properties and implications for international B2B buyers, particularly those operating in diverse environments like Africa, South America, the Middle East, and Europe.

Plastic is often used in the housings of tire gauges due to its lightweight and cost-effective nature. Key properties include good resistance to corrosion and a moderate temperature rating, typically around -20°C to 70°C. Plastics can be molded into complex shapes, allowing for ergonomic designs.

Profis: Plastic is generally low-cost and lightweight, making it an economical choice for high-volume production. It can also be produced in various colors, appealing to branding and aesthetic preferences.

Nachteile: Plastic is less durable than metals and may degrade under extreme temperatures or UV exposure. It can also be less precise in pressure readings compared to metal gauges.

Auswirkungen auf die Anwendung: Plastic gauges are suitable for light-duty applications and consumer markets but may not withstand rigorous industrial use.

Überlegungen für internationale Einkäufer: Buyers should ensure compliance with local regulations concerning plastic materials, particularly regarding recyclability and environmental impact. Standards such as ASTM D6400 for compostability may be relevant.

Aluminum is favored for its lightweight yet durable properties. It has excellent corrosion resistance and can withstand higher temperature ranges, typically from -40°C to 120°C. Its strength-to-weight ratio makes it ideal for portable tire gauges.

Profis: Aluminum is relatively inexpensive and offers a good balance between durability and weight. It can be easily machined and anodized for additional protection and aesthetics.

Nachteile: While aluminum is durable, it can be prone to dents and scratches, which may affect the gauge’s accuracy over time. Additionally, it may not be suitable for extreme pressure applications without reinforcement.

Auswirkungen auf die Anwendung: Aluminum gauges are versatile and can be used in various environments, making them suitable for both consumer and commercial applications.

Illustrative image related to tire gauge autozone

Überlegungen für internationale Einkäufer: Compliance with standards such as DIN EN 573 for aluminum alloys may be necessary. Buyers should also consider the availability of aluminum in their region to avoid supply chain disruptions.

Stainless steel is often used in high-end tire gauges due to its exceptional durability and resistance to corrosion. It typically maintains performance in a wide temperature range, from -50°C to 150°C, making it suitable for extreme conditions.

Profis: Stainless steel is highly durable and resistant to wear and tear, ensuring long-term accuracy and reliability. It also provides a premium feel, appealing to professional users.

Nachteile: The primary drawback is the higher cost compared to plastic and aluminum. Manufacturing stainless steel components can also be more complex, requiring specialized equipment.

Illustrative image related to tire gauge autozone

Auswirkungen auf die Anwendung: Stainless steel gauges are ideal for heavy-duty applications, including commercial and industrial use, where precision and durability are paramount.

Überlegungen für internationale Einkäufer: Buyers should ensure adherence to international standards such as ASTM A240 for stainless steel, especially in regions with stringent quality controls.

Rubber is primarily used for seals and grips in tire gauges. It offers excellent elasticity and can withstand a range of temperatures, typically from -30°C to 100°C. Rubber is also resistant to moisture and provides a non-slip grip.

Profis: Rubber enhances the functionality of tire gauges by providing a secure grip and protecting sensitive components from shock. It is relatively inexpensive and easy to source.

Nachteile: Rubber can degrade over time, especially when exposed to oils, UV light, and extreme temperatures. Its lifespan may be shorter compared to metal components.

Auswirkungen auf die Anwendung: Rubber components are essential for ensuring the longevity and reliability of tire gauges, particularly in consumer products.

Überlegungen für internationale Einkäufer: Compliance with standards such as ASTM D2000 for rubber materials is crucial. Buyers should also consider the climatic conditions of their region, as extreme temperatures can affect rubber performance.

| Material | Typical Use Case for tire gauge autozone | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kunststoff | Consumer-grade tire gauges | Leicht und kostengünstig | Weniger haltbar unter extremen Bedingungen | Niedrig |

| Aluminium | Portable and commercial tire gauges | Good strength-to-weight ratio | Anfällig für Dellen und Kratzer | Mittel |

| Rostfreier Stahl | Heavy-duty and industrial tire gauges | Exceptional durability and accuracy | Höhere Kosten und komplexere Herstellung | Hoch |

| Gummi | Seals and grips in tire gauges | Provides secure grip and shock protection | Verschlechtert sich mit der Zeit | Niedrig |

This analysis provides B2B buyers with insights into material selection for tire gauges, emphasizing the importance of considering performance, cost, and regional compliance standards.

The manufacturing process of tire gauges involves several critical stages that ensure the product meets high standards of quality and performance.

Illustrative image related to tire gauge autozone

The first stage is material preparation, which typically involves selecting high-quality materials for the gauge’s body, internal mechanisms, and display components. Common materials include durable plastics, stainless steel, and aluminum, which provide both resilience and accuracy. Suppliers often source these materials from certified vendors to ensure compliance with international quality standards.

Following material preparation, the next step is forming. This includes processes like injection molding for plastic parts and machining for metal components. The formed parts are then assembled using precision techniques to ensure that all components fit seamlessly. Automated assembly lines may be utilized to enhance efficiency, while skilled workers carry out final assembly tasks that require fine motor skills and attention to detail.

The finishing stage involves several techniques aimed at enhancing the product’s aesthetics and functionality. This may include surface treatments such as anodizing or painting to prevent corrosion, as well as applying protective coatings to ensure durability. Additionally, final inspections are performed to check for any defects or inconsistencies.

Illustrative image related to tire gauge autozone

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that every tire gauge meets specific performance criteria before reaching the market.

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with CE marking may also be necessary, indicating that the product meets European safety, health, and environmental protection requirements. For suppliers targeting the Middle Eastern markets, adherence to API standards can be crucial, particularly for products involving safety and reliability.

Quality control (QC) is integrated into various stages of the manufacturing process through checkpoints such as:

Testing methods for tire gauges typically include pressure accuracy tests, durability tests, and environmental tests. Pressure accuracy tests ensure that the gauge provides precise readings, while durability tests simulate real-world usage to confirm the product can withstand wear and tear. Environmental tests check the gauge’s performance under various temperature and humidity conditions, ensuring reliability across different climates.

For international B2B buyers, especially from regions like Africa, South America, and Europe, verifying supplier QC processes is essential to ensure product quality and compliance with local standards. Buyers can conduct audits to assess the supplier’s manufacturing processes and QC practices. Requesting detailed quality reports and certifications can provide insights into the supplier’s commitment to quality.

Third-party inspections can also be beneficial, as they offer an unbiased evaluation of the product quality and compliance with international standards. Engaging with accredited testing laboratories can provide additional verification of the tire gauge’s performance and safety.

International B2B buyers should be aware of the specific regulations and standards that apply to their regions. For instance, European buyers need to ensure CE compliance, while those in the Middle East may require adherence to local standards, which can differ significantly. Understanding these nuances can facilitate smoother transactions and reduce the risk of compliance issues.

Moreover, buyers from Africa and South America should consider the logistics of importing products that meet international standards. This includes ensuring that the supplier can provide all necessary documentation and certifications, which can streamline customs processes and avoid delays.

In summary, the manufacturing processes and quality assurance protocols for tire gauges are designed to ensure that products are reliable, accurate, and compliant with international standards. For B2B buyers, understanding these processes is crucial for making informed purchasing decisions. By focusing on suppliers that adhere to rigorous quality control practices and international standards, buyers can ensure that they receive high-quality tire gauges that meet their specific needs.

When sourcing tire gauges, particularly from AutoZone, it is essential for B2B buyers to follow a structured approach to ensure they make informed decisions. This guide outlines a practical checklist to facilitate the procurement process, focusing on quality, compatibility, and supplier reliability.

Begin by clearly defining the types of tire gauges required for your operations. Consider factors such as:

– Types of vehicles: Different gauges may be necessary for passenger cars, trucks, or heavy machinery.

– Pressure range: Ensure the gauges can measure the required PSI range suitable for your fleet.

Understanding your specific needs will streamline the sourcing process and help avoid unnecessary purchases.

Illustrative image related to tire gauge autozone

Explore various suppliers, focusing on those with a strong reputation in the tire gauge market. Key considerations include:

– Product range: Ensure they offer a variety of gauges, including digital and analog options.

– Availability of additional tools: Look for suppliers that also provide complementary tools like tire inflators and repair kits.

A diverse supplier base can enhance your procurement flexibility and provide opportunities for bulk purchasing.

Assess the quality of the tire gauges available from potential suppliers. Look for indicators such as:

– Material durability: Consider gauges made from high-quality materials that withstand regular use.

– User reviews: Read customer feedback to gauge reliability and accuracy.

Investing in high-quality gauges minimizes the risk of errors and enhances operational efficiency.

Before finalizing your supplier, check for relevant certifications and compliance with industry standards. Important certifications may include:

– ISO certification: Indicates adherence to quality management standards.

– Safety certifications: Ensure products meet safety regulations applicable in your region.

Certifications provide assurance of product quality and reliability, which is vital for maintaining safety standards in your operations.

Whenever possible, request samples of the tire gauges for testing before placing a bulk order. This allows you to:

– Evaluate performance: Test the accuracy and ease of use in real-world scenarios.

– Assess compatibility: Ensure the gauges meet your operational requirements and integrate well with existing tools.

Testing samples can prevent costly mistakes and help you select the best products for your needs.

Engage in negotiations with shortlisted suppliers to secure favorable terms. Consider aspects such as:

– Pricing structure: Inquire about bulk discounts and payment terms.

– Shipping options: Assess logistics, delivery times, and costs associated with importing to your region.

Effective negotiation can lead to better pricing and terms, ultimately enhancing your bottom line.

After placing your order, create a follow-up plan to monitor the performance of the tire gauges. This should include:

– Regular checks: Schedule periodic evaluations of the gauges to ensure they maintain accuracy.

– Supplier relationship management: Maintain communication with your supplier for ongoing support and feedback.

A proactive follow-up strategy will help you sustain quality and address any issues promptly, ensuring long-term satisfaction with your procurement.

By adhering to this checklist, B2B buyers can effectively navigate the procurement process for tire gauges, ensuring they secure the best products for their operational needs.

When considering the sourcing of tire gauges, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materialien: The choice of materials significantly impacts the overall cost. Tire gauges are commonly made from durable plastics or metals, each having different price points. High-quality materials may command a premium but can lead to longer-lasting products, reducing the need for frequent replacements.

Arbeit: Labor costs vary by region and can be influenced by local wage standards and skill levels. In countries with lower labor costs, such as certain regions in South America or Africa, sourcing may be more economical, yet this can affect the overall quality and consistency of the product.

Fertigungsgemeinkosten: This includes indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, which is beneficial for both the manufacturer and the buyer.

Werkzeugbau: The initial setup for production requires investment in tooling, which can be substantial. Custom designs or unique features will increase tooling costs, potentially leading to higher prices for the buyer.

Qualitätskontrolle (QC): Ensuring that tire gauges meet specific standards is essential. Implementing stringent QC processes may increase costs but is vital for maintaining product reliability, especially when dealing with international markets where compliance with safety standards is critical.

Logistik: Shipping and handling costs can vary significantly based on the destination. International buyers must factor in duties, taxes, and shipping fees, which can substantially affect the total cost of ownership.

Marge: Suppliers typically add a profit margin to the manufacturing cost, which can vary based on market conditions, demand, and competition.

Several factors can influence pricing for tire gauges, particularly for international buyers:

Volumen/MOQ: Bulk purchasing often leads to lower per-unit costs. Establishing a minimum order quantity (MOQ) can help suppliers maintain profitability while offering discounts to buyers.

Spezifikationen und Anpassungen: Customized tire gauges with specific features will typically incur higher costs. Buyers should weigh the necessity of these features against the additional expense.

Materialien und Qualitätszertifikate: The use of certified materials can increase costs but may be necessary for compliance with local regulations. Buyers should assess the quality certifications required in their regions.

Lieferanten-Faktoren: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers with a history of quality may charge a premium, but this often translates into better service and product reliability.

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential. These terms define the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability, influencing the final price.

Negotiation Strategies: Buyers should engage in open discussions about pricing and be willing to negotiate terms. Highlighting long-term relationships can encourage suppliers to offer better pricing.

Kosteneffizienz: Assess the total cost of ownership, not just the purchase price. Consider factors like durability, maintenance, and potential savings from using high-quality gauges that reduce tire wear.

Understanding Pricing Nuances: International buyers should be aware of regional price differences and exchange rates. This can significantly affect procurement costs, especially in volatile markets.

Logistics Planning: Include logistics in your pricing discussions. Understanding shipping routes, costs, and potential delays can lead to better budgeting and planning.

Marktforschung: Stay informed about market trends and competitor pricing. This knowledge can provide leverage in negotiations and help buyers secure the best deals.

While this analysis provides a comprehensive overview of the cost structure and pricing dynamics for tire gauges sourced from AutoZone, it is important to note that prices can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult with suppliers for the most accurate and current pricing.

When it comes to maintaining optimal tire pressure, having the right tools is essential. While the tire gauge available at AutoZone is a popular choice, various alternatives may better suit specific needs, especially for B2B buyers across diverse regions like Africa, South America, the Middle East, and Europe. This section provides a comparative analysis of the AutoZone tire gauge against other viable options, allowing businesses to make informed decisions based on performance, cost, and usability.

| Vergleich Aspekt | Tire Gauge AutoZone | Digital Tire Pressure Gauge | Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Leistung | Accurate readings, manual use | High accuracy, easy reading | Continuous monitoring, alerts for pressure drop |

| Kosten | $10 – $20 | $30 – $100 | $50 – $200+ depending on vehicle model |

| Leichte Implementierung | Simple, requires manual input | User-friendly, easy to use | Installed in vehicle, requires setup |

| Wartung | Low, requires no special care | Moderate, battery replacement needed | Low, but may require professional service |

| Bester Anwendungsfall | Individual tire checks | Quick checks for multiple vehicles | Fleet management and continuous monitoring |

The digital tire pressure gauge is an advanced alternative that provides high accuracy and a user-friendly interface. Unlike manual gauges, which require precise placement and reading, digital gauges display pressure readings on an easy-to-read screen. They typically come with additional features such as backlighting and various measurement units. However, they can be more expensive, ranging from $30 to $100, and may require battery replacements, adding to their maintenance needs. This option is ideal for businesses that need frequent tire checks across multiple vehicles and prioritize speed and convenience.

The Tire Pressure Monitoring System (TPMS) offers a comprehensive solution for tire pressure management by providing real-time monitoring. This system alerts drivers when tire pressure drops below a certain threshold, making it invaluable for fleet management where timely maintenance can prevent accidents and prolong tire life. While the initial cost can be higher (ranging from $50 to over $200 depending on vehicle type), the investment pays off through enhanced safety and reduced downtime. However, TPMS requires proper installation and occasional professional servicing, which may be a consideration for some buyers.

When selecting the most suitable tire pressure measurement solution, B2B buyers should consider their specific operational needs. For businesses requiring frequent tire checks on multiple vehicles, a digital tire pressure gauge may offer the right balance of accuracy and ease of use. Conversely, companies managing larger fleets may find that a TPMS provides the necessary oversight to ensure optimal tire performance and safety. Ultimately, understanding the unique demands of your operations will guide you in choosing the best tire pressure solution, allowing for improved vehicle safety and efficiency in your fleet management.

When selecting tire gauges from AutoZone for B2B procurement, understanding the essential technical properties is crucial. Here are some critical specifications that define the quality and functionality of tire gauges:

Pressure Measurement Range

Tire gauges typically have a specific range of pressure measurements, often between 0 to 174 PSI. This range is vital for ensuring compatibility with various vehicle types, from passenger cars to heavy-duty trucks. Knowing the measurement range helps buyers choose a gauge that meets their specific operational needs.

Accuracy Tolerance

Accuracy tolerance refers to the permissible deviation from the true pressure reading, usually expressed as a percentage. A tolerance of ±1 PSI is standard for high-quality gauges. This precision is crucial for maintaining optimal tire pressure, which affects vehicle safety, fuel efficiency, and tire longevity. B2B buyers should prioritize gauges with tight tolerances to ensure reliable performance.

Materialzusammensetzung

The materials used in the construction of tire gauges, such as aluminum die-cast and rubber, play a significant role in durability and ease of use. A robust gauge can withstand harsh working conditions, making it suitable for both professional and non-professional settings. Buyers should consider the material composition to ensure longevity and reliability.

Display Type

Tire gauges come with various display types, including analog dials, digital screens, and backlit displays. A digital gauge with a backlit feature is particularly advantageous for use in low-light conditions. Choosing the right display type enhances usability and ensures accurate readings, which is essential for maintaining tire health.

Multi-Functionality

Many modern tire gauges offer multi-functional capabilities such as inflating, deflating, and measuring tire pressure. This versatility can streamline operations for businesses that require quick and efficient tire maintenance. B2B buyers should assess whether a multi-functional tool can provide added value to their service offerings.

Pressure Units

Tire gauges may measure pressure in various units, including PSI, bar, kPa, and kgf. A gauge that offers multiple pressure unit options increases its usability across different markets. Understanding the units of measurement helps international buyers ensure compatibility with their local standards.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms that buyers should be familiar with:

Illustrative image related to tire gauge autozone

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tire gauges, purchasing OEM products ensures that the gauges meet the original specifications set by vehicle manufacturers, enhancing reliability.

MOQ (Mindestbestellmenge)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs effectively. It helps them plan their purchases according to operational needs and budget constraints.

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. This term is vital for initiating negotiations and obtaining competitive pricing for tire gauges.

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and insurance responsibilities when procuring tire gauges internationally.

Vorlaufzeit

Lead time refers to the amount of time it takes from placing an order to receiving it. Understanding lead times is essential for inventory management, especially when planning for seasonal demands or product launches.

Gewährleistungsfrist

The warranty period defines the duration for which a manufacturer guarantees the performance of a product. A clear warranty policy is crucial for B2B buyers to ensure they receive support for defects or failures, enhancing the overall value of the purchase.

In summary, understanding both the technical properties and trade terminology associated with tire gauges at AutoZone is essential for making informed B2B purchasing decisions. This knowledge empowers international buyers to choose the right products, negotiate effectively, and manage logistics efficiently.

The tire gauge market is experiencing significant shifts driven by technological advancements and changing consumer behaviors. One of the primary global drivers is the increasing emphasis on vehicle safety and maintenance. As awareness of the importance of proper tire pressure grows, businesses are focusing on providing high-quality tire gauges that ensure optimal performance and longevity of tires. Additionally, the rising prevalence of electric and hybrid vehicles is creating demand for specialized tire gauges that can handle varying pressure requirements.

Emerging B2B technologies are enhancing sourcing capabilities. Digital tire inflators, like the Vaper 0-174 PSI model, are becoming increasingly popular due to their multifunctionality—allowing users to inflate, deflate, and measure tire pressure. This trend is particularly relevant for international buyers from Africa, South America, the Middle East, and Europe, where varying market conditions necessitate versatile tools. E-commerce platforms are also playing a crucial role, facilitating easier access to a wider range of products, thus allowing buyers to source efficiently across borders.

Moreover, environmental considerations are shaping market dynamics. Buyers are increasingly prioritizing products that contribute to sustainability, leading to the rise of eco-friendly tire gauges and inflators that utilize ‘green’ materials. These trends indicate a robust market poised for growth, with ample opportunities for B2B buyers looking to invest in innovative and sustainable solutions.

As global markets evolve, the focus on sustainability and ethical sourcing is becoming paramount, especially in the tire gauge sector. Environmental impact assessments are essential for businesses aiming to minimize their carbon footprint. The production of tire gauges often involves materials that can be harmful to the environment, such as plastics and metals. Therefore, international B2B buyers should seek suppliers who prioritize eco-friendly manufacturing processes and materials.

Illustrative image related to tire gauge autozone

Certifications such as ISO 14001 (Environmental Management) and the use of recycled materials are becoming critical factors in the purchasing decision. Buyers from regions like Europe and North America are increasingly scrutinizing their supply chains for ethical practices, ensuring that their partners uphold responsible sourcing standards. This trend is gaining traction in developing markets as well, as businesses recognize the long-term benefits of sustainable practices.

Moreover, the push for sustainability is influencing product innovation. Manufacturers are investing in research and development to create tire gauges that are not only high-performing but also environmentally friendly. For example, tire gauges that feature digital displays made from recycled materials or inflators that reduce energy consumption during use are becoming more common. By aligning with suppliers who share these values, B2B buyers can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

The tire gauge market has evolved significantly over the decades, transitioning from basic mechanical gauges to sophisticated digital inflators with multifunctional capabilities. Early tire gauges were simple analog devices that required manual calibration, often leading to inaccuracies. However, advancements in technology have introduced digital tire gauges that provide precise readings and enhance user experience through features such as backlit displays and one-button operation.

This evolution reflects broader trends in automotive technology, where digital solutions are increasingly integrated into vehicle maintenance tools. The demand for accuracy and ease of use has driven manufacturers to innovate continuously, catering to both professional and DIY markets. As the automotive landscape continues to change, particularly with the rise of electric vehicles, the tire gauge market is expected to further adapt, offering solutions that meet the diverse needs of global B2B buyers.

How do I ensure accurate tire pressure measurements with a tire gauge?

To achieve accurate tire pressure readings, always use a high-quality tire gauge, such as those available at AutoZone. Before checking, ensure the gauge is calibrated. Remove the valve stem cap from the tire, firmly press the gauge onto the valve stem, and ensure it forms a proper seal to prevent air leakage. Take the reading quickly, as prolonged exposure can lead to air loss. Finally, cross-reference the measurement with the manufacturer’s recommended tire pressure, which can typically be found in the vehicle’s owner’s manual or on a sticker inside the driver’s door.

What is the best tire gauge for international B2B sourcing?

For international B2B buyers, digital tire gauges with multiple pressure unit options (PSI, bar, kPa) are ideal. These gauges, like the Vaper Digital Tire Inflator from AutoZone, offer precision and ease of use, making them suitable for various vehicle types. Look for features such as backlit displays for visibility in low light and durable construction for longevity. When sourcing, consider factors like supplier reliability, warranty terms, and customer reviews to ensure the product meets your business’s quality standards.

How can I verify the quality of tire gauges from a supplier?

To verify the quality of tire gauges, request samples from the supplier before placing a bulk order. Check for certifications or compliance with international standards, such as ISO or CE markings. Additionally, review the supplier’s production processes and quality assurance practices. Engaging with current customers for feedback can also provide insights into product reliability and performance. Conducting a factory audit can further assure that the supplier adheres to quality standards throughout the manufacturing process.

What are the typical minimum order quantities (MOQ) for tire gauges?

Minimum order quantities (MOQ) for tire gauges can vary widely among suppliers. Generally, MOQs range from 100 to 1,000 units, depending on the gauge type and customization requirements. It’s advisable to negotiate MOQs directly with the supplier, especially if you are a new buyer or looking to test market demand. Some suppliers may offer flexibility in MOQs for first-time orders or larger orders in the future. Always clarify MOQs before finalizing agreements to avoid unexpected costs.

What payment terms should I expect when sourcing tire gauges?

Payment terms when sourcing tire gauges often include options such as advance payment, letters of credit, or payment upon delivery. Common practices involve a 30% deposit upfront, with the remaining 70% due before shipment. For larger orders, some suppliers may offer extended payment terms or financing options. It is crucial to negotiate terms that align with your cash flow and operational needs. Always ensure that payment terms are documented in the purchase agreement to prevent misunderstandings.

How does logistics impact the sourcing of tire gauges internationally?

Logistics plays a vital role in international sourcing of tire gauges, affecting delivery times and costs. Factors such as shipping methods (air vs. sea), customs regulations, and local infrastructure can influence the overall efficiency of the supply chain. It’s essential to partner with reliable freight forwarders who understand the specific requirements of your region. Additionally, consider the lead times required for production and shipping when planning your inventory to avoid stockouts.

What are the common customs regulations to consider when importing tire gauges?

When importing tire gauges, familiarize yourself with the customs regulations of your country. This includes understanding tariff classifications, import duties, and any necessary certifications or documentation required for compliance. Some countries may have specific safety or environmental standards that products must meet before they can be imported. Engaging a customs broker can help navigate these complexities and ensure that your shipment clears customs without delays.

How can I ensure timely delivery of tire gauges from suppliers?

To ensure timely delivery of tire gauges, establish clear communication with your supplier regarding production timelines and shipping schedules. Set realistic deadlines that account for potential delays in manufacturing or shipping. Regular follow-ups and updates can help keep the process on track. Additionally, consider using local suppliers when possible, as this can significantly reduce lead times and shipping costs, especially for urgent orders. Always have contingency plans in place to mitigate potential delays.

Could not verify enough suppliers for tire gauge autozone to create a list at this time.

As the global demand for reliable automotive tools continues to rise, strategic sourcing of tire gauges, especially from reputable suppliers like AutoZone, becomes paramount for B2B buyers. Understanding the intricate balance between quality, pricing, and functionality is essential. By investing in high-quality tire gauges, businesses can enhance vehicle safety, reduce maintenance costs, and improve operational efficiency. Features such as digital readings, multi-unit compatibility, and durability ensure that these tools meet diverse market needs across various regions.

For buyers in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing partnerships can lead to better pricing structures and improved supply chain reliability. By aligning with suppliers that prioritize quality and customer service, businesses can ensure they are equipped with the best tools for their operations.

Looking ahead, the tire gauge market is poised for innovation and growth. International B2B buyers are encouraged to engage with suppliers who not only provide exceptional products but also offer insights into industry trends and advancements. This proactive approach will not only enhance operational capabilities but also position businesses for long-term success in a competitive landscape. Take the next step in optimizing your sourcing strategy by exploring partnerships with trusted suppliers like AutoZone today.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.