In the competitive landscape of the global automotive industry, sourcing the right tire light load inflation solutions for the Ram 2500 can be a complex endeavor. International B2B buyers face the challenge of finding products that not only meet regulatory standards but also enhance performance and safety. This comprehensive guide delves into the intricacies of tire light load inflation for the Ram 2500, covering essential topics such as types of inflation systems, applications across various industries, and the critical process of supplier vetting.

By equipping decision-makers with insights into cost factors, performance metrics, and innovative technologies, this guide empowers buyers to make informed purchasing decisions. Whether you are operating in the bustling markets of Africa, South America, the Middle East, or Europe—countries like Germany and Brazil—the information presented here will help streamline your procurement process.

Understanding the nuances of tire inflation systems is crucial for optimizing vehicle performance and ensuring compliance with local regulations. From the benefits of lower tire pressure for light loads to the importance of accurate pressure settings for heavy hauling, this guide serves as a vital resource for B2B buyers aiming to enhance their operational efficiency and reliability.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Light Load | Allows lower tire pressure for empty driving; typically 45 PSI rear, 65 PSI front | Fleet management, logistics, transportation | Vorteile: Improved ride comfort; Nachteile: May reduce load capacity. |

| Heavy Load Configuration | Higher pressure settings for loaded conditions; often 75-85 PSI | Construction, heavy-duty towing | Vorteile: Enhanced stability; Nachteile: Stiffer ride quality. |

| JScan Custom Settings | Customizable tire pressures using JScan; allows quick adjustments | Custom fleet operations, specialized transport | Vorteile: Flexibility in pressure adjustments; Nachteile: Requires technical knowledge. |

| Dually Light Load | Specific for dual rear wheels; optimized pressure for reduced wear | Heavy-duty transport, agricultural use | Vorteile: Extended tire life; Nachteile: Complexity in pressure management. |

| OEM Factory Settings | Manufacturer recommended settings; listed on door jamb | General fleet operations | Vorteile: Reliable performance; Nachteile: Limited adaptability. |

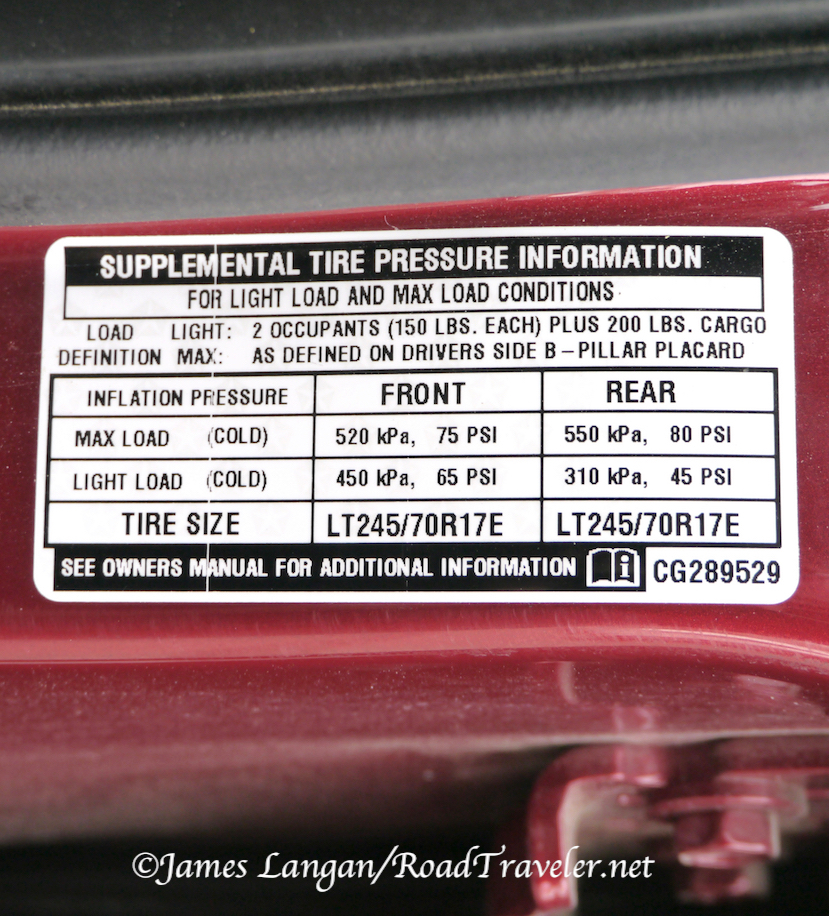

The Standard Light Load configuration for the Ram 2500 is designed to optimize tire pressure for empty or lightly loaded conditions, typically allowing for a rear tire pressure of 45 PSI and a front tire pressure of 65 PSI. This setting is crucial for businesses engaged in fleet management or logistics, as it significantly enhances ride comfort and handling during non-loaded trips. However, while it improves driving quality, buyers should be aware that running at lower pressures may compromise load capacity.

The Heavy Load Configuration is tailored for situations where the vehicle is fully loaded, with pressure settings often ranging from 75 to 85 PSI. This setup is essential for industries such as construction and heavy-duty towing, where stability and safety are paramount. The higher tire pressure enhances vehicle handling and reduces the risk of tire blowouts under heavy loads. However, buyers should consider the trade-off of a stiffer ride, which may affect driver comfort during long hauls.

Illustrative image related to tire light load inflation ram 2500

JScan Custom Settings allow users to adjust tire pressures quickly and efficiently, catering to varying load conditions. This feature is particularly beneficial for businesses that operate specialized transport services or custom fleet operations, as it enables rapid adaptations to tire pressure based on current loads. While this flexibility is a significant advantage, it requires some technical knowledge to implement effectively, which could be a barrier for less experienced operators.

Dually Light Load configurations are specific to vehicles with dual rear wheels, optimizing tire pressure to reduce wear and tear while maintaining performance. This setup is particularly relevant for businesses in heavy-duty transport or agricultural sectors, where load distribution is critical. The primary benefit is an extended tire lifespan, but managing pressure can be complex due to the dual setup, which may necessitate additional training or systems for fleet operators.

OEM Factory Settings are the manufacturer’s recommended tire pressures, typically found on the vehicle’s door jamb. These settings provide a reliable baseline for general fleet operations, ensuring that vehicles operate within safe and efficient parameters. While they offer dependable performance, the limitation lies in their lack of adaptability to specific business needs, which may require adjustments based on varied load conditions or driving environments.

| Industrie/Sektor | Specific Application of tire light load inflation ram 2500 | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Logistics and Transportation | Adjusting tire pressure for light loads in delivery trucks | Enhanced fuel efficiency and improved vehicle handling | Compatibility with various tire types and local regulations |

| Landwirtschaft | Utilizing lighter tire pressure for transporting goods | Reduced soil compaction and better crop yield | Availability of service centers and local support |

| Bauwesen | Managing tire pressure for light-duty transport vehicles | Increased comfort and reduced tire wear | Durability and resistance to harsh environments |

| Automotive Services | Providing tire inflation services for light-duty vehicles | Increased customer satisfaction and repeat business | Equipment reliability and ease of maintenance |

| Mining and Resource Extraction | Optimizing tire pressure for light load transport vehicles | Improved safety and reduced operational costs | Compliance with industry safety standards |

In the logistics and transportation sector, the tire light load inflation ram 2500 is employed to adjust tire pressure for delivery trucks carrying lighter loads. By allowing lower tire pressure, companies can enhance fuel efficiency and improve vehicle handling, leading to cost savings on fuel and maintenance. International buyers should ensure compatibility with various tire types and understand local regulations regarding tire pressure to maximize benefits.

In agriculture, the tire light load inflation ram 2500 is crucial for transporting goods with lighter loads, enabling farmers to reduce soil compaction. This not only enhances the stability of the vehicle but also promotes better crop yield. Buyers in this sector should consider the availability of local service centers for ongoing support, ensuring that they can maintain optimal tire pressure for various agricultural applications.

Illustrative image related to tire light load inflation ram 2500

Construction companies utilize the tire light load inflation ram 2500 to manage tire pressure in light-duty transport vehicles. Adjusting tire pressure can significantly increase comfort for operators and reduce tire wear, which is critical on rugged job sites. When sourcing this equipment, businesses should prioritize durability and resistance to harsh environments, ensuring that the inflation system can withstand the demands of construction work.

Automotive service providers leverage the tire light load inflation ram 2500 to offer tire inflation services for light-duty vehicles. By providing accurate tire pressure adjustments, businesses can enhance customer satisfaction and foster repeat business. Key considerations for sourcing this equipment include reliability and ease of maintenance, as service providers need tools that can operate efficiently over time.

In the mining and resource extraction industry, the tire light load inflation ram 2500 is essential for optimizing tire pressure in light load transport vehicles. This adjustment improves safety and reduces operational costs by enhancing vehicle performance on uneven terrain. Buyers in this sector must ensure compliance with industry safety standards and consider the ruggedness of the inflation system to withstand demanding conditions.

Das Problem: Many B2B buyers operating the Ram 2500 face the challenge of maintaining consistent tire pressure when transporting light loads. This inconsistency can lead to poor vehicle handling, increased tire wear, and reduced fuel efficiency. Buyers often overlook the importance of adjusting tire pressure according to load weight, resulting in either over-inflation or under-inflation, both of which compromise performance and safety.

Illustrative image related to tire light load inflation ram 2500

Die Lösung: To effectively manage tire pressure for light loads, buyers should utilize the built-in tire inflation feature of the Ram 2500, specifically the light load button. This function allows for the adjustment of rear tire pressure from the standard 70 psi to a lower 45 psi when the vehicle is not heavily loaded. Buyers should regularly consult the vehicle’s door jamb sticker for specific PSI recommendations and ensure that they adjust tire pressure before any journey. Implementing regular checks and adjustments using a reliable tire pressure gauge can help maintain optimal tire performance and extend tire lifespan. Moreover, training drivers on the importance of these adjustments can foster a culture of safety and efficiency within the fleet.

Das Problem: B2B buyers, especially those new to the Ram 2500, often struggle with understanding the various tire inflation settings, including how to effectively utilize the light load inflation feature. This confusion can lead to incorrect tire pressure settings, which can adversely affect vehicle safety and operational costs.

Die Lösung: To alleviate this confusion, buyers should invest in comprehensive training resources that explain the vehicle’s tire inflation features in detail. This could include manuals, instructional videos, or workshops focused on tire maintenance. Additionally, leveraging technology such as apps or diagnostic tools (like JScan) can provide real-time data and guidance on tire pressure settings based on load weight. Buyers should also encourage their teams to familiarize themselves with the specific pressure settings listed on the door jamb sticker, which clearly outlines the recommended PSI for both light and heavy loads. Providing a visual reference can enhance understanding and ensure that all team members are equipped to make informed decisions regarding tire maintenance.

Das Problem: B2B buyers may underestimate the significant impact that improper tire pressure has on vehicle performance and operational costs. A lack of awareness can lead to inefficient fuel consumption, increased maintenance costs, and potential safety hazards due to compromised vehicle handling.

Die Lösung: To combat this issue, businesses should conduct regular training sessions focusing on the effects of tire pressure on performance metrics such as fuel efficiency and tire longevity. Sharing case studies or real-world examples that illustrate the cost savings achieved through proper tire inflation can motivate teams to prioritize this aspect of vehicle maintenance. Additionally, establishing a routine maintenance schedule that includes tire pressure checks can help instill the importance of this practice among drivers. By integrating tire pressure management into the broader maintenance protocols, businesses can enhance overall fleet performance while minimizing operational costs associated with tire wear and fuel consumption.

When selecting materials for the tire light load inflation system in the Ram 2500, it’s essential to consider various factors such as performance properties, cost, and regional standards. Here, we analyze four common materials used in this application: rubber, aluminum, steel, and composite materials.

Rubber is a primary material for tire components due to its excellent elasticity and ability to withstand varying pressures. It has a high-temperature rating, typically around 100°C (212°F), and can endure significant pressure fluctuations, making it suitable for tire inflation applications.

Vorteile: Rubber is durable and provides good resistance to wear and tear. It is also relatively inexpensive and easy to manufacture, making it a cost-effective choice for mass production.

Nachteile: However, rubber can degrade over time due to exposure to UV light and ozone, leading to potential failures. Additionally, its performance can be affected by extreme temperatures, particularly in hotter climates.

Auswirkungen auf die Anwendung: Rubber’s compatibility with air and nitrogen makes it ideal for tire inflation. However, buyers in regions with high UV exposure should consider protective coatings or treatments to enhance longevity.

Aluminum is often used in tire inflation systems due to its lightweight nature and excellent corrosion resistance. It typically has a pressure rating of around 150 psi, which is sufficient for tire applications.

Vorteile: Aluminum is lightweight, which can contribute to overall vehicle efficiency. It also offers good thermal conductivity and is resistant to corrosion, making it suitable for various environmental conditions.

Nachteile: The main drawback is its higher cost compared to rubber. Additionally, aluminum can be more complex to manufacture, requiring specialized processes that may increase lead times.

Auswirkungen auf die Anwendung: Aluminum’s resistance to corrosion is particularly beneficial in humid or saline environments, such as coastal regions. Buyers should ensure compliance with international standards for aluminum alloys, such as ASTM B221.

Steel is another common material, especially for structural components within the tire inflation system. It has a high strength-to-weight ratio and can handle high pressure, often rated above 200 psi.

Vorteile: Steel is incredibly durable and can withstand harsh conditions, making it suitable for heavy-duty applications. Its cost is generally lower than aluminum, providing a good balance between performance and expense.

Nachteile: However, steel is prone to corrosion if not properly treated or coated. This can be a significant concern in regions with high humidity or exposure to salt.

Auswirkungen auf die Anwendung: Steel’s strength makes it ideal for components that require high pressure and durability. International buyers should consider coatings or treatments that meet standards like DIN 50976 for corrosion resistance.

Composite materials, which combine various substances to enhance performance, are increasingly used in tire inflation systems. They can be engineered to provide specific properties, such as flexibility and strength.

Vorteile: Composites are lightweight and can be tailored to meet specific performance criteria. They also offer excellent resistance to corrosion and temperature fluctuations.

Nachteile: The main limitation is the higher manufacturing complexity, which can lead to increased costs. Additionally, not all composites are suitable for high-pressure applications.

Auswirkungen auf die Anwendung: Composites can provide unique advantages in specialized applications, particularly where weight savings are critical. Buyers should ensure that the composites used comply with relevant international standards, such as JIS K 6251 for rubber-like materials.

| Material | Typical Use Case for tire light load inflation ram 2500 | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Tire components and seals | Durable and cost-effective | Degrades with UV exposure | Niedrig |

| Aluminium | Structural components in tire inflation systems | Leicht und korrosionsbeständig | Höhere Kosten und komplexere Herstellung | Med |

| Stahl | High-pressure structural components | Extremely durable | Prone to corrosion | Niedrig |

| Komposit | Specialized lightweight components | Tailored performance properties | Höhere Fertigungskomplexität | Hoch |

This guide serves as a foundational resource for international B2B buyers, helping them make informed decisions regarding material selection for tire light load inflation systems in the Ram 2500. Understanding the properties, pros and cons, and regional considerations will facilitate better procurement strategies and product performance.

The manufacturing process for tire light load inflation systems in the Ram 2500 involves several critical stages that ensure the product’s reliability and performance. The main stages include material preparation, forming, assembly, and finishing.

Vorbereitung des Materials: The first step in manufacturing involves sourcing high-quality materials such as steel, aluminum, and various polymers. These materials must meet specific industry standards for durability and resistance to environmental factors. Suppliers often provide Material Safety Data Sheets (MSDS) to ensure compliance with safety and regulatory requirements.

Bildung von: In this stage, the prepared materials undergo processes like stamping, extrusion, and machining to create the various components of the tire inflation system. Advanced techniques such as CNC (Computer Numerical Control) machining are employed to achieve high precision and consistency in the components. This step is crucial for ensuring that parts fit together seamlessly during assembly.

Montage: The assembly process involves integrating all components into the final product. This may include the installation of electronic control units, sensors, and pneumatic systems that enable the tire inflation feature. Skilled technicians often perform this work, and it may include both manual and automated assembly lines to enhance efficiency.

Fertigstellung: The final stage includes surface treatments, painting, and quality checks. Components may undergo processes such as anodizing or powder coating to enhance corrosion resistance and aesthetic appeal. This stage ensures that the final product meets both functional and visual standards.

Quality assurance is a pivotal aspect of manufacturing, particularly for products like tire inflation systems that must operate reliably under various conditions. International standards such as ISO 9001 are widely adopted, emphasizing a systematic approach to quality management. In addition, industry-specific certifications such as CE marking for European markets and API standards for automotive components may also apply.

ISO 9001: This standard focuses on establishing a quality management system (QMS) that ensures consistent product quality and customer satisfaction. Manufacturers must document processes, conduct regular audits, and implement corrective actions.

CE-Kennzeichnung: For products sold within the European Economic Area, CE marking demonstrates compliance with health, safety, and environmental protection standards. This certification is essential for gaining market access in Europe.

API-Normen: The American Petroleum Institute (API) provides guidelines that may apply to components used in tire inflation systems, particularly those involving pneumatic technology. Compliance with these standards can enhance product credibility in North American markets.

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that every component meets the required specifications. Common QC checkpoints include:

Eingehende Qualitätskontrolle (IQC): This initial checkpoint verifies the quality of raw materials and components received from suppliers. It involves inspections and testing to ensure compliance with specifications before production begins.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, IPQC monitors various stages to ensure that production adheres to established standards. This includes checking dimensions, tolerances, and assembly accuracy.

Endgültige Qualitätskontrolle (FQC): Once the product is assembled, FQC involves thorough testing of the entire tire inflation system. This may include functional testing, pressure tests, and performance evaluations under simulated conditions to ensure reliability and safety.

To maintain high-quality standards, manufacturers utilize various testing methods throughout the production process. Some common testing methods include:

Funktionelle Prüfung: This assesses the tire inflation system’s performance under typical operational conditions. It verifies that the system can accurately inflate tires to the specified pressure levels.

Pressure Testing: Conducted to ensure that the system can withstand the pressures it will encounter in real-world usage. This testing is critical for safety and reliability.

Umweltprüfungen: This involves exposing the product to extreme temperatures, humidity, and other environmental conditions to assess durability and performance longevity.

B2B buyers can take several steps to verify a supplier’s quality control practices before making a purchase. These include:

Lieferanten-Audits: Conducting on-site audits allows buyers to evaluate the manufacturing process, QC checkpoints, and overall production capabilities. This firsthand observation can provide insight into the supplier’s commitment to quality.

Requesting Documentation: Buyers should ask for quality assurance documentation, including ISO certifications, test reports, and compliance certificates. This information can validate the supplier’s adherence to international standards.

Inspektionen durch Dritte: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can conduct inspections at various stages of production to ensure compliance with specified standards.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific quality control considerations:

Einhaltung von Vorschriften: Understanding local regulations and standards is crucial for ensuring that products meet the required safety and performance criteria in different markets.

Cultural and Logistical Differences: Buyers should consider potential cultural differences that may affect communication and expectations regarding quality. Additionally, logistical challenges, such as shipping and customs regulations, can impact product delivery and compliance.

Market-Specific Certifications: Buyers should verify that suppliers hold necessary certifications relevant to their specific markets, such as CE marking for Europe or other regional certifications that demonstrate compliance with local standards.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance standards for tire light load inflation systems in the Ram 2500 is essential for international B2B buyers. By focusing on these key areas, buyers can make informed decisions and ensure they source high-quality products that meet their operational needs.

The following guide outlines a practical checklist for B2B buyers interested in sourcing the ‘tire light load inflation’ system specifically for the Ram 2500. This step-by-step approach will ensure that you make informed decisions while meeting your operational requirements.

Before initiating your search for suppliers, clearly outline your technical requirements. This includes understanding the specific tire pressure settings for light loads, such as 45 PSI for the rear tires and the maximum allowable pressures for heavier loads. Having precise specifications helps ensure that suppliers can meet your needs and provides a benchmark for evaluating their offerings.

Illustrative image related to tire light load inflation ram 2500

It is essential to verify the credentials of potential suppliers to ensure reliability and quality. Look for certifications such as ISO 9001 or industry-specific qualifications. Additionally, check for their experience in supplying tire inflation systems for heavy-duty vehicles, particularly the Ram 2500, to gauge their expertise.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This not only provides insight into their capabilities but also builds confidence in their ability to deliver quality products. Consider asking for testimonials specifically regarding tire inflation systems for heavy-duty trucks.

Ensure that the tire light load inflation system you are considering is compatible with the Ram 2500. Review technical documentation and installation guides to confirm that the system can integrate seamlessly with the truck’s existing infrastructure. Compatibility reduces installation costs and potential operational disruptions.

Strong after-sales support is crucial for any equipment purchase. Engage with suppliers to understand their warranty policies, maintenance services, and availability of replacement parts. A reliable after-sales support system can significantly reduce downtime and enhance the longevity of your investment.

Where feasible, request samples or demonstrations of the tire light load inflation systems. This hands-on approach allows you to evaluate the product’s performance and ease of use in real-world conditions. It also provides an opportunity to assess the supplier’s responsiveness and customer service quality.

Finally, gather pricing information from multiple suppliers and compare their offerings. Look beyond the initial purchase price; consider the total cost of ownership, including installation, maintenance, and any additional fees. Additionally, negotiate payment terms that align with your financial capabilities and project timelines to ensure a smooth procurement process.

By following this checklist, B2B buyers can effectively navigate the procurement process for tire light load inflation systems for the Ram 2500, ensuring a sound investment that meets their operational needs.

When sourcing tire light load inflation systems for the Ram 2500, it’s essential to understand the breakdown of costs involved. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Materialien: The cost of raw materials can vary significantly based on the quality of components used in the inflation system. High-grade rubber, metal alloys for valves, and advanced sensors contribute to higher material costs but may enhance durability and performance.

Arbeit: Labor costs encompass wages for skilled workers involved in the assembly and quality assurance processes. Depending on the region, labor rates can fluctuate, impacting overall pricing. Countries with lower labor costs may present more attractive pricing options for buyers.

Fertigungsgemeinkosten: This includes indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can minimize these costs, leading to more competitive pricing.

Werkzeugbau: Tooling costs are associated with the machinery and equipment required to produce tire inflation systems. Custom tooling for unique specifications can significantly increase upfront costs.

Qualitätskontrolle (QC): Rigorous QC processes ensure that the products meet safety and performance standards. While this adds to the cost, it is crucial for maintaining quality, especially in international markets where regulations may differ.

Logistik: Shipping and handling costs can be substantial, particularly for international buyers. Factors like distance, shipping method, and customs duties play a role in logistics pricing.

Marge: Supplier margins vary based on market competition and perceived value. Negotiating effectively can help buyers secure more favorable terms.

Several factors influence the pricing of tire light load inflation systems for the Ram 2500. These include volume or minimum order quantities (MOQ), specifications and customization, materials used, quality certifications, supplier relationships, and Incoterms.

Illustrative image related to tire light load inflation ram 2500

Volumen/MOQ: Larger orders typically lead to reduced per-unit costs due to economies of scale. Buyers should evaluate their needs to determine if consolidating orders is feasible.

Spezifikationen/Anpassung: Custom designs or specific performance requirements can increase costs. Buyers must balance the need for customization with budget constraints.

Materialien und Qualität/Zertifizierungen: The choice of materials directly impacts pricing. Higher-quality materials may incur additional costs but offer better performance and longer lifespans. Certifications can also affect pricing, especially in regulated markets.

Lieferanten-Faktoren: Established suppliers with a track record of reliability may charge a premium for their products. However, they often provide better support and warranty options, which can justify the cost.

Incoterms: Understanding the implications of Incoterms is vital for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, risk, and delivery, impacting the total landed cost.

To maximize cost efficiency in sourcing tire light load inflation systems, buyers should consider the following strategies:

Bedingungen verhandeln: Always negotiate pricing and terms with suppliers. Leverage multiple quotes to foster competition and drive down costs.

Bewerten Sie die Gesamtbetriebskosten: Look beyond initial purchase prices. Consider maintenance, durability, and potential downtime costs associated with lower-quality products.

Understand Pricing Nuances for International Markets: Each region may have unique pricing dynamics. For instance, tariffs in South America or currency fluctuations in Africa can significantly affect total costs.

Build Strong Supplier Relationships: Developing long-term relationships with suppliers can lead to better pricing, priority service, and access to new products.

Stay Informed on Market Trends: Regularly review market conditions, material costs, and technological advancements that may affect pricing. This knowledge can inform your purchasing decisions and timing.

Pricing for tire light load inflation systems can vary widely based on the factors mentioned above. Buyers should conduct thorough market research and engage with multiple suppliers to obtain accurate and competitive pricing tailored to their specific needs.

When it comes to optimizing the performance of heavy-duty vehicles like the Ram 2500, selecting the right tire inflation solution is crucial. The ‘Tire Light Load Inflation Ram 2500’ system allows users to adjust tire pressures for improved ride quality when the vehicle is lightly loaded. However, several alternative methods and technologies can achieve similar results. This section will explore these alternatives, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to tire light load inflation ram 2500

| Vergleich Aspekt | Tire Light Load Inflation Ram 2500 | Tire Pressure Monitoring System (TPMS) | Manual Tire Inflation Adjustment |

|---|---|---|---|

| Leistung | Optimizes ride quality for light loads | Monitors tire pressure in real-time | Provides flexibility but requires manual adjustment |

| Kosten | Moderate initial investment | Varies by vehicle but generally affordable | Minimal cost for tools, time-intensive |

| Leichte Implementierung | Simple button operation | Requires installation, often factory-fitted | Requires knowledge and physical labor |

| Wartung | Geringe Wartung | Low maintenance, but sensors may fail | Requires regular checks and adjustments |

| Bester Anwendungsfall | Ideal for fleet vehicles needing quick adjustments | Best for safety and efficiency monitoring | Suitable for occasional users or small fleets |

TPMS is a technology that continuously monitors tire pressure and alerts the driver when it falls below a predetermined threshold. This system enhances safety by preventing under-inflation, which can lead to tire blowouts and decreased fuel efficiency. While the initial cost may vary depending on whether it is factory-installed or an aftermarket addition, it generally remains affordable for most businesses. The ease of maintenance is another advantage, as users only need to replace sensors occasionally. However, TPMS does not allow for dynamic pressure adjustments like the Ram 2500’s light load feature, which may be a drawback for those who frequently transition between loaded and unloaded states.

This method involves physically checking and adjusting tire pressures using manual tools such as air compressors and pressure gauges. The primary benefit of this approach is its low cost, as it requires minimal investment in tools. Additionally, it provides full control over tire pressure settings. However, this method can be time-consuming and labor-intensive, particularly for larger fleets. It requires ongoing vigilance to ensure that tire pressures are maintained correctly, which could lead to inefficiencies if not managed well. Therefore, while it is suitable for occasional users or smaller fleets, larger operations may find it burdensome.

Selecting the appropriate tire inflation solution for your fleet depends on various factors, including operational needs, budget, and the frequency of load changes. The ‘Tire Light Load Inflation Ram 2500’ offers a convenient option for businesses that require quick adjustments for light loads, ensuring enhanced ride quality and comfort. In contrast, TPMS provides real-time monitoring, promoting safety and efficiency, while manual adjustments offer flexibility at a lower cost but require more time and effort. B2B buyers should assess their specific operational requirements and consider the trade-offs associated with each solution to make an informed decision that best suits their needs.

Tire Pressure Ratings

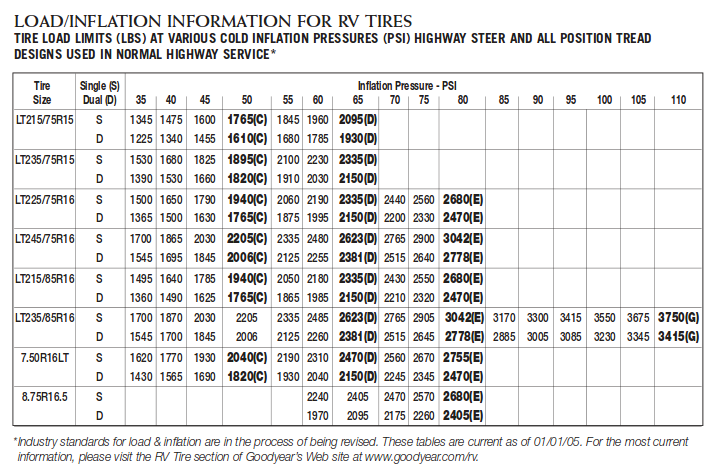

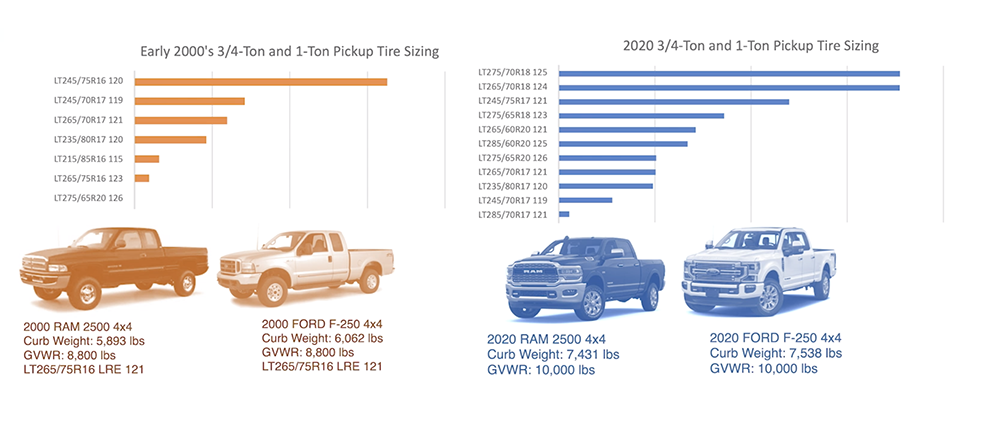

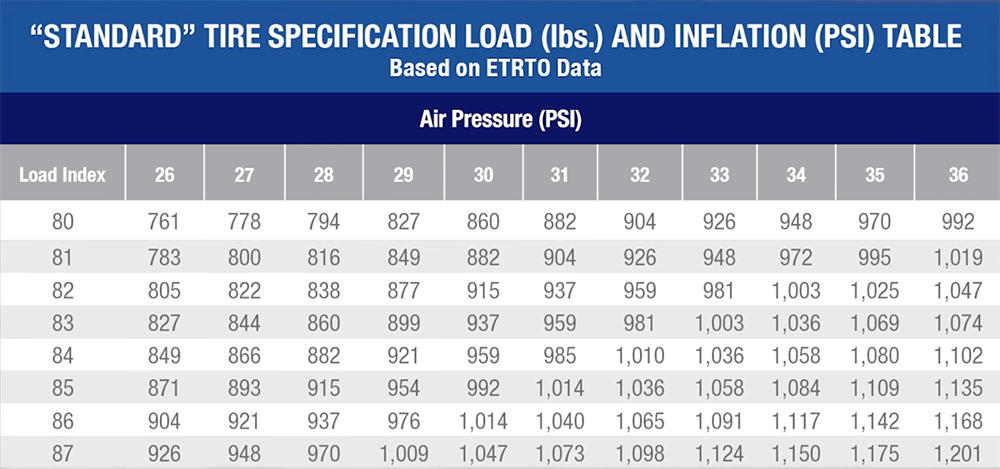

Tire pressure ratings are crucial for ensuring optimal performance and safety. For the Ram 2500, light load inflation typically suggests a front tire pressure of 65 PSI and a rear tire pressure of 45 PSI. Maintaining these pressures allows for improved ride quality and handling when the vehicle is not heavily loaded. For B2B buyers, adhering to these specifications is vital to prevent premature tire wear and enhance fuel efficiency, making it a cost-effective choice.

Tragfähigkeit

The load capacity of tires indicates the maximum weight they can safely carry. For the Ram 2500, understanding the load capacity is essential, particularly when switching between light and heavy loads. This specification helps buyers ensure they select the appropriate tires that can handle varying loads without compromising safety or performance. Incorrect load management can lead to increased operational costs due to tire replacement and potential accidents.

Materialzusammensetzung

Tires for the Ram 2500 are typically made from a blend of rubber compounds and reinforcing materials such as steel or nylon. The material composition affects durability, traction, and resistance to punctures. For B2B buyers, understanding these materials can guide them in selecting tires that offer longevity and performance suited to their specific needs, especially in regions with challenging terrains.

Temperature Ratings

Temperature ratings indicate how well a tire can perform under varying heat conditions. For heavy-duty vehicles like the Ram 2500, tires with high-temperature ratings are essential to prevent blowouts and maintain structural integrity. B2B buyers should prioritize tires with appropriate temperature ratings for their operational environments, especially in hotter climates or heavy-use situations.

Tread Design

The tread design significantly influences traction, handling, and noise levels. For light load applications, a tread pattern designed for highway use can provide a quieter ride and better fuel efficiency. B2B buyers should consider their typical driving conditions when evaluating tread designs, as this can affect both safety and operational costs.

OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the vehicle or its parts. In the context of tires for the Ram 2500, OEM tires are specifically designed to meet the vehicle’s performance standards. B2B buyers should look for OEM specifications to ensure compatibility and reliability.

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it impacts inventory management and cost-effectiveness. Buyers should negotiate MOQs to align with their purchasing strategies and demand forecasts.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For tire procurement, an RFQ can help buyers secure competitive pricing and favorable terms from multiple suppliers, ensuring they make informed purchasing decisions.

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. They are crucial for B2B transactions, especially in the context of importing tires. Understanding Incoterms can help buyers mitigate risks and clarify shipping responsibilities.

TPMS (Tire Pressure Monitoring System)

TPMS is a safety feature that monitors tire pressure in real-time. This technology is particularly beneficial for the Ram 2500, as it alerts drivers to under-inflation, enhancing safety and fuel efficiency. B2B buyers should consider vehicles equipped with TPMS to improve operational safety and reduce maintenance costs.

Load Index

The load index is a numerical code that indicates the maximum load a tire can carry at a specified pressure. For the Ram 2500, knowing the load index helps buyers select tires that meet their specific load requirements, ensuring safety and performance during operation.

The tire light load inflation sector for the Ram 2500 is shaped by a variety of global drivers and emerging trends that international B2B buyers should be aware of. A significant driver is the growing demand for enhanced vehicle performance and fuel efficiency. As businesses increasingly seek to reduce operational costs, proper tire inflation management becomes essential. The adoption of advanced tire pressure monitoring systems (TPMS) is on the rise, enabling real-time monitoring of tire pressure, which can lead to better fuel economy and longer tire life.

Additionally, the sector is experiencing a shift towards digital solutions that facilitate tire pressure adjustments. Tools like JScan allow users to easily modify tire pressure settings based on load conditions, enhancing the user experience and operational efficiency. This trend is particularly relevant in regions like Africa and South America, where fluctuating road conditions necessitate adaptive tire management strategies.

International buyers are also influenced by regulatory changes emphasizing safety and environmental sustainability. As markets in Europe and the Middle East tighten regulations around vehicle emissions and fuel consumption, the importance of maintaining optimal tire pressure will continue to grow. This creates a significant opportunity for suppliers who can offer products that enhance tire performance while complying with regional regulations.

Sustainability and ethical sourcing are increasingly vital considerations for B2B buyers in the tire light load inflation market. The environmental impact of tire production and disposal poses significant challenges, making it essential for businesses to seek suppliers committed to sustainable practices. This includes using eco-friendly materials and processes that minimize carbon footprints.

Buyers should look for suppliers who have obtained “green” certifications, indicating that their products meet specific environmental standards. These certifications often cover aspects such as the use of recycled materials, energy-efficient manufacturing processes, and responsible waste management practices. Ethical supply chains not only enhance brand reputation but also appeal to a growing consumer base that prioritizes sustainability.

Moreover, companies that adopt sustainable practices often experience cost savings in the long run. By investing in high-quality tires that maintain optimal pressure and performance, businesses can reduce fuel consumption and extend tire life, ultimately lowering operational costs. In regions like Europe, where there is a strong emphasis on corporate social responsibility, aligning sourcing strategies with sustainability goals can provide a competitive edge.

The evolution of tire light load inflation technologies has been marked by significant advancements aimed at enhancing vehicle performance and safety. Initially, tire pressure management was a manual process, relying on drivers to check tire pressure regularly. However, the introduction of tire pressure monitoring systems (TPMS) revolutionized this approach by providing real-time data on tire conditions.

Over the years, manufacturers have integrated more sophisticated technologies, such as electronic inflation systems that automatically adjust tire pressure based on load conditions. This evolution is particularly beneficial for heavy-duty vehicles like the Ram 2500, where load variations can significantly impact performance and safety.

The development of mobile applications and tools like JScan further illustrates the trend toward digital solutions in tire management. These innovations allow users to easily adjust tire pressure settings, ensuring optimal performance for both light and heavy loads. As technology continues to advance, the tire light load inflation sector will likely see further enhancements that improve efficiency and safety for B2B buyers worldwide.

How do I determine the correct tire pressure for light load on a Ram 2500?

To determine the correct tire pressure for light load on a Ram 2500, refer to the vehicle’s door jamb sticker, which provides specific PSI recommendations for both light and heavy loads. Generally, for light load conditions, the front tires should be inflated to around 60 PSI, while the rear tires can be adjusted down to approximately 45 PSI. It’s crucial to adjust these pressures based on your load to ensure optimal performance, ride comfort, and tire longevity.

What features should I look for in a tire inflation system for a Ram 2500?

When sourcing a tire inflation system for a Ram 2500, prioritize features such as automatic pressure adjustment, compatibility with the vehicle’s TPMS (Tire Pressure Monitoring System), and ease of use. Additionally, look for systems that allow for quick changes between light and heavy load pressures. A reliable system will improve handling, fuel efficiency, and safety, especially for international buyers needing solutions for varied road conditions.

What are the benefits of using a light load inflation button?

The light load inflation button allows drivers to reduce tire pressure without triggering warning lights, improving ride quality and comfort when the vehicle is not heavily loaded. This feature can lead to better fuel efficiency and reduced tire wear, making it an attractive option for businesses that prioritize operational cost savings. Understanding how to utilize this feature can enhance vehicle performance for those transporting lighter loads.

How can I ensure quality when sourcing tire inflation products internationally?

To ensure quality when sourcing tire inflation products internationally, conduct thorough supplier vetting. Look for manufacturers with ISO certifications and positive reviews from other B2B clients. Request samples and check for compliance with international safety and quality standards. Establish clear communication regarding product specifications and quality assurance processes to mitigate risks and ensure that the products meet your operational needs.

What are the typical minimum order quantities (MOQ) for tire inflation systems?

Minimum order quantities (MOQ) for tire inflation systems can vary widely depending on the supplier and product specifications. Generally, MOQs may range from a few dozen units to several hundred. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are a small or medium-sized enterprise. Building a relationship with the supplier can also lead to more flexible ordering options.

What payment terms are common for international B2B transactions in this industry?

Common payment terms for international B2B transactions in the tire inflation industry typically include options such as Letters of Credit (LC), telegraphic transfers (T/T), and sometimes escrow services. Payment terms often range from 30% upfront and 70% upon shipment to net 30 or 60 days after delivery, depending on the supplier’s policies and your negotiation. Always clarify payment terms before finalizing contracts to ensure smooth financial transactions.

How do I handle logistics and shipping for tire inflation systems?

Handling logistics and shipping for tire inflation systems involves selecting a reliable freight forwarder experienced in international shipping. Discuss shipping options such as air freight for quicker delivery or sea freight for cost-effectiveness. Ensure that all customs documentation is correctly prepared to avoid delays. Additionally, consider insurance for high-value shipments to protect against loss or damage during transit.

What customization options are available for tire inflation systems?

Many suppliers offer customization options for tire inflation systems, including specific PSI settings, system compatibility with different vehicle models, and branding options for businesses. When discussing customization, provide detailed specifications about your requirements, including any unique features you need for your market. Collaborating closely with the manufacturer during the design phase can lead to tailored solutions that better meet your operational needs.

Bereich: hdrams.com

Registriert: 2018 (7 Jahre)

Einleitung: Light Load Inflation Pressure settings for front and rear tires; JScan application used for adjusting tire pressures; recommended rear tire pressure of 35 psi when unloaded and 65 psi when towing; front tire pressure adjustment from 65 to 70 psi; TPMS (Tire Pressure Monitoring System) conversion mentioned; ability to set max load pressure and light load pressure; emphasis on using tire load/inflat…

Bereich: ebay.de

Registriert: 1995 (30 Jahre)

Einleitung: This company, Ram – Part Number 68137078AC, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, Ram 2500 – Tire Pressure Settings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: community.goodsam.com

Registriert: 1996 (29 Jahre)

Einleitung: This company, Ram – Tire Pressure Monitor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: dodgeforum.com

Registered: 2002 (23 years)

Einleitung: The Light Load button adjusts the signal to the wireless control module to indicate that tire pressures will be at a lower level. This prevents the Tire Pressure Monitoring System from activating the low pressure dash light indicator. It is recommended to use this button when not hauling anything or only carrying light loads, as lower tire pressure can improve ride quality. Light load tire pressur…

In summary, understanding the intricacies of tire light load inflation for the Ram 2500 is crucial for optimizing vehicle performance and safety. By strategically sourcing the right tire inflation solutions, businesses can enhance operational efficiency and reduce costs. Key takeaways include the importance of adhering to the recommended tire pressure settings for both light and heavy loads, as indicated on the vehicle’s door jamb sticker. This ensures optimal handling, improved ride quality, and extends tire life, ultimately leading to significant savings.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, it is essential to leverage local suppliers and manufacturers who understand the unique demands of your markets. Investing in high-quality tire inflation systems not only meets regulatory standards but also boosts the overall performance of your fleet.

Looking ahead, businesses should prioritize partnerships with suppliers that offer innovative solutions and robust support. By doing so, you position your operations for success in an increasingly competitive landscape. Take action today to enhance your sourcing strategies and ensure your fleet operates at peak efficiency.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.