In an increasingly competitive global marketplace, sourcing reliable tire pumps with pressure gauges can pose significant challenges for international B2B buyers. Ensuring that your fleet or service offering is equipped with high-quality inflators not only enhances operational efficiency but also mitigates the risks associated with tire maintenance, such as blowouts and reduced fuel efficiency. This comprehensive guide delves into the various types of tire pumps with pressure gauges available, their applications across different industries, and the critical factors to consider when vetting suppliers.

From digital inflators to manual options, understanding the nuances of each type will empower your purchasing decisions, enabling you to select the most suitable products for your business needs. Additionally, this guide will provide insights into cost considerations, highlighting how to optimize your budget without compromising on quality.

By focusing on the unique requirements of buyers from diverse regions—including Africa, South America, the Middle East, and Europe—this resource aims to equip you with actionable knowledge. Whether you are looking to enhance your product lineup or streamline your tire maintenance processes, this guide serves as a valuable tool for making informed, strategic purchasing decisions in the global market.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Digital Tire Inflators | Accurate digital readouts, often with preset PSI | Automotive repair shops, fleet services | Vorteile: High accuracy, easy to read; Nachteile: Battery-dependent, may be more expensive. |

| Analog Tire Pressure Gauges | Mechanical gauges with dial readouts | Tire retailers, roadside assistance | Vorteile: No batteries needed, durable; Nachteile: Less precise, harder to read in low light. |

| Portable Electric Tire Pumps | Battery-operated, compact design, fast inflation | Emergency kits, roadside assistance | Vorteile: Convenient, quick inflation; Nachteile: Limited battery life, may require frequent charging. |

| Manual Hand Pumps | Simple, manual operation, lightweight | Outdoor recreation, bicycles | Vorteile: Cost-effective, no power source required; Nachteile: Arbeitsintensiv, langsamere Inflation. |

| Schnurlose Reifenfüller | Wireless operation, rechargeable batteries | Automotive service, personal vehicles | Vorteile: Versatile, easy to use; Nachteile: Higher upfront cost, battery maintenance needed. |

Digital tire inflators are equipped with advanced features such as digital displays and preset pressure settings, ensuring precise inflation. They are ideal for automotive repair shops and fleet services where accuracy is paramount. B2B buyers should consider the reliability of the battery life and the gauge’s calibration, as these factors influence operational efficiency and customer satisfaction.

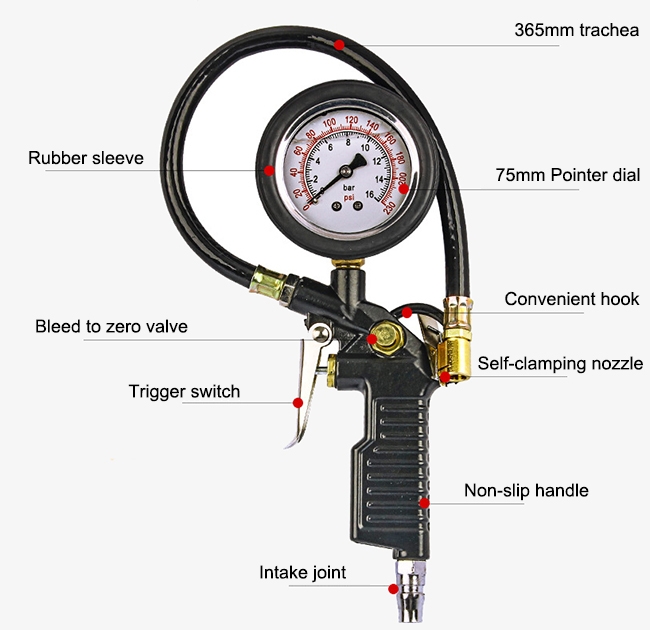

Illustrative image related to tire pump with pressure gauge

Analog tire pressure gauges use mechanical dials to indicate tire pressure. These gauges are commonly found in tire retailers and roadside assistance services, where durability and simplicity are essential. They do not require batteries, making them a reliable choice for long-term use. However, B2B buyers should be aware that analog gauges may lack the precision of digital options, especially in low-light conditions.

Portable electric tire pumps are designed for quick and efficient inflation, making them suitable for emergency kits and roadside assistance services. Their compact design allows for easy transport, while the fast inflation capability can save valuable time. Buyers should evaluate the battery life and charging time to ensure they meet the demands of their operations, as frequent recharging can hinder performance.

Manual hand pumps are an economical choice for businesses involved in outdoor recreation or bicycle maintenance. These pumps are lightweight and do not require a power source, making them highly portable. However, B2B buyers must consider the labor-intensive nature of manual inflation and the slower inflation rates compared to electric options, which may not be ideal for high-volume operations.

Cordless tire inflators offer the convenience of wireless operation with rechargeable batteries, making them versatile for automotive services and personal vehicles. Their ease of use and portability are significant advantages in various settings. However, potential buyers should assess the initial investment costs and the need for battery maintenance, which can affect long-term operational efficiency.

| Industrie/Sektor | Specific Application of tire pump with pressure gauge | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automotive Repair & Service | Routine tire maintenance and inflation for vehicles | Ensures vehicle safety, enhances customer satisfaction, and reduces tire wear | Durability, accuracy, and ease of use; consider local service support |

| Logistics & Transportation | Maintenance of fleet vehicles and trailers | Increases fuel efficiency, extends tire lifespan, and minimizes breakdowns | Compatibility with various tire types; robust design for heavy use |

| Manufacturing & Warehousing | Inflation of tires for forklifts and material handling equipment | Improves operational efficiency and reduces equipment downtime | Must meet specific PSI requirements; consider the gauge’s accuracy |

| Landwirtschaft und Landbau | Inflation of tires on agricultural machinery | Enhances productivity and reduces the risk of accidents due to tire failure | Adaptability to different tire sizes; reliability in outdoor conditions |

| Sports & Recreation | Maintenance of tires for bicycles and recreational vehicles | Optimizes performance and safety for recreational activities | Portability and ease of use; specific PSI settings for various tire types |

In the automotive repair and service sector, tire pumps with pressure gauges are essential for routine tire maintenance. Mechanics utilize these tools to ensure that customer vehicles maintain optimal tire pressure, which is crucial for safety and performance. Accurate inflation helps in reducing tire wear and enhances overall vehicle efficiency. For international buyers, especially in regions with varying climate conditions, sourcing pumps that offer durability and reliability is vital.

In logistics and transportation, maintaining the correct tire pressure on fleet vehicles is critical for operational efficiency. Using tire pumps with pressure gauges helps logistics companies reduce fuel consumption, extend the lifespan of tires, and minimize the risk of breakdowns during transit. Buyers in this sector should focus on the compatibility of these pumps with various tire types and the robustness of the design, ensuring they can withstand heavy usage.

Illustrative image related to tire pump with pressure gauge

In manufacturing and warehousing, tire pumps are often used for inflating tires on forklifts and other material handling equipment. Proper tire inflation is essential for ensuring safety and operational efficiency in warehouses. A reliable tire pump with an accurate gauge can significantly reduce equipment downtime caused by tire-related issues. Buyers should consider the specific PSI requirements of their machinery and the gauge’s accuracy to ensure optimal performance.

Agricultural operations also benefit from tire pumps with pressure gauges, particularly for inflating tires on tractors and other farming equipment. Properly inflated tires enhance productivity and reduce the risk of accidents caused by tire failure in the field. Buyers in this sector should look for pumps that can adapt to different tire sizes and maintain reliability in outdoor conditions, where ruggedness is essential.

Lastly, in the sports and recreation industry, tire pumps are crucial for maintaining tires on bicycles and recreational vehicles. Proper inflation is vital for optimizing performance and safety during recreational activities. Buyers should prioritize the portability and ease of use of these pumps, along with the ability to set specific PSI levels for various tire types, ensuring they meet the diverse needs of recreational users.

Das Problem: A B2B buyer responsible for maintaining a fleet of vehicles faces the challenge of ensuring optimal tire pressure for safety and efficiency. However, they often find that the pressure gauges on their tire pumps provide inconsistent readings. This inconsistency leads to either under-inflation, resulting in increased fuel consumption, or over-inflation, which can cause premature tire wear and potential blowouts. The buyer is frustrated, as they cannot rely on their current equipment to maintain their fleet’s operational standards.

Die Lösung: To mitigate this issue, it is essential to invest in high-accuracy digital tire pressure gauges that have been recognized for their precision. Look for products that have received accolades for accuracy, such as those featured in industry reviews or product tests. When sourcing, prioritize gauges with a calibration certificate, ensuring they meet industry standards. Additionally, regular calibration checks should be implemented as part of a maintenance schedule to maintain accuracy over time. Educating staff on proper usage techniques, including waiting a few moments for readings to stabilize, can further enhance the reliability of pressure measurements.

Illustrative image related to tire pump with pressure gauge

Das Problem: A buyer managing a mobile tire repair service in a developing market encounters difficulties due to the bulkiness of their current tire pump with pressure gauge. The lack of portability means they struggle to transport their equipment to various job sites, leading to delays and inefficiencies in service delivery. As a result, they risk losing customers who require prompt assistance, impacting overall business growth and reputation.

Die Lösung: Investing in compact, lightweight tire inflators that come equipped with an integrated pressure gauge can greatly enhance operational efficiency. Look for models that are battery-operated or have a cord-free design, which adds flexibility in accessing hard-to-reach areas. When selecting a product, consider those that feature built-in storage for accessories to streamline the setup process at job sites. Training employees on how to quickly set up and operate these portable inflators can also improve service speed and customer satisfaction. Additionally, establishing partnerships with suppliers who offer reliable after-sales support can ensure that any issues encountered can be resolved swiftly.

Das Problem: A buyer in the automotive service industry faces challenges when dealing with a variety of tire types and sizes, including those for heavy-duty vehicles and passenger cars. Their current tire pump with pressure gauge lacks the versatility to accommodate these diverse requirements, leading to inefficiencies and customer dissatisfaction. The inability to quickly adjust and measure tire pressures for different vehicles results in extended service times and increased labor costs.

Die Lösung: To address this pain point, consider sourcing tire pumps with adjustable pressure settings and multiple nozzle attachments. These features allow for easy switching between different tire types without the need for multiple tools. Look for inflators that come with a digital pressure gauge capable of displaying a wide range of PSI levels, accommodating everything from low-pressure tires on motorcycles to high-pressure tires on commercial trucks. Investing in a comprehensive training program for staff on how to utilize these versatile tools can significantly reduce service times and enhance the customer experience. Additionally, maintaining an inventory of adapters and attachments can prepare the service team for any tire type that may come through the shop, ensuring readiness and flexibility in operations.

When selecting materials for tire pumps with pressure gauges, various factors such as performance, durability, cost, and regional compliance must be considered. Below is an analysis of four common materials used in the construction of these products.

Illustrative image related to tire pump with pressure gauge

Aluminum is a popular choice for tire pumps due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand pressures exceeding 200 PSI, making it suitable for various tire inflation tasks.

Vorteile: Aluminum offers a good strength-to-weight ratio, which enhances portability. It is also relatively easy to manufacture and can be anodized for additional protection against corrosion.

Nachteile: While durable, aluminum can be prone to dents and scratches, which may affect aesthetics and functionality over time. It is generally more expensive than plastic options.

Illustrative image related to tire pump with pressure gauge

Auswirkungen auf die Anwendung: Aluminum is compatible with air and other gases, but care must be taken with aggressive chemicals that could degrade the material.

Überlegungen für internationale Käufer: Compliance with ASTM standards is crucial. Buyers in regions like Africa and South America may prefer lightweight options for ease of transport, while European buyers often emphasize durability and longevity.

Steel, particularly stainless steel, is another common material used for tire pumps. It boasts high strength and excellent pressure resistance, with capabilities of handling pressures above 300 PSI.

Vorteile: Steel’s durability makes it ideal for heavy-duty applications. It is less likely to deform under stress compared to aluminum and can withstand harsher environments.

Nachteile: The main drawback is its weight, which can make the pump less portable. Additionally, while stainless steel is corrosion-resistant, it can still rust if the protective layer is compromised.

Auswirkungen auf die Anwendung: Steel is suitable for high-pressure applications and is compatible with various gases. However, it may not be ideal for corrosive environments unless adequately treated.

Überlegungen für internationale Käufer: Buyers should ensure that the products meet regional standards such as DIN or JIS. In the Middle East, where humidity can be high, corrosion-resistant treatments are essential.

Plastic is often used for more affordable tire pumps, particularly in the gauge components. Common types include ABS and polypropylene, which offer good chemical resistance and can handle moderate pressure levels.

Vorteile: Plastic is lightweight and cost-effective, making it an attractive option for budget-conscious buyers. It is also resistant to corrosion and can be molded into complex shapes.

Nachteile: Plastic is generally less durable than metal options, especially under high pressure or extreme temperatures. It may also become brittle over time.

Illustrative image related to tire pump with pressure gauge

Auswirkungen auf die Anwendung: Plastic is suitable for air and non-corrosive gases but should be avoided in applications involving high pressures or temperatures.

Überlegungen für internationale Käufer: Compliance with local standards is vital. Buyers in South America may prefer plastic for its cost-effectiveness, while European buyers may prioritize durability.

Rubber is commonly used for seals and hoses in tire pumps. It is flexible, has good pressure resistance, and can withstand temperatures up to 100°C.

Vorteile: Rubber provides excellent sealing capabilities, preventing air leaks. It is also resistant to wear and can handle repeated flexing.

Nachteile: Rubber can degrade over time due to exposure to UV light and ozone, which may lead to cracks and leaks. It is also less durable than metal components.

Illustrative image related to tire pump with pressure gauge

Auswirkungen auf die Anwendung: Rubber is essential for maintaining pressure in the pump and is compatible with air and most non-aggressive gases.

Überlegungen für internationale Käufer: Buyers should look for rubber components that meet ASTM or ISO standards for durability. In regions with extreme weather conditions, UV-resistant rubber is highly recommended.

| Material | Typical Use Case for tire pump with pressure gauge | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Body of portable tire pumps | Leicht und korrosionsbeständig | Anfällig für Dellen und Kratzer | Mittel |

| Stahl | Heavy-duty tire pumps | Hohe Festigkeit und Haltbarkeit | Heavier and potential rusting | Hoch |

| Kunststoff | Gauge components and low-cost pumps | Kostengünstig und leicht | Less durable under high pressure | Niedrig |

| Gummi | Dichtungen und Schläuche | Hervorragende Dichtungseigenschaften | Verschlechtert sich mit der Zeit | Mittel |

This material selection guide provides B2B buyers with critical insights into the various materials used in tire pumps with pressure gauges, helping them make informed decisions based on performance, cost, and regional compliance.

The manufacturing process of tire pumps with pressure gauges involves several critical stages: material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in ensuring the final product meets quality and performance standards that international buyers expect.

The selection of materials is fundamental in the production of tire pumps. Common materials include high-grade plastics, aluminum, and brass for the body, along with rubber seals and O-rings for airtightness. The preparation phase involves sourcing these materials from certified suppliers, ensuring they meet specific international standards for durability and safety.

Materials undergo rigorous checks for quality before being approved for production. This often includes tests for tensile strength, flexibility, and resistance to wear and tear. Suppliers must provide material certifications that demonstrate compliance with relevant standards, which is crucial for B2B buyers seeking reliable products.

Forming techniques vary based on the design of the tire pump. For plastic components, injection molding is a common method, where heated plastic is injected into molds to create the desired shapes. Metal parts may be produced through die-casting or machining, which ensures precision in dimensions and performance.

Illustrative image related to tire pump with pressure gauge

Following the forming process, the components are prepared for assembly. This phase may include surface treatments such as anodizing or powder coating to enhance corrosion resistance and aesthetic appeal. Quality assurance begins here, with initial checks on the dimensions and surface finishes of the formed parts to ensure they align with specifications.

The assembly stage involves bringing together all the components, including the pump body, pressure gauge, hoses, and valves. This process is typically automated but may also include manual assembly for complex components. Skilled operators oversee the assembly to ensure that each part is fitted correctly.

During assembly, various tests are conducted to ensure proper functionality. For instance, pressure tests check for leaks, and operational tests assess the ease of use and responsiveness of the pressure gauge. Each pump undergoes a thorough inspection before moving to the finishing stage.

The finishing stage focuses on enhancing the product’s appearance and performance. This may involve applying protective coatings, adding labels, and packaging the final product. Quality checks are crucial at this stage, ensuring that all products meet branding and aesthetic standards while maintaining functionality.

Quality assurance (QA) is integral to the manufacturing process of tire pumps with pressure gauges. It involves a structured approach to monitoring and improving product quality at each stage of production.

Illustrative image related to tire pump with pressure gauge

International standards such as ISO 9001 provide a framework for quality management systems, ensuring consistency and continuous improvement. Compliance with these standards is essential for manufacturers targeting international markets, as they demonstrate a commitment to quality.

Other certifications may include CE marking for products sold in Europe and API standards for those in the oil and gas industry. For tire pumps, adherence to these standards assures buyers of product safety and reliability.

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that defects are identified and rectified early. Key checkpoints include:

Eingehende Qualitätskontrolle (IQC): This stage involves inspecting raw materials and components as they arrive at the facility. Suppliers must provide documentation proving compliance with specified standards.

Prozessbegleitende Qualitätskontrolle (IPQC): During production, random samples are taken to ensure that the assembly process adheres to quality standards. This involves monitoring dimensions, functionalities, and assembly techniques.

Endgültige Qualitätskontrolle (FQC): Once assembly is complete, every tire pump undergoes comprehensive testing to verify performance and durability. This may include pressure testing and functionality assessments to ensure the product meets specifications.

B2B buyers can verify a supplier’s quality control measures through several methods:

Audits: Conducting factory audits allows buyers to assess the manufacturing processes, quality management systems, and compliance with international standards firsthand.

Qualitätsberichte: Requesting detailed QC reports provides insights into the testing methods used, defect rates, and corrective actions taken by the supplier.

Inspektionen durch Dritte: Engaging third-party inspection agencies can ensure unbiased evaluations of product quality and adherence to specifications. This is particularly important for buyers from regions such as Africa and South America, where local regulations may differ.

International buyers must navigate various nuances in quality control and certifications. For instance, buyers in Europe may require CE certification, while those in the Middle East might prioritize compliance with local standards. Understanding these differences is essential for ensuring product acceptance in target markets.

Additionally, cultural factors can influence quality perceptions. For instance, buyers from different regions may have varying expectations regarding product durability and performance, which manufacturers should consider during the design and production phases.

Illustrative image related to tire pump with pressure gauge

The manufacturing process for tire pumps with pressure gauges is a complex interplay of material selection, forming techniques, assembly, and finishing, all underpinned by rigorous quality assurance protocols. For B2B buyers, understanding these processes and the relevant quality control measures is crucial in sourcing reliable products that meet international standards. By focusing on these aspects, buyers can ensure they partner with manufacturers committed to delivering quality and performance.

The procurement of a tire pump with a pressure gauge requires careful consideration of various factors to ensure that you select the best product for your needs. This guide offers a comprehensive checklist to assist B2B buyers in making informed purchasing decisions.

Clearly outline the technical specifications that your tire pumps must meet. Consider factors such as maximum pressure, type of pump (manual vs. electric), and compatibility with different tire types. Establishing these criteria upfront will streamline the sourcing process and help you avoid products that do not meet your operational needs.

Understand the specific requirements of the markets you intend to serve. Different regions may have unique preferences regarding tire pump features, such as pressure gauges in PSI or bar units. Tailoring your product selection to align with local preferences can enhance market acceptance and customer satisfaction.

Illustrative image related to tire pump with pressure gauge

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, case studies, and references from other clients in your industry. Pay attention to suppliers’ certifications, such as ISO, to ensure they meet quality standards. This step helps mitigate risks associated with poor-quality products.

Investigate the quality of the tire pumps and pressure gauges offered by potential suppliers. Look for features such as digital displays, automatic shut-off, and durable materials. Ensure that the products have received positive reviews and have been recognized for accuracy and reliability in various industry publications.

Always request samples before placing a bulk order. Testing samples allows you to evaluate the functionality, durability, and user experience of the tire pumps firsthand. This step is crucial for identifying any potential issues and ensuring that the product meets your quality expectations.

Compare pricing structures among different suppliers, considering not only the unit cost but also shipping fees, payment terms, and warranty conditions. A lower price may not always indicate the best value; assess the overall cost of ownership, including maintenance and potential replacements.

Once you have selected a supplier, engage in negotiations to establish favorable terms. Clearly outline delivery timelines, payment schedules, and quality assurance measures in your contracts. Having a well-defined agreement can prevent disputes and ensure that both parties have aligned expectations.

Illustrative image related to tire pump with pressure gauge

By following these steps, B2B buyers can effectively navigate the sourcing process for tire pumps with pressure gauges, ensuring that they select products that meet their operational requirements while fostering positive supplier relationships.

Understanding the cost structure and pricing dynamics of tire pumps with pressure gauges is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. Below is a comprehensive breakdown of the cost components, price influencers, and essential buyer tips.

Materialien: The primary materials used in manufacturing tire pumps and gauges include durable plastics, metals (such as brass for the pressure gauge), and electronic components. The choice of materials can significantly impact both cost and quality. For instance, high-grade metals and reinforced plastics can enhance durability but also increase the base cost.

Arbeit: Labor costs can vary widely depending on the manufacturing location. For example, factories in countries with lower labor costs (such as Vietnam) may offer more competitive pricing compared to those in Europe. Labor also includes skilled technicians who ensure the precision required for accurate pressure readings.

Fertigungsgemeinkosten: This includes expenses related to utilities, factory maintenance, and administrative costs. Efficient production processes can help minimize overhead, thereby reducing overall product costs.

Werkzeugbau: Initial setup costs for molds and specialized machinery can be significant. These costs are usually amortized over large production runs, meaning higher volume orders can lead to lower per-unit costs.

Qualitätskontrolle (QC): Ensuring product quality is vital, particularly for safety-related products like tire pumps. Quality assurance processes may involve testing and certification, which can add to the overall cost but are essential for maintaining brand reputation.

Logistik: Shipping costs can fluctuate based on the mode of transportation, distance, and volume. Incoterms also play a critical role in defining responsibilities and costs related to shipping, which can impact the total landed cost.

Marge: Suppliers typically add a margin to cover their costs and profit. This margin can vary depending on market competition, brand positioning, and product demand.

Volumen/MOQ: Minimum Order Quantities (MOQs) can greatly affect pricing. Suppliers often offer discounts for larger orders, allowing buyers to achieve better pricing per unit.

Spezifikationen und Anpassungen: Customized products or those with advanced features (like digital displays) may come at a premium. Buyers should assess whether the added features justify the higher costs.

Materialien und Qualitätszertifikate: Products made from high-quality materials or those that meet specific industry certifications (e.g., ISO, CE) can command higher prices. Buyers should consider the Total Cost of Ownership (TCO) when evaluating these options.

Lieferanten-Faktoren: Established suppliers may offer better reliability and service but at a higher cost. Newer or less known suppliers might offer lower prices but could come with risks related to product quality or service.

Incoterms: Understanding the terms of shipment can influence the overall price. For example, FOB (Free On Board) means the buyer takes on costs and risks once the goods are loaded onto the shipping vessel, which can affect total pricing.

Negotiate Wisely: Leverage bulk purchasing and long-term contracts to negotiate better pricing. Being transparent about your purchasing intentions can lead to favorable terms.

Assess Total Cost of Ownership: Don’t just focus on the purchase price. Consider maintenance, durability, and potential downtime costs associated with lower-quality products.

Forschung Marktpreise: Regularly benchmark prices against competitors and suppliers to ensure you are receiving competitive quotes.

Understand Pricing Nuances for International Sourcing: Be aware of tariffs, import duties, and local regulations that can affect pricing when sourcing from international suppliers.

Stay Informed on Market Trends: Keep an eye on technological advancements and market shifts that can impact material costs and pricing strategies.

The prices discussed in this analysis are indicative and can vary based on supplier, market conditions, and specific product features. Always seek formal quotes and conduct thorough due diligence before making purchasing decisions.

Illustrative image related to tire pump with pressure gauge

In the realm of tire maintenance, the tire pump with pressure gauge stands out as a popular choice among B2B buyers. However, several alternative solutions are available that can also effectively address tire inflation and pressure monitoring needs. Understanding these alternatives allows businesses to make informed decisions based on their specific requirements, budget, and operational context.

| Vergleich Aspekt | Tire Pump With Pressure Gauge | Electric Tire Inflator | Tragbarer Luftkompressor |

|---|---|---|---|

| Leistung | Provides manual inflation and pressure reading; requires physical effort. | Quick inflation, often automatic; integrated gauges for precise readings. | Versatile; can inflate tires and other equipment; may require more power. |

| Kosten | Generally low-cost, ranging from $20-$60. | Mid-range, typically $50-$150 depending on features. | Higher initial investment, often $100 and above. |

| Leichte Implementierung | Simple to use; requires minimal setup. | User-friendly; plug-and-play functionality with less manual effort. | More complex setup; may require additional power sources or adapters. |

| Wartung | Low maintenance; occasional checks for wear and tear. | Minimal maintenance; typically requires battery care or cord checks. | Regular maintenance needed for motor and electrical components. |

| Bester Anwendungsfall | Ideal for personal use or small fleets needing manual inflation. | Best for quick inflation needs, especially in emergency situations. | Suitable for larger operations requiring frequent inflation of various equipment. |

Electric tire inflators are designed for efficiency, significantly reducing the time and effort required for tire inflation. These devices often feature automatic shut-off functions and built-in pressure gauges, allowing for precise inflation without the need for manual adjustments. However, they typically come at a higher price point and may require access to a power source, which can limit their portability in certain situations.

Portable air compressors offer a versatile solution for inflating tires and other equipment. These devices can handle larger volumes of air and are often equipped to inflate various items beyond tires, such as sports equipment and air mattresses. While they provide great flexibility, they generally require a higher initial investment and may necessitate more maintenance due to their motorized components. Additionally, their operation can be less straightforward than that of simpler tire pumps, which may be a consideration for less tech-savvy users.

When selecting between a tire pump with pressure gauge and its alternatives, B2B buyers should assess their specific needs and operational context. Considerations such as the frequency of use, the range of applications needed, budget constraints, and the technical expertise of staff are crucial in making an informed decision. For businesses that prioritize efficiency and speed, electric tire inflators may be the best option. Conversely, those seeking a straightforward, cost-effective solution might find that a traditional tire pump with a pressure gauge meets their needs effectively. Ultimately, aligning the chosen solution with operational requirements will ensure optimal performance and value.

Illustrative image related to tire pump with pressure gauge

When sourcing tire pumps with pressure gauges, understanding critical technical specifications is vital for making informed purchasing decisions. Here are some key properties to consider:

The pressure range indicates the maximum and minimum pressure the pump can handle, typically measured in PSI (pounds per square inch). A wider range, such as 0-200 PSI, accommodates various tire types, from bicycles to heavy-duty vehicles. For B2B buyers, selecting a pump with an appropriate pressure range ensures compatibility with their entire fleet, reducing the need for multiple devices.

The materials used in construction, such as aluminum, brass, or high-grade plastics, determine durability and performance. Aluminum and brass offer robust resistance to corrosion, making them ideal for long-term use in diverse environmental conditions. Buyers in regions with harsh climates should prioritize pumps with high-quality materials to ensure longevity and reliability, thus minimizing replacement costs.

Accuracy, often specified as a percentage (e.g., ±1%), is critical for tire pressure gauges. A precise gauge prevents under-inflation or over-inflation, which can lead to tire wear or failure. Calibration is the process of adjusting the gauge to ensure it provides accurate readings. B2B buyers should look for products that come with calibration certificates or adjustable features to maintain accuracy over time.

Illustrative image related to tire pump with pressure gauge

Inflation speed, measured in liters per minute (L/min), indicates how quickly the pump can inflate a tire. Faster inflation times can enhance operational efficiency, particularly in commercial settings where time is crucial. A pump that can inflate a standard car tire in under five minutes can significantly improve service turnaround for tire shops or fleet operators.

Tire pumps may be powered by electricity, batteries, or manual operation. Electric pumps provide consistent power but require access to electricity, while battery-operated models offer portability. Manual pumps are less common in commercial settings due to their labor-intensive nature. Understanding the power source helps buyers assess suitability for their specific operational needs and logistical considerations.

Familiarity with trade terminology is essential for effective communication and negotiation in the tire pump market. Here are some common terms:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire pumps, understanding OEM relationships can help buyers secure quality products that meet industry standards, ensuring compatibility with existing equipment.

Illustrative image related to tire pump with pressure gauge

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and overall purchasing strategy. Knowing the MOQ helps businesses plan their stock levels and negotiate better terms with suppliers.

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For tire pumps, issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they secure the best deal based on price, quality, and delivery terms.

Incoterms define the responsibilities of buyers and sellers in international transactions, including delivery, risk, and costs. Familiarity with these terms helps buyers understand shipping logistics, cost allocation, and potential risks involved in importing tire pumps from different regions.

SKU is a unique identifier used to track products in inventory. Understanding SKUs allows businesses to manage their stock efficiently and streamline the ordering process, ensuring they maintain adequate supplies of tire pumps and related equipment.

In conclusion, a comprehensive understanding of the essential technical properties and trade terminology related to tire pumps with pressure gauges equips B2B buyers with the knowledge needed for effective decision-making. Prioritizing the right specifications and familiarizing themselves with industry jargon can significantly enhance procurement strategies and operational efficiency.

Illustrative image related to tire pump with pressure gauge

The tire pump with pressure gauge sector is witnessing significant transformation driven by several global factors. The increasing awareness of vehicle maintenance and safety, particularly in emerging markets such as Africa and South America, is propelling demand for reliable tire maintenance solutions. B2B buyers are increasingly prioritizing products that combine functionality with innovative technology, such as digital gauges that offer enhanced accuracy and ease of use. Additionally, the rise of electric vehicles (EVs) is influencing product design, with manufacturers developing pumps that cater specifically to the unique requirements of EVs, such as higher inflation pressures and faster inflation times.

Emerging technologies, such as IoT integration, are also becoming prevalent. Smart tire pressure monitoring systems can provide real-time data, enhancing both user experience and operational efficiency for businesses. Furthermore, the shift towards e-commerce platforms for procurement is reshaping sourcing strategies, allowing international buyers to access a broader range of products and suppliers. As logistics improve and shipping costs decrease, businesses can leverage global supply chains to source high-quality products at competitive prices.

Sustainability has become a paramount concern in the tire pump with pressure gauge sector. The environmental impact of manufacturing processes, including resource consumption and waste generation, is under scrutiny. B2B buyers are increasingly seeking products that are made from sustainable materials and manufactured through processes that minimize ecological footprints. Companies that adopt ethical sourcing practices not only contribute to environmental preservation but also enhance their brand reputation among environmentally-conscious consumers.

Buyers should look for suppliers who prioritize green certifications, such as ISO 14001 for environmental management systems or certifications related to the use of recycled materials. Incorporating sustainable practices can also extend to packaging, with a growing trend towards biodegradable or recyclable packaging materials. This shift not only meets regulatory requirements but also resonates with a customer base that values corporate responsibility. By prioritizing sustainable sourcing, B2B buyers can align their procurement strategies with global sustainability goals, ultimately contributing to a healthier planet.

Illustrative image related to tire pump with pressure gauge

The tire pump with pressure gauge has evolved significantly since its inception. Initially, manual pumps dominated the market, requiring considerable physical effort to achieve desired tire pressures. However, advancements in technology have led to the introduction of electric and digital options, which enhance user convenience and measurement accuracy. The integration of digital displays and automated inflation systems has transformed how consumers interact with these products.

In recent years, the sector has seen an increasing emphasis on portability and ease of use, with manufacturers designing compact and lightweight models suitable for both personal and commercial use. This evolution reflects broader trends in consumer electronics and automotive maintenance, where efficiency and user experience are paramount. As the industry continues to innovate, B2B buyers can expect ongoing developments that cater to the changing needs of their markets.

1. How do I choose the right tire pump with pressure gauge for my business needs?

When selecting a tire pump with a pressure gauge, consider factors such as the intended use (e.g., automotive, commercial, or industrial), the desired PSI range, and the pump’s portability. Evaluate the gauge’s accuracy, ease of reading, and durability, especially in harsh environments. It’s also vital to assess the pump’s power source—manual, electric, or battery-operated—based on your operational context. Lastly, look for additional features like built-in LED lights or automatic shut-off functions that enhance usability.

2. What is the best tire pump with a pressure gauge for commercial use?

For commercial applications, the best tire pump is typically one that offers a high PSI rating, durability, and efficiency. Models like the FlowPro® Digital Tire Inflator are popular choices due to their robust construction and fast inflation capabilities. Additionally, consider pumps that come with features like automatic pressure settings and large digital displays for ease of use. Always prioritize products recognized for their accuracy and reliability, as these factors significantly impact operational efficiency.

3. How can I verify the quality of tire pumps from potential suppliers?

To verify the quality of tire pumps, request samples before placing bulk orders. Conduct thorough research on the supplier’s reputation by checking reviews and ratings from other B2B buyers. It’s also beneficial to ask for certifications that indicate compliance with international quality standards (e.g., ISO). Additionally, consider arranging factory visits or audits to assess manufacturing processes and quality control measures firsthand. Establishing clear communication regarding your quality expectations is crucial for maintaining standards.

4. What are the typical minimum order quantities (MOQs) for tire pumps with pressure gauges?

Minimum order quantities (MOQs) for tire pumps can vary significantly based on the supplier and the specific product. Generally, MOQs may range from 50 to 500 units for standard models, while customized or specialized pumps may require higher MOQs. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you’re testing a new product line. Some suppliers may offer tiered pricing based on order volume, which can be advantageous for budgeting.

5. What payment terms should I expect when sourcing tire pumps internationally?

Payment terms for international purchases of tire pumps typically include options like advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Many suppliers may request a deposit upfront, followed by the balance upon shipment or receipt of goods. It’s essential to clarify payment methods accepted (bank transfer, PayPal, etc.) and understand any currency conversion implications. Discussing payment terms upfront helps avoid misunderstandings and ensures smoother transactions.

6. How do logistics and shipping impact my tire pump procurement?

Logistics and shipping are critical factors in tire pump procurement, influencing delivery times and costs. Consider the shipping method (air, sea, or land) based on urgency and budget. Assess the supplier’s ability to handle customs clearance and documentation, which can affect delivery efficiency. It’s wise to work with logistics partners experienced in international shipping to navigate regulations and potential delays. Always factor in shipping costs when calculating the overall product price.

7. Can I customize tire pumps with specific features for my market?

Yes, many manufacturers offer customization options for tire pumps to meet specific market needs. Customizations can include branding, color schemes, pressure ratings, and additional functionalities like built-in lights or digital displays. When discussing customization with suppliers, ensure you provide detailed specifications and understand any implications on pricing and lead times. Collaborating closely with the manufacturer during the design phase can lead to a product that better suits your target market.

8. What should I include in my quality assurance (QA) process for tire pumps?

In your quality assurance process for tire pumps, include a comprehensive checklist that covers product specifications, performance testing, and safety standards compliance. Establish inspection criteria for incoming shipments, including physical checks for damage and functional tests for pressure accuracy. Additionally, consider periodic audits of the supplier’s production processes to ensure ongoing compliance with quality standards. Document all findings and communicate any issues promptly to maintain product integrity and customer satisfaction.

Bereich: jacosuperiorproducts.com

Registriert: 2014 (11 Jahre)

Einleitung: 1. ElitePro™ Digital Tire Pressure Gauge – Professional Accuracy – 100 PSI

– Price: $29.95 (Original: $79.99)

– Featured in “Top 10 Products of 2025” by Project Farm

– Crowned “Most Accurate Tire Gauge” by Project Farm in 2024

– Rated “Best Overall Tire Pressure Gauge” in 2024

2. ElitePro™ Digital Tire Pressure Gauge – Professional Accuracy – 200 PSI

– Price: $29.95 (Original: $79….

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: 1. Tire Gauge Brands: Longacre (known for analog and digital models, accurate, temperature compensated, used by racers). 2. Tire Inflator Recommendations: Astro (approximately $80, noted for quality), Matco DT6 (approximately $160, rebranded Astro 3018, approximately $90). 3. General Advice: Tire inflators should not be trusted to measure pressure accurately; choose based on convenience and speed …

Bereich: fanttik.com

Registered: 2020 (5 years)

Einleitung: 2X Faster Electric Tire Inflators, Various Models: X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Prices range from $48.99 to $199.97 with discounts up to 50%. Regular price for X9 Pro is $79.97, currently on sale for $75.99. X8 APEX is priced at $89.99, down from $99.99. X9 Classic is available for $69.99, reduced from $109.99. X10 APEX is priced at $109.99, down from $119.99….

Bereich: matcotools.com

Registriert: 1996 (29 Jahre)

Einleitung: This company, Matco Tools – Rechargeable Digital Tire Inflator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the rapidly evolving market for tire pumps with pressure gauges, strategic sourcing has become essential for international B2B buyers. The emphasis on accuracy, durability, and innovative features like digital displays and fast inflation times positions quality products as key differentiators. Buyers should prioritize suppliers who offer proven performance, as evidenced by accolades and customer reviews, ensuring they meet the diverse needs of various regional markets.

Illustrative image related to tire pump with pressure gauge

As businesses in Africa, South America, the Middle East, and Europe seek reliable tire inflation solutions, understanding local demand and leveraging supplier relationships will drive success. Investing in high-quality tire pumps not only enhances operational efficiency but also strengthens brand reputation by providing customers with dependable products.

Looking ahead, the increasing adoption of electric vehicles and the demand for portable solutions highlight the need for suppliers to innovate continually. B2B buyers are encouraged to explore partnerships that align with these trends, ensuring they remain competitive in a dynamic marketplace. By prioritizing strategic sourcing, businesses can secure the right products to meet future challenges and capitalize on emerging opportunities in the tire inflation sector.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.