In the rapidly evolving landscape of industrial machinery, sourcing the right air machine compressor can be a daunting task for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With varying regional requirements, compliance standards, and technological advancements, the challenge lies not just in selecting a compressor that meets operational needs but also in ensuring it aligns with budgetary constraints and supply chain capabilities.

This comprehensive guide serves as an essential resource for international buyers, detailing the spectrum of air machine compressors available on the market. From portable models ideal for small workshops to robust industrial units designed for large-scale operations, we will explore various types and their specific applications across different industries. Additionally, the guide will offer insights on supplier vetting processes, helping you identify reputable manufacturers and distributors, while also addressing cost considerations that can significantly impact your purchasing decisions.

By leveraging the insights and strategies outlined in this guide, B2B buyers can confidently navigate the complexities of the air machine compressor market. Empowered with knowledge about product specifications, market trends, and supplier reliability, you will be well-equipped to make informed purchasing decisions that enhance operational efficiency and drive business growth in your respective regions.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Reciprocating Compressors | Uses pistons to compress air; can be single or multi-stage. | Construction, automotive, manufacturing. | Vorteile: High pressure, versatile. Nachteile: Noisy, requires maintenance. |

| Rotary Screw Compressors | Continuous operation; uses two rotating screws. | Industrial manufacturing, HVAC systems. | Vorteile: Efficient, low noise, long lifespan. Nachteile: Höhere Anfangskosten. |

| Centrifugal Compressors | Uses a rotating disk to compress air; suitable for high-volume applications. | Power plants, petrochemical industries. | Vorteile: High efficiency for large volumes. Nachteile: Expensive, complex maintenance. |

| Scroll Compressors | Uses spiral elements for compression; compact and quiet. | Refrigeration, medical equipment. | Vorteile: Quiet, low vibration, energy-efficient. Nachteile: Limited pressure output. |

| Gas Compressors | Compresses gases other than air; can be reciprocating or rotary. | Oil & gas, chemical processing. | Vorteile: Versatile for different gases. Nachteile: Specialized maintenance required. |

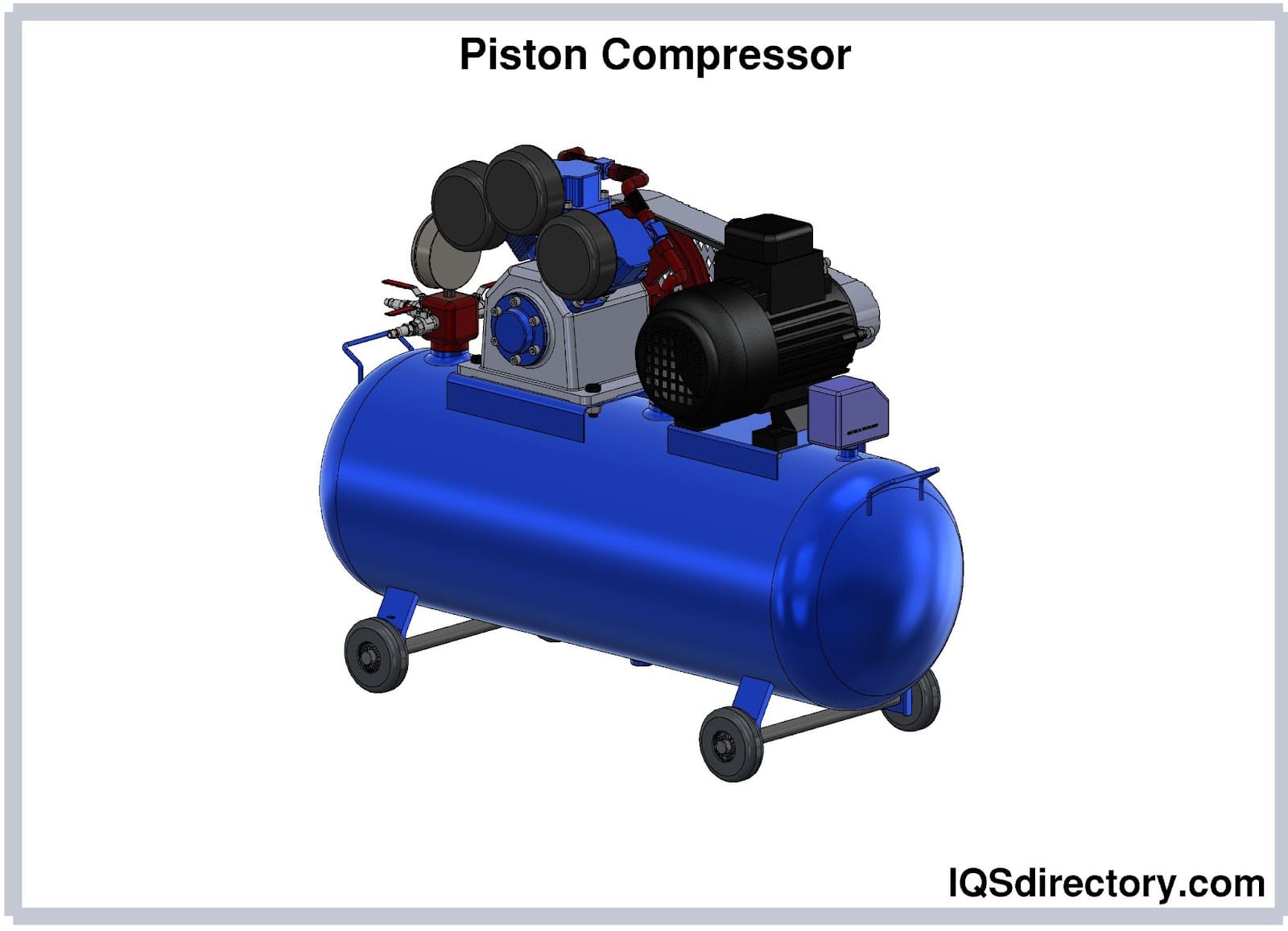

Reciprocating compressors are characterized by their use of pistons to compress air, making them suitable for both low and high-pressure applications. They are often found in construction and automotive sectors due to their ability to generate high pressure. However, they can be noisy and require regular maintenance, which may be a consideration for B2B buyers in noise-sensitive environments.

Rotary screw compressors operate continuously by utilizing two interlocking screws to compress air. This design makes them ideal for industrial manufacturing and HVAC systems where a constant air supply is needed. While they offer a longer lifespan and quieter operation, their higher initial investment may deter some buyers. Companies should weigh the long-term efficiency against upfront costs.

Centrifugal compressors are designed for high-volume applications, utilizing a rotating disk to compress air. They are primarily used in power plants and petrochemical industries due to their efficiency in handling large air volumes. However, they come with a higher price tag and complex maintenance requirements, making them suitable for businesses that can afford the initial investment and ongoing upkeep.

Scroll compressors utilize spiral elements to compress air, offering a compact and quiet operation. They are commonly used in refrigeration and medical equipment, where noise and vibration can be critical factors. While they are energy-efficient, their limited pressure output makes them less suitable for high-demand applications. Buyers should consider their specific pressure requirements when choosing this type.

Gas compressors, which can be either reciprocating or rotary, are designed to compress gases other than air, such as natural gas or refrigerants. They are essential in industries like oil and gas and chemical processing. While they provide versatility for different gases, they also require specialized maintenance, which can impact operational efficiency. B2B buyers should assess their specific gas compression needs and maintenance capabilities before purchasing.

| Industrie/Sektor | Specific Application of air machine compressor | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Herstellung | Betrieb von Druckluftwerkzeugen | Increased productivity and efficiency | Energy efficiency, maintenance support, and capacity |

| Bauwesen | Concrete compaction | Enhanced project timelines and quality | Durability, mobility, and pressure specifications |

| Automobilindustrie | Paint spraying and surface finishing | Superior finish quality and reduced waste | Compatibility with paint types, air pressure control |

| Food & Beverage | Packaging and bottling processes | Improved hygiene and operational speed | Compliance with health standards, material compatibility |

| Öl und Gas | Drilling and extraction operations | Enhanced operational safety and efficiency | Robustness, pressure ratings, and service availability |

In the manufacturing sector, air machine compressors power pneumatic tools essential for assembly lines, material handling, and machine operation. They significantly enhance productivity by providing a reliable air supply for tools such as drills, impact wrenches, and conveyor systems. For international buyers, sourcing compressors with energy efficiency ratings and robust maintenance support is crucial to minimize downtime and operational costs.

In construction, air compressors are vital for concrete compaction and powering pneumatic equipment. This application accelerates project timelines and ensures high-quality results in tasks such as drilling, demolition, and surface preparation. Buyers in regions like Africa and South America should prioritize compressors that offer mobility and durability, especially in remote or rugged environments.

Air compressors are extensively used in the automotive industry for paint spraying and surface finishing. They provide a consistent air supply that ensures a smooth application and reduces overspray, leading to less waste and a superior finish. B2B buyers must consider compatibility with various paint types and the ability to control air pressure to achieve optimal results.

In the food and beverage industry, air compressors are used in packaging and bottling processes, enhancing operational speed and maintaining hygiene standards. Compressors help in tasks such as sealing and filling, which are crucial for product preservation. Buyers should ensure that the compressors meet health compliance standards and are made from food-grade materials to prevent contamination.

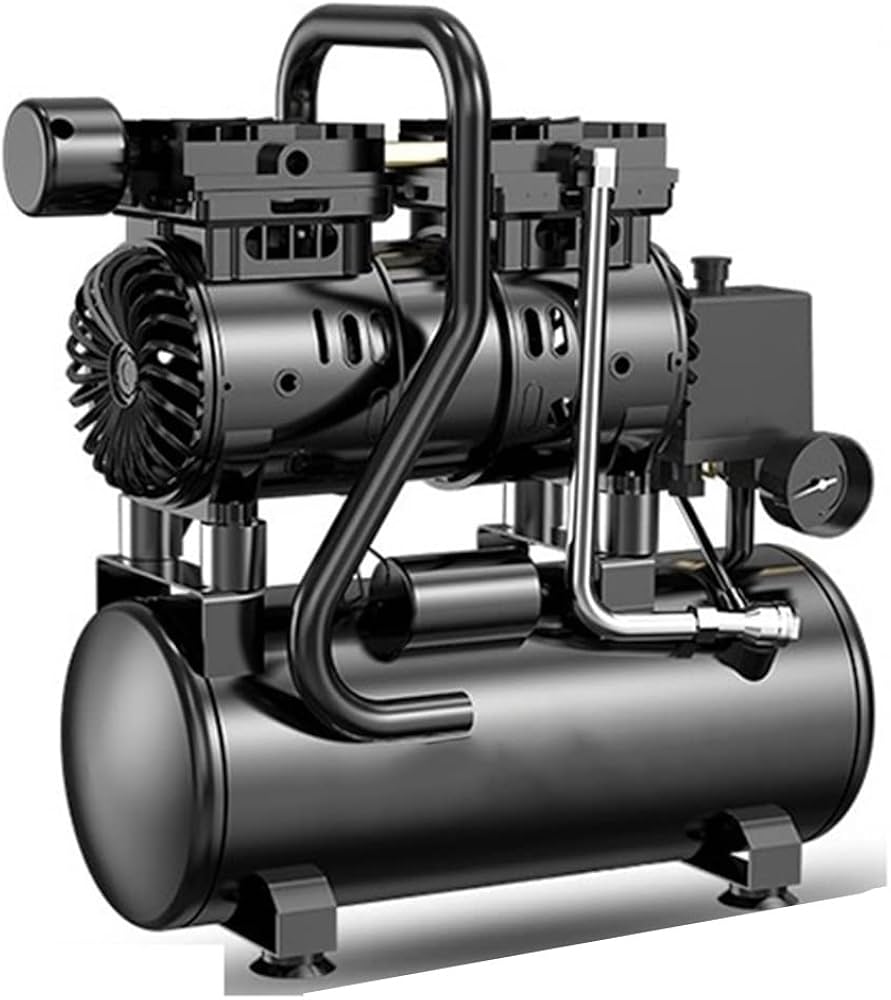

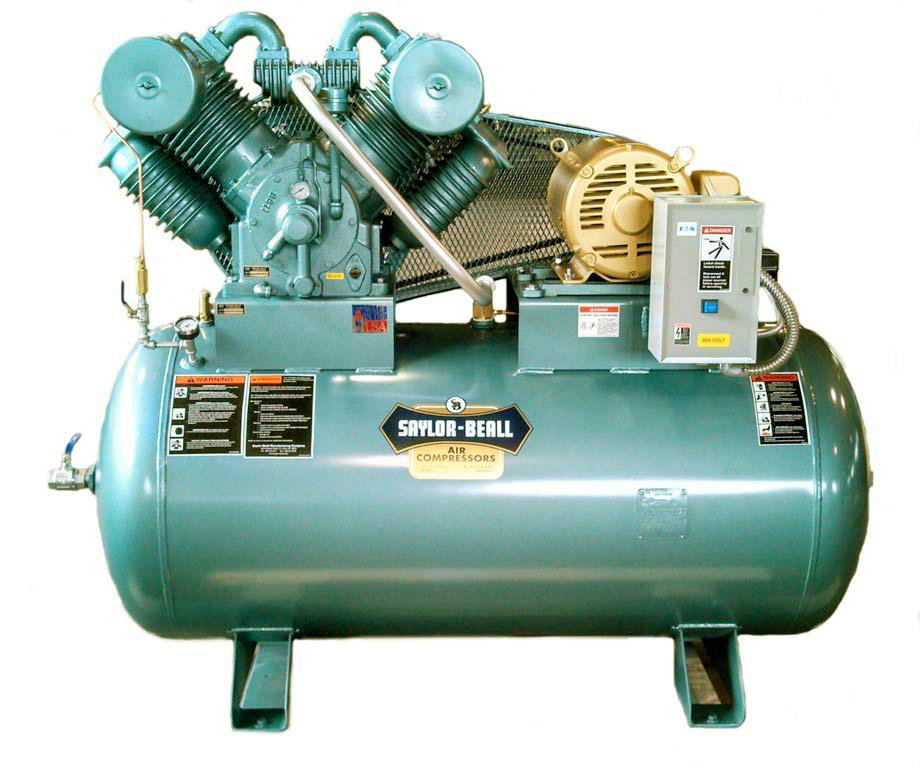

Illustrative image related to air machine compressor

Air compressors play a pivotal role in the oil and gas sector, particularly in drilling and extraction operations. They provide the necessary power for drilling rigs and other equipment, enhancing operational safety and efficiency. For international buyers, sourcing compressors that are robust and have high-pressure ratings is essential, given the demanding nature of the industry and the need for reliable service availability.

Das Problem: In many industrial settings, such as manufacturing plants or construction sites, B2B buyers often face the challenge of insufficient air supply from their compressors. This can lead to equipment downtime, decreased productivity, and ultimately financial losses. For instance, a factory that relies on pneumatic tools may find that their current compressor cannot keep up with the air demand during peak operation hours, forcing teams to halt work until the compressor can catch up or be manually adjusted.

Die Lösung: To prevent such disruptions, it’s essential for B2B buyers to conduct a thorough air demand analysis before purchasing or upgrading an air machine compressor. Start by cataloging all pneumatic tools and equipment that will be used, noting their air consumption rates (typically measured in cubic feet per minute, or CFM). Once you have this data, select a compressor that not only meets but exceeds the total demand to accommodate peak usage and future growth. Additionally, consider investing in a variable speed drive (VSD) compressor, which can adjust its speed based on the demand, thus improving energy efficiency and extending the life of the equipment.

Das Problem: Another common issue faced by B2B buyers is the frequent breakdown of air compressors, often due to inadequate maintenance or improper usage. For example, a construction company may find that their portable air compressor consistently fails during critical tasks, resulting in project delays and increased labor costs. These breakdowns can stem from a lack of regular maintenance checks or using the compressor beyond its designed capabilities, leading to wear and tear.

Illustrative image related to air machine compressor

Die Lösung: To mitigate these risks, establishing a proactive maintenance schedule is crucial. Buyers should create a checklist for daily, weekly, and monthly maintenance tasks, including checking oil levels, inspecting hoses for leaks, and cleaning air filters. Additionally, invest in training for operators on the proper use of the compressors to ensure they are not overloading the machines or using them incorrectly. For companies with multiple compressors, consider implementing a centralized monitoring system that tracks performance and alerts maintenance teams to potential issues before they lead to failures.

Das Problem: B2B buyers often struggle with sourcing compatible replacement parts for their air machine compressors. This can become particularly frustrating when specific parts are required for older or less common models, leading to extended downtime as companies scramble to find solutions. In some cases, international buyers may face additional challenges with shipping delays or tariffs, complicating the replacement process further.

Die Lösung: To streamline the sourcing of replacement parts, buyers should maintain an inventory of essential spare parts that are frequently required for their specific compressor models. Establish relationships with reliable suppliers who specialize in air compressor parts and can provide quick access to both common and hard-to-find components. Additionally, consider signing a service agreement with the compressor manufacturer or a certified repair service to ensure timely access to parts and expert assistance when needed. Utilizing an online marketplace or dedicated platforms for industrial parts can also enhance sourcing efficiency, allowing for better price comparisons and availability checks across different regions.

Illustrative image related to air machine compressor

When selecting materials for air machine compressors, understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and ensuring longevity. Here, we analyze four common materials used in the construction of air compressors: aluminum, cast iron, steel, and composite materials.

Aluminum is widely used in air compressor manufacturing due to its excellent strength-to-weight ratio. It typically has a temperature rating up to 300°F (149°C) and can withstand moderate pressures. Its corrosion resistance is notable, making it suitable for environments with high humidity or exposure to chemicals.

Vorteile: Aluminum is lightweight, which simplifies installation and reduces shipping costs. It also offers good thermal conductivity, aiding in heat dissipation.

Nachteile: However, aluminum can be more expensive than other materials and may not be suitable for high-pressure applications due to its lower tensile strength compared to steel or cast iron.

Auswirkungen auf die Anwendung: Aluminum is compatible with various media, including air and non-corrosive gases, making it a versatile choice for many applications.

Illustrative image related to air machine compressor

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM and EN is essential, especially in regions like Europe and the Middle East where regulations are stringent.

Cast iron is a traditional material for air compressors, particularly in heavy-duty applications. It has excellent durability and can withstand high temperatures and pressures, typically rated up to 500°F (260°C) and 175 psi.

Vorteile: Cast iron is highly durable and resistant to wear and tear, making it ideal for industrial environments.

Nachteile: The primary drawback is its weight, which can complicate transportation and installation. Additionally, cast iron is more prone to corrosion if not properly maintained.

Auswirkungen auf die Anwendung: Cast iron is suitable for applications requiring high pressure and temperature stability, such as in manufacturing and automotive industries.

Überlegungen für internationale Käufer: Buyers should ensure compliance with local standards and certifications, particularly in regions where heavy machinery regulations are strict.

Steel is another common material used in air compressors, offering a balance of strength and cost-effectiveness. Its temperature rating can reach up to 600°F (316°C), and it is capable of handling high pressures.

Vorteile: Steel is strong and relatively inexpensive, making it a popular choice for manufacturers. It also has good resistance to deformation under stress.

Nachteile: However, steel is susceptible to corrosion if not properly treated, requiring protective coatings or regular maintenance.

Auswirkungen auf die Anwendung: Steel is suitable for a wide range of applications, including those involving air, water, and various gases, provided proper corrosion protection is applied.

Überlegungen für internationale Käufer: Buyers should look for compliance with international standards such as JIS in Japan or DIN in Germany, especially for export purposes.

Composite materials are increasingly used in air compressors due to their lightweight and corrosion-resistant properties. They can typically handle temperatures up to 300°F (149°C) and moderate pressures.

Vorteile: Composites are lightweight and can be molded into complex shapes, enhancing design flexibility. They also provide excellent resistance to corrosion.

Nachteile: The cost of composite materials can be higher than traditional metals, and they may not be suitable for high-pressure applications.

Auswirkungen auf die Anwendung: Composites are ideal for portable air compressors or applications where weight is a critical factor.

Illustrative image related to air machine compressor

Überlegungen für internationale Käufer: Buyers should verify the material’s compliance with relevant international standards, as composite materials may have varying regulations across different regions.

| Material | Typical Use Case for air machine compressor | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Portable and lightweight compressors | Excellent corrosion resistance | Higher cost, lower tensile strength | Mittel |

| Gusseisen | Heavy-duty industrial compressors | Highly durable and wear-resistant | Heavy, prone to corrosion | Mittel |

| Stahl | General-purpose compressors | Strong and cost-effective | Susceptible to corrosion | Niedrig |

| Komposit | Lightweight and portable compressors | Lightweight and design flexibility | Higher cost, limited pressure rating | Hoch |

This strategic material selection guide provides essential insights for B2B buyers, enabling informed decisions that align with operational requirements and compliance standards across diverse markets.

The manufacturing process of air machine compressors is a complex sequence that involves several critical stages to ensure high-quality output. Understanding these stages helps B2B buyers make informed decisions when selecting suppliers.

The first stage involves sourcing and preparing the materials. Commonly used materials include cast iron for compressor bodies due to its durability and resistance to wear, and aluminum for lightweight components. Suppliers often conduct material tests to confirm the quality and specifications of the raw materials. This stage may also involve cutting, machining, and treating the materials to enhance their properties, ensuring they meet the necessary standards for strength and performance.

Once the materials are ready, the forming stage begins. This typically includes processes like casting, forging, or machining, depending on the component. For example, compressor cylinders are usually cast to achieve the required precision and strength. Advanced techniques like CNC machining are employed to ensure tight tolerances and surface finishes that reduce friction and wear during operation. Additionally, the use of advanced forming technologies can lead to lighter and more efficient designs, which are crucial for optimizing compressor performance.

Illustrative image related to air machine compressor

After forming, the components are assembled. This stage is critical as it involves integrating various parts such as pistons, valves, and motors into a functional unit. Manufacturers often utilize automated assembly lines to enhance efficiency and consistency. Each assembly line is designed to minimize human error while maximizing productivity. Quality checks are integrated into the assembly process to ensure that each component fits correctly and functions as intended.

The final stage is finishing, which includes surface treatments, painting, and coating to protect against corrosion and wear. This is particularly important for compressors that will be used in harsh environments. Finishing techniques such as powder coating or anodizing not only enhance aesthetic appeal but also improve the longevity of the equipment. Manufacturers typically conduct final inspections to ensure that the finish meets quality standards before the compressors are packaged and shipped.

Quality assurance is a vital aspect of the manufacturing process, ensuring that each air machine compressor meets international and industry-specific standards. B2B buyers should be familiar with these quality assurance practices to ensure they are sourcing from reputable manufacturers.

Illustrative image related to air machine compressor

International standards such as ISO 9001 provide a framework for quality management systems, focusing on customer satisfaction and continuous improvement. Compliance with these standards is essential for manufacturers aiming to compete in the global market. Additionally, certifications like CE mark, which indicates conformity with health, safety, and environmental protection standards, are crucial for products sold in Europe.

Industry-specific standards, such as those set by the American Petroleum Institute (API), are also relevant for compressors used in oil and gas applications. These standards ensure that products can withstand the unique pressures and challenges of the industry.

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

Eingehende Qualitätskontrolle (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. Any materials that do not comply are rejected and replaced.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, various checks are performed to monitor quality. This may include measuring tolerances, checking assembly accuracy, and testing components under simulated operational conditions.

Endgültige Qualitätskontrolle (FQC): After assembly and finishing, a comprehensive inspection is carried out. This includes functional testing of the compressors to ensure they operate correctly and meet performance specifications.

Manufacturers employ several testing methods to validate the quality of air machine compressors. Common methods include:

Druckprüfung: Ensures the compressor can handle the required operational pressures without leaking or failing.

Vibration Testing: Assesses the performance and durability of the compressor under operational conditions.

Leistungstests: Measures the output capacity and efficiency of the compressor to ensure it meets the specified criteria.

B2B buyers should inquire about the specific testing methods employed by potential suppliers to ensure their products meet industry standards.

To ensure that a supplier maintains high-quality standards, B2B buyers should implement several verification strategies:

Conducting on-site audits of potential suppliers is an effective way to assess their manufacturing processes and quality control measures. During the audit, buyers should evaluate the supplier’s adherence to international standards, the efficiency of their QC checkpoints, and the overall state of their manufacturing facilities.

Buyers can request quality assurance reports from suppliers, detailing their compliance with relevant standards and the results of their testing procedures. A reputable supplier should be transparent about their quality practices and willing to provide documentation.

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct independent audits and testing, ensuring that the compressors meet the required specifications before shipment.

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing air machine compressors.

Einhaltung von Vorschriften: Different regions have unique regulatory requirements that may affect product design and testing. Buyers should ensure that the compressors comply with local regulations, such as those related to emissions and safety.

Kulturelle Erwägungen: Understanding cultural differences in business practices can also impact supplier relationships. Effective communication and clear expectations are essential for successful partnerships.

Logistical Challenges: Buyers should consider the logistical aspects of sourcing from international suppliers, including shipping times, import duties, and potential delays in customs. Ensuring that quality standards are maintained throughout the supply chain is crucial.

By understanding the manufacturing processes and quality assurance practices specific to air machine compressors, B2B buyers can make informed decisions and establish reliable partnerships with suppliers that meet their quality expectations.

Sourcing an air machine compressor requires a systematic approach to ensure that the selected equipment meets your operational needs while aligning with your budget and quality standards. This checklist is designed to guide B2B buyers through the essential steps in the procurement process, helping you make informed decisions that will enhance efficiency and productivity.

Establishing clear technical specifications is vital for identifying the right air compressor for your application. Consider factors such as pressure requirements, airflow rate (CFM), and tank size. Additionally, evaluate the type of compressor needed—whether reciprocating, rotary screw, or centrifugal—based on your intended use.

Having a realistic budget is crucial in narrowing down your options. Air compressors can vary significantly in price based on their specifications and features. Be prepared to consider both initial purchase costs and long-term operational costs, such as energy consumption and maintenance.

Conduct thorough research to identify potential suppliers that specialize in air compressors. Look for companies with a strong reputation in your industry, and consider their geographical presence, especially if you are sourcing from regions like Africa, South America, or the Middle East.

Before finalizing a supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 or local safety standards can indicate a commitment to quality and reliability.

Illustrative image related to air machine compressor

Once you have shortlisted potential suppliers, request detailed quotations. This should include pricing, delivery timelines, warranty information, and after-sales support. A comprehensive quotation will provide insights into the overall value offered by each supplier.

If possible, arrange a site visit or a virtual tour of the supplier’s facilities. This step allows you to assess their manufacturing processes, quality control measures, and overall operational capabilities.

Once you have selected a supplier, draft a purchase agreement that outlines all terms, including payment schedules, delivery dates, and warranty conditions. This document protects both parties and ensures clarity throughout the transaction.

By following this checklist, B2B buyers can streamline the sourcing process for air machine compressors, ensuring that they make informed decisions that support their operational needs.

When sourcing air machine compressors, understanding the cost structure is crucial for B2B buyers. The overall cost comprises several components:

Materialien: The cost of raw materials such as steel, aluminum, and other alloys significantly influences the final price. Higher-grade materials often lead to better durability and performance, which can justify a higher upfront cost.

Arbeit: Labor costs can vary based on the region of production. In countries with higher wage standards, labor can account for a larger portion of the overall cost. However, lower labor costs in some regions may lead to cheaper products, which could impact quality.

Fertigungsgemeinkosten: This includes costs related to factory operations, maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help in reducing these overhead costs, allowing suppliers to offer more competitive pricing.

Werkzeugbau: Specialized tools and machinery used in the production of compressors can represent a significant investment. The cost of tooling is often amortized over production volumes, impacting pricing structures.

Qualitätskontrolle (QC): Implementing strict QC processes ensures product reliability and compliance with industry standards. While this adds to the cost, it can prevent costly returns and repairs, making it a valuable investment.

Logistik: Shipping costs, including freight and insurance, can vary widely depending on the destination and mode of transport. These costs are particularly important for international buyers, where freight can constitute a significant portion of the total price.

Marge: Supplier profit margins can vary based on competition, brand reputation, and market demand. Understanding the typical margins in the industry can aid in negotiations.

Several factors can influence the pricing of air machine compressors:

Volumen und Mindestbestellmenge (MOQ): Larger orders typically lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can significantly affect pricing strategies.

Spezifikationen und Anpassungen: Custom specifications can increase costs due to the need for specialized materials or design alterations. Buyers should be clear about their requirements to avoid unexpected expenses.

Materialqualität und Zertifizierungen: Compressors that meet higher quality standards or specific certifications (e.g., ISO, CE) often come at a premium. These certifications can be essential for compliance in certain markets, making them a crucial consideration.

Lieferanten-Faktoren: The reputation and reliability of the supplier play a critical role. Established suppliers with a proven track record may charge more but offer better warranties and service.

Incoterms: Understanding the Incoterms (International Commercial Terms) is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence overall costs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management can lead to substantial savings:

Hebelwirkung auf die Gesamtbetriebskosten (TCO): Instead of focusing solely on the initial purchase price, consider the total cost of ownership, which includes maintenance, energy consumption, and potential downtime. A higher initial investment may yield lower operational costs.

Nuancen der Preisgestaltung verstehen: Familiarize yourself with regional pricing trends and currency fluctuations that can impact costs. This knowledge can provide leverage during negotiations.

Beziehungen aufbauen: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and favorable payment terms. Long-term partnerships often yield more benefits than one-off transactions.

Be Prepared to Walk Away: Knowing your budget and being willing to seek alternative suppliers can strengthen your negotiating position. It signals to the supplier that you are serious about finding the best deal.

Request Transparent Pricing: Ask suppliers for a detailed breakdown of costs. This can help identify areas where savings can be made, such as adjustments in materials or logistics.

It is important to note that prices for air machine compressors can vary significantly based on various factors, including market conditions, supplier pricing strategies, and regional economic conditions. Buyers should conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Illustrative image related to air machine compressor

In the industrial landscape, air machine compressors are widely utilized for their ability to convert power into potential energy stored as pressurized air. However, various alternative technologies and methods can serve similar functions depending on the specific needs and operational contexts of businesses. This section will explore these alternatives and provide a comparative analysis that can assist B2B buyers in making informed decisions.

| Vergleich Aspekt | Air Machine Compressor | Electric Vacuum Pumps | Gas-Powered Generators |

|---|---|---|---|

| Leistung | High efficiency for consistent airflow and pressure | Excellent for low-pressure applications | Reliable power source for heavy-duty tasks |

| Kosten | Initial investment can be high; operational costs vary | Generally lower initial cost, but ongoing electricity costs | Higher upfront cost; fuel expenses can be significant |

| Leichte Implementierung | Requires professional installation and maintenance | Simple installation; minimal training required | Installation can be complex; requires understanding of fuel systems |

| Wartung | Regular maintenance needed for optimal performance | Low maintenance; fewer moving parts | Regular maintenance required for engine and fuel systems |

| Bester Anwendungsfall | Ideal for manufacturing and pneumatic tools | Suitable for medical and laboratory applications | Best for remote sites or backup power needs |

Electric vacuum pumps are an alternative solution particularly suited for applications requiring low pressure and high precision, such as in laboratories or medical equipment. They operate quietly and have fewer moving parts, which translates to lower maintenance costs and minimal operational noise. However, they may not provide the same level of performance as air compressors in high-demand industrial settings. Additionally, their reliance on electrical power can be a drawback in areas with unstable electricity supply.

Gas-powered generators provide another alternative, particularly useful in scenarios where electricity is unavailable or unreliable. They can deliver substantial power for various industrial applications, making them a preferred choice for construction sites or remote locations. While they offer high performance, their high initial cost and ongoing fuel expenses can be significant factors to consider. Moreover, they require regular maintenance and can produce noise and emissions, which may not align with environmental regulations in certain regions.

When evaluating alternatives to air machine compressors, it is crucial for B2B buyers to consider their specific operational needs, budget constraints, and the environment in which they operate. Electric vacuum pumps might be ideal for businesses focused on precision and low noise, while gas-powered generators could serve well in remote locations needing reliable power. Ultimately, a thorough assessment of performance requirements, cost implications, and maintenance demands will guide buyers in selecting the most suitable solution for their operations. By aligning the choice with the business’s operational goals, buyers can optimize productivity and efficiency in their respective industries.

When evaluating air machine compressors, several critical technical properties can significantly impact performance, reliability, and overall value. Understanding these specifications is essential for B2B buyers, as they directly influence operational efficiency and cost-effectiveness.

Horsepower (HP)

Horsepower indicates the power output of the compressor’s motor. Higher horsepower typically means greater air delivery capacity, making it crucial for heavy-duty applications. For B2B buyers, selecting the appropriate horsepower ensures that the compressor meets specific operational demands without underperforming, which could lead to production delays.

Tank Size (Gallons)

The tank size determines the amount of compressed air available at any given time. Larger tanks can store more air, allowing for longer usage periods without the need for constant cycling. This is particularly important for industries requiring sustained air pressure for tools and equipment. A well-sized tank contributes to efficiency and reduces wear on the compressor.

Druckstufe (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. Different applications require varying pressure levels, so understanding this specification helps buyers select a compressor that meets their specific operational needs. Insufficient pressure can result in inadequate performance, leading to increased costs and inefficiencies.

Durchflussmenge (CFM)

Flow rate, measured in cubic feet per minute (CFM), denotes the volume of air the compressor can deliver. This specification is vital for determining how well the compressor can support pneumatic tools and processes. A higher CFM rating is essential for industries that rely on multiple tools operating simultaneously, ensuring consistent performance across operations.

Material Klasse

The materials used in the construction of the compressor, such as cast iron or aluminum, affect durability and maintenance requirements. Buyers should prioritize compressors made from high-grade materials for longevity and reduced maintenance costs. Understanding material properties helps in making informed decisions about the total cost of ownership.

Stage Type (Single vs. Two-Stage)

Compressors can be single-stage or two-stage, with the latter offering higher efficiency and greater pressure capabilities. Two-stage compressors compress air twice, resulting in higher PSI ratings and more effective cooling. B2B buyers should evaluate their air demand to determine the most suitable stage type for their applications.

Familiarizing yourself with industry terminology is essential for successful negotiations and procurement processes in the compressor market. Here are some key terms to know:

Illustrative image related to air machine compressor

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers seeking quality and compatibility when sourcing replacement parts or entire units.

MOQ (Mindestbestellmenge)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it influences purchasing decisions and inventory management, particularly for businesses looking to maintain cost efficiency.

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. This process allows buyers to compare pricing, terms, and capabilities, facilitating informed decision-making.

Incoterms (Internationale Handelsklauseln)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, delivery, and insurance. Familiarity with these terms helps B2B buyers navigate international transactions more effectively, reducing risks associated with logistics.

Gewährleistungsfrist

The warranty period indicates the duration for which the manufacturer guarantees the product against defects. Understanding warranty terms is crucial for assessing the long-term value of the compressor and planning for potential repairs or replacements.

Service Interval

This term refers to the recommended frequency of maintenance checks and servicing for the compressor. Knowing the service interval helps buyers plan maintenance schedules, ensuring optimal performance and extending the lifespan of the equipment.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting air machine compressors, ensuring they invest in equipment that meets their specific operational needs and contributes to their overall business success.

The global air machine compressor market is currently experiencing significant growth, driven by rising industrialization and the increasing demand for energy-efficient solutions across various sectors, including manufacturing, automotive, and construction. In particular, regions such as Africa, South America, and the Middle East are witnessing a surge in infrastructure development projects, necessitating robust air compressor systems. Technological advancements such as IoT integration and predictive maintenance tools are reshaping the B2B landscape, enabling buyers to monitor equipment performance in real-time and optimize operational efficiency.

Emerging trends indicate a shift towards portable and versatile compressor models, which cater to the demands of diverse applications, particularly in remote or on-site environments. Additionally, the rise of e-commerce platforms is revolutionizing how international buyers source air compressors, allowing for greater price transparency and access to a wider range of products. Buyers are increasingly leveraging digital tools to compare specifications, pricing, and supplier reliability, which enhances their decision-making process.

Moreover, regional factors play a crucial role in market dynamics. In Africa and South America, for instance, the availability of local suppliers and the potential for cost savings through regional sourcing are becoming key considerations for international buyers. Understanding these market dynamics is essential for B2B buyers to navigate the complexities of sourcing air machine compressors effectively.

The importance of sustainability and ethical sourcing in the air machine compressor industry cannot be overstated. As global awareness of environmental issues rises, buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact. This includes using energy-efficient technologies, minimizing waste, and employing sustainable materials in their manufacturing processes.

Ethical supply chains also play a critical role in supplier selection. Buyers should seek manufacturers that adhere to fair labor practices and ensure safe working conditions for their employees. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. Moreover, utilizing compressors that incorporate eco-friendly refrigerants and materials can significantly reduce the carbon footprint of operations.

In regions like Africa and South America, where environmental regulations are evolving, aligning with suppliers that prioritize sustainability can enhance a company’s reputation and competitiveness. By choosing ethically sourced air machine compressors, businesses not only contribute to a healthier planet but also align with the values of increasingly conscientious consumers and partners.

The air machine compressor industry has seen remarkable evolution since its inception in the 19th century. Initially, these machines were primarily used in manufacturing and mining industries. However, technological advancements have broadened their applications to include sectors such as healthcare, automotive, and even renewable energy.

The transition from steam-powered to electric compressors marked a significant milestone, enhancing efficiency and reducing operational costs. Over the years, innovations such as rotary screw compressors and variable speed drives have emerged, providing businesses with more energy-efficient and versatile options. Today, with the integration of digital technologies, air compressors are not only more efficient but also smarter, allowing for predictive maintenance and remote monitoring, which are increasingly important for international B2B buyers seeking reliability and reduced downtime in their operations.

Understanding this historical context can help buyers appreciate the advancements in technology and sustainability that are now available, enabling more informed purchasing decisions in the evolving landscape of air machine compressors.

1. Wie wähle ich den richtigen Luftkompressor für meine geschäftlichen Anforderungen?

Selecting the right air compressor involves assessing your specific requirements such as air demand, pressure, and intended applications. Determine the tools and equipment you plan to use, as this will guide you in choosing the appropriate horsepower and tank size. Additionally, consider the compressor type (e.g., reciprocating, rotary screw) that best suits your operation’s efficiency and maintenance capabilities. Consulting with suppliers who have expertise in your industry can also provide valuable insights to ensure you make an informed decision.

2. What factors should I consider when vetting international air compressor suppliers?

When vetting suppliers, prioritize their experience in the air compressor industry, reputation, and compliance with international quality standards. Evaluate their manufacturing capabilities, certifications (such as ISO), and customer reviews to assess reliability. Additionally, inquire about their after-sales support, warranty policies, and delivery timelines. Establishing communication with past clients can provide further assurance of their credibility and service quality.

3. What customization options are available for air compressors?

Many manufacturers offer customization options for air compressors to meet specific operational needs. Common customization includes tank size, pressure settings, and voltage compatibility. Some suppliers may also provide options for noise reduction features, mobility enhancements, or specialized coatings for harsh environments. It’s advisable to discuss your unique requirements with the supplier to explore available modifications that can enhance performance and efficiency.

4. What is the typical minimum order quantity (MOQ) for air compressors?

Minimum order quantities (MOQ) can vary significantly by supplier and the type of air compressor. Some manufacturers may have MOQs as low as one unit for standard models, while others may require larger orders for customized or specialized units. It’s essential to confirm the MOQ with potential suppliers to align your purchasing strategy with your business needs and budget. In some cases, negotiating the MOQ may be possible, especially for established business relationships.

5. What payment terms should I expect when sourcing air compressors internationally?

Payment terms for international transactions can vary, but common options include advance payment, letter of credit, or a combination of upfront and balance payments upon delivery. Ensure you discuss and agree upon payment methods that provide adequate security for both parties. Additionally, consider currency fluctuations, transaction fees, and the reliability of payment platforms. Establishing clear terms in the contract can help avoid misunderstandings and protect your investment.

6. How can I ensure quality assurance when purchasing air compressors?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Conduct factory audits or third-party inspections to verify manufacturing practices and quality control processes. Additionally, inquire about warranty terms and after-sales service options, as reputable suppliers often provide support in case of defects. Establishing a clear quality agreement in your purchase contract can help safeguard against potential issues.

7. What are the logistics considerations for importing air compressors?

When importing air compressors, consider shipping methods, customs regulations, and potential tariffs that may apply to your region. It’s crucial to work with logistics providers experienced in handling heavy machinery, as they can navigate shipping requirements and ensure safe transport. Prepare necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. Additionally, factor in delivery timelines and storage solutions upon arrival to minimize disruptions to your operations.

8. What are the common applications for industrial air compressors in various industries?

Industrial air compressors are widely used across various sectors, including manufacturing, automotive, construction, and healthcare. They power pneumatic tools, assist in material handling, and are essential in processes like painting, sanding, and assembly. In healthcare, they provide compressed air for medical devices. Understanding the specific applications in your industry can help you select the right compressor type and features, ensuring optimal performance and efficiency for your operations.

Bereich: alliedelectronics.com

Registriert: 1996 (29 Jahre)

Einleitung: Air Machines available from Allied Electronics include various models with GAST compressors, suitable for different mounting options (pedestal or wall). Key products include:

1. Air Machine with GAST compressor – FREE to consumer – push button start (Part Number: 8685-2FG) – $1,487.50

2. Air Machine w/ GAST compressor – wall or pedestal mount (Part Number: 8685-2G) – $1,537.50

3. Air Machine, n…

In the evolving landscape of air machine compressors, strategic sourcing emerges as a pivotal component for B2B buyers seeking to optimize their procurement processes. Key takeaways highlight the importance of evaluating suppliers based on product quality, availability, and support services. Engaging with manufacturers that offer robust warranties and responsive customer service can significantly enhance operational efficiency and reduce downtime.

Furthermore, understanding regional market dynamics is crucial, especially for buyers in Africa, South America, the Middle East, and Europe. Tailoring your sourcing strategy to align with local regulations and logistical considerations will not only streamline operations but also foster stronger supplier relationships.

Looking ahead, the demand for innovative and energy-efficient air compressor solutions is set to grow. B2B buyers should actively seek partnerships with suppliers who prioritize sustainability and technological advancements. By doing so, businesses can position themselves competitively in their respective markets.

Illustrative image related to air machine compressor

Embrace the opportunity to refine your sourcing strategy today—explore diverse suppliers, leverage technology, and ensure your business stays ahead of the curve in the air compressor industry. Your proactive approach to strategic sourcing will yield long-term benefits and drive success in a rapidly changing marketplace.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.