In the competitive landscape of international logistics and transportation, achieving optimal fuel efficiency through proper tire inflation is a pivotal concern for B2B buyers. Tire pressure not only affects the performance and safety of vehicles but also directly influences fuel consumption, significantly impacting operational costs. As companies in regions such as Africa, South America, the Middle East, and Europe grapple with fluctuating fuel prices and sustainability mandates, understanding the nuances of tire inflation becomes essential for informed purchasing decisions.

This comprehensive guide delves into the multifaceted aspects of tire inflation and its correlation with fuel efficiency. It covers everything from the types of tire pressure management systems available in the market to best practices for maintenance, supplier vetting processes, and cost considerations. By equipping B2B buyers with actionable insights, this guide empowers them to make strategic choices that enhance vehicle performance while reducing environmental impact.

Navigating the global market for tire inflation solutions requires a thorough understanding of regional regulations, supplier capabilities, and technological advancements. This guide aims to bridge the knowledge gap, enabling businesses to optimize their fleet operations and contribute to a greener future. By prioritizing proper tire inflation, organizations can achieve significant cost savings and bolster their commitment to sustainability, ultimately driving long-term success in an increasingly eco-conscious marketplace.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Tire Pressure | Typically 30-35 PSI; recommended for most vehicles | Fleet management, logistics companies | Vorteile: Easy to maintain; widely applicable. Nachteile: May not optimize fuel efficiency for specific conditions. |

| High-Performance Inflation | Higher PSI for performance vehicles; enhances handling | Automotive racing, high-performance fleets | Vorteile: Improved handling and fuel efficiency; better tire longevity. Nachteile: Not suitable for everyday vehicles; may lead to a rough ride. |

| Eco-Friendly Inflation | Lower rolling resistance; promotes fuel economy | Green logistics, eco-conscious fleets | Vorteile: Reduces carbon footprint; cost savings on fuel. Nachteile: Requires regular monitoring; may not be suitable for all terrains. |

| Adaptive Tire Pressure | Systems that adjust pressure based on load and terrain | Heavy-duty transport, construction vehicles | Vorteile: Optimizes performance and fuel efficiency; enhances safety. Nachteile: Higher initial investment; requires technical expertise for maintenance. |

| Seasonal Tire Pressure | Adjustments based on seasonal temperature changes | Seasonal logistics, agricultural vehicles | Vorteile: Maintains optimal performance year-round; reduces wear. Nachteile: Requires frequent adjustments; may complicate maintenance schedules. |

Standard tire pressure systems are designed to maintain the recommended PSI range of 30-35 for most vehicles, making them suitable for general use in fleet management and logistics. They are easy to monitor and maintain, allowing businesses to ensure that their vehicles operate efficiently. Buyers should consider the simplicity of upkeep and the widespread applicability of standard tire pressure systems, although they may not provide optimal fuel efficiency in varying driving conditions.

High-performance inflation systems operate at higher PSI levels, which can significantly improve handling and fuel efficiency for performance vehicles. These systems are primarily utilized in automotive racing and high-performance fleets, where precision and control are paramount. Buyers should weigh the benefits of improved performance against the potential downsides, such as a rougher ride and unsuitability for everyday driving.

Eco-friendly inflation systems focus on minimizing rolling resistance, which can lead to substantial fuel economy improvements. These systems are ideal for businesses prioritizing sustainability, such as green logistics companies. While they can help reduce a fleet’s carbon footprint and fuel costs, buyers must be prepared for the need for regular monitoring to maintain optimal performance, especially in diverse driving conditions.

Illustrative image related to proper tire inflation fuel efficiency

Adaptive tire pressure systems automatically adjust tire pressure based on load and terrain, making them particularly useful for heavy-duty transport and construction vehicles. These systems enhance safety and optimize both performance and fuel efficiency. While they represent a significant investment and require technical expertise for maintenance, the long-term benefits in terms of safety and operational efficiency can justify the costs for businesses with demanding transportation needs.

Seasonal tire pressure adjustments are crucial for maintaining optimal performance as temperatures fluctuate throughout the year. This approach is particularly relevant for seasonal logistics and agricultural vehicles that operate in varying climates. Buyers should consider the advantages of reduced tire wear and enhanced performance; however, they must also factor in the need for frequent adjustments, which can complicate maintenance schedules.

| Industrie/Sektor | Specific Application of Proper Tire Inflation Fuel Efficiency | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Logistics and Transportation | Fleet management for cargo and delivery vehicles | Enhanced fuel economy reduces operational costs and emissions. | Reliable tire pressure monitoring systems and inflators are essential. |

| Landwirtschaft | Tire maintenance for agricultural machinery | Improved fuel efficiency leads to reduced fuel costs and better productivity. | Durable tire inflators suited for rough terrains and weather conditions. |

| Mining | Tire management in heavy machinery | Proper inflation minimizes downtime and extends tire lifespan. | Heavy-duty tire pressure gauges and inflators designed for harsh environments. |

| Bauwesen | Maintenance for construction vehicles | Optimized fuel consumption lowers project costs and improves safety. | Portable tire pressure monitoring tools for remote job sites. |

| Public Transportation | Bus and taxi fleet tire management | Enhanced safety and reduced fuel expenses improve service reliability. | Investment in comprehensive tire maintenance solutions for fleets. |

In the logistics and transportation sector, maintaining proper tire inflation is crucial for fleet management. Vehicles that operate with optimal tire pressure experience reduced rolling resistance, leading to significant fuel savings. This efficiency not only lowers operational costs but also minimizes greenhouse gas emissions, aligning with corporate sustainability goals. For international buyers, sourcing reliable tire pressure monitoring systems and inflators is essential to ensure consistent performance across diverse geographical conditions.

Illustrative image related to proper tire inflation fuel efficiency

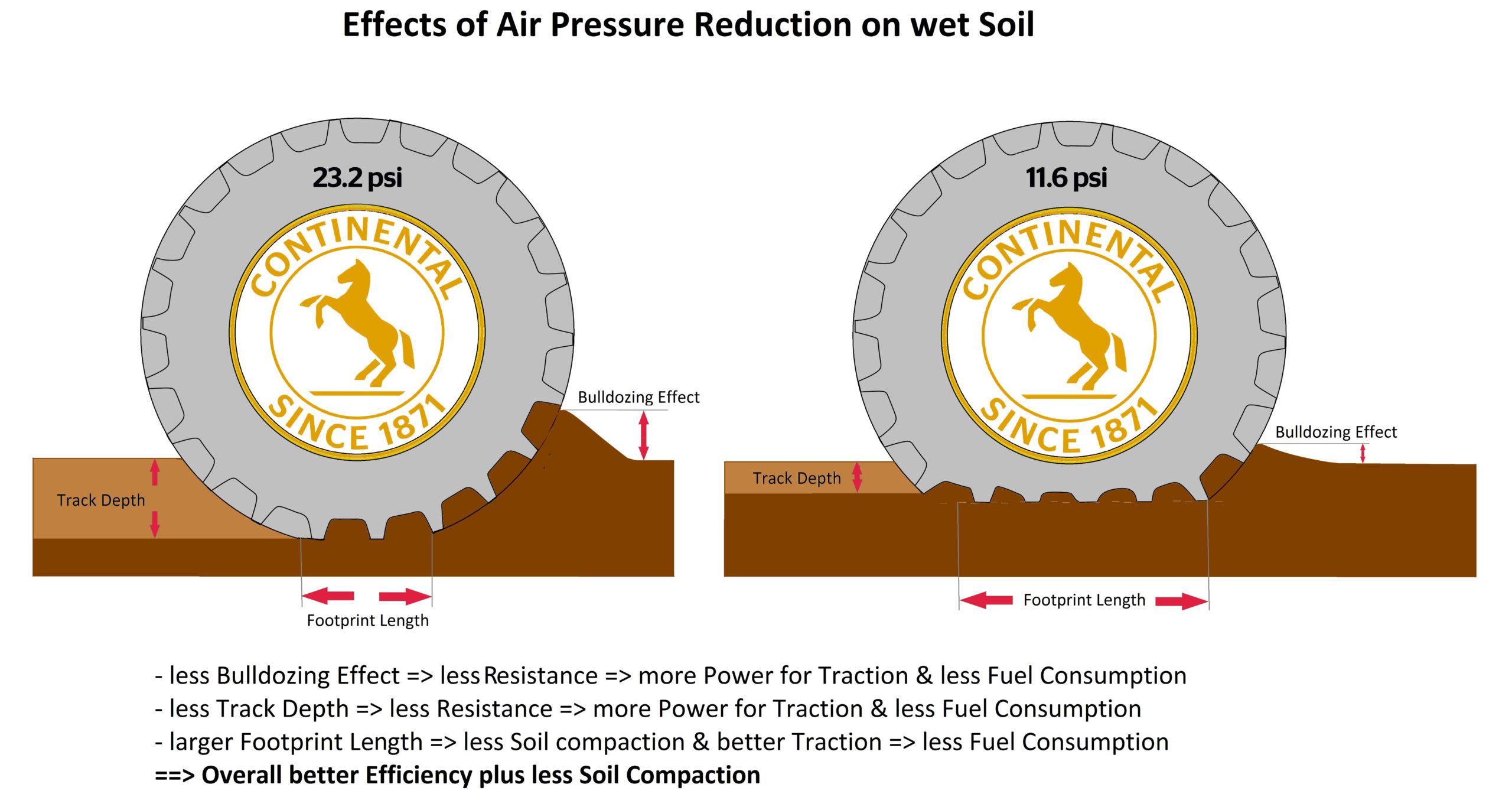

In agriculture, proper tire inflation on machinery such as tractors and harvesters is vital for enhancing fuel efficiency. Correct tire pressure improves traction and reduces soil compaction, leading to better crop yields and lower fuel expenditures. Farmers in regions like South America and Africa must consider durable tire inflators that can withstand rough terrains and varying weather conditions to maintain optimal tire performance, ensuring productivity and cost-effectiveness.

The mining industry relies heavily on heavy machinery that operates in challenging environments. Proper tire inflation is critical to minimize downtime caused by tire wear and failures. By ensuring that tires are inflated to the recommended PSI, mining companies can extend tire lifespan and reduce fuel consumption, which is particularly important given the high operational costs in this sector. Buyers should focus on sourcing heavy-duty tire pressure gauges and inflators that can endure the harsh conditions typical of mining operations.

In construction, the efficiency of vehicles and machinery directly impacts project timelines and costs. Maintaining proper tire inflation ensures that construction vehicles operate efficiently, leading to reduced fuel consumption and enhanced safety. This is particularly crucial in Europe, where regulatory compliance regarding emissions is stringent. Buyers should invest in portable tire pressure monitoring tools that can be easily used on various job sites, ensuring consistent maintenance across the fleet.

For public transportation systems, such as buses and taxis, proper tire inflation is essential for ensuring passenger safety and operational efficiency. Well-maintained tires enhance fuel efficiency, which translates into lower operational costs and improved service reliability. In regions like the Middle East, where fluctuating temperatures can affect tire pressure, it is vital for fleet managers to invest in comprehensive tire maintenance solutions that include both monitoring and inflation systems to ensure consistent performance across diverse conditions.

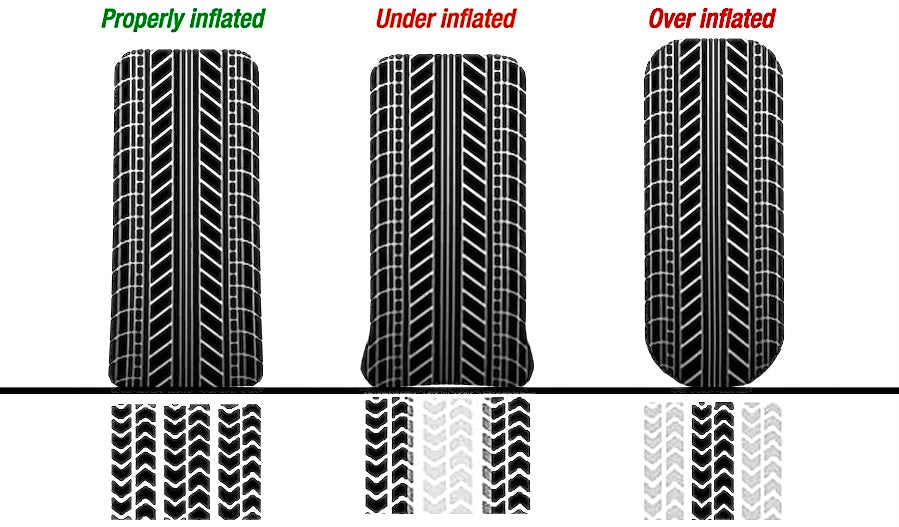

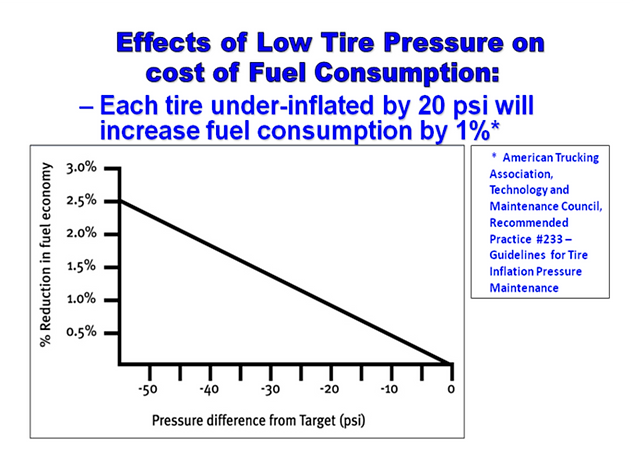

Das Problem: For many B2B buyers managing fleets, underinflated tires represent a significant, yet often overlooked, operational cost. When tires are not maintained at the recommended pressure, it can lead to increased rolling resistance, resulting in higher fuel consumption. This inefficiency can escalate costs, particularly for businesses with large fleets that depend on fuel efficiency to maintain competitive pricing. Furthermore, underinflation can accelerate tire wear, necessitating more frequent replacements and increasing maintenance expenses.

Illustrative image related to proper tire inflation fuel efficiency

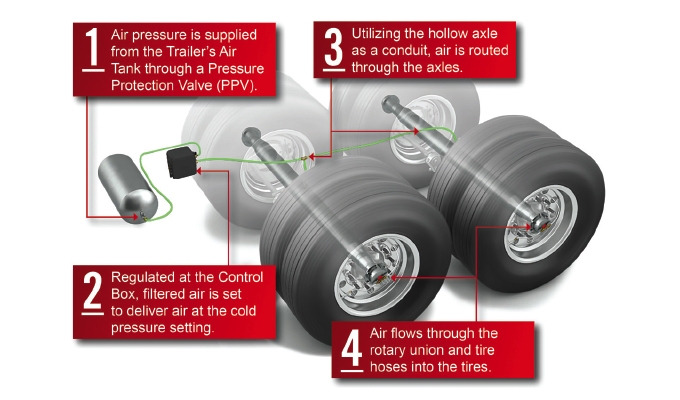

Die Lösung: To combat this issue, fleet managers should implement a systematic tire pressure monitoring program. This involves investing in high-quality tire pressure monitoring systems (TPMS) that provide real-time data on tire conditions. Regular training sessions for drivers on the importance of tire maintenance can also foster a culture of accountability. Additionally, establishing a routine schedule for manual checks and maintenance using reliable tire inflators can ensure that tire pressure is consistently monitored and adjusted. By proactively addressing tire inflation, businesses can significantly reduce fuel costs and extend tire lifespan, ultimately improving overall fleet efficiency.

Das Problem: Businesses operating across regions with varying climates face unique challenges in maintaining proper tire inflation. Temperature fluctuations can lead to significant changes in tire pressure, as tire pressure typically decreases by 1 PSI for every 10°F drop in temperature. This variability can result in inconsistent fuel efficiency and increased risk of tire-related incidents, impacting safety and operational reliability.

Die Lösung: To address this challenge, B2B buyers should establish a climate-responsive tire management strategy. This includes utilizing digital tire pressure gauges that provide accurate readings and can adjust for temperature variations. Additionally, businesses should create a comprehensive checklist that incorporates seasonal tire pressure adjustments based on anticipated weather changes. Collaborating with local tire suppliers for timely updates on regional climate impacts can also help in adjusting tire maintenance schedules. By adapting tire maintenance practices to regional climate conditions, businesses can optimize fuel efficiency and ensure safer operations.

Das Problem: Many B2B buyers underestimate the relationship between tire maintenance and fuel efficiency, often leading to a lack of awareness about the hidden costs associated with improper tire inflation. This oversight can result in wasted resources and missed opportunities for savings. For example, companies may not recognize that a mere 1 PSI drop can lead to a 0.2% decrease in fuel efficiency, which, over time and with high vehicle mileage, can translate into significant financial losses.

Illustrative image related to proper tire inflation fuel efficiency

Die Lösung: To bridge this knowledge gap, businesses should invest in training and awareness programs that emphasize the importance of tire maintenance and its direct impact on fuel efficiency. Developing informational materials, such as guides or workshops, can help educate employees about the long-term benefits of maintaining proper tire pressure. Additionally, implementing regular audits of tire conditions and performance metrics can help identify trends and areas for improvement. By fostering an environment where tire maintenance is prioritized, businesses can enhance fuel efficiency, reduce costs, and promote a culture of sustainability within their operations.

When it comes to maintaining proper tire inflation for fuel efficiency, the choice of materials used in tire construction and inflation equipment plays a significant role. Here, we analyze three common materials relevant to this application: rubber, nylon, and aluminum. Each material has distinct properties, advantages, and limitations that can impact performance, durability, and overall cost.

Rubber is the primary material used in tire manufacturing. Its key properties include excellent elasticity, temperature resistance, and the ability to withstand varying pressures. Rubber tires are designed to maintain optimal contact with the road surface, which is crucial for fuel efficiency.

Vorteile: Rubber is durable and provides good traction, which enhances safety and performance. It is also relatively low-cost compared to other materials, making it a preferred choice for mass production.

Nachteile: However, rubber can degrade over time due to exposure to UV light and ozone, leading to potential safety issues. Moreover, the manufacturing process can be complex, requiring careful formulation to achieve the desired performance characteristics.

For international B2B buyers, compliance with local standards such as ASTM or ISO is essential. In regions like Africa and the Middle East, where road conditions can vary significantly, selecting high-quality rubber that meets these standards is critical for ensuring safety and performance.

Nylon is often used in the tire’s inner layers, providing structural integrity and enhancing resistance to punctures. Its key properties include high tensile strength and flexibility, which help maintain tire shape and performance under varying loads and pressures.

Vorteile: Nylon’s durability contributes to longer tire life and reduces the frequency of replacements, ultimately lowering costs for fleet operators.

Nachteile: On the downside, nylon can be more expensive than rubber, which may deter some buyers. Additionally, its performance can be affected by extreme temperatures, which is a consideration in hotter climates.

B2B buyers from regions like South America and Europe should ensure that the nylon used in tire construction complies with relevant standards, as this can significantly affect tire performance in diverse environmental conditions.

Aluminum is commonly used in tire inflators and gauges due to its lightweight nature and resistance to corrosion. Its properties include high strength-to-weight ratio and excellent thermal conductivity, which make it suitable for precision instruments.

Vorteile: The lightweight nature of aluminum makes it easy to handle, while its corrosion resistance ensures longevity, especially in harsh environments.

Nachteile: However, aluminum can be more expensive than plastic alternatives, which may be a consideration for budget-conscious buyers. Additionally, while durable, it can be prone to dents if not handled carefully.

For international buyers, particularly in regions like Saudi Arabia where extreme temperatures are common, selecting aluminum products that meet local standards for durability and performance is crucial.

| Material | Typical Use Case for proper tire inflation fuel efficiency | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Primary material for tire construction | Excellent elasticity and durability | Degrades over time due to UV exposure | Niedrig |

| Nylon | Inner layers of tires for structural integrity | High tensile strength and flexibility | More expensive, affected by extreme temperatures | Med |

| Aluminium | Tire inflators and gauges | Leicht und korrosionsbeständig | Höhere Kosten und Anfälligkeit für Beulen | Hoch |

In conclusion, selecting the right materials for tire construction and inflation equipment is essential for optimizing fuel efficiency. Understanding the properties, advantages, and limitations of rubber, nylon, and aluminum can help international B2B buyers make informed decisions that align with their operational needs and regional standards.

Illustrative image related to proper tire inflation fuel efficiency

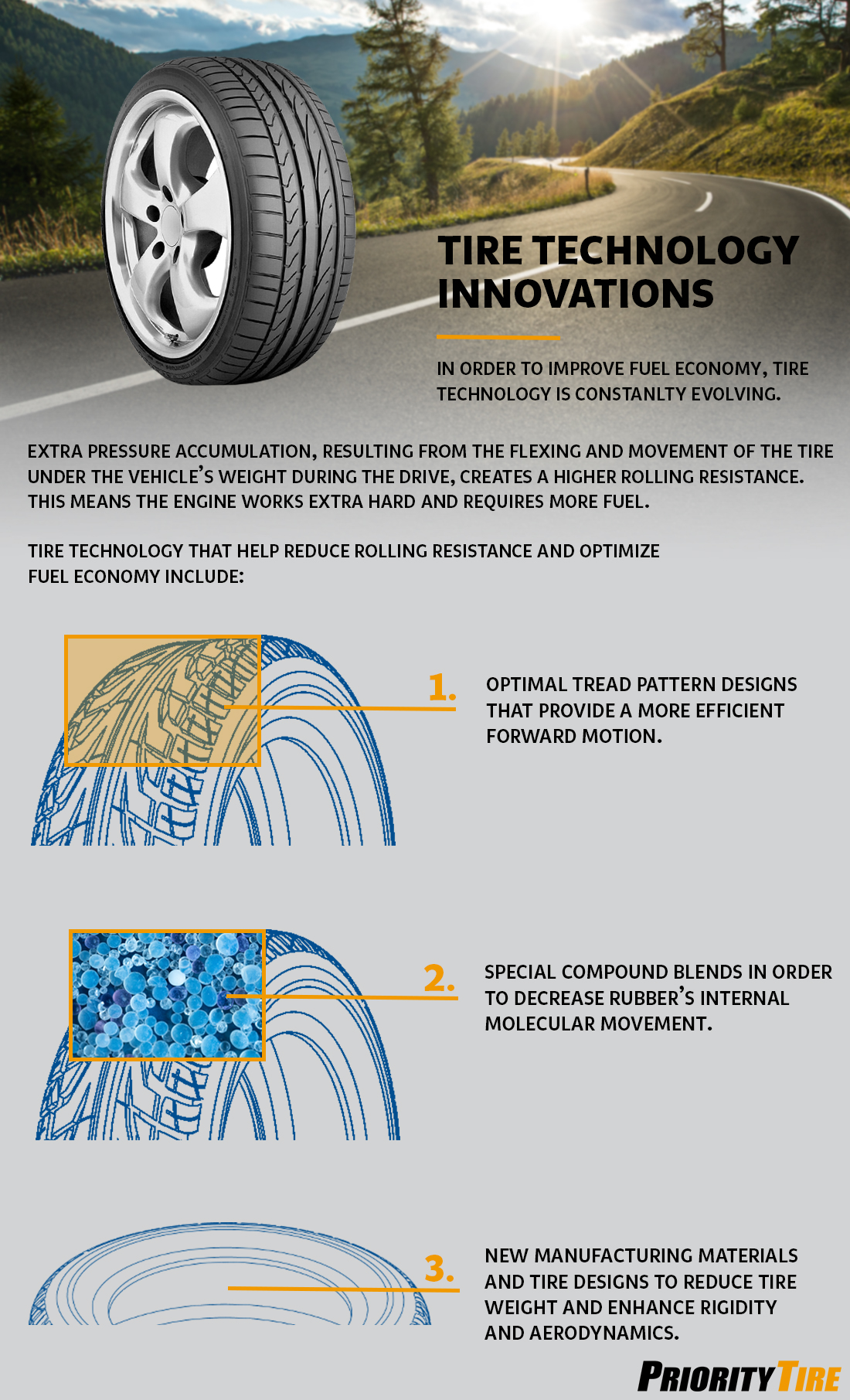

The manufacturing process of tires is intricate and involves several key stages that directly influence their performance, including fuel efficiency. Understanding these processes can help B2B buyers make informed decisions when sourcing tires.

The first stage involves the selection and preparation of raw materials. High-quality materials, such as natural rubber, synthetic rubber, fabric, and steel, are chosen for their durability and performance characteristics. The formulation of rubber compounds is critical; additives such as carbon black enhance the tire’s strength and improve rolling resistance, which directly impacts fuel efficiency.

In the forming stage, the prepared materials are shaped into tire components. This involves creating the inner lining, tread, and sidewalls. Advanced techniques, such as precision molding and extrusion, ensure that the tire’s design optimally balances grip and rolling resistance. A well-formed tire will have a uniform tread pattern that contributes to better fuel economy by minimizing rolling resistance.

During assembly, the various components are combined. This step requires meticulous attention to detail to ensure that all parts are securely bonded, which is crucial for performance and safety. Techniques such as bead assembly and curing under controlled heat and pressure are employed. This stage is vital for ensuring that the tire maintains its shape and structural integrity, allowing for proper inflation and optimal fuel efficiency.

The finishing stage involves quality checks and final touches, such as applying a protective coating. This stage is essential for ensuring that the tire meets industry standards and performs well under various conditions. Proper finishing can significantly enhance a tire’s lifespan and fuel efficiency by preventing premature wear.

Quality control (QC) in tire manufacturing is critical to ensuring that the final product meets both safety and performance standards. International and industry-specific standards guide these QC processes.

ISO 9001 is one of the most recognized international standards for quality management systems. Compliance with ISO standards ensures that manufacturers have a systematic approach to managing processes, which improves consistency and quality. For B2B buyers, choosing suppliers that adhere to these standards can provide assurance of product reliability and performance.

Illustrative image related to proper tire inflation fuel efficiency

In addition to ISO certifications, tires may need to meet industry-specific standards such as CE (Conformité Européenne) for the European market or API (American Petroleum Institute) for certain applications. These certifications indicate compliance with safety and performance criteria, which is crucial for ensuring fuel efficiency and overall vehicle safety.

Quality control in tire manufacturing typically involves several checkpoints throughout the production process:

IQC is the first checkpoint where raw materials are inspected for defects or inconsistencies. This step is critical for ensuring that only high-quality materials enter the production process. B2B buyers should inquire about suppliers’ IQC procedures to ensure they source materials that contribute to tire performance.

IPQC involves monitoring processes during manufacturing to catch any deviations from quality standards. This may include checks on material thickness, pressure during curing, and uniformity in tread design. Regular audits of these procedures can help B2B buyers verify that manufacturers maintain stringent quality standards.

FQC is the last checkpoint where finished tires undergo rigorous testing, including visual inspections, pressure tests, and performance assessments. These tests ensure that the tires meet all specifications and are safe for use. Buyers should request FQC reports to confirm that tires have passed all necessary evaluations.

Testing methods are essential for verifying the performance characteristics of tires. Common methods include:

These tests are vital for ensuring that tires deliver optimal performance, thereby enhancing fuel efficiency.

B2B buyers should take proactive steps to verify the quality control practices of tire suppliers. Here are some effective methods:

Illustrative image related to proper tire inflation fuel efficiency

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should focus on evaluating compliance with international standards, inspection protocols, and testing methods. This due diligence helps ensure that suppliers maintain high-quality standards.

Requesting detailed quality control reports from suppliers can give buyers a comprehensive view of the manufacturing process. Reports should include information on IQC, IPQC, and FQC results, along with any corrective actions taken to address issues. Consistency in these reports indicates a reliable supplier.

Utilizing third-party inspection services can add an additional layer of assurance. These independent firms can conduct unbiased evaluations of the manufacturing processes and quality control measures, ensuring that suppliers meet the necessary standards for performance and safety.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances in quality control to consider:

By focusing on these aspects of tire manufacturing and quality assurance, B2B buyers can make informed decisions that enhance fuel efficiency and overall vehicle performance.

In the pursuit of enhanced fuel efficiency through proper tire inflation, this practical sourcing guide serves as an essential checklist for B2B buyers. By following these actionable steps, organizations can optimize their vehicle performance while contributing to environmental sustainability.

Before implementing new tire inflation strategies, evaluate your existing maintenance protocols. Identify gaps in your current practices, such as the frequency of tire pressure checks or the tools being used. This assessment will help you understand what improvements can be made and set the foundation for effective sourcing.

Establish clear technical specifications for tire inflation products and services. Consider factors such as the types of vehicles in your fleet, the average load they carry, and the typical driving conditions. Specifying these details will help you find solutions tailored to your specific needs, ultimately improving fuel efficiency.

Illustrative image related to proper tire inflation fuel efficiency

Research and compile a list of potential suppliers that specialize in tire inflation products. Look for companies with proven track records in your region, especially those that understand the unique challenges faced by businesses in Africa, South America, the Middle East, and Europe. Reliable suppliers should have strong customer reviews and industry certifications, ensuring they provide quality products.

Once you have identified potential suppliers, evaluate their product offerings. Focus on tire pressure gauges, inflators, and monitoring systems that align with your technical specifications. Look for features like accuracy, durability, and ease of use, as these can significantly impact the effectiveness of your tire maintenance routine.

To ensure the products meet your expectations, request samples or demonstrations from shortlisted suppliers. Testing these products in real-world scenarios will provide insights into their performance and usability. This step is crucial for making informed purchasing decisions and ensuring that the products will enhance your fuel efficiency strategy.

Illustrative image related to proper tire inflation fuel efficiency

Engage in discussions with suppliers to negotiate favorable terms, including pricing, delivery schedules, and after-sales support. A well-negotiated contract can lead to better financial outcomes and ensure that you have access to necessary maintenance resources over time. Be sure to clarify warranty terms and service agreements.

Once you have procured the necessary tools and supplies, establish a routine maintenance schedule for checking tire pressure. Regular monitoring is vital for maintaining optimal tire performance and ensuring fuel efficiency. Aim to check tire pressure monthly and more frequently during temperature fluctuations to adapt to changing conditions.

By following these steps, B2B buyers can effectively source solutions that enhance tire inflation practices, leading to improved fuel efficiency and sustainability in their operations.

When sourcing products related to proper tire inflation for fuel efficiency, understanding the cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to proper tire inflation fuel efficiency

Materialien: High-quality rubber and advanced materials that enhance durability and performance can significantly impact the cost. For instance, tires designed for better fuel efficiency often incorporate specialized compounds that may be more expensive than standard materials.

Arbeit: Labor costs will vary based on the region of manufacture. Countries with lower labor costs may offer competitive pricing, but this should be weighed against quality and certification standards.

Fertigungsgemeinkosten: This includes costs related to facilities, equipment, and utilities. Manufacturers that invest in energy-efficient processes may pass these savings on to buyers.

Werkzeugbau: Custom molds and manufacturing setups for specialized tire designs can add to upfront costs. Buyers should consider the potential for amortization over larger production runs.

Qualitätskontrolle (QC): Rigorous QC processes ensure that products meet safety and performance standards, which can influence the overall pricing. Certifications such as ISO or regional standards also add to the cost but enhance product reliability.

Logistik: Shipping costs can vary significantly based on distance, mode of transportation, and local regulations. International buyers should factor in customs duties and tariffs, which can further affect the final price.

Marge: Suppliers will typically include a margin to cover their operational costs and profit. Understanding the typical margins in your region can aid in negotiations.

Several factors can influence the pricing of tire inflation products, making it crucial for buyers to navigate these effectively:

Volumen und Mindestbestellmenge (MOQ): Larger orders often lead to bulk pricing discounts. Buyers should assess their inventory needs to negotiate favorable terms.

Spezifikationen und Anpassungen: Custom specifications can lead to higher costs, but they may be necessary for specific applications. It’s essential to balance the need for customization with budget constraints.

Materialien und Qualitätszertifikate: Products that use high-grade materials or possess quality certifications will typically command a higher price. Buyers should prioritize products that align with their performance and regulatory requirements.

Lieferanten-Faktoren: Supplier reliability, reputation, and service levels can impact pricing. A trustworthy supplier may justify a higher price due to their commitment to quality and service.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms define the responsibilities of buyers and sellers in shipping costs, insurance, and risk. Choosing the right Incoterms can help manage overall costs effectively.

B2B buyers, especially in emerging markets such as Africa, South America, the Middle East, and Europe, should adopt strategic approaches to optimize their sourcing costs:

Negotiation Skills: Engage suppliers in open discussions about pricing. Establishing long-term relationships may lead to better pricing structures and terms.

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis, which considers not only the purchase price but also maintenance, operational efficiency, and potential savings from improved fuel economy.

Understanding Pricing Nuances: Be aware that pricing can fluctuate based on market demand, raw material costs, and geopolitical factors. Staying informed about global trends can help buyers make timely purchasing decisions.

Leverage Local Knowledge: Utilize local agents or representatives who understand the regional market dynamics. Their insights can be invaluable in navigating supplier negotiations and logistics.

Pricing for tire inflation products can vary widely based on multiple factors, including market conditions, supplier negotiations, and order volume. Always seek updated quotes and consider all cost components to ensure a comprehensive understanding of your sourcing expenses.

In the quest for enhanced fuel efficiency, businesses often explore various strategies. While maintaining proper tire inflation is a proven method, several alternative solutions can also contribute to improved fuel economy. This section compares proper tire inflation with two viable alternatives: the use of fuel-efficient tires and advanced telematics systems.

| Vergleich Aspekt | Proper Tire Inflation Fuel Efficiency | Fuel-Efficient Tires | Advanced Telematics Systems |

|---|---|---|---|

| Leistung | Reduces rolling resistance, improving fuel economy by up to 3% per PSI | Designed to minimize rolling resistance and enhance fuel efficiency | Provides real-time data to optimize driving behavior, reducing fuel consumption |

| Kosten | Low-cost maintenance; negligible impact on operational budget | Higher initial cost; long-term savings on fuel | Moderate initial investment; potential for significant long-term savings |

| Leichte Implementierung | Simple checks and adjustments; requires minimal training | Requires selection and installation of specialized tires | Requires integration with existing systems and training for drivers |

| Wartung | Regular checks recommended (monthly); easy to perform | Minimal maintenance post-installation; monitor tire condition | Regular software updates and monitoring required |

| Bester Anwendungsfall | Suitable for all vehicles; essential for safety and performance | Ideal for fleets focused on long-term fuel savings | Best for large fleets with data-driven management strategies |

Fuel-efficient tires are designed with specific tread patterns and materials that reduce rolling resistance. This can lead to a fuel economy improvement of up to 10% compared to standard tires. The main advantage of using fuel-efficient tires lies in their ability to maintain performance while offering longer lifespan and lower fuel costs. However, the initial investment can be significantly higher, which may deter some businesses. Additionally, they may not always perform optimally in adverse weather conditions, which is an important consideration for regions with extreme climates.

Advanced telematics systems utilize GPS and onboard diagnostics to monitor vehicle performance and driver behavior in real-time. By providing insights into speed, acceleration, and braking patterns, these systems can help fleet managers optimize routes and reduce fuel consumption. The primary benefit is the potential for substantial long-term savings through improved operational efficiency. However, this solution requires a moderate investment and ongoing maintenance, including software updates and driver training, which could be a barrier for smaller businesses.

When evaluating the best solution for fuel efficiency, B2B buyers should consider their specific operational requirements, budget, and vehicle types. Proper tire inflation remains a fundamental practice due to its low cost and significant impact on safety and performance. However, investing in fuel-efficient tires or advanced telematics systems may yield greater long-term savings and efficiency for businesses with larger fleets or specific operational challenges. Ultimately, the right choice will depend on a balance between upfront costs, maintenance capabilities, and the desired return on investment.

Understanding the technical properties related to tire inflation is crucial for B2B buyers, especially those in logistics, transportation, and automotive industries. Here are some essential specifications:

Tire pressure, measured in pounds per square inch (PSI), is a fundamental specification. The correct PSI varies by vehicle type and tire design, typically ranging from 30 to 35 PSI for passenger vehicles. Maintaining the correct tire pressure is vital for fuel efficiency; underinflated tires increase rolling resistance, leading to higher fuel consumption. For businesses, ensuring proper PSI can translate into significant savings over time.

The load index indicates the maximum weight a tire can safely support when properly inflated. This specification is essential for B2B buyers managing fleets, as overloading tires can lead to increased wear, reduced fuel efficiency, and higher risks of tire failure. Understanding load index helps businesses choose the right tires for their vehicles, ensuring safety and efficiency.

Tread depth affects both tire performance and fuel efficiency. A deeper tread can improve traction but may also increase rolling resistance if not balanced correctly. For businesses operating in diverse environments, knowing the optimal tread depth helps in selecting tires that will perform well under specific conditions, reducing the likelihood of fuel inefficiency due to improper tire selection.

The materials used in tire construction, including rubber compounds and reinforcement materials, significantly influence performance. Tires made from advanced compounds may offer lower rolling resistance, enhancing fuel efficiency. For B2B buyers, investing in high-quality tires can yield long-term savings through improved fuel economy and extended tire life.

Tires are subjected to various temperature conditions, which can affect their pressure and performance. Understanding the temperature tolerance of tires helps buyers make informed decisions regarding tire selection based on climate and operational conditions. In regions with extreme weather, this knowledge is crucial for maintaining optimal tire pressure and ensuring fuel efficiency.

Illustrative image related to proper tire inflation fuel efficiency

Familiarity with industry-specific jargon is essential for effective communication and negotiation in the tire market. Here are some common terms:

OEM refers to the manufacturer that produces parts or equipment that may be marketed by another manufacturer. In tire procurement, understanding OEM specifications ensures that businesses select tires that meet original performance standards, crucial for maintaining fuel efficiency in fleet operations.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ for tires can help in budgeting and inventory management. An appropriate MOQ can lead to cost savings, especially when purchasing tires in bulk for fleet maintenance.

Illustrative image related to proper tire inflation fuel efficiency

An RFQ is a document sent to suppliers to request pricing information on specific products. For B2B buyers in the tire industry, issuing RFQs can facilitate competitive pricing and ensure that they are making informed purchasing decisions regarding tire inflation products that enhance fuel efficiency.

Incoterms are international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial for managing shipping costs and risks associated with tire procurement. This knowledge can impact the overall cost of ownership and operational efficiency.

Rolling resistance is the force that opposes the motion of a tire as it rolls on a surface. It is a critical factor in fuel efficiency; lower rolling resistance tires require less energy to maintain speed. For B2B buyers, selecting tires with optimal rolling resistance can lead to significant fuel savings, particularly for fleets with high mileage.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance tire performance, improve fuel efficiency, and ultimately contribute to cost savings and operational excellence.

The global market for proper tire inflation and its impact on fuel efficiency is influenced by a multitude of factors. One of the primary drivers is the increasing focus on sustainability and cost reduction among businesses, particularly in regions like Africa, South America, the Middle East, and Europe. Companies are under pressure to optimize operational costs while simultaneously adhering to environmental regulations, which has led to a growing demand for fuel-efficient technologies.

Illustrative image related to proper tire inflation fuel efficiency

Emerging technologies, such as smart tire monitoring systems and advanced tire pressure management tools, are revolutionizing the way businesses approach tire maintenance. These technologies offer real-time data on tire pressure and temperature, allowing fleet managers to make informed decisions that enhance fuel efficiency. Additionally, the integration of Internet of Things (IoT) capabilities into tire management systems is a significant trend, enabling predictive maintenance and reducing the likelihood of under-inflation.

Market dynamics are also shaped by fluctuating fuel prices and varying regulatory environments across regions. For instance, in markets like Saudi Arabia and Nigeria, where fuel subsidies can distort pricing, the emphasis on fuel efficiency may not be as pronounced compared to Europe, where carbon emissions regulations are stringent. As a result, international B2B buyers must navigate these complexities and evaluate sourcing options that align with their regional market conditions.

Sustainability has become a cornerstone of B2B sourcing strategies, particularly concerning proper tire inflation for fuel efficiency. The environmental impact of transportation is a growing concern, prompting businesses to seek solutions that reduce their carbon footprint. Properly inflated tires not only enhance fuel efficiency but also contribute to lower greenhouse gas emissions, making them a critical focus for companies aiming for sustainability.

Moreover, the importance of ethical supply chains cannot be overstated. Businesses are increasingly held accountable for their sourcing practices, with stakeholders demanding transparency and responsibility. As a result, suppliers of tire inflation solutions are prioritizing sustainable materials and processes. For example, tire manufacturers are exploring eco-friendly materials, such as recycled rubber and biodegradable compounds, to minimize environmental impact.

Green certifications also play a vital role in B2B purchasing decisions. Certifications such as ISO 14001 for environmental management systems or the Global Recycled Standard can provide assurance that the products sourced are aligned with sustainability goals. By prioritizing these certifications, international buyers can ensure that their procurement strategies support broader environmental objectives while enhancing their brand reputation.

Illustrative image related to proper tire inflation fuel efficiency

The relationship between tire inflation and fuel efficiency has evolved significantly over the decades. Initially, tire technology focused primarily on durability and performance, with less emphasis on fuel economy. However, as fuel prices surged in the late 20th century, the automotive industry began recognizing the critical role that tire pressure plays in overall vehicle efficiency.

In the 1980s and 1990s, studies emerged linking under-inflated tires to increased fuel consumption, prompting manufacturers to recommend regular tire maintenance. The introduction of tire pressure monitoring systems (TPMS) in the early 2000s represented a significant technological advancement, enabling drivers to maintain optimal tire pressure more easily.

Today, with an increasing emphasis on sustainability and cost-effectiveness, the focus on proper tire inflation has reached new heights. Businesses are now leveraging advanced technologies to ensure tire maintenance, further underscoring the importance of this aspect in achieving fuel efficiency and reducing environmental impact. As the market continues to evolve, understanding this historical context can provide valuable insights for B2B buyers looking to optimize their operations.

How can I ensure proper tire inflation for my fleet vehicles?

To ensure proper tire inflation for your fleet, implement a routine tire pressure monitoring system. Regularly check tire pressure at least once a month or before long trips, using reliable tire pressure gauges. Invest in high-quality tire inflators to maintain optimal pressure levels. Training your drivers on the importance of tire maintenance can also enhance compliance. Additionally, consider using telematics systems that provide real-time data on tire pressure, allowing for proactive management and improved fuel efficiency across your fleet.

What is the best tire pressure monitoring system for commercial vehicles?

The best tire pressure monitoring system (TPMS) for commercial vehicles combines accuracy, durability, and ease of use. Look for systems that offer real-time monitoring, alerting drivers to low pressure conditions immediately. Brands like TireMinder and PressurePro provide robust solutions with features like temperature monitoring and alerts for multiple vehicles. Ensure that the TPMS is compatible with your fleet’s specific tire sizes and types, and consider systems that offer cloud connectivity for centralized data management.

What are the risks of underinflated tires in commercial fleets?

Underinflated tires pose significant risks for commercial fleets, including decreased fuel efficiency, increased tire wear, and safety hazards. For every 1 PSI drop in tire pressure, fuel efficiency can decrease by approximately 0.2%. This not only leads to higher operational costs but also increases the likelihood of tire blowouts and accidents, which can result in costly downtime and liability issues. Regular tire pressure checks and maintenance are essential to mitigate these risks and ensure safe operations.

How do I find reliable suppliers for tire inflators and gauges?

Finding reliable suppliers for tire inflators and gauges involves researching reputable manufacturers and distributors. Start by reviewing industry certifications and customer testimonials. Utilize trade platforms like Alibaba and Global Sources to connect with suppliers, and consider attending trade shows to meet manufacturers face-to-face. Verify the supplier’s track record, inquire about their quality assurance processes, and request samples before making bulk purchases. Establishing a solid relationship can also facilitate better terms and support.

What minimum order quantity (MOQ) should I expect when sourcing tire maintenance products?

Minimum order quantities (MOQs) for tire maintenance products can vary significantly based on the supplier and the type of product. Generally, MOQs for tire inflators and gauges range from 50 to 200 units. However, some suppliers may offer lower MOQs for new clients or trial orders. When negotiating, express your needs clearly and inquire about flexibility in MOQs, especially if you are testing a new product line or entering a new market.

What payment terms are typical for international tire suppliers?

Typical payment terms for international tire suppliers can include options like letters of credit, advance payments, or net 30/60 days after delivery. Many suppliers may require a deposit upfront, often around 30%, with the balance due upon shipment or delivery. It is advisable to discuss payment terms upfront and negotiate based on your purchasing volume and relationship with the supplier. Ensure that all payment terms are clearly documented in the contract to avoid misunderstandings.

How can I customize tire inflators for my brand?

To customize tire inflators for your brand, approach suppliers who offer OEM (Original Equipment Manufacturer) services. Discuss your branding requirements, including logo placement, color schemes, and packaging. Many manufacturers can accommodate these requests, but be prepared for potential MOQ increases for custom orders. Collaborate closely with the supplier during the design process to ensure that the final product aligns with your brand image and quality standards.

What quality assurance practices should I expect from tire maintenance suppliers?

Quality assurance practices from tire maintenance suppliers should include comprehensive testing protocols, adherence to international standards, and certifications (such as ISO 9001). Expect suppliers to conduct regular inspections of their products throughout the manufacturing process and provide documentation of these practices. Ask about their warranty policies and after-sales support, as these are indicators of a supplier’s commitment to quality and customer satisfaction. Regular audits and feedback can also help maintain high standards.

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Tire pressure affects gas mileage; lower pressure can decrease mileage by about 0.2% for every 1 psi drop in average tire pressure. Higher inflation leads to better mileage due to reduced friction.

Bereich: continental-tires.com

Registriert: 2000 (25 Jahre)

Einleitung: Maintaining correct tire pressure can boost fuel efficiency by up to 3%. Proper alignment and tire balance may add up to 2.2% in savings. Switching from low-efficiency (Class G) to high-efficiency (Class A) tires can save up to 440 liters of fuel over a tire’s lifespan. Low rolling resistance tires can improve fuel economy by up to 9% and reduce CO₂ emissions. Rotating tires every 5,000–10,000 km …

Bereich: forums.tdiclub.com

Registriert: 1999 (26 Jahre)

Einleitung: Max tire PSI: 44 PSI; Current tire PSI: 42 PSI; Recommended tire PSI for best fuel economy: 80% of max PSI (35 PSI); Recommended tire PSI according to door jam: 38 PSI; Average mileage reported: 46-46.5 MPG; Tire model mentioned: Michelin Primacy MXV4.

Bereich: freeway.com

Registriert: 1998 (27 Jahre)

Einleitung: Freeway Insurance offers a variety of insurance products including vehicle insurance (auto, motorcycle, RV/motorhome, boat, ATV, snowmobile, SR-22, classic car), property insurance (renters, homeowners, mobile/manufactured home), personal protection (health, dental, telemedicine, pet, life), travel club services (AD&D, identity theft protection, hospital indemnity), and business insurance (landlor…

In conclusion, the significance of proper tire inflation extends beyond individual vehicle performance; it represents a strategic advantage for businesses across various sectors. By ensuring optimal tire pressure, companies can enhance fuel efficiency, reduce operational costs, and contribute to environmental sustainability. The data indicates that even minor adjustments in tire pressure can lead to substantial fuel savings—critical for fleets operating in diverse terrains and climates, particularly in regions like Africa, South America, the Middle East, and Europe.

Strategic sourcing of high-quality tire maintenance tools, such as reliable tire inflators and gauges, should be a priority for B2B buyers. By investing in these resources, organizations can not only safeguard their assets but also drive down costs associated with fuel consumption and tire replacements.

Illustrative image related to proper tire inflation fuel efficiency

As we look to the future, it is imperative for international buyers to prioritize tire maintenance in their operational strategies. By doing so, they can improve efficiency and ensure safer travel for their fleets. Embrace this opportunity to optimize your fleet’s performance and sustainability—start implementing best practices for tire inflation today.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.