Navigating the complexities of tire nitrogen inflation can be a formidable challenge for international B2B buyers seeking to enhance vehicle performance and safety. As markets evolve, the demand for reliable, high-quality tire inflation solutions has surged, particularly in regions like Africa, South America, the Middle East, and Europe, including key players such as Germany and Nigeria. This comprehensive guide delves into the multifaceted world of tire nitrogen inflation, addressing critical aspects such as types of nitrogen inflation systems, their applications across various industries, and effective supplier vetting processes.

With a focus on cost analysis and return on investment, this resource empowers businesses to make informed purchasing decisions that align with their operational needs. Understanding the nuances of tire nitrogen inflation not only contributes to improved tire longevity and fuel efficiency but also enhances overall safety standards for fleets and commercial vehicles.

By equipping international buyers with actionable insights, this guide facilitates strategic sourcing and fosters partnerships with reputable suppliers, ultimately driving value in a competitive marketplace. Whether you are exploring the benefits of nitrogen inflation for passenger vehicles, commercial fleets, or specialized machinery, this guide serves as your essential resource for navigating the global tire nitrogen inflation landscape.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Commercial Nitrogen Fill | High purity nitrogen (95%+) for heavy-duty vehicles | Trucking, logistics, construction | Vorteile: Reduces tire wear, enhances safety. Nachteile: Higher initial cost, requires specialized equipment. |

| Portable Nitrogen Systems | Mobile units for on-site nitrogen inflation | Fleets, remote operations, outdoor events | Vorteile: Convenient, reduces downtime. Nachteile: Limited capacity, may require frequent refills. |

| Bulk Nitrogen Supply | Large-scale nitrogen supply for tire shops and service centers | Automotive service providers, dealerships | Vorteile: Cost-effective for high volume, consistent supply. Nachteile: Storage space needed, potential delivery delays. |

| Nitrogen Tire Inflation Kits | DIY kits for individual or small fleet use | Small businesses, personal use | Vorteile: Economical, user-friendly. Nachteile: Limited to small volumes, may lack professional-grade purity. |

| Specialty Nitrogen Mixes | Customized nitrogen blends for specific tire applications | Racing, aerospace, aviation | Vorteile: Optimized performance, tailored solutions. Nachteile: Higher complexity, specialized knowledge required. |

Commercial nitrogen fill systems are designed for heavy-duty vehicles, utilizing high-purity nitrogen (typically over 95%) to enhance tire performance. This method is particularly suitable for trucking, logistics, and construction industries where tire longevity and safety are paramount. B2B buyers should consider the initial investment in specialized equipment and maintenance costs, as well as the potential for reduced tire wear and improved fuel efficiency, which can ultimately lead to significant savings.

Illustrative image related to tire nitrogen inflation

Portable nitrogen systems offer mobile solutions for tire inflation, making them ideal for fleets and remote operations. These systems can be deployed at outdoor events or job sites, minimizing downtime for vehicles. While they provide the convenience of on-site service, B2B buyers must consider their limited capacity and the need for frequent refills. The ability to inflate tires with nitrogen on the go can greatly enhance operational efficiency.

Bulk nitrogen supply is an excellent option for automotive service providers and tire dealerships that require a consistent and cost-effective source of nitrogen. This approach allows for high-volume tire inflation, reducing the per-unit cost of nitrogen. However, businesses must factor in the need for adequate storage space and potential delivery delays when considering this option. The long-term savings and operational benefits can outweigh these challenges.

Nitrogen tire inflation kits are designed for small businesses or individual users who prefer a DIY approach. These kits are economical and user-friendly, allowing users to inflate tires with nitrogen without needing a professional service. However, their limited capacity and potential lack of professional-grade purity may not meet the demands of larger operations. Buyers should assess their specific needs and volume requirements before investing in such kits.

Specialty nitrogen mixes are tailored for unique tire applications, such as racing, aerospace, and aviation. These customized blends optimize tire performance under specific conditions, providing a competitive edge in high-stakes environments. B2B buyers should consider the higher complexity and specialized knowledge required for these solutions, as well as the potential benefits of enhanced performance. Such tailored solutions are often worth the investment for businesses operating in specialized sectors.

| Industrie/Sektor | Specific Application of Tire Nitrogen Inflation | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Aviation | Aircraft Tire Inflation | Enhanced safety and performance in high-pressure environments | Consistent nitrogen purity, compliance with aviation standards |

| Transport und Logistik | Fleet Vehicle Maintenance | Reduced tire wear, improved fuel efficiency, and lower operational costs | Reliable nitrogen supply, availability of on-site inflation services |

| Mining | Heavy Machinery Tire Maintenance | Extended tire life, reduced risk of blowouts in harsh conditions | High-capacity nitrogen generation systems, local service support |

| Bauwesen | Construction Equipment Tire Inflation | Improved safety, reduced downtime due to tire failures | Scalable nitrogen solutions, training for operational staff |

| Motorsports | Race Car Tire Management | Optimal tire performance, better handling, and safety at high speeds | Access to specialized nitrogen filling equipment, real-time monitoring capabilities |

In the aviation industry, tire nitrogen inflation is critical for aircraft safety and performance. Aircraft tires are subject to extreme conditions, including high speeds and heavy loads. Nitrogen, being inert and less prone to pressure fluctuations, helps maintain optimal tire pressure, enhancing safety and performance. International buyers must ensure that nitrogen suppliers meet stringent aviation standards and provide consistent purity levels to avoid any operational risks.

Illustrative image related to tire nitrogen inflation

For transportation and logistics companies, utilizing nitrogen inflation in fleet vehicles can lead to significant cost savings. Nitrogen-filled tires experience less pressure loss, which results in reduced tire wear and improved fuel efficiency. This is particularly beneficial for businesses operating in regions with fluctuating temperatures. Buyers should consider suppliers that offer reliable nitrogen generation systems and on-site services to facilitate routine maintenance.

In the mining sector, where heavy machinery operates in challenging environments, tire nitrogen inflation plays a vital role in extending tire life and preventing blowouts. The inert nature of nitrogen reduces oxidation and degradation, which is crucial for tires exposed to abrasive surfaces and heavy loads. Buyers in this industry should prioritize sourcing high-capacity nitrogen systems and ensure local service support for timely maintenance, minimizing downtime.

Construction equipment benefits from nitrogen inflation by experiencing fewer tire failures and improved overall safety. This is particularly important on job sites where equipment must operate under heavy loads and in rugged conditions. Buyers should look for scalable nitrogen solutions that can accommodate varying equipment sizes and ensure staff are trained to manage tire maintenance effectively.

In motorsports, tire performance is paramount. Nitrogen inflation allows for precise tire pressure management, which is crucial for handling and safety at high speeds. Teams must have access to specialized nitrogen filling equipment and the ability to monitor tire conditions in real-time. This ensures optimal performance during races, making it essential for buyers to partner with suppliers who understand the unique demands of the motorsports industry.

Das Problem: Many B2B buyers, especially those managing fleets in regions like Africa or South America, grapple with the escalating costs associated with nitrogen inflation services. These costs can include the price per tire for nitrogen filling, the need for specialized equipment, and the potential for increased service fees from tire shops. For companies operating under tight budgets, these expenses can quickly add up, leading to concerns about return on investment and overall cost-effectiveness of using nitrogen over regular air.

Die Lösung: To mitigate these costs, businesses should consider investing in nitrogen generation systems that can be installed on-site. This not only reduces dependency on external tire service providers but also allows for immediate inflation and maintenance of tire pressure without additional charges. When selecting a nitrogen generator, look for systems that provide high purity levels and are capable of meeting the specific tire volume needs of your fleet. Additionally, training your staff on the proper use and maintenance of the system will enhance efficiency and ensure that nitrogen inflation becomes a seamless part of your tire management process.

Das Problem: Another common pain point is the misconception regarding the benefits of nitrogen inflation. B2B buyers might be sold on the idea that nitrogen significantly improves fuel efficiency and tire lifespan, only to find that the practical advantages are marginal compared to regular air. This can lead to frustration and skepticism about the long-term value of nitrogen, particularly if they don’t see a marked improvement in performance or savings.

Die Lösung: It’s crucial for businesses to conduct thorough research and engage with experts who can provide a realistic overview of nitrogen inflation’s benefits and limitations. Create a comparison study that measures tire performance over time with both nitrogen and air, focusing on metrics like pressure retention, tire wear, and overall fuel efficiency. This data-driven approach can help in making informed decisions, ensuring that the choice to use nitrogen is backed by solid evidence. Additionally, consider collaborating with tire manufacturers who can provide insights and possibly co-develop a maintenance strategy that maximizes the benefits of both inflation methods.

Das Problem: Consistent tire pressure monitoring is essential for safety and efficiency, yet many B2B buyers fail to implement a reliable system for checking tire pressure after switching to nitrogen. This inconsistency can lead to under-inflation, which compromises safety, increases tire wear, and ultimately affects operational efficiency. Companies may also face challenges in educating their staff about the importance of regular checks, especially if they have transitioned from using regular air, where pressure fluctuations might have been more manageable.

Die Lösung: To address this, businesses should implement a structured tire maintenance program that includes regular training sessions for staff on the importance of tire pressure management. Investing in automated tire pressure monitoring systems (TPMS) can also streamline the process by providing real-time data on tire pressure, alerting staff to any discrepancies. Additionally, integrating a schedule for routine checks—ideally monthly or bi-weekly—can help maintain optimal pressure levels. Ensure that all staff are educated on the implications of nitrogen inflation, including the need for consistent monitoring to avoid mixing with regular air, which diminishes the benefits of nitrogen.

When selecting materials for tire nitrogen inflation systems, several factors come into play, including performance properties, cost, and international compliance. Here, we analyze four common materials: aluminum, steel, rubber, and nitrogen generation systems, providing insights that cater specifically to international B2B buyers.

Illustrative image related to tire nitrogen inflation

Wichtige Eigenschaften: Aluminum is lightweight and exhibits excellent corrosion resistance, making it suitable for various environmental conditions. Its pressure rating is generally high, allowing for safe inflation even under extreme conditions.

Pro und Kontra: The durability of aluminum is commendable, as it can withstand significant wear and tear. However, it may be more expensive than other materials, which can affect overall manufacturing costs. The complexity of manufacturing aluminum components can also lead to longer lead times.

Auswirkungen auf die Anwendung: Aluminum’s compatibility with nitrogen is favorable, as it does not react adversely with nitrogen gas. This ensures that the integrity of the nitrogen remains intact during storage and inflation.

Überlegungen für internationale Einkäufer: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN. The preference for lightweight materials in automotive applications makes aluminum an attractive option.

Wichtige Eigenschaften: Steel is known for its high tensile strength and durability, making it a common choice for tire inflation systems. It has a good pressure rating but is heavier than aluminum.

Pro und Kontra: The primary advantage of steel is its cost-effectiveness and robustness. However, it is prone to corrosion if not properly treated, which can lead to failure over time. The manufacturing process for steel components can be complex, particularly when ensuring corrosion resistance.

Auswirkungen auf die Anwendung: Steel can handle high-pressure environments, but its weight may be a disadvantage in applications where weight savings are crucial. Additionally, steel’s potential for corrosion could compromise the nitrogen’s purity if moisture is introduced.

Überlegungen für internationale Einkäufer: Buyers in South America and Africa should be aware of local corrosion resistance standards, as untreated steel may not meet durability expectations in humid climates.

Wichtige Eigenschaften: Rubber is flexible and provides excellent sealing capabilities, essential for maintaining tire pressure. It can handle a range of temperatures and pressures, making it suitable for various applications.

Pro und Kontra: The main advantage of rubber is its ability to create airtight seals, preventing nitrogen loss. However, it can degrade over time, especially when exposed to UV light and extreme temperatures, which may necessitate more frequent replacements.

Auswirkungen auf die Anwendung: Rubber’s compatibility with nitrogen is excellent, ensuring that the gas remains contained without any adverse reactions. However, the degradation factor must be considered in regions with harsh climates.

Überlegungen für internationale Einkäufer: Buyers from regions like Nigeria and Germany should consider the local climate’s impact on rubber longevity. Compliance with standards such as JIS for rubber components is also crucial.

Wichtige Eigenschaften: Nitrogen generation systems utilize advanced technology to produce high-purity nitrogen, often exceeding 95% purity. These systems are designed to operate efficiently under various environmental conditions.

Pro und Kontra: The primary advantage of nitrogen generation systems is their ability to provide a continuous supply of nitrogen without the need for external gas cylinders. However, the initial investment can be high, and maintenance may require specialized knowledge.

Auswirkungen auf die Anwendung: These systems ensure that the nitrogen used for tire inflation is of the highest quality, reducing the risk of contamination. They are particularly beneficial in high-demand environments, such as commercial fleets.

Überlegungen für internationale Einkäufer: Buyers in Europe and the Middle East should ensure that the systems comply with local safety and operational standards. The availability of technical support and maintenance services is also a critical factor.

Illustrative image related to tire nitrogen inflation

| Material | Typical Use Case for tire nitrogen inflation | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Tire inflation systems | Leicht und korrosionsbeständig | Höhere Kosten und komplexere Herstellung | Hoch |

| Stahl | Tire inflation valves and tanks | Cost-effective and robust | Prone to corrosion without treatment | Mittel |

| Gummi | Seals and gaskets for tire valves | Hervorragende Dichtungseigenschaften | Degrades over time in harsh conditions | Niedrig |

| Nitrogen Generation Systems | Commercial tire inflation | Continuous supply of high-purity nitrogen | High initial investment and maintenance | Hoch |

This analysis provides a comprehensive overview of the materials used in tire nitrogen inflation, allowing international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

The manufacturing process for tire nitrogen inflation systems involves several critical stages that ensure both efficiency and quality. The key stages include material preparation, forming, assembly, and finishing.

Vorbereitung des Materials

This initial stage involves sourcing high-purity nitrogen and other necessary materials. Suppliers must ensure that the nitrogen is processed to remove impurities and moisture, which are crucial for effective tire inflation. The materials used for the inflation systems, such as hoses, valves, and pressure gauges, must meet specific industry standards to guarantee durability and reliability.

Bildung von

During the forming stage, components are manufactured using techniques such as extrusion, molding, or machining. For example, hoses may be extruded from high-quality rubber or synthetic materials to withstand high pressures. Precision machining is often employed for valves and fittings to ensure tight seals and prevent leaks.

Montage

The assembly stage involves integrating the various components into a complete nitrogen inflation system. This process typically includes assembling the nitrogen generator, storage tanks, and distribution lines. Automation is increasingly common in this stage, allowing for greater consistency and reduced human error.

Fertigstellung

The finishing stage includes rigorous testing and quality checks. Products are cleaned, labeled, and packaged according to regulatory requirements. This stage often involves applying protective coatings or treatments to enhance durability, especially for components exposed to environmental factors.

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that products meet industry standards and customer expectations. For tire nitrogen inflation systems, QA involves several international and industry-specific standards, as well as multiple quality checkpoints.

Internationale Normen und branchenspezifische Zertifizierungen

Manufacturers typically adhere to international quality management standards, such as ISO 9001, which outlines criteria for a quality management system. Additionally, certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for components used in various industries provide a framework for quality assurance in tire nitrogen inflation systems.

Illustrative image related to tire nitrogen inflation

Qualitätskontrollpunkte

Quality control checkpoints are essential in the manufacturing process to ensure that products meet specified standards:

Eingehende Qualitätskontrolle (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specified requirements is crucial for maintaining product integrity.

Prozessbegleitende Qualitätskontrolle (IPQC): Throughout the manufacturing process, various checks are conducted to monitor quality at different stages. This may include visual inspections, dimensional checks, and functional tests to ensure that components are being produced correctly.

Endgültige Qualitätskontrolle (FQC): Before products are packaged and shipped, they undergo comprehensive testing to ensure they meet performance specifications. This includes leak tests for inflation systems and performance assessments to verify nitrogen purity and pressure retention capabilities.

Testing methods are essential in verifying the quality and performance of tire nitrogen inflation systems. Common testing methodologies include:

Pressure Testing: This test checks for leaks and ensures that components can withstand the pressures they will encounter during operation. It typically involves pressurizing the system and monitoring for any drop in pressure over time.

Nitrogen Purity Testing: Ensuring the nitrogen used in tire inflation is of high purity is critical. Testing methods, such as gas chromatography, can be employed to verify that nitrogen meets the specified purity levels (typically 95% or higher).

Funktionelle Prüfung: This involves simulating real-world conditions to assess the performance of the nitrogen inflation system. Functional tests may include checking the response time of valves and the efficiency of nitrogen generation.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure they receive reliable products. Here are several actionable steps buyers can take:

Lieferanten-Audits: Conducting on-site audits allows buyers to assess the manufacturing facility’s adherence to quality standards. This includes reviewing QA processes, testing methodologies, and compliance with international certifications.

Request Quality Reports: Buyers should request detailed quality reports from suppliers, including results from IQC, IPQC, and FQC stages. These reports provide insight into the supplier’s commitment to quality and any potential issues encountered during production.

Inspektionen durch Dritte: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing process. These agencies can conduct audits, perform testing, and validate compliance with industry standards, offering additional assurance to buyers.

International B2B buyers face unique challenges regarding quality control, particularly when sourcing from diverse regions. Understanding these nuances can help buyers make informed decisions:

Illustrative image related to tire nitrogen inflation

Einhaltung von Vorschriften: Different countries have varying regulatory requirements for manufacturing and product safety. Buyers should familiarize themselves with local regulations and ensure suppliers comply with them.

Kulturelle Unterschiede: Business practices and attitudes towards quality can differ significantly across regions. Buyers should consider these cultural aspects when evaluating suppliers and developing quality assurance partnerships.

Transparenz der Lieferkette: Ensuring transparency in the supply chain is vital for maintaining quality. Buyers should seek suppliers who are willing to provide insight into their sourcing practices, manufacturing processes, and quality control measures.

By understanding the manufacturing processes and quality assurance practices surrounding tire nitrogen inflation systems, B2B buyers can make informed decisions that enhance their operational efficiency and product reliability. This knowledge not only supports effective supplier selection but also fosters long-term partnerships built on quality and trust.

This guide serves as a comprehensive checklist for B2B buyers looking to procure tire nitrogen inflation services. With the growing popularity of nitrogen for tire inflation in various industries, understanding the procurement process is essential for ensuring quality, efficiency, and cost-effectiveness. This step-by-step checklist will help you navigate the complexities of sourcing nitrogen inflation solutions tailored to your specific needs.

Before starting the procurement process, it’s vital to define your specific needs. Consider factors such as the type of vehicles or machinery using nitrogen, the volume of nitrogen required, and the frequency of inflation services.

Conduct thorough research to identify potential suppliers who specialize in nitrogen inflation services. Look for companies with a proven track record in your region, especially those that understand the local market dynamics.

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region to gain insights into their reliability and service quality.

Illustrative image related to tire nitrogen inflation

Once you have shortlisted potential suppliers, request detailed quotes outlining their services, pricing structures, and terms of service. This step is crucial for comparing options and ensuring transparency.

If feasible, conduct site visits to the suppliers’ facilities or request virtual tours. This can provide valuable insights into their operations, safety standards, and equipment used for nitrogen inflation.

Once you have selected a supplier, negotiate terms that align with your operational needs and budget. This is the final step before formalizing the partnership.

Illustrative image related to tire nitrogen inflation

After securing a supplier, set up a monitoring system to track the performance of the nitrogen inflation service. This includes measuring tire pressure retention, safety outcomes, and overall cost-effectiveness.

By following this checklist, B2B buyers can effectively navigate the sourcing of tire nitrogen inflation services, ensuring they choose a supplier that meets their operational needs while maximizing value.

When evaluating the cost structure for tire nitrogen inflation, various components must be considered. The primary cost components include:

Materialien: The main material is nitrogen gas itself, which is typically produced through fractional distillation or membrane separation processes. The cost of producing or procuring high-purity nitrogen can vary based on location and supplier.

Arbeit: Labor costs encompass personnel responsible for the inflation process, equipment maintenance, and customer service. This includes technicians who operate nitrogen filling stations and those involved in routine maintenance.

Fertigungsgemeinkosten: This includes the costs associated with facility operations, utilities, and administrative expenses. Overhead can significantly impact pricing, especially in regions with higher operational costs.

Werkzeugbau: Investment in specialized equipment for nitrogen generation and inflation is necessary. This includes compressors, storage tanks, and dispensing units. The initial capital expenditure can be substantial but is often amortized over time.

Qualitätskontrolle (QC): Ensuring the nitrogen meets purity standards involves testing and monitoring, which incurs additional costs. Certifications for quality assurance can also add to the overall expense.

Logistik: Distribution costs for transporting nitrogen or the equipment needed for inflation can vary widely based on geographic location and logistics infrastructure.

Marge: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can fluctuate based on market competition and demand.

Several factors influence the pricing of tire nitrogen inflation services:

Volumen und Mindestbestellmenge (MOQ): Bulk purchases or high-volume contracts can lead to reduced prices per unit. Suppliers are often willing to negotiate better rates for clients committing to larger volumes.

Spezifikationen und Anpassungen: Customized solutions, such as specialized equipment or tailored service packages, can increase costs. However, they may provide a competitive advantage that justifies the expense.

Materialien: The quality and purity of nitrogen gas directly affect pricing. Higher purity levels may be required for specific applications, influencing the overall cost structure.

Qualität und Zertifizierungen: Obtaining certifications can increase costs but may be necessary to meet regulatory requirements, particularly in regions with stringent safety and environmental standards.

Lieferanten-Faktoren: Reliability, reputation, and service offerings from suppliers can affect pricing. Established suppliers may command higher prices but offer better service and consistency.

Incoterms: The terms of shipping and delivery can significantly impact costs. Understanding Incoterms is crucial for international buyers to avoid unexpected expenses related to transportation and customs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Bedingungen verhandeln: Leverage volume commitments and long-term contracts to negotiate better pricing. Establishing strong relationships with suppliers can lead to more favorable terms.

Konzentration auf die Gesamtbetriebskosten (TCO): Assess not only the initial pricing but also the long-term costs associated with tire maintenance, safety, and fuel efficiency. A lower upfront cost may lead to higher TCO if it results in increased operational issues or inefficiencies.

Nuancen der Preisgestaltung verstehen: Different regions may experience varying pricing structures due to local economic conditions, supply chain factors, and regulatory environments. Conducting market research can provide insights into fair pricing.

Explore Local Suppliers: Sourcing from local suppliers can reduce logistics costs and improve turnaround times. However, ensure that local options meet the required quality standards.

Monitor Market Trends: Stay informed about market dynamics, including changes in nitrogen pricing, technological advancements, and regulatory shifts. This knowledge can aid in making informed purchasing decisions.

Pricing for tire nitrogen inflation services can vary widely based on multiple factors, including geographic location, supplier relationships, and market conditions. Therefore, the prices discussed herein are indicative and should be confirmed with specific suppliers for accurate quotations.

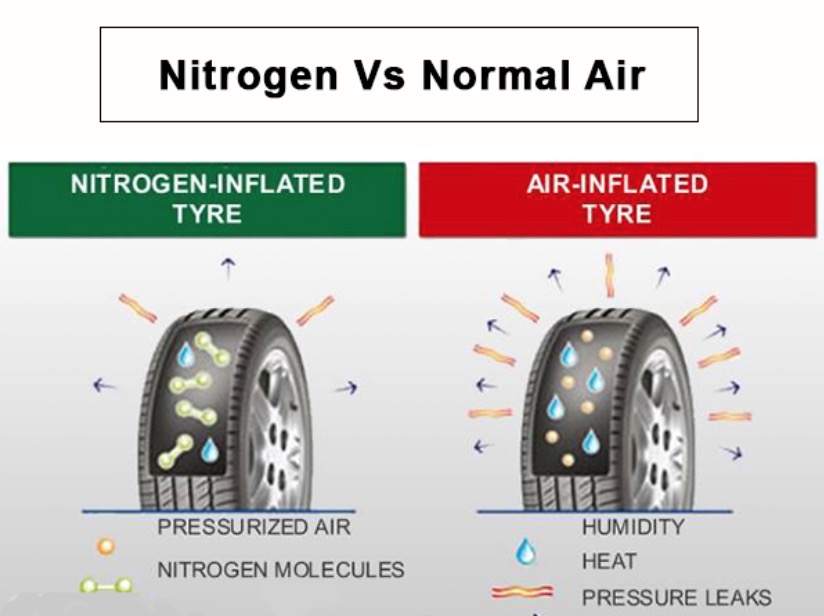

In the realm of tire maintenance, nitrogen inflation has garnered attention for its purported benefits, such as improved pressure retention and reduced tire degradation. However, several alternative solutions exist that can also enhance tire performance and longevity. This section delves into a comparison of tire nitrogen inflation with two viable alternatives: traditional air inflation and tire pressure monitoring systems (TPMS).

| Vergleich Aspekt | Tire Nitrogen Inflation | Traditional Air Inflation | Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Leistung | Moderate pressure retention; minimal degradation | Standard pressure retention; requires regular checks | Constant monitoring of tire pressure; alerts for low pressure |

| Kosten | Higher initial cost; ongoing maintenance costs | Low cost; air is generally free or minimal charge | Moderate cost; initial investment with potential savings on tire wear |

| Leichte Implementierung | Requires special equipment for nitrogen filling | Easy; available at most service stations | Requires installation; may need calibration |

| Wartung | Requires periodic refilling with nitrogen | Requires regular pressure checks and top-offs | Low maintenance; alerts for pressure changes reduce manual checks |

| Bester Anwendungsfall | Heavy-duty applications (trucks, aircraft) | Everyday passenger vehicles | Fleets and vehicles requiring constant pressure monitoring |

Traditional air inflation is the most common method used for tire inflation across various vehicle types. It is easily accessible, with air stations available at gas stations and repair shops. The primary advantage of this method is its low cost—air is often free or comes at a minimal charge. However, air-filled tires tend to lose pressure more quickly than nitrogen-filled tires, requiring more frequent checks and top-offs. For businesses operating standard passenger vehicles, this method is often sufficient, provided that routine maintenance is diligently followed.

TPMS offers a modern solution by providing real-time tire pressure readings, alerting drivers when tire pressure drops below optimal levels. This technology enhances safety and can lead to increased fuel efficiency by ensuring tires are always properly inflated. While the initial investment in a TPMS can be moderate, the long-term savings from reduced tire wear and improved fuel economy can justify the cost. The main drawback is that TPMS does not prevent pressure loss; it merely alerts users to it, necessitating a proactive approach to tire maintenance.

When evaluating the best tire inflation method for your business, consider factors such as the type of vehicles in your fleet, operational costs, and maintenance capabilities. For companies operating heavy-duty vehicles or those that prioritize performance and safety, nitrogen inflation may offer tangible benefits despite its higher costs. Conversely, for standard passenger vehicles, traditional air inflation paired with diligent monitoring may suffice. TPMS can be an excellent middle ground, enhancing safety and efficiency without the ongoing costs associated with nitrogen inflation. By aligning your tire maintenance strategy with your operational goals, you can optimize performance, safety, and cost-effectiveness in your fleet management.

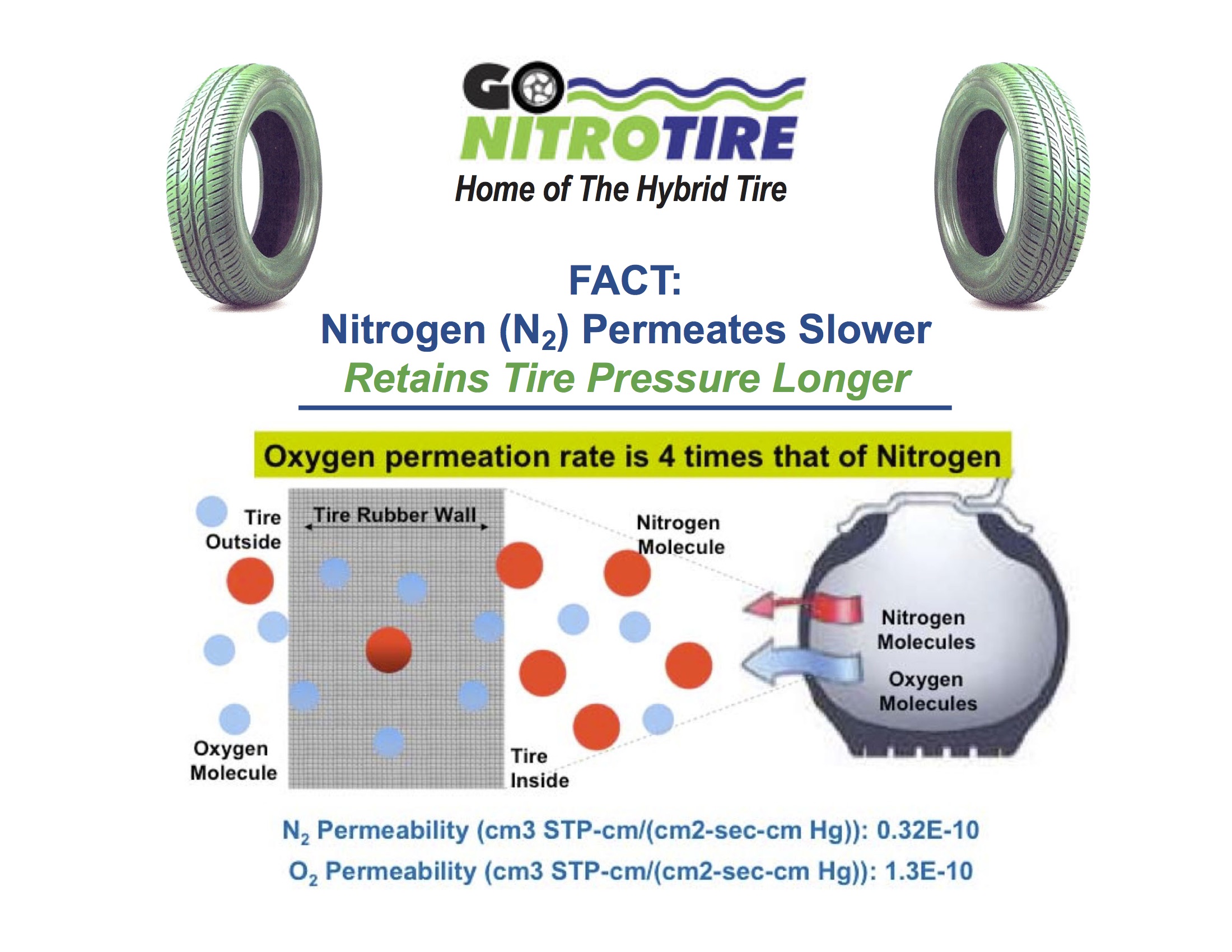

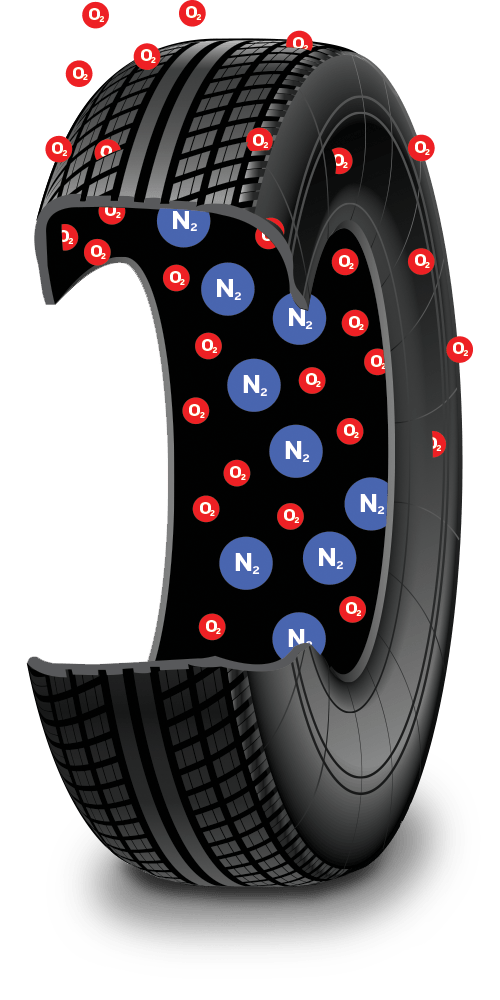

Purity level refers to the concentration of nitrogen in the gas used for tire inflation. For effective nitrogen inflation, a purity level of at least 95% is recommended. This high purity minimizes the presence of oxygen and moisture, which can contribute to tire degradation over time. B2B buyers should ensure that their suppliers can guarantee this level of purity, as it directly impacts tire longevity and performance.

Pressure retention is a critical property that indicates how well a tire maintains its inflation over time. Nitrogen-filled tires typically exhibit lower pressure loss compared to those inflated with regular air. This characteristic is particularly important for businesses operating fleets or high-performance vehicles, as it translates to reduced maintenance costs and improved fuel efficiency.

Temperature stability refers to how nitrogen reacts to temperature changes compared to air. Nitrogen is less affected by temperature fluctuations, making it a suitable choice for environments with extreme weather conditions. For B2B buyers in regions with variable climates, this property is essential as it ensures consistent tire performance and safety.

Oxidation resistance is the ability of nitrogen to reduce the risk of tire degradation caused by oxidation. Regular air contains oxygen, which can deteriorate rubber over time. By using nitrogen, businesses can extend tire life and improve safety, making it a valuable consideration for fleet operators and tire retailers.

Illustrative image related to tire nitrogen inflation

Moisture content in the gas used for inflation can lead to tire pressure variations and internal corrosion. Nitrogen inflation systems are designed to eliminate moisture, ensuring a dry environment within the tire. This is particularly important for B2B buyers in industries reliant on heavy-duty vehicles, where tire reliability is paramount.

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire nitrogen inflation, OEMs may supply nitrogen generators or tire inflation systems. B2B buyers should consider working with reputable OEMs to ensure quality and compatibility with their existing systems.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For tire nitrogen inflation systems, understanding the MOQ is essential for B2B buyers to manage inventory costs effectively. Suppliers may impose MOQs to maintain profitability, making it crucial for buyers to negotiate terms that fit their operational needs.

An RFQ is a document used by companies to solicit price quotes from suppliers for specific products or services. When exploring options for nitrogen inflation systems, businesses should prepare detailed RFQs to ensure they receive accurate pricing and terms. This process helps in making informed purchasing decisions.

Illustrative image related to tire nitrogen inflation

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers in different regions, as they can significantly affect overall costs and logistics planning for tire nitrogen inflation systems.

PSI is a unit of measurement used to express tire pressure. It is crucial for B2B buyers to understand the optimal PSI for various tire types to ensure safety and performance. Maintaining proper PSI is essential for maximizing the benefits of nitrogen inflation, as it contributes to tire efficiency and longevity.

In summary, comprehending these technical properties and trade terms is essential for B2B buyers involved in tire nitrogen inflation. Such knowledge not only aids in making informed purchasing decisions but also enhances operational efficiency and safety in tire management.

The tire nitrogen inflation sector is experiencing significant growth driven by several global factors. Increased awareness of vehicle maintenance and the cost-saving potential of nitrogen inflation is capturing the attention of B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. Notably, the adoption of nitrogen inflation is more pronounced in commercial sectors, such as logistics and transportation, where tire performance directly impacts operational efficiency.

Emerging technologies are reshaping the landscape, with advancements in nitrogen generation systems allowing for more efficient and cost-effective solutions. Businesses are increasingly investing in on-site nitrogen generation, which reduces reliance on external suppliers and ensures consistent quality. This trend is particularly relevant for companies with large fleets, as it allows for better control over tire maintenance practices and reduces downtime associated with tire inflation.

Additionally, the demand for enhanced safety features in vehicles is driving the market. Companies that prioritize safety and reliability are more likely to adopt nitrogen inflation as it offers better pressure retention and minimizes the risks associated with tire blowouts. B2B buyers are also looking for suppliers who can provide comprehensive service packages, including tire maintenance, monitoring, and inflation solutions, to streamline their operations.

Sustainability is becoming a crucial consideration for businesses sourcing tire nitrogen inflation solutions. The environmental impact of traditional tire inflation methods, which often rely on compressed air that can contain moisture and impurities, has led to an increased focus on using high-purity nitrogen. By switching to nitrogen, companies can reduce the degradation of tires, leading to longer lifespans and less frequent replacements, which ultimately contributes to waste reduction.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are now more conscious of the origins of the materials and gases used in their tire inflation processes. This has led to a growing demand for suppliers that can demonstrate adherence to environmental regulations and ethical sourcing practices. Certifications such as ISO 14001 for environmental management systems and adherence to green standards can significantly enhance a supplier’s credibility.

Illustrative image related to tire nitrogen inflation

Investing in ‘green’ nitrogen generation technologies, such as those that utilize renewable energy sources, further aligns with corporate social responsibility goals. This not only helps in reducing carbon footprints but also positions companies favorably in the eyes of eco-conscious consumers and partners.

The evolution of tire nitrogen inflation dates back to its initial use in aviation and motorsports, where performance and safety are paramount. Over time, these benefits have been recognized in the consumer and commercial vehicle markets. The shift toward nitrogen inflation in everyday vehicles gained momentum in the early 2000s, as tire retailers began to market its advantages over traditional air inflation.

Initially, the focus was primarily on performance enhancements, such as improved fuel efficiency and tire longevity. However, as research evolved, the understanding of nitrogen’s role in maintaining tire pressure and reducing oxidation became clearer. This has led to a broader acceptance of nitrogen inflation across various sectors, particularly among businesses looking to optimize fleet performance and safety.

Today, tire nitrogen inflation is not just about filling tires with gas; it encompasses a comprehensive approach to tire maintenance, integrating technology and sustainability into operations. As the market continues to grow, international B2B buyers must stay informed about the latest innovations and trends to make strategic sourcing decisions that align with their operational goals and sustainability commitments.

How do I ensure the quality of nitrogen inflation systems for tires?

To ensure quality, evaluate potential suppliers based on their certifications, such as ISO 9001 for quality management systems. Request product samples to test their nitrogen purity and performance. Additionally, inquire about their manufacturing processes, quality control measures, and customer reviews. It is also beneficial to visit the supplier’s facility if possible, or request third-party audits to validate their claims. Establishing a clear quality assurance agreement can further protect your interests.

What is the best nitrogen inflation system for commercial fleets?

The best nitrogen inflation system for commercial fleets should feature high nitrogen purity levels (ideally above 95%), fast inflation capabilities, and durability for continuous use. Look for systems that offer real-time monitoring of tire pressure and nitrogen levels, as well as ease of maintenance. Brands known for reliability and efficiency in commercial applications include PressurePro and TireSaver. Consider the specific needs of your fleet, such as tire sizes and types, when selecting the right system.

What are the minimum order quantities (MOQ) for tire nitrogen inflation equipment?

Minimum order quantities for tire nitrogen inflation equipment can vary significantly among suppliers. Generally, MOQs may range from 5 to 50 units, depending on the manufacturer’s production capabilities and your specific requirements. For larger orders, negotiate terms to secure better pricing and payment options. If you’re a smaller buyer, consider forming a consortium with other businesses to meet MOQ requirements or seeking suppliers who specialize in smaller-scale orders.

What payment terms should I negotiate with suppliers?

When negotiating payment terms with suppliers, aim for favorable conditions such as net 30 or net 60 days, allowing ample time for cash flow management. Consider using letters of credit or escrow services to mitigate risks, especially for international transactions. Additionally, inquire about discounts for early payments or bulk purchases. Establishing a clear payment schedule and understanding the implications of currency fluctuations can also be beneficial.

How can I customize nitrogen inflation systems for my specific needs?

Customization options for nitrogen inflation systems can include adjustments to the nitrogen purity level, inflation speed, and the inclusion of monitoring technology for real-time data tracking. Discuss your specific operational needs with suppliers and request tailored solutions that align with your business model. Some manufacturers may offer modular designs that allow for future upgrades or expansions as your fleet grows.

What logistics considerations should I be aware of when importing nitrogen inflation systems?

When importing nitrogen inflation systems, consider shipping costs, transit times, and customs regulations specific to your region. Ensure that the supplier provides all necessary documentation, including compliance certifications and safety data sheets. Establish a reliable logistics partner familiar with international trade to streamline the import process. Additionally, factor in potential duties and taxes that may apply to your purchase.

How do I vet suppliers for tire nitrogen inflation systems?

Vetting suppliers involves researching their industry reputation, reviewing client testimonials, and checking for relevant certifications. Utilize platforms like LinkedIn or trade shows to connect with other businesses that have used their services. Request detailed product specifications and after-sales support information. A trial order can also serve as an effective method to assess the supplier’s reliability and product quality before committing to larger purchases.

What are the safety considerations when using nitrogen inflation systems?

Safety considerations include ensuring proper training for personnel handling nitrogen equipment, as well as maintaining adequate ventilation in work areas to prevent nitrogen accumulation. Use appropriate protective gear and ensure that equipment is regularly inspected for leaks or malfunctions. Familiarize yourself with emergency procedures and first aid measures related to nitrogen exposure. Additionally, follow local regulations regarding the storage and handling of compressed gases to ensure compliance.

Bereich: continental-tires.com

Registriert: 2000 (25 Jahre)

Einleitung: Nitrogen in tires can provide benefits such as improved tire pressure retention, reduced oxidation, and enhanced fuel efficiency. It is increasingly offered by tire dealers and garages, appealing to driving enthusiasts. Proper tire maintenance, including regular pressure checks, is essential for optimal tire performance.

Bereich: dunntire.com

Registriert: 1996 (29 Jahre)

Einleitung: Nitrogen Fuel Savings System provides nitrogen inflation for tires, which is a safe, non-flammable, inert gas. Key benefits include increased fuel efficiency, longer tire tread life, improved tire performance, enhanced vehicle handling and safety, and longer rim life. Nitrogen molecules are less permeable than oxygen, allowing tires to maintain proper pressure longer. This leads to reduced rolling…

Bereich: robertson-tire.com

Registriert: 1999 (26 Jahre)

Einleitung: Nitrogen-filled tires lose pressure about 40% slower than regular air. They can contain up to 98% pure nitrogen, which helps maintain air pressure longer. Benefits include: increased tread life, better tire pressure retention, cooler-running tire temperatures, improved handling and performance, extended tire lifespan, and maximized tire pressure.

Bereich: sunsationall.com

Registriert: 2012 (13 Jahre)

Einleitung: Nitrogen Tire Inflation service offered at SUNSATIONall for $20.00. The service uses a state-of-the-art Branick® nitrogen inflation system that purges tires of 95-99% of oxygen through a 3 purge cycle and inflates all 4 tires simultaneously in about 5 minutes. Benefits include prevention of oxidation, moisture, and corrosion, leading to increased tire life and safety. Nitrogen-filled tires retain …

In conclusion, the strategic sourcing of nitrogen inflation for tire management presents compelling advantages for international B2B buyers. While nitrogen offers marginal improvements in pressure retention and can mitigate oxidation, the key takeaway is the importance of regular tire maintenance regardless of inflation method. Companies operating in heavy-duty sectors, such as transportation and logistics, may find greater value in nitrogen’s benefits, potentially leading to improved safety and reduced operational costs.

For businesses in Africa, South America, the Middle East, and Europe, investing in nitrogen inflation systems can enhance the longevity of tires, thus optimizing fleet performance. However, it is essential to educate teams on the importance of routine pressure checks to maximize these benefits.

As the industry evolves, the demand for cost-effective and efficient tire management solutions will only increase. We encourage B2B buyers to evaluate their sourcing strategies and consider the integration of nitrogen systems as a part of a comprehensive tire management approach. By embracing these advancements, businesses can position themselves for success in a competitive landscape.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to tire nitrogen inflation

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.