In today’s rapidly evolving industrial landscape, sourcing efficient and reliable air compressor wireless solutions poses a significant challenge for B2B buyers. As companies expand their operations across diverse geographies—from the bustling markets of Africa and South America to the established sectors in the Middle East and Europe—finding the right air compressor wireless products that meet specific operational needs becomes paramount. This guide serves as a comprehensive resource, exploring various types of wireless air compressors, their applications, and critical considerations for supplier vetting.

International buyers can expect to navigate through detailed sections that cover the latest advancements in technology, performance metrics, and cost-effectiveness of air compressor wireless systems. We delve into the unique requirements of different industries, ensuring that you understand which models best suit your operational demands. Moreover, we provide actionable insights on how to evaluate potential suppliers, ensuring that quality and reliability are never compromised.

This guide empowers B2B buyers to make informed purchasing decisions, tailored to their regional and sector-specific needs. By understanding the intricacies of the global market for air compressor wireless systems, you will be better equipped to enhance productivity, reduce operational costs, and ultimately drive your business forward in a competitive marketplace.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Schnurlose Reifenfüller | Compact, battery-operated, portable | Automotive, recreational, emergency | Vorteile: Lightweight, easy to use. Nachteile: Limited runtime on battery, less power than larger models. |

| Portable Air Compressors | Versatile, can inflate tires and power tools | Bauwesen, Automobilindustrie, DIY | Vorteile: Multi-functional, robust performance. Nachteile: May require frequent recharging, heavier than cordless models. |

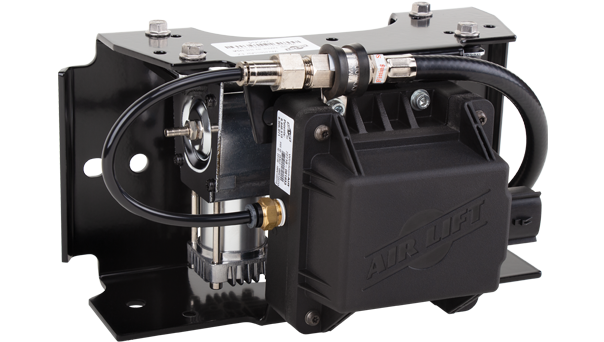

| On-Board Air Systems | Integrated systems for vehicles, wireless control | Fleet management, automotive upgrades | Vorteile: Seamless integration, remote operation. Nachteile: Installation complexity, higher initial cost. |

| Inflation Pumps | Designed for specific tasks (e.g., sports equipment) | Sports, outdoor activities | Vorteile: Highly specialized, quick inflation. Nachteile: Limited to specific applications, often less durable. |

| Heavy-Duty Wireless Compressors | High-capacity, suitable for demanding tasks | Industrial, construction, large-scale operations | Vorteile: High efficiency, durable construction. Nachteile: Expensive, less portable due to size. |

Cordless tire inflators are compact, battery-operated devices designed for easy tire inflation. Their portability makes them ideal for automotive businesses that require quick and efficient service. When considering a purchase, B2B buyers should evaluate the battery life and inflation speed, as these factors can significantly impact operational efficiency. While they offer convenience, buyers must also consider the potential limitations in power compared to larger compressors.

Illustrative image related to air compressor wireless

Portable air compressors are versatile tools that can inflate tires, power pneumatic tools, and assist in various DIY projects. They are particularly beneficial in construction and automotive sectors, where mobility and performance are critical. Buyers should assess the compressor’s power output and battery life, as these will determine its effectiveness in demanding environments. While they provide robust performance, their weight and need for recharging can be a drawback for some users.

On-board air systems offer integrated solutions for vehicles, allowing for wireless control of air pressure adjustments. These systems are particularly advantageous for fleet management and automotive upgrades, providing seamless integration with existing vehicle systems. B2B buyers should consider the complexity of installation and the initial investment required. Although they offer convenience and efficiency, the higher costs and installation challenges can be significant factors in the purchasing decision.

Specialized inflation pumps are designed for specific tasks, such as inflating sports equipment or outdoor gear. Their focused functionality allows for quick and efficient inflation, making them popular in sports and recreational industries. B2B buyers should evaluate the durability and speed of these pumps, as they can vary significantly. While they excel in their niche applications, their limited scope may not justify the investment for all businesses.

Illustrative image related to air compressor wireless

Heavy-duty wireless compressors are designed for high-capacity applications, making them suitable for industrial and construction environments. They offer exceptional efficiency and durability, essential for large-scale operations. Buyers should consider the cost and portability of these compressors, as they can be more expensive and less mobile than other options. However, their ability to handle demanding tasks often outweighs these drawbacks for businesses focused on performance and reliability.

| Industrie/Sektor | Specific Application of air compressor wireless | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | Reifendruck und Wartung | Enhances operational efficiency and reduces downtime | Durability, battery life, and compatibility with various tire sizes |

| Bauwesen | Powering pneumatic tools | Increases productivity on job sites and reduces labor costs | Portability, pressure capacity, and noise levels |

| Landwirtschaft | Crop spraying and irrigation systems | Improves efficiency in farm operations and reduces water waste | Battery capacity, pressure output, and weather resistance |

| Herstellung | Operating air-powered machinery | Streamlines production processes and minimizes energy costs | Reliability, maintenance needs, and support services |

| Recreational Vehicles | Inflating and maintaining RV tires and air mattresses | Enhances user experience and ensures safety on the road | Portability, ease of use, and charging options |

In the automotive sector, wireless air compressors are essential for tire inflation and maintenance. They enable quick and efficient inflation of tires, which is crucial for fleet management and service stations. The ability to operate without cords allows technicians to move freely around vehicles, reducing downtime and improving service speed. Buyers in this sector should consider battery life, durability, and compatibility with various tire sizes to meet diverse customer needs, especially in regions like Africa and South America where road conditions can be challenging.

In construction, wireless air compressors are used to power pneumatic tools such as nail guns, drills, and impact wrenches. Their portability allows workers to easily transport them across job sites, significantly increasing productivity. Additionally, they help reduce labor costs by minimizing the time spent setting up equipment. When sourcing for construction applications, businesses should prioritize factors such as pressure capacity, noise levels, and overall durability, particularly in harsh environments found in the Middle East and Europe.

Illustrative image related to air compressor wireless

Agricultural operations benefit from wireless air compressors for tasks like crop spraying and irrigation system maintenance. These compressors allow farmers to operate spraying equipment efficiently, ensuring even distribution of fertilizers and pesticides while conserving water. The cordless design enhances mobility across large fields, making it easier to manage diverse tasks. Buyers in this sector should focus on battery capacity, pressure output, and weather resistance when sourcing equipment, as agricultural activities are often conducted in varying climates.

Within manufacturing, wireless air compressors are crucial for operating air-powered machinery, including assembly line tools and packaging equipment. By providing a reliable air supply, they help streamline production processes and minimize energy costs. Their wireless nature allows for flexible configurations on the factory floor, adapting to changing production needs. When sourcing for manufacturing applications, businesses should consider reliability, maintenance requirements, and the availability of support services to ensure uninterrupted operations.

In the recreational vehicle (RV) sector, wireless air compressors are vital for inflating tires and air mattresses. They enhance user experience by providing a convenient solution for maintaining optimal tire pressure, which is essential for safety on the road. Additionally, their portability makes them ideal for outdoor enthusiasts who require quick inflation solutions during camping or road trips. Buyers should prioritize factors like ease of use, portability, and charging options to meet the demands of this active consumer base.

Illustrative image related to air compressor wireless

Das Problem: Many B2B buyers in sectors like automotive repair or manufacturing face challenges in maintaining consistent air pressure when using wireless air compressors. This inconsistency can lead to inefficient operation of pneumatic tools, resulting in decreased productivity and potential safety hazards. For example, a tire shop might find that the varying air pressure affects the accuracy of tire inflation, leading to customer dissatisfaction and increased warranty claims.

Die Lösung: To ensure consistent air pressure, B2B buyers should select wireless air compressors with adjustable pressure settings and built-in pressure gauges. When sourcing these compressors, look for models that offer digital displays for real-time pressure monitoring. Additionally, consider investing in compressors equipped with automatic shut-off features that prevent over-inflation. Regular maintenance checks, including calibration of pressure gauges, can further enhance the reliability of air pressure outputs. By selecting high-quality, well-reviewed products, businesses can mitigate issues related to inconsistent air pressure.

Das Problem: A significant pain point for businesses using wireless air compressors is battery life, especially in high-demand environments like construction sites or remote locations. When batteries run out during critical tasks, it leads to downtime, which can be costly. A contractor in the Middle East, for example, may find that the compressor’s battery lasts only a few hours, disrupting workflow and delaying project timelines.

Die Lösung: To address battery life concerns, B2B buyers should prioritize models known for extended battery life or those that allow for quick battery swaps. It’s advisable to conduct a thorough assessment of the compressor’s battery specifications and user reviews before purchasing. Additionally, consider investing in extra batteries to ensure that there is always a backup available. For operations that require prolonged use, look for compressors that can be used while plugged into a power source, providing a continuous supply of air without the need for battery reliance.

Das Problem: Many businesses struggle with integrating new wireless air compressors into their existing systems. For example, a manufacturing facility in South America may have pneumatic tools that require specific air compressor specifications. If the new wireless compressor cannot match the necessary output or is incompatible with the existing tools, it can lead to delays and wasted investment.

Die Lösung: To avoid integration issues, B2B buyers should conduct a compatibility assessment before acquiring new equipment. This involves checking the specifications of existing pneumatic tools and ensuring that the new wireless compressor meets or exceeds these requirements. Collaborating with suppliers who offer comprehensive technical support can also aid in this process. Additionally, consider compressors that come with customizable settings or modular attachments that can adapt to various applications. Investing in training for staff on how to effectively integrate and utilize the new equipment can further streamline the transition, ensuring that operations remain uninterrupted.

In summary, by understanding and addressing these common pain points, B2B buyers can make more informed decisions when sourcing wireless air compressors, ultimately enhancing productivity and operational efficiency.

When selecting materials for wireless air compressors, several options stand out due to their unique properties and performance characteristics. This analysis will focus on aluminum, steel, plastic, and composite materials, providing insights into their suitability for various applications in the B2B sector.

Aluminum is a popular choice for many components in wireless air compressors due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand pressures of around 200 psi. The primary advantage of aluminum is its durability combined with low weight, making it ideal for portable applications.

Profis: Aluminum is relatively easy to manufacture, which can reduce production costs. Its resistance to corrosion is especially beneficial in humid or coastal environments, common in regions like Brazil and parts of the Middle East.

Nachteile: While aluminum is durable, it can be more expensive than other materials like steel. It also has lower tensile strength, which may limit its use in high-stress applications.

Auswirkungen auf die Anwendung: Aluminum is compatible with various media, including air and non-corrosive gases. However, it may not be suitable for applications involving high-temperature fluids.

Steel, particularly stainless steel, is another common material used in the construction of wireless air compressors. It offers high tensile strength and can handle pressures exceeding 300 psi, making it suitable for heavy-duty applications.

Profis: Steel is highly durable and resistant to wear, making it ideal for long-term use. Its cost-effectiveness is also a significant advantage, especially for large-scale manufacturing.

Illustrative image related to air compressor wireless

Nachteile: The primary drawback of steel is its susceptibility to corrosion, which can be mitigated with coatings but may increase manufacturing complexity. Additionally, steel components are heavier, which can affect portability.

Auswirkungen auf die Anwendung: Steel is well-suited for applications requiring high pressure and durability, such as industrial settings. However, it may not be the best choice in environments with high humidity unless adequately protected.

Plastics, particularly engineering plastics like polycarbonate or nylon, are increasingly used in wireless air compressors. They offer good chemical resistance and can operate effectively at temperatures up to 80°C.

Profis: Plastics are lightweight and can be molded into complex shapes, allowing for innovative designs. They are generally less expensive than metals, making them attractive for cost-sensitive applications.

Nachteile: While plastics are resistant to corrosion, they may not withstand high pressures as effectively as metals. Their mechanical properties can also degrade over time with exposure to UV light.

Auswirkungen auf die Anwendung: Plastics are suitable for non-structural components, such as housings or covers, but may not be ideal for critical pressure-bearing parts.

Composite materials, often a combination of fibers and resins, are gaining traction in the air compressor market due to their high strength-to-weight ratio and excellent corrosion resistance. They can handle moderate pressures and temperatures, making them versatile.

Profis: Composites are lightweight and can be tailored for specific applications, providing flexibility in design. They also offer significant resistance to environmental factors, which is beneficial in diverse climates.

Nachteile: The primary limitation of composites is their cost, as they can be more expensive than traditional materials. Additionally, manufacturing processes can be complex, requiring specialized equipment.

Auswirkungen auf die Anwendung: Composites can be used in various applications, including automotive and aerospace sectors, where weight savings are critical. However, they may not be suitable for high-pressure applications without careful engineering.

| Material | Typical Use Case for air compressor wireless | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Portable air compressors | Leicht und korrosionsbeständig | Higher cost than steel | Mittel |

| Stahl | Industrial air compressors | High durability and cost-effective | Susceptible to corrosion | Niedrig |

| Kunststoff | Non-structural components | Lightweight and low cost | Limited pressure resistance | Niedrig |

| Komposit | Leistungsstarke Anwendungen | Hohes Verhältnis von Festigkeit zu Gewicht | Höhere Kosten und komplexe Herstellung | Hoch |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on performance characteristics and regional considerations.

Illustrative image related to air compressor wireless

The manufacturing of wireless air compressors involves several critical stages, each designed to ensure product quality and performance. Understanding these stages can help B2B buyers identify reliable suppliers and assess product quality before making purchasing decisions.

The first stage in the manufacturing process involves selecting and preparing high-quality materials. Common materials used in air compressors include aluminum, steel, and various polymers. These materials must meet specific mechanical and thermal properties to ensure durability and performance.

Suppliers often conduct material inspections to verify that all components meet industry standards. Materials are subjected to tests like tensile strength evaluations and hardness tests to ensure they can withstand the operational demands of wireless air compressors.

Illustrative image related to air compressor wireless

Once materials are prepared, the next stage is forming. This involves shaping the raw materials into the desired components of the air compressor. Techniques such as die casting, machining, and injection molding are commonly used.

For instance, die casting is often utilized for aluminum parts due to its ability to produce complex shapes with high precision. Machining may be applied to create precise fittings and surfaces that ensure optimal performance. The choice of technique can significantly impact the quality and longevity of the final product.

The assembly stage is where individual components come together to form the complete wireless air compressor. This process usually involves both manual and automated assembly techniques.

Automated assembly lines are increasingly popular as they enhance efficiency and reduce human error. During this stage, components such as the motor, battery, and air tank are integrated. Proper alignment and secure fastening are essential to ensure that the compressor operates effectively without leaks or mechanical failures.

Illustrative image related to air compressor wireless

Finishing touches are crucial for both aesthetics and functionality. This stage may include surface treatments, painting, and the application of protective coatings. These processes help prevent corrosion and enhance the overall appearance of the compressor.

Quality control checks are often conducted during the finishing stage to ensure that any surface imperfections are corrected and that the finished product meets the required specifications.

Quality assurance (QA) is vital in the manufacturing of wireless air compressors, particularly for B2B buyers who need assurance of product reliability. Understanding the standards and practices in place can help in evaluating potential suppliers.

Many manufacturers adhere to international standards to ensure product quality. ISO 9001 is one of the most recognized quality management systems that outlines requirements for consistent quality in products and services. Compliance with ISO standards indicates that a supplier has robust quality management practices in place.

In addition, certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) certifications for specific applications can enhance buyer confidence. These certifications ensure that the products meet safety and environmental requirements.

Quality control checkpoints are integral to the manufacturing process. They typically include:

Eingehende Qualitätskontrolle (IQC): This is the first checkpoint where raw materials are inspected upon arrival. Suppliers should verify that all materials meet specified standards before they are used in production.

Prozessbegleitende Qualitätskontrolle (IPQC): During assembly and manufacturing, IPQC involves regular inspections to ensure that processes are followed correctly and that any defects are identified early.

Endgültige Qualitätskontrolle (FQC): At the end of the manufacturing process, FQC checks the finished product against specifications. This includes functional testing to ensure the compressor operates as intended.

Testing methods play a crucial role in quality assurance for wireless air compressors. Common tests include:

Funktionsprüfung: This assesses the operational capability of the compressor, ensuring it meets performance specifications such as pressure output and noise levels.

Dauerhaftigkeitsprüfung: This involves subjecting the compressor to various stress tests to evaluate its longevity and resistance to wear.

Sicherheitsprüfung: Manufacturers must ensure that their products meet safety standards, which may include electrical safety tests and pressure vessel integrity assessments.

B2B buyers should adopt a proactive approach to verify the quality control practices of their suppliers. Here are effective strategies:

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should consider conducting on-site audits to evaluate the supplier’s facilities, machinery, and adherence to quality standards.

Requesting quality assurance reports and certifications from suppliers can help assess their commitment to quality. These documents often detail the results of various tests and inspections conducted throughout the manufacturing process.

Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services can conduct inspections at various stages of production and provide detailed reports, helping buyers make informed decisions.

International buyers, particularly from Africa, South America, the Middle East, and Europe, must consider specific nuances when dealing with quality assurance in manufacturing.

Kulturelle Unterschiede: Understanding cultural differences in business practices can aid in building strong relationships with suppliers. Communication styles and negotiation practices may vary significantly across regions.

Einhaltung von Vorschriften: Different countries have varying regulations regarding product safety and quality. International buyers should familiarize themselves with local regulations to ensure that imported products comply with regional standards.

Logistics and Supply Chain Considerations: Supply chain logistics can affect product delivery and quality. Buyers should assess the reliability of suppliers’ logistics capabilities, especially for international shipping.

By focusing on these aspects, B2B buyers can enhance their procurement processes and ensure they partner with manufacturers committed to delivering high-quality wireless air compressors.

This practical sourcing guide is designed to assist B2B buyers in procuring wireless air compressors effectively. With the rise in demand for portable and efficient air compression solutions across various industries, understanding the key aspects of sourcing these products is essential for making informed purchasing decisions. This checklist outlines the critical steps to ensure you select the right wireless air compressor that meets your operational requirements.

Clearly outline the technical requirements for your wireless air compressor. Consider factors such as power output, pressure capacity, and intended applications (e.g., automotive, construction, or recreational use). Establishing these specifications helps narrow down options and ensures that the product will meet your specific operational needs.

Establish a budget before beginning your search. Understanding your financial limits will help filter out options that are either too expensive or do not offer sufficient value for your investment. This is particularly important in international markets where pricing may vary significantly.

Illustrative image related to air compressor wireless

Conduct thorough research on potential suppliers of wireless air compressors. Look for manufacturers and distributors with a strong reputation in the industry, especially those that cater to your region.

Ensure that the suppliers you consider have the necessary certifications and quality standards. This is crucial for compliance with local regulations and to guarantee product quality.

Before making a large purchase, request samples or arrange for demonstrations of the wireless air compressors. This allows you to assess the product’s performance and suitability firsthand.

Once you have selected a supplier, negotiate the terms and conditions of the purchase. This includes pricing, delivery schedules, payment terms, and return policies.

After thorough evaluation and negotiation, proceed to finalize your purchase. Ensure that all agreements are documented and that you have a clear understanding of delivery timelines and post-purchase support.

Illustrative image related to air compressor wireless

By following this checklist, B2B buyers can effectively navigate the sourcing process for wireless air compressors, ensuring they make informed decisions that align with their operational needs and budget constraints.

When sourcing wireless air compressors, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materialien: The choice of materials significantly impacts the overall cost. High-quality components such as durable casings and efficient motors can elevate costs but improve longevity and performance.

Arbeit: Labor costs encompass the wages paid to workers involved in manufacturing and assembly. In regions with higher labor costs, such as Europe, these expenses can be substantial, affecting pricing.

Fertigungsgemeinkosten: This includes expenses related to utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these overheads.

Werkzeugbau: The initial investment in tooling for production can be significant, especially for customized models. Buyers should consider whether they require standard or bespoke designs, as this will influence tooling costs.

Qualitätskontrolle (QC): Ensuring product reliability through rigorous QC processes adds to the cost but is essential for maintaining quality standards and avoiding returns or warranty claims.

Logistik: Transportation costs vary based on distance, mode of transport, and the nature of the products being shipped. International shipments may incur additional fees, including customs and duties.

Marge: Suppliers will include a profit margin in their pricing, which can vary widely based on market conditions and competition.

Pricing for wireless air compressors is influenced by several factors:

Volumen/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Larger orders typically secure lower per-unit costs due to economies of scale.

Spezifikationen und Anpassungen: Customized features or specifications can increase costs. Buyers must clearly define their requirements to avoid unexpected price hikes.

Materialien und Qualitätszertifikate: High-grade materials and certifications (e.g., ISO, CE) validate product quality but can raise prices. Buyers should assess the importance of these factors relative to their needs.

Lieferanten-Faktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance.

Incoterms: The chosen Incoterms (International Commercial Terms) determine the responsibilities of buyers and sellers in shipping. Understanding these terms can help buyers manage logistics costs effectively.

B2B buyers can employ several strategies to enhance cost-efficiency in their sourcing efforts:

Verhandlung: Engage in negotiations with suppliers to secure better pricing. Highlighting long-term partnership potential can be advantageous.

Gesamtbetriebskosten (TCO): Evaluate the TCO, which includes purchase price, maintenance, operation, and disposal costs. A higher upfront cost may be justified by lower operational costs over time.

Nuancen in der Preisgestaltung für internationale Käufer: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, import duties, and local market conditions, which can affect overall pricing.

Supplier Diversity: Exploring multiple suppliers can lead to competitive pricing and better terms. However, it’s essential to vet suppliers thoroughly to ensure quality and reliability.

While the initial costs associated with sourcing wireless air compressors can be significant, understanding the cost structure and pricing influencers can aid buyers in making informed decisions. By considering the aforementioned factors and employing strategic sourcing tactics, international B2B buyers can optimize their purchasing process and achieve favorable outcomes in their supply chain management.

In the realm of air compression, various technologies and methods can meet the diverse needs of businesses. While wireless air compressors offer significant advantages, exploring alternative solutions can help B2B buyers make informed decisions based on performance, cost, and application. This analysis compares wireless air compressors with two viable alternatives: traditional corded air compressors and portable inflators, providing insights that cater to international buyers from regions like Africa, South America, the Middle East, and Europe.

| Vergleich Aspekt | Air Compressor Wireless | Corded Air Compressor | Tragbarer Reifenfüller |

|---|---|---|---|

| Leistung | High (variable PSI) | Very High (consistent PSI) | Moderate (limited PSI) |

| Kosten | Moderate to High | Low to Moderate | Niedrig |

| Leichte Implementierung | Easy (no cords) | Moderate (requires outlet) | Very Easy (battery-operated) |

| Wartung | Niedrig | Moderate | Very Low |

| Bester Anwendungsfall | Versatile applications | Heavy-duty tasks | Quick inflation needs |

Corded Air Compressor

Corded air compressors are traditionally used in both industrial and commercial settings due to their high performance and consistent pressure output. They are best suited for heavy-duty tasks such as powering pneumatic tools or inflating large tires. However, they require a power outlet, limiting mobility. While initial costs may be lower, ongoing maintenance is needed to ensure optimal performance, including checking for wear on hoses and electrical components.

Tragbarer Reifenfüller

Portable tire inflators are compact, battery-operated devices that offer convenience for quick inflation tasks. They are ideal for emergency situations or light-duty applications, such as inflating car tires or sports equipment. While their cost is generally low, performance may be limited in terms of PSI output compared to larger compressors. Additionally, they require regular charging or battery replacements, which can be a consideration for frequent use. Their simplicity and ease of use make them appealing for personal or small business applications.

Selecting the appropriate air compression solution hinges on understanding specific operational needs, budget constraints, and application scenarios. For businesses that require high performance and consistent power, a corded air compressor may be the best option despite its limitations in mobility. Conversely, for those seeking versatility and ease of use in various environments, a wireless air compressor stands out. Portable tire inflators serve as a practical solution for low-pressure needs and emergency situations but may not suffice for more demanding tasks. By evaluating these factors, B2B buyers can make a strategic choice that aligns with their operational goals and budget considerations.

Illustrative image related to air compressor wireless

When evaluating wireless air compressors, several technical properties are vital for B2B buyers to consider. These specifications not only impact performance but also influence the overall reliability and suitability for specific applications.

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can deliver. For instance, a unit with a pressure rating of 150 PSI is ideal for inflating tires or powering pneumatic tools. Understanding the required PSI for specific applications ensures the selected compressor meets operational needs without risking equipment failure or inefficiency.

Air flow rate, expressed in cubic feet per minute (CFM), measures the volume of air the compressor can deliver. A higher CFM is essential for tasks that require continuous air supply, such as powering spray guns or multiple pneumatic tools simultaneously. Buyers should assess their operational requirements to choose a compressor with an adequate CFM rating for optimal performance.

For wireless models, battery life is crucial. It dictates how long the compressor can operate before needing a recharge. Additionally, a shorter recharge time can enhance productivity, especially in environments where downtime is costly. Buyers should evaluate the battery specifications to ensure they align with their usage patterns and operational demands.

The weight of the compressor affects its portability, which is particularly important for mobile applications or when transporting equipment to job sites. Lightweight models are easier to carry and maneuver, making them more versatile for various tasks. Buyers should consider the balance between performance specifications and portability to find a suitable option for their needs.

Durability is often linked to the materials used in manufacturing the compressor. High-quality materials, such as reinforced plastics or aluminum, enhance the unit’s lifespan and resistance to environmental factors. Buyers should inquire about the material grade to ensure the compressor can withstand the demands of their specific working conditions.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to wireless air compressors:

Illustrative image related to air compressor wireless

OEM refers to companies that produce components or equipment that may be marketed by another manufacturer. In the context of air compressors, an OEM might supply components used in various brands. Recognizing OEM relationships can help buyers identify quality and compatibility when sourcing parts or equipment.

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers, as it can impact inventory management and cash flow. Negotiating favorable MOQs can lead to better pricing and more efficient procurement processes.

An RFQ is a document sent to suppliers requesting pricing and other relevant details for specific products or services. For B2B buyers, issuing an RFQ allows for comparison of quotes, fostering competitive pricing and informed purchasing decisions.

Illustrative image related to air compressor wireless

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions, helping buyers navigate logistics and minimize risks.

Warranties provide assurance regarding the quality and durability of the product, outlining the manufacturer’s responsibilities in case of defects. Service agreements may cover routine maintenance and repairs, which are crucial for maximizing the longevity and performance of the compressor. Understanding these agreements can influence purchasing decisions and total cost of ownership.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing wireless air compressors, ensuring they choose products that meet their operational needs while optimizing cost and efficiency.

The global air compressor wireless market is witnessing significant growth driven by technological advancements and increased demand across various industries, including automotive, construction, and manufacturing. Key trends influencing this sector include the rise of portable and compact units, which cater to the growing need for mobility and convenience in operations. Additionally, the integration of smart technology, such as IoT capabilities, is enhancing operational efficiency and enabling real-time monitoring of compressor performance.

Emerging markets in Africa, South America, the Middle East, and Europe are pivotal to this growth trajectory. Countries like Saudi Arabia and Brazil are investing heavily in infrastructure and industrial projects, thus increasing the demand for efficient and reliable air compression solutions. International B2B buyers are focusing on sourcing products that not only meet performance specifications but also align with their operational needs regarding scalability and adaptability.

Illustrative image related to air compressor wireless

Moreover, the shift towards battery-operated and rechargeable air compressors is a response to increasing environmental concerns and the demand for energy-efficient solutions. This trend is particularly relevant for B2B buyers looking to enhance their sustainability credentials while maintaining high operational standards.

Sustainability has become a cornerstone of B2B procurement strategies, and the air compressor wireless sector is no exception. The environmental impact of manufacturing and operating air compressors is significant, prompting businesses to prioritize ethical sourcing and sustainability in their supply chains. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to reducing carbon footprints through eco-friendly practices and materials.

The adoption of ‘green’ certifications, such as Energy Star or ISO 14001, is becoming essential in supplier evaluations. These certifications not only assure buyers of a product’s environmental compliance but also enhance brand reputation and customer loyalty. Furthermore, the use of recyclable and sustainable materials in the production of air compressors is gaining traction, allowing companies to minimize waste and promote circular economy principles.

In regions like Africa and South America, where environmental regulations are evolving, aligning with sustainable practices can provide a competitive edge. Companies that prioritize ethical sourcing can also mitigate risks associated with supply chain disruptions and foster long-term partnerships with stakeholders who share similar values.

The air compressor industry has evolved significantly over the past few decades, transitioning from traditional, bulky models to sleek, efficient, and wireless solutions. Initially, air compressors were primarily pneumatic systems reliant on power outlets, limiting their usability in remote or challenging environments. The introduction of portable and cordless models has revolutionized the market, particularly benefiting industries requiring mobility, such as automotive repair and outdoor activities.

Technological advancements have further propelled this evolution, with the incorporation of digital controls and battery technology allowing for enhanced performance and ease of use. Today’s air compressors are designed to be lightweight, compact, and user-friendly, catering to both professional and consumer markets. As global demand for versatile and sustainable solutions continues to rise, the air compressor wireless sector is poised for further innovation and growth, making it a critical focus area for international B2B buyers.

1. How do I solve issues with wireless air compressor connectivity?

To troubleshoot connectivity problems with your wireless air compressor, first ensure that the device is fully charged and within the operating range of your wireless network. Check for any interference from other devices or obstacles that might weaken the signal. If issues persist, consult the user manual for specific resetting instructions or firmware updates. Additionally, contacting the manufacturer’s customer support can provide tailored solutions based on your model and issue.

2. What is the best wireless air compressor for industrial applications?

When selecting a wireless air compressor for industrial use, consider models that offer high performance, durability, and a substantial battery life. Look for compressors with features such as oil-free operation, high PSI ratings, and the ability to power pneumatic tools. Brands like VIAIR and Fanttik offer robust models designed for demanding applications. Always evaluate your specific requirements, such as size, weight, and noise levels, to find the best fit for your operational needs.

3. How can I vet suppliers of wireless air compressors for international trade?

To effectively vet suppliers, start by checking their certifications and compliance with international standards, such as ISO or CE. Request references from previous clients and evaluate their track record in delivering quality products on time. Utilize platforms like Alibaba or Global Sources for additional insights and reviews. Conduct video calls to discuss your requirements and assess their responsiveness and professionalism. This thorough vetting process helps minimize risks associated with international transactions.

4. What are common customization options for wireless air compressors?

Many manufacturers offer customization options, including specific PSI outputs, tank sizes, and battery capacities tailored to your operational needs. Some may also provide branding opportunities, allowing you to add your logo or color scheme. Discuss your requirements with the supplier to explore available options. Ensure that any customizations do not compromise the compressor’s performance or warranty conditions.

5. What is the minimum order quantity (MOQ) for wireless air compressors?

MOQs can vary significantly depending on the supplier and the specific model of the wireless air compressor. Typically, MOQs range from 10 to 100 units for bulk orders. Some suppliers may offer lower MOQs for new customers or for specific promotional products. Always confirm the MOQ before placing an order, as this can affect your overall budget and inventory management.

6. What payment terms should I expect when sourcing wireless air compressors internationally?

Payment terms for international transactions can vary widely. Common options include upfront payment, a deposit followed by the balance upon delivery, or letters of credit. It’s crucial to clarify terms before committing to an order to ensure both parties are aligned. Consider using secure payment methods that offer buyer protection, especially for larger orders, to mitigate risks associated with international trade.

7. How do I ensure quality assurance for wireless air compressors?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Ask for samples before placing a bulk order to evaluate performance and reliability. Additionally, inquire about the warranty and after-sales support offered. Implementing a third-party inspection service can also help verify that products meet your standards prior to shipment, especially when dealing with overseas suppliers.

8. What logistics considerations should I keep in mind when importing wireless air compressors?

When importing wireless air compressors, consider shipping methods, customs duties, and import regulations specific to your country. Evaluate the total landed cost, which includes product price, shipping, and taxes, to avoid unexpected expenses. Collaborate with a reliable freight forwarder experienced in handling similar products, as they can navigate complex logistics and ensure timely delivery. Always stay updated on local regulations to ensure compliance and smooth customs clearance.

Bereich: airliftcompany.com

Registriert: 1996 (29 Jahre)

Einleitung: On Board Air Compressor Systems Wireless includes various models such as WirelessAir, WirelessOne, LoadController, and Compact LoadController. Key products listed are: WirelessAir Tank plus EZ Mount (PN 74100EZ), WirelessOne Tank plus EZ Mount (PN 25981EZ), WirelessAir App Only, No Controller + EZ Mount (PN 73000EZ), WirelessAir with EZ Mount (PN 74000EZ), WirelessAir (PN 74000), WirelessONE with …

Bereich: fanttik.com

Registered: 2020 (5 years)

Einleitung: 2X Faster Electric Tire Inflators, Various Models: X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Prices range from $48.99 to $199.97 with discounts up to 50%. Features include upgraded versions, portable designs, and high ratings (4.8). Black Friday Sale from 11.20-12.7 with significant savings.

In today’s competitive marketplace, strategic sourcing of wireless air compressors presents significant advantages for international B2B buyers. By prioritizing quality, efficiency, and innovation, companies can enhance operational productivity while reducing costs. Wireless air compressors, known for their portability and convenience, cater to various applications ranging from automotive to industrial uses. This flexibility is especially beneficial in diverse markets across Africa, South America, the Middle East, and Europe, where mobility and adaptability are paramount.

Investing in advanced wireless technology ensures that businesses can stay ahead of the curve. Features such as fast inflation times, compact designs, and user-friendly interfaces not only improve customer satisfaction but also drive loyalty. As global demand for reliable and efficient equipment continues to rise, sourcing partners that prioritize these innovations will be crucial.

Looking forward, international buyers should leverage strategic partnerships with manufacturers that align with their operational needs and regional requirements. Embrace the future of air compression technology and explore opportunities that can elevate your business to new heights. Don’t miss out on the chance to enhance your supply chain and operational efficiency—start your sourcing journey today.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.