In the competitive landscape of the cycling industry, sourcing reliable bike tire CO2 inflators presents a significant challenge for international B2B buyers. As cyclists increasingly demand quick and efficient solutions for tire inflation, understanding the nuances of various inflator types becomes crucial. This guide offers a comprehensive overview, delving into the different categories of CO2 inflators, their specific applications, and essential factors to consider when selecting suppliers.

From compact inflators ideal for road bikes to robust options suited for mountain biking, the diversity in product offerings can be overwhelming. Furthermore, we will discuss key aspects such as supplier vetting processes, cost considerations, and the growing importance of sustainability in product selection. This guide aims to empower B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including markets like Nigeria and Germany—by equipping them with the knowledge needed to make informed purchasing decisions.

By navigating the complexities of the global market for bike tire CO2 inflators, businesses can enhance their product offerings, meet customer demands, and ultimately drive sales. Understanding the intricacies of this essential cycling accessory not only fosters better procurement strategies but also positions companies to capitalize on emerging trends within the cycling community.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Stand-Alone CO2 Chucks | Simple design, easy to use, compatible with Presta and Schrader valves | Retail bike shops, cycling events | Vorteile: Lightweight, cost-effective. Nachteile: Limited features, may require practice for effective use. |

| Integrated CO2 Pumps | Combines hand pump and CO2 inflator, portable, dual functionality | Wholesale distributors, bike rental services | Vorteile: Versatile, reliable backup option. Nachteile: Bulkier than stand-alone chucks, potentially higher cost. |

| Cartridge Systems | Uses disposable CO2 cartridges, varying sizes (16g, 20g, 25g) | E-commerce platforms, bike repair shops | Vorteile: Quick inflation, easy to store. Nachteile: Ongoing costs for cartridges, environmental considerations. |

| Electric CO2 Inflators | Battery-operated, automated inflation, suitable for high-volume tires | Bike manufacturing, high-end retail | Vorteile: Effortless operation, consistent pressure. Nachteile: Higher initial investment, battery dependency. |

| Multi-Tool CO2 Inflators | Combines multiple bike tools with CO2 inflator functionality | Repair shops, cycling tour operators | Vorteile: Space-saving, multifunctional. Nachteile: Can be more expensive, may sacrifice inflator performance. |

Stand-alone CO2 chucks are designed for simplicity and speed, making them a favorite among cyclists needing quick inflation. They typically feature a straightforward design that connects directly to the tire valve, allowing for rapid air release from CO2 cartridges. These inflators are ideal for retail bike shops and cycling events where space and weight are concerns. When considering procurement, B2B buyers should focus on the ease of use, compatibility with various valve types, and the cost-effectiveness of the units.

Integrated CO2 pumps offer the dual functionality of a hand pump and a CO2 inflator, making them a versatile choice for businesses like bike rental services and wholesale distributors. They are portable and provide a reliable backup in case CO2 cartridges run out. B2B buyers should evaluate the durability, ease of switching between pump and inflator modes, and overall weight, as these factors can impact customer satisfaction and operational efficiency.

Cartridge systems utilize disposable CO2 cartridges of various sizes, such as 16g, 20g, and 25g, to achieve quick tire inflation. These systems are particularly popular in e-commerce platforms and bike repair shops due to their ease of storage and rapid deployment. When purchasing, businesses should consider the ongoing costs associated with cartridges and the environmental impact of disposable products, as these factors can influence customer preferences and brand reputation.

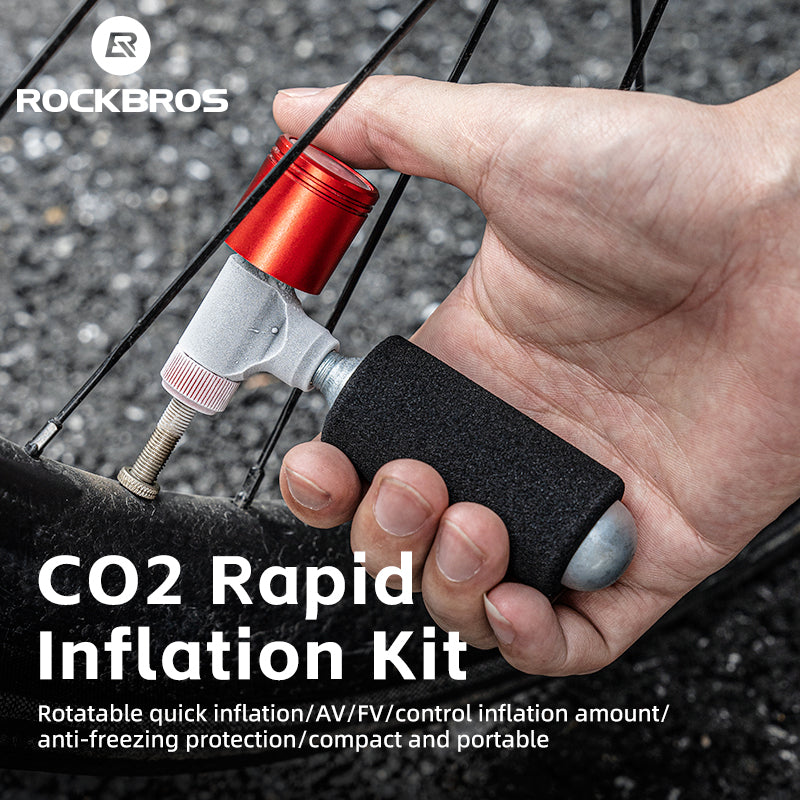

Illustrative image related to bike tire co2 inflator

Electric CO2 inflators represent a modern solution for cyclists, providing automated inflation and consistent pressure without manual effort. They are especially suitable for high-volume tires and are gaining traction in bike manufacturing and high-end retail sectors. B2B buyers need to weigh the initial investment against the convenience and efficiency offered, alongside considerations for battery life and maintenance.

Multi-tool CO2 inflators combine essential bike tools with inflation capabilities, catering to repair shops and cycling tour operators looking to maximize functionality while minimizing space. These tools save room in a cyclist’s kit and provide a comprehensive solution for on-the-go repairs. However, B2B buyers should assess the performance of the inflator component and the overall cost to ensure value for their customers.

| Industrie/Sektor | Specific Application of bike tire co2 inflator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Cycling Retail | Retail stores offering emergency bike repair kits | Enhances customer satisfaction and loyalty by providing quick solutions for flat tires | Ensure compatibility with various valve types and CO2 cartridge availability |

| Bicycle Rental Services | On-site maintenance for rental bikes | Reduces downtime for rental bikes, ensuring high availability for customers | Look for compact and lightweight models for easy transport and storage |

| Event Management | Support for cycling events and races | Facilitates quick tire repairs, minimizing disruptions during events | Consider inflators with fast inflation times and multiple cartridge options |

| Logistik und Lieferdienste | Maintenance for delivery bicycles | Ensures reliable operations and reduces delays caused by flat tires | Source durable inflators that can withstand frequent use and rough handling |

| Outdoor Adventure Companies | Equipment for guided cycling tours | Provides safety and reliability for clients during tours, enhancing overall experience | Choose inflators that are portable and easy to use in various terrain conditions |

In the cycling retail sector, bike tire CO2 inflators are essential tools for emergency repairs. Retailers can offer these inflators as part of a bike repair kit or as standalone products. This not only enhances customer satisfaction by providing immediate solutions to flat tires but also encourages repeat business as cyclists appreciate the convenience. When sourcing inflators, retailers should prioritize compatibility with various valve types and ensure the availability of CO2 cartridges to meet customer needs effectively.

Bicycle rental services utilize bike tire CO2 inflators to maintain their fleet efficiently. With high turnover rates, ensuring that rental bikes are quickly operational after a flat tire is crucial. CO2 inflators allow for rapid inflation, significantly reducing downtime and enhancing customer satisfaction. For rental companies, sourcing compact and lightweight inflators is vital, as they need to be easily transportable and stored without taking up much space.

During cycling events and races, having bike tire CO2 inflators on hand is critical for minimizing disruptions. Event management companies can provide these inflators to participants, allowing for quick tire repairs that keep riders moving. This not only enhances the overall experience but also demonstrates a commitment to participant safety and convenience. When selecting inflators, it’s important to consider models with fast inflation times and options for multiple cartridge sizes to accommodate different needs.

In logistics and delivery services, particularly those using bicycles, maintaining operational efficiency is key. Bike tire CO2 inflators play a vital role in ensuring that delivery personnel can quickly address flat tires, thus minimizing delays. Businesses in this sector should source durable inflators that can withstand frequent use and rough handling, ensuring reliability even in challenging conditions. This proactive approach to maintenance can enhance overall service quality and customer satisfaction.

Outdoor adventure companies that offer guided cycling tours greatly benefit from bike tire CO2 inflators. These inflators provide a reliable means for tour guides to manage tire issues on the go, ensuring the safety and enjoyment of their clients. When sourcing these inflators, companies should prioritize portability and ease of use, as they will be required in diverse terrains and conditions. This not only enhances the adventure experience but also builds trust with clients who rely on the company for safety and support.

Das Problem: B2B buyers often struggle with sourcing high-quality CO2 cartridges for inflators. In many regions, particularly in Africa and South America, the availability of reliable suppliers can be inconsistent. This leads to concerns about the cartridges’ performance, such as whether they will deliver the required pressure effectively and whether they will fit the inflators properly. Poor-quality cartridges can cause leaks or fail to inflate tires, leading to customer dissatisfaction and increased operational costs.

Die Lösung: To mitigate these sourcing challenges, B2B buyers should establish relationships with reputable manufacturers or distributors who specialize in cycling accessories. Conducting thorough market research can help identify suppliers with a proven track record of quality. It’s also advisable to request samples before making bulk purchases to assess compatibility and performance. Additionally, buyers should consider integrating a quality assurance process in their procurement strategy, ensuring that all cartridges meet specific safety and performance standards. Engaging with local cycling communities or industry forums can provide insights into the best suppliers and practices to ensure a consistent supply of quality CO2 cartridges.

Das Problem: Another common issue is that users often misunderstand how to operate CO2 inflators effectively, leading to improper inflation of bike tires. This can be particularly problematic in regions where cycling is less common, and users may not have received proper training or guidance. Users may inadvertently over-inflate or under-inflate tires, affecting riding performance and safety.

Die Lösung: B2B buyers should invest in providing comprehensive training materials and support for their customers. This could include instructional videos, step-by-step guides, and workshops demonstrating the proper use of CO2 inflators. Moreover, it’s essential to ensure that the inflators purchased are user-friendly, featuring clear markings and instructions. Packaging should also include quick tips for inflating tires correctly. Consider providing a dedicated customer service channel for users to reach out with questions. By fostering a better understanding of how to use CO2 inflators, businesses can enhance customer satisfaction and reduce the likelihood of product returns or complaints.

Illustrative image related to bike tire co2 inflator

Das Problem: With increasing awareness of environmental issues, many B2B buyers are concerned about the environmental impact of using CO2 inflators. The production and disposal of CO2 cartridges can contribute to carbon emissions and waste. This is particularly relevant in European markets, where sustainability is a significant factor in purchasing decisions.

Die Lösung: To address these concerns, B2B buyers should consider sourcing CO2 inflators that offer environmentally friendly alternatives. For example, look for manufacturers that provide refillable CO2 systems or those that use biodegradable materials in cartridge production. Additionally, educating customers about responsible disposal practices and the environmental impact of CO2 can enhance brand reputation. Highlighting sustainability efforts in marketing materials can also attract environmentally conscious buyers. Establishing a take-back program for used cartridges can further demonstrate a commitment to sustainability and can improve customer loyalty while addressing their environmental concerns. By prioritizing eco-friendly practices, businesses can align their products with the values of modern consumers, especially in markets sensitive to environmental issues.

When selecting materials for bike tire CO2 inflators, several factors come into play, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of CO2 inflators: aluminum, plastic, stainless steel, and brass.

Aluminum is a popular choice for CO2 inflators due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating of -50°C to 150°C and can withstand pressures up to 200 psi, making it suitable for high-performance applications.

Illustrative image related to bike tire co2 inflator

Profis: Aluminum is durable and resistant to corrosion, which is crucial for products exposed to varying weather conditions. It is also relatively cost-effective and easy to manufacture, allowing for complex designs that enhance functionality.

Nachteile: While aluminum is strong, it can be prone to denting and scratching, which may affect aesthetics and performance over time. Additionally, it may require anodizing or other treatments to enhance its corrosion resistance.

Auswirkungen auf die Anwendung: Aluminum is compatible with various media, including CO2, and does not react adversely, making it an excellent choice for inflators.

Überlegungen für internationale Einkäufer: Buyers from regions like Africa and South America should ensure that aluminum inflators meet local regulations regarding material safety and environmental impact. Compliance with standards like ASTM or DIN can enhance marketability.

Plastic is often used in the housing or components of CO2 inflators due to its lightweight and cost-effective nature. Common plastics include ABS and polycarbonate, which can handle temperatures from -20°C to 80°C and pressures around 100 psi.

Illustrative image related to bike tire co2 inflator

Profis: Plastic is inexpensive and can be molded into intricate shapes, allowing for innovative designs. It is also resistant to corrosion and can be produced in various colors, appealing to consumer preferences.

Nachteile: The main drawback of plastic is its lower durability compared to metals. It can become brittle over time, especially when exposed to UV light or extreme temperatures, potentially leading to failure.

Auswirkungen auf die Anwendung: While plastic is suitable for CO2, it may not withstand high-pressure applications as effectively as metals, limiting its use in high-performance inflators.

Überlegungen für internationale Einkäufer: Buyers should verify that plastic components comply with safety standards and regulations in their respective markets, particularly in Europe, where stricter environmental regulations may apply.

Stainless steel is known for its exceptional strength and corrosion resistance, making it a premium choice for CO2 inflators. It can handle extreme temperatures (-200°C to 800°C) and pressures well above 200 psi.

Profis: Its durability ensures a long lifespan, and it maintains structural integrity even under high stress. Stainless steel is also resistant to rust and corrosion, making it ideal for outdoor use.

Nachteile: The main drawback is its cost; stainless steel is more expensive than aluminum or plastic. Additionally, manufacturing processes can be more complex, leading to higher production costs.

Auswirkungen auf die Anwendung: Stainless steel is highly compatible with CO2 and can withstand the pressures involved in tire inflation without risk of failure.

Überlegungen für internationale Einkäufer: Compliance with international standards like JIS or ASTM is crucial, especially in regions with stringent quality controls like Germany. Buyers should also consider the environmental impact of stainless steel production.

Illustrative image related to bike tire co2 inflator

Brass is often used for valves and fittings in CO2 inflators due to its excellent machinability and resistance to corrosion. It can handle temperatures from -20°C to 150°C and pressures up to 150 psi.

Profis: Brass provides a good balance of strength, durability, and cost. It is also resistant to rust and offers a classic aesthetic appeal, often preferred in high-end products.

Nachteile: Brass can be heavier than aluminum and may require additional treatments to prevent tarnishing. It is also more expensive than plastic.

Auswirkungen auf die Anwendung: Brass is compatible with CO2 and provides reliable sealing, making it suitable for valve components in inflators.

Überlegungen für internationale Einkäufer: Buyers should ensure that brass components meet local regulations concerning lead content and environmental impact, particularly in Europe, where such regulations are stringent.

| Material | Typical Use Case for bike tire CO2 inflator | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Body and housing | Leicht und korrosionsbeständig | Prone to denting | Mittel |

| Kunststoff | Housing and non-critical components | Cost-effective and moldable | Lower durability | Niedrig |

| Rostfreier Stahl | High-stress components and valves | Exceptional strength and durability | Höhere Kosten und komplexere Herstellung | Hoch |

| Brass | Valves and fittings | Good machinability and corrosion resistance | Heavier and more expensive than aluminum | Mittel |

This analysis provides B2B buyers with actionable insights into material selection for bike tire CO2 inflators, enabling informed decisions that align with performance needs and compliance requirements in their respective markets.

The manufacturing process for bike tire CO2 inflators involves several critical stages that ensure the final product meets quality and performance standards.

Vorbereitung des Materials: The manufacturing process begins with the selection of high-quality materials, typically aluminum or durable plastics, for the body and components of the inflator. These materials are chosen for their lightweight properties, strength, and resistance to corrosion. Suppliers of these raw materials often need to provide certifications to ensure they meet specific mechanical and chemical properties.

Bildung von: The selected materials undergo various forming techniques, including extrusion, machining, and injection molding. For example, aluminum components may be extruded into profiles and then machined to create precise fittings. Injection molding is commonly used for plastic components, ensuring that parts like the handle and safety cover are produced with consistent quality and dimensional accuracy.

Montage: Once the individual components are formed, they are assembled into the final product. This stage typically involves manual or automated assembly techniques, where parts are securely fitted together, often using screws or adhesives. Attention to detail is crucial at this stage to ensure that the inflator operates smoothly and effectively.

Fertigstellung: The final step in the manufacturing process includes surface treatments such as anodizing for aluminum parts, which enhances corrosion resistance and aesthetic appeal. Additionally, quality checks are performed to ensure that there are no defects in the finishing process.

Quality assurance is paramount in the manufacturing of bike tire CO2 inflators, as it ensures safety, reliability, and performance. Manufacturers often adopt international standards such as ISO 9001 to guide their quality management systems.

Einhaltung internationaler Normen: Compliance with standards like ISO 9001 helps manufacturers establish a framework for consistent quality control throughout the production process. This standard emphasizes the importance of process documentation, employee training, and continual improvement.

Industry-Specific Certifications: Depending on the target market, additional certifications may be required. For instance, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. In regions like the Middle East and Africa, adherence to local regulations and standards can also be a crucial factor for market entry.

Kontrollpunkte der Qualitätskontrolle: Manufacturers implement a series of quality control checkpoints throughout the production process:

Eingehende Qualitätskontrolle (IQC): This initial inspection ensures that raw materials meet specified standards before they enter the production line.

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, ongoing inspections are conducted to identify any deviations from quality standards. This can include checking the dimensions and functionality of components as they are assembled.

Endgültige Qualitätskontrolle (FQC): Before packaging, each inflator undergoes a final inspection to ensure it meets all performance and aesthetic criteria. This often includes pressure testing and functional assessments to verify that each unit operates correctly.

To ensure that bike tire CO2 inflators meet stringent quality and safety standards, manufacturers employ various testing methods:

Pressure Testing: This involves subjecting the inflator to pressures beyond normal operating conditions to ensure that it can handle real-world stresses without failing.

Funktionelle Prüfung: Each unit is tested to confirm that it can inflate a tire effectively. This may involve measuring the time taken to inflate and ensuring that the CO2 release mechanism works smoothly.

Dauerhaftigkeitsprüfung: Inflators are often subjected to wear and tear simulations to ensure longevity. This testing assesses the resistance of materials to corrosion, impact, and temperature changes.

Umweltprüfungen: Some manufacturers conduct tests to determine how the inflator performs under various environmental conditions, such as extreme temperatures or humidity levels.

B2B buyers seeking to purchase bike tire CO2 inflators should take proactive steps to verify the quality control measures of their suppliers:

Lieferanten-Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. During the audit, buyers can assess compliance with international standards and observe the implementation of quality checks.

Anforderung von Qualitätsberichten: Buyers should request documentation that outlines the quality control processes, including IQC, IPQC, and FQC results. This documentation can help buyers understand how rigorously the manufacturer adheres to quality standards.

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control systems. These inspections can be particularly valuable for buyers in regions with less familiarity with local manufacturing practices.

Certification Verification: Buyers should verify any certifications claimed by the manufacturer. This can include checking with certification bodies to confirm that the supplier has indeed met the necessary standards.

For international buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is critical:

Regional Compliance Requirements: Different regions may have varying compliance requirements. For instance, products sold in Europe must meet CE standards, while Middle Eastern countries may have their own certification processes. Buyers should be aware of these requirements to ensure their products are market-ready.

Cultural Differences in Quality Expectations: Quality expectations can vary significantly across cultures. Buyers should consider local market preferences and standards when selecting suppliers. This may involve additional discussions about quality expectations and product specifications.

Language Barriers: Communication issues can arise when dealing with international suppliers. It’s essential for buyers to ensure clear and effective communication regarding quality control processes, expectations, and documentation requirements.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing bike tire CO2 inflators, ensuring that they partner with reliable manufacturers who prioritize quality and safety.

The purpose of this guide is to provide B2B buyers with a structured checklist for sourcing bike tire CO2 inflators effectively. This ensures that you procure quality products that meet your business needs while navigating the complexities of international supply chains.

Before beginning your sourcing process, it’s essential to outline the technical specifications that your CO2 inflators must meet. Consider factors such as compatibility with Presta and Schrader valves, inflation speed, and the size and weight of the inflator. This step will help narrow down your options and ensure the inflators you choose will meet the expectations of your customers.

Understanding current market trends in the bike accessory industry can inform your purchasing decisions. Analyze the demand for CO2 inflators in your target regions—Africa, South America, the Middle East, and Europe. Look for insights on popular features, such as compact designs or integrated pumps, which can enhance your product offerings.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Ensure that suppliers have a solid reputation for quality, reliability, and timely delivery to avoid disruptions in your supply chain.

Illustrative image related to bike tire co2 inflator

Once you’ve shortlisted potential suppliers, request samples of their CO2 inflators. Testing the products will allow you to evaluate their performance and quality firsthand. Pay attention to ease of use, inflation speed, and build quality, as these factors can significantly impact customer satisfaction.

Gather detailed quotes from your shortlisted suppliers and compare pricing structures, including bulk discounts and shipping costs. Evaluate the terms of payment, delivery timelines, and warranty policies. This step ensures you secure the best deal while maintaining product quality.

Communication is critical in any business relationship. Gauge the responsiveness of potential suppliers during your inquiry process. A supplier that promptly addresses your questions and concerns is likely to provide better support throughout your partnership.

Once you’ve selected a supplier, finalize your order with clear agreements regarding specifications, pricing, and delivery timelines. Ensure that all terms are documented to prevent any misunderstandings. This step establishes a solid foundation for your business relationship and sets expectations for both parties.

Illustrative image related to bike tire co2 inflator

By following this checklist, you can streamline the sourcing process for bike tire CO2 inflators, ensuring you make informed decisions that align with your business goals and customer needs.

When sourcing bike tire CO2 inflators, understanding the cost structure is essential for effective budgeting and pricing strategy. The primary components of the cost structure include:

Materialien: This encompasses the raw materials used in manufacturing inflators, such as metal for the body and plastic for the nozzle. The choice of materials affects durability and performance, directly impacting cost.

Arbeit: Labor costs are influenced by the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, particularly for inflators with more advanced features.

Fertigungsgemeinkosten: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient production processes can help reduce these costs.

Werkzeugbau: The initial investment in molds and tooling is significant for manufacturing inflators. Depending on the design complexity, this can represent a substantial portion of the upfront costs.

Qualitätskontrolle (QC): Ensuring product quality is crucial for customer satisfaction and brand reputation. QC processes involve testing for functionality and safety, adding to overall costs.

Logistik: Shipping and handling costs can vary significantly based on the destination, volume, and Incoterms. Efficient logistics strategies can mitigate these expenses.

Marge: Finally, suppliers will add a margin to cover their costs and ensure profitability. This margin varies based on market competition and perceived value.

Several factors can influence the pricing of bike tire CO2 inflators in the B2B market:

Volumen/MOQ: Suppliers often provide better pricing for larger orders due to economies of scale. Understanding the minimum order quantity (MOQ) is vital for budget planning.

Spezifikationen und Anpassungen: Custom designs or specifications, such as branding or unique features, can increase costs. Buyers should assess the necessity of these customizations against their budget.

Materialien: The choice of high-quality materials can lead to higher costs but may also enhance the product’s longevity and reliability, making it a worthwhile investment.

Qualität und Zertifizierungen: Products that meet international safety and quality standards can command higher prices. Certifications can also serve as a marketing advantage.

Lieferanten-Faktoren: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers may charge a premium for their perceived quality and service.

Incoterms: Different Incoterms can significantly impact the total cost, including who bears the risk and responsibility for shipping. Clarity on these terms is essential for accurate cost forecasting.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are several actionable strategies:

Illustrative image related to bike tire co2 inflator

Negotiate Pricing: Engage in negotiations with suppliers, especially when placing larger orders. Building a relationship with suppliers can lead to better pricing and terms.

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors like maintenance, durability, and replacement costs.

Nuancen der Preisgestaltung verstehen: Different regions may have varying pricing strategies based on local market dynamics. Buyers should research local suppliers and market conditions to make informed decisions.

Leverage Volume Discounts: If possible, consolidate orders across different products or categories to reach higher volume thresholds that can unlock discounts.

Assess Supplier Reliability: Before finalizing a supplier, consider their track record in delivering quality products on time. Reliability can save costs associated with returns and delays.

It is essential to note that the prices for bike tire CO2 inflators can vary widely based on the factors discussed. The indicative prices sourced from various suppliers may not reflect the final costs due to fluctuations in raw material prices, shipping rates, and supplier pricing strategies. Buyers should conduct thorough market research and request quotes tailored to their specific needs.

In the competitive landscape of cycling equipment, choosing the right tire inflation solution is crucial for performance and convenience. While bike tire CO2 inflators are popular for their speed and compactness, several viable alternatives exist. Understanding the nuances of each option can empower international B2B buyers to make informed decisions tailored to their specific market needs.

| Vergleich Aspekt | Bike Tire CO2 Inflator | Hand Pump | Electric Pump |

|---|---|---|---|

| Leistung | Rapid inflation, quick refills | Slower inflation, requires physical effort | Consistent inflation, variable speed |

| Kosten | Moderate ($14.99 – $54.99) | Low ($10 – $30) | Higher ($50 – $150) |

| Leichte Implementierung | Simple and straightforward | Requires physical strength, can be cumbersome | Easy, but needs charging or battery replacement |

| Wartung | Minimal, replace cartridges | Low, clean and store | Moderate, battery care and maintenance required |

| Bester Anwendungsfall | Emergency repairs, racing | General cycling, touring | Home use, longer rides, multiple tires |

Hand pumps are a traditional and budget-friendly alternative to CO2 inflators. They are generally compact and can be easily carried on rides. While they do require physical effort to inflate tires, they provide a reliable inflation method without the need for cartridges. This makes them especially appealing for long-distance cyclists or those in remote areas where CO2 cartridges may not be readily available. However, the downside is that hand pumps can be labor-intensive and time-consuming, potentially causing delays during rides, especially in competitive scenarios.

Illustrative image related to bike tire co2 inflator

Electric pumps are becoming increasingly popular due to their ease of use and consistent performance. These pumps can quickly inflate tires with the push of a button, making them ideal for home use or in bike shops where efficiency is paramount. They often come with built-in pressure gauges and multiple settings for different tire types. However, electric pumps are typically more expensive than CO2 inflators and require a power source, which can be a limitation in remote areas. Their maintenance involves keeping the battery charged and ensuring the mechanical components are in working order.

When selecting the right tire inflation solution, B2B buyers must consider their target market’s unique needs and preferences. Bike tire CO2 inflators excel in situations requiring speed and compactness, making them ideal for competitive cyclists and emergency repairs. Hand pumps offer a cost-effective and reliable alternative for general cyclists, while electric pumps cater to those seeking convenience and efficiency for home use. By evaluating performance, cost, ease of implementation, maintenance, and use cases, businesses can strategically align their inventory with the demands of their customers, ensuring they provide the best solutions for their cycling needs.

When evaluating bike tire CO2 inflators, several technical specifications are critical for ensuring efficiency and reliability. Understanding these properties is essential for B2B buyers to make informed decisions.

Material Klasse

The construction material of a CO2 inflator significantly influences its durability and performance. Common materials include aluminum for its lightweight properties and resistance to corrosion, and high-grade plastics for weight reduction. A higher material grade often results in a longer lifespan and better performance under pressure, making it crucial for long-term investments.

Pressure Rating

The pressure rating indicates the maximum pressure the inflator can handle, typically measured in PSI (pounds per square inch). Most bike tires require inflation to pressures between 30 to 100 PSI. A CO2 inflator with a higher pressure rating ensures compatibility with various tire types, particularly high-performance road and mountain bikes. Understanding this rating helps buyers select inflators that meet their customers’ needs.

Flow Control Mechanism

Many advanced CO2 inflators come equipped with a flow control mechanism, allowing users to regulate the inflation rate. This feature is critical for achieving the desired tire pressure without over-inflating or wasting CO2 cartridges. For B2B buyers, offering inflators with flow control can enhance customer satisfaction and reduce complaints about product performance.

Valve Compatibility

Compatibility with different valve types—Presta and Schrader—is essential for a versatile inflator. An inflator that can accommodate both types ensures that it can be used with a wide range of bicycles, catering to diverse customer bases. Providing this information can be a selling point for retailers targeting various cycling demographics.

Weight and Size

The weight and compactness of a CO2 inflator are vital for portability, especially for cyclists who prioritize lightweight gear. Inflators designed to be easily stowed in a jersey pocket or bike bag appeal to consumers looking for convenience. B2B buyers should consider these aspects when sourcing products for markets where portability is a key concern.

Cartridge Compatibility

CO2 inflators typically use cartridges of varying sizes, commonly 16g, 20g, and 25g. Understanding cartridge compatibility is essential for ensuring that end-users have access to the necessary supplies. Offering inflators that can utilize multiple cartridge sizes can attract a broader customer base and encourage repeat purchases.

In the B2B landscape, familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common terms associated with bike tire CO2 inflators:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. B2B buyers often collaborate with OEMs to source components for branded products, ensuring quality and consistency.

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs and ensure they can meet market demand without overstocking.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other information on specific products. It helps buyers compare offers from different manufacturers, enabling them to make cost-effective purchasing decisions.

Incoterms

International Commercial Terms (Incoterms) are a set of predefined rules that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and obligations associated with importing products.

Vorlaufzeit

This term refers to the time taken from placing an order to receiving the goods. Understanding lead times is critical for B2B buyers to manage supply chain logistics and ensure timely product availability.

Aftermarket

The aftermarket refers to the secondary market where parts and accessories are sold after the initial sale of a product. For CO2 inflators, this includes cartridges and repair kits, and being knowledgeable about the aftermarket can enhance a buyer’s ability to offer comprehensive solutions to customers.

By comprehending these technical properties and trade terminology, B2B buyers can make better purchasing decisions, ensuring they meet their customers’ needs effectively and efficiently.

The bike tire CO2 inflator market is experiencing robust growth, driven by an increase in cycling popularity and the rise of urban cycling as a sustainable transportation solution. Globally, the demand for quick, portable inflation solutions is surging, particularly among urban commuters and recreational cyclists. Key regions such as Africa, South America, the Middle East, and Europe are witnessing a shift towards lightweight and compact inflators that can easily fit into backpacks or jersey pockets, catering to the needs of cyclists who prioritize convenience.

Emerging trends in B2B tech and sourcing include the integration of smart technology into inflators, enhancing user experience through features like pressure gauges and smartphone connectivity. Additionally, manufacturers are increasingly focusing on multifunctional products that combine CO2 inflators with hand pumps or other tools, providing added value for B2B buyers. The rise of e-commerce platforms is also reshaping the procurement landscape, allowing international buyers to access a wider variety of products with competitive pricing.

Market dynamics are influenced by the competitive landscape, where established brands are innovating rapidly to differentiate their offerings. For instance, the combination of CO2 inflators with eco-friendly materials and sustainable practices is becoming a focal point for manufacturers aiming to capture environmentally conscious consumers. As B2B buyers navigate this market, understanding these dynamics will be crucial for making informed sourcing decisions that align with both consumer demand and market trends.

Illustrative image related to bike tire co2 inflator

Sustainability is becoming a critical factor in the bike tire CO2 inflator sector, with an increasing focus on minimizing environmental impact. As global awareness of climate change intensifies, B2B buyers are prioritizing suppliers that adhere to sustainable practices. This includes sourcing materials that are recyclable or made from eco-friendly substances, as well as ensuring that the production processes are energy-efficient and reduce carbon footprints.

Ethical sourcing is equally important, as businesses are scrutinizing their supply chains for transparency and social responsibility. Certifications such as Fair Trade and ISO 14001 are gaining traction among manufacturers, signaling a commitment to ethical labor practices and environmental management. B2B buyers are encouraged to seek partnerships with companies that not only produce high-quality inflators but also demonstrate a commitment to ethical supply chain practices.

In addition, the demand for ‘green’ certifications is on the rise, with consumers increasingly inclined to support brands that prioritize sustainability. Suppliers who can showcase their environmentally friendly initiatives, such as using biodegradable packaging or engaging in community sustainability projects, are likely to gain a competitive edge in the market. This focus on sustainability and ethical sourcing not only fulfills corporate social responsibility goals but also resonates with the values of a growing segment of eco-conscious consumers.

The evolution of the bike tire CO2 inflator market can be traced back to the late 20th century when traditional hand pumps were the primary means of inflation. The introduction of CO2 inflators revolutionized this sector, offering cyclists a rapid and efficient solution to tire inflation, especially during races or long rides. The technology has advanced significantly, with modern inflators now featuring user-friendly designs, improved safety mechanisms, and compatibility with various valve types.

Initially, CO2 inflators were perceived as a luxury item, but their practicality has made them a staple for cyclists of all levels. As cycling gained popularity in urban areas and among fitness enthusiasts, the demand for portable and lightweight inflators surged, leading to the development of diverse product lines tailored to different cycling needs. Today, the market is characterized by innovative designs that enhance functionality and performance, reflecting the ongoing commitment to meet the evolving demands of cyclists globally.

1. How do I choose the right CO2 inflator for my business needs?

Selecting the right CO2 inflator involves evaluating several factors. Consider the inflator’s compatibility with both Presta and Schrader valves, as this ensures versatility for various bike types. Look for features like flow control for precise inflation and compact design for portability. Assess the available cartridge sizes and whether your target market prefers disposable or refillable options. Additionally, review customer feedback on durability and ease of use, which can significantly affect customer satisfaction and repeat purchases.

2. What is the best CO2 inflator for high-volume bike tire inflation?

For high-volume bike tire inflation, the Muc-Off Road Inflator Kit is an excellent choice due to its efficient design and user-friendly features. It allows for quick inflation with controllable gas flow, making it ideal for both road and mountain bikes. Additionally, its dual compatibility with Presta and Schrader valves ensures it meets diverse customer needs. When sourcing, ensure that the supplier can provide adequate stock levels to meet demand, especially during peak cycling seasons.

3. What are the minimum order quantities (MOQ) for CO2 inflators when sourcing internationally?

Minimum order quantities (MOQ) for CO2 inflators can vary significantly by supplier and product type. Typically, you might encounter MOQs ranging from 100 to 1,000 units. It’s crucial to communicate your specific needs to suppliers and negotiate favorable terms, especially if you are testing a new product line or entering a new market. Ensure that the supplier can accommodate your business scale and consider potential volume discounts for larger orders.

4. How can I ensure quality assurance (QA) for CO2 inflators sourced internationally?

To ensure quality assurance for CO2 inflators, request detailed product specifications and certifications from suppliers. Conduct factory audits to verify manufacturing processes and quality control measures. Establish clear quality expectations in your contracts, including acceptable defect rates and testing protocols. Additionally, consider third-party inspections before shipment to catch any issues early, ensuring that the products meet both your standards and regulatory requirements in your target markets.

5. What payment terms should I negotiate when purchasing CO2 inflators from international suppliers?

When negotiating payment terms, aim for conditions that balance risk and cash flow. Common terms include a 30% deposit upfront with the remaining balance due upon shipment or delivery. For larger orders, consider negotiating payment upon receipt or after a quality inspection. Be aware of currency fluctuations and potential fees associated with international transactions. Using secure payment methods, such as letters of credit or escrow services, can also protect your investment.

Illustrative image related to bike tire co2 inflator

6. How should I vet suppliers when sourcing CO2 inflators for my business?

Vetting suppliers is crucial to ensure reliability and product quality. Start by researching their reputation through online reviews and industry references. Request samples to evaluate product quality firsthand and assess their production capabilities. Additionally, inquire about their manufacturing processes, certifications, and compliance with international standards. Establishing clear communication and responsiveness during your initial interactions can also provide insight into their professionalism and customer service.

7. What logistics considerations are important when importing CO2 inflators?

Logistics considerations include shipping methods, lead times, and customs regulations. Determine the most cost-effective shipping option based on your timeline and budget, whether by air or sea. Be aware of customs duties and import regulations in your country, as these can affect overall costs and delivery times. Partnering with a reliable logistics provider can streamline the process, ensuring timely delivery and compliance with all necessary documentation and regulations.

8. Are there customization options available for CO2 inflators, and how do I request them?

Many suppliers offer customization options for CO2 inflators, such as branding, color choices, and packaging design. To request customization, clearly outline your requirements in your initial communication with the supplier. Discuss any potential design limitations and request samples of customized products to evaluate before placing a bulk order. Customization can enhance brand visibility and differentiate your products in competitive markets, making it a valuable consideration for your business strategy.

Bereich: reiten.lezyne.com

Registriert: 2007 (18 Jahre)

Einleitung: Lezyne CO2 inflators provide instant, reliable tire inflation in seconds, ideal for road bikes and mountain bikes. Key products include: PRESSURE DRIVE CFH ($54.99), CLIK™ DRIVE CO2 WITH 20G CARTRIDGE ($37.99), CADDY KIT ($32.99), CONTROL DRIVE CO2 (from $29.99), TWIN KIT (from $29.99), 25G CO2 – 5 PACK ($27.99), REPAIR KIT ($24.99), 20G CO2 – 5 PACK ($19.99), TRIGGER SPEED DRIVE CO2 (from $19.99)…

Bereich: ridepdw.com

Registriert: 2008 (17 Jahre)

Einleitung: Bike Pumps & CO2 Tire Inflators from Portland Design Works include various models such as:

– Timber to Town: Cloud Cap CO2 Inflator – $39.00

– Shiny Object – from $19.00

– Tiny Object – $22.00

– Fatty Object – from $19.00

– Timber to Town: Cloud Cap Gravel Pump + CO2 Inflator – $89.00

– Ninja Pump – $35.00

– 38g CO2 Cartridge – $15.00

– 16g CO2 Cartridge Packs – from $10.00

– Leather CO2 …

Bereich: planetbike.com

Registriert: 1997 (28 Jahre)

Einleitung: {“products”:[{“name”:”ALX 2.0 bike floor pump”,”price”:”$60.00″},{“name”:”20g CO2 replacement cartridges – threaded”,”price”:”$15.00 – $55.00″},{“name”:”Red Zeppelin CO2 bike tire inflator”,”price”:”$20.00″},{“name”:”Comp 2.0 bike floor pump”,”price”:”$30.00″},{“name”:”STX bike floor pump”,”price”:”$55.00″,”availability”:”Out of stock”},{“name”:”Fresh Air mini pump”,”price”:”$20.00″},{“name”:”Shoc…

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: 1. Portland Design Works Shiny Object CO2 Inflator: Easy and simple to use, easy to take apart, no need for servicing but parts/o-rings are available from the manufacturer website. 2. Pro Bike Tool Inflator: Works well, used sparingly over the years. 3. Dynaplug: A two-in-one plug-it and air-it CO2 device. 4. Specialized Inflator: Threads onto the valve to prevent air loss, available with or witho…

Bereich: pureridecycles.com

Registriert: 2014 (11 Jahre)

Einleitung: {“products”:[{“name”:”Planet Bike Red Zeppelin CO2 bike tire inflator (w/ 2 16g CO2)”,”price”:”$19.99″,”features”:[“Ultra light”,”Super reliable”,”Easy to use”,”Accepts all types of threaded cartridges”,”Precision control knob for accurate inflation”]},{“name”:”MSW Airstream Pump”,”price”:”$20.00″,”features”:[“Ultra-small, minimalist design”,”Easy twist-on/twist-off operation”,”Cartridge storage t…

Bereich: blackburndesign.com

Registriert: 1996 (29 Jahre)

Einleitung: {“product_name”: “Pro Plugger CO2 Inflator Kit”, “price”: “$79.95”, “color”: “Black”, “size”: “One Size”, “availability”: “In Stock”, “weight”: “75 grams”, “features”: [{“feature_name”: “Pre-loaded tire plugs”, “description”: “Includes 10 tire plugs for emergency repairs.”}, {“feature_name”: “Presta valve core tool”, “description”: “Integrated threaded Presta core remover for easy inflation.”}, {“…

Bereich: bicycles.stackexchange.com

Registriert: 2009 (16 Jahre)

Einleitung: Advantages of CO₂ inflators: 1. Fast tire inflation compared to hand pumps. 2. Requires less physical effort to use. 3. Potentially lighter than some hand pumps. 4. Lower initial cost for a valve and cartridges compared to a good small pump. Disadvantages: 1. Cartridges are consumable and can become costly with frequent use. 2. No backup inflation method if a flat is patched incorrectly. 3. Limite…

In the ever-evolving market for bike tire CO2 inflators, strategic sourcing emerges as a critical component for B2B buyers seeking to optimize their product offerings and supply chain efficiency. The landscape is characterized by a diverse range of products, from compact inflators to integrated systems that enhance user experience. By prioritizing suppliers who emphasize quality, reliability, and innovation, businesses can ensure they meet the demands of cyclists across various regions, including Africa, South America, the Middle East, and Europe.

Illustrative image related to bike tire co2 inflator

Understanding the nuances of CO2 inflators—such as compatibility with both Presta and Schrader valves, ease of use, and the importance of flow control—can significantly influence purchasing decisions. Moreover, as sustainability concerns grow, selecting suppliers that consider the environmental impact of their products will resonate well with eco-conscious consumers.

Looking ahead, the potential for growth in this sector is substantial. International B2B buyers are encouraged to seize this opportunity by engaging with manufacturers and distributors that align with their values and market needs. By doing so, they can foster stronger partnerships that not only enhance their product lines but also contribute to a thriving cycling community globally.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.