In the demanding world of logistics and transportation, sourcing a reliable semi truck tire inflator is crucial for maintaining operational efficiency and safety. With the complexities of tire maintenance, particularly in remote locations, international B2B buyers face the challenge of identifying high-quality inflators that cater to diverse environments and regulatory standards. This guide serves as a comprehensive resource, covering various types of semi truck tire inflators, their applications, supplier vetting processes, and cost considerations.

Navigating the global market can be daunting, especially for businesses in Africa, South America, the Middle East, and Europe, including regions like Germany and Vietnam. This guide empowers buyers by providing actionable insights into the features that matter most, such as maximum working pressure, durability in extreme weather conditions, and compatibility with on-board air systems. Buyers will learn how to evaluate suppliers effectively, ensuring they partner with manufacturers who prioritize quality and reliability.

By equipping businesses with the knowledge to make informed purchasing decisions, this guide not only addresses the immediate need for efficient tire inflation solutions but also enhances long-term operational success. The result is a streamlined approach to sourcing semi truck tire inflators that contribute significantly to safety, productivity, and overall fleet performance.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| On-Board Air Supply Inflators | Utilizes the truck’s existing air system; often equipped with a glad-hand attachment. | Long-haul trucking, fleet maintenance | Vorteile: Convenient, no need for external power; Nachteile: Limited to trucks with compatible systems. |

| Portable Electric Compressors | Rechargeable battery or plug-in models; suitable for various tire sizes. | Emergency roadside assistance, small fleets | Vorteile: Versatile, can be used for multiple vehicles; Nachteile: Limited power and air output for large tires. |

| Manual Handheld Inflators | Lightweight, battery-operated devices; designed for quick inflation. | Individual truck drivers, personal use | Vorteile: Easy to carry, affordable; Nachteile: Slow inflation rate, not suitable for heavy-duty tires. |

| Tire Inflation Kits | Complete kits with hoses, air chucks, and attachments; often compatible with glad-hand systems. | Fleet maintenance, emergency repairs | Vorteile: Comprehensive solution, durable materials; Nachteile: Requires manual operation, can be cumbersome. |

| High-Pressure Shop Compressors | Industrial-grade compressors with high CFM output; used in tire shops. | Commercial tire shops, fleet service centers | Vorteile: Fast inflation, suitable for multiple tires; Nachteile: High initial investment, requires space and power supply. |

On-board air supply inflators are designed to leverage a truck’s existing air system, making them a practical choice for long-haul trucking and fleet maintenance. These systems typically feature a glad-hand attachment that connects directly to the truck’s air supply, allowing for quick and efficient tire inflation. B2B buyers should consider the compatibility of these inflators with their fleet vehicles, as they provide convenience without the need for additional equipment. Their limitation lies in the requirement for a compatible air supply system, which may not be available on all vehicles.

Portable electric compressors are versatile tools that can be utilized for various tire sizes and types, making them ideal for emergency roadside assistance and small fleet operations. These devices can be powered by rechargeable batteries or plugged into a power source, providing flexibility in usage. When purchasing, B2B buyers should assess the compressor’s air output and battery life, as these factors will influence its effectiveness for large truck tires. While they offer convenience, their lower power output may not be sufficient for heavy-duty applications.

Manual handheld inflators are lightweight and designed for ease of use, making them a popular choice among individual truck drivers. These devices are typically battery-operated and provide a quick inflation solution for minor tire issues. However, B2B buyers should be aware of their limitations, particularly regarding inflation speed and suitability for heavy-duty tires. While they are affordable and easy to carry, their slow inflation rate may not meet the demands of high-volume operations.

Tire inflation kits offer a comprehensive solution for tire maintenance, including hoses, air chucks, and attachments that are often compatible with glad-hand systems. These kits are particularly useful for fleet maintenance and emergency repairs, providing durability and ease of use in various climates. B2B buyers should consider the quality of materials and the ease of operation when selecting a kit. Although they require manual operation, their versatility and comprehensive nature make them a valuable investment for fleet operators.

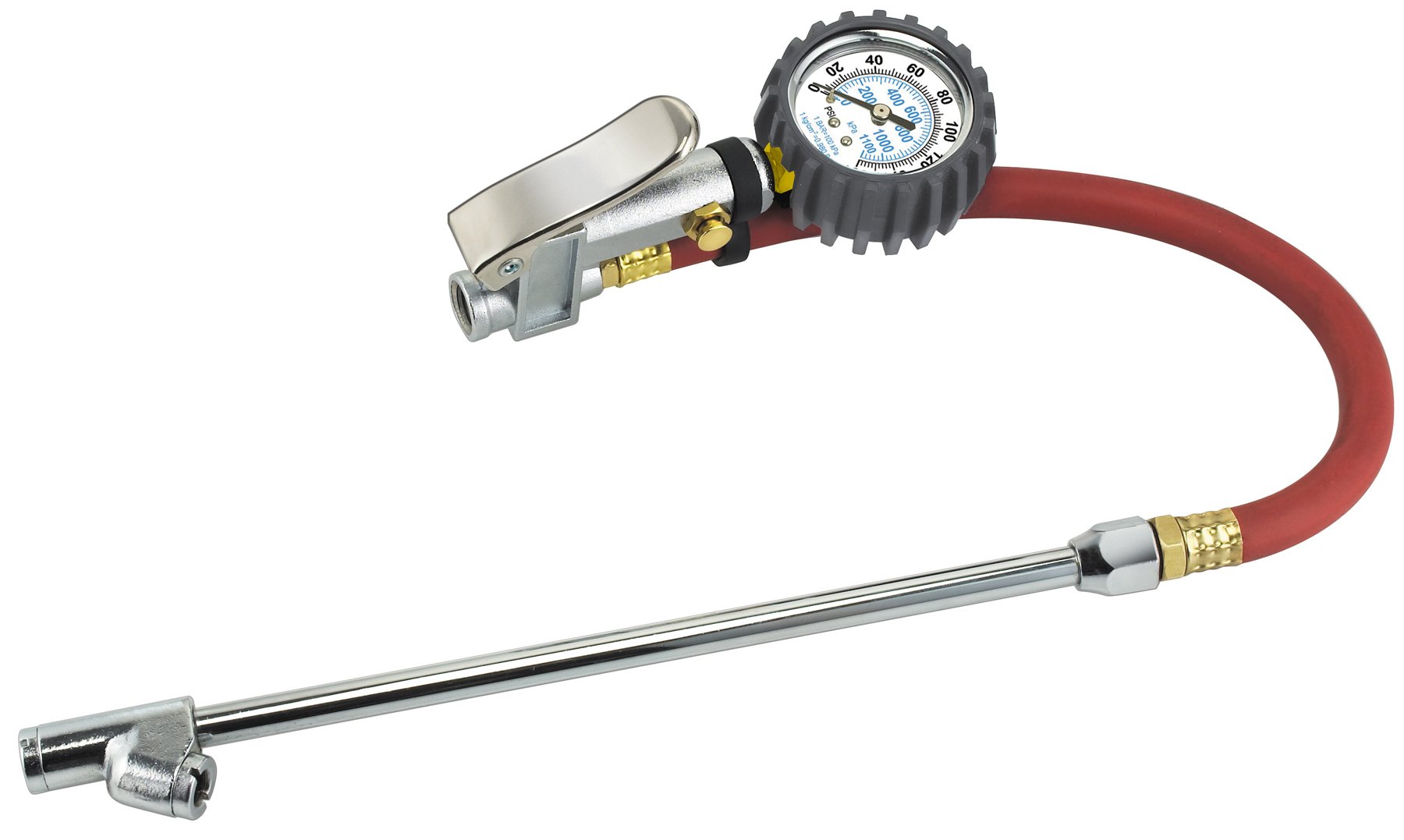

Illustrative image related to semi truck tire inflator

High-pressure shop compressors are industrial-grade machines designed for fast inflation with high CFM output, making them essential for commercial tire shops and fleet service centers. These compressors can efficiently inflate multiple tires in a short time, significantly improving service speed. B2B buyers should evaluate the compressor’s power requirements and space needs, as these units require a substantial initial investment. While they are a significant capital outlay, their efficiency in a commercial setting can lead to increased productivity and customer satisfaction.

| Industrie/Sektor | Specific Application of Semi Truck Tire Inflator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Logistics & Freight | On-site tire inflation during transport | Reduces downtime, ensuring timely deliveries | Durability, portability, and compatibility with truck systems |

| Bauwesen | Maintenance of heavy-duty vehicles on job sites | Enhances safety and efficiency in equipment operations | Resistance to harsh environments and ease of use |

| Landwirtschaft | Tire inflation for transport vehicles and machinery | Maintains operational efficiency in remote locations | Adaptability to various tire sizes and inflation pressures |

| Mining | Tire inflation for haul trucks in remote areas | Minimizes tire-related delays, improving productivity | Robustness and high-pressure capabilities |

| Public Transport | Routine maintenance for buses and commercial vehicles | Ensures safety and compliance with regulations | Availability of service kits and support for diverse vehicle types |

In the logistics and freight industry, semi truck tire inflators are essential tools for on-site tire inflation. Trucks often face varying tire pressures during long hauls, which can lead to increased fuel consumption and tire wear. By utilizing a semi truck tire inflator, logistics companies can quickly adjust tire pressure at loading docks or during transport, minimizing downtime and ensuring timely deliveries. International buyers should consider inflators that are compatible with their trucks’ onboard air supply and can withstand diverse climatic conditions found in regions like Africa and South America.

Construction sites rely heavily on heavy-duty vehicles, making tire maintenance critical. A semi truck tire inflator allows construction companies to perform tire inflation directly on-site, thereby enhancing the safety and efficiency of operations. This is particularly vital in rugged environments where access to traditional inflation methods may be limited. Buyers should seek inflators designed for durability and flexibility in extreme weather, ensuring they can operate effectively in various climates encountered in construction zones across Europe and the Middle East.

In agriculture, tire inflation is crucial for ensuring the optimal performance of transport vehicles and machinery. Farmers often operate in remote areas where access to service stations is limited. A semi truck tire inflator enables agricultural businesses to maintain tire pressure, ensuring that vehicles can transport goods without delays. Buyers in this sector should prioritize inflators that can accommodate a range of tire sizes and pressures, as well as those that are easy to transport and set up in the field.

Illustrative image related to semi truck tire inflator

Mining operations frequently utilize haul trucks that operate in challenging terrains. A semi truck tire inflator is vital for maintaining tire pressure, which directly impacts productivity and safety. By ensuring that tires are properly inflated, mining companies can reduce the risk of blowouts and improve fuel efficiency. Buyers in the mining sector should focus on inflators that are robust and capable of achieving high pressure, allowing them to tackle the demanding conditions typical of mining environments.

In the public transport sector, regular tire maintenance is essential for ensuring safety and compliance with regulatory standards. A semi truck tire inflator allows for quick and efficient tire inflation for buses and commercial vehicles, helping to maintain optimal performance and safety. Buyers should consider inflators that come with comprehensive service kits and support for various vehicle types, ensuring that they can meet the diverse needs of their fleet while adhering to safety regulations across different regions.

Das Problem: Many B2B buyers face the significant challenge of inflating semi truck tires in remote areas where access to conventional air supply sources is limited. This situation is especially prevalent in regions such as Africa and South America, where long stretches of highway may lack service stations or reliable tire inflation facilities. In such circumstances, a breakdown due to under-inflated tires can lead to costly delays and disruptions in logistics, impacting overall operational efficiency.

Die Lösung: To address this issue, businesses should invest in tire inflators that utilize the truck’s onboard air supply, such as those equipped with a glad-hand attachment. By sourcing high-quality tire inflator kits, like those from Flexzilla or Mytee Products, companies can ensure they have the necessary tools to maintain tire pressure even in the most isolated conditions. When selecting an inflator, look for features like a durable, flexible hose that can withstand extreme temperatures and a high maximum working pressure (at least 300 psi). Additionally, consider training staff on the proper use of these inflators to ensure quick and efficient tire maintenance on the road.

Das Problem: Another common pain point arises from the physical challenge of reaching all tires on a semi truck, particularly the inner dual tires. Many inflators may not provide the necessary reach or flexibility to adequately inflate these tires, leading to under-inflation and increased wear and tear. This issue is compounded by the fact that many B2B buyers are looking for solutions that minimize downtime while maximizing safety and compliance with industry regulations.

Die Lösung: To overcome this challenge, businesses should prioritize inflators that come with specialized attachments, such as a 30-degree dual air chuck. This design allows for easier access to inner tires without the need for excessive maneuvering or awkward positioning. When sourcing tire inflators, ensure that the selected model includes a long enough hose (at least 50 feet) to reach all tires comfortably. Furthermore, investing in additional accessories such as tire pressure gauges can help monitor tire health and prevent inflation issues from occurring in the first place.

Das Problem: B2B buyers often express concerns about the durability and reliability of tire inflators, especially when used in harsh environments. For instance, in regions with extreme weather conditions—such as the heat of the Middle East or the cold of northern Europe—equipment can fail if not built to withstand these challenges. This can lead to unplanned downtime and additional costs associated with repairs or replacements.

Die Lösung: To mitigate these risks, companies should thoroughly vet the materials and construction of tire inflators before making a purchase. Look for inflators made from high-quality materials that offer abrasion resistance and flexibility in varying temperatures (from -40°F to 140°F). Products like the Flexzilla tire inflator kits are specifically designed to remain functional in extreme conditions, ensuring reliability regardless of the environment. Additionally, consider creating a maintenance schedule that includes regular inspections of inflators and hoses to identify wear and tear before they lead to equipment failure. This proactive approach not only enhances the lifespan of the inflators but also ensures continuous operational efficiency.

When selecting materials for semi truck tire inflators, it is essential to consider their properties and how they align with the specific needs of the application. Below, we analyze four common materials used in the construction of tire inflators, focusing on their performance characteristics, advantages, disadvantages, and implications for international B2B buyers.

Rubber is a traditional choice for tire inflators due to its excellent elasticity and resilience. It can withstand high pressures, typically rated up to 300 psi, making it suitable for heavy-duty applications. Additionally, rubber exhibits good resistance to abrasion and wear, which is crucial for inflators exposed to harsh environments.

Pro und Kontra:

Rubber is relatively inexpensive and easy to manufacture, but it can degrade over time when exposed to UV light and ozone. This limits its lifespan, especially in regions with extreme weather conditions. For international buyers, particularly in Africa and South America, the availability of high-quality rubber can vary, impacting product reliability.

Polyvinyl Chloride (PVC) is another common material used in tire inflators. It offers good flexibility and is resistant to chemicals, making it suitable for various applications. PVC can handle moderate temperature ranges, typically from -10°C to 60°C, and has a pressure rating similar to rubber.

Illustrative image related to semi truck tire inflator

Pro und Kontra:

While PVC is cost-effective and lightweight, it can become rigid in colder temperatures, which may hinder performance in regions with extreme climates, such as the Middle East. Additionally, PVC may not be as durable as rubber in heavy-duty applications, which could lead to higher replacement costs over time. Compliance with international standards like ASTM is essential when sourcing PVC products.

Hybrid polymer materials, such as those used in Flexzilla products, combine the best properties of rubber and PVC. These materials offer superior flexibility, even in extreme temperatures ranging from -40°F to 140°F. They are also lightweight and resistant to kinking, which enhances usability in various conditions.

Pro und Kontra:

The primary advantage of hybrid polymers is their durability and performance in diverse climates, making them suitable for international markets. However, they typically come at a higher cost than traditional materials, which may be a consideration for budget-conscious buyers. Ensuring compliance with local regulations and standards is crucial for successful market entry in regions like Europe and Germany.

Illustrative image related to semi truck tire inflator

Metal components, such as air chucks and glad-hand attachments, are critical for the functionality of tire inflators. Metals like brass and aluminum are commonly used due to their strength and corrosion resistance. These materials can withstand high pressures and provide a reliable connection to the air supply.

Pro und Kontra:

Metal attachments are durable and can handle the rigors of heavy-duty use, but they can be heavier and more expensive than plastic alternatives. For buyers in regions with high humidity or corrosive environments, selecting corrosion-resistant metals is vital to ensure longevity. Compliance with international standards for metal components is also essential to avoid issues during shipping and usage.

| Material | Typical Use Case for Semi Truck Tire Inflator | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Gummi | Hoses for high-pressure applications | Excellent elasticity and resilience | Degrades under UV light and ozone | Niedrig |

| PVC | Lightweight hoses for moderate applications | Kostengünstig und leicht | Becomes rigid in cold temperatures | Niedrig |

| Hybrid Polymer | Flexible hoses for extreme conditions | Superior flexibility and durability | Higher cost compared to traditional materials | Hoch |

| Metal (Brass/Aluminum) | Attachments for secure air connections | Stark und korrosionsbeständig | Heavier and more expensive than plastic | Mittel |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

The manufacturing process of semi truck tire inflators involves several critical stages that ensure product quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

The first step in manufacturing semi truck tire inflators is the selection and preparation of materials. Typically, high-quality synthetic rubber and durable polymers are chosen for their flexibility and resistance to environmental factors. These materials undergo rigorous testing to ensure they meet industry standards for strength and durability. The preparation may involve the mixing of raw materials and additives to enhance performance, such as anti-aging agents and UV stabilizers.

Illustrative image related to semi truck tire inflator

Once the materials are prepared, they are subjected to forming processes. This can include extrusion, where the rubber is shaped into hoses, or molding for components like air chucks and fittings. Advanced techniques such as blow molding can be employed for creating complex shapes that enhance the inflator’s functionality. The forming stage is crucial, as it directly impacts the product’s integrity and performance under high-pressure conditions.

After forming, the components are assembled into the final product. This stage involves integrating various parts, such as hoses, air chucks, and glad-hand attachments. Automated assembly lines may be utilized to increase efficiency and reduce human error. Quality checks are conducted at this stage to ensure all components fit correctly and function as intended.

The finishing process is the final step before the product is packaged and shipped. This may include surface treatments to enhance durability and appearance, as well as labeling and packaging. Proper finishing ensures that the inflators can withstand harsh conditions, such as extreme temperatures and abrasive environments, which are common in regions like Africa and the Middle East.

Quality assurance (QA) is critical in the manufacturing of semi truck tire inflators, ensuring that products meet international standards. One of the most recognized standards is ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has implemented processes for consistent quality and customer satisfaction.

In addition to ISO 9001, other certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for performance may apply. These certifications ensure that products are safe, reliable, and environmentally friendly. For B2B buyers, verifying these certifications can provide assurance of a product’s quality and compliance with regional regulations.

Quality control (QC) is integral to ensuring that semi truck tire inflators meet both regulatory and customer expectations. Key QC checkpoints typically include:

Eingehende Qualitätskontrolle (IQC): Inspection of raw materials and components upon arrival at the manufacturing facility. This ensures that only materials that meet predefined specifications are used in production.

Prozessbegleitende Qualitätskontrolle (IPQC): Ongoing inspections during the manufacturing process, including checks on dimensions, pressure testing of hoses, and functionality of air chucks. This step helps identify defects early, reducing waste and rework.

Endgültige Qualitätskontrolle (FQC): A comprehensive evaluation of the completed inflators before they are packaged. This includes pressure testing to verify that the product can withstand its rated specifications, as well as visual inspections for any cosmetic defects.

Manufacturers employ various testing methods to ensure the durability and reliability of semi truck tire inflators. Common tests include:

Illustrative image related to semi truck tire inflator

Druckprüfung: Inflators are subjected to high-pressure conditions to ensure they can withstand operational demands without failure. This is especially critical for products designed to operate in extreme conditions.

Temperature Resistance Testing: Given the wide range of operating temperatures, inflators are tested to ensure they remain flexible and functional in both high and low temperatures.

Abrasion Resistance Testing: This evaluates the inflator’s ability to resist wear and tear from environmental factors, ensuring longevity and reliability.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, it is crucial to ensure that suppliers maintain rigorous quality control practices. Buyers can take several steps to verify this:

Audits: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s processes and adherence to quality standards. This can include reviewing their quality management system and observing their QC practices in action.

Qualitätsberichte: Requesting quality assurance reports and testing documentation can help buyers understand the supplier’s commitment to quality. This documentation should detail testing methodologies, results, and compliance with relevant standards.

Inspektionen durch Dritte: Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can perform checks at various stages of production, providing unbiased evaluations of product quality.

International B2B buyers should be aware of specific nuances in quality control that may differ across regions. For instance, regulatory requirements and standards may vary significantly between Europe and Africa, requiring buyers to ensure that suppliers are compliant with local laws. Additionally, cultural differences in business practices can impact communication and expectations regarding quality.

Buyers should also consider the logistics of shipping and handling, as products that meet quality standards may still be vulnerable to damage during transport. Ensuring that suppliers implement protective packaging and handling practices can help maintain product integrity upon arrival.

By understanding the manufacturing processes and quality assurance practices for semi truck tire inflators, B2B buyers can make informed purchasing decisions, ensuring they select reliable products that meet their operational needs.

Illustrative image related to semi truck tire inflator

To assist B2B buyers in procuring semi truck tire inflators, this practical sourcing guide provides a step-by-step checklist. This resource aims to streamline the purchasing process and ensure that you acquire reliable and effective tire inflation solutions tailored to your operational needs.

Understanding your specific requirements is paramount. Consider the types of tires you’ll be inflating and the environment in which the inflators will be used. Look for specifications such as hose length, maximum pressure ratings, and compatibility with your truck’s onboard air supply, as these factors can significantly impact performance in different settings.

Conduct thorough research to identify reputable suppliers in the market. Look for companies that specialize in commercial vehicle equipment and have a strong track record. Examine their customer reviews, industry reputation, and product offerings to ensure they meet your expectations for quality and reliability.

When assessing potential inflators, focus on essential features that enhance usability and performance. For instance, check if the inflator includes a glad-hand attachment for easy connection to your truck’s air system. Also, consider the material of the hoses; durable, flexible materials that withstand extreme temperatures and resist kinking are preferable for long-term use.

Ensure that the suppliers you are considering have the necessary certifications that align with international standards. Certifications indicate compliance with safety and quality regulations, which can be particularly important in regions with strict automotive regulations, such as Europe and South America. Request documentation to confirm their adherence to these standards.

Before making a bulk purchase, consider requesting samples or demonstrations of the inflators. This allows you to evaluate the quality and functionality firsthand. Pay attention to ease of use, performance under pressure, and overall build quality, which can be critical for ensuring that the inflators meet your operational needs.

Evaluate the after-sales support offered by potential suppliers. Reliable customer service can be crucial, especially if issues arise post-purchase. Additionally, inquire about warranty terms; a strong warranty can provide peace of mind and protect your investment, especially when dealing with heavy-duty equipment.

Once you have identified a suitable supplier, engage in negotiations to secure the best pricing and terms. Discuss bulk purchase discounts, payment options, and shipping logistics. A well-negotiated deal can lead to significant cost savings and ensure that you receive the best value for your investment.

By following this checklist, B2B buyers can make informed decisions when sourcing semi truck tire inflators, ensuring they select reliable products that enhance operational efficiency.

When evaluating the costs associated with sourcing semi truck tire inflators, several key components must be considered:

Materialien: The primary materials used in tire inflators, such as hoses, air chucks, and fittings, significantly influence cost. High-quality materials, such as flexible hybrid polymers, enhance durability and performance but may raise the price.

Arbeit: Labor costs vary based on the region and expertise required for manufacturing. Regions with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

Fertigungsgemeinkosten: This includes expenses related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, leading to more competitive pricing.

Werkzeugbau: The initial investment in tooling and equipment for production can impact pricing. Customization or unique specifications often require specialized tooling, which can increase costs.

Qualitätskontrolle (QC): Robust QC processes ensure product reliability and compliance with industry standards. While these processes may increase costs, they are essential for minimizing defects and returns.

Logistik: Transportation costs can vary widely based on the distance from the supplier to the buyer, shipping methods, and import/export tariffs. International buyers must consider these logistics when calculating total costs.

Marge: Suppliers typically add a markup to cover their operational costs and desired profit margin. Understanding the market landscape can help buyers gauge whether the proposed margins are reasonable.

Several factors can influence the pricing structure for semi truck tire inflators:

Volumen/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for higher Minimum Order Quantities (MOQs), making it advantageous for buyers to negotiate favorable terms.

Spezifikationen und Anpassungen: Custom features, such as specialized air chucks or enhanced hose lengths, can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materialqualität und Zertifizierungen: Higher quality materials that meet industry certifications typically command higher prices. Buyers should assess the importance of certifications such as ISO or CE in their purchasing decisions.

Lieferanten-Faktoren: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge a premium, but this often translates to better quality and service.

Incoterms: The chosen Incoterms (International Commercial Terms) can affect total costs by determining who is responsible for shipping, insurance, and tariffs. Understanding these terms is crucial for international buyers to avoid unexpected expenses.

Hebelwirkung auf die Gesamtbetriebskosten (TCO): Buyers should consider TCO rather than just upfront costs. Evaluating long-term performance and maintenance can reveal that higher initial costs may lead to lower overall expenses.

Be Informed About Market Rates: Conducting market research to understand typical pricing for semi truck tire inflators can empower buyers during negotiations.

Consider Multi-Year Contracts: Committing to long-term agreements can provide leverage for more favorable pricing and terms, reducing volatility in costs.

Establish Relationships: Building strong relationships with suppliers can lead to better pricing, improved service, and priority during inventory shortages.

Factor in Currency Fluctuations: For international buyers, understanding the impact of currency fluctuations on costs is vital. Hedging strategies or negotiating in stable currencies can mitigate risks.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should approach sourcing semi truck tire inflators with a comprehensive understanding of cost structures and pricing influencers. By focusing on key components like materials, labor, and logistics, alongside effective negotiation strategies, buyers can optimize their purchasing process and secure the best deals. Always remember that indicative prices may vary based on market conditions, supplier negotiations, and specific requirements.

In the realm of tire maintenance for semi trucks, selecting the right inflating solution is crucial for operational efficiency and safety. While semi truck tire inflators are popular for their functionality, several alternative methods and tools can also effectively maintain tire pressure. This section explores these alternatives, enabling B2B buyers to make informed decisions based on their specific needs and circumstances.

Illustrative image related to semi truck tire inflator

| Vergleich Aspekt | Semi Truck Tire Inflator | Tragbarer Reifenfüller | Glad Hand Hose Kit |

|---|---|---|---|

| Leistung | High PSI capacity, fast inflation | Limited PSI, slower inflation | High PSI, quick inflation |

| Kosten | Moderate to high (typically $30-$100) | Low to moderate (around $30-$120) | Moderate (typically $25-$50) |

| Leichte Implementierung | Simple setup, requires power source | Portable, easy to use | Requires connection to truck’s air system |

| Wartung | Low maintenance, durable | Varies by model, may require battery replacement | Low, generally durable |

| Bester Anwendungsfall | Regular tire maintenance on-site | Emergency situations, portable use | Routine tire checks, long-haul routes |

Portable tire inflators are compact devices that can be used to inflate tires on-the-go. While these devices are highly convenient due to their size and portability, they often have limitations in terms of performance. Most portable inflators can only achieve a maximum pressure of around 120 PSI, making them unsuitable for the high demands of semi truck tires, which typically require 90-110 PSI. Additionally, the inflation process can be slow, taking significantly longer to fill a semi tire compared to a dedicated inflator. However, they are ideal for emergency situations where immediate inflation is necessary, especially for smaller vehicles or when a power source is not available.

Glad hand hose kits are designed to utilize a truck’s onboard air supply, allowing for fast and efficient tire inflation. These kits often come with a long hose and various attachments, enabling users to reach all tires easily, even in remote areas. The high PSI capability (up to 300 PSI) ensures that tires can be inflated quickly and effectively. However, these kits require a truck’s air system, which may not be available in all situations, such as when the truck is not running. Additionally, while the initial investment is relatively low, the need for regular checks and maintenance of the air system is a consideration.

When selecting a tire inflation solution, B2B buyers should assess their operational needs, budget, and frequency of tire maintenance. For companies that prioritize rapid tire inflation and have consistent access to their trucks, a semi truck tire inflator or glad hand hose kit may be the best choice. Conversely, for businesses that require a portable solution for emergency situations, a portable tire inflator could be more suitable despite its limitations in performance. Ultimately, the decision should align with the company’s operational strategies, maintenance schedules, and the specific challenges faced in their geographic regions. By carefully evaluating these factors, buyers can choose the most effective and efficient tire inflation solution for their fleet.

Understanding the technical specifications of semi truck tire inflators is essential for B2B buyers, especially when ensuring compatibility and reliability in various operating conditions. Here are the critical properties to consider:

Illustrative image related to semi truck tire inflator

Materialzusammensetzung

Most tire inflators utilize specialized hoses made from flexible polymer blends or rubber. For example, the Flexzilla inflator employs a Flexible Hybrid Polymer that remains pliable in extreme temperatures (-40°F to 140°F). This flexibility is crucial for ease of use in various climates and ensures longevity against wear and tear, making it a smart investment for fleet operators.

Maximum Working Pressure (MWP)

The MWP is a vital specification indicating the highest pressure the inflator can withstand. Typical MWPs for semi truck tire inflators range from 300 to 400 psi. This specification is crucial for ensuring that the inflator can effectively operate under the high-pressure demands of truck tires, which can require significant air volume to inflate, especially when they are deflated.

Hose Length and Diameter

Hose length and diameter directly impact the inflator’s efficiency and usability. A common size for semi truck tire inflators is a 3/8″ diameter with lengths up to 50 feet. Longer hoses allow for greater reach, enabling users to inflate tires on trailers without repositioning the truck. A larger diameter also facilitates quicker air flow, reducing the time required to inflate tires.

Operating Temperature Range

The ability of a tire inflator to function across a wide temperature range is crucial for international buyers who may operate in diverse climates. Equipment that can withstand extreme conditions ensures reliability and reduces the risk of failure, thereby enhancing operational efficiency and safety.

Gewicht und Tragbarkeit

The weight of an inflator can affect its portability and ease of use. Lightweight models are easier to handle and transport, making them preferable for truck drivers who often need to use them in various locations. This aspect is particularly important for businesses looking to maintain operational flexibility.

Familiarity with trade terminology can facilitate smoother transactions and negotiations. Here are some essential terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For tire inflators, knowing whether a product is OEM can indicate quality assurance and compatibility with existing truck systems.

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to gauge inventory needs and manage cash flow effectively, particularly when dealing with bulk purchases.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing, availability, and terms for a specified product or service. For B2B buyers, submitting an RFQ can streamline the procurement process, ensuring they receive competitive offers tailored to their specifications.

Incoterms (Internationale Handelsklauseln)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms is critical for buyers to navigate shipping costs, insurance, and liability effectively.

PPE (Personal Protective Equipment)

In the context of tire inflation, PPE refers to safety gear that operators should wear while inflating tires. Knowledge of PPE requirements can help businesses ensure compliance with safety regulations and protect their workforce.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting semi truck tire inflators that meet their operational needs and comply with industry standards.

The semi truck tire inflator market is influenced by several global drivers, including the increasing demand for efficient logistics and freight transportation. As international trade expands, the need for reliable and durable tire inflation solutions has become paramount, especially in regions such as Africa, South America, the Middle East, and Europe. One notable trend is the rise of advanced tire inflators that utilize onboard air supplies and technology to improve efficiency. This shift is largely driven by the need for quick response times in remote locations, where traditional inflation methods may be inadequate.

B2B buyers are increasingly seeking products that offer enhanced durability and flexibility, particularly in extreme weather conditions. Innovations such as lightweight hoses made from hybrid polymers, which resist kinking and maintain functionality across varying temperatures, are gaining traction. Furthermore, there is a growing emphasis on user-friendly designs that facilitate easy handling, which is crucial for operators who may need to address tire issues quickly while on the road.

Emerging technologies, such as digital pressure gauges and automatic inflation systems, are also reshaping the sector. These advancements not only streamline the inflation process but also enhance safety by ensuring tires are maintained at optimal pressure levels. For international buyers, particularly in developing markets, understanding these trends can help inform sourcing decisions that align with their operational needs and budget constraints.

The environmental impact of manufacturing and distributing semi truck tire inflators is becoming an increasingly important consideration for B2B buyers. Companies are under pressure to adopt sustainable practices, and this extends to the sourcing of tire inflators. Ethical supply chains are crucial in minimizing carbon footprints and ensuring responsible production methods. Buyers are now looking for suppliers that prioritize sustainability, which includes using recycled materials and reducing waste in their manufacturing processes.

Moreover, certifications such as ISO 14001 for environmental management systems are becoming essential in supplier assessments. These certifications provide assurance that the manufacturers adhere to environmentally friendly practices. As global supply chains become more scrutinized, buyers from regions like Europe and the Middle East are particularly focused on sourcing products that meet stringent environmental standards.

In addition to sustainability, there is a rising demand for products made from ‘green’ materials that do not compromise on performance. B2B buyers are increasingly inclined to partner with manufacturers who invest in research and development to create eco-friendly alternatives without sacrificing quality or durability. This shift not only addresses environmental concerns but also enhances brand reputation, making ethical sourcing a vital aspect of procurement strategies in the tire inflator sector.

The semi truck tire inflator market has evolved significantly over the past few decades. Initially, inflators were rudimentary devices that required manual operation and were often cumbersome to use. However, as the trucking industry grew and technology advanced, so did the designs and functionalities of tire inflators. The introduction of pneumatic systems and onboard air supply capabilities revolutionized the market, allowing operators to inflate tires quickly and efficiently.

In recent years, the focus has shifted towards creating more user-friendly and durable products, with innovations aimed at improving flexibility and operational efficiency. The integration of digital technology has further transformed the landscape, allowing for precise inflation and monitoring of tire pressure, which is critical for safety and efficiency in logistics. Understanding this evolution provides B2B buyers with insights into product development trends and the importance of investing in advanced tire inflation solutions that meet contemporary demands.

Illustrative image related to semi truck tire inflator

1. How do I choose the right semi truck tire inflator for my fleet?

Selecting the right semi truck tire inflator involves considering several factors. First, evaluate the inflator’s maximum pressure and hose length; a unit with a working pressure of at least 300 PSI and a 50-foot hose is ideal for reaching all tire locations. Look for features like a glad-hand attachment that connects to the truck’s air supply for convenience in remote areas. Additionally, ensure the material is durable and flexible to withstand various weather conditions, as this will affect usability in different climates, especially in regions like Africa and South America.

2. What are the key features to look for in a semi truck tire inflator?

When sourcing a semi truck tire inflator, prioritize features such as maximum working pressure, hose length, and attachment types. A good inflator should offer a minimum of 300 PSI and a hose length of 50 feet to reach all tires effectively. Look for durable materials that can handle extreme temperatures, as well as flexibility to avoid kinking. An easy-to-use dual-angle air chuck is also beneficial for efficient inflation. Lastly, consider if the inflator is compatible with your truck’s onboard air system to enhance convenience.

3. What is the typical lead time for ordering semi truck tire inflators internationally?

Lead times for international orders of semi truck tire inflators can vary significantly based on the supplier’s location, production capacity, and shipping logistics. Generally, you can expect a lead time of 4 to 12 weeks, which includes manufacturing, quality assurance, and shipping. To minimize delays, communicate clearly with suppliers about your needs and deadlines. Establishing a reliable relationship with your supplier can also lead to faster turnaround times for future orders.

4. How can I vet suppliers for semi truck tire inflators?

Vetting suppliers for semi truck tire inflators requires a systematic approach. Start by researching their business history, customer reviews, and industry reputation. Request product samples to assess quality firsthand. It’s also beneficial to inquire about their manufacturing processes, certifications, and compliance with international standards. Establish communication to gauge responsiveness and customer service. Finally, consider visiting their facility if possible, or request references from other clients, especially those in your region.

5. What are the minimum order quantities (MOQ) for semi truck tire inflators?

Minimum order quantities (MOQ) for semi truck tire inflators can vary widely among suppliers, typically ranging from 50 to 500 units. Factors influencing MOQ include production capacity, the complexity of the product, and the supplier’s operational costs. If you’re a smaller buyer, discuss your needs with potential suppliers; some may be willing to negotiate on MOQ, especially if you can demonstrate a reliable purchasing plan or if you’re entering a new market.

6. Can I customize semi truck tire inflators for my brand?

Yes, many manufacturers offer customization options for semi truck tire inflators. Customization can include branding (such as your logo), color choices, and specific features tailored to your fleet’s requirements. When discussing customization with suppliers, be clear about your specifications and the intended use of the inflators. Keep in mind that custom products may have higher MOQs and longer lead times, so plan accordingly to meet your business needs.

7. What payment terms should I expect when purchasing semi truck tire inflators?

Payment terms for semi truck tire inflators often vary by supplier and region. Common terms include a deposit of 30-50% upfront, with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within 30 to 90 days after receipt. It’s essential to discuss and agree on payment terms upfront to avoid any misunderstandings. Additionally, consider using secure payment methods to protect your transaction, especially for international orders.

8. How do I ensure quality assurance for my semi truck tire inflators?

To ensure quality assurance for semi truck tire inflators, establish clear quality control standards with your supplier before production. Request detailed specifications and quality testing protocols. Consider conducting inspections at the manufacturer’s facility, or utilize third-party inspection services to verify product quality before shipment. Additionally, ensure that the products comply with relevant international standards and certifications. After receiving the inflators, perform your own quality checks to confirm they meet your expectations.

Illustrative image related to semi truck tire inflator

Bereich: shop.aperiatech.com

Registriert: 2010 (15 Jahre)

Einleitung: Product Name: Halo Tire Inflator

Price: $770.00

Discount: Limited Time Offer! 22% Off with code “22” at checkout

Wesentliche Merkmale:

– Only Tire Management Platform for all wheel positions

– Extends tire life, improves fuel economy, maximizes uptime, enhances safety

– Each kit includes all Halos, brackets, and necessary hoses for full vehicle installation

– Each Halo arrives pre-set to fleet’s target c…

Bereich: myteeproducts.com

Registriert: 2003 (22 Jahre)

Einleitung: {“product_name”: “Truck Tire Inflation Kit 3/8″ ID w/ Air Chuck & Gladhand”, “SKU”: “MP-TTIK”, “regular_price”: “$31.99”, “special_price”: “$27.09”, “discount”: “15% Off”, “features”: [“3/8″ x 50′ Hose”, “Glad Hand Attachment”, “30° Dual Air Chuck”], “maximum_working_pressure”: “300 lbs per Square Inch”, “weight”: “5.75 lbs”, “color”: “Orange”, “availability”: “In stock”, “shipping_info”: “Eligibl…

Bereich: thetruckersreport.com

Registriert: 2003 (22 Jahre)

Einleitung: AstroAI Cordless Tire Inflator Air Compressor 20V Rechargeable Battery Powered 160PSI Portable Handheld Air Pump with 12V Car Power Adapter Digital Pressure Gauge for Cars Motorcycles.

In the evolving landscape of logistics and transportation, the strategic sourcing of semi truck tire inflators emerges as a critical component for ensuring operational efficiency and safety. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, investing in high-quality inflators can enhance fleet performance while minimizing downtime due to tire-related issues. The integration of advanced features, such as durable hoses and high-pressure capabilities, allows for effective tire maintenance even in remote locations.

Moreover, leveraging the on-board air supply of trucks through universally compatible attachments can significantly streamline the inflating process, making it more accessible during long hauls. As supply chains become increasingly globalized, the demand for reliable and efficient tire inflators will continue to rise, presenting an opportunity for buyers to source innovative solutions that meet their unique operational challenges.

As we look ahead, it is essential for businesses to prioritize strategic partnerships with reputable suppliers who understand the complexities of the industry. By doing so, B2B buyers can ensure they are equipped with the best tools to keep their fleets running smoothly. Now is the time to explore and invest in tire inflators that will not only meet current needs but also adapt to the future demands of transportation.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.