In the ever-evolving landscape of global commerce, sourcing quality up tires poses a significant challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With diverse applications ranging from agricultural machinery to commercial vehicles, the demand for reliable and durable tires is paramount. This guide aims to equip international buyers with the knowledge needed to navigate the complexities of the up tire market, ensuring that they make informed purchasing decisions that align with their operational needs.

Throughout this comprehensive resource, we will delve into various types of up tires, their specific applications, and the critical factors to consider when vetting suppliers. We will also explore cost considerations, helping buyers understand pricing structures and potential hidden costs that can impact their bottom line. By addressing these key aspects, this guide empowers B2B buyers to confidently engage with suppliers, negotiate effectively, and ultimately enhance their procurement strategies.

As you navigate this guide, expect actionable insights tailored to the unique challenges faced by businesses in emerging markets. From selecting the right tire for diverse terrains to establishing long-term supplier relationships, we provide a roadmap to success in the global up tire market, ensuring that your operations remain efficient and profitable.

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Agricultural Tires | Deep treads for traction, larger sidewalls | Farming equipment, tractors, harvesters | Vorteile: Excellent grip on soft terrain; durable. Nachteile: Higher initial cost; limited versatility. |

| Commercial Vehicle Tires | Reinforced sidewalls, designed for heavy loads | Trucks, buses, delivery vehicles | Vorteile: Enhanced load capacity; longevity. Nachteile: Heavier; may reduce fuel efficiency. |

| Light Truck Tires | Versatile tread patterns, designed for comfort | SUVs, light trucks | Vorteile: Good on-road performance; comfortable ride. Nachteile: May wear faster under heavy loads. |

| Passenger Car Tires | Smooth tread patterns, designed for road grip | Sedans, hatchbacks | Vorteile: Quieter ride; better fuel efficiency. Nachteile: Less traction in off-road conditions. |

| Recreational Vehicle Tires | Specialized for off-road and varied terrains | RVs, trailers, ATVs | Vorteile: All-terrain capability; rugged design. Nachteile: Can be expensive; may compromise on-road handling. |

Agricultural tires are specifically designed to provide optimal traction on soft, uneven terrain often found in farming environments. Their deep treads and larger sidewalls help prevent soil compaction while providing stability for heavy machinery like tractors and harvesters. When purchasing agricultural tires, B2B buyers should consider the specific soil conditions and types of crops, as well as the tire’s durability against wear from constant use. Investing in high-quality agricultural tires can significantly impact operational efficiency.

Commercial vehicle tires are engineered with reinforced sidewalls to support heavy loads, making them ideal for trucks, buses, and delivery vehicles. They typically feature a more robust tread design to enhance grip and durability on highways and urban roads. B2B buyers should evaluate the load index and tread wear characteristics when selecting these tires, as they directly affect operational costs and vehicle performance. While they offer longevity and strength, they may also add weight, potentially affecting fuel efficiency.

Light truck tires are known for their versatility, featuring tread patterns that balance on-road comfort with off-road capability. They are suitable for SUVs and light trucks that encounter a mix of terrain. When selecting light truck tires, B2B buyers should consider the vehicle’s primary use, load requirements, and desired comfort level. While these tires provide a smooth ride, they may wear out more quickly under heavy loads, making it essential to match the tire choice to the vehicle’s usage.

Passenger car tires prioritize smooth tread patterns for enhanced road grip and fuel efficiency, making them suitable for sedans and hatchbacks. They are designed to provide a quieter ride and improved handling on paved roads. B2B buyers should focus on the tire’s performance ratings, tread life, and warranty when making a selection. While they excel in urban environments, passenger car tires may lack the traction needed for off-road conditions, which could limit their versatility.

Recreational vehicle tires are tailored for diverse terrains, offering robust designs to handle off-road conditions encountered by RVs, trailers, and ATVs. Their rugged tread patterns provide superior traction and stability, making them ideal for adventurous applications. B2B buyers should assess the terrain types and frequency of use when choosing recreational vehicle tires. While these tires are designed for all-terrain capability, they can be pricier and may compromise on-road handling, necessitating a careful balance between performance and cost.

| Industrie/Sektor | Specific Application of up tire | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Landwirtschaft | Agricultural Equipment Tires | Enhanced productivity and reduced downtime due to tire failure. | Durability, load capacity, and compatibility with various equipment. |

| Transport und Logistik | Commercial Vehicle Tires | Improved safety and efficiency in freight transport. | Tire performance under load, lifespan, and availability of mobile services. |

| Bauwesen | Heavy Machinery Tires | Increased operational efficiency and reduced equipment downtime. | Tire specifications for load-bearing capacity and terrain adaptability. |

| Automotive Services | Passenger and Light Truck Tires | Reliable performance and safety for consumer vehicles. | Quality assurance, warranty options, and local availability of service. |

| Recreational Vehicles | Tires for RVs and Off-Road Vehicles | Enhanced safety and performance on diverse terrains. | Tire tread design, weather resistance, and size compatibility. |

Agricultural equipment tires are crucial in farming operations, where they support heavy machinery like tractors and harvesters. These tires are designed for durability and traction on various terrains, enhancing productivity and minimizing downtime due to tire failures. For international buyers, especially in regions such as Africa and South America, sourcing tires that can withstand diverse soil conditions and heavy loads is critical. Buyers should prioritize suppliers that offer robust tires with extended warranties and local support to ensure quick replacements.

In the transportation and logistics sector, commercial vehicle tires are essential for ensuring the safety and efficiency of freight transport. These tires are designed to handle heavy loads and provide optimal performance over long distances. For B2B buyers in the Middle East and Europe, considerations such as tire tread patterns for fuel efficiency, longevity, and the availability of mobile repair services are vital. Businesses should seek suppliers that can guarantee timely delivery and support, minimizing the risk of operational disruptions.

Illustrative image related to up tire

Heavy machinery tires are integral to construction projects, where they support equipment like excavators and loaders. These tires must withstand harsh working conditions and heavy loads, contributing to increased operational efficiency. For international buyers, particularly in developing regions, sourcing tires that are adaptable to various terrains and that comply with local safety standards is essential. Buyers should focus on suppliers who offer specialized tires tailored to specific machinery and provide comprehensive service options.

In the automotive sector, passenger and light truck tires are vital for ensuring vehicle safety and performance. These tires need to meet specific standards for grip and durability, especially in diverse weather conditions. For B2B buyers in Europe and Africa, sourcing high-quality tires from reputable manufacturers is crucial to maintain customer satisfaction and safety. Buyers should consider factors such as warranty terms, tire technology, and the ability to access after-sales services to ensure reliability.

Tires for recreational vehicles (RVs) and off-road vehicles are designed to enhance safety and performance across various terrains. They must provide excellent traction and durability for activities like camping and off-roading. For buyers in regions like South America and the Middle East, understanding the specific tire specifications required for different recreational activities is essential. Buyers should prioritize suppliers that offer a range of tire options suited for different weather conditions and terrains, along with robust customer support for maintenance and repairs.

Das Problem: B2B buyers managing diverse fleets often struggle to source high-quality tires that meet the specific needs of various vehicles, such as agricultural machinery, commercial trucks, and light passenger vehicles. This can lead to downtime, increased operational costs, and safety risks. Many suppliers may offer a limited selection or fail to provide the necessary specifications, making it challenging for businesses to ensure that they are using the right tires for each vehicle type.

Die Lösung: To effectively source tires for diverse fleet needs, B2B buyers should partner with suppliers that offer a comprehensive inventory and expertise in tire selection. Engage with suppliers like U.P. Tire, which has a robust range of products tailored to different vehicles. Utilize their experienced staff to discuss specific requirements, such as load ratings, tread patterns, and seasonal performance. Additionally, consider creating a standardized tire selection guide for your fleet to streamline the purchasing process and ensure that all vehicles are equipped with the appropriate tires, minimizing risks associated with improper tire usage.

Das Problem: Unexpected tire failures can disrupt business operations and lead to costly downtime. B2B buyers may find themselves in a crisis when a critical vehicle is out of commission due to tire issues, especially if they lack a reliable repair service or quick access to replacement tires. This situation is particularly challenging in remote areas where tire service options are limited.

Die Lösung: Implementing a proactive tire maintenance strategy is crucial for mitigating unexpected failures. Establish a relationship with a tire service provider that offers mobile repair services, such as U.P. Tire’s mobile service, which can reach customers in remote locations. Schedule regular inspections and maintenance checks to identify potential issues before they lead to failures. Additionally, maintain an inventory of essential tire types that are commonly used within your fleet, enabling swift replacement when needed. This approach not only reduces downtime but also enhances overall fleet reliability.

Das Problem: B2B buyers often face confusion regarding tire specifications and the regulatory compliance requirements for different regions, particularly when operating in international markets. Misunderstanding these requirements can result in legal issues, safety concerns, and financial penalties. Buyers may struggle to interpret load ratings, speed ratings, and environmental regulations affecting tire selection.

Die Lösung: To navigate the complexities of tire specifications and compliance, B2B buyers should invest in education and resources that clarify these aspects. Collaborate with knowledgeable suppliers who can provide detailed information about tire specifications relevant to your business needs. Attend industry seminars or workshops that focus on tire regulations and best practices for different regions, especially if operating across continents like Africa, South America, and Europe. Create a checklist of compliance requirements specific to each market your business operates in and review this regularly with your tire supplier to ensure ongoing adherence to regulations. By being well-informed, buyers can make more confident purchasing decisions and maintain compliance, ultimately safeguarding their operations.

When selecting materials for up tire manufacturing, it is essential to consider properties that directly impact performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the production of up tires, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to up tire

Rubber Compounds are the primary material used in tire manufacturing, providing flexibility, traction, and durability.

Steel Belts are commonly used in tire construction to enhance strength and stability.

Synthetic Fibers, such as polyester and nylon, are often used in tire construction to provide flexibility and strength.

Natural Rubber is another material option, known for its elasticity and resilience.

| Material | Typical Use Case for up tire | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Rubber Compounds | General tire manufacturing | Hohe Haltbarkeit und Flexibilität | High production costs | Hoch |

| Steel Belts | Heavy-duty and commercial tires | Excellent strength and puncture resistance | Adds weight, complex manufacturing | Mittel |

| Synthetic Fibers | Passenger and light truck tires | Lightweight, improves fuel efficiency | Weniger haltbar unter extremen Bedingungen | Mittel |

| Natural Rubber | High-performance tires | Superior grip and comfort | Susceptible to environmental degradation | Mittel |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, enabling informed decisions that align with performance requirements and compliance standards.

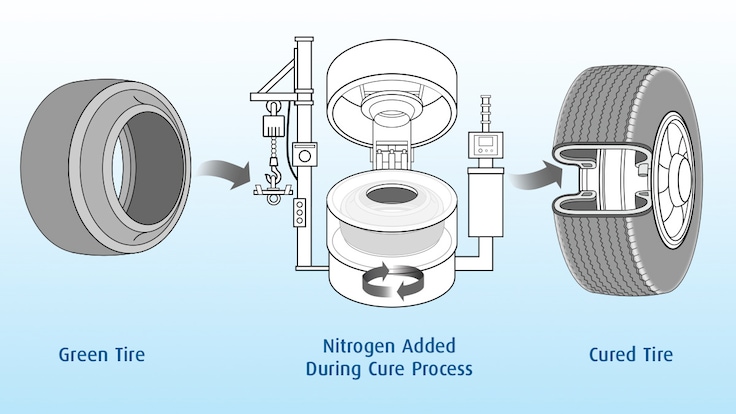

The manufacturing process for up tires involves several key stages that ensure the final product meets both quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

The manufacturing journey begins with the selection and preparation of raw materials. The primary components of up tires typically include natural rubber, synthetic rubber, reinforcing fabrics, and steel belts. Each material is sourced from suppliers who meet international standards for quality. During this stage, materials undergo rigorous testing for consistency and performance characteristics.

Once the materials are prepared, they enter the forming stage. This is where the rubber compounds are mixed to achieve the desired properties. The mixing process involves precision to ensure that the right proportions of chemicals and additives are used. After mixing, the rubber is shaped into various components like treads, sidewalls, and inner linings using advanced machinery such as calenders and extruders.

The assembly stage is where the various components come together. This typically involves layering the inner linings, steel belts, and tread materials. Advanced techniques such as vulcanization are employed here, which involves heating the assembled tire to bond the components chemically. This stage is critical as it determines the structural integrity and performance of the tire.

The final stage, finishing, involves the inspection and testing of the tires before they are packaged for distribution. This includes surface finishing to enhance appearance and provide protective coatings. Additionally, tires are marked with relevant certifications and branding.

Quality assurance in tire manufacturing is paramount, especially for B2B buyers operating in international markets. The most recognized standard is ISO 9001, which provides a framework for quality management systems. Compliance with this standard indicates that a manufacturer is committed to continuous improvement and customer satisfaction.

Illustrative image related to up tire

In addition to ISO 9001, up tires may require industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for applications involving heavy machinery. These certifications assure buyers that the tires meet stringent safety and performance criteria.

Quality control (QC) checkpoints are critical throughout the manufacturing process to ensure that tires meet the established standards. Key checkpoints include:

To maintain high-quality standards, several testing methods are employed during the manufacturing process. Common tests include:

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are several strategies:

Illustrative image related to up tire

B2B buyers from regions like Africa, South America, the Middle East, and Europe must consider regional regulations and standards that may differ from those in their home countries. Understanding these nuances is essential for compliance and quality assurance.

By taking a comprehensive approach to understanding manufacturing processes and quality assurance, B2B buyers can make informed decisions that align with their operational needs and market requirements. This diligence not only ensures product quality but also builds strong partnerships with tire manufacturers committed to excellence.

To assist B2B buyers in procuring ‘up tire,’ this practical sourcing guide provides a structured checklist designed to streamline the procurement process. By following these steps, you can ensure that you select the right tire supplier for your specific needs while maximizing value and minimizing risk.

Before reaching out to suppliers, clearly outline the technical specifications of the tires you require. This includes size, tread type, load capacity, and intended use (e.g., passenger vehicles, agricultural equipment, or commercial trucks). Having a precise understanding of your requirements will help you communicate effectively with potential suppliers and avoid purchasing unsuitable products.

Conduct thorough market research to compile a list of potential suppliers. Utilize online resources, industry directories, and trade shows to find reputable manufacturers and distributors. Pay attention to suppliers that specialize in the type of tires you need, as this specialization often correlates with higher quality products and better service.

Before making a decision, vet potential suppliers to ensure they meet industry standards and regulations. Look for certifications (e.g., ISO, DOT) that indicate compliance with safety and quality benchmarks. Additionally, check customer reviews and testimonials to gauge their reputation in the market, focusing on their reliability and service quality.

Once you have narrowed down your options, request detailed quotations from shortlisted suppliers. This should include pricing, payment terms, lead times, and shipping options. Compare the quotations not just on price but also on the value offered, such as warranty terms, after-sales support, and delivery timelines.

Quality assurance is critical in tire procurement, as it directly impacts safety and performance. Inquire about the supplier’s quality control measures and testing procedures. A reputable supplier will be transparent about how they ensure the consistency and reliability of their products, which is essential for minimizing defects and enhancing longevity.

Once you have selected a preferred supplier, engage in negotiations to finalize the terms and conditions. This includes pricing, delivery schedules, and return policies. Be clear about your expectations and do not hesitate to negotiate for better terms that align with your budget and operational needs.

After finalizing your order, establish a clear communication plan with the supplier. This should include regular updates on order status, delivery timelines, and any potential issues that may arise. A proactive communication approach fosters a strong relationship and ensures transparency, which is vital for ongoing procurement needs.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing ‘up tire,’ ensuring they make informed decisions that support their business objectives.

When sourcing ‘up tire’ products, understanding the cost structure is crucial for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

Materialien: The quality and type of materials used significantly affect the overall cost. For instance, premium rubber compounds or specialized materials for agricultural and commercial vehicle tires will incur higher expenses but can enhance performance and durability.

Arbeit: Labor costs encompass wages for skilled technicians involved in tire manufacturing, assembly, and repair. In regions with higher wage standards, such as parts of Europe, labor costs can be a substantial part of the total expense.

Fertigungsgemeinkosten: This includes utilities, facility costs, and indirect labor. Efficient manufacturing processes can lower overhead costs, impacting the final price.

Werkzeugbau: Investment in advanced machinery and tools for tire production can lead to increased initial costs. However, these investments can result in long-term savings through improved efficiency and reduced waste.

Qualitätskontrolle (QC): Implementing rigorous QC measures ensures product reliability but can add to costs. Buyers should weigh the importance of certifications and quality assurance against potential savings from lower-quality products.

Logistik: Shipping costs, including freight and handling, are critical, particularly for international transactions. Buyers must consider the total logistics expenses, which can vary widely based on the destination and shipping terms.

Marge: Suppliers typically add a markup to cover their costs and profit. Understanding the margin expectations of suppliers can aid in negotiations.

Several factors influence the pricing of ‘up tire’ products:

Volumen/MOQ (Mindestbestellmenge): Larger orders often qualify for discounts, impacting the unit price. Buyers should assess their inventory needs to optimize order sizes.

Spezifikationen und Anpassungen: Custom tires tailored to specific applications will generally cost more due to additional design and manufacturing processes. Clear communication of requirements is essential for accurate pricing.

Materialien: As mentioned, the choice of materials can drastically change costs. Opting for innovative or eco-friendly materials may offer long-term benefits despite higher upfront costs.

Qualität und Zertifizierungen: Tires that meet stringent international standards (like ISO or DOT certifications) may carry higher price tags. However, these certifications often correlate with better performance and safety, justifying the expense.

Lieferanten-Faktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service.

Incoterms: The terms of shipment (e.g., FOB, CIF) play a significant role in the total cost. Buyers should understand the implications of each term to avoid unexpected charges.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost efficiency:

Verhandlung: Engage suppliers in discussions about pricing, especially if you can commit to larger orders or longer-term partnerships. Leverage competitive quotes from multiple suppliers to strengthen your position.

Gesamtbetriebskosten (TCO): Consider not just the purchase price but the entire lifecycle cost of the tires, including installation, maintenance, and potential downtime. Investing in higher-quality tires may yield savings over time through reduced failure rates and maintenance costs.

Nuancen der Preisgestaltung verstehen: Be aware of regional pricing variations due to labor costs, tariffs, and import duties. Research local market conditions to better negotiate terms and pricing.

Evaluate Supplier Stability: Choose suppliers with a solid financial background and good customer reviews. This can prevent disruptions in supply that might lead to increased costs down the line.

In summary, a comprehensive understanding of cost components, price influencers, and strategic procurement practices is vital for B2B buyers in the ‘up tire’ market. By leveraging these insights, businesses can make informed decisions that align with their operational needs and financial goals.

Illustrative image related to up tire

In today’s competitive marketplace, B2B buyers often seek the best solutions to enhance their operations. When evaluating ‘Up Tire’, it’s essential to consider viable alternatives that can provide similar benefits. This analysis compares ‘Up Tire’ against other tire solutions, focusing on their performance, cost-effectiveness, ease of implementation, maintenance requirements, and best use cases.

| Vergleich Aspekt | ‘Up Tire’ | Alternative 1: Mobile Tire Services | Alternative 2: Tire Leasing Solutions |

|---|---|---|---|

| Leistung | High-quality tire sales and repairs | Quick response time; convenient | Flexible tire options; low commitment |

| Kosten | Competitive pricing | Often premium pricing | Monthly fees can add up |

| Leichte Implementierung | Simple appointment scheduling | Requires coordination for service | Contractual obligations may apply |

| Wartung | In-house service | Minimal maintenance required | Maintenance included |

| Bester Anwendungsfall | Local businesses needing reliability | Fleets requiring fast service | Companies with fluctuating needs |

Mobile tire services provide convenience by offering on-site tire repair and replacement. This solution is particularly beneficial for businesses with a fleet of vehicles that require minimal downtime. However, while these services can be quick and efficient, they often come at a premium price. Furthermore, coordinating schedules can be challenging, especially in high-demand situations.

Tire leasing solutions allow businesses to use tires without the upfront cost of purchase. This approach is advantageous for companies with fluctuating tire needs, as it offers flexibility and access to newer tire models. However, the costs can accumulate over time, and businesses may face contractual obligations that limit their options. Maintenance is typically included, which can alleviate some concerns about tire upkeep.

Illustrative image related to up tire

Selecting the right tire solution depends on your specific needs and operational context. For businesses prioritizing reliability and community support, ‘Up Tire’ offers a compelling value proposition with its extensive range of services and commitment to customer satisfaction. Conversely, if convenience and speed are paramount, mobile tire services may suit your requirements better. Lastly, for organizations needing flexibility and minimal initial investment, tire leasing could be the optimal choice. By carefully assessing these factors, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Understanding the technical properties of up tires is crucial for B2B buyers to make informed purchasing decisions. Here are some of the most critical specifications:

Material Klasse

– Definition: This refers to the quality and type of materials used in tire manufacturing, such as rubber compounds and steel belts.

– Bedeutung: Higher-grade materials typically enhance durability, traction, and performance. For businesses operating in diverse climates, investing in tires made from premium materials can lead to longer service life and reduced downtime.

Load Index

– Definition: This numerical code indicates the maximum load a tire can safely carry at a specified inflation pressure.

– Bedeutung: Understanding the load index is essential for businesses that rely on heavy vehicles or equipment. Selecting the correct load index ensures safety and compliance with industry regulations, preventing potential liability issues.

Tread Depth

– Definition: The depth of the grooves in the tire tread, usually measured in millimeters.

– Bedeutung: Adequate tread depth is vital for ensuring traction, especially in wet or off-road conditions. For B2B buyers, maintaining the right tread depth can lead to improved vehicle handling and safety, impacting overall operational efficiency.

Aspect Ratio

– Definition: This is the ratio of a tire’s height to its width, expressed as a percentage.

– Bedeutung: The aspect ratio affects the tire’s performance characteristics, including handling and ride comfort. Businesses must consider this when selecting tires for different types of vehicles to ensure optimal performance.

Speed Rating

– Definition: A letter designation indicating the maximum speed a tire can sustain under load.

– Bedeutung: For companies involved in logistics or transportation, understanding the speed rating can help in selecting tires that align with operational speed requirements, enhancing safety and performance.

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

OEM (Original Equipment Manufacturer)

– Definition: Refers to tires produced by the original manufacturer for a specific vehicle model.

– Relevanz: B2B buyers often seek OEM tires to ensure compatibility and maintain warranty coverage. Understanding this term helps buyers make informed choices about replacements.

MOQ (Mindestbestellmenge)

– Definition: The smallest quantity of goods a supplier is willing to sell.

– Relevanz: Knowing the MOQ is crucial for businesses looking to manage inventory costs effectively. It helps in planning purchases and negotiating with suppliers to ensure they meet operational needs without overstocking.

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a price quotation for specific products or services.

– Relevanz: Utilizing RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal. This process is essential for budget management in B2B transactions.

Incoterms (Internationale Handelsklauseln)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Relevanz: Understanding Incoterms is vital for businesses involved in cross-border trade. These terms clarify who bears the costs and risks during shipping, impacting pricing and logistics strategies.

Treadwear Warranty

– Definition: A guarantee from the manufacturer regarding the expected lifespan of the tire tread.

– Relevanz: For businesses, a treadwear warranty can be a significant factor in evaluating tire value. It reflects the manufacturer’s confidence in their product and can influence purchasing decisions based on projected costs over time.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement processes, ensuring they select the right up tires for their operational needs.

Illustrative image related to up tire

The global tire market is undergoing significant transformation, driven by various factors including technological advancements, changing consumer preferences, and sustainability demands. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed purchasing decisions. A notable trend is the integration of smart technology into tire manufacturing, enhancing performance, safety, and monitoring capabilities. The rise of telematics in fleet management allows for real-time tracking and predictive maintenance, minimizing downtime and optimizing operational efficiency.

Moreover, the demand for specialized tires, including those for electric vehicles (EVs) and heavy-duty machinery, is on the rise. As industries evolve, B2B buyers are increasingly seeking out suppliers who can offer tailored solutions that meet specific operational needs. Geopolitical factors, such as trade agreements and tariffs, also influence sourcing strategies, necessitating a keen awareness of regional market conditions. Buyers must stay informed about these trends to ensure they are sourcing tires that not only meet current demands but also anticipate future developments.

Sustainability is becoming a pivotal factor in the tire industry, with environmental impact and ethical sourcing gaining prominence among B2B buyers. As global awareness of climate change and resource depletion rises, companies are under pressure to adopt more sustainable practices. The tire manufacturing process is resource-intensive, often involving petroleum-based materials that can be harmful to the environment. Thus, suppliers who prioritize the use of eco-friendly materials and processes are increasingly favored.

B2B buyers are also recognizing the importance of ethical supply chains. This includes ensuring that raw materials are sourced responsibly and that labor practices comply with international standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can provide assurance of a supplier’s commitment to sustainability. By choosing partners who adhere to these standards, buyers not only contribute to environmental protection but also enhance their brand reputation and appeal to a growing base of environmentally-conscious consumers.

The up tire sector has evolved significantly over the decades, with its origins rooted in the late 19th century when the first rubber tires were developed. Early advancements focused primarily on improving durability and performance. Over the years, the industry has witnessed transformative changes driven by technological innovation, such as the introduction of radial tires in the 1940s, which revolutionized vehicle handling and fuel efficiency.

In recent years, the rise of digital technologies has further accelerated the evolution of the sector. From the use of computer-aided design (CAD) in tire development to the implementation of data analytics in supply chain management, these advancements have enhanced the efficiency and effectiveness of tire production and distribution. Understanding this historical context enables B2B buyers to appreciate the innovations that have shaped the current landscape and informs their decisions when sourcing tires in a rapidly changing market.

How do I solve tire supply chain issues in my region?

To address tire supply chain challenges, begin by identifying reliable suppliers with a proven track record in international shipping. Establish strong communication channels to monitor inventory levels and delivery schedules. Collaborating with local logistics firms can help navigate customs regulations and ensure timely deliveries. Additionally, consider diversifying your supplier base to mitigate risks associated with single-source dependencies. Regularly review market trends to anticipate demand fluctuations and adjust orders accordingly.

What is the best tire type for agricultural vehicles in varying climates?

When selecting tires for agricultural vehicles, consider the specific climate and soil conditions of your region. For wet or muddy conditions, opt for tires with deep treads for better traction. In contrast, for dry or rocky terrains, choose tires with reinforced sidewalls to withstand punctures. Additionally, consult with suppliers who offer customization options tailored to your agricultural needs. Quality brands known for durability and performance in challenging environments are essential for minimizing downtime and maximizing productivity.

What factors should I consider when vetting tire suppliers?

When vetting tire suppliers, assess their industry reputation and experience, particularly in your target market. Evaluate their product range and whether they meet international quality standards, such as ISO certifications. Investigate their logistics capabilities, including shipping times and customs handling. Additionally, review customer testimonials and case studies to gauge their reliability and service quality. Establishing a solid relationship with suppliers who prioritize communication and support can enhance your procurement process.

What are the typical minimum order quantities (MOQs) for bulk tire purchases?

Minimum order quantities for tires can vary significantly based on supplier policies and tire types. Generally, MOQs may range from 50 to 100 units for standard passenger and light truck tires. For specialized tires, such as those for agricultural or heavy-duty vehicles, MOQs may be higher. Always confirm specific MOQs with your supplier, as negotiating larger orders can lead to better pricing and terms. Ensure that your order aligns with your inventory management strategy to optimize stock levels.

What payment terms are commonly offered by tire suppliers?

Payment terms for tire purchases can vary widely, typically depending on the supplier’s policies and your relationship with them. Common terms include net 30 or net 60 days, allowing time for payment after delivery. Some suppliers may offer discounts for early payment or flexible financing options for larger orders. Always clarify payment methods accepted, such as wire transfers, letters of credit, or credit cards, to facilitate smooth transactions. Establishing a good credit history with suppliers can lead to more favorable terms.

How do I ensure quality assurance for tire purchases?

To ensure quality assurance in tire purchases, request certifications and test reports from suppliers that confirm adherence to international standards, such as DOT or ECE regulations. Conduct regular audits and inspections of the tires upon receipt to verify quality and performance specifications. Establish a return or warranty policy with your supplier for defective products. Engaging in a transparent dialogue about quality expectations can foster trust and improve the overall procurement experience.

What logistics considerations should I keep in mind for importing tires?

When importing tires, consider shipping methods, transit times, and associated costs. Choose a freight forwarder experienced in handling automotive products to navigate customs efficiently. Be aware of import regulations and tariffs that may apply in your country, particularly in regions with strict trade policies. Additionally, plan for warehousing and distribution logistics to manage inventory effectively upon arrival. Collaborating with local partners can streamline the process and reduce potential delays.

How can I customize tires for my specific business needs?

Customizing tires involves collaborating closely with suppliers to specify requirements such as tread patterns, sizes, and materials suited to your operational needs. Discuss your unique applications, whether for heavy machinery, agricultural use, or off-road vehicles, to determine optimal specifications. Some manufacturers may offer options for branding or labeling, enhancing your business identity. Always assess the feasibility and cost implications of custom orders to ensure they align with your budget and market demand.

Bereich: uptire.com

Registriert: 2005 (20 Jahre)

Einleitung: U.P. Tire provides new tire sales and repair services, including mobile service from St. Ignace to Newberry. They offer tires for agricultural equipment, commercial vehicles, light trucks, passenger cars, and recreational vehicles. The company has been in operation for 41 years and emphasizes quick service at reasonable prices. Their hours are Monday to Friday from 9:00 a.m. to 5:30 p.m., with spe…

Bereich: universityplacetireandauto.com

Registriert: 2010 (15 Jahre)

Einleitung: University Place Tire & Auto offers complete auto repair services including routine maintenance, tire installation and repair, diagnostics, electrical services, steering and suspension, brakes, and cooling system services. They provide a comfortable waiting area for customers and emphasize preventative routine maintenance to avoid costly breakdowns.

Bereich: facebook.com

Registriert: 1997 (28 Jahre)

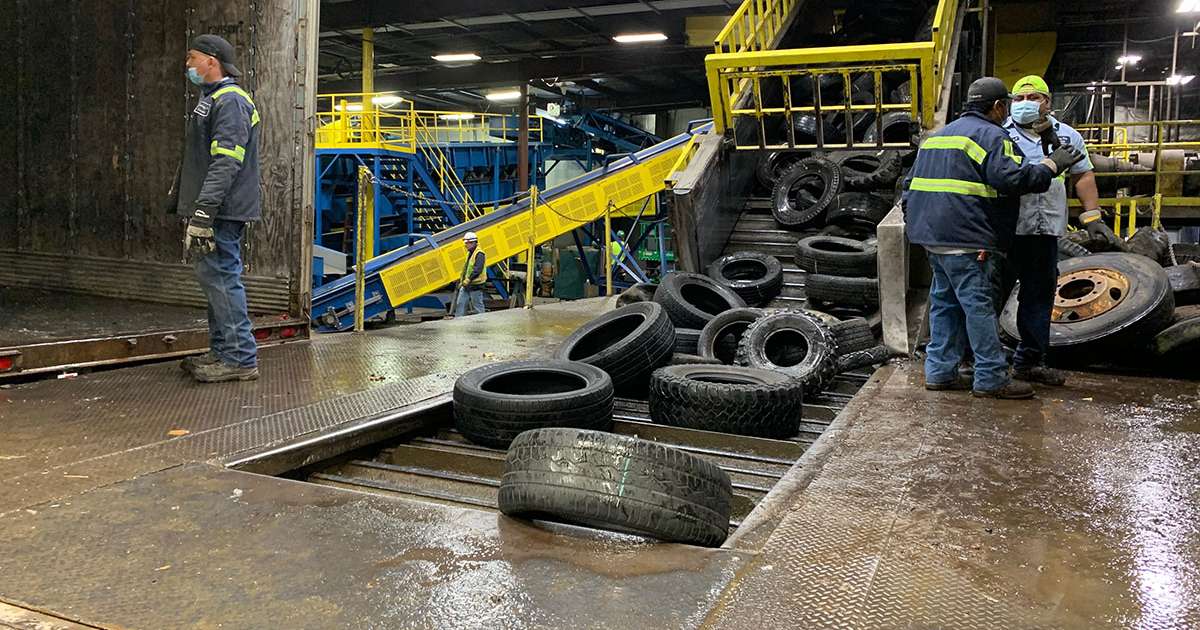

Einleitung: This company, U.P. Tire – Used Tire Disposal, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Bereich: shoptireup.com

Registered: 2020 (5 years)

Einleitung: TireUp offers a wide range of tires and wheels for cars, trucks, and SUVs, including brands like Cooper, Toyo, Michelin®, Pirelli, Goodyear, and Nexen. Services provided include tire balancing, tire installation, tire repair, tire rotation, and custom wheels. The shop is located at 2208 N. Stone Avenue, Tucson, AZ 85705, and operates Monday to Friday from 8:30 AM to 5:30 PM. Customers can book app…

Bereich: upnorthtire.com

Registered: 2020 (5 years)

Einleitung: New Tires: Large inventory of brand name tires, available within 24 hours if not in stock. Used Tires: Certified used tire inventory with savings up to 80% off new prices, inspected for tread integrity and blemishes. Tire Rotation: Recommended every 7500 miles to ensure even wear and prolong tire life. Fix a Leak: Easy and inexpensive repairs for slow leaks. Individual Replacement: Purchase any nu…

In the evolving landscape of tire procurement, strategic sourcing plays a crucial role in ensuring that B2B buyers secure high-quality products while optimizing costs. By understanding local market dynamics and leveraging supplier relationships, businesses from Africa, South America, the Middle East, and Europe can enhance their operational efficiency and customer satisfaction. The emphasis on comprehensive tire services—from sales to repair—underscores the need for reliable partners who can provide both products and expertise.

Investing in quality tires is not merely a transaction; it is a commitment to safety and performance. Buyers should prioritize suppliers who demonstrate a strong service ethic, wide inventory, and community involvement, as these factors often correlate with reliability and customer care. As the market continues to diversify, proactive sourcing strategies will empower buyers to navigate challenges and seize opportunities.

Looking ahead, international B2B buyers are encouraged to forge partnerships that prioritize not only cost but also value-added services. Embrace the potential of local suppliers who understand regional needs, and consider the benefits of mobile service options to enhance your fleet’s readiness. Together, let’s drive towards a future of sustainable and efficient tire solutions.

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.