In today’s dynamic global market, sourcing the right tire deflator can significantly impact your business operations, especially for those engaged in off-road and adventure vehicle industries. Tire deflators are essential tools for optimizing tire performance on various terrains, ensuring safety and efficiency. However, navigating the vast array of options available can be challenging for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil. This guide aims to simplify that process.

This comprehensive resource covers everything you need to know about tire deflators, including the different types available, their specific applications across various industries, and the importance of supplier vetting to ensure quality and reliability. Additionally, we will delve into cost considerations, helping you to make informed purchasing decisions that align with your budget and operational needs.

By equipping you with actionable insights and detailed information, this guide empowers B2B buyers to confidently navigate the tire deflator market. Whether you are looking for adjustable kits for varying PSI requirements or durable options suited for rugged environments, our guide will provide the knowledge necessary to choose the right products that meet your specific needs, ultimately enhancing your operational efficiency and customer satisfaction.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Tire Deflators | Simple design, requires manual operation to deflate tires. | Off-road vehicles, agricultural machinery | Pros: Cost-effective, easy to use. Cons: Slower process, less precision. |

| Automatic Tire Deflators | Automatically stops deflation at preset PSI; tool-free adjustability. | Commercial fleets, adventure tourism | Pros: Fast, accurate, hands-free operation. Cons: Higher initial investment. |

| Adjustable Tire Deflators | Allows users to set specific PSI levels; often comes with gauges. | Off-road enthusiasts, heavy equipment | Pros: Versatile, precise control over tire pressure. Cons: May require more maintenance. |

| Digital Tire Deflators | Features digital gauges for real-time pressure monitoring. | Racing, logistics, and transportation sectors | Pros: High accuracy, easy to read. Cons: Battery dependency, potentially higher costs. |

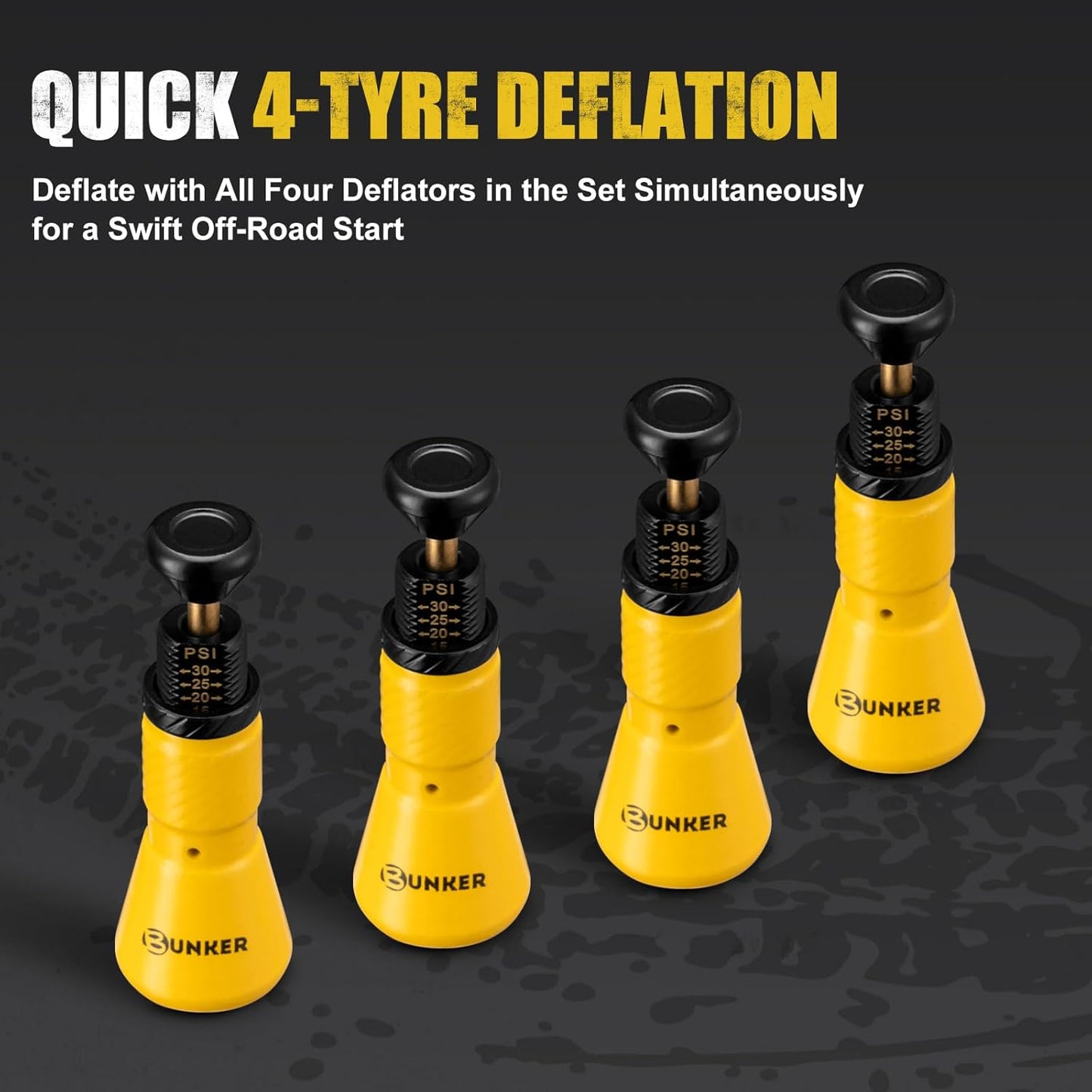

| Multi-Tire Deflation Systems | Designed to deflate multiple tires simultaneously. | Commercial off-road vehicles, fleet services | Pros: Time-efficient, ideal for large vehicles. Cons: Bulkier, may require more storage space. |

Manual tire deflators are the most basic type of tire deflation tool. They typically consist of a simple valve mechanism that allows operators to bleed air from tires manually. This type is ideal for businesses operating in rural or less technologically advanced areas where budget constraints are significant. While manual deflators are cost-effective and straightforward, they may lack the precision and speed of more advanced options, making them less suitable for high-volume operations.

Automatic tire deflators represent a significant advancement in tire management technology. They allow users to set a desired tire pressure, and the device automatically stops deflating when that pressure is reached. This hands-free convenience is particularly beneficial for commercial fleets and adventure tourism businesses where time efficiency and accuracy are paramount. While they come at a higher price point, the investment can lead to reduced labor costs and improved operational efficiency.

Illustrative image related to deflator tire

Adjustable tire deflators offer the flexibility to set specific PSI levels, making them ideal for off-road enthusiasts and businesses that operate in diverse terrains. These devices often include integrated gauges, enabling precise monitoring during deflation. B2B buyers should consider the adaptability of these tools, particularly if their operations frequently involve varying tire pressure requirements. However, potential maintenance needs should also be factored into purchasing decisions.

Digital tire deflators come equipped with electronic gauges that provide real-time pressure readings, enhancing accuracy and user-friendliness. They are particularly suited for sectors like racing and logistics, where precise tire pressure is crucial for performance and safety. While they can be more expensive and reliant on battery power, the advantages of high accuracy and ease of use make them a worthwhile investment for B2B buyers focused on performance.

Multi-tire deflation systems are designed to deflate several tires simultaneously, making them an excellent choice for commercial off-road vehicles and fleet services. By streamlining the deflation process, these systems save significant time and labor. However, they can be bulkier and require more storage space, which could be a consideration for businesses with limited operational space. The efficiency gains, however, often outweigh these drawbacks for larger operations.

| Industry/Sector | Specific Application of deflator tire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Off-Road Vehicles | Tire pressure adjustment for off-road adventures | Enhances traction and vehicle performance on uneven terrain | Durability, ease of use, and compatibility with various vehicle types |

| Agriculture | Tire deflation for agricultural vehicles | Reduces soil compaction, improving crop yield and soil health | Adjustable pressure settings and robust construction for harsh conditions |

| Mining and Construction | Tire deflation for heavy machinery | Improves stability and safety on uneven or soft ground | High PSI tolerance, fast deflation capabilities, and rugged design |

| Adventure Tourism | Tire pressure management for tour vehicles | Increases customer satisfaction and safety during excursions | Versatility, ease of use, and reliable performance across terrains |

| Emergency Services | Quick tire deflation for rescue vehicles | Ensures optimal maneuverability in challenging environments | Speed of deflation, accuracy, and robust materials for reliability |

In the off-road vehicle sector, tire deflators are essential tools for adjusting tire pressure to enhance traction on loose surfaces such as sand, mud, or rocky terrain. By allowing for quick and precise deflation, these devices help vehicles navigate challenging environments more effectively. International buyers, particularly in regions like Africa and South America, must consider the durability and compatibility of deflators with various vehicle types, as well as the ease of use in rugged conditions.

Illustrative image related to deflator tire

In agriculture, tire deflators are used on tractors and other farm equipment to lower tire pressure, which minimizes soil compaction. This practice is crucial for maintaining soil health and maximizing crop yields. Buyers in this sector should look for adjustable deflators that can handle varying PSI levels and are built to withstand harsh agricultural environments. Ensuring that these tools are reliable and easy to use can significantly impact operational efficiency.

In mining and construction, tire deflators are utilized to optimize the performance of heavy machinery on uneven terrain. Proper tire pressure can improve stability and safety, reducing the risk of accidents. Businesses in these industries should prioritize deflators with high PSI tolerance and fast deflation capabilities, as well as rugged designs that can endure the demands of harsh work sites. The reliability of these tools can directly affect operational productivity and safety.

Adventure tourism companies rely on tire deflators to manage tire pressure in tour vehicles, ensuring safety and enhancing the experience for customers during off-road excursions. By allowing for quick adjustments, these devices enable vehicles to adapt to various terrains, increasing customer satisfaction. For international buyers, factors such as versatility, ease of use, and reliable performance across different environments are critical when sourcing these tools.

In emergency services, quick tire deflation is vital for rescue vehicles to maneuver effectively in challenging environments. Tire deflators allow for rapid adjustments, ensuring optimal vehicle performance in critical situations. Buyers in this sector should focus on the speed of deflation, accuracy, and the robustness of materials used in deflators. These features are essential for ensuring that rescue operations can proceed without delays or complications.

Illustrative image related to deflator tire

The Problem: For businesses involved in off-road vehicle sales or rentals, the need to adjust tire pressure frequently can become a bottleneck. Manual tire deflation methods can be labor-intensive, often requiring multiple tools and time-consuming processes. This inefficiency not only delays operations but also frustrates customers who are eager to hit the trails. The challenge lies in finding a solution that combines speed with accuracy, ensuring that tire pressures are adjusted correctly without sacrificing valuable time.

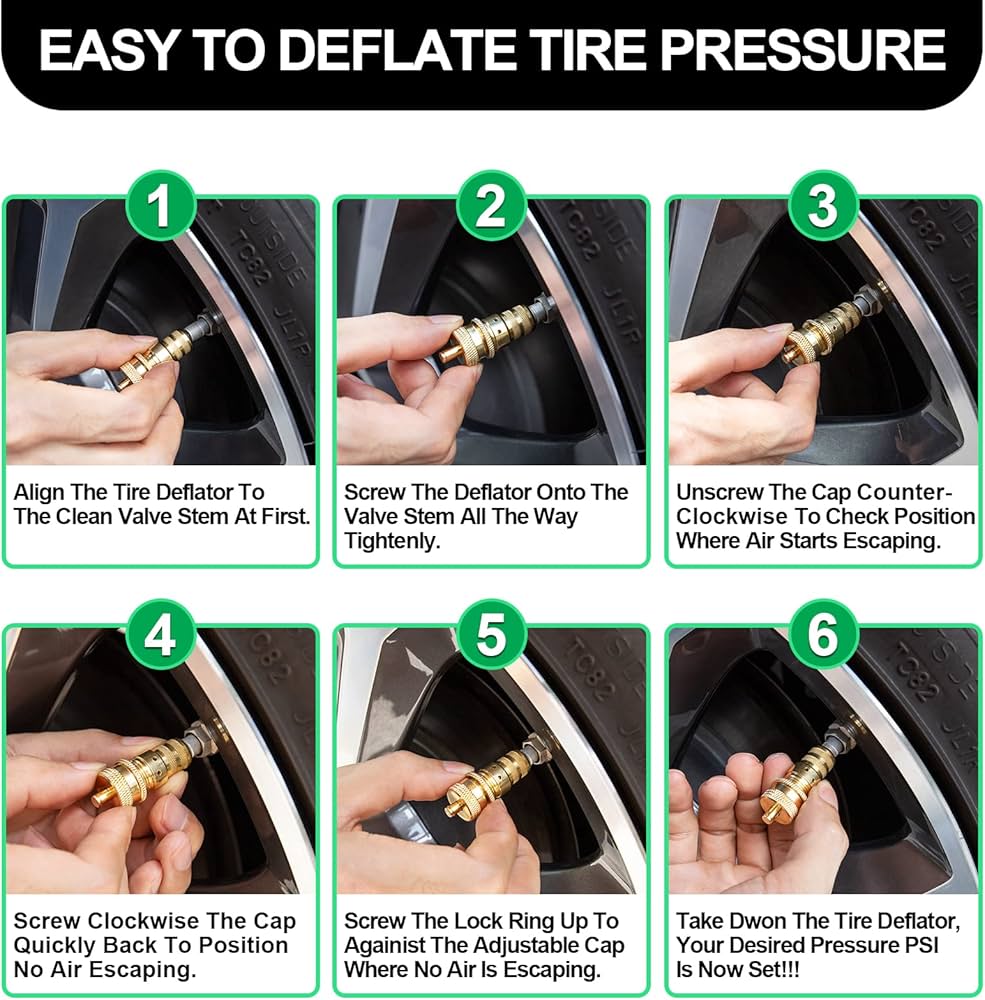

The Solution: To address this pain point, B2B buyers should consider investing in automatic tire deflator kits that feature preset PSI settings and automatic shut-off capabilities. These kits allow users to set the desired tire pressure, and the device will automatically stop deflating once the target PSI is reached. This hands-free convenience minimizes the need for constant monitoring and allows for simultaneous deflation of multiple tires, saving precious time. When sourcing these deflators, prioritize models that are factory-calibrated for accuracy and include clear scale displays for easy adjustments. By implementing such efficient tools, businesses can streamline their operations and enhance customer satisfaction.

The Problem: Maintaining consistent tire pressure is crucial for off-road performance, yet many businesses struggle with the accuracy of manual deflation methods. Variability in tire pressure can lead to safety hazards and reduced vehicle performance, impacting customer experiences negatively. For B2B buyers, ensuring that their fleet of vehicles operates at optimal tire pressures is essential, but the lack of reliable tools can complicate this task.

The Solution: To overcome this challenge, B2B buyers should invest in high-quality tire deflators that offer precise calibration within a ±2 PSI accuracy range. These tools not only improve safety but also enhance vehicle performance on varied terrains. When purchasing, look for deflators that come with integrated pressure gauges to provide real-time monitoring during the deflation process. This feature allows operators to make quick adjustments and ensures that all tires are accurately deflated to the desired pressure. Additionally, consider training staff on the importance of tire pressure management and the benefits of using accurate deflation tools, which will further improve operational efficiency.

Illustrative image related to deflator tire

The Problem: Companies that deal with a wide range of off-road vehicles often face challenges when it comes to managing different tire sizes and pressure requirements. This complexity can lead to confusion and errors during tire deflation, potentially resulting in improper tire settings that compromise vehicle performance. B2B buyers need a solution that accommodates various tire specifications without requiring extensive adjustments or separate tools.

The Solution: A versatile solution for this pain point is to choose adjustable tire deflator kits that can accommodate a broad range of PSI levels. These kits should feature easy-to-use mechanisms that allow for quick adjustments between different tire pressures, catering to various vehicle types and sizes. When sourcing these kits, focus on those that offer clear instructions and tool-free adjustability to simplify the process for staff. Additionally, creating a standardized pressure chart for different vehicles can help streamline operations, ensuring that all personnel are aware of the correct settings for each tire size. By implementing these solutions, businesses can effectively manage diverse tire specifications and ensure optimal performance across their fleet.

When selecting materials for tire deflators, it is essential to consider properties such as durability, pressure resistance, and corrosion resistance. The choice of material directly impacts the performance, longevity, and overall suitability of the deflator for various applications, especially in rugged environments. Below are analyses of four common materials used in the production of deflator tires.

Brass is a popular choice for tire deflators due to its excellent corrosion resistance and mechanical properties. It can withstand high pressures, making it suitable for off-road applications where tire pressure may fluctuate significantly.

Illustrative image related to deflator tire

Pros: Brass is durable, relatively inexpensive, and easy to machine. Its resistance to corrosion ensures that it maintains functionality even in harsh environments, which is particularly important for users in regions like Africa and South America, where humidity and corrosive conditions can be prevalent.

Cons: While brass is robust, it can be heavier than alternative materials like aluminum. Additionally, brass components may require additional protective coatings to enhance their longevity against corrosive agents.

Impact on Application: Brass is compatible with various media, including air and nitrogen, which are commonly used in tire inflation. However, it may not be suitable for aggressive chemical environments.

Illustrative image related to deflator tire

Aluminum is another commonly used material, known for its lightweight properties and resistance to corrosion. It is particularly advantageous for applications requiring frequent handling, such as off-road adventures.

Pros: The primary advantage of aluminum is its lightweight nature, which reduces the overall weight of the deflator. It is also resistant to corrosion, making it suitable for diverse climates, including the humid conditions often found in the Middle East and coastal areas of South America.

Cons: Aluminum can be less durable than brass, particularly under high-stress conditions. It may also be more expensive due to the manufacturing processes involved.

Impact on Application: Aluminum is compatible with air and nitrogen, making it a versatile choice for tire deflators. However, its lower tensile strength may be a consideration for heavy-duty applications.

Stainless steel is favored for its exceptional strength and corrosion resistance, making it ideal for demanding applications where durability is paramount.

Illustrative image related to deflator tire

Pros: Stainless steel offers high tensile strength and is resistant to rust and corrosion. This makes it suitable for extreme environments, such as deserts or coastal areas, where moisture can lead to rapid degradation of other materials.

Cons: The primary drawback of stainless steel is its cost; it is generally more expensive than both brass and aluminum. Additionally, it can be heavier, which may not be ideal for all applications.

Impact on Application: Stainless steel is compatible with various gases and can withstand high pressures, making it suitable for both recreational and professional off-road use. Compliance with international standards is often easier with stainless steel due to its widespread acceptance.

Illustrative image related to deflator tire

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly being used in tire deflator designs due to their lightweight and cost-effective nature.

Pros: Plastics are lightweight and resistant to corrosion, making them suitable for applications where weight is a critical factor. They are also generally less expensive than metal options, which can be appealing for budget-conscious buyers.

Cons: The primary limitation of plastic is its lower strength compared to metals, which may lead to failure under high-stress conditions. Additionally, plastics may not be suitable for high-temperature applications.

Impact on Application: Plastics are compatible with air but may not be suitable for all tire pressures. Buyers in regions with extreme temperatures should consider the thermal stability of the plastic used.

| Material | Typical Use Case for deflator tire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General off-road applications | Excellent corrosion resistance | Heavier than alternatives | Medium |

| Aluminum | Lightweight off-road use | Lightweight and corrosion-resistant | Less durable under stress | Medium |

| Stainless Steel | Heavy-duty off-road applications | High strength and durability | Higher cost | High |

| Plastic | Budget-friendly applications | Cost-effective and lightweight | Lower strength and temperature sensitivity | Low |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in tire deflator manufacturing, helping them make informed purchasing decisions tailored to their specific regional needs and operational requirements.

The manufacturing process of tire deflators involves several critical stages that ensure the final product meets high-performance standards. Here’s a breakdown of the main stages:

The first step in the manufacturing process is the selection and preparation of raw materials. High-quality materials such as brass, stainless steel, and durable plastics are typically chosen for their strength and corrosion resistance. Suppliers often source these materials from reputable vendors, ensuring compliance with international standards. Before production begins, materials undergo rigorous testing to confirm their suitability for the intended application.

Illustrative image related to deflator tire

During the forming stage, raw materials are shaped into components using various techniques such as machining, molding, and stamping. For example, brass components may be machined to precise dimensions, while plastic parts could be produced through injection molding. Advanced technology, including CNC (Computer Numerical Control) machines, is often employed to achieve high levels of accuracy and repeatability, crucial for ensuring that all parts fit together seamlessly.

The assembly process involves the integration of individual components into the final tire deflator product. This stage typically includes the installation of valves, pressure gauges, and adjustment mechanisms. Skilled technicians perform this task to ensure that all parts function correctly and meet design specifications. Automation may also play a role, with assembly lines utilizing robotic systems for tasks such as attaching components or quality checks.

Finishing processes enhance the product’s durability and aesthetic appeal. This may involve surface treatments like anodizing or powder coating to prevent corrosion and improve wear resistance. Final inspections are conducted to ensure that the product meets design specifications and is free from defects. The finishing stage is crucial for ensuring that the tire deflator is not only functional but also visually appealing to the end user.

Quality assurance is a vital component of the manufacturing process, especially for international B2B transactions. Buyers should be familiar with the following standards and practices:

ISO 9001 is the most recognized quality management standard globally. It outlines a framework for consistent quality in manufacturing, focusing on customer satisfaction, process improvement, and risk management. Compliance with ISO 9001 indicates that a manufacturer adheres to best practices, which can significantly reduce the likelihood of defects in the final product.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain applications may be relevant. These certifications assure buyers that the products meet specific safety and performance criteria established by regulatory bodies.

Illustrative image related to deflator tire

Quality control (QC) is integrated at various stages of the manufacturing process to ensure that products meet the required standards. Here are some common QC checkpoints:

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step ensures that all materials meet predefined quality specifications before they enter the production line. Suppliers may be required to provide certification documents confirming material quality.

During the manufacturing process, IPQC involves monitoring production to identify any deviations from quality standards in real-time. This may include checking dimensions, pressure settings, and assembly integrity. Continuous monitoring helps prevent defects and ensures that corrective actions can be taken immediately.

FQC is the last line of defense before products are shipped to customers. This stage typically involves comprehensive testing of the final product to ensure it meets all performance standards. Common testing methods include pressure testing, leak testing, and functional testing to verify that each tire deflator operates correctly.

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

Illustrative image related to deflator tire

Performing on-site audits allows buyers to assess a supplier’s manufacturing processes, quality control measures, and overall compliance with industry standards. Audits can provide valuable insights into the supplier’s operational effectiveness and adherence to quality practices.

Buyers should request detailed quality reports from suppliers, including information on past QC results, defect rates, and compliance with relevant standards. This documentation can provide reassurance regarding the supplier’s commitment to quality.

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspections can occur at various stages of production, ensuring that products meet specifications before they are shipped.

Illustrative image related to deflator tire

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

Different regions may have varying requirements for product certification and quality assurance. For instance, products sold in Europe must meet CE marking requirements, while those in the U.S. may need to comply with ANSI (American National Standards Institute) standards. Buyers should familiarize themselves with these regional nuances to ensure compliance.

Language differences can sometimes complicate the verification process. Buyers should ensure that all quality documentation is available in a language they understand, or they may choose to engage translation services to avoid miscommunication.

Quality control is not only about the manufacturing process; it also extends to logistics. Buyers should consider how products will be packaged and shipped, as poor handling during transport can lead to damage. Ensuring that suppliers have robust logistics practices is essential for maintaining product integrity.

By understanding the manufacturing processes and quality assurance practices involved in tire deflator production, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring that they receive high-quality products that meet their specific needs.

Illustrative image related to deflator tire

This sourcing guide is designed to assist B2B buyers in procuring tire deflators, essential tools for optimizing tire performance in off-road conditions. By following this step-by-step checklist, you can ensure a well-informed purchasing decision that meets your operational needs and enhances your off-road capabilities.

Before initiating the sourcing process, clearly outline the technical specifications required for your tire deflators. Consider factors such as the desired PSI range, compatibility with various tire sizes, and the specific environments in which they will be used, like sandy or rocky terrains. This clarity will guide your selection and help you communicate effectively with potential suppliers.

Conduct thorough research to identify reputable suppliers specializing in tire deflators. Look for companies with a strong track record in the off-road sector and positive reviews from other B2B customers. Use platforms like trade shows, industry publications, and online directories to gather information on potential suppliers.

Examine the product offerings from shortlisted suppliers to ensure they provide a diverse range of tire deflators. Look for features such as automatic shut-off, ease of use, and precision calibration. A comprehensive product range indicates that the supplier understands the varying needs of different users.

Illustrative image related to deflator tire

Quality assurance is paramount when selecting tire deflators. Request samples or detailed product specifications to assess the materials used and the construction quality. Durable components, such as brass or stainless steel, can withstand harsh outdoor conditions and prolonged use.

Request detailed quotes from multiple suppliers to compare pricing structures. Ensure that you understand the full cost, including shipping and handling. Additionally, inquire about payment terms and conditions, as favorable terms can significantly impact your cash flow.

Evaluate the level of customer support provided by potential suppliers. Reliable after-sales service is crucial for addressing any issues that may arise post-purchase. Look for suppliers that offer hassle-free returns, dedicated customer service, and technical support.

After completing your evaluations, make an informed decision on which supplier to partner with. Ensure that all agreed-upon terms are documented in a formal contract to protect your interests. Once finalized, proceed with the order and establish a communication channel for ongoing support.

By adhering to this checklist, B2B buyers can confidently navigate the procurement process for tire deflators, ensuring they select a product that enhances their operational efficiency and meets their specific needs.

Illustrative image related to deflator tire

When sourcing tire deflators for B2B purposes, understanding the cost structure is crucial for making informed purchasing decisions. The primary components that contribute to the overall cost include:

Materials: The choice of materials directly impacts the durability and functionality of tire deflators. Common materials include brass and stainless steel, which offer corrosion resistance and longevity. These materials can vary significantly in price based on quality and supplier sourcing.

Labor: Labor costs encompass the wages paid to workers during the manufacturing process. These costs can differ based on the geographic location of production facilities, with regions like Southeast Asia generally offering lower labor costs compared to Europe or North America.

Manufacturing Overhead: This includes costs related to the factory environment, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overhead costs, ultimately affecting the final price of the tire deflators.

Tooling: The cost of molds and tools required for production can be significant, particularly for customized or specialized tire deflators. These costs are typically amortized over production runs, influencing the pricing based on volume.

Quality Control (QC): Implementing rigorous quality control processes ensures that products meet safety and performance standards. While this may increase initial costs, it significantly reduces the risk of returns and warranty claims, ultimately benefiting the buyer.

Logistics: Shipping and handling costs can vary widely, especially for international buyers. Factors such as distance, shipping method, and import duties play a crucial role in determining the total cost.

Margin: Suppliers typically include a profit margin in their pricing, which can fluctuate based on market demand and competitive landscape.

Several factors influence the pricing of tire deflators beyond the basic cost components:

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Negotiating favorable terms based on anticipated sales can lead to significant savings.

Specifications and Customization: Customized tire deflators that meet specific performance requirements may command higher prices. Buyers should weigh the benefits of customization against the potential cost increase.

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) often lead to increased costs. Buyers should assess the importance of these factors based on their target market and end-user expectations.

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge a premium for their products, but they often provide better support and quality assurance.

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of products.

Negotiation: Cultivating a good relationship with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on volume discounts, payment terms, or shipping costs.

Total Cost of Ownership (TCO): Consider the long-term costs associated with tire deflators, including maintenance, replacements, and performance reliability. Sometimes, investing in higher-quality deflators may yield lower overall costs.

Pricing Nuances for International B2B Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and other import/export regulations that can affect pricing. It’s advisable to stay informed about local market conditions and logistics challenges.

Research and Benchmarking: Conduct thorough market research to compare prices across different suppliers. Utilize industry reports and peer feedback to gauge typical pricing and quality standards.

The prices mentioned in various sources, such as $29.90 for a Pro Tire Deflator Kit or $27.49 for an adjustable kit, are indicative and may vary based on market conditions, supplier negotiations, and other factors. Always verify current pricing directly with suppliers before making purchasing decisions.

In the realm of off-road and adventure vehicles, managing tire pressure is crucial for optimizing performance and safety. While tire deflators are a popular choice for achieving the desired tire pressure quickly, several alternative solutions exist. This analysis compares tire deflators against automatic tire inflation systems and manual tire pressure gauges, examining their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to deflator tire

| Comparison Aspect | Deflator Tire | Automatic Tire Inflation System | Manual Tire Pressure Gauge |

|---|---|---|---|

| Performance | High precision; rapid deflation | High precision; maintains preset pressure | Variable accuracy; relies on user skill |

| Cost | Moderate ($30 – $150) | High ($100 – $300+) | Low ($10 – $50) |

| Ease of Implementation | Simple; minimal setup required | Complex; installation needed | Simple; requires user knowledge |

| Maintenance | Low; durable materials | Moderate; periodic checks needed | Low; requires no maintenance |

| Best Use Case | Off-road adventures requiring quick tire changes | Long-distance travel with consistent tire pressure needs | Regular vehicle maintenance or casual users |

An automatic tire inflation system offers a sophisticated solution for maintaining tire pressure. These systems can continuously monitor and adjust tire pressure while driving, ensuring optimal performance and safety. The primary advantage is their convenience for long-distance travel, where consistent tire pressure is crucial. However, they come at a higher initial cost and require professional installation, which may not be feasible for all users, especially those operating in remote areas. Maintenance is also necessary to ensure the system functions correctly, adding to the overall cost of ownership.

Manual tire pressure gauges provide a low-cost, straightforward alternative for measuring tire pressure. They are widely available and easy to use, making them suitable for casual vehicle owners or those who regularly check their tire pressure as part of routine maintenance. However, the accuracy of manual gauges can vary significantly based on the user’s skill, and they do not facilitate rapid deflation or inflation. While they serve well for everyday use, they lack the efficiency required for off-road scenarios where quick adjustments are necessary.

When selecting a tire pressure management solution, B2B buyers should consider their specific operational needs. For those frequently venturing off-road, investing in a high-quality deflator tire or an automatic tire inflation system may be the best option due to their efficiency and performance. Conversely, businesses with lower frequency requirements or those focused on cost savings might find manual tire pressure gauges to be adequate. Ultimately, the decision should be based on the balance between budget, ease of use, and the specific demands of the terrain and driving conditions.

Illustrative image related to deflator tire

Understanding the essential technical properties of tire deflators is crucial for B2B buyers, especially those in diverse markets such as Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

Material Composition

Tire deflators are typically constructed from high-grade materials like brass or stainless steel. The choice of material is important as it affects durability and corrosion resistance, especially in harsh outdoor conditions. For B2B buyers, selecting a deflator made from premium materials ensures long-term usability and minimizes replacement costs.

Pressure Range (PSI)

Deflators usually have a specified pressure range, such as 10-30 PSI or 0-60 PSI. This range indicates the minimum and maximum pressure settings the device can handle. Understanding this property is vital for businesses that cater to specific off-road vehicles or environments, as it affects performance and safety during operation.

Calibration Accuracy

The accuracy of a tire deflator is often expressed in terms of tolerance, typically within ±1 to ±2 PSI. This means that the device will measure and release air at a pressure close to the desired setting. Accurate calibration is essential for B2B buyers who require precise tire pressure for optimal vehicle performance in varying terrains.

Deflation Speed

This refers to how quickly the tire deflator can reduce tire pressure. Devices designed for fast and even deflation help save time, particularly for businesses operating in time-sensitive environments, such as racing or off-road events. Faster deflation rates can lead to increased efficiency in operations.

Adjustability Features

Many tire deflators come with adjustable settings, allowing users to customize the desired PSI. This feature is beneficial for businesses that operate different types of vehicles, as it provides flexibility to meet varying tire pressure requirements. Adjustable models can often accommodate a wider range of applications.

Ease of Use

Design elements that enhance user convenience, such as tool-free adjustments and automatic shut-off mechanisms, contribute to the overall functionality of the deflator. For B2B buyers, selecting easy-to-use products can enhance operational efficiency and reduce the need for extensive training.

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms related to tire deflators:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For tire deflators, understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This is a crucial consideration for B2B buyers, as it can impact inventory levels and cash flow. Understanding MOQ helps in planning purchases effectively.

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. B2B buyers should utilize RFQs to obtain competitive pricing and gauge supplier capabilities for tire deflators.

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define responsibilities and risks between buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, insurance, and delivery responsibilities associated with tire deflator purchases.

Lead Time

This term refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for B2B buyers to manage inventory and ensure timely project execution.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the product’s quality and longevity. B2B buyers should pay attention to warranty terms as they can indicate the manufacturer’s confidence in their tire deflators and provide assurance for future use.

By understanding these technical properties and industry terms, B2B buyers can make more informed purchasing decisions, ultimately enhancing their operational efficiency and product performance in various applications.

Illustrative image related to deflator tire

The deflator tire sector is witnessing robust growth driven by several global trends. The increasing popularity of off-road activities, particularly in regions like Africa, South America, and the Middle East, is propelling demand for high-quality tire deflation solutions. As adventure tourism and outdoor recreational activities gain traction, the need for efficient tire pressure management systems is paramount. Furthermore, technological advancements in tire deflation products—such as automatic shut-off features and precision calibration—are becoming essential selling points for B2B buyers looking for efficiency and reliability in their supply chains.

Emerging B2B tech trends, such as e-commerce platforms and digital supply chain management tools, are reshaping the sourcing landscape. International buyers are increasingly leveraging these technologies to streamline procurement processes, enabling them to access a wider range of products and suppliers. The rise of online marketplaces facilitates better price comparisons and fosters competition among suppliers, ultimately benefiting buyers. Additionally, sustainability considerations are becoming a key factor in sourcing decisions, with many businesses prioritizing suppliers that align with environmentally friendly practices.

Sustainability is an increasingly important aspect of the deflator tire sector, influencing sourcing decisions across international markets. The environmental impact of tire production and disposal is significant, prompting buyers to seek solutions that minimize ecological footprints. Ethical supply chains are now a priority, with businesses looking for manufacturers that adhere to responsible sourcing practices and use sustainable materials.

Green certifications and eco-friendly materials are gaining traction among B2B buyers, who are keen to partner with companies that demonstrate a commitment to environmental stewardship. For instance, suppliers using recycled materials or those that have implemented energy-efficient manufacturing processes are becoming more attractive. By prioritizing sustainability, businesses can not only fulfill regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers. This trend is particularly relevant in markets like Europe, where regulations around sustainability are stringent and consumer expectations are high.

The deflator tire sector has evolved significantly over the decades, driven by advancements in automotive technology and changing consumer preferences. Initially, tire deflation was a manual and cumbersome process, often relying on basic tools and gauges. However, as off-road driving gained popularity, the need for more efficient solutions led to the development of specialized tire deflators.

Illustrative image related to deflator tire

Today’s market offers a range of innovative products that cater to various consumer needs, from off-road enthusiasts to commercial vehicle operators. The integration of technology, such as automatic shut-off systems and precise calibration, reflects the industry’s response to the demands for efficiency and accuracy in tire pressure management. As the sector continues to innovate, B2B buyers can expect even more sophisticated solutions that enhance performance and simplify the off-road experience.

How do I choose the right tire deflator for my business needs?

Selecting the right tire deflator involves understanding your specific application and terrain. Consider factors such as the range of PSI adjustments needed, the type of vehicles you operate, and whether you require features like automatic shut-off or integrated gauges. Also, evaluate the build quality and materials, especially if you operate in rugged environments. Consulting with suppliers about compatibility with your existing equipment can also ensure you make a well-informed decision.

What is the best tire deflator for off-road applications?

For off-road applications, the best tire deflator is one that offers fast and precise deflation, such as models with preset PSI settings and automatic shut-off features. Look for durable construction from materials like brass or stainless steel to withstand harsh conditions. Additionally, a kit that allows for simultaneous deflation of all tires can save time and enhance efficiency during off-road adventures.

What minimum order quantities (MOQ) should I expect when sourcing tire deflators?

Minimum order quantities can vary widely between manufacturers and suppliers. Typically, MOQs for tire deflators might range from 50 to 200 units, depending on the brand and product customization options. Always confirm MOQs with your supplier before placing an order, as some may offer lower MOQs for first-time buyers or larger orders over time.

How can I ensure the quality of the tire deflators I am purchasing?

To ensure quality, request samples before committing to a bulk order. Review the manufacturer’s certifications, such as ISO standards, which reflect their quality assurance processes. Additionally, seek feedback from other businesses that have previously purchased from the supplier. Establishing a clear quality control process, including inspection upon arrival, will help maintain high standards in your supply chain.

What payment terms are typically offered for international purchases of tire deflators?

Payment terms can vary, but common practices include upfront payment, a 30% deposit with the balance due before shipment, or net 30/60/90 days after delivery. It’s essential to discuss and agree upon these terms before finalizing your order. Using letters of credit or escrow services can also provide additional security for both parties in international transactions.

What logistics considerations should I keep in mind when importing tire deflators?

When importing tire deflators, consider shipping methods, customs duties, and potential tariffs that may apply. Choose a reliable freight forwarder with experience in handling goods in your destination region. Understanding the lead times for shipping and the import regulations in your country will help you avoid delays and additional costs.

Can I customize tire deflators with my branding for resale?

Many manufacturers offer customization options such as logo printing or specific packaging for bulk orders. Discuss your branding needs with potential suppliers and inquire about the minimum quantities required for customization. Ensure that the customization process does not compromise the quality or functionality of the tire deflators.

What are the common uses of tire deflators in various industries?

Tire deflators are widely used in industries such as off-roading, agriculture, construction, and emergency services. In off-roading, they enhance vehicle performance on uneven terrain. In agriculture, they help optimize tire pressure for better traction on soft ground. Construction sites may use them to adapt to changing conditions, while emergency services benefit from their efficiency in rapidly adjusting tire pressures for rescue operations. Understanding these applications can help you target the right market segments for your business.

Domain: morrflate.com

Registered: 2019 (6 years)

Introduction: Coyote Vortex Automatic Tire Deflators are designed for off-road enthusiasts. They automatically deflate tires to a preset pressure, ensuring optimal performance on various terrains. The deflators are easy to use, durable, and made from high-quality materials. They feature a compact design for portability and come with a protective case for storage. Ideal for those who frequently adjust tire press…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Staun Tire Deflators: Known for reliability once set, but can be difficult to set initially and may lose their setting, requiring a reset.

2. Over Sand Tire Deflators: Similar design to Stauns but reportedly easier to set.

3. ARB Quick Deflator: Works well for larger tires (e.g., 37s), but requires manual stopping at desired PSI.

4. Trailhead Deflators: Allows for hands-free operation, can be s…

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: {‘name’: ‘E-Z Tire Deflator’, ‘part_number’: ‘ARB600’, ‘price’: ‘$58.95’, ‘features’: [‘Includes Extended Valve’, ‘Fully geared, solid brass precision movement’, ‘Protective rubber gauge guard’, ‘Easy to read dial with one PSI increments’, ‘Includes recovery bag’], ‘warranty’: ‘3 YR’, ‘downloads’: ‘ARB 4×4 Accessories – ARB USA Warranty Booklet October 2020’}

Domain: rockjock4x4.com

Registered: 2005 (20 years)

Introduction: RJ-9029PRO – Digital EZ-Tire Deflator Pro (Beadlock Friendly)\n- SKU: RJ-9029PRO\n- Price: $29.00\n- Features: \n – Illuminated digital gauge\n – LED flashlight on the back\n – Extended tip designed for beadlock wheels\n – +/- 0.5 p.s.i. accuracy\n – High quality logoed zipper case included\n- In Stock: 402 units available

In the evolving landscape of tire deflation solutions, strategic sourcing remains pivotal for businesses seeking to enhance their operational efficiency and performance. By investing in high-quality tire deflators, companies can ensure optimal traction and safety across diverse terrains, particularly in regions such as Africa, South America, the Middle East, and Europe. The market offers a variety of options, from manual to advanced automatic systems, catering to different user needs and preferences.

Key considerations for B2B buyers include the durability of materials, precision in pressure calibration, and the ease of use, which can significantly impact productivity in off-road environments. Additionally, the availability of warranties and reliable customer service further strengthens the value proposition of tire deflator products.

As the demand for off-road adventures continues to rise, the importance of efficient tire management will only increase. International buyers should capitalize on this trend by exploring partnerships with reputable suppliers who prioritize quality and innovation. By doing so, businesses can not only enhance their operational capabilities but also position themselves as leaders in the market. Take the next step in your sourcing strategy today—invest in tire deflation solutions that will empower your business for the challenges ahead.

Illustrative image related to deflator tire

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.