In an increasingly competitive landscape, sourcing the best solutions for nitrogen tire inflation can be a complex challenge for international B2B buyers. Understanding the cost implications of nitrogen tire inflation is crucial for businesses looking to enhance vehicle performance, safety, and fuel efficiency while managing operational budgets. This comprehensive guide delves into the various types of nitrogen inflation systems, their applications across different industries, and the factors influencing pricing, enabling businesses to make informed decisions.

We explore the advantages and disadvantages of nitrogen versus traditional air, providing insights into performance metrics and long-term benefits. Additionally, we cover essential aspects of supplier vetting, helping buyers from regions such as Africa, South America, the Middle East, and Europe—specifically in markets like Brazil and Saudi Arabia—identify reliable partners. By equipping decision-makers with actionable insights and data-driven analysis, this guide empowers them to navigate the global market effectively and optimize their procurement strategies for nitrogen tire inflation. Ultimately, our goal is to facilitate smarter purchasing decisions that align with the unique needs and challenges faced by international businesses today.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Retail Nitrogen Inflation | Offered at tire shops; typically $5+ per tire. | Passenger vehicles, light trucks. | Pros: Convenient; enhances customer service. Contras: Higher ongoing costs; requires regular maintenance. |

| Commercial Fleet Services | Bulk nitrogen filling; often included in service contracts. | Trucking, logistics, and transport companies. | Pros: Cost-effective for high-volume needs; reduces downtime. Contras: Initial setup costs; may require specialized equipment. |

| Nitrogen Generation Systems | On-site generation of nitrogen; lower long-term costs. | Large manufacturing, aviation, and heavy machinery. | Pros: Reduces dependency on suppliers; lowers per-tire cost. Contras: High initial investment; requires maintenance. |

| Mobile Nitrogen Services | Mobile units providing nitrogen inflation on-site. | Construction sites, remote locations. | Pros: Flexibility; immediate service. Contras: Potentially higher per-use costs; availability may vary. |

| DIY Nitrogen Inflation Kits | Portable kits for nitrogen inflation; lower cost. | Small businesses, individual users. | Pros: Cost-effective; control over inflation process. Contras: Limited capacity; requires training for effective use. |

Retail nitrogen inflation services are commonly available at tire shops, where customers pay a premium (typically $5 or more per tire) for nitrogen filling during routine maintenance. This service appeals to B2B buyers looking to enhance customer satisfaction by offering perceived benefits such as improved tire pressure retention and safety. However, the ongoing costs can accumulate, and it necessitates regular monitoring and topping off with nitrogen to maintain the intended advantages.

Commercial fleet services provide bulk nitrogen filling as part of service contracts, making them ideal for trucking and logistics companies that operate numerous vehicles. This approach is cost-effective due to economies of scale, significantly reducing downtime related to tire maintenance. While initial setup costs may be higher, the long-term savings and operational efficiency gained are often worth the investment for businesses managing large fleets.

Nitrogen generation systems allow businesses to produce nitrogen on-site, which can lead to lower long-term costs for industries such as manufacturing, aviation, and heavy machinery. This option minimizes reliance on external suppliers and reduces the per-tire inflation cost. However, the initial investment can be substantial, and companies need to consider the ongoing maintenance and operational requirements associated with these systems.

Mobile nitrogen services provide on-site inflation, making them particularly useful for construction sites and remote locations where access to traditional tire shops may be limited. The flexibility of these services allows for immediate tire maintenance, which is crucial for minimizing downtime. However, the per-use costs can be higher than traditional methods, and availability may vary based on location.

DIY nitrogen inflation kits are portable and designed for businesses and individuals looking to control their tire inflation process at a lower cost. These kits can be particularly appealing for small businesses with limited budgets. However, they have a limited capacity and may require training to ensure effective use, which could be a barrier for some buyers.

| Industria/Sector | Specific Application of cost of nitrogen tire inflation | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Aviation | Tire inflation for aircraft | Enhanced safety, reduced tire wear, improved fuel efficiency | Certification of nitrogen purity, compliance with aviation standards |

| Transportation & Logistics | Fleet management for commercial trucks | Improved fuel economy, reduced maintenance costs, extended tire life | Availability of nitrogen filling stations, cost of nitrogen vs. air |

| Mining | Heavy equipment tire inflation | Decreased downtime, enhanced safety, improved performance | Access to nitrogen generation equipment, reliability of supply |

| Automotive Service | Tire shops offering nitrogen inflation services | Increased service revenue, customer loyalty, improved safety | Training for technicians, equipment for nitrogen inflation |

| Agricultura | Inflation of agricultural machinery tires | Enhanced operational efficiency, reduced tire wear, improved safety | Availability of nitrogen inflation systems, cost-effectiveness |

In the aviation industry, nitrogen tire inflation is essential for aircraft safety and performance. Using nitrogen reduces the risk of tire blowouts and extends tire life due to lower oxidation rates. For international buyers, especially in regions like the Middle East and Europe, sourcing high-purity nitrogen is critical, as it must meet stringent aviation standards. Buyers should consider suppliers that provide certified nitrogen and understand the implications of tire pressure management on overall aircraft performance.

In the transportation and logistics sector, nitrogen tire inflation is increasingly adopted for commercial truck fleets. By maintaining optimal tire pressure, businesses can achieve better fuel economy and reduce maintenance costs, leading to significant savings over time. For buyers in regions such as South America and Africa, it’s important to evaluate the availability of nitrogen filling stations and the cost-effectiveness of nitrogen compared to traditional air inflation. This helps in making informed decisions about long-term fleet management strategies.

The mining industry benefits significantly from nitrogen tire inflation in heavy equipment. This application helps minimize downtime caused by tire failure and enhances the safety of operations. Buyers need to consider the accessibility of nitrogen generation equipment and the reliability of supply chains, particularly in remote locations. Understanding these factors can influence operational efficiency and cost management in challenging environments.

Automotive service providers can enhance their offerings by incorporating nitrogen tire inflation services. This not only generates additional revenue but also improves customer safety and satisfaction through better tire performance. Buyers in Europe and the Middle East should focus on training technicians and investing in specialized equipment for nitrogen inflation. This investment can lead to a competitive edge in the automotive service market, attracting more customers seeking advanced tire maintenance solutions.

In agriculture, nitrogen tire inflation is vital for the efficient operation of machinery. By reducing tire wear and improving safety, farmers can enhance productivity during critical planting and harvesting seasons. Buyers should evaluate the availability of nitrogen inflation systems and their cost-effectiveness to ensure optimal performance of agricultural equipment. Understanding regional differences in machinery usage can further inform decisions about the adoption of nitrogen inflation practices in agriculture.

El problema: B2B buyers often face confusion regarding the true cost implications of nitrogen tire inflation. While the initial investment may seem justified due to advertised benefits like improved tire longevity and better fuel efficiency, the ongoing expenses can accumulate quickly. Companies may find themselves paying for regular nitrogen fills, which can add up significantly over time. Furthermore, if the nitrogen isn’t consistently maintained or if tires are mixed with regular air, the anticipated benefits may not materialize, leading to a sense of financial loss.

La solución: To effectively manage costs, B2B buyers should conduct a comprehensive cost-benefit analysis before committing to nitrogen tire inflation. Start by comparing the upfront costs of nitrogen filling services with the long-term savings on fuel and tire replacements. Engage with reputable nitrogen suppliers who can provide transparent pricing structures and service agreements. Additionally, consider investing in tire pressure monitoring systems (TPMS) to ensure optimal tire pressure is maintained, whether using nitrogen or regular air. This proactive approach helps in maximizing the benefits of nitrogen while minimizing unnecessary expenditures.

El problema: Another common pain point for B2B buyers involves the inconsistency in nitrogen quality and maintenance. Many suppliers may not guarantee that the nitrogen being used is of the required purity, which can undermine the advantages of nitrogen inflation. Furthermore, without proper maintenance schedules, tires filled with nitrogen can still lose pressure, leading to operational inefficiencies and safety concerns.

La solución: B2B buyers should prioritize sourcing nitrogen from certified providers who can guarantee a high level of purity, ideally 95% or higher. Establishing a regular maintenance schedule for tire pressure checks can help ensure that nitrogen levels are consistently monitored. It’s advisable to train staff on the importance of maintaining proper tire pressure and how to identify when nitrogen levels are low. By implementing these practices, businesses can ensure they are getting the most out of their nitrogen inflation investment and avoid the pitfalls of inconsistent quality.

El problema: B2B buyers often encounter marketing claims about nitrogen tire inflation that may not align with real-world performance. Misunderstandings about the benefits—like significantly improved fuel efficiency and reduced tire wear—can lead to inflated expectations and disappointment when these outcomes are not realized. This can impact budget planning and operational efficiency, especially for companies with large fleets relying on effective tire management.

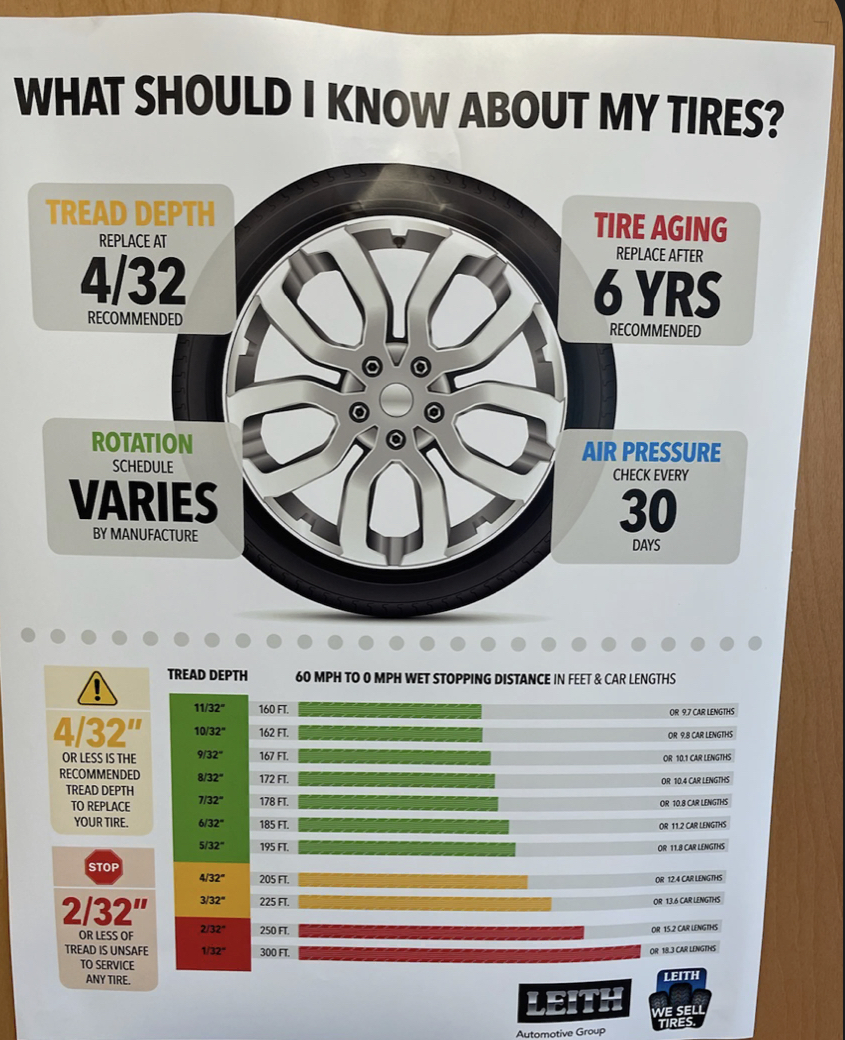

Illustrative image related to cost of nitrogen tire inflation

La solución: To address these misconceptions, B2B buyers should educate themselves and their teams about the realistic benefits of nitrogen tire inflation. Consulting industry research, such as studies from reputable organizations like Consumer Reports and the National Highway Traffic Safety Administration, can provide valuable insights into the performance differences between nitrogen and air. Create internal workshops or training sessions to disseminate this knowledge, ensuring all stakeholders have a clear understanding of what to expect. Additionally, consider pilot testing nitrogen inflation on a small segment of your fleet before full-scale implementation. This allows for real-time data collection and assessment of actual performance against the predicted benefits, helping refine your strategy and budget accordingly.

When considering the cost of nitrogen tire inflation, the choice of materials used in the inflation systems plays a crucial role in performance, durability, and overall cost. Below, we analyze several common materials, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand moderate pressure and is often used in valves and connectors for nitrogen inflation systems.

Pros y contras: Aluminum’s durability and resistance to corrosion make it a popular choice. However, it can be more expensive than other materials like plastic or steel. Manufacturing complexity is moderate, as aluminum requires specialized machining processes.

Impacto en la aplicación: Aluminum components are compatible with nitrogen and can maintain integrity under varying temperature conditions. However, care must be taken to avoid galvanic corrosion when paired with dissimilar metals.

Consideraciones para compradores internacionales: Compliance with standards such as ASTM or DIN is essential. In regions like Africa and South America, where corrosion can be a significant issue, aluminum’s properties can be particularly beneficial.

Key Properties: Steel is known for its high strength and durability, with excellent pressure ratings. It is often used for high-pressure tanks and fittings in nitrogen inflation systems.

Pros y contras: Steel’s primary advantage is its strength, making it suitable for high-pressure applications. However, it is heavier than aluminum and can be prone to rust if not adequately coated. The manufacturing process can also be more complex due to welding and finishing requirements.

Impacto en la aplicación: Steel’s robustness is ideal for commercial applications, including heavy-duty vehicles. However, its weight can be a disadvantage in applications where weight savings are critical.

Consideraciones para compradores internacionales: Buyers in the Middle East and Europe should ensure compliance with local regulations and standards, as well as consider the availability of corrosion-resistant coatings.

Key Properties: Plastic is lightweight, corrosion-resistant, and can be molded into complex shapes. It is often used for valves and connectors in lower-pressure applications.

Illustrative image related to cost of nitrogen tire inflation

Pros y contras: The low cost and ease of manufacturing make plastic an attractive option. However, it may not withstand high pressures as effectively as metal alternatives, and its durability can be a concern in harsh environments.

Impacto en la aplicación: Plastic components are suitable for consumer vehicles but may not be ideal for heavy-duty applications where high pressure is required. They are also sensitive to temperature extremes.

Consideraciones para compradores internacionales: In regions with high temperatures, such as parts of Africa and the Middle East, selecting high-temperature-resistant plastics is crucial. Compliance with relevant standards is also necessary.

Key Properties: Composite materials combine the benefits of various materials, offering high strength-to-weight ratios and excellent corrosion resistance. They are increasingly used in high-performance applications.

Illustrative image related to cost of nitrogen tire inflation

Pros y contras: Composites are lightweight and can be engineered for specific applications, providing flexibility in design. However, they can be more expensive than traditional materials and may require specialized manufacturing processes.

Impacto en la aplicación: Composites are particularly advantageous in applications requiring weight savings without compromising strength, such as in aviation or high-performance automotive sectors.

Consideraciones para compradores internacionales: Buyers should consider the availability of composite materials in their regions and ensure compliance with international standards, as these materials may not be as widely available as metals or plastics.

Illustrative image related to cost of nitrogen tire inflation

| Material | Typical Use Case for cost of nitrogen tire inflation | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Valves and connectors in consumer vehicles | Ligero y resistente a la corrosión | Mayor coste que el plástico | Medio |

| Acero | High-pressure tanks for commercial vehicles | Alta resistencia y durabilidad | Más pesado y propenso a oxidarse | Medio |

| Plástico | Low-pressure valves and connectors | Bajo coste y fácil de fabricar | Limited pressure tolerance | Bajo |

| Compuesto | High-performance applications in aviation/automotive | Elevada relación resistencia/peso | Mayor coste y complejidad de fabricación | Alta |

This analysis provides a comprehensive overview of the materials involved in nitrogen tire inflation systems, equipping B2B buyers with the knowledge needed to make informed purchasing decisions.

The manufacturing process for nitrogen tire inflation systems involves several critical stages, each designed to ensure efficiency and quality. The primary stages include material preparation, forming, assembly, and finishing.

Preparación del material: The initial step involves sourcing high-purity nitrogen gas, typically through the fractional distillation of air or from specialized nitrogen generators. Ensuring the purity of nitrogen (usually 95% or higher) is crucial, as impurities can affect tire performance and safety. Additionally, manufacturers must prepare components like valves, hoses, and gauges, which are often made from durable materials resistant to corrosion and wear.

Formando: This stage focuses on shaping and molding the various components of the nitrogen inflation system. Techniques such as injection molding for plastic parts and machining for metal components are commonly employed. Precision in this stage is essential, as any defects can lead to leaks or malfunctions in the system.

Montaje: Once individual components are formed, they are assembled into a complete system. This process may involve manual assembly or automated systems, depending on the scale of production. During this phase, the assembly line must maintain stringent quality controls to ensure that each unit meets specified standards.

Acabado: The final stage involves testing and finishing touches. This can include painting, applying protective coatings, and ensuring that all components function correctly. Testing often involves pressure checks and performance assessments to guarantee that the system operates efficiently under various conditions.

Quality control (QC) is vital at each stage of the manufacturing process to ensure the reliability and safety of nitrogen tire inflation systems. Relevant international and industry-specific standards, such as ISO 9001, provide a framework for effective quality management systems.

Normas internacionales: Compliance with ISO 9001 ensures that manufacturers adhere to quality management principles, including a strong customer focus, the involvement of top management, and a process approach. This standard is recognized globally, making it essential for B2B buyers to verify that their suppliers are certified.

Normas específicas del sector: Depending on the region and application, additional certifications such as CE marking in Europe or API standards for certain industrial applications may be required. These certifications indicate that products meet specific safety and performance criteria relevant to their intended use.

Puntos de control de calidad: Effective QC involves multiple checkpoints:

– Control de calidad entrante (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified quality standards.

– Control de calidad durante el proceso (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process and identify any deviations from quality standards.

– Control de calidad final (CCF): Once the systems are assembled, they undergo final testing to confirm they function as intended and meet all regulatory requirements.

Various testing methods are employed to assess the performance and reliability of nitrogen tire inflation systems:

Pressure Testing: This method involves subjecting the system to high-pressure conditions to ensure it can withstand the operational pressures without leaking.

Leak Testing: Specialized equipment is used to detect any leaks in the system, ensuring that the nitrogen remains contained and effective over time.

Performance Testing: Systems are tested under simulated conditions to evaluate their effectiveness in maintaining tire pressure and performance metrics such as fuel efficiency and rolling resistance.

Pruebas de durabilidad: Components are subjected to wear and tear simulations to assess their longevity and performance over time.

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability. Here are several actionable steps:

Auditorías de proveedores: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. Buyers should assess whether suppliers comply with international standards and industry-specific regulations.

Solicitud de informes de calidad: Buyers should request detailed quality assurance reports from suppliers, which should include information on quality metrics, inspection results, and compliance with standards. These reports can reveal the supplier’s commitment to maintaining high-quality standards.

Inspecciones de terceros: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can include site visits and product testing, ensuring that the supplier meets established quality benchmarks.

Certifications and Documentation: Buyers should ensure that suppliers provide up-to-date certifications for ISO 9001 and any other relevant standards. Documentation should be readily available for review, confirming the supplier’s adherence to quality protocols.

International B2B buyers face unique challenges and considerations regarding quality control:

Diferencias culturales y normativas: Understanding the cultural context and regulatory environment in different regions is essential. Buyers must navigate varying standards and expectations concerning quality control.

Logistical Challenges: The logistics of transporting nitrogen inflation systems can impact quality. Buyers should ensure that suppliers have robust shipping and handling practices to prevent damage during transit.

Communication Barriers: Language differences may complicate the verification of quality control processes. Establishing clear communication channels is vital for ensuring that expectations are met.

Adaptability to Local Markets: Suppliers should be adaptable to local market needs and requirements, which may involve modifications to products or processes to comply with regional standards.

By understanding the manufacturing processes, quality control measures, and verification methods, B2B buyers can make informed decisions when sourcing nitrogen tire inflation systems, ensuring that they receive high-quality, reliable products tailored to their specific needs.

This guide serves as a comprehensive checklist for B2B buyers interested in procuring nitrogen tire inflation services. With the rising costs associated with tire maintenance and the benefits attributed to nitrogen inflation, it’s essential to understand the practical steps needed to make informed sourcing decisions. This checklist will help you navigate the complexities of selecting suppliers and evaluating costs effectively.

Understanding your specific inflation requirements is the first step in the procurement process. Consider the types of vehicles in your fleet and their operating conditions, as this will determine the volume of nitrogen needed and the frequency of inflation services. Different applications, such as passenger vehicles versus heavy-duty trucks, may have varying requirements for nitrogen purity and pressure retention.

Illustrative image related to cost of nitrogen tire inflation

Before engaging suppliers, familiarize yourself with the typical cost structure of nitrogen tire inflation. Costs can vary based on location, service frequency, and the type of nitrogen generation equipment used. Be prepared to ask suppliers about their pricing models, including one-time service fees versus long-term contracts, to ensure you receive competitive rates.

Thoroughly vet potential suppliers to ensure they meet your operational needs. Request detailed company profiles, including years in business, client testimonials, and case studies relevant to your industry. Additionally, check for certifications that demonstrate compliance with industry standards, which can indicate reliability and professionalism.

Investigate the technology and equipment used by suppliers for nitrogen generation and inflation. Look for suppliers that utilize advanced nitrogen generation systems that ensure high purity levels and efficient inflation processes. Equipment quality can directly impact the effectiveness of nitrogen inflation, so ensure that the supplier uses reliable and well-maintained machinery.

Illustrative image related to cost of nitrogen tire inflation

Not all suppliers offer the same range of services. Confirm that the supplier can provide ongoing support, including regular tire pressure checks, maintenance, and emergency services. Additionally, inquire whether they can accommodate your fleet size and offer flexible scheduling to minimize downtime.

Consider any additional services that suppliers may offer that can enhance your procurement decision. Value-added services might include training for your team on tire maintenance, tracking tire performance data, or providing environmental benefits assessments. These services can contribute to overall cost savings and operational efficiency.

Once you have selected a supplier, it’s time to negotiate terms and finalize contracts. Ensure that all aspects of the agreement are clearly defined, including pricing, service frequency, and liability issues. Having a well-structured contract will protect your interests and ensure a smooth working relationship with the supplier.

By following these steps, B2B buyers can strategically approach the procurement of nitrogen tire inflation services, ensuring that they achieve the best possible outcomes for their fleet operations.

When analyzing the cost structure for nitrogen tire inflation, several key components contribute to the overall pricing. These include:

Materiales: The primary material is nitrogen gas, which can be generated on-site or purchased from suppliers. On-site generation typically involves the use of specialized equipment, which can be a significant upfront investment but reduces long-term costs. Additionally, the purity of nitrogen can influence pricing; higher purity levels may incur higher costs.

Trabajo: Skilled labor is required for the installation and maintenance of nitrogen inflation systems. This includes technicians for equipment operation and maintenance, as well as staff for customer service and technical support.

Gastos generales de fabricación: This includes costs associated with the production and maintenance of nitrogen generation systems, including utilities, equipment depreciation, and facility maintenance.

Herramientas: Specialized tools for nitrogen inflation may be necessary, depending on the volume of tires being serviced. This can include hoses, gauges, and inflation systems.

Control de calidad: Ensuring the purity of nitrogen and the proper functioning of inflation systems requires rigorous quality control measures. This may involve regular testing and compliance with safety and industry standards.

Logística: The distribution of nitrogen systems and the transportation of equipment or bulk nitrogen must be factored into costs, especially for international sourcing.

Margen: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and demand.

Several factors can influence the pricing of nitrogen tire inflation services:

Volumen/MOQ (Cantidad mínima de pedido): Bulk purchases often lead to lower per-unit costs. For businesses with high tire turnover, negotiating favorable terms based on volume can significantly reduce costs.

Especificaciones y personalización: Specific requirements for nitrogen purity or specialized inflation equipment may lead to increased costs. Custom solutions tend to have higher price tags due to additional engineering and manufacturing efforts.

Materials Quality and Certifications: Higher-quality materials and certified processes can lead to increased costs. For instance, nitrogen with a purity of 99.9% may be more expensive than standard commercial-grade nitrogen.

Factores del proveedor: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge premium prices for their services.

Incoterms: The terms of delivery and responsibility for shipping costs can also affect pricing. Understanding the implications of Incoterms in international transactions is crucial for budgeting.

International B2B buyers can adopt several strategies to enhance cost-efficiency in sourcing nitrogen tire inflation:

Negociación: Leverage volume commitments or long-term contracts to negotiate better pricing. Establishing a relationship with suppliers can also lead to discounts and favorable terms.

Coste total de propiedad (TCO): Evaluate the TCO rather than just initial costs. Consider factors such as maintenance, potential savings from improved fuel efficiency, and tire longevity when assessing the value of nitrogen inflation.

Matización de precios para compradores internacionales: Be aware of currency fluctuations, import duties, and taxes that can affect overall costs. Establishing contracts in stable currencies can mitigate some financial risks.

Buscar y comparar proveedores: Conduct thorough research and compare multiple suppliers to identify the best price-to-quality ratio. Request quotes and inquire about additional services that may add value.

Consider Local Regulations and Standards: Understanding local regulations regarding nitrogen inflation can help avoid compliance costs and potential penalties.

While nitrogen tire inflation presents various advantages, understanding the comprehensive cost and pricing analysis is essential for B2B buyers. By considering the key cost components, price influencers, and practical buyer tips, companies can make informed decisions that enhance their operational efficiency and profitability. Always remember that indicative prices can vary significantly based on market conditions, supplier relationships, and geographic location, so it’s crucial to stay updated on industry trends and pricing fluctuations.

In the quest for optimal tire performance, businesses often evaluate various inflation methods to enhance safety and efficiency. While nitrogen tire inflation is widely marketed for its potential benefits, it’s essential to consider alternative options. This analysis compares nitrogen inflation against traditional air inflation and advanced tire monitoring systems, helping B2B buyers make informed decisions.

| Aspecto comparativo | Cost Of Nitrogen Tire Inflation | Traditional Air Inflation | Advanced Tire Monitoring Systems |

|---|---|---|---|

| Rendimiento | Moderate pressure retention, minimal oxidation | Good pressure retention; requires regular checks | Excellent performance; continuous monitoring |

| Coste | $5+ per tire for inflation; ongoing costs for refills | Generally free; minimal cost for occasional air pumps | Initial setup cost; ongoing subscription for data services |

| Facilidad de aplicación | Requires specialized equipment | Easily accessible; available at most gas stations | Requires installation and training for effective use |

| Mantenimiento | Requires periodic refills with nitrogen | Minimal; check pressure regularly | Regular software updates; requires monitoring |

| El mejor caso de uso | High-performance vehicles, racing, and aviation | General use vehicles, light-duty applications | Fleet management, commercial vehicles, and high-usage scenarios |

Traditional air inflation remains the most prevalent method for tire inflation due to its accessibility and cost-effectiveness. Most gas stations offer free air, making it an economical choice for businesses that operate a fleet of vehicles. However, this method requires regular pressure checks, as tires filled with air can lose pressure more quickly than those filled with nitrogen. While it is sufficient for most vehicles, businesses with high-performance demands may find the need for more consistent pressure management.

Advanced tire monitoring systems leverage technology to provide real-time data on tire pressure and health. These systems often include sensors that alert drivers to pressure changes, thus minimizing the risk of underinflation and enhancing safety. While the initial setup cost can be significant, the long-term benefits often outweigh the investment, particularly for businesses managing large fleets. These systems reduce the need for manual checks and can improve overall fuel efficiency. However, they require ongoing maintenance and potential subscription fees for data services.

When determining the best tire inflation method for your business, consider your specific operational needs, budget constraints, and performance requirements. Nitrogen inflation may offer benefits for specialized applications, but traditional air inflation is a cost-effective solution for everyday use. Alternatively, advanced tire monitoring systems present a high-tech option that can enhance safety and efficiency for fleets. Evaluating these alternatives will enable B2B buyers to select a tire inflation strategy that aligns with their operational goals and budgetary considerations.

When evaluating the cost of nitrogen tire inflation, several technical properties play a pivotal role in determining value, performance, and overall effectiveness. Understanding these specifications can empower B2B buyers to make informed decisions regarding tire maintenance solutions.

The purity level of nitrogen gas used for tire inflation is critical. Ideally, nitrogen should be around 95% pure to maximize its benefits, such as reduced oxidation and slower pressure loss. Higher purity levels reduce the introduction of oxygen and moisture, which can degrade tire performance over time. For B2B buyers, ensuring high purity levels can lead to enhanced tire longevity and safety, ultimately lowering long-term costs.

Maintaining optimal tire pressure is vital for performance and safety. Nitrogen-filled tires tend to maintain pressure better than air-filled tires, as nitrogen molecules are larger and less permeable, leading to slower loss of inflation. For businesses operating fleets, this property can translate to decreased fuel costs and improved vehicle efficiency, making it a key consideration in the overall cost analysis.

Nitrogen inflation mitigates oxidation within the tire structure, which can cause rubber degradation. By minimizing exposure to oxygen, nitrogen helps maintain tire integrity over time. For companies investing in fleet management, this property can reduce the frequency of tire replacements and associated costs, making nitrogen a potentially cost-effective solution in the long run.

Nitrogen exhibits better temperature stability compared to air, meaning that tire pressure remains more consistent across varying environmental conditions. This stability is particularly crucial for businesses operating in regions with extreme temperatures, as it can prevent performance issues and enhance safety. Understanding this property can help B2B buyers optimize their tire management strategies.

Familiarity with industry jargon can streamline procurement processes and enhance communication between suppliers and buyers. Below are several common trade terms relevant to nitrogen tire inflation.

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of nitrogen tire inflation, OEMs may offer specific nitrogen generation systems tailored for tire maintenance. Understanding OEM relationships can help businesses source reliable products that meet their specific tire inflation needs.

MOQ is the minimum amount of a product that a supplier is willing to sell. For businesses considering nitrogen tire inflation systems or services, knowing the MOQ can aid in budgeting and inventory management. This term is particularly important for B2B buyers seeking bulk purchasing options to reduce overall costs.

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. In the context of nitrogen tire inflation, an RFQ can help businesses compare costs and services offered by different suppliers, ensuring competitive pricing and better value.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Understanding these terms is crucial for B2B transactions involving nitrogen inflation equipment, as they outline who is responsible for shipping, insurance, and tariffs, thereby helping to avoid potential disputes and additional costs.

PSI is a unit of pressure measurement commonly used in tire inflation. Understanding the appropriate PSI levels for different types of tires is essential for maintaining optimal performance. For businesses, maintaining correct PSI can prevent tire wear and enhance vehicle safety.

Treadwear refers to the wear and tear on tire treads over time. The rate of treadwear can be influenced by factors such as inflation pressure and driving conditions. For B2B buyers, understanding treadwear can help in forecasting tire replacement needs and managing fleet costs effectively.

By grasping these technical properties and industry terminologies, international B2B buyers can navigate the complexities of nitrogen tire inflation, ensuring they make well-informed purchasing decisions that align with their operational goals.

Illustrative image related to cost of nitrogen tire inflation

The market for nitrogen tire inflation has evolved significantly, driven by several global factors. One of the primary drivers is the increasing focus on fuel efficiency and vehicle safety. Businesses in the automotive sector are keen to adopt practices that enhance tire performance, leading to reduced rolling resistance and improved fuel economy. Moreover, the growing awareness of the benefits of nitrogen inflation—such as lower pressure loss over time—has prompted many fleet operators and transportation companies to consider nitrogen as a viable option for tire maintenance.

Emerging technologies in tire monitoring systems are also influencing sourcing trends. Advanced tire pressure monitoring systems (TPMS) integrated with IoT capabilities are becoming popular, allowing companies to track tire health and inflation levels in real-time. This technology can be particularly valuable for logistics and transportation companies operating in regions like Africa and South America, where road conditions can vary dramatically. Additionally, as the automotive industry pivots towards electric vehicles, the demand for specialized tire inflation solutions is expected to rise, creating opportunities for B2B buyers in various markets.

Sustainability is increasingly becoming a focal point for businesses in the tire inflation sector. The environmental impact of traditional air inflation—primarily due to the presence of moisture and oxygen—can lead to accelerated tire degradation, which has downstream effects on waste generation. As a result, companies are exploring more sustainable alternatives, including the use of nitrogen, which minimizes oxidation and extends tire life.

Ethical sourcing practices are also gaining traction. B2B buyers are now prioritizing suppliers that adhere to sustainable practices, including the use of ‘green’ certifications and materials in their operations. For instance, sourcing nitrogen from suppliers that utilize eco-friendly methods for gas production can significantly enhance a company’s sustainability profile. This is particularly relevant in regions like the Middle East and Europe, where environmental regulations are stringent, and consumer preferences are shifting towards sustainable products.

The use of nitrogen for tire inflation has a rich history, initially gaining traction in aviation and motorsports due to its benefits over traditional air. The transition to commercial vehicles and passenger cars began in the early 2000s, as tire manufacturers and service providers started to promote nitrogen as a means to improve tire performance and safety. Over the years, the market has expanded significantly, with tire shops and automotive service centers increasingly offering nitrogen inflation services.

Illustrative image related to cost of nitrogen tire inflation

Today, the landscape is shaped by technological advancements and a growing emphasis on sustainability, making nitrogen inflation not just a niche offering but a relevant solution for various industries. As international B2B buyers continue to navigate these dynamics, understanding the evolution and current trends in nitrogen tire inflation will be critical for making informed sourcing decisions.

How do I determine the cost-effectiveness of nitrogen tire inflation for my fleet?

To assess the cost-effectiveness of nitrogen tire inflation for your fleet, consider both the initial investment and ongoing costs. While nitrogen inflation typically costs more upfront (around $5 per tire), it may lead to reduced tire wear and lower fuel consumption due to better pressure retention. Analyze your fleet’s tire replacement frequency and fuel expenses to calculate potential savings over time. Conduct a pilot program to compare performance between nitrogen and air inflation across several vehicles to make an informed decision.

What are the benefits of using nitrogen instead of air for tire inflation?

Using nitrogen for tire inflation can offer several advantages, particularly for heavy-duty vehicles. Nitrogen-filled tires experience slower pressure loss, which can lead to improved fuel efficiency and safety by maintaining optimal tire pressure. Additionally, nitrogen reduces oxidation, potentially extending tire life. However, it’s essential to weigh these benefits against the higher costs and ensure that your operations can accommodate regular nitrogen top-offs to maximize the advantages.

What factors should I consider when sourcing nitrogen tire inflation suppliers?

When sourcing suppliers for nitrogen tire inflation, evaluate their reliability, pricing structures, and service capabilities. Look for suppliers with a proven track record in your region, particularly those familiar with the local market dynamics in Africa, South America, the Middle East, or Europe. Request references and check reviews to gauge their service quality. Additionally, inquire about their equipment for nitrogen generation, as higher purity levels can enhance the benefits of nitrogen inflation.

What are typical minimum order quantities (MOQ) for nitrogen tire inflation services?

Minimum order quantities for nitrogen tire inflation services can vary significantly between suppliers. Generally, service providers may have MOQs based on the size of your fleet or the frequency of service. Some may require a minimum number of tires to be inflated at once, while others might offer flexibility for smaller operations. It’s advisable to discuss your specific needs and negotiate terms that align with your operational capacity.

What payment terms are common when sourcing nitrogen tire inflation services internationally?

Payment terms for nitrogen tire inflation services can vary by supplier and region. Common terms include net 30 or net 60 days, but upfront payments or deposits may be required, especially for new customers or larger orders. When sourcing internationally, consider currency fluctuations and potential transaction fees. It’s essential to clarify payment expectations in advance and ensure that terms are mutually agreeable to avoid future disputes.

How can I ensure quality assurance in nitrogen tire inflation services?

To ensure quality assurance in nitrogen tire inflation services, request detailed information about the supplier’s processes and equipment. Verify that they use high-purity nitrogen and have standardized procedures for tire inflation. Conduct periodic audits and inspections to assess the quality of service. Additionally, establish clear metrics for performance evaluation, such as pressure retention rates and customer feedback, to maintain service quality over time.

What logistical considerations should I keep in mind for nitrogen tire inflation services?

Logistical considerations for nitrogen tire inflation include the location of service providers, transportation of vehicles, and the availability of nitrogen inflation equipment. Ensure that the supplier can efficiently service your fleet’s location, especially if your operations span multiple regions. Additionally, consider the scheduling of service visits to minimize downtime and the logistics of transporting tires if off-site services are required. Clear communication with your supplier can help streamline these processes.

How does nitrogen tire inflation impact international shipping and compliance?

When considering nitrogen tire inflation in the context of international shipping, be aware of compliance with local regulations regarding gas storage and transportation. Certain countries may have specific guidelines for handling compressed gases, including nitrogen. Ensure that your supplier is knowledgeable about these regulations and can provide documentation as needed. Additionally, consider any potential impacts on shipping costs and timelines, as the need for specialized handling may affect logistics.

Dominio: suburbantire.com

Matriculado: 1996 (29 años)

Introducción: Nitrogen Tire Inflation service at Suburban Tire offers the following key details:

– Nitrogen is a dry, non-corrosive, non-flammable gas that maintains tire pressure better than standard air.

– Benefits of using Nitrogen include:

– Convenience: Maintains tire pressure longer due to larger nitrogen molecules.

– Improved Fuel Economy: Better gas mileage over time.

– Longer Tire Life: Redu…

Dominio: wiygul.com

Matriculado: 1996 (29 años)

Introducción: Major tire manufacturers recommend nitrogen tire inflation due to several advantages over regular air. Nitrogen is 93-95% pure, drier, and reduces moisture buildup, which minimizes oxidation and corrosion, extending tire life and protecting Tire Pressure Monitoring System (TPMS) sensors. Nitrogen-filled tires maintain steadier air pressure, losing only about 2 psi over time compared to 3 psi for a…

In summary, the strategic sourcing of nitrogen for tire inflation presents both opportunities and considerations for international B2B buyers. While nitrogen can offer benefits such as reduced pressure loss and extended tire life, these advantages are often marginal when compared to the routine maintenance of air-filled tires. Buyers should weigh the costs associated with nitrogen inflation against the operational efficiencies it may provide, particularly in high-demand sectors such as transportation and logistics.

Furthermore, investing in nitrogen tire inflation can enhance fleet performance and safety, especially in regions where extreme temperatures can affect tire pressure. As markets in Africa, South America, the Middle East, and Europe continue to evolve, aligning procurement strategies with reliable nitrogen suppliers can yield substantial long-term benefits.

Moving forward, we encourage B2B buyers to conduct thorough market analyses and supplier assessments to make informed decisions regarding nitrogen tire inflation. By leveraging strategic sourcing and fostering partnerships with established suppliers, businesses can optimize their tire management practices, ultimately leading to improved operational efficiency and cost savings in the competitive global marketplace.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.