In an increasingly interconnected world, sourcing effective solutions for emergency tire repairs, such as a fix a flat tire inflator, presents unique challenges for B2B buyers across diverse markets. Fluctuating supply chains, varying regional regulations, and the demand for eco-friendly products complicate the purchasing landscape. This guide aims to provide comprehensive insights into the global market for tire inflators, addressing essential factors such as product types, applications, supplier vetting processes, and cost considerations.

With a focus on empowering international buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—this guide equips decision-makers with actionable knowledge to navigate their purchasing journey. By understanding the nuances of different tire inflator options, including their performance in sealing punctures and their environmental impact, businesses can make informed choices that enhance their operational efficiency and customer satisfaction.

From evaluating the effectiveness of various formulations to ensuring compliance with local safety standards, this guide serves as a valuable resource for buyers seeking to invest wisely in tire repair solutions. It not only highlights the importance of choosing reliable suppliers but also emphasizes the long-term benefits of integrating high-quality products into their service offerings. Prepare to explore the global landscape of tire inflators and make strategic purchasing decisions that align with your business goals.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Aerosol Tire Inflator | Quick application, seals punctures up to 1/4″, eco-friendly | Automotive repair shops, fleet services | Pros: Fast and easy to use; Contras: Temporary fix, requires follow-up repair. |

| Portable Electric Pump | Battery-operated, can inflate multiple tires, versatile | Transportation companies, service providers | Pros: Reusable; Contras: Requires charging, potential for mechanical failure. |

| Heavy-Duty Inflator | Designed for larger tires, robust construction | Construction, agriculture, off-road vehicles | Pros: High pressure capability; Contras: Bulkier and more expensive. |

| Compact Tire Sealant | Smaller size, ideal for personal vehicles, seals minor leaks | Individual consumers, small businesses | Pros: Easy to store; Contras: Limited to smaller punctures. |

| Multi-Purpose Inflator | Combines tire inflating with other functions (e.g., air mattress) | General retail, outdoor equipment rentals | Pros: Versatile use; Contras: May lack power for heavy-duty applications. |

Aerosol tire inflators are designed for quick and effective emergency repairs, making them a staple for automotive repair shops and fleet services. These inflators can seal punctures up to 1/4 inch in diameter and are eco-friendly, allowing for safe disposal and minimal environmental impact. B2B buyers should consider the ease of use and the speed of application, as these factors can significantly reduce downtime for vehicles.

Portable electric pumps offer versatility and the ability to inflate multiple tires without needing to replace canisters. They are particularly useful for transportation companies and service providers that require a reliable solution for on-the-go repairs. B2B buyers should assess battery life and maintenance needs, as these pumps must be charged and can be subject to mechanical issues.

Heavy-duty inflators are built to handle larger tires commonly found in construction, agriculture, and off-road vehicles. Their robust construction allows for high-pressure inflation, making them suitable for demanding environments. When purchasing, businesses should evaluate the inflator’s pressure capabilities and durability to ensure it meets the rigorous demands of their operations.

Compact tire sealants are perfect for personal vehicles and small businesses due to their size and ease of storage. They are designed to seal minor leaks quickly, providing a temporary solution until a professional repair can be made. B2B buyers must consider the limitations of these products, such as the size of punctures they can seal, to ensure they meet their specific needs.

Multi-purpose inflators combine tire inflating capabilities with additional features, such as inflating air mattresses or sports equipment. This versatility makes them attractive to general retail and outdoor equipment rental businesses. However, B2B buyers should weigh the potential trade-offs in power and performance, as these units may not be suitable for heavy-duty applications.

| Industria/Sector | Specific Application of fix a flat tire inflator | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Transportation & Logistics | Emergency tire repair for delivery vehicles | Minimizes downtime and enhances operational efficiency | Ensure compatibility with various tire sizes and types |

| Automotive Services | Quick tire repair for roadside assistance services | Increases customer satisfaction and loyalty | Look for eco-friendly formulas and ease of use |

| Construction & Heavy Equipment | Tire maintenance for construction vehicles | Reduces delays on job sites due to flat tires | Source larger can sizes for heavy-duty applications |

| Gestión de flotas | Routine maintenance for fleet vehicles | Cuts costs by avoiding tire replacements and repairs | Consider bulk purchasing options for cost savings |

| Car Rental & Leasing | Emergency tire inflators for rental cars | Enhances customer experience and reduces liability | Evaluate the shelf-life and ease of use for customers |

In the transportation and logistics sector, fix-a-flat tire inflators are critical for emergency tire repairs on delivery vehicles. When a flat tire occurs, the inflator allows drivers to quickly seal punctures without needing to change the tire, significantly reducing downtime. This is particularly valuable in regions with challenging road conditions, such as parts of Africa and South America, where tire issues can lead to costly delays. Buyers should ensure that the inflators are compatible with various tire sizes and types used in their fleet.

Automotive service providers utilize fix-a-flat tire inflators to offer rapid roadside assistance for clients experiencing flat tires. The ease of use and quick application can enhance customer satisfaction and loyalty, as clients appreciate prompt service. For international buyers, particularly in regions with high vehicle usage, sourcing products with eco-friendly formulas is essential to meet regulatory standards and customer expectations regarding environmental responsibility.

In construction, fix-a-flat tire inflators are invaluable for maintaining heavy machinery and vehicles, which often face rugged terrains that can lead to punctured tires. The ability to quickly address tire issues helps avoid project delays, ensuring that work continues smoothly. Buyers in this sector should consider sourcing larger can sizes to accommodate the heavy-duty tires commonly found on construction equipment.

Fleet management companies can leverage fix-a-flat tire inflators as part of their routine maintenance to prolong the life of tires and reduce costs associated with replacements. By using these inflators, fleet operators can address minor punctures immediately, thus minimizing the operational disruptions caused by flat tires. Bulk purchasing options are advantageous for these businesses to maximize cost savings and ensure a consistent supply of tire inflators across their fleets.

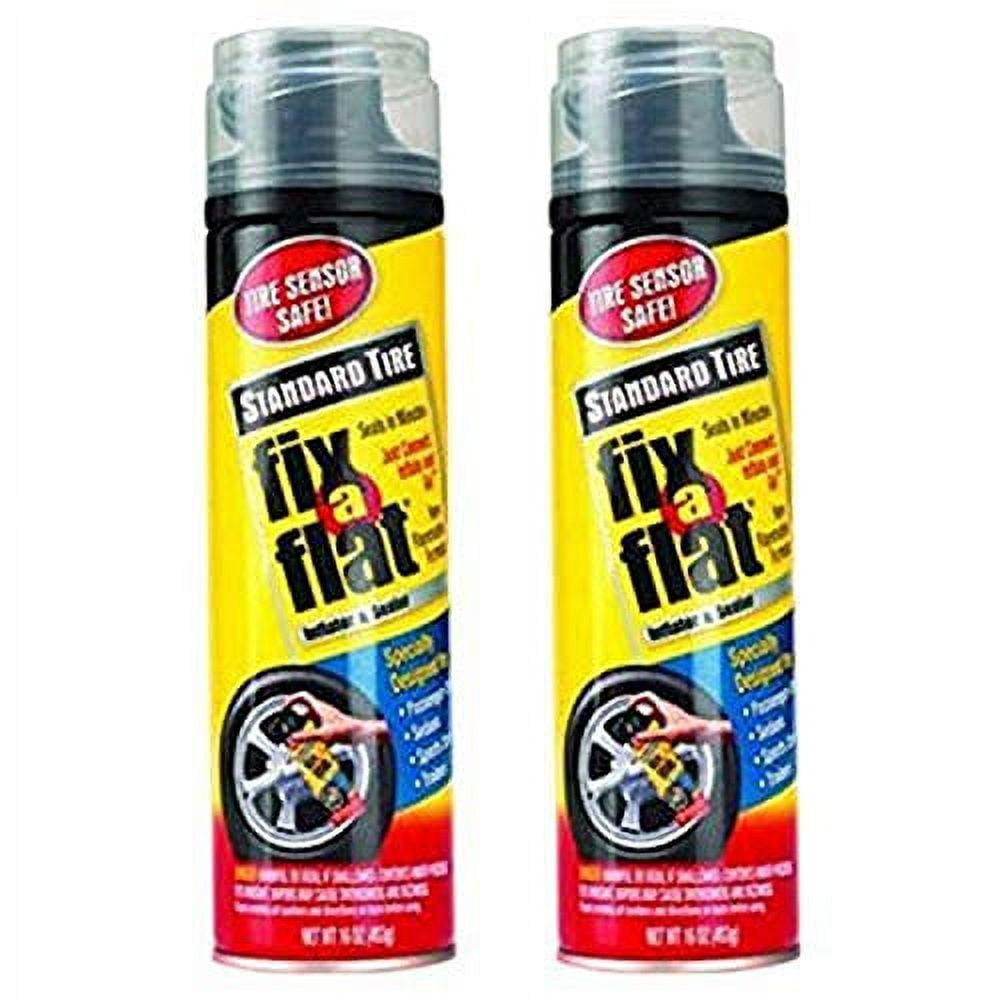

Illustrative image related to fix a flat tire inflator

For car rental and leasing companies, having fix-a-flat tire inflators available in rental vehicles enhances the customer experience by providing a quick solution for flat tires. This not only reduces the liability associated with roadside emergencies but also improves customer confidence in the rental service. Evaluating the shelf-life and ease of use of these inflators is crucial for ensuring that customers can effectively manage tire issues without relying heavily on assistance.

El problema: Many B2B buyers, especially those managing fleets or automotive service centers, often face challenges when it comes to selecting the appropriate size of a fix-a-flat tire inflator. With various vehicles on the road, from compact cars to larger trucks, choosing the wrong size can lead to ineffective repairs. This not only frustrates the user but can also result in increased downtime for vehicles, impacting overall service efficiency.

La solución: To ensure the right inflator is chosen, buyers should utilize the Fix-a-Flat size calculator available on the manufacturer’s website. By entering specific tire dimensions and vehicle types, you can receive tailored recommendations. Additionally, maintaining a diverse inventory of inflators, including 12 oz. for compact cars, 16 oz. for sedans, and 24 oz. for trucks, can provide flexibility and readiness for various situations. Regular training for staff on the importance of matching the inflator size to tire specifications can further enhance operational efficiency and reduce the likelihood of errors.

El problema: As environmental awareness grows, B2B buyers are increasingly concerned about the ecological footprint of products they purchase. The use of tire inflators that are not environmentally friendly can lead to negative perceptions among customers and regulatory scrutiny. This issue is particularly relevant in markets where eco-friendly products are becoming a purchasing criterion.

La solución: When sourcing fix-a-flat tire inflators, opt for those with eco-friendly formulations, such as those that are non-toxic and non-corrosive. Highlight these features in your marketing materials to appeal to environmentally conscious consumers. Additionally, establish partnerships with manufacturers who prioritize sustainability and offer transparent information regarding their product compositions. This not only aligns with global sustainability goals but also positions your business as a responsible entity in the industry, enhancing brand reputation and customer trust.

Illustrative image related to fix a flat tire inflator

El problema: In emergency situations, time is of the essence. Many B2B buyers, particularly those in roadside assistance or transportation services, often find that their teams struggle with the proper and efficient use of fix-a-flat inflators under pressure. Ineffective usage can lead to improper tire repairs, resulting in further complications and potential accidents.

La solución: Implementing comprehensive training programs focused on the correct usage of fix-a-flat inflators can drastically reduce errors during emergencies. Consider creating easy-to-follow instructional materials, such as video tutorials or quick reference guides, to assist your teams. Moreover, conducting regular drills can help staff become familiar with the process of connecting, inflating, and ensuring safety protocols are followed. Investing in high-quality, user-friendly inflators that are designed for quick application can also streamline the repair process, ensuring that your team can act swiftly and effectively when emergencies arise.

When selecting materials for a fix-a-flat tire inflator, it is essential to consider the properties and performance characteristics that will impact the product’s effectiveness and durability. The following analysis explores four common materials used in the construction of tire inflators, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to fix a flat tire inflator

Plastic (Polypropylene or Polyethylene)

Plastic materials like polypropylene and polyethylene are commonly used in the canisters of tire inflators due to their lightweight and corrosion-resistant properties. They typically have a temperature rating ranging from -40°F to 180°F (-40°C to 82°C), making them suitable for various climates. Additionally, these plastics are non-toxic and can be produced in various colors and finishes.

Ventajas e inconvenientes:

Plastics are generally cost-effective and easy to manufacture, allowing for high-volume production. However, they may not withstand extreme temperatures or mechanical stress as well as metals, leading to potential failures in harsh conditions. Their environmental impact is also a consideration, as they can contribute to plastic waste if not properly recycled.

Impacto en la aplicación:

Plastic materials are compatible with most tire sealants and air, making them ideal for inflators. However, their susceptibility to UV degradation can be a concern in regions with high sun exposure.

Consideraciones para compradores internacionales:

B2B buyers should consider compliance with local environmental regulations regarding plastic use and disposal. Standards such as ASTM D6400 for biodegradable plastics may be relevant in certain markets, particularly in Europe.

Aluminio

Aluminum is often used for the valve components and nozzles of tire inflators due to its excellent strength-to-weight ratio and resistance to corrosion. It can withstand high pressures, typically rated up to 150 psi, making it suitable for various tire types.

Ventajas e inconvenientes:

Aluminum components are durable and lightweight, enhancing the overall portability of the inflator. However, the cost of aluminum can be higher than that of plastic, and manufacturing processes like machining can add complexity and expense.

Impacto en la aplicación:

The use of aluminum ensures that the inflator can handle high-pressure applications effectively, which is critical for maintaining tire integrity. Additionally, aluminum is compatible with most tire sealants.

Illustrative image related to fix a flat tire inflator

Consideraciones para compradores internacionales:

Buyers should ensure that aluminum components meet standards such as ASTM B221 for extruded aluminum, especially in markets where quality control is strict, such as Europe.

Goma

Rubber is primarily used in seals and gaskets within tire inflators. Its elasticity and ability to create airtight seals are crucial for maintaining pressure. Rubber can typically withstand temperatures from -40°F to 212°F (-40°C to 100°C).

Ventajas e inconvenientes:

Rubber provides excellent sealing properties and is relatively inexpensive. However, it can degrade over time, especially when exposed to ozone or UV light, which may limit its lifespan.

Impacto en la aplicación:

The effectiveness of the inflator relies heavily on the quality of the rubber seals, as any failure can lead to air leakage and ineffective repairs.

Consideraciones para compradores internacionales:

Buyers should look for rubber materials that comply with standards such as ASTM D2000 for rubber quality, particularly in regions with stringent quality requirements.

Illustrative image related to fix a flat tire inflator

Materiales compuestos

Composite materials, such as reinforced plastics or fiberglass, are increasingly used in tire inflators to enhance strength while reducing weight. These materials can offer temperature resistance similar to metals while maintaining the lightweight properties of plastics.

Ventajas e inconvenientes:

Composites can provide superior durability and resistance to environmental factors compared to traditional plastics. However, they can be more expensive and complex to manufacture.

Impacto en la aplicación:

The use of composites can lead to a more robust inflator design, suitable for rugged environments, particularly in developing markets where durability is essential.

Illustrative image related to fix a flat tire inflator

Consideraciones para compradores internacionales:

B2B buyers should evaluate the specific composite standards applicable in their region, such as ISO 9001 for quality management, to ensure product reliability.

| Material | Typical Use Case for fix a flat tire inflator | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plástico | Canisters and housing | Ligero y resistente a la corrosión | Limited temperature tolerance | Bajo |

| Aluminio | Valves and nozzles | High strength and pressure rating | Mayor coste y complejidad de fabricación | Med |

| Goma | Juntas y empaquetaduras | Excellent sealing properties | Se degrada con el tiempo | Bajo |

| Materiales compuestos | Structural components | Superior durability | Higher cost and complexity | Alta |

This strategic material selection guide provides a comprehensive overview for B2B buyers, highlighting the critical factors to consider when sourcing materials for fix-a-flat tire inflators in diverse global markets.

The manufacturing process of a Fix-a-Flat tire inflator involves several critical stages, each designed to ensure the product’s efficiency and reliability. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to fix a flat tire inflator

Preparación del material: This initial stage involves sourcing high-quality materials, including the eco-friendly sealant, aerosol canisters, and propellant gases. Suppliers must adhere to stringent quality standards to ensure that all materials are non-toxic, non-corrosive, and environmentally safe. For B2B buyers, verifying the origin and quality of these materials is crucial, as they directly impact the product’s effectiveness and safety.

Formando: During this stage, raw materials are processed into the necessary components. For instance, the aerosol cans are formed from metal sheets through processes like stamping and deep drawing. This ensures that the cans are durable enough to withstand internal pressure and external handling. Buyers should inquire about the manufacturing techniques used and whether they comply with international standards to ensure consistency and safety.

Montaje: After forming, the components are assembled. This includes filling the canisters with the sealant and propellant, attaching the nozzle, and ensuring that all parts fit securely. Automated assembly lines are often used to enhance precision and reduce human error. Buyers should assess the level of automation in the assembly process, as this often correlates with product quality and production efficiency.

Acabado: The final stage involves labeling, packaging, and conducting a visual inspection to ensure that all products meet the required specifications. This stage is critical for branding and compliance with regulatory standards. For B2B buyers, understanding the finishing process can help evaluate the product’s market readiness and compliance with local regulations.

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each tire inflator meets stringent performance and safety standards. Various international and industry-specific standards guide the QA process.

Normas internacionales: Compliance with ISO 9001 is fundamental, as this standard focuses on quality management systems. Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. B2B buyers should request ISO certification documentation from suppliers to verify adherence to these standards.

Normas específicas del sector: Additionally, certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for materials used in tire inflators are crucial. These certifications ensure that products are safe for consumer use and meet specific performance criteria.

Puntos de control de calidad: The QA process includes several checkpoints:

– Control de calidad entrante (IQC): This initial inspection verifies the quality of raw materials before production begins. Suppliers should provide detailed reports on the materials used.

– Control de calidad durante el proceso (IPQC): Throughout the manufacturing process, random samples are tested to ensure compliance with specifications. This stage is vital for identifying defects early.

– Control de calidad final (CCF): Before products are packaged and shipped, they undergo final inspections and testing. This includes checking for leaks, verifying the sealant’s effectiveness, and ensuring that the product meets all performance standards.

Various testing methods are employed to validate the performance and safety of Fix-a-Flat tire inflators. These methods help ensure that products meet the required specifications before they reach the market.

Pressure Testing: This method assesses the integrity of the aerosol canisters under pressure. It ensures that the cans can withstand the internal pressures generated by the propellant without leaking or bursting.

Sealant Performance Testing: This involves simulating punctures in tire samples and evaluating how effectively the sealant can seal leaks. It often includes tests for different puncture sizes and conditions, which is critical for validating the product’s claims.

Environmental Testing: Given that Fix-a-Flat products are used in various climates, testing for performance under extreme temperatures is essential. This ensures that the product remains effective in both hot and cold conditions.

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability and compliance with international standards. Here are some strategies for doing so:

Auditorías de proveedores: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality control measures. These audits can assess adherence to international standards and identify areas for improvement.

Quality Assurance Reports: Requesting detailed QA reports from suppliers can offer transparency regarding their processes and testing outcomes. These reports should include results from IQC, IPQC, and FQC stages.

Inspecciones de terceros: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These inspections can be particularly useful for buyers in regions with less stringent regulatory oversight.

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

Cumplimiento de la normativa: Different regions have varying regulatory requirements. It is essential for buyers to familiarize themselves with local regulations that may impact product specifications, labeling, and safety standards.

Cultural and Economic Factors: Understanding the cultural and economic contexts of suppliers can influence negotiations and quality expectations. Buyers should consider the supplier’s reputation, experience, and commitment to quality in their respective markets.

Logistical Considerations: Importing products from overseas may involve additional quality checks and certifications to meet destination country standards. Buyers should plan for these potential requirements to avoid delays and ensure compliance.

By understanding the manufacturing processes and quality assurance practices involved in producing Fix-a-Flat tire inflators, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive reliable and compliant products for their markets.

To assist B2B buyers in procuring ‘fix a flat tire inflator’ products, this practical sourcing guide offers a structured checklist. By following these steps, businesses can ensure they select the right products from reliable suppliers while meeting their operational needs.

Begin by identifying the specific requirements for the tire inflators you intend to procure. Consider factors such as the size of the canister, the type of vehicles it will service, and the puncture size it can effectively seal. This step is crucial as it helps narrow down the options to those that meet your operational needs and ensures compatibility with your target market.

Conduct thorough market research to understand current trends in tire inflators, especially in your target regions. Analyze demand patterns, preferred product features, and competitive pricing. This information will help you make informed decisions and position your product effectively within your market.

Illustrative image related to fix a flat tire inflator

Before committing to a supplier, it’s essential to conduct a comprehensive evaluation. Look for suppliers with a proven track record in the industry, and request company profiles, product samples, and case studies. Assess their customer service, reliability, and ability to meet delivery timelines, as these factors will influence your overall procurement experience.

Quality assurance is paramount when sourcing tire inflators. Review product specifications and ensure they meet industry standards and regulations, especially in terms of safety and environmental impact. Look for eco-friendly formulations and non-toxic ingredients that align with sustainability goals.

Review the pricing structure for the tire inflators from various suppliers. Compare costs while considering the total cost of ownership, including shipping and handling. Negotiate favorable payment terms to optimize cash flow and reduce financial risk.

After-sales support can significantly impact your procurement decision. Ensure that the supplier provides adequate customer service, including troubleshooting assistance and product replacement options. A solid warranty policy is also essential as it protects your investment and ensures you can maintain product quality over time.

Finally, consider the logistics involved in importing and distributing the tire inflators. Assess shipping options, lead times, and the reliability of logistics partners. Effective planning will ensure timely delivery to your customers and help maintain service quality.

By following this checklist, B2B buyers can streamline their procurement process, ensuring they select high-quality ‘fix a flat tire inflators’ that meet their business needs and customer expectations.

When sourcing ‘Fix-a-Flat’ tire inflators, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This analysis will provide insights into the various cost components, price influencers, and essential buyer tips to facilitate informed purchasing decisions.

The cost structure for manufacturing tire inflators encompasses several components:

Materiales: The primary costs arise from raw materials used in the production of the inflators, including the aerosol can, sealant compounds, and propellants. Eco-friendly formulations may incur higher material costs but appeal to environmentally conscious markets.

Trabajo: Labor costs involve the wages of workers involved in production, assembly, and packaging. Efficient labor management can significantly impact overall production costs.

Gastos generales de fabricación: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient operational processes can help minimize these overhead costs.

Herramientas: Initial setup and tooling costs are essential for producing customized or high-spec inflators. These costs can vary significantly based on the complexity of the product design.

Control de calidad: Ensuring product quality through rigorous testing and compliance with international safety standards can add to costs, but it is vital for maintaining brand reputation and customer trust.

Logística: Transportation and warehousing costs are critical, especially for international shipments. These can be influenced by shipping methods, distance, and handling requirements.

Margen: Suppliers typically mark up costs to ensure profitability. Understanding the expected margin can help buyers gauge fair pricing.

Several factors influence pricing in the market for tire inflators:

Volumen y cantidad mínima de pedido (MOQ): Bulk purchasing often results in significant cost savings. Suppliers may offer discounts for larger orders, making it beneficial for buyers to assess their inventory needs accurately.

Especificaciones y personalización: Custom features or specialized formulations can lead to increased costs. Buyers should clarify their needs to avoid unnecessary expenses.

Materiales y certificaciones de calidad: Higher-quality materials or certifications (e.g., ISO, environmental standards) can raise production costs but may offer better performance and compliance with local regulations.

Factores del proveedor: The supplier’s location, production capabilities, and reputation can all influence pricing. Establishing relationships with reliable suppliers can lead to better terms and pricing.

Incoterms: Understanding Incoterms is essential for international buyers as they determine the responsibilities of buyers and sellers during shipping. This can affect overall cost and risk management.

To maximize value and efficiency when sourcing tire inflators, consider the following buyer tips:

Research and Compare Prices: Gather quotes from multiple suppliers to understand the market price range. This can provide leverage during negotiations.

Negotiate Based on Total Cost of Ownership (TCO): Assess the long-term value and performance of the product rather than just the upfront cost. A slightly higher initial investment in a quality product may yield better durability and fewer replacements.

Leverage Volume Discounts: If you anticipate ongoing demand, negotiate bulk pricing or explore long-term contracts to secure lower rates.

Understand Local Market Conditions: Be aware of regional pricing variations, especially in emerging markets like Africa and South America, where economic conditions can influence supply chains.

Build Strong Relationships: Cultivating good relationships with suppliers can lead to better pricing, favorable terms, and priority treatment in times of limited supply.

In conclusion, navigating the cost and pricing landscape for Fix-a-Flat tire inflators requires a thorough understanding of the various cost components, pricing influencers, and strategic negotiation tactics. By employing these insights, international B2B buyers can make informed purchasing decisions that optimize their investments. Prices may vary based on market conditions and specific supplier agreements, so always seek updated quotes for the most accurate financial planning.

In the realm of emergency tire repair solutions, the Fix-a-Flat tire inflator stands out as a popular choice among drivers. However, various alternatives exist that can provide similar benefits. This section explores these alternatives, highlighting their strengths and weaknesses to help B2B buyers make informed decisions.

Illustrative image related to fix a flat tire inflator

| Aspecto comparativo | Fix A Flat Tire Inflator | Tire Sealant (Liquid) | Compresor de aire portátil |

|---|---|---|---|

| Rendimiento | Seals punctures up to 1/4″ and inflates within seconds | Seals small punctures; effectiveness varies | Inflates tires; requires prior sealant for punctures |

| Coste | $15.49 (16 oz.) | $10 – $30 (varies by brand) | $25 – $100 (depending on features) |

| Facilidad de aplicación | Simple, just connect and inflate | Requires application through valve | Requires setup and connection to power source |

| Mantenimiento | Temporary solution; recommended repair within 3 days | Can last until tire replacement; requires inspection | Needs regular checks; may require repairs |

| El mejor caso de uso | Emergency situations; quick fixes for sedans and coupes | Long-term use; suitable for regular maintenance | Best for regular tire inflation; useful for multiple vehicles |

Tire sealants, typically in liquid form, offer a different approach to flat tire repair. These products can be poured into the tire through the valve stem, where they seal small punctures as they rotate. The primary advantage is their ability to provide a long-lasting repair, potentially lasting until the tire is replaced. However, their effectiveness can vary based on the size and location of the puncture, and they can complicate future tire repairs due to the residue left behind. Additionally, they require a bit of skill to apply correctly, which may be a drawback for less experienced users.

A portable air compressor serves a different primary function—inflation rather than sealing. While it can inflate a tire back to the appropriate pressure, it does not seal punctures on its own. This solution is ideal for regular maintenance, allowing users to top up tire pressure as needed. However, it requires a power source, which can be a limitation in emergency situations. The initial investment is typically higher than that of a Fix-a-Flat inflator, and it may require more maintenance over time. The compressor is more versatile, suitable for multiple vehicles and various inflation tasks beyond tires.

When evaluating tire repair solutions, B2B buyers should consider their specific use cases and operational environments. If speed and ease of use are paramount for emergency situations, the Fix-a-Flat tire inflator is a compelling choice. For businesses that require a longer-term solution and have the capacity for regular maintenance, tire sealants may be more appropriate. On the other hand, companies with a fleet of vehicles may benefit from investing in a portable air compressor, which can serve multiple purposes beyond just tire repair. Ultimately, the right choice will depend on balancing factors such as cost, performance, and the specific needs of the organization.

When considering the purchase of fix-a-flat tire inflators, understanding their technical properties is crucial for B2B buyers. Here are some essential specifications to consider:

Sealing Capability

Fix-a-flat tire inflators are designed to seal punctures up to 1/4 inch in diameter, which is significantly larger than many competitors. This property is vital for ensuring quick repairs, minimizing downtime for vehicles, and enhancing customer satisfaction. For businesses operating fleets or in tire repair services, choosing products with superior sealing capabilities can lead to reduced operational costs.

Inflation Speed

These inflators can seal and inflate a tire in seconds. Fast inflation means that drivers can resume their journeys quickly, which is particularly important for commercial vehicles that rely on timely deliveries. This attribute can be a selling point for businesses that prioritize efficiency and customer service.

Temperature Range

The recommended operating temperature range for many fix-a-flat products is between -2 °C and 45 °C (28.4 °F to 113 °F). This specification is crucial for international buyers, particularly in regions with extreme temperatures. Ensuring that the product performs effectively across varying climates can prevent product failures and enhance reliability.

Eco-Friendly Composition

Many tire inflators, such as those from Fix-a-Flat, feature eco-friendly formulas that are non-toxic, non-corrosive, and easy to clean up with water. As sustainability becomes increasingly important in global markets, products that prioritize environmental safety can be more appealing to buyers who are looking to align with eco-conscious practices.

Compatibility with Tire Sensors

Modern vehicles often come equipped with tire pressure monitoring systems (TPMS). Fix-a-flat inflators that are safe for use with these sensors help prevent damage during repairs, ensuring that the integrity of vehicle systems is maintained. For B2B buyers, this compatibility is crucial when choosing repair solutions for contemporary vehicles.

Temporary Repair Notice

It’s essential to note that fix-a-flat products are designed for temporary repairs, with recommendations for permanent fixes within a specified timeframe (typically 3 days or 100 miles). This property is important for businesses involved in automotive services, as it sets clear expectations for customers regarding the longevity of the repair.

Understanding trade terminology can enhance communication and negotiation in the B2B environment. Here are some commonly used terms related to fix-a-flat tire inflators:

OEM (fabricante de equipos originales)

This term refers to companies that produce parts or products that are sold under another brand’s name. For buyers, understanding OEM relationships can help in sourcing high-quality tire inflators that meet original specifications for vehicle maintenance.

MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is a critical consideration for B2B buyers, as it affects inventory management and cost efficiency. Understanding the MOQ can aid in budgeting and planning for bulk purchases.

RFQ (solicitud de presupuesto)

An RFQ is a document sent to suppliers to request pricing and other terms for specified products. For B2B buyers, issuing an RFQ can facilitate competitive pricing and ensure that they are getting the best value for their purchases.

Incoterms (Términos comerciales internacionales)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for navigating shipping costs, insurance, and risk, especially when sourcing products globally.

Plazos de entrega

This term refers to the amount of time it takes from placing an order until it is delivered. For businesses, understanding lead times is crucial for planning and ensuring that products are available when needed, particularly in industries reliant on quick turnaround times.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing fix-a-flat tire inflators, ensuring they meet their operational needs while also aligning with market standards.

The global market for fix-a-flat tire inflators is witnessing a robust growth trajectory, driven by several factors. One of the primary drivers is the increasing reliance on personal and commercial vehicles across emerging markets in Africa, South America, and parts of Europe. As urbanization accelerates and vehicle ownership rises, the demand for efficient and quick tire repair solutions becomes paramount. Additionally, the rise in e-commerce has made these products more accessible to international B2B buyers, enhancing market reach.

Current trends indicate a shift towards more technologically advanced inflators, incorporating features such as digital pressure gauges and integrated LED lights for nighttime use. Furthermore, the adoption of smart technology is emerging, with products that can connect to mobile apps for monitoring tire health and providing maintenance reminders. This trend aligns with the growing consumer preference for convenience and functionality, particularly in regions where roadside assistance may not be readily available.

Illustrative image related to fix a flat tire inflator

In terms of sourcing dynamics, international buyers are increasingly looking for suppliers who can offer competitive pricing without compromising quality. B2B partnerships are also evolving, with buyers favoring suppliers who provide comprehensive service packages, including training on product usage and after-sales support. The emphasis on quick delivery times and reliable logistics channels is crucial, especially for markets in regions like Brazil and Vietnam, where supply chain efficiency can significantly impact business operations.

Sustainability is becoming a central tenet in the sourcing strategies for tire inflators. B2B buyers are increasingly prioritizing products that minimize environmental impact, prompting manufacturers to adopt eco-friendly materials and production processes. For instance, the development of non-toxic and non-corrosive formulas in tire repair products meets the demand for safer alternatives that do not harm the environment.

Moreover, ethical sourcing practices are gaining traction among international buyers. Companies are now more vigilant in vetting their suppliers to ensure adherence to fair labor practices and sustainable resource management. Certifications such as ISO 14001 for environmental management and other green certifications are becoming prerequisites for partnerships, particularly for buyers in Europe and the Middle East, where regulatory standards are stringent.

The importance of transparency in the supply chain cannot be overstated. B2B buyers are seeking suppliers who can provide detailed information about their sourcing practices and the lifecycle of their products. This focus not only enhances brand reputation but also aligns with the increasing consumer demand for socially responsible products.

The fix-a-flat tire inflator sector has evolved significantly since its inception over 50 years ago. Initially designed as a temporary solution for flat tires, these products have undergone considerable advancements in technology and formulation. Early versions often relied on basic aerosol mechanics, while modern inflators now include eco-friendly materials and advanced sealing capabilities that address larger punctures more effectively.

Illustrative image related to fix a flat tire inflator

As the automotive industry has progressed, so too have the expectations of consumers and B2B buyers. The shift towards convenience and immediate solutions has driven innovation in product development. Today, fix-a-flat inflators are not just a stopgap measure but are integral components of vehicle maintenance kits, reflecting broader changes in consumer behavior and market dynamics. This historical perspective underscores the importance of continuous innovation in meeting the evolving needs of a global marketplace.

How do I select the right fix-a-flat tire inflator for my business needs?

When selecting a fix-a-flat tire inflator, consider the type of vehicles your customers primarily use. Different models are designed for varying tire sizes, such as sedans, SUVs, or trucks. Assess the average tire size and puncture dimensions in your target market; for instance, the 16 oz. can is ideal for standard tires, while larger sizes accommodate bigger vehicles. Additionally, evaluate the product’s eco-friendliness, ease of use, and safety features to ensure they meet your business’s sustainability and operational standards.

What is the shelf life of fix-a-flat tire inflators?

Generally, fix-a-flat tire inflators have a shelf life of around 2-3 years when stored in a cool, dry place, away from direct sunlight. It’s crucial to check the expiration date on the canister before purchasing to ensure product efficacy. Regularly rotating your stock and maintaining optimal storage conditions can help reduce wastage and ensure that your customers receive effective, reliable products. Always consult the supplier for specific shelf life details and storage recommendations.

What are the minimum order quantities (MOQ) for fix-a-flat tire inflators?

Minimum order quantities can vary significantly based on the supplier and the region. Typically, MOQs range from 100 to 1,000 units for B2B purchases. It’s advisable to directly communicate with potential suppliers to negotiate terms that fit your purchasing capabilities. Consider consolidating orders with other businesses to meet MOQ requirements or seeking suppliers that offer flexible ordering options to help manage inventory costs effectively.

How can I vet suppliers for fix-a-flat tire inflators?

Vetting suppliers involves several steps: check their credentials, including certifications and industry experience, and request product samples to evaluate quality. Investigate customer reviews and feedback to gauge reliability and service levels. Additionally, inquire about their production processes, adherence to safety standards, and whether they can accommodate customization requests. Establishing communication to assess responsiveness and support is also critical in ensuring a productive supplier relationship.

What payment terms are commonly offered for bulk purchases?

Payment terms can vary widely but often include options such as net 30, net 60, or letter of credit for international transactions. Some suppliers may require a deposit upfront, with the balance due upon shipment or delivery. It’s essential to clarify payment terms before finalizing orders to avoid misunderstandings. Additionally, consider negotiating terms that align with your cash flow management strategies and operational needs to maintain financial health.

Are fix-a-flat tire inflators customizable for branding?

Yes, many suppliers offer customization options for branding purposes. You can often request private labeling, where your company logo and details are printed on the canister. Customization may also extend to packaging design and included instructions. Discuss these options with potential suppliers early in the negotiation process to ensure they can meet your specific branding requirements and to understand any additional costs involved.

What quality assurance measures should I expect from suppliers?

Reputable suppliers typically implement stringent quality assurance (QA) measures to ensure their products meet safety and performance standards. Expect to see certifications from recognized authorities, detailed testing protocols, and compliance with local and international regulations. Inquire about their QA processes, including inspections during manufacturing, batch testing, and the availability of safety data sheets (SDS) for the products. A robust QA program is essential for maintaining product reliability and customer satisfaction.

How can I manage logistics and shipping for international orders?

Managing logistics for international orders involves careful planning of shipping methods, customs clearance, and delivery timelines. Collaborate with suppliers who have experience in international shipping to ensure compliance with local regulations. Consider using freight forwarders to simplify logistics and reduce costs. Additionally, establish clear communication channels with your suppliers regarding shipping schedules and documentation requirements to avoid delays and ensure timely delivery of your products.

Dominio: fixaflat.com

Matriculado: 1999 (26 años)

Introducción: {“product_name”: “Fix-a-Flat 16 oz.”, “suitable_for”: “Standard Tires (Sedan | Coupe)”, “price”: “$15.49”, “description”: “Fix-a-Flat aerosol tire inflators are the easiest and quickest way to repair a flat tire in an emergency. Designed to seal small tire punctures in seconds and provide enough inflation to lift the rim off the ground.”, “puncture_sealing_capacity”: “Seals tread area punctures up…

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Fix-a-flat products can help temporarily seal punctures in tires, but they may make the tire unrepairable. They do not void tire warranties, but reputable tire shops will not repair tires that have had fix-a-flat used on them due to potential corrosion of steel belts and risk of belt separation. These products are recommended for emergency situations only.

In today’s fast-paced global market, the strategic sourcing of fix-a-flat tire inflators presents a substantial opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The demand for quick and effective tire repair solutions is rising, driven by a growing emphasis on convenience and safety. Fix-a-flat products, with their eco-friendly formulations and user-friendly designs, not only address immediate tire issues but also align with sustainable practices that are increasingly important to consumers.

Buyers should prioritize suppliers that offer a range of product sizes to cater to different vehicle types, ensuring they can meet diverse customer needs. Additionally, understanding the regulatory landscape in various regions can enhance sourcing strategies, ensuring compliance and fostering trust with end-users.

Illustrative image related to fix a flat tire inflator

As the market evolves, staying informed about product innovations and environmental considerations will be crucial. Engage with suppliers who demonstrate a commitment to quality and sustainability, paving the way for long-term partnerships. Now is the time to leverage these insights and enhance your sourcing strategy to capture the growing demand for effective tire repair solutions. Embrace this opportunity to differentiate your offerings and provide exceptional value to your customers.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.