In the increasingly competitive landscape of global trade, sourcing reliable pump tires can pose significant challenges for international B2B buyers. With varying regulations, quality standards, and supply chain complexities across regions, particularly in Africa, South America, the Middle East, and Europe, making informed purchasing decisions is paramount. This comprehensive guide aims to simplify the process of navigating the global market for pump tires, addressing critical aspects such as types, applications, supplier vetting, and cost considerations.

Buyers will discover an array of pump tire options tailored to diverse applications, from automotive to industrial uses. Understanding the nuances of each type will enable businesses to select products that best meet their operational needs. Additionally, we will provide insights into effective supplier evaluation strategies, ensuring that buyers can identify trustworthy partners who adhere to international quality standards.

By delving into pricing structures and market trends, this guide empowers B2B buyers to negotiate better deals and optimize their procurement strategies. With a focus on actionable insights and expert recommendations, this resource is designed to enhance your purchasing capabilities, ensuring that you can confidently source pump tires that deliver performance and reliability in any market.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Manual Hand Pumps | Lightweight, portable, requires manual operation | Small workshops, bicycle shops | Pros: Cost-effective, easy to use. Contras: Labor-intensive, slower inflation speed. |

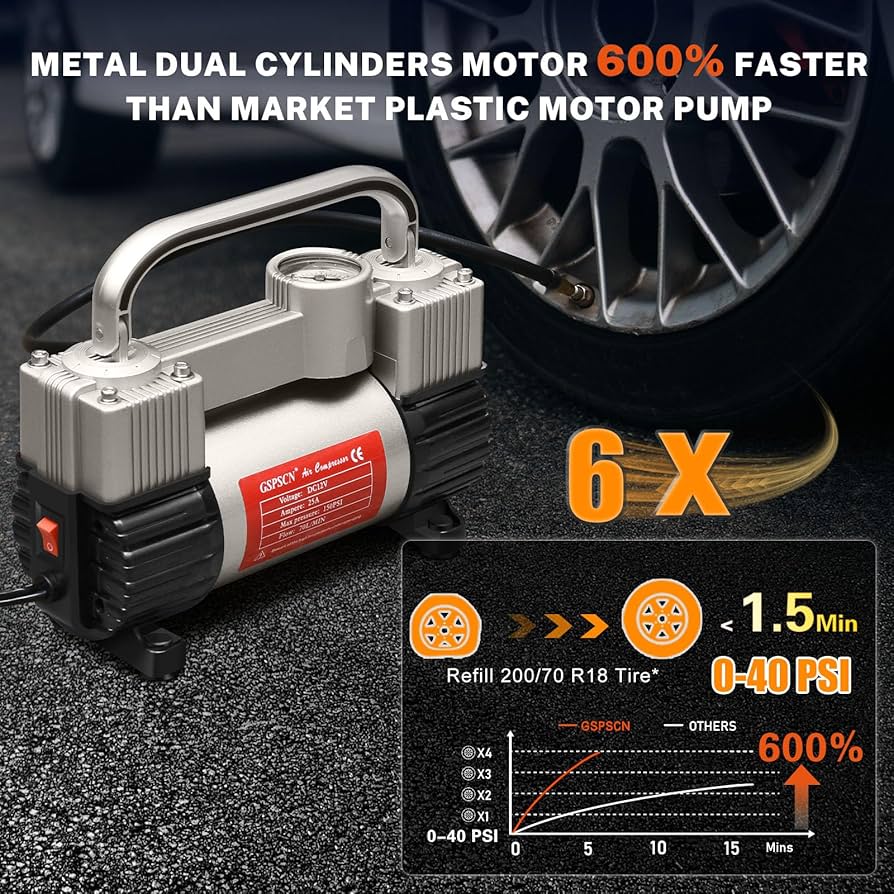

| Electric Air Compressors | Powered by electricity, capable of high PSI | Automotive service centers, fleet management | Pros: Fast inflation, consistent pressure. Contras: Requires power source, higher initial cost. |

| Portable Battery Pumps | Cordless, rechargeable, compact design | Mobile repair services, roadside assistance | Pros: Convenient, versatile. Contras: Limited battery life, may lack power for larger tires. |

| Dual-Action Pumps | Pumps air on both up and down strokes | Bicycle repair shops, outdoor events | Pros: Faster inflation, efficient. Contras: More complex design, potentially higher cost. |

| Air Tank Systems | Store compressed air for quick inflation | Heavy machinery, construction sites | Pros: High volume, immediate availability. Contras: Requires significant space, higher maintenance. |

Manual hand pumps are the most basic type of tire inflators, designed for portability and ease of use. They are lightweight and typically made from durable materials, making them ideal for small workshops or bicycle repair shops. B2B buyers should consider their cost-effectiveness and simplicity, as these pumps do not require electricity and can be used anywhere. However, the labor-intensive nature of manual operation and slower inflation speed may deter those needing rapid service.

Electric air compressors are essential tools in automotive service centers and fleet management applications. They provide quick and efficient tire inflation, often delivering high PSI levels necessary for larger vehicle tires. Their ability to maintain consistent pressure is a significant advantage for businesses focused on efficiency. While they come with a higher initial investment and require a power source, the speed and reliability they offer can lead to improved service turnaround times, making them a worthwhile investment for many B2B buyers.

Portable battery pumps are designed for convenience and versatility, catering to mobile repair services and roadside assistance operations. These cordless, rechargeable devices offer the flexibility to inflate tires without being tethered to a power source, making them ideal for on-the-go scenarios. However, potential buyers should be aware of their limited battery life and the possibility that they may not provide sufficient power for larger tires. Despite these drawbacks, their compact design and ease of use make them a popular choice in the field.

Dual-action pumps are specifically engineered to inflate tires more efficiently by pushing air into the tire on both the up and down strokes. This feature makes them particularly suitable for bicycle repair shops and outdoor events where quick tire inflation is essential. B2B buyers should appreciate the faster inflation times and increased efficiency, although the more complex design may come at a higher cost. Understanding the trade-offs between speed and price is crucial for businesses looking to enhance their service offerings.

Air tank systems are designed to store compressed air, providing immediate access to high volumes of air for tire inflation. This makes them indispensable in industries involving heavy machinery and construction sites, where quick and efficient inflation is critical. While they offer significant advantages in terms of volume and availability, B2B buyers should consider the space requirements and maintenance needs associated with these systems. Proper assessment of operational needs will guide businesses in determining whether an air tank system is the right fit for their applications.

| Industria/Sector | Specific Application of pump tires | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Agricultura | Irrigation systems with pump tires | Improved efficiency in water distribution and reduced labor costs | Durability, resistance to agricultural chemicals, and compatibility with existing systems |

| Construcción | Heavy machinery and equipment | Enhanced mobility and safety on job sites | Load capacity, puncture resistance, and availability in local markets |

| Transportation & Logistics | Fleet management for delivery vehicles | Increased uptime and reduced maintenance costs | Quality assurance, warranty options, and local service availability |

| Mining | Mobile equipment for mineral extraction | Enhanced operational efficiency and reduced downtime | Robustness, adaptability to varying terrains, and supplier reliability |

| Energy | Pumping systems for oil and gas extraction | Optimized production rates and reduced operational costs | Compliance with industry standards, material quality, and sourcing from reputable suppliers |

In the agriculture sector, pump tires are integral to irrigation systems, facilitating the movement of water across vast fields. These tires are designed to withstand harsh environmental conditions and exposure to chemicals, ensuring they can operate efficiently over time. For international buyers, especially in regions like Africa and South America, sourcing durable pump tires that can handle varying soil types and weather conditions is crucial to maintaining productivity and reducing operational costs.

Pump tires are vital in construction for heavy machinery, including excavators and bulldozers. They provide the necessary traction and stability on uneven terrain, which is essential for safety and efficiency on job sites. Buyers in Europe and the Middle East should consider factors such as load capacity and puncture resistance when sourcing pump tires, as these characteristics directly impact the machinery’s operational effectiveness and longevity.

In the transportation and logistics sector, pump tires are used in delivery vehicles to ensure reliable performance and safety. High-quality tires reduce the frequency of breakdowns, leading to increased uptime and lower maintenance costs. For B2B buyers in regions like Saudi Arabia and Germany, it’s essential to prioritize quality assurance and warranty options when procuring pump tires, as these factors contribute significantly to the overall cost-effectiveness of fleet operations.

Within the mining industry, pump tires are utilized in mobile equipment for mineral extraction. Their robust construction allows for operation in challenging terrains, significantly enhancing operational efficiency. Buyers must consider the adaptability of these tires to various environmental conditions and the reliability of suppliers, particularly in emerging markets, to ensure consistent performance and minimize downtime.

In the energy sector, particularly in oil and gas extraction, pump tires support pumping systems that are critical for efficient production. The right tires can optimize production rates while reducing operational costs. For international buyers, compliance with industry standards and sourcing from reputable suppliers are vital considerations to ensure that the tires can withstand the demanding conditions typical of energy operations.

El problema: In the B2B landscape, companies often struggle to find pump tires that meet the specific needs of their diverse fleet or equipment. This challenge is compounded by varying regional standards and customer expectations across markets such as Africa, South America, and Europe. Buyers face frustration due to inconsistent quality, limited availability, or lack of technical specifications that cater to their unique operational requirements. These issues can lead to downtime, increased operational costs, and potential safety hazards, which are unacceptable in a competitive business environment.

La solución: To effectively address this sourcing challenge, B2B buyers should prioritize building relationships with multiple suppliers who specialize in pump tires. Conducting thorough market research can help identify reputable manufacturers that offer a range of products tailored to different applications. Buyers should request detailed product specifications, certifications, and performance guarantees to ensure compliance with local regulations and industry standards. Leveraging trade shows and industry conferences can facilitate direct interactions with suppliers, allowing for negotiation on bulk purchasing and long-term contracts. Additionally, utilizing online platforms that aggregate supplier information can streamline the selection process, enabling buyers to compare product features, pricing, and customer reviews efficiently.

El problema: Many businesses face the dual challenge of managing maintenance costs while ensuring the longevity of their pump tires. In industries where pump tires are subject to frequent use, such as logistics and construction, wear and tear can significantly impact overall productivity. Buyers may find themselves caught between the need for affordable solutions and the long-term benefits of investing in high-quality products, leading to a cycle of purchasing cheaper tires that fail prematurely and incur higher replacement costs.

La solución: To combat maintenance costs effectively, B2B buyers should adopt a proactive approach to tire management. This includes implementing a regular inspection and maintenance schedule to monitor tire health and performance. Investing in high-quality pump tires that come with robust warranties can provide significant long-term savings by reducing the frequency of replacements. Furthermore, buyers should consider utilizing tire pressure monitoring systems (TPMS) to maintain optimal inflation levels, which can extend the life of the tires and improve fuel efficiency. Partnering with tire service providers who offer maintenance packages can also streamline this process, allowing companies to focus on core operations while ensuring their tires are in peak condition.

El problema: For international buyers, navigating the complexities of import regulations and compliance standards when sourcing pump tires can be daunting. Each region has its own set of rules regarding safety standards, environmental regulations, and tariffs, which can lead to delays, unexpected costs, and legal complications. In regions like the Middle East and Africa, where regulations can vary widely, B2B buyers often feel overwhelmed by the bureaucratic hurdles that accompany international trade.

La solución: To mitigate these challenges, buyers must equip themselves with knowledge about the specific regulations governing tire imports in their target markets. Engaging a local customs broker or legal expert can provide valuable insights into compliance requirements and streamline the import process. Additionally, establishing relationships with suppliers who are experienced in international shipping can help ensure that all necessary documentation is in place. Utilizing freight forwarders that specialize in tire logistics can also minimize delays and reduce costs associated with customs clearance. By proactively addressing these regulatory hurdles, B2B buyers can facilitate smoother transactions and maintain a reliable supply chain.

Illustrative image related to pump tires

When selecting materials for pump tires, it is essential to consider various factors that affect performance, durability, and cost. Below is an analysis of four common materials used in pump tire manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Rubber is the most commonly used material for pump tires due to its elasticity and resilience. It typically has a high-temperature rating, often exceeding 100°C, and can withstand significant pressure, making it suitable for various applications. Rubber also exhibits excellent corrosion resistance, particularly against water and certain chemicals, which is crucial for maintaining performance in diverse environments.

Pros: The primary advantage of rubber is its durability and flexibility, allowing it to absorb shocks and resist wear and tear. Additionally, rubber is cost-effective and widely available, making it a preferred choice for manufacturers.

Contras: However, rubber can degrade under extreme temperatures and may not be suitable for high-pressure applications beyond its limits. Its manufacturing complexity can also increase costs if specialized formulations are required.

Illustrative image related to pump tires

Impacto en la aplicación: Rubber is compatible with a wide range of media, including air and water, making it versatile for various pump applications. However, buyers must ensure that the specific rubber formulation meets the operational requirements of their applications.

Polyurethane is another popular material for pump tires, known for its excellent abrasion resistance and durability. It can withstand temperatures ranging from -30°C to 80°C and offers good pressure ratings, making it suitable for demanding environments.

Pros: The key advantage of polyurethane is its superior wear resistance, which extends the lifespan of pump tires in abrasive conditions. It also maintains flexibility at lower temperatures, providing reliable performance in colder climates.

Contras: On the downside, polyurethane is generally more expensive than rubber and can be more complex to manufacture, which may increase overall costs for buyers.

Impacto en la aplicación: Polyurethane is particularly effective in applications involving abrasive materials, such as in mining or construction. Buyers in regions with such industries, like South America and Africa, should consider polyurethane for its enhanced durability.

Polyvinyl chloride (PVC) is a synthetic plastic polymer that offers a unique blend of properties for pump tire applications. It has a temperature rating of up to 60°C and provides good pressure resistance.

Pros: PVC is lightweight and cost-effective, making it an attractive option for manufacturers looking to minimize costs. Its chemical resistance is also noteworthy, allowing it to withstand exposure to various substances.

Contras: However, PVC lacks the flexibility of rubber and polyurethane, which can lead to cracking under stress or extreme temperatures. Its lower durability may also limit its use in high-demand applications.

Impacto en la aplicación: PVC is suitable for low-pressure applications and environments where chemical exposure is a concern. Buyers from the Middle East, where chemical industries are prevalent, may find PVC a viable option for specific applications.

Illustrative image related to pump tires

Metal reinforcement, such as steel or aluminum, is often used in conjunction with other materials to enhance the structural integrity of pump tires. It can withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Pros: The primary advantage of metal reinforcement is its strength and durability, providing additional support and extending the lifespan of pump tires in demanding environments.

Contras: The downside is that metal can add significant weight to the tire, which may not be suitable for all applications. Additionally, the cost of metal materials can be high, impacting overall manufacturing expenses.

Impacto en la aplicación: Metal-reinforced pump tires are ideal for industrial applications where high pressure and heavy loads are common. Buyers from Europe, particularly in sectors like manufacturing and logistics, may prioritize this option for its robustness.

| Material | Typical Use Case for pump tires | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | General-purpose applications | High durability and flexibility | Degrades under extreme conditions | Bajo |

| Polyurethane | Abrasive environments (mining, etc.) | Superior wear resistance | Mayor coste y complejidad de fabricación | Medio |

| PVC | Low-pressure and chemical exposure | Ligero y rentable | Less flexibility and durability | Bajo |

| Metal Reinforcement | Heavy-duty industrial applications | Enhanced strength and durability | Increased weight and cost | Alta |

This guide provides a clear overview of the materials available for pump tires, along with their respective advantages and limitations, aiding international B2B buyers in making informed decisions tailored to their specific needs and regional standards.

Illustrative image related to pump tires

The manufacturing process for pump tires involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material preparation is the foundational step in producing pump tires. This stage involves sourcing high-quality raw materials, such as rubber compounds, textiles, and reinforcements. Manufacturers typically use synthetic rubber for its durability and performance characteristics. The materials undergo rigorous testing to ensure they meet industry specifications for elasticity, tensile strength, and resistance to wear and tear.

Once the materials are sourced, they are mixed according to specific formulas that can include various additives for enhanced performance. The mixing process is conducted in controlled environments to maintain consistency and quality. Proper material preparation sets the tone for the entire manufacturing process, as any defects at this stage can lead to compromised tire quality.

The forming stage is where the prepared materials are shaped into the desired tire form. This process often involves advanced techniques such as extrusion and molding. In extrusion, the rubber is forced through a die to create specific shapes, such as the tire tread or sidewall.

Following extrusion, the formed materials are often cured or vulcanized. This step involves applying heat and pressure to cross-link the rubber molecules, enhancing the tire’s strength and elasticity. The curing process is critical, as it directly affects the tire’s performance characteristics, including grip, durability, and resistance to deformation.

Assembly is a meticulous stage where different tire components come together. This can include the inner liner, tread, sidewalls, and belts. Manufacturers typically use automated machinery to ensure precision and reduce the risk of human error. The assembly process may also involve the application of adhesives and sealants to enhance the bond between components.

Quality assurance checks are integrated into the assembly line to identify any defects or inconsistencies before the tires proceed to the next stage. This proactive approach minimizes the likelihood of faulty products reaching the market.

The finishing stage is crucial for preparing pump tires for distribution. This stage includes several processes, such as trimming, inspection, and labeling. Trimming removes any excess material from the tire, ensuring a clean and professional appearance.

Illustrative image related to pump tires

After trimming, each tire undergoes a thorough inspection to identify any imperfections or deviations from quality standards. This inspection often includes visual checks and measurements to ensure that the tires meet the specified dimensions and tolerances. Once approved, tires are labeled for identification and packaged for shipment.

Quality assurance (QA) is a vital component of pump tire manufacturing, ensuring that products meet both safety and performance standards. International standards, such as ISO 9001, provide a framework for quality management systems. ISO 9001 focuses on continuous improvement and customer satisfaction, making it an essential certification for manufacturers aiming to compete in the global market.

In addition to ISO 9001, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are also relevant. These certifications validate that the products comply with safety regulations and performance criteria specific to the regions and industries they serve.

Illustrative image related to pump tires

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

Control de calidad entrante (IQC): This step involves inspecting raw materials upon arrival to ensure they meet the required specifications. Any substandard materials are rejected and replaced.

Control de calidad durante el proceso (IPQC): This ongoing inspection occurs throughout the manufacturing process, monitoring each stage to catch defects early. It can include monitoring temperature, pressure, and material properties during curing and forming.

Control de calidad final (CCF): Before packaging, finished tires undergo a comprehensive inspection. This includes visual assessments, dimensional checks, and performance testing to ensure they meet all safety and quality standards.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several actionable steps to ensure supplier reliability:

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the operational standards and quality control measures in place. Buyers should request audit reports and review them thoroughly.

Solicitar informes de calidad: Suppliers should be able to provide detailed quality control reports that outline their testing methods, results, and any corrective actions taken in response to defects.

Inspecciones de terceros: Engaging third-party inspection agencies can offer an impartial assessment of the supplier’s quality assurance practices. These inspections can be particularly useful for verifying compliance with international standards.

Understand Certification Nuances: Different regions may have varying requirements for certifications. Buyers should familiarize themselves with the certifications relevant to their market to ensure compliance and quality.

Evaluate Traceability: A robust traceability system allows buyers to track the origin of materials and the quality control measures applied at each stage. This transparency is critical for maintaining quality assurance in the supply chain.

International buyers must navigate various regulatory landscapes that can affect quality control. For example, different countries may have specific requirements for product safety, labeling, and performance testing. It is crucial for buyers to understand these nuances to avoid compliance issues and ensure that the products they import meet local regulations.

Additionally, cultural differences may impact communication and expectations regarding quality. Establishing clear communication channels and setting mutual quality expectations can help bridge these gaps and foster a strong supplier relationship.

Illustrative image related to pump tires

In conclusion, understanding the manufacturing processes and quality assurance measures for pump tires is vital for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their operational needs and market requirements.

To facilitate a successful procurement process for pump tires, this guide offers a structured checklist designed for international B2B buyers. By following these steps, you can ensure that you select the right products and suppliers to meet your operational needs.

Before initiating the sourcing process, it’s essential to clearly define your technical requirements for pump tires. This includes specifications such as tire size, pressure ratings, and intended applications (e.g., passenger vehicles, commercial trucks, or specialty vehicles). Having a well-defined specification will guide your discussions with suppliers and help you identify products that align with your needs.

Understanding current market trends and pricing for pump tires is crucial. Analyze how prices fluctuate based on material costs, demand, and regional variations. This knowledge will empower you during negotiations and help you recognize a fair price range for the products you are considering.

Before committing to a supplier, thorough vetting is essential. Request comprehensive company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of reliability and quality to mitigate risks associated with procurement.

Once you have shortlisted potential suppliers, request samples of the pump tires you are considering. Testing samples allows you to assess the quality, durability, and performance of the tires under real-world conditions. Ensure that the samples align with your specifications and meet your performance criteria.

Evaluate the supply chain capabilities of your potential suppliers to ensure they can meet your volume and delivery requirements. Check their production capacity, lead times, and logistics management. A robust supply chain is vital for timely deliveries and maintaining your operational efficiency.

Engage in negotiations with your selected suppliers to establish favorable terms and conditions. This includes pricing, payment terms, delivery schedules, and warranties. Clear agreements will help prevent misunderstandings and protect both parties in the transaction.

After negotiations, finalize contracts with the chosen supplier and establish performance metrics to monitor their service levels. Regularly review supplier performance against these metrics to ensure compliance and maintain quality standards over time.

By following this checklist, B2B buyers can navigate the complexities of sourcing pump tires effectively, ensuring they make informed decisions that align with their business needs.

When sourcing pump tires, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Several factors influence the pricing of pump tires, especially for international B2B buyers.

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms.

International B2B buyers must navigate unique pricing challenges. Currency fluctuations can impact costs, as can changes in international shipping rates. Additionally, tariffs and trade agreements should be factored into the total cost. It is advisable to consult with logistics experts and trade specialists to understand these dynamics fully.

While indicative prices can vary widely based on the above factors, buyers should approach sourcing with a comprehensive understanding of cost components and pricing influences. Engaging in informed negotiations, considering TCO, and being aware of international pricing nuances will empower buyers to make strategic purchasing decisions in the pump tire market.

Illustrative image related to pump tires

In the ever-evolving landscape of tire technology, businesses face the challenge of selecting the most efficient and cost-effective solutions. Pump tires, designed to provide convenience and adaptability, are not the only option available. This section explores various alternatives, highlighting their strengths and weaknesses to aid B2B buyers in making informed decisions tailored to their operational needs.

| Aspecto comparativo | Pump Tires | Portable Air Compressors | Tire Sealants |

|---|---|---|---|

| Rendimiento | Good traction; versatile applications | High inflation speed; reliable | Quick fix for punctures; reduces air loss |

| Coste | Moderate initial investment | Varies (typically higher) | Low-cost, one-time purchase |

| Facilidad de aplicación | Simple to install and use | Requires some technical knowledge | Easy to apply; no tools needed |

| Mantenimiento | Low maintenance | Requires regular upkeep | Minimal maintenance; check seal integrity |

| El mejor caso de uso | Varied terrains; off-road vehicles | Emergency situations; high-volume needs | Temporary solution for small leaks |

Portable air compressors are a prevalent alternative to pump tires, especially for businesses that require rapid inflation of multiple tires. They are known for their high inflation speed and reliability, making them ideal for fleets or emergency situations. However, their initial cost can be higher, and they often require some technical knowledge to operate effectively. Additionally, maintenance is crucial to ensure performance, which may add to operational costs over time.

Tire sealants offer a unique solution for puncture repair, allowing businesses to minimize downtime. They work by sealing small holes and preventing air loss, making them an excellent choice for vehicles that frequently encounter rough terrains. The application process is straightforward, requiring no special tools. However, sealants are typically a temporary fix and may not work for larger punctures or damage. Their cost-effectiveness is appealing, but the need for eventual replacement or professional repair should be considered.

When selecting the most appropriate tire solution, B2B buyers should consider specific operational requirements, including performance demands, cost constraints, and ease of implementation. Each alternative presents distinct advantages and drawbacks, making it essential to align the choice with the operational context. By evaluating these factors, businesses can optimize their tire management strategies, ensuring efficiency and reliability while potentially reducing costs.

Illustrative image related to pump tires

When evaluating pump tires for industrial or commercial applications, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

Calidad del material

– The material grade of pump tires typically refers to the type of rubber or composite materials used in their construction. Higher-grade materials offer better durability, resistance to wear, and performance under various environmental conditions. For B2B buyers, selecting the right material grade can impact the longevity of the tires and reduce overall maintenance costs.

Niveles de tolerancia

– Tolerance refers to the permissible limits of variation in the dimensions of the tire. Precise tolerances ensure that tires fit correctly on pumps, preventing operational issues such as slippage or misalignment. For businesses, understanding tolerance levels is critical for maintaining operational efficiency and ensuring compatibility with existing equipment.

Capacidad de carga

– This specification indicates the maximum weight a pump tire can safely support. Load capacity is essential for B2B buyers, as it directly impacts the tire’s performance in real-world applications. Choosing tires with the appropriate load capacity is crucial for safety and operational effectiveness, especially in heavy-duty environments.

Pressure Rating

– The pressure rating denotes the maximum internal pressure that a tire can withstand. This is particularly important for pump tires, as improper pressure can lead to tire failure. For businesses, understanding pressure ratings helps in selecting tires that meet the operational demands of specific applications, thereby enhancing safety and performance.

Tread Design

– The tread design of a pump tire affects traction, stability, and performance in various conditions. Different tread patterns are optimized for specific applications, whether in wet or dry environments. B2B buyers should consider tread design to match the operational environment of their pumps, ensuring optimal performance and safety.

Familiarity with industry jargon can streamline the purchasing process and improve negotiations. Here are some common trade terms related to pump tires:

OEM (fabricante de equipos originales)

– OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pump tires, understanding OEM specifications ensures compatibility with specific pump models. B2B buyers should confirm whether they are purchasing OEM parts to avoid compatibility issues.

MOQ (Cantidad mínima de pedido)

– MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for businesses to plan their inventory and budget accordingly. It also influences the overall cost-effectiveness of purchasing decisions.

RFQ (solicitud de presupuesto)

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ can help gather competitive pricing and terms from multiple suppliers, facilitating better negotiation and decision-making.

Incoterms (Términos comerciales internacionales)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify who is responsible for shipping, insurance, and tariffs, thus preventing misunderstandings in cross-border transactions.

Plazos de entrega

– Lead time refers to the time taken from placing an order to receiving the product. For businesses, understanding lead times is crucial for inventory management and ensuring timely operations, particularly in industries where equipment downtime can lead to significant losses.

By grasping these technical properties and trade terms, B2B buyers can make more informed choices when purchasing pump tires, ultimately enhancing their operational efficiency and cost-effectiveness.

The global pump tires market is witnessing a significant transformation driven by several key factors. First and foremost, the increasing demand for vehicle safety and efficiency is propelling the growth of this sector. As international regulations tighten around vehicle emissions and safety standards, manufacturers are innovating to produce pump tires that meet these requirements. Additionally, the rise of e-commerce has made sourcing more accessible for B2B buyers, allowing them to find competitive prices and diverse product offerings from suppliers across the globe, particularly in regions like Africa, South America, the Middle East, and Europe.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are also shaping sourcing trends. Smart tire technologies that monitor pressure and temperature in real-time are becoming increasingly popular, enhancing vehicle performance and safety. B2B buyers should look for suppliers that offer these advanced products, as they can provide a competitive edge in the market.

Moreover, sustainability is becoming a pivotal aspect of the pump tires sector. Manufacturers are increasingly focusing on developing eco-friendly materials and production processes, driven by consumer demand for greener products and stricter environmental regulations. For international B2B buyers, understanding these dynamics is essential to making informed sourcing decisions that align with both market trends and corporate responsibility.

Sustainability and ethical sourcing are no longer optional in the pump tires sector; they are imperative. The environmental impact of tire production and disposal has led to a growing demand for sustainable practices within the industry. B2B buyers must consider suppliers that prioritize eco-friendly materials, such as natural rubber and recycled components, in their manufacturing processes. This not only reduces the carbon footprint but also aligns with global efforts to combat climate change.

Ethical supply chains are also becoming increasingly important, as consumers and businesses alike are holding manufacturers accountable for their sourcing practices. Certifications such as the Global Recycled Standard (GRS) and ISO 14001 can indicate a supplier’s commitment to sustainability and ethical practices. For international buyers, particularly in regions like Europe, where consumer awareness is high, partnering with suppliers who have these certifications can enhance brand reputation and customer loyalty.

Investing in sustainable pump tires not only fulfills ethical obligations but can also lead to cost savings in the long run. Efficient production methods, reduced waste, and lower energy consumption contribute to a more sustainable business model that appeals to environmentally conscious consumers.

The evolution of the pump tires sector can be traced back to the early 20th century when the introduction of pneumatic tires revolutionized the automotive industry. Initially made from natural rubber, these tires provided enhanced comfort and performance compared to solid tires. Over the decades, technological advancements led to the development of synthetic rubber, which improved durability and performance while reducing costs.

By the late 20th century, the focus began to shift towards safety and environmental impact, leading to innovations in tire design and materials. The introduction of eco-friendly alternatives and smart tire technologies has further transformed the sector, making it imperative for B2B buyers to stay informed about these developments. Understanding this historical context allows buyers to appreciate the advancements in technology and sustainability that define the current landscape of the pump tires market.

In summary, the pump tires sector is a dynamic field influenced by market demands for safety, sustainability, and technological advancements. For international B2B buyers, recognizing these trends and their implications is crucial for strategic sourcing and maintaining a competitive edge in a rapidly evolving marketplace.

How do I choose the right pump tires for my business needs?

Choosing the right pump tires involves assessing the specific requirements of your operations, including the type of vehicles or machinery they will be used on, the load capacity, and the environmental conditions they will face. Consider factors such as durability, puncture resistance, and compatibility with your equipment. Additionally, consult with suppliers about the materials and designs they offer, and request samples when possible to evaluate performance before making bulk purchases.

What specifications should I look for in high-quality pump tires?

Key specifications to evaluate include the tire’s tread pattern, size, load index, and speed rating. A robust tread design enhances grip and traction, while the size must match your equipment’s requirements. The load index indicates the maximum weight the tire can support, and the speed rating informs you of the safe operational speeds. Always request detailed technical data sheets from suppliers to ensure the tires meet your standards.

What are the common minimum order quantities (MOQs) for pump tires?

Minimum order quantities (MOQs) for pump tires can vary significantly between suppliers, typically ranging from 50 to 500 units depending on the manufacturer and type of tire. It’s essential to clarify MOQs upfront during negotiations to align with your budget and inventory needs. Some suppliers may offer flexible MOQs for first-time buyers or bulk orders, so don’t hesitate to discuss your specific requirements.

How do I vet suppliers for pump tires in international markets?

Vetting suppliers involves researching their reputation, checking for certifications (such as ISO or local standards), and assessing their experience in the industry. Look for reviews or testimonials from other businesses and request references. Additionally, consider visiting their facilities if possible or utilizing third-party inspection services to evaluate their production processes and quality control measures.

What payment terms are commonly accepted for international pump tire purchases?

Payment terms can vary widely among suppliers, but common options include letters of credit, wire transfers, or payment on delivery. It’s advisable to negotiate terms that provide security, such as partial upfront payments with the balance due upon delivery. Always ensure that payment methods are secure and that you have a clear understanding of any associated fees, especially when dealing with international transactions.

How can I ensure quality assurance (QA) for pump tires?

To ensure quality assurance, request that suppliers provide detailed quality control processes and testing standards they adhere to. Implement a system for regular inspections during production and upon delivery. Establish clear specifications and performance criteria in your purchase agreement, and consider third-party QA inspections for large orders to ensure compliance with your standards.

What logistics considerations should I keep in mind when importing pump tires?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Determine whether you will use air or sea freight, and understand the associated costs and transit times. Familiarize yourself with import tariffs and customs clearance procedures in your country. Working with a reliable logistics partner can streamline the process and help avoid delays or additional fees.

Are there customization options available for pump tires?

Many manufacturers offer customization options, including tread patterns, sizes, and branding elements. Discuss your specific needs with potential suppliers, and inquire about their capabilities for bespoke solutions. Customization may involve additional costs and longer lead times, so it’s crucial to balance your requirements with your budget and delivery expectations.

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: 1. Electric tire pump – approximately $35, available at auto parts stores. 2. Tire pressure gauge – recommended to ensure accurate tire pressure readings. 3. Tire pressure information – typically found on a sticker on the door jamb of the driver’s door for vehicles sold in the US, usually around 30 pounds for most cars. 4. Digital tire pumps – available that allow you to set desired pressure autom…

Dominio: pompstire.com

Inscrito: 1998 (27 años)

Introducción: Pomp’s Tire Service offers a wide range of products and services including automotive repair, fleet service, tires, and wheels. They provide tires for commercial vehicles, light trucks, cars, SUVs, and farm equipment. The company has nearly 200 locations across 17 states, providing 24-hour road service and retreading services. Customers can get quotes for automotive repair services and tires, and …

Dominio: freeairpump.com

Inscrito: 2012 (13 años)

Introducción: FreeAirPump.com provides a crowdsourced map of locations that offer free air for tires, including gas stations and bike repair stations. Users can add locations and report errors. The site also offers a guide to portable air compressors for those who can’t find free air. In Connecticut, free air is available at gas stations, while in California, it’s available for paying customers only. The site e…

In the dynamic landscape of pump tires, strategic sourcing emerges as a critical driver of competitive advantage for international B2B buyers. By leveraging strong supplier relationships and negotiating favorable terms, businesses can secure high-quality products while optimizing costs. The increasing demand for efficiency and sustainability in tire management underscores the need for suppliers who not only meet performance standards but also align with the evolving expectations of end-users.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the importance of agility in sourcing practices cannot be overstated. Buyers should prioritize suppliers who demonstrate innovation and responsiveness to market trends, ensuring that they remain ahead of the curve. Engaging with local distributors and manufacturers can also enhance supply chain resilience and reduce lead times.

Looking ahead, the future of pump tires is promising, with advancements in technology and materials paving the way for enhanced durability and performance. International buyers are encouraged to explore new partnerships and invest in sustainable sourcing practices that will not only benefit their bottom line but also contribute to a more sustainable future. Take proactive steps today to align your sourcing strategies with the demands of tomorrow’s market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Illustrative image related to pump tires

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.