Navigating the complexities of tire inflation charts is essential for international B2B buyers seeking to optimize their fleet operations. One of the key challenges faced by businesses in regions such as Africa, South America, the Middle East, and Europe—especially in countries like Germany and Saudi Arabia—is ensuring that their vehicles are equipped with the correct tire pressure for maximum load capacity and safety. This guide provides a comprehensive overview of tire inflation charts, detailing various types, applications, and essential calculations that can significantly impact operational efficiency.

In this resource, buyers will discover how to effectively source accurate tire inflation data tailored to their specific vehicle needs, from passenger cars to heavy-duty trucks. The guide also emphasizes the importance of supplier vetting, cost considerations, and the latest industry standards to ensure compliance and safety. By empowering B2B buyers with actionable insights and a deeper understanding of tire inflation metrics, this guide aims to facilitate informed purchasing decisions that enhance fleet performance and reduce operational risks.

With an authoritative approach, we aim to equip businesses with the knowledge necessary to navigate the global market effectively, ensuring that they remain competitive and compliant in their respective regions.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Standard Load & Inflation | Based on tire size and load index, providing recommended PSI. | Commercial fleets, logistics companies | Pros: Easy to use, standardized; Contras: May not account for specific vehicle conditions. |

| Plus Size Load & Inflation | Adapted for non-standard tire sizes, including larger vehicles. | Specialty vehicles, RVs, heavy-duty trucks | Pros: Tailored for unique applications; Contras: Requires additional knowledge of tire specs. |

| RV Load & Inflation | Specific to RV tire configurations, considering dual vs. single axles. | RV manufacturers, rental services | Pros: Ensures safety and performance; Contras: Limited to RV applications. |

| CO2 Inflation Chart | Details PSI based on CO2 cartridge sizes for quick inflations. | Cycling, motorsports, emergency kits | Pros: Convenient for rapid inflation; Contras: Not suitable for regular maintenance. |

| Commercial Truck Load & Inflation | Focused on truck tire specifications and axle weight distribution. | Freight transport, logistics | Pros: Optimizes load capacity and safety; Contras: Complex for non-specialized users. |

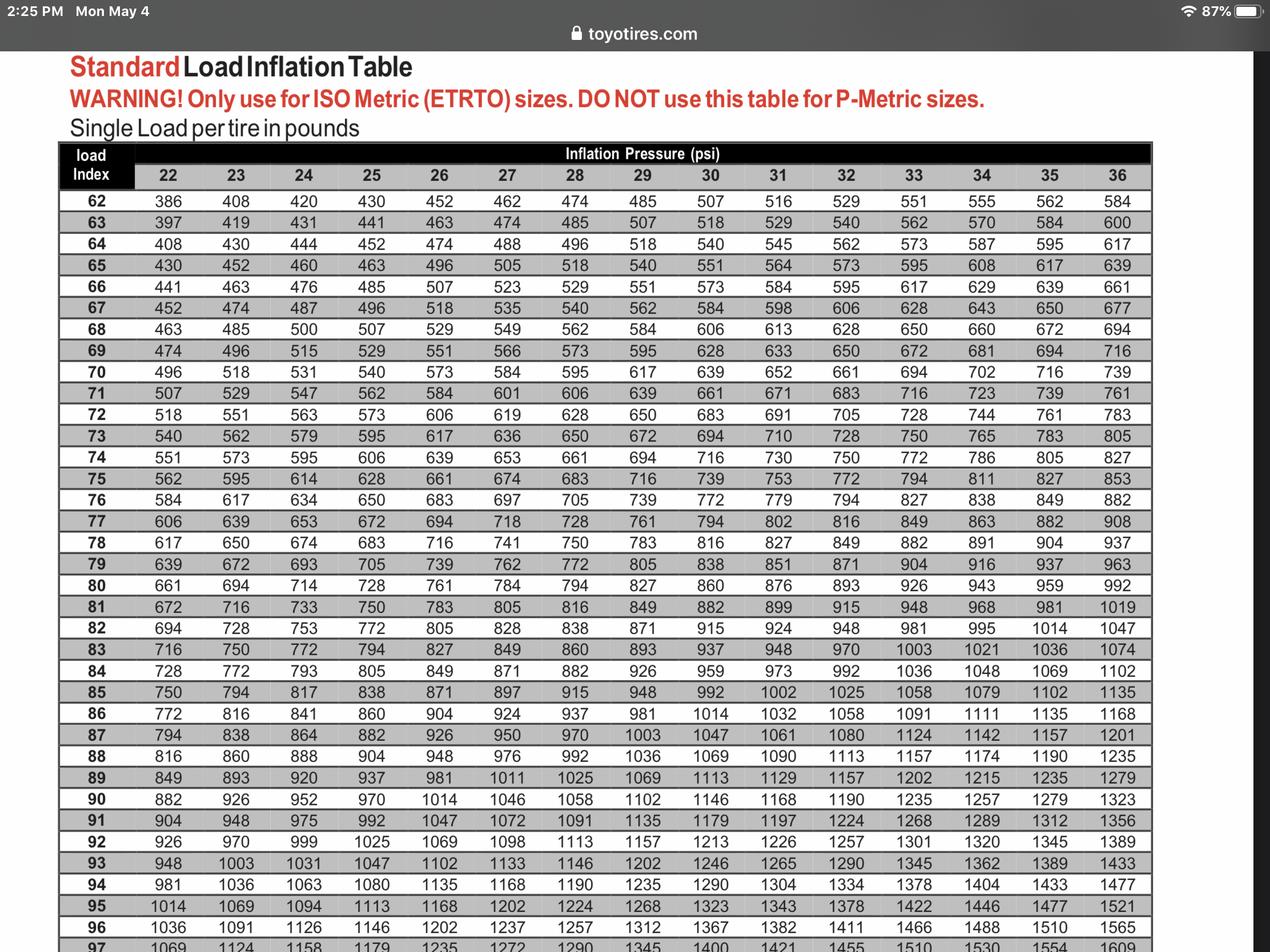

Standard load and inflation charts are designed to provide tire pressure recommendations based on the tire size and load index. These charts are widely used across various industries, particularly in commercial fleets and logistics companies, to ensure optimal tire performance. Buyers should consider the ease of use and the standardization of these charts, which can simplify maintenance routines. However, they may not account for specific vehicle conditions, leading to potential under- or over-inflation if not used correctly.

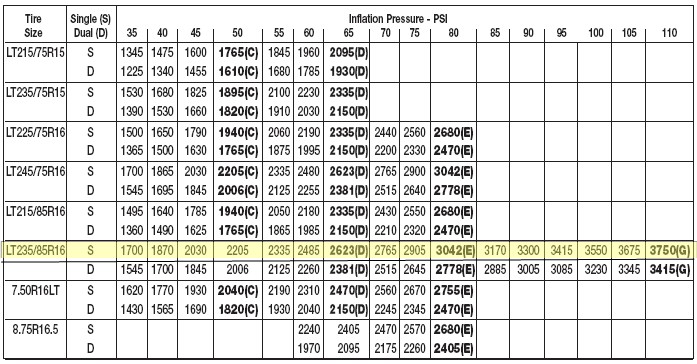

Plus size load and inflation charts cater to non-standard tire sizes, including those used on larger vehicles such as RVs and heavy-duty trucks. They offer tailored recommendations based on unique tire specifications, making them ideal for businesses that operate specialty vehicles. While these charts provide an advantage in terms of customization, they require users to have a solid understanding of tire specifications to ensure accurate application.

RV load and inflation charts are specifically designed for recreational vehicle tires, taking into account configurations such as dual versus single axles. These charts are essential for RV manufacturers and rental services to maintain safety and performance standards. Buyers benefit from the precise recommendations provided, but the charts are limited to RV applications, which may not be suitable for businesses involved in other sectors.

CO2 inflation charts outline the approximate PSI achievable using common-sized CO2 cartridges. These charts are particularly useful in cycling, motorsports, and emergency kits where quick tire inflation is necessary. While CO2 inflation offers convenience for rapid adjustments, it’s not intended for regular maintenance, which may deter some B2B buyers who require comprehensive tire management solutions.

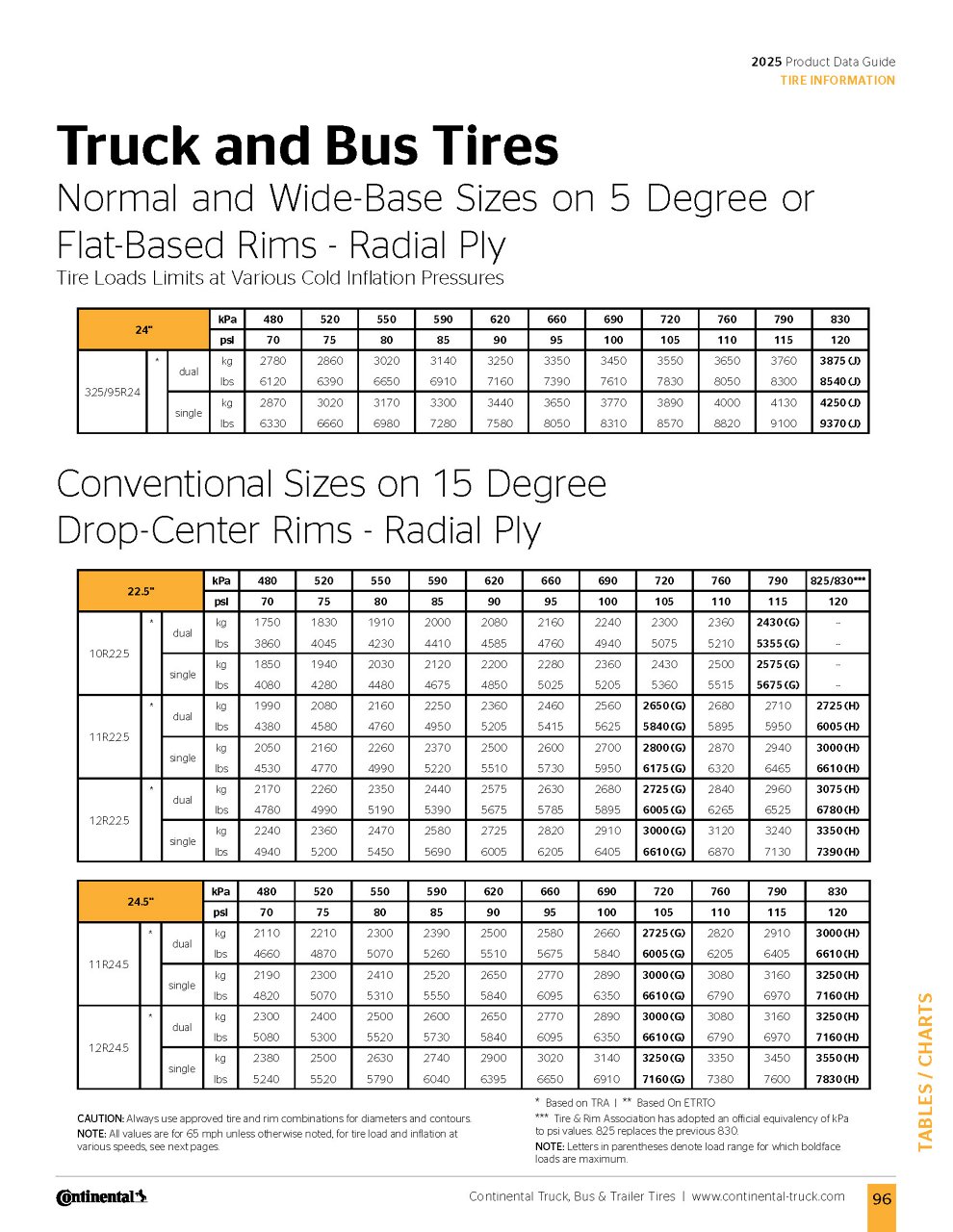

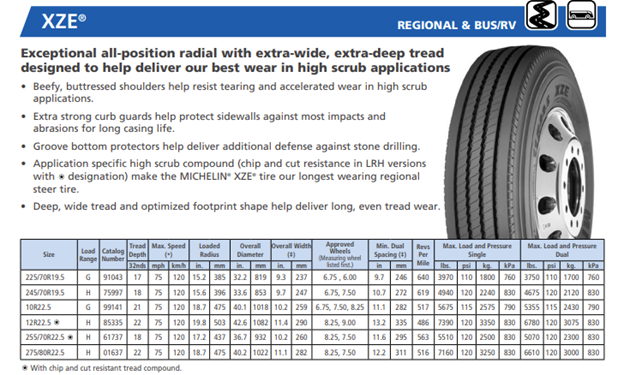

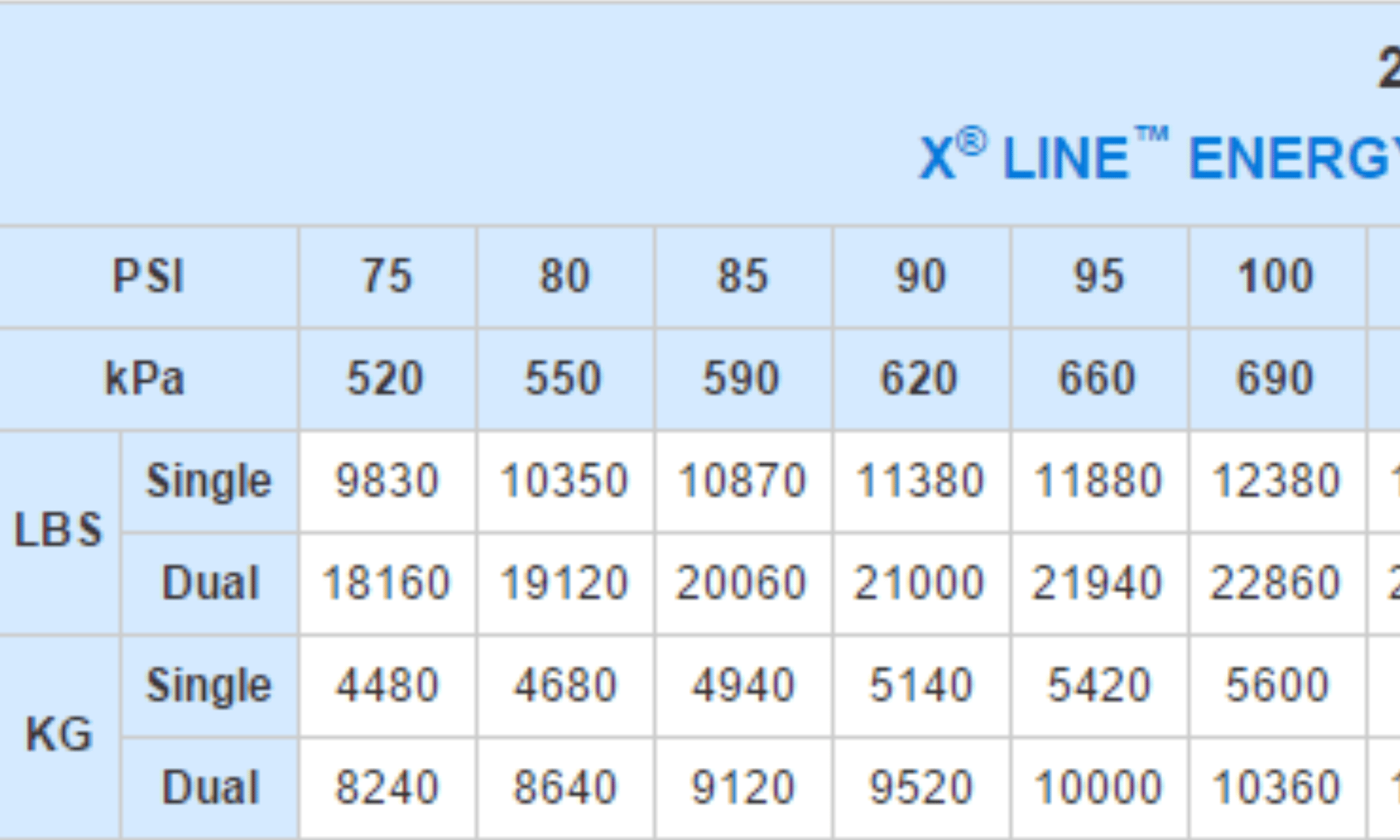

Commercial truck load and inflation charts focus on tire specifications and axle weight distribution, critical for freight transport and logistics operations. These charts help optimize load capacity and enhance safety, making them indispensable for companies in the trucking industry. However, their complexity may pose challenges for users who lack specialized knowledge, highlighting the need for proper training or support when utilizing these resources.

| Industria/Sector | Specific Application of tire inflation chart | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Transportation | Fleet management for commercial vehicles | Enhances safety and fuel efficiency | Compliance with local regulations and tire standards |

| Agricultura | Tire management for agricultural machinery | Increases productivity and reduces downtime | Availability of charts for various tire sizes and loads |

| Construcción | Heavy machinery tire inflation for construction sites | Maximizes load capacity and minimizes tire wear | Need for durable and accurate inflation charts |

| Reparación de automóviles | Tire pressure monitoring for service shops | Improves service quality and customer satisfaction | Access to comprehensive tire inflation data |

| Logística y transporte | Tire management for long-haul trucking companies | Reduces operational costs and enhances safety | Consideration of regional tire specifications and standards |

In the transportation sector, tire inflation charts are essential for fleet management. Businesses use these charts to ensure that commercial vehicles are properly inflated, which enhances safety and improves fuel efficiency. Accurate tire pressure can significantly affect vehicle handling, braking distance, and overall performance. For international buyers, particularly in regions like Europe and the Middle East, compliance with local tire pressure regulations is crucial, necessitating sourcing charts that adhere to regional standards.

In agriculture, maintaining the correct tire pressure on machinery such as tractors and harvesters is vital for operational efficiency. Tire inflation charts help farmers determine the ideal pressure for various loads, which can lead to increased productivity and reduced downtime due to tire issues. Buyers in Africa and South America may face challenges in accessing accurate tire inflation data for diverse agricultural machinery, making it important to source comprehensive charts that cover a wide range of tire sizes.

For construction companies, tire inflation charts are critical for managing heavy machinery. Properly inflated tires maximize load capacity and minimize wear, which is essential for maintaining operational efficiency on job sites. Buyers should consider the durability and accuracy of the inflation charts they source, as construction environments can be harsh. Additionally, international buyers may need to ensure that the charts comply with local regulations regarding tire specifications.

Automotive repair shops utilize tire inflation charts to provide effective tire pressure monitoring services. By referencing these charts, technicians can ensure that vehicles are safely maintained and provide better service to customers. For B2B buyers in Europe, where consumer safety regulations are strict, having access to comprehensive tire inflation data is crucial for maintaining compliance and enhancing customer satisfaction.

In the logistics and shipping industry, tire inflation charts are vital for managing the tire health of long-haul trucks. Proper tire inflation reduces operational costs by improving fuel efficiency and enhancing safety on the road. Buyers in regions like Saudi Arabia and South America should consider the availability of tire inflation charts that align with local tire specifications to ensure optimal performance and compliance with industry standards.

El problema:

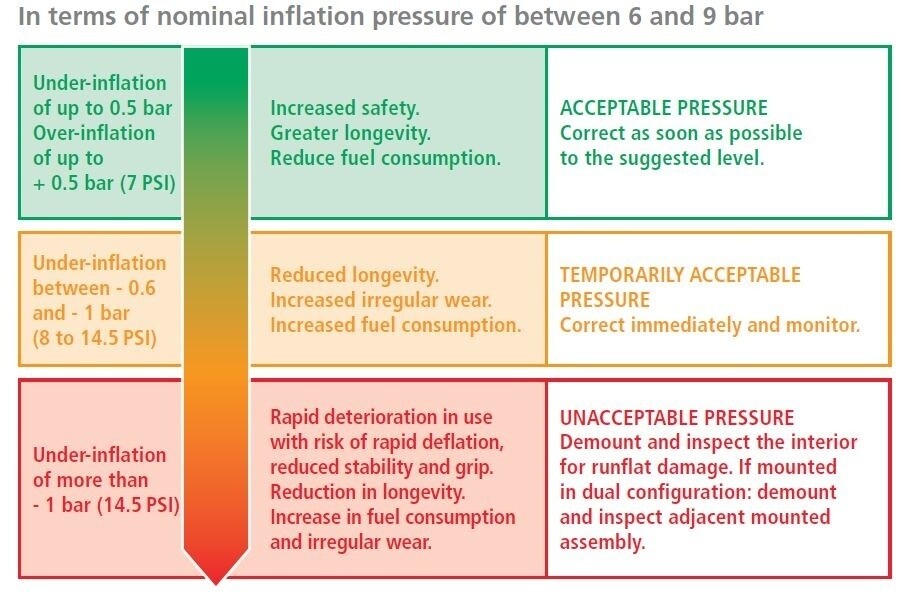

B2B buyers, particularly those managing fleets or commercial vehicles, often struggle with accurately assessing tire pressure. This challenge is compounded by the variability in tire sizes and specifications across different vehicles. A miscalculation can lead to improper inflation, resulting in reduced fuel efficiency, increased tire wear, and potential safety hazards. These issues can translate into costly downtime and repairs, impacting operational efficiency and profitability.

La solución:

To tackle this problem, it is essential to implement a systematic approach to tire pressure assessment using a comprehensive tire inflation chart. Start by ensuring that all staff are trained to read and interpret these charts correctly. For each vehicle in the fleet, maintain a centralized database that includes the specific tire sizes and corresponding inflation pressures as outlined in the tire inflation chart. Regularly scheduled maintenance checks should include verifying tire pressures against these charts to ensure compliance with manufacturer recommendations.

Additionally, investing in Tire Pressure Monitoring Systems (TPMS) can provide real-time data, allowing for timely adjustments. Regular training sessions for your maintenance team on the importance of tire pressure and the correct use of inflation charts will further enhance operational safety and efficiency.

El problema:

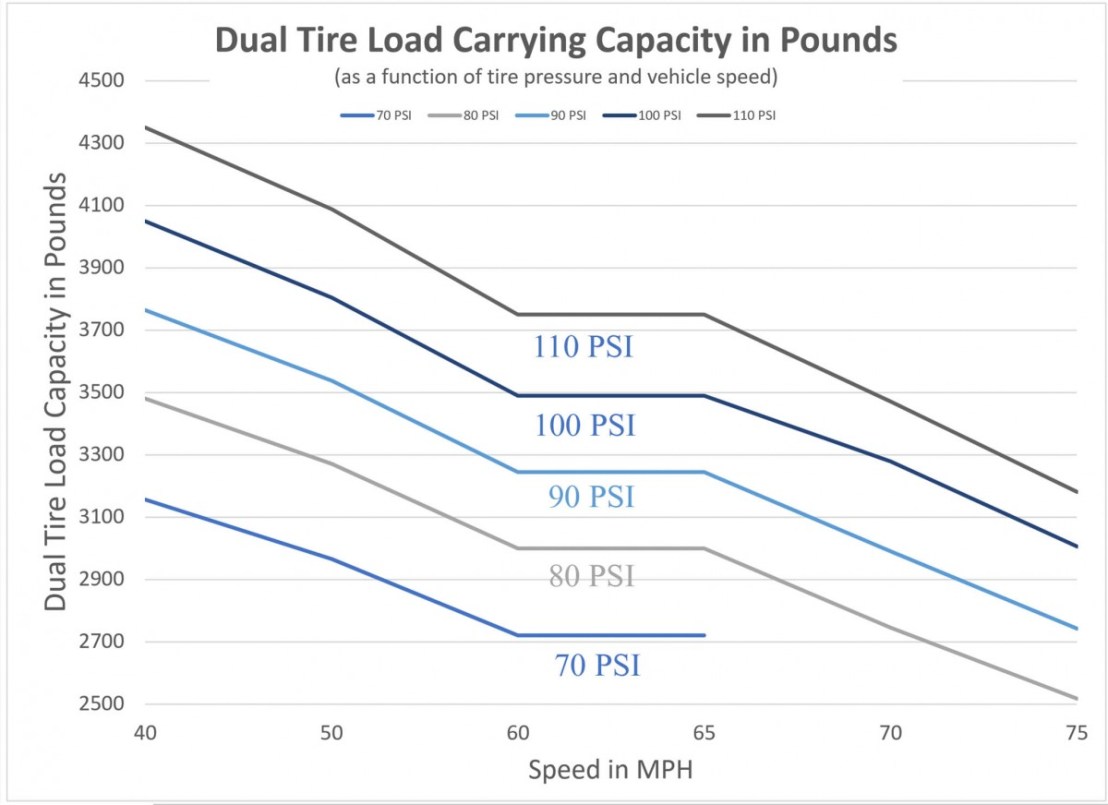

International buyers, especially those operating in diverse regions like Africa and South America, often face confusion regarding load capacities and corresponding inflation pressures for different tire sizes. Without clear guidance on how to match tire load with appropriate inflation levels, businesses risk overloading tires, leading to premature failures and increased liability.

Illustrative image related to tire inflation chart

La solución:

To eliminate confusion, create a detailed reference guide that consolidates information from various tire inflation charts tailored to the specific regions you operate in. This guide should include load capacity information alongside the recommended inflation pressures for all tire sizes used in your fleet.

Moreover, consider partnering with tire manufacturers to obtain their load and inflation tables specific to your geographic area, ensuring that they are compliant with local regulations and standards. Regular workshops or seminars can be organized to educate staff on how to interpret these charts effectively, emphasizing the importance of adhering to load capacities for safety and performance.

El problema:

For B2B buyers managing operations across multiple locations, maintaining consistent tire inflation practices can be a significant pain point. Variability in tire maintenance practices can lead to uneven wear and tear, impacting vehicle performance and safety. This inconsistency can stem from differing levels of staff training and a lack of standardized procedures.

La solución:

Establishing a standardized tire inflation protocol is crucial for uniformity across all locations. Begin by developing a comprehensive manual that outlines the correct procedures for measuring tire pressure and using tire inflation charts. This manual should be accessible to all maintenance personnel and include visual aids for easier comprehension.

Illustrative image related to tire inflation chart

Implementing a digital tracking system can also help monitor tire pressure and maintenance records across locations. This system should generate alerts for tire checks and adjustments based on the tire inflation charts. Regular audits and feedback loops can ensure adherence to these standards, promoting accountability and reinforcing best practices.

By addressing these common pain points with actionable solutions, B2B buyers can significantly improve their tire management processes, ultimately enhancing safety, efficiency, and cost-effectiveness.

When selecting materials for tire inflation charts, it is essential to consider their properties, advantages, and limitations to ensure optimal performance in various applications. Below, we analyze four common materials used in the production of tire inflation charts, focusing on their suitability for international B2B buyers.

Rubber is a widely used material in the manufacturing of tire inflation charts due to its flexibility and durability. It typically has a temperature rating of -40°F to 200°F (-40°C to 93°C) and can withstand significant pressure variations.

Illustrative image related to tire inflation chart

Pros: Rubber is cost-effective and provides excellent sealing properties, making it ideal for applications that require airtight conditions. Its durability ensures a long service life, especially in environments with varying temperatures.

Contras: However, rubber can degrade over time when exposed to UV light and ozone, leading to potential failures. Additionally, its manufacturing process can be complex, requiring specific formulations to enhance its resistance to environmental factors.

Impacto en la aplicación: Rubber’s compatibility with various media, including air and nitrogen, makes it suitable for tire inflation. However, international buyers must consider local regulations regarding materials that may affect environmental compliance.

Metal, particularly aluminum and stainless steel, is often used for the components of tire inflation systems, such as valves and pressure gauges. These metals have high corrosion resistance and can handle extreme temperatures and pressures.

Pros: Metals are highly durable and can withstand harsh conditions without significant wear. They offer excellent performance in high-pressure applications, ensuring accurate readings and reliable functionality.

Contras: The primary drawback of metal components is their higher cost compared to rubber. Additionally, metal parts can be heavier, which may be a consideration for mobile applications.

Impacto en la aplicación: Metal components are essential for ensuring the integrity of tire inflation systems. International buyers should be aware of compliance with standards such as ASTM and DIN, which govern the quality and safety of metal products.

Plastics, such as polycarbonate and polyethylene, are increasingly used in tire inflation charts for their lightweight and versatile properties. They typically have a temperature rating of -40°F to 180°F (-40°C to 82°C) and can be engineered for specific applications.

Illustrative image related to tire inflation chart

Pros: Plastics are generally less expensive than metals and can be molded into complex shapes, making them suitable for various design requirements. They also offer good resistance to chemicals and moisture.

Contras: However, plastics may not withstand high temperatures and pressures as effectively as metals, limiting their use in certain applications. Additionally, some plastics can become brittle over time, particularly when exposed to UV light.

Impacto en la aplicación: The use of plastics in tire inflation charts can help reduce weight and cost. Buyers should consider the specific environmental conditions in their regions, as some plastics may not perform well in extreme climates.

Composite materials, which combine two or more materials, are gaining popularity in tire inflation applications due to their unique properties. These materials can be engineered to provide specific benefits, such as enhanced strength-to-weight ratios and improved resistance to environmental factors.

Pros: Composites can offer the best of both worlds, combining the lightweight nature of plastics with the durability of metals. They are also highly customizable, allowing manufacturers to tailor properties to specific applications.

Contras: The main limitation of composites is their higher production cost and complexity in manufacturing. Additionally, not all composites are suitable for high-pressure applications, which can limit their use in tire inflation systems.

Impacto en la aplicación: Composites can provide significant advantages in performance and longevity. Buyers should ensure that the composites meet international standards for safety and durability, particularly in regions with stringent regulations.

Illustrative image related to tire inflation chart

| Material | Typical Use Case for tire inflation chart | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | Seals and flexible components | Cost-effective and durable | Degrades with UV exposure | Bajo |

| Metal | Valves and pressure gauges | High durability and pressure resistance | Higher cost and weight | Alta |

| Plástico | Lightweight components | Low cost and versatile | Limited high-temperature performance | Medio |

| Compuesto | Specialized applications | Enhanced strength-to-weight ratio | Higher production cost | Alta |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions regarding tire inflation charts, ensuring compliance and performance across diverse international markets.

The manufacturing of tire inflation charts involves several critical stages to ensure accuracy and reliability. These stages include material preparation, forming, assembly, and finishing.

Preparación del material: The initial phase focuses on gathering and preparing data related to tire specifications, including dimensions, load capacities, and recommended inflation pressures. This data is often sourced from tire manufacturers and industry standards organizations, ensuring that all relevant information is considered.

Formando: During this stage, the prepared data is organized into a format that is easy to read and interpret. This may involve designing tables or charts that clearly display the relationship between tire sizes, inflation pressures, and load capacities. Advanced software tools are typically used to create these visual representations, ensuring clarity and accuracy.

Montaje: The assembled charts must integrate multiple data points, such as tire types, sizes, and their corresponding inflation pressures. This step is crucial for creating comprehensive and user-friendly charts that B2B buyers can use effectively. Collaboration with tire manufacturers can enhance the quality of data presented.

Acabado: The final stage involves quality checks and the preparation of the charts for distribution. This includes ensuring that all data points are correctly aligned and that the charts meet industry standards. The finished product may be available in various formats, including digital and printed versions, to accommodate different user preferences.

Quality assurance (QA) is vital in ensuring that tire inflation charts are accurate, reliable, and compliant with international standards. Effective QA processes typically include adherence to ISO 9001 and industry-specific certifications like CE and API.

Normas internacionales: Adhering to ISO 9001 ensures that the manufacturing process follows a systematic approach to quality management. This certification requires organizations to implement processes that enhance customer satisfaction through effective quality management practices.

Industry-Specific Certifications: Certifications like CE (Conformité Européenne) and API (American Petroleum Institute) provide additional assurance of quality and safety. These certifications indicate that the tire inflation charts meet specific regulatory requirements and industry standards, which is particularly important for B2B buyers operating in regulated markets.

Quality control (QC) is an integral part of the manufacturing process for tire inflation charts. It typically involves several checkpoints to ensure that the final product meets quality standards.

Illustrative image related to tire inflation chart

Control de calidad entrante (IQC): At this stage, raw data and materials are inspected for accuracy and completeness before they enter the production process. This step is crucial for preventing errors from propagating through subsequent stages.

Control de calidad durante el proceso (IPQC): During the manufacturing process, periodic checks are performed to ensure that the charts are being developed according to specifications. This may involve verifying data accuracy and ensuring that the chart format remains consistent.

Control de calidad final (CCF): Once the charts are completed, a thorough review is conducted to check for any discrepancies or errors. This includes validating the data against original sources and ensuring that all information is up-to-date.

Several testing methods can be employed to verify the quality of tire inflation charts. These methods help ensure that the charts are not only accurate but also reliable for end users.

Data Validation: This involves cross-referencing the data presented in the charts with authoritative sources, such as tire manufacturers and industry standards. This process helps identify any inaccuracies or outdated information.

User Testing: Engaging with end users, such as fleet managers or tire retailers, can provide valuable feedback on the usability and clarity of the charts. This testing helps refine the product to better meet the needs of B2B buyers.

Third-Party Audits: Independent audits by third-party organizations can provide an unbiased assessment of the chart’s quality. These audits often include a review of the manufacturing process, data sources, and compliance with industry standards.

For international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some strategies to ensure that suppliers maintain high-quality standards.

Auditorías de proveedores: Regular audits of suppliers can help verify their adherence to quality standards. These audits can assess the supplier’s processes, data management, and compliance with relevant certifications.

Solicitud de informes de calidad: Suppliers should provide detailed reports on their quality control processes, including IQC, IPQC, and FQC results. These reports can help buyers understand the supplier’s commitment to quality.

Engaging Third-Party Inspection Services: Utilizing third-party inspection services can provide additional assurance of the supplier’s quality control practices. These services can conduct independent evaluations and verify compliance with international standards.

International B2B buyers must navigate various quality control nuances when sourcing tire inflation charts. Understanding these nuances can facilitate smoother transactions and enhance product reliability.

Cumplimiento de la normativa: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with the specific regulations applicable in their region and ensure that suppliers comply with these standards.

Consideraciones culturales: Cultural differences can impact quality perceptions. B2B buyers should communicate openly with suppliers about their quality expectations and ensure that both parties understand the quality standards being implemented.

Local Market Practices: Regional market practices can influence the quality control processes of suppliers. Buyers should consider the local context when evaluating supplier capabilities and ensure that they align with international best practices.

By understanding the manufacturing processes and quality assurance practices behind tire inflation charts, B2B buyers can make informed decisions that enhance their operational efficiency and ensure product reliability.

In the procurement of tire inflation charts, B2B buyers must ensure they select the right resources that meet their specific operational needs. This guide outlines a practical step-by-step checklist to facilitate an efficient sourcing process.

Before beginning your search for tire inflation charts, clarify your organization’s specific needs. Consider factors such as the types of vehicles you operate, the tire sizes in your fleet, and the geographical regions where these vehicles will be used. Understanding these details will help you narrow down the most relevant charts and ensure they align with your operational requirements.

Conduct thorough research to find suppliers that specialize in tire inflation charts. Look for companies with a strong track record in the industry and positive customer reviews. It’s beneficial to check their experience in your specific market regions, such as Africa or Europe, to ensure they understand local regulations and standards.

Ensure that the tire inflation charts you consider comply with industry standards and regulations. This includes checking certifications from organizations such as the Tire and Rim Association or the European Tyre and Rim Technical Organization. Compliance is crucial for safety and can also affect insurance and liability considerations.

Once you’ve shortlisted potential suppliers, request samples of their tire inflation charts. This allows you to evaluate the clarity, usability, and accuracy of the information presented. Ensure that the charts are easy to read and include all necessary details, such as tire sizes, load capacities, and recommended pressures.

Evaluate the level of customer support offered by each supplier. Good suppliers should provide comprehensive resources, including usage guides, FAQs, and access to technical support. This can be particularly important when you need assistance with complex specifications or when adjustments to your fleet occur.

Inquire whether suppliers offer customization for tire inflation charts. Depending on your fleet size and diversity, you may need charts tailored to specific vehicle models or configurations. Customization can enhance the relevance of the charts and improve operational efficiency.

Finally, evaluate the pricing structures and payment terms of your shortlisted suppliers. Look for transparency in pricing and consider any potential bulk purchase discounts. Understanding the financial terms will help you make a budget-conscious decision while ensuring you receive high-quality products.

By following this checklist, B2B buyers can efficiently source tire inflation charts that meet their specific needs, ensuring safe and effective tire management across their vehicle fleets.

When evaluating the sourcing of tire inflation charts, it is essential to understand the cost structure involved. Key components include:

Materiales: The primary materials used in tire inflation charts are often paper or synthetic substrates for printed charts, along with digital formats for online resources. The choice of material can significantly affect costs; for instance, waterproof or tear-resistant materials may incur higher expenses.

Trabajo: Skilled labor is required for design, formatting, and quality control of the charts. This includes graphic designers and quality assurance personnel who ensure accuracy and compliance with industry standards.

Gastos generales de fabricación: This encompasses the costs associated with running production facilities, including utilities, rent, and administrative expenses. Efficient operations can reduce overhead and ultimately lower the price of the final product.

Herramientas: Initial setup costs for production tools and equipment can be substantial. However, these costs are amortized over time, especially for larger orders, making them less impactful on unit pricing.

Control de calidad: Ensuring that tire inflation charts meet the necessary safety and regulatory standards involves rigorous quality control processes. This adds to the overall cost but is crucial for maintaining credibility and compliance.

Logística: Shipping costs can vary significantly based on geographic location and delivery speed. For international buyers, understanding local tariffs and shipping regulations is critical.

Margen: Suppliers typically add a margin to cover their costs and profit. This margin can vary widely based on supplier reputation, market competition, and demand.

Several factors influence the pricing of tire inflation charts, including:

Volumen/MOQ (Cantidad mínima de pedido): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate more favorable terms.

Especificaciones y personalización: Tailoring charts to specific requirements, such as language or size, can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

Calidad del material y certificaciones: Higher quality materials and certifications (e.g., ISO standards) can elevate prices. Buyers should assess whether these enhancements provide sufficient value.

Factores del proveedor: The reliability and reputation of the supplier can impact pricing. Established suppliers may charge a premium for their products due to perceived quality and service.

Incoterms: Familiarity with Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers in shipping, which can affect overall costs.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, effective negotiation strategies and cost-efficiency practices can lead to significant savings:

Leverage Volume Discounts: Buyers should consider consolidating orders to meet MOQs, thereby securing discounts and reducing per-unit costs.

Evaluar el coste total de propiedad (TCO): Beyond the initial price, assess the TCO, which includes maintenance, durability, and operational efficiency. Investing in higher-quality charts may yield long-term savings.

Research Supplier Backgrounds: Conduct due diligence on potential suppliers to ensure they meet quality and reliability standards. This can prevent costly issues down the line.

Negotiate Payment Terms: Flexibility in payment terms can improve cash flow. Buyers should discuss options such as installment payments or discounts for early payments.

Understand Local Regulations: Being aware of local import duties and regulations can help avoid unexpected costs. Engage with local experts or consultants to navigate these complexities.

Pricing for tire inflation charts can fluctuate based on market conditions, supplier pricing strategies, and international shipping costs. It is advisable for buyers to request current quotes from multiple suppliers to ensure competitive pricing and make informed purchasing decisions.

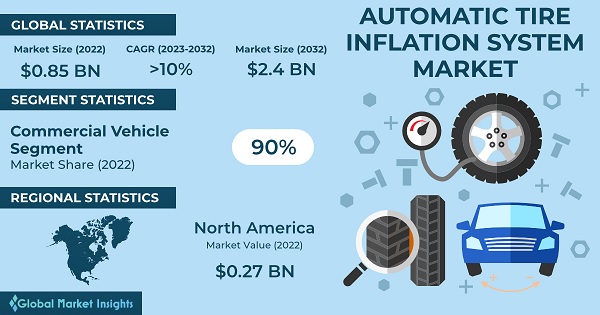

In the realm of tire management, ensuring optimal inflation is critical for safety, performance, and cost-efficiency. While tire inflation charts serve as a reliable method for determining the appropriate air pressure based on load and tire specifications, various alternative solutions exist. These alternatives include advanced tire pressure monitoring systems (TPMS) and automated inflation systems, each offering unique advantages and drawbacks that may better suit specific operational needs.

| Aspecto comparativo | Tire Inflation Chart | Tire Pressure Monitoring System (TPMS) | Automated Tire Inflation Systems |

|---|---|---|---|

| Rendimiento | Reliable for static measurements and load calculations | Provides real-time pressure readings and alerts | Automatically adjusts tire pressure based on real-time data |

| Coste | Low cost (manual reference) | Moderate cost (device purchase and installation) | High cost (installation and equipment) |

| Facilidad de aplicación | Simple to use; requires manual lookup | Requires installation and calibration | Requires infrastructure setup and maintenance |

| Mantenimiento | Minimal; requires periodic review | Moderate; battery replacements and system checks needed | High; ongoing maintenance and calibration required |

| El mejor caso de uso | Small fleets and individual users needing basic guidance | Large fleets requiring constant monitoring and quick response | Commercial operations needing automated pressure management |

TPMS are electronic systems that monitor tire pressure in real-time, providing alerts when pressures fall below recommended levels. The primary advantage of a TPMS is its ability to enhance safety by preventing under-inflation, which can lead to blowouts or reduced fuel efficiency. However, the initial investment can be significant, especially for large fleets, and ongoing maintenance is necessary to ensure the system’s reliability.

Automated tire inflation systems take tire management a step further by automatically adjusting tire pressure based on real-time data. These systems are particularly beneficial for commercial operations where tire pressure needs to be consistently monitored and adjusted. The main advantages include reduced manual labor and enhanced tire longevity. However, the costs associated with installation and maintenance can be prohibitive, making this solution more suitable for larger enterprises with high tire usage.

When evaluating tire inflation solutions, B2B buyers must consider their specific operational needs, budget constraints, and the scale of their fleet. Tire inflation charts offer a cost-effective, straightforward method for smaller operations, while TPMS and automated systems provide enhanced safety and efficiency for larger fleets. Ultimately, the right choice will depend on the balance between investment capacity and the desired level of tire management sophistication. By carefully assessing these factors, buyers can select the most suitable solution that aligns with their business objectives and operational requirements.

Illustrative image related to tire inflation chart

Understanding the critical specifications of tire inflation charts is essential for international B2B buyers, particularly when it comes to ensuring safety, performance, and compliance with regional regulations. Here are some key technical properties:

Capacidad de carga

This specification indicates the maximum weight a tire can support at a given inflation pressure. Load capacity is typically expressed in pounds or kilograms and is crucial for ensuring that tires can safely carry the intended load. For B2B buyers, accurately matching load capacities to vehicle requirements helps prevent tire blowouts and enhances operational efficiency.

Inflation Pressure

Measured in PSI (pounds per square inch), inflation pressure is the amount of air pressure inside the tire. This parameter affects tire performance, fuel efficiency, and tread wear. B2B buyers must ensure that the tires are inflated to the recommended pressure to maintain optimal vehicle performance and safety, reducing the risk of accidents.

Tire Ply Rating

The ply rating indicates the strength and durability of a tire. A higher ply rating suggests a stronger tire capable of handling greater loads. For businesses, selecting tires with appropriate ply ratings according to their operational needs can lead to cost savings through reduced maintenance and longer tire life.

Tread Depth

This specification measures the depth of the grooves in a tire’s tread, affecting traction, handling, and water displacement. Insufficient tread depth can lead to hydroplaning and loss of control. B2B buyers need to monitor tread depth regularly to ensure safety and compliance with local regulations.

Temperature Rating

This rating indicates the tire’s ability to dissipate heat generated during operation. A high-temperature rating is vital for preventing tire failure, especially in heavy-load applications. Buyers should consider temperature ratings to ensure tires perform reliably under various operating conditions.

Speed Rating

Speed ratings denote the maximum speed a tire can safely sustain. These ratings are essential for applications where vehicles operate at high speeds. Buyers must ensure that the tires selected meet or exceed the speed requirements of their fleet operations.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B tire market. Here are some common terms:

OEM (fabricante de equipos originales)

This term refers to companies that produce parts or components that are sold to other manufacturers for inclusion in their final products. In the tire industry, OEM tires are specifically designed for a vehicle model, making it critical for B2B buyers to understand when sourcing replacements.

MOQ (Cantidad mínima de pedido)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers as it affects inventory management and purchasing decisions. Buyers should negotiate MOQs to align with their operational needs and budgets.

RFQ (solicitud de presupuesto)

An RFQ is a formal document issued by a buyer to suppliers to request pricing and other information for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing and terms.

Incoterms (Términos comerciales internacionales)

These are internationally recognized rules that define the responsibilities of buyers and sellers for the delivery of goods. B2B buyers should be well-versed in Incoterms to navigate shipping and logistics effectively, ensuring that they understand cost responsibilities and risk transfer points.

Treadwear Warranty

This warranty guarantees a certain mileage or time period during which the tire’s tread is expected to last. B2B buyers should consider treadwear warranties when evaluating tire options, as they can indicate the expected longevity and overall value of the investment.

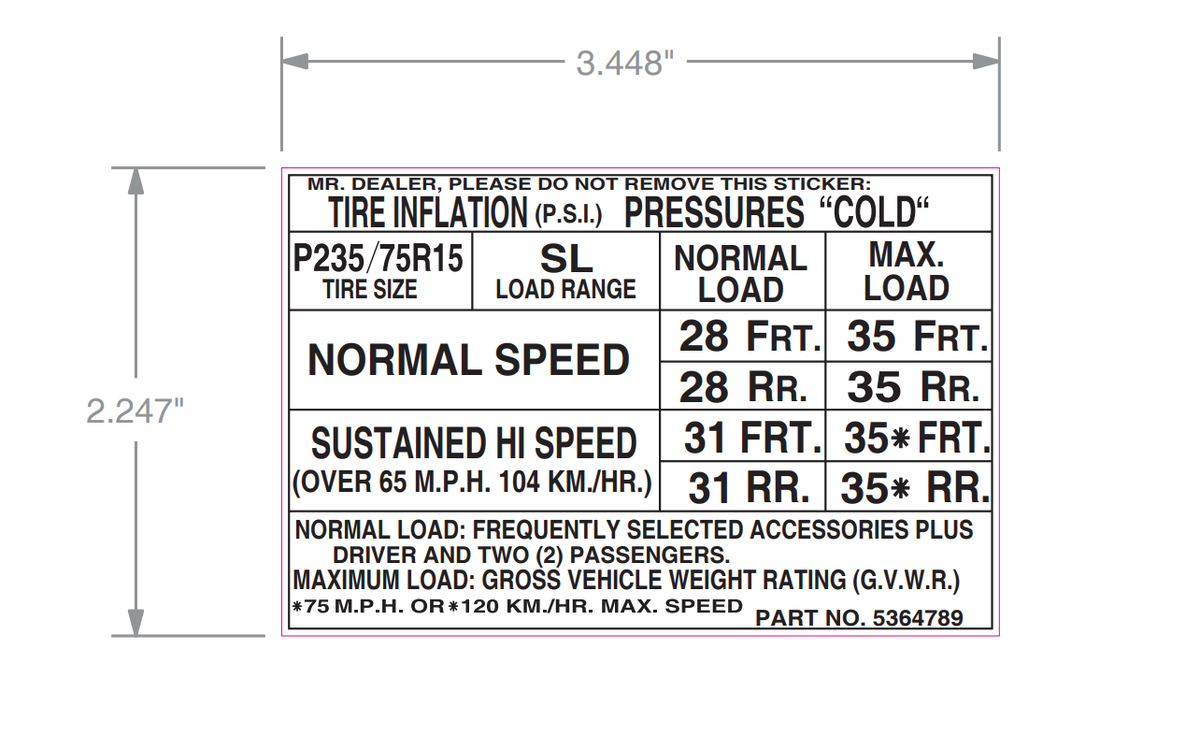

Cold Inflation Pressure

This term refers to the tire pressure when the tire is not heated from driving. It is crucial for maintaining optimal tire performance and safety. B2B buyers should always check the cold inflation pressure before use to ensure compliance with manufacturer recommendations.

Understanding these technical properties and trade terms will equip B2B buyers with the knowledge needed to make informed purchasing decisions, ultimately enhancing operational efficiency and safety in their tire management practices.

Illustrative image related to tire inflation chart

The tire inflation chart sector is witnessing significant transformations driven by various global factors. One of the primary drivers is the increasing demand for commercial vehicles across Africa, South America, the Middle East, and Europe. This growth necessitates precise tire management solutions to enhance safety, fuel efficiency, and overall vehicle performance. As a result, B2B buyers are increasingly focusing on sourcing advanced tire inflation technologies, including smart tire pressure monitoring systems (TPMS) that provide real-time data on tire pressure and load capacity.

Emerging trends also highlight the importance of digital solutions in the tire inflation domain. The integration of IoT (Internet of Things) technology enables predictive maintenance and data analytics, allowing businesses to optimize tire performance and reduce downtime. Furthermore, the rise of e-commerce platforms is reshaping how international buyers in regions like Germany and Saudi Arabia procure tire inflation solutions, facilitating easier access to specialized products and competitive pricing.

International B2B buyers are also adapting to shifting regulatory frameworks aimed at enhancing road safety and environmental sustainability. Compliance with these regulations often requires businesses to invest in certified tire inflation solutions that meet international standards, creating opportunities for suppliers who can demonstrate their adherence to these guidelines.

Sustainability has become a cornerstone of business strategy in the tire inflation chart sector. With increasing awareness of environmental issues, companies are prioritizing ethical sourcing and sustainable practices. This shift is critical for B2B buyers seeking to align with consumer expectations and regulatory requirements regarding environmental impact.

The environmental implications of tire production and disposal are significant. Buyers are increasingly scrutinizing their supply chains to ensure that their suppliers utilize ‘green’ materials and practices, such as recycled rubber and eco-friendly manufacturing processes. Certifications like ISO 14001 (Environmental Management) and the Global Recycled Standard are becoming crucial benchmarks for suppliers aiming to demonstrate their commitment to sustainability.

Illustrative image related to tire inflation chart

Moreover, the demand for transparency in supply chains is rising. B2B buyers are looking for partners who can provide clear documentation of their sourcing practices and the environmental impact of their products. By collaborating with suppliers that emphasize sustainability, businesses can not only enhance their corporate responsibility but also tap into a growing market segment that values eco-friendly products.

The tire inflation chart sector has evolved significantly over the decades, transitioning from basic manual methods to sophisticated digital solutions. Historically, tire pressure was managed through simple gauges and charts that required manual input and adjustments. This process often led to inaccuracies and potential safety hazards, particularly in commercial applications.

As vehicle technology advanced, so did the methods for managing tire inflation. The introduction of tire pressure monitoring systems in the late 1990s marked a significant turning point, allowing for automatic monitoring and alerts regarding tire pressure. This innovation not only improved safety but also enhanced fuel efficiency and extended tire lifespan, creating substantial cost savings for businesses.

In recent years, the emergence of smart technology, including mobile apps and IoT solutions, has further transformed the landscape. These advancements enable real-time data analysis and predictive maintenance, allowing B2B buyers to make informed decisions about tire management. Understanding this evolution is essential for international buyers looking to invest in reliable and innovative tire inflation solutions that meet the demands of a rapidly changing market.

How do I determine the correct tire pressure for my fleet?

To find the correct tire pressure for your fleet, refer to the tire information placard located on the vehicle, typically found in the door jam, glove compartment, or near the gas cap. Each tire size has a designated pressure for optimal performance. Additionally, consider using tire inflation charts specific to your tire brand, which can detail load capacities at various pressures. Regularly checking and maintaining the recommended tire pressure not only enhances safety but also improves fuel efficiency and tire longevity.

What is the best tire inflation chart for commercial vehicles?

The best tire inflation chart for commercial vehicles is one that is tailored to the specific tire type and application. Major tire manufacturers, such as Michelin and Goodyear, provide comprehensive load and inflation tables that cater to a variety of tire sizes and configurations. Ensure you select a chart that corresponds with your tire’s sidewall markings, and always consult the vehicle’s owner’s manual for specific recommendations. Using the correct chart will help maintain optimal performance and safety.

How can I ensure the accuracy of tire inflation charts?

To ensure the accuracy of tire inflation charts, source them directly from reputable tire manufacturers or industry organizations such as the Tire and Rim Association. Cross-reference the information with the tire’s sidewall specifications and the vehicle’s owner manual. It is also advisable to conduct regular tire pressure checks using a reliable gauge. This proactive approach helps identify discrepancies that could affect load capacity and safety.

What are the minimum order quantities (MOQ) for tire inflation charts?

Minimum order quantities for tire inflation charts can vary depending on the supplier and the type of charts required. Typically, manufacturers may offer bulk pricing for large orders, which can range from 50 to 100 copies for printed charts. For digital versions, there may be no MOQ. It is advisable to communicate directly with suppliers to negotiate terms that suit your business needs, especially if you require customization.

What payment terms should I expect when ordering tire inflation charts?

Payment terms for ordering tire inflation charts can vary significantly among suppliers. Common terms include net 30 or net 60 days, which allow you to pay within 30 or 60 days after receiving the invoice. Some suppliers may require a deposit upfront, especially for custom orders. Always confirm payment methods accepted, such as wire transfer, credit card, or PayPal, and ensure that all terms are clearly outlined in your purchase agreement to avoid misunderstandings.

How do I vet suppliers for tire inflation charts?

To vet suppliers for tire inflation charts, start by researching their reputation within the industry. Look for reviews and testimonials from previous clients, and check their certifications or affiliations with recognized industry bodies. Request samples of their charts to assess quality and accuracy. Additionally, consider their responsiveness to inquiries and willingness to provide references, as these factors can indicate reliability and customer service.

What logistics considerations should I keep in mind when ordering tire inflation charts internationally?

When ordering tire inflation charts internationally, consider shipping methods, customs regulations, and potential tariffs. Choose a logistics partner experienced in international shipping to ensure timely delivery. Be aware of the lead times involved in production and shipping, and factor these into your planning. Additionally, confirm that the supplier provides tracking information for your order, allowing you to monitor its progress.

Can I customize tire inflation charts for my specific needs?

Yes, many suppliers offer customization options for tire inflation charts. You can request charts that include your branding, specific tire sizes, or additional information pertinent to your fleet. Discuss your requirements with potential suppliers to determine their capabilities and any associated costs. Custom charts can enhance your operations by ensuring that all relevant data is readily available for your team, promoting safety and efficiency.

Dominio: toyotires.com

Inscrita: 1997 (28 años)

Introducción: Load and Inflation Tables provide assistance for replacing tires with optional sizes, including plus sizes not listed on the vehicle’s tire information placard (T.I.P) or in the owner’s manual. For original equipment (OE) size inflation pressure, refer to the T.I.P. found on the vehicle door jam, glove compartment, or near the gas cap. It is important to consult the vehicle’s owner’s manual for sp…

Dominio: yournexttire.com

Inscrito: 2008 (17 años)

Introducción: Tire Inflation Chart: The formula for calculating load capacity is Tire Weight / Tire Pressure = Load Capacity Pounds per PSI. Example: A 265/75R16 10-ply tire at 80 psi carries 3,085 pounds; at 60 psi, it carries 2,314 pounds; at 65 psi, it carries 2,507 pounds. A 265/75R16 6-ply tire at 50 psi holds 2,470 pounds, which is more than a 10-ply tire at 60 psi.

Dominio: rvsafety.com

Inscrita: 1997 (28 años)

Introducción: Tire Inflation Tables & Codes for various tire brands including Michelin, Goodyear, Bridgestone, Firestone, B.F. Goodrich, Hankook, Yokohama, Toyo, Continental, Maxxis, Cooper, Sailun, and Towmax. Includes speed ratings (G to T) with corresponding speeds (56 to 124 mph) and load index with load capacities ranging from 81 (1019 lbs) to 170 (13228 lbs).

Dominio: business.michelinman.com

Matriculado: 2001 (24 años)

Introducción: Michelin offers a range of RV tires with specific load and inflation tables based on tire size. Key details include:

– Tire sizes available: 15″, 16″, 19.5″, and 22.5″ wheel diameters.

– Example tire models: Agilis CrossClimate, XPS RIB, Agilis HD Z, X MULTI Z, X LINE ENERGY Z.

– Load and inflation standards are updated regularly to reflect changes in the motorhome industry.

– Terminology: ‘Si…

Dominio: crossroadscyclingco.com

Inscrito: 2017 (8 años)

Introducción: CO2 tire inflation chart provides approximate pressure achieved with common sized CO2 cartridges. Values vary due to factors like tire manufacturer, ambient temperature, and altitude. CO2 molecules permeate faster than air, leading to potential underinflation within 24 hours. Tire sizes and corresponding pressures for 16g, 20g, and 25g CO2 cartridges are listed, including: 700C x 23 (130 PSI, 80 P…

In conclusion, the strategic sourcing of tire inflation charts is essential for international B2B buyers aiming to optimize their logistics and enhance safety across diverse markets. Understanding the correlation between tire pressure and load capacity can lead to significant improvements in operational efficiency and cost reduction. By leveraging accurate tire inflation data, businesses can ensure their fleets operate at peak performance, reducing wear and tear while maximizing load-carrying capabilities.

For companies in Africa, South America, the Middle East, and Europe, the importance of sourcing reliable tire inflation charts cannot be overstated. These charts not only provide critical information for vehicle maintenance but also support compliance with regional regulations and safety standards. As the global marketplace continues to evolve, embracing strategic sourcing practices will empower businesses to make informed decisions that drive growth and sustainability.

As we look to the future, it is imperative for B2B buyers to prioritize partnerships with reputable suppliers who offer comprehensive tire inflation resources. By doing so, organizations can position themselves to navigate the complexities of the tire industry effectively, ensuring their fleets are safe, efficient, and ready to meet the demands of the global market. Take the next step today—invest in accurate tire inflation data and watch your operational performance soar.

Illustrative image related to tire inflation chart

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.