In today’s rapidly evolving automotive industry, sourcing the right air compressor for tire shops presents a significant challenge for B2B buyers. With a plethora of options available, it is crucial to understand which type of compressor will meet the specific demands of your operations—be it for mobile service applications or a stationary workshop setup. This comprehensive guide will delve into the various types of air compressors, their applications, and key considerations for effective supplier vetting, enabling you to make informed purchasing decisions that align with your operational needs.

As international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Saudi Arabia—navigate the complexities of sourcing equipment, this guide serves as a valuable resource. It not only outlines the essential specifications and features to consider, such as tank capacity, horsepower, and CFM ratings, but also provides insights into cost structures and maintenance requirements.

Furthermore, we will explore the importance of quality assurance and supplier reliability, ensuring that your investment in air compressors translates into long-term operational efficiency. By equipping yourself with the right knowledge and insights, you can confidently select the best air compressor to enhance your tire shop’s productivity and service quality.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Two-Stage Compressors | Higher efficiency, longer lifespan, and better pressure | Medium to large tire shops | Pros: Continuous airflow; suitable for heavy-duty tools. Contras: Higher initial cost. |

| Single-Stage Compressors | Simpler design, lower cost, and lighter weight | Small tire shops and mobile services | Pros: Affordable; easy to maintain. Contras: Limited pressure output. |

| Portable Compressors | Compact, lightweight, and often gas-powered | Mobile tire services and roadside assistance | Pros: Easy transport; versatile applications. Contras: Lower capacity; may require frequent refueling. |

| Rotary Screw Compressors | Continuous operation, high efficiency, and low noise | Large tire service centers | Pros: High volume; energy-efficient. Contras: High upfront investment; complex maintenance. |

| Oil-Free Compressors | No oil lubrication, lower maintenance, and cleaner air | Environments requiring clean air | Pros: Ideal for sensitive applications; reduced maintenance. Contras: Generally lower pressure output. |

Two-stage compressors are designed to compress air in two stages, resulting in higher efficiency and greater pressure output. They are ideal for medium to large tire shops that require a consistent air supply for multiple pneumatic tools and applications. When considering a two-stage compressor, buyers should assess their shop’s airflow needs, as these units typically offer continuous airflow, making them suitable for heavy-duty tasks. While the initial investment is higher, the long-term benefits in efficiency and durability can justify the cost.

Single-stage compressors are characterized by their simpler design and lower cost, making them an attractive option for small tire shops or mobile tire services. They operate efficiently for light to moderate tasks, but their pressure output is limited compared to two-stage models. B2B buyers should consider the specific air tools they intend to use, as these compressors are best suited for less demanding applications. Their affordability and ease of maintenance make them a popular choice for startups or shops with budget constraints.

Illustrative image related to air compressor for tire shop

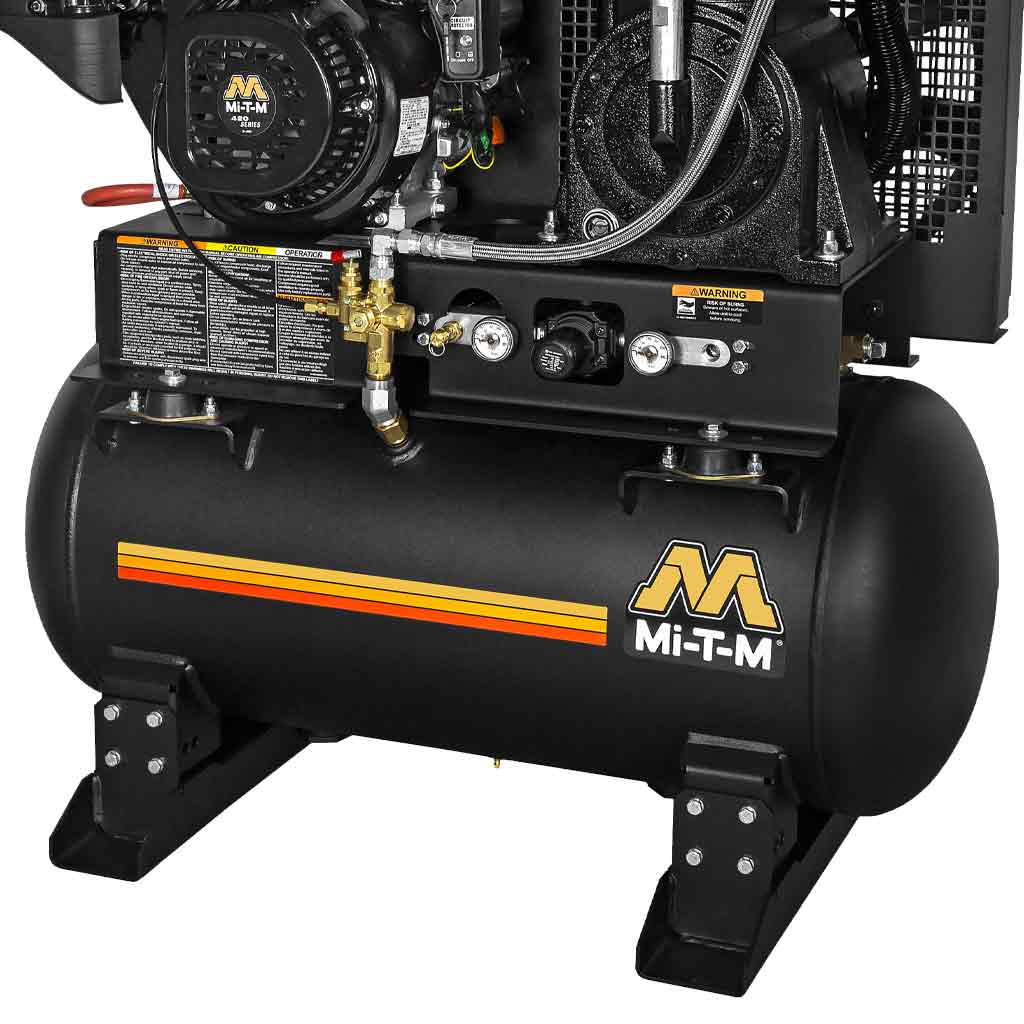

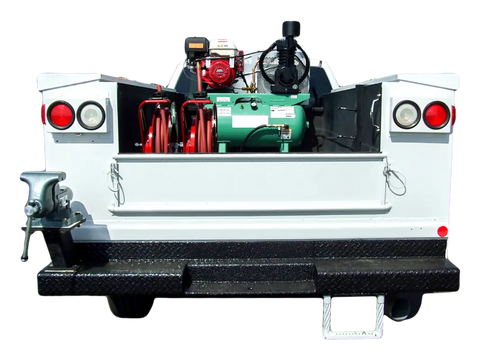

Portable compressors are compact and lightweight, often powered by gas, making them ideal for mobile tire services and roadside assistance. Their ease of transport allows tire technicians to provide services anywhere, enhancing customer satisfaction. However, buyers should keep in mind that portable units typically have lower capacity and may require frequent refueling. For businesses focused on mobility and versatility, investing in a portable compressor can significantly improve service delivery and operational efficiency.

Rotary screw compressors provide continuous operation and are highly efficient, making them suitable for large tire service centers with high air demand. These compressors can deliver a substantial volume of compressed air while maintaining low noise levels, which is beneficial in a busy workshop environment. Although the upfront investment is significant and maintenance can be complex, their long-term energy savings and reliability often outweigh the initial costs for larger operations.

Oil-free compressors are designed to operate without oil lubrication, producing cleaner air and requiring less maintenance. This makes them particularly suitable for environments where air quality is critical, such as in tire shops that also handle sensitive equipment or specialized tasks. While they may have lower pressure output compared to oil-lubricated models, their reduced maintenance needs and cleaner air supply can be a decisive factor for B2B buyers in industries that prioritize hygiene and efficiency.

| Industria/Sector | Specific Application of air compressor for tire shop | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Tire inflation and repair services | Ensures quick service turnaround, improving customer satisfaction | Capacity (CFM), durability, and ease of maintenance |

| Mobile Tire Services | On-site tire repair and inflation | Enhances service flexibility, reducing downtime for clients | Portability, fuel type (gas vs electric), and size |

| Heavy Equipment Rental | Tire maintenance for construction and agricultural machinery | Minimizes equipment downtime, optimizing operational efficiency | High pressure capabilities, tank size, and reliability |

| Gestión de flotas | Routine tire inspections and repairs | Reduces overall fleet maintenance costs and improves safety | Compatibility with various tire sizes, CFM requirements |

| Manufacturing and Logistics | Tire servicing for forklifts and material handling equipment | Increases operational uptime and productivity | Versatility in applications, robust construction, and power source options |

In automotive repair, air compressors are essential for tire inflation and repair services. They provide the necessary pressure to inflate tires quickly and efficiently, which is crucial for maintaining customer satisfaction and reducing wait times. Additionally, compressors can power pneumatic tools used for tire changes, ensuring that repairs are completed swiftly. Buyers should consider compressors with adequate CFM ratings and durability, as frequent use can lead to wear and tear.

Illustrative image related to air compressor for tire shop

For mobile tire services, air compressors are invaluable as they enable technicians to perform tire repairs and inflation on-site. This flexibility reduces downtime for clients, as they do not need to travel to a shop for service. When sourcing compressors for mobile applications, factors such as portability, fuel type (gas or electric), and size are critical to ensure that the equipment can be easily transported and operated in various environments.

Heavy equipment rental companies rely on air compressors for tire maintenance on construction and agricultural machinery. These compressors help minimize equipment downtime, which is vital for maintaining productivity and meeting project deadlines. Buyers in this sector should prioritize compressors with high-pressure capabilities and larger tank sizes to accommodate the demands of heavy machinery.

In fleet management, air compressors facilitate routine tire inspections and repairs, which are essential for safety and efficiency. Regular maintenance helps reduce overall fleet costs by extending tire life and improving fuel efficiency. When sourcing compressors, it’s important to ensure compatibility with various tire sizes and to evaluate the CFM requirements to meet the fleet’s operational needs.

In manufacturing and logistics, air compressors are crucial for servicing tires on forklifts and other material handling equipment. By ensuring that these tires are properly inflated, businesses can increase operational uptime and productivity. When selecting compressors for this application, versatility in operations, robust construction, and a range of power source options should be key considerations for international buyers, particularly in regions with varying infrastructure.

Illustrative image related to air compressor for tire shop

El problema: A tire shop in a bustling urban area is experiencing delays in service due to insufficient air pressure from their current air compressor. As the demand for quick tire inflation and repairs increases, the existing unit struggles to maintain the required pressure, leading to longer wait times for customers. This not only impacts customer satisfaction but also reduces potential revenue due to lost business opportunities.

La solución: To address this challenge, the tire shop should consider investing in a two-stage air compressor with a larger tank capacity, ideally around 60 gallons or more, depending on the shop’s volume. This type of compressor provides a more consistent flow of air at higher pressures, making it suitable for both tire inflation and operating pneumatic tools. When sourcing a new compressor, it’s crucial to look for models that deliver a minimum of 20-25 CFM (cubic feet per minute) to ensure they can handle peak demands. Additionally, implementing regular maintenance checks will help sustain performance levels and extend the lifespan of the equipment, ensuring the shop remains efficient during busy periods.

El problema: In regions with high humidity, a tire shop is facing issues with moisture accumulation in their air compressor system. The excess moisture not only affects the quality of the compressed air but also leads to corrosion and damage to pneumatic tools and tire inflation equipment. This has resulted in increased maintenance costs and downtime, as technicians must frequently repair or replace affected tools.

Illustrative image related to air compressor for tire shop

La solución: To combat moisture issues, the tire shop should install a high-quality air dryer and moisture separator in conjunction with their compressor. These systems remove moisture from the compressed air before it reaches the tools, thereby preventing damage and extending the life of the equipment. Regularly draining the compressor’s tank and checking for moisture buildup is essential, and a routine maintenance schedule should include inspections of filters and separators to ensure optimal performance. Furthermore, educating staff on the importance of moisture control can foster a culture of proactive maintenance, ultimately enhancing the shop’s operational efficiency.

El problema: A tire shop owner is overwhelmed by the variety of air compressors available in the market and struggles to identify the best option for their specific needs. They require a compressor that can handle both tire inflation and operate various pneumatic tools, but are unsure whether to choose a portable or stationary model, leading to confusion and potential misinvestment.

La solución: To make an informed decision, the shop owner should conduct a thorough assessment of their operational requirements, considering factors such as the types of tools used, the volume of work, and available space. For shops that perform a mix of tire services and tool operation, a stationary two-stage compressor is generally recommended due to its durability and higher output capacity. It’s also advisable to consult with manufacturers or suppliers who specialize in automotive service equipment, as they can provide tailored recommendations based on the shop’s specific workflow. Additionally, reviewing customer testimonials and performance ratings can offer insights into the reliability and efficiency of different models, ensuring the shop invests in a compressor that meets their diverse needs effectively.

When selecting an air compressor for a tire shop, the materials used in its construction are critical to performance, durability, and maintenance. Understanding the properties and implications of these materials can help international B2B buyers make informed decisions tailored to their operational needs.

Illustrative image related to air compressor for tire shop

Key Properties: Cast iron is known for its excellent strength and durability, with a high-temperature rating that can withstand the heat generated during prolonged use. It also exhibits good wear resistance, which is crucial for the longevity of the compressor.

Pros y contras: The primary advantage of cast iron is its robustness, making it ideal for heavy-duty applications. However, it is heavier and more expensive than alternatives like aluminum, which can complicate installation and increase shipping costs.

Impacto en la aplicación: Cast iron is particularly suitable for high-pressure applications, ensuring a reliable performance in tire inflation and pneumatic tools. Its compatibility with various media types makes it a versatile choice.

Consideraciones para compradores internacionales: Buyers in regions like Africa and the Middle East should ensure compliance with local standards for manufacturing and safety. Cast iron components often adhere to ASTM standards, which are recognized internationally.

Key Properties: Aluminum is lightweight and has a natural resistance to corrosion, making it ideal for mobile applications and environments where humidity is a concern. It also has a lower thermal conductivity, which can help manage heat dissipation.

Illustrative image related to air compressor for tire shop

Pros y contras: The lightweight nature of aluminum allows for easier transport and installation, especially in mobile tire service trucks. However, it may not withstand the same pressure levels as cast iron, potentially limiting its use in heavy-duty applications.

Impacto en la aplicación: Aluminum is suitable for lower-pressure applications and is often used in portable compressors. Its corrosion resistance is particularly beneficial in humid climates, ensuring longevity.

Consideraciones para compradores internacionales: Buyers should look for aluminum components that meet JIS standards, especially in regions like Japan and South Korea. Additionally, understanding local recycling regulations can impact the overall lifecycle costs of aluminum products.

Key Properties: Steel combines strength and affordability, offering a good balance between durability and cost. It has a high tensile strength and can be treated for corrosion resistance, making it suitable for various environments.

Pros y contras: Steel is less expensive than cast iron and aluminum, making it an attractive option for budget-conscious buyers. However, untreated steel can rust, which may require additional maintenance in humid or corrosive environments.

Impacto en la aplicación: Steel is versatile, suitable for a wide range of applications from small tire shops to larger industrial settings. It can handle moderate pressure levels effectively.

Consideraciones para compradores internacionales: Compliance with DIN standards is essential for steel components, especially in Europe. Buyers should also consider the availability of maintenance services in their region to address potential corrosion issues.

Illustrative image related to air compressor for tire shop

Key Properties: Composite materials are engineered to offer high strength-to-weight ratios and can be designed to resist corrosion and wear. They are often used in the housing of compressors and other non-structural components.

Pros y contras: The main advantage of composites is their lightweight nature and resistance to environmental factors. However, they can be more expensive to manufacture and may not be suitable for high-pressure applications.

Impacto en la aplicación: Composites are ideal for applications requiring lightweight solutions, such as portable compressors used in mobile tire services. Their resistance to environmental factors enhances longevity.

Illustrative image related to air compressor for tire shop

Consideraciones para compradores internacionales: Buyers should ensure that composite materials meet relevant international standards for safety and performance, particularly in regions with stringent regulations.

| Material | Typical Use Case for air compressor for tire shop | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Cast Iron | Heavy-duty stationary compressors | High durability and wear resistance | Heavy and expensive to transport | Alta |

| Aluminio | Portable compressors for mobile service | Ligero y resistente a la corrosión | Limited pressure capacity | Medio |

| Acero | Versatile applications in various settings | Cost-effective and strong | Can rust without treatment | Bajo |

| Compuesto | Lightweight, portable compressors | Elevada relación resistencia/peso | Mayor coste de fabricación | Medio |

This guide provides a comprehensive overview of material options for air compressors in tire shops, enabling international B2B buyers to make informed decisions based on their specific operational needs and regional considerations.

The manufacturing process of air compressors for tire shops is a complex journey that involves several critical stages. Each stage is designed to ensure that the final product meets the high performance and reliability standards required in automotive applications.

Illustrative image related to air compressor for tire shop

The initial phase of manufacturing begins with material preparation, where manufacturers source high-quality raw materials such as steel, aluminum, and various plastics. These materials are selected for their durability and ability to withstand high pressures. Suppliers often conduct stringent checks to verify material specifications before they are accepted into production.

The preparation process may also involve cutting, shaping, and treating materials to enhance their properties, such as corrosion resistance. Advanced techniques like laser cutting and CNC machining are often employed to achieve precise dimensions, ensuring that components fit together seamlessly during assembly.

Following material preparation, the forming stage takes place. This includes processes like forging, casting, and machining to create essential components such as pistons, cylinders, and tanks. For instance, the cylinders may be cast from aluminum or iron, providing a balance between weight and strength.

Manufacturers may utilize advanced forming techniques like hydroforming or deep drawing to create complex shapes that enhance performance. The choice of forming technique often depends on the component’s design and the required mechanical properties, impacting efficiency and cost.

Illustrative image related to air compressor for tire shop

Once the components are formed, the assembly stage begins. This is where all individual parts, including motors, pumps, and tanks, are brought together. Assembly requires skilled technicians who ensure that each component is installed correctly and functions as intended.

Quality control checkpoints are integrated into the assembly line to catch any defects early. Techniques like torque testing, alignment checks, and visual inspections are common during this phase. Furthermore, automated assembly systems may be used to enhance precision and efficiency, reducing the risk of human error.

The final stage of manufacturing is finishing, which focuses on surface treatment and protective coatings. This may involve processes like powder coating, painting, or anodizing to prevent corrosion and improve the aesthetic appeal of the compressor.

Finishing is crucial for durability, especially in environments prone to moisture and harsh conditions. Manufacturers may also conduct final inspections to ensure that all components meet aesthetic and functional standards before packaging.

Illustrative image related to air compressor for tire shop

Quality assurance (QA) is paramount in manufacturing air compressors, particularly for international B2B buyers who expect high reliability. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain consistent quality throughout their processes.

In addition to ISO 9001, air compressor manufacturers may need to comply with various industry-specific standards, including:

Understanding these certifications helps B2B buyers assess the credibility of suppliers and the quality of their products.

Effective quality control involves multiple checkpoints throughout the manufacturing process. These checkpoints ensure that any deviations from the required standards are identified and rectified promptly.

Control de calidad entrante (IQC): This initial checkpoint focuses on raw materials and components received from suppliers. Each batch is inspected for conformity to specifications before it is accepted for production.

Control de calidad durante el proceso (IPQC): During the manufacturing stages, IPQC involves continuous monitoring of processes. This may include measurements, visual inspections, and functional tests to ensure that each component meets quality standards as it is produced.

Control de calidad final (CCF): Once assembly is complete, the FQC stage involves comprehensive testing of the finished product. This may include performance tests, pressure tests, and safety inspections to ensure that the compressor operates efficiently and safely.

For international B2B buyers, verifying the quality control measures of suppliers is essential to ensure product reliability and compliance with local standards.

Auditorías de proveedores: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control systems, and compliance with international standards firsthand.

Quality Assurance Reports: Requesting detailed QA reports from suppliers can provide insights into their manufacturing practices and the results of quality tests performed.

Inspecciones de terceros: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures and product reliability.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the specific quality control nuances that can impact their procurement decisions.

Different regions may have distinct regulations and standards that affect the manufacturing and quality assurance processes. Buyers must familiarize themselves with these local requirements to ensure compliance and avoid potential issues during importation.

Illustrative image related to air compressor for tire shop

Furthermore, cultural differences in business practices may influence communication and negotiation with suppliers. Establishing clear expectations and maintaining open lines of communication can mitigate misunderstandings and enhance the procurement experience.

Understanding the manufacturing processes and quality assurance measures for air compressors is vital for B2B buyers in the tire shop sector. By being informed about the stages of production, relevant standards, and effective quality control practices, buyers can make educated decisions that ensure they acquire reliable and efficient equipment for their operations.

To assist B2B buyers in procuring air compressors for tire shops, this guide outlines essential steps to ensure a successful purchase. It is crucial to consider various factors, from technical specifications to supplier evaluations, to secure equipment that meets operational needs and budget constraints.

Establishing clear technical specifications is vital for selecting the right air compressor. Consider factors such as the intended use, required tank size, horsepower, and CFM (cubic feet per minute) ratings. For tire shops, a compressor with a minimum tank capacity of 60 gallons and a CFM rating of at least 20-25 is typically ideal to handle multiple pneumatic tools efficiently.

Understanding the power needs of your air compressor is essential for compatibility with your facility’s electrical system. Determine whether you will need a single-phase or three-phase compressor based on your operational scale. Additionally, ensure that the compressor’s voltage aligns with your shop’s electrical infrastructure to avoid costly modifications.

Illustrative image related to air compressor for tire shop

Before finalizing a purchase, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and customer references. Look for suppliers with experience in the automotive sector, particularly those who understand the unique demands of tire shops, as this will enhance your confidence in their reliability and expertise.

Ensure that your chosen supplier holds relevant certifications and adheres to industry standards. Certifications such as ISO or CE can indicate that the compressors meet safety and quality benchmarks. This step is crucial for minimizing risks associated with equipment failure and ensuring compliance with local regulations.

If possible, arrange for demonstrations or trial periods of the compressors you are considering. This allows you to assess the performance and suitability of the equipment in real-world conditions. Pay attention to factors such as noise levels, ease of use, and maintenance requirements during the trial.

Illustrative image related to air compressor for tire shop

Investigate the after-sales support offered by the supplier, including maintenance services and availability of spare parts. A robust warranty is also important, as it protects your investment and ensures you receive assistance in case of equipment failure. Look for suppliers who provide comprehensive training for your staff on equipment operation and maintenance.

Finally, assess the total cost of ownership (TCO) associated with the air compressor. This includes not only the initial purchase price but also maintenance costs, energy consumption, and potential downtime. A compressor with higher upfront costs might offer lower long-term expenses, making it a more economical choice over time.

By following this checklist, B2B buyers can make informed decisions when sourcing air compressors for tire shops, ensuring they choose equipment that meets their specific operational needs while maximizing return on investment.

Illustrative image related to air compressor for tire shop

To effectively source air compressors for tire shops, understanding the comprehensive cost structure and pricing dynamics is essential. This analysis highlights key cost components, price influencers, and offers actionable buyer tips for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

The cost structure for air compressors typically includes several key components:

Materiales: The primary materials involved are steel for the tank, various alloys for internal components, and electrical parts. The quality and source of these materials can significantly affect pricing.

Trabajo: Labor costs encompass assembly, quality control, and testing. Skilled labor is often required for complex models, such as two-stage compressors, which can increase labor costs.

Gastos generales de fabricación: This includes factory costs such as utilities, equipment depreciation, and indirect labor. Efficient manufacturing processes can help reduce these overheads.

Herramientas: Custom tooling for specialized compressor designs can incur additional costs. Standardized models tend to have lower tooling expenses.

Control de calidad: Ensuring compressors meet international standards (such as ISO certifications) involves rigorous QC processes, which can add to overall costs but are vital for reliability.

Logística: Shipping costs can vary widely depending on the origin of the compressor, the destination, and the chosen shipping method. This is particularly relevant for international buyers who must consider duties and tariffs.

Margen: Suppliers typically mark up prices to ensure profitability. This margin can vary based on market demand, competition, and brand reputation.

Several factors can influence the pricing of air compressors, including:

Volumen/MOQ: Larger orders often qualify for discounts. Buyers should assess their needs and explore bulk purchasing options to optimize costs.

Especificaciones y personalización: Custom features, such as enhanced pressure ratings or specific tank sizes, can increase the price. Standard models are usually more cost-effective.

Materiales: High-grade materials or eco-friendly options can lead to higher costs but may offer better durability and efficiency.

Calidad y certificaciones: Compressors with recognized certifications (e.g., CE or UL) might be priced higher due to the assurance of quality and safety.

Factores del proveedor: The supplier’s reputation, production capacity, and location can impact pricing. Established suppliers may charge a premium for their reliability and service.

Incoterms: The agreed-upon Incoterms (e.g., FOB, CIF) can significantly affect the total landed cost. Understanding these terms is crucial for accurate cost estimation.

International buyers should consider the following strategies to enhance cost-efficiency:

Negotiate Prices: Engage in discussions with suppliers to negotiate better pricing based on order volume or long-term contracts. Building a relationship can lead to more favorable terms.

Evaluar el coste total de propiedad (TCO): Look beyond initial purchase costs. Consider maintenance, energy consumption, and potential downtime when assessing overall value.

Entender los matices de los precios: Be aware that pricing may vary significantly based on regional market conditions. Conduct market research to ensure you’re getting competitive rates.

Consider Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times. Additionally, local companies may offer better service and support.

Stay Informed on Trends: Keep abreast of trends in compressor technology and market dynamics. Emerging technologies may provide more efficient options that can reduce long-term costs.

Prices for air compressors can vary widely based on specifications, supplier, and regional factors. It’s essential to request quotes from multiple suppliers to ensure competitive pricing tailored to your specific requirements.

In the tire repair and maintenance industry, selecting the right equipment is crucial for operational efficiency and service quality. While air compressors are the traditional choice for powering pneumatic tools and inflating tires, there are alternative solutions that may offer unique benefits. This analysis compares air compressors specifically designed for tire shops with two viable alternatives: electric tire inflators and nitrogen tire inflation systems.

Illustrative image related to air compressor for tire shop

| Aspecto comparativo | Air Compressor for Tire Shop | Electric Tire Inflator | Nitrogen Tire Inflation System |

|---|---|---|---|

| Rendimiento | High CFM, suitable for multiple tools | Moderate CFM, best for single use | Consistent pressure, reduces tire wear |

| Coste | Higher initial investment; ongoing maintenance | Lower upfront cost; less durable | Moderate investment; cost-effective over time |

| Facilidad de aplicación | Requires plumbing and electrical setup | Plug-and-play, easy to use | Requires specialized equipment and training |

| Mantenimiento | Regular maintenance needed; prone to wear | Requiere un mantenimiento mínimo | Low maintenance; periodic checks needed |

| El mejor caso de uso | High-volume tire shops needing versatility | Mobile service or low-volume shops | Specialty shops focusing on performance |

Electric tire inflators are compact, portable devices designed to quickly inflate tires. They operate on standard electrical outlets and are ideal for mobile service technicians or smaller shops with limited space. The primary advantages include their affordability and ease of use. However, they generally have a lower CFM rating compared to air compressors, making them less suitable for shops that require powering multiple pneumatic tools simultaneously. This limits their versatility in a busy tire shop environment where efficiency is key.

Nitrogen tire inflation systems utilize nitrogen gas to fill tires instead of regular air. The benefits include reduced tire wear and improved fuel efficiency due to nitrogen’s larger molecular size, which minimizes pressure loss over time. This system is particularly advantageous for high-performance vehicles or commercial fleets seeking to maximize tire lifespan. However, the initial investment is moderate, and it requires specialized training to implement correctly. Additionally, while maintenance is low, there are costs associated with nitrogen refills, which may be a consideration for budget-conscious businesses.

When deciding between an air compressor, electric tire inflator, or nitrogen inflation system, B2B buyers must consider their specific operational needs. For high-volume shops that require versatility and the ability to power various tools, an air compressor remains the best option despite its higher cost and maintenance requirements. Conversely, for mobile service technicians or shops with lower inflating demands, an electric tire inflator may provide a cost-effective and user-friendly solution. Lastly, for businesses focused on maximizing tire performance and longevity, investing in a nitrogen tire inflation system could yield significant long-term benefits. Ultimately, the right choice hinges on balancing performance requirements, budget constraints, and operational goals.

When selecting an air compressor for a tire shop, understanding the technical specifications is crucial for ensuring optimal performance and reliability. Here are key properties to consider:

CFM measures the volume of air delivered by the compressor. It is essential to match the CFM rating with the requirements of pneumatic tools used in tire servicing. A higher CFM ensures that multiple tools can operate simultaneously without loss of pressure, which is vital for efficiency in busy tire shops.

Horsepower indicates the power output of the compressor’s motor. Generally, a tire shop should look for compressors with motors ranging from 5 to 15 HP, depending on the size and scale of operations. More horsepower translates to faster recovery time and the ability to handle heavy-duty tasks, which is critical for tire installations and repairs.

Tank capacity, measured in gallons, determines how much compressed air can be stored. For most tire shops, a tank capacity of at least 60 gallons is recommended to accommodate high-demand situations without frequent cycling of the compressor. This leads to less wear on the motor and improved operational efficiency.

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can deliver. Tire shops typically require a minimum of 90-120 PSI for effective tire inflation. Ensuring the compressor meets these pressure requirements is vital for delivering the necessary performance during tire servicing.

Two-stage compressors compress air in two stages, allowing for higher pressure and improved efficiency. They are ideal for tire shops that require constant high-pressure air for extended periods. Single-stage compressors are suitable for lighter applications but may not meet the demands of a busy tire shop.

Illustrative image related to air compressor for tire shop

The construction material of the compressor, typically steel or cast iron, affects its durability and lifespan. High-quality materials ensure that the compressor can withstand the rigors of a tire shop environment, which may involve exposure to moisture and debris.

Familiarity with industry terminology is important for effective communication and decision-making in B2B transactions. Here are some common terms:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For air compressors, purchasing OEM parts ensures compatibility and reliability, which is critical for maintaining equipment performance in tire shops.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for tire shop owners to manage inventory effectively and ensure they are not overstocking or understocking essential equipment.

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Tire shops should use RFQs when comparing offers from multiple suppliers to ensure they are getting the best deal on air compressors and related accessories.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms can help tire shop owners navigate shipping, insurance, and delivery logistics when importing compressors from overseas suppliers.

PSI is a unit of measurement for pressure. It is a critical specification for air compressors, particularly in tire shops where precise inflation pressure is necessary for safety and performance.

This refers to the planned routine for servicing the air compressor to ensure its longevity and efficiency. Regular maintenance is vital to prevent unexpected breakdowns and to maintain consistent air supply for tire servicing.

Understanding these properties and terms enables tire shop owners to make informed purchasing decisions, ensuring that their operations run smoothly and efficiently.

Illustrative image related to air compressor for tire shop

The global market for air compressors, particularly in the tire shop sector, is experiencing significant growth driven by the increasing demand for automotive services and the rise in vehicle ownership across emerging economies. In regions such as Africa, South America, the Middle East, and Europe, the expansion of automotive repair and maintenance services is a key driver. This growth is complemented by advancements in technology, including the introduction of energy-efficient compressors and smart connectivity features that allow for real-time monitoring and maintenance alerts.

Emerging B2B technology trends are shaping sourcing strategies as buyers seek out compressors that not only meet performance needs but also offer longevity and reliability. The shift towards two-stage compressors is notable, as these units provide higher efficiency and consistent airflow, crucial for tire inflation and pneumatic tool operation. Additionally, mobile service capabilities are becoming more prevalent, with compact and portable compressor designs gaining traction among tire shops that offer roadside assistance.

International buyers are increasingly focused on understanding the specific requirements of their markets, such as power supply variations and service conditions, which impacts the selection of appropriate compressor models. This regional insight is crucial for informed purchasing decisions, ensuring compatibility and optimal performance in diverse operational environments.

Illustrative image related to air compressor for tire shop

Sustainability is becoming a pivotal factor in the B2B sourcing landscape for air compressors. The environmental impact of manufacturing and operating air compressors, particularly in tire shops, necessitates a shift towards more sustainable practices. Companies are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint through energy-efficient products and sustainable manufacturing processes.

Ethical sourcing is gaining traction, with buyers emphasizing the importance of transparent supply chains. This includes ensuring that materials used in compressor production are sourced responsibly and that manufacturing practices adhere to environmental regulations. Certifications such as ISO 14001 (Environmental Management) and energy efficiency ratings can significantly influence purchasing decisions, as they provide assurance regarding a product’s sustainability credentials.

The adoption of ‘green’ materials and technologies is also on the rise. Compressors designed with lower emissions and energy consumption not only align with corporate sustainability goals but also offer cost savings in the long run. B2B buyers are encouraged to engage with manufacturers that prioritize these aspects, thus enhancing their brand reputation and supporting global sustainability initiatives.

The evolution of air compressors in the tire shop industry has been marked by technological advancements and shifts in market demands. Initially, tire shops utilized simple, single-stage compressors that provided basic air supply for tire inflation. However, as the automotive sector grew and the need for more efficient service increased, the industry saw a transition towards more sophisticated two-stage compressors. These models offered improved performance, durability, and the ability to power various pneumatic tools, catering to the expanding service offerings of tire shops.

Illustrative image related to air compressor for tire shop

In recent years, the integration of digital technologies has further transformed the landscape. Modern air compressors now feature smart technologies that allow for enhanced diagnostics, remote monitoring, and predictive maintenance. This evolution reflects a broader trend within the B2B sector towards automation and efficiency, enabling tire shops to optimize their operations and respond more effectively to customer needs. As the market continues to evolve, the focus on sustainability and ethical sourcing is poised to shape the next chapter in the history of air compressors for tire shops.

How do I choose the right air compressor for my tire shop?

Selecting the appropriate air compressor involves assessing your shop’s specific needs. For a tire shop, a two-stage compressor with a tank capacity of at least 60 gallons is recommended for continuous operation. Consider the cubic feet per minute (CFM) rating required by your tools; a total of 20-25 CFM is typically adequate for small to medium-sized shops. Evaluate the power source (electric vs. gas) based on your facility’s setup and ensure you have the necessary fittings and filters for optimal performance.

What is the best type of air compressor for tire inflation?

For tire inflation, a belt-driven two-stage air compressor is usually the best option. This type provides a higher CFM and is capable of maintaining consistent pressure, which is crucial for efficiently inflating tires. Additionally, it is advisable to choose a compressor with a built-in moisture filter to prevent water from contaminating the air supply, ensuring the longevity of your pneumatic tools and equipment.

What are the typical payment terms for purchasing air compressors internationally?

Payment terms can vary significantly based on the supplier and the nature of the transaction. Common arrangements include 30% upfront payment with the balance due upon shipment or delivery. Some suppliers may offer letter of credit options for larger orders, providing security for both parties. Always clarify payment methods, currencies accepted, and any potential additional fees before finalizing the purchase.

How can I vet suppliers for air compressors?

To ensure you’re working with a reliable supplier, conduct thorough research. Look for certifications, customer reviews, and testimonials, and check their track record in the industry. Request references from previous clients and confirm their ability to meet your specific needs, including customization options and delivery timelines. Additionally, consider visiting their facilities or attending trade shows to assess their operations firsthand.

What is the minimum order quantity (MOQ) for air compressors?

Minimum order quantities can vary widely among suppliers. Some may have no MOQ for single units, especially for standard models, while others might require bulk orders to achieve better pricing or to cover manufacturing costs. When negotiating, inquire about flexible MOQ options or discounts for larger purchases, as this can significantly impact your procurement strategy.

What logistics considerations should I keep in mind when importing air compressors?

Logistics play a critical role in the timely delivery of air compressors. Assess shipping methods, lead times, and customs clearance processes specific to your country. Ensure that the supplier can provide proper documentation, such as invoices and certificates of origin, to facilitate smooth customs processing. Additionally, consider the costs associated with shipping, insurance, and any potential tariffs that may apply.

How do I ensure quality assurance (QA) for my air compressor purchases?

To ensure quality assurance, request detailed product specifications and quality certifications from your supplier. Inquire about their manufacturing processes and quality control measures. It’s beneficial to conduct inspections either through third-party services or by visiting the factory yourself, especially for larger orders. Establishing a clear return policy can also protect your investment in case of defective products.

Can I customize air compressors for my tire shop’s specific needs?

Many manufacturers offer customization options to tailor air compressors to your specific requirements. This can include modifications in tank size, pressure ratings, or additional features such as integrated dryers or filters. Discuss your unique needs with potential suppliers and request prototypes or samples if possible to ensure the final product meets your operational demands. Custom solutions can enhance efficiency and productivity in your tire shop.

Dominio: automotiveequipmentspecialists.com

Registrado: 2014 (11 años)

Introducción: This company, Ingersoll – Auto Shop Air Compressors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: alltiresupply.com

Matriculado: 2001 (24 años)

Introducción: When choosing an air compressor for tire repair or an automotive garage, consider the following key details: 1. **Tank Capacity**: For a shop, a tank capacity of at least 60 gallons is recommended. For mobile service trucks, a smaller unit with a gas-powered motor is preferable. 2. **Compressor Type**: A two-stage compressor is recommended for small to medium-sized shops, as it provides nearly con…

Dominio: tiresupplynetwork.com

Registrado: 2018 (7 años)

Introducción: Air Compressors & Accessories (50 products) – Brands: ABAC (11), BelAire (10), BendPak (5), Champion (8), Mi-T-M (2), Quincy (11). Capacities: 8 Gallons (1), 24 Gallons (2), 30 Gallons (8), 60 Gallons (3), 80 Gallons (19), 120 Gallons (5), 131 Gallons (2). Examples of products: Quincy 5.5-HP 8-Gallon Wheelbarrow Air Compressor with Honda Engine – Sale price $1,399.00; ABAC Two Stage 13HP, 30 Gallo…

Dominio: us.kaeser.com

Matriculado: 1996 (29 años)

Introducción: Automotive & Auto Shop Air Compressors by Kaeser include: 1. AIRCENTER Series: Complete compressed air systems for automotive shops. 2. SX AIRCENTER: Flow at 125 psig 12 – 28 cfm, Motor power 3 – 7.5 hp, Dimensions 23 1/4 x 43 x 61 3/8 in, Sound level 61 – 66 dB(A). 3. SM AIRCENTER: Flow at 125 psig 33 – 55 cfm, Motor power 7.5 – 15 hp, Dimensions 24 3/4 x 48 x 67 3/4 in, Sound level 65 – 68 dB(A)…

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: A good size air compressor for a mechanic should be capable of being used all day, every day, for any car, while also being small enough to transport in the bed of a truck.

In the competitive landscape of tire shops, strategic sourcing of air compressors is crucial for operational efficiency and cost-effectiveness. Understanding the specific needs—be it for mobile service trucks or stationary garage setups—allows buyers to select the right type of compressor, ensuring optimal performance. Key factors such as tank capacity, CFM ratings, and the durability of the equipment must be considered to align with business operations and customer demands.

Furthermore, sourcing from reputable suppliers not only guarantees quality but also facilitates access to essential accessories like filters and hoses, which are vital for maintaining compressor functionality. This holistic approach to procurement can significantly reduce downtime and enhance service delivery.

As we look ahead, international buyers from Africa, South America, the Middle East, and Europe should prioritize building strong supplier relationships. By engaging with trusted manufacturers and distributors, you can secure competitive pricing and innovative solutions that keep pace with market demands. Embrace this opportunity to streamline your operations and elevate your tire shop’s service capabilities. Take the next step in your sourcing strategy today and invest in the right air compressor solutions for your business.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.