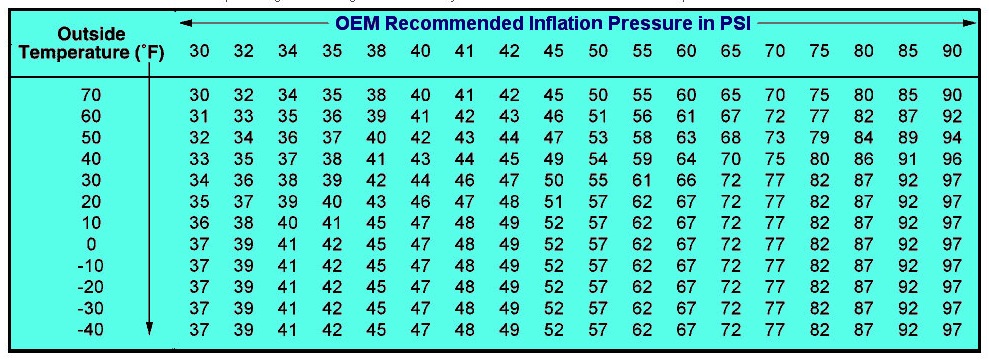

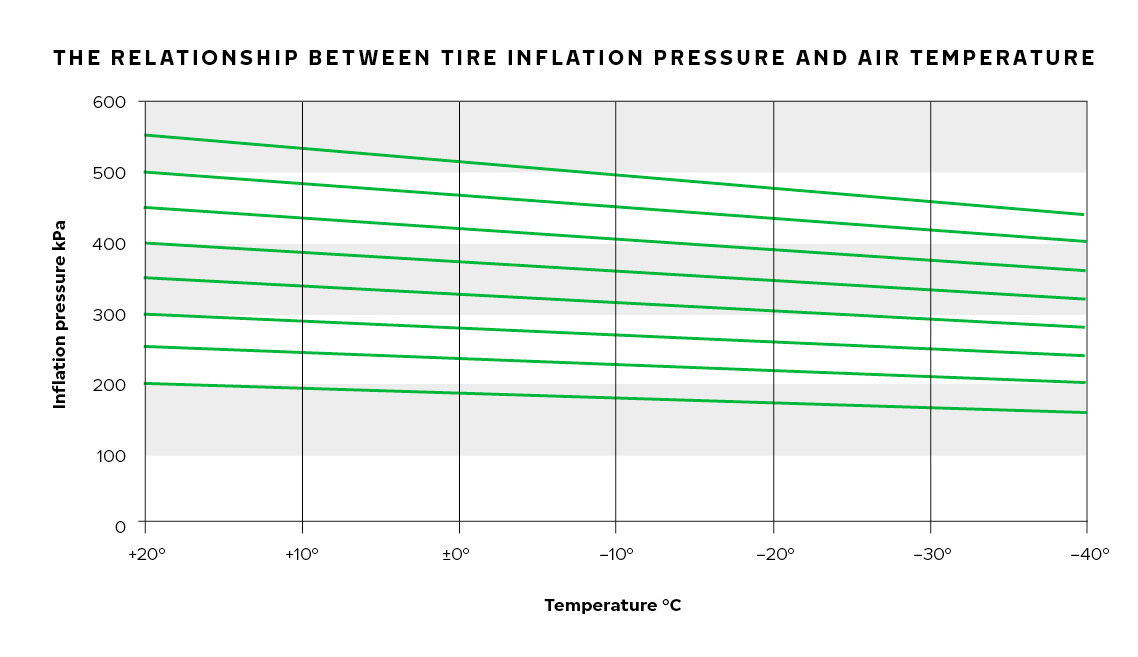

As winter approaches, the challenge of maintaining optimal tire inflation pressure in cold weather becomes increasingly critical for businesses operating in diverse climates. For B2B buyers—especially those sourcing vehicle fleets or tire products across regions like Africa, South America, the Middle East, and Europe—understanding how temperature fluctuations impact tire performance is essential. Cold weather can reduce tire pressure by 1 to 2 PSI for every 10°C drop, potentially compromising vehicle safety, fuel efficiency, and overall operational effectiveness.

This comprehensive guide delves into various aspects of tire inflation pressure in cold weather, covering essential topics such as tire types, applications, and the importance of regular monitoring. It also provides actionable insights on supplier vetting processes, cost considerations, and the latest industry standards to ensure that your fleet remains safe and efficient during winter months. By equipping international B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to foster a proactive approach to tire management, enhancing both safety and cost-effectiveness.

In navigating the complexities of the global tire market, your ability to adapt to seasonal changes in tire pressure will not only improve vehicle performance but also contribute to sustainability goals by reducing CO2 emissions. This guide serves as a valuable resource for businesses looking to optimize their tire management strategies and drive operational success in challenging weather conditions.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Standard Tire Pressure | Based on manufacturer specifications, requires regular checks | Fleet management, logistics companies | Pros: Optimal performance; Contras: Requires frequent monitoring. |

| Cold Weather Adjustment | Adjusts for temperature drops, typically 1-2 PSI per 10°C | Automotive service providers | Pros: Enhanced safety; Contras: May require recalibration. |

| Tire Pressure Monitoring Systems (TPMS) | Automated monitoring of tire pressure levels | Vehicle manufacturers, fleet operators | Pros: Real-time data; Contras: May not detect slow leaks. |

| Studded Tire Pressure | Specific to studded winter tires, requires careful inflation | Snow removal services, regional transport | Pros: Improved traction; Contras: Higher maintenance needs. |

| Altitude Consideration | Adjusts for elevation changes impacting pressure | Transportation companies operating in mountainous regions | Pros: Better handling; Contras: Needs regular altitude assessments. |

Standard tire pressure is defined by the vehicle manufacturer and is essential for optimal vehicle performance. For B2B buyers in fleet management or logistics, maintaining the recommended pressure ensures safety and efficiency. Regular monitoring is crucial, as under-inflated tires can lead to increased fuel consumption and reduced tire lifespan. Fleet operators should invest in training their drivers to check tire pressure regularly, enhancing operational reliability.

Cold weather adjustment refers to the practice of recalibrating tire pressure in response to temperature drops. As temperatures decrease, tire pressure can drop significantly, affecting vehicle handling and safety. This adjustment is particularly relevant for automotive service providers who need to educate customers on the importance of maintaining proper tire pressure during winter months. B2B buyers should consider providing educational resources to their clients, promoting safe driving practices.

Tire Pressure Monitoring Systems (TPMS) provide real-time data about tire pressure, alerting drivers to any significant changes. This technology is increasingly adopted by vehicle manufacturers and fleet operators looking to enhance safety and operational efficiency. While TPMS offers convenience, B2B buyers should be aware that these systems may not detect slow leaks, necessitating periodic manual checks. Investing in a comprehensive tire maintenance program that includes TPMS can significantly reduce overall costs.

Studded tire pressure is crucial for vehicles equipped with studded winter tires, which are designed for icy conditions. Proper inflation is essential for maximizing traction and safety in challenging winter weather. Businesses involved in snow removal or regional transport must ensure that their fleets are equipped with well-maintained studded tires. Regular checks and adjustments are necessary to prevent premature stud loss, making it important for B2B buyers to establish a robust tire maintenance schedule.

Altitude consideration involves adjusting tire pressure based on elevation changes, which can influence tire performance. Transportation companies operating in mountainous regions must be aware that tire pressure decreases with altitude. This knowledge is vital for maintaining vehicle safety and performance in varying terrains. B2B buyers should consider training programs for drivers, emphasizing the importance of monitoring tire pressure in relation to altitude to ensure optimal handling and safety.

| Industria/Sector | Specific Application of tire inflation pressure in cold weather | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Transportation & Logistics | Regular monitoring of tire pressure in delivery trucks | Enhanced safety, improved fuel efficiency, reduced breakdowns | Reliable tire pressure monitoring systems and gauges |

| Agricultura | Tire pressure management for farm machinery | Increased operational efficiency, reduced tire wear | Durable, weather-resistant tire pressure gauges |

| Construcción | Ensuring proper tire inflation for heavy equipment | Improved safety and productivity on job sites | High-capacity tire inflators and monitoring systems |

| Mining | Monitoring tire pressure in off-road vehicles | Enhanced traction and reduced operational risks | Robust tire pressure monitoring solutions for harsh environments |

| Automotive Services | Tire inflation services in cold weather for customers | Increased customer satisfaction and safety | Quality tire inflation equipment and training for staff |

In the transportation and logistics sector, maintaining correct tire inflation pressure is crucial, especially during cold weather. Delivery trucks often operate in varying climates, making regular monitoring essential. Under-inflated tires can lead to increased fuel consumption and safety hazards. Businesses need reliable tire pressure monitoring systems to ensure optimal performance and prevent breakdowns. Buyers should prioritize sourcing equipment that can withstand temperature fluctuations and provide accurate readings.

Illustrative image related to tire inflation pressure in cold weather

For agricultural machinery, proper tire inflation is vital for ensuring efficient operations during cold weather. Under-inflated tires can lead to poor traction and increased tire wear, negatively impacting productivity on farms. Regular checks and adjustments are necessary to maintain optimal tire pressure, particularly in regions with significant temperature changes. Buyers in the agricultural sector should consider durable, weather-resistant tire pressure gauges and inflators that can perform reliably in outdoor conditions.

In the construction industry, tire inflation pressure directly influences the safety and productivity of heavy equipment. Cold temperatures can cause tire pressure to drop, leading to compromised performance on job sites. Ensuring that machinery is equipped with properly inflated tires minimizes the risk of accidents and enhances operational efficiency. Construction firms should source high-capacity tire inflators and monitoring systems that can handle the demands of their equipment while providing accurate pressure readings.

Mining operations often rely on off-road vehicles that face extreme conditions. Monitoring tire pressure in these vehicles is critical for ensuring maximum traction and reducing operational risks. Cold weather can significantly affect tire performance, making regular checks essential. Mining companies should invest in robust tire pressure monitoring solutions that can function effectively in harsh environments. Buyers should prioritize equipment that offers durability and accuracy to maintain safety and efficiency in their operations.

Automotive service providers can enhance customer satisfaction by offering tire inflation services tailored for cold weather. As temperatures drop, the likelihood of tire pressure issues increases, making it essential for service centers to be equipped to handle these challenges. Providing accurate tire inflation not only improves vehicle safety but also helps customers avoid costly repairs. Automotive businesses should focus on sourcing quality tire inflation equipment and ensure staff are trained to offer effective service, especially in regions with fluctuating temperatures.

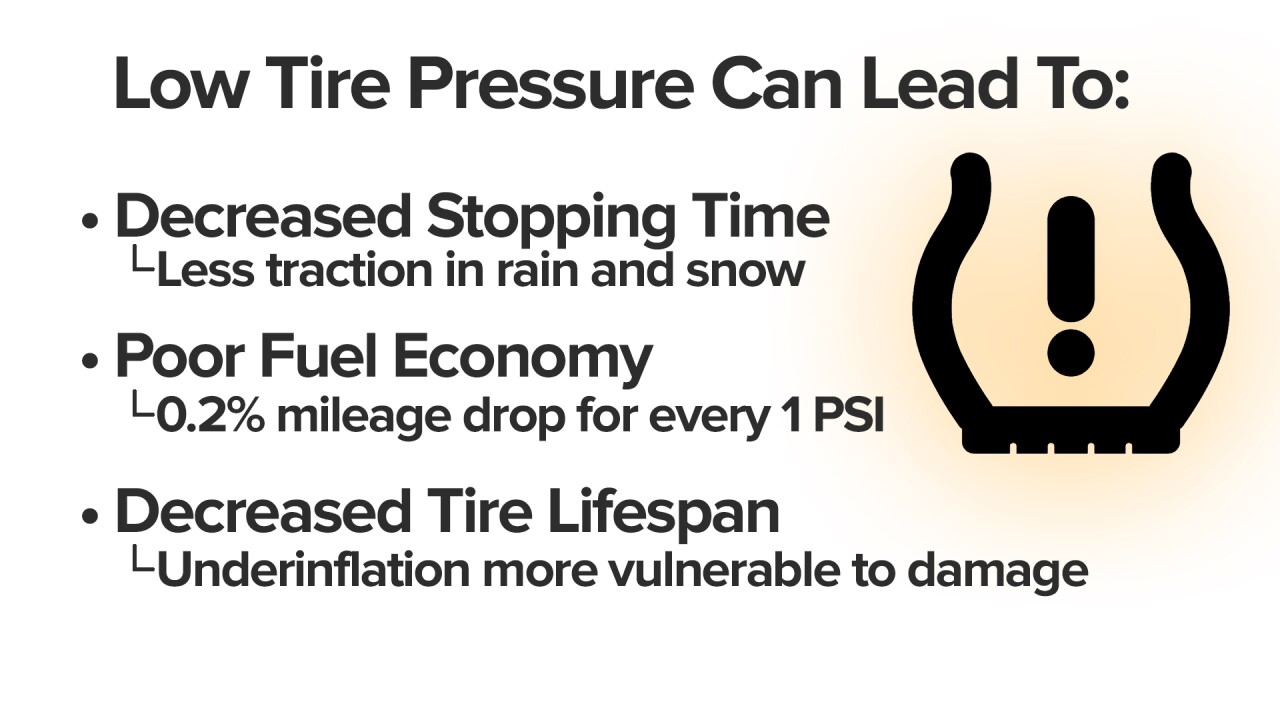

El problema: B2B buyers, particularly in logistics and transportation, often overlook the impact of cold weather on tire pressure. As temperatures drop, tire pressure decreases, leading to under-inflation. This situation can result in decreased fuel efficiency, increased tire wear, and compromised safety. For fleet operators, the financial implications are significant—higher fuel costs, more frequent tire replacements, and potential accidents that could lead to liability issues.

Illustrative image related to tire inflation pressure in cold weather

La solución: To mitigate these risks, implement a robust tire management program that includes regular tire pressure checks, particularly during colder months. Encourage fleet drivers to check tire pressure at least bi-weekly, preferably in the morning when tires are cold for accurate readings. Utilize tire pressure monitoring systems (TPMS) to provide real-time data but do not solely rely on them. Provide training for drivers on how to manually check tire pressure and the importance of maintaining the correct PSI as recommended by the vehicle manufacturer. This proactive approach not only extends the lifespan of tires but also enhances overall fleet safety and efficiency.

El problema: Companies operating in regions with harsh winter conditions face compliance challenges related to vehicle safety regulations. Under-inflated tires can lead to accidents and injuries, resulting in legal liabilities and damage to the company’s reputation. In some regions, regulations mandate specific tire conditions for commercial vehicles, and failing to meet these standards can result in hefty fines or even the suspension of operating licenses.

La solución: Establish a compliance checklist that includes tire pressure as a critical component. Conduct regular audits to ensure that all vehicles meet the required standards for tire inflation. Partner with tire manufacturers or local tire service providers to offer training sessions for staff on the importance of proper tire maintenance in cold weather. Additionally, invest in high-quality tire inflation equipment and ensure that all service stations used by the fleet are equipped to handle tire inflation accurately. By prioritizing compliance and safety, companies can reduce risks and foster a culture of accountability among employees.

El problema: Many B2B buyers, especially those managing vehicle fleets, face challenges due to inadequate tire maintenance equipment. In colder climates, it’s crucial to have the right tools to maintain tire pressure, but not all companies invest in high-quality gauges and compressors. This lack of proper equipment can lead to incorrect tire inflation, further exacerbating issues related to tire wear and safety.

La solución: Invest in reliable tire maintenance equipment that can withstand cold temperatures and provide accurate readings. Consider sourcing digital tire pressure gauges and air compressors that are specifically designed for winter conditions. Develop a partnership with equipment suppliers who can offer advice on the best products for your operational needs. Additionally, create a tire maintenance toolkit that includes essential items like a tire pressure gauge, an air compressor, and a tire repair kit. By ensuring that your team is equipped with the right tools, you empower them to maintain optimal tire pressure, which can lead to enhanced vehicle performance and reduced operational costs.

When considering tire inflation pressure in cold weather, selecting the right materials for tire components is crucial. The performance of tires under low temperatures can be significantly influenced by the materials used in their construction and inflation systems. Below, we analyze four common materials that play a vital role in ensuring optimal tire inflation pressure during cold weather conditions.

Rubber is the primary material used in tire manufacturing. Its key properties include excellent elasticity, temperature resistance, and a good balance of strength and flexibility. However, rubber can become stiffer in extreme cold, potentially impacting traction and handling.

Illustrative image related to tire inflation pressure in cold weather

Pros: Rubber is relatively inexpensive and can be produced in various formulations to enhance performance under different conditions. Its ability to maintain grip even in cold weather is a significant advantage for winter tires.

Contras: The durability of rubber can be affected by prolonged exposure to UV light and ozone, leading to degradation over time. Additionally, while rubber performs well in cold weather, its performance can vary significantly based on the specific formulation used.

For international B2B buyers, compliance with local standards such as ASTM or DIN is essential, especially in regions with varying climates like Europe and the Middle East. Buyers should consider sourcing rubber from suppliers who adhere to these standards to ensure quality and performance.

Steel is often used in tire reinforcement and valve components. It offers high tensile strength and excellent temperature resistance, making it suitable for maintaining tire integrity under varying pressures.

Pros: Steel’s durability ensures that tire valves and rims can withstand the stresses of cold weather without deforming or failing. Its resistance to corrosion, especially when treated, makes it a reliable choice for tire inflation systems.

Contras: The primary disadvantage of steel is its weight, which can negatively affect fuel efficiency. Additionally, if not properly treated, steel can corrode, especially in regions with high humidity or salt exposure, which is common in coastal areas.

International buyers should prioritize suppliers who provide steel components that meet corrosion resistance standards, particularly in regions like Africa and South America, where environmental conditions can vary widely.

Thermoplastic elastomers (TPEs) are increasingly being used in tire applications due to their flexibility and durability. They combine the properties of rubber with the processing advantages of plastics.

Pros: TPEs offer excellent temperature stability and can maintain their performance in cold weather without becoming brittle. They are also lightweight, which can contribute to overall vehicle efficiency.

Contras: The cost of TPEs can be higher than traditional rubber, which may deter some manufacturers. Additionally, their performance can vary significantly based on the specific formulation, which necessitates careful selection.

For B2B buyers, understanding the specific properties and certifications of TPEs is vital, especially in regions like Europe where environmental regulations are stringent. Ensuring compliance with local standards can enhance product acceptance in the market.

Composite materials, which combine different materials to optimize performance, are also gaining traction in tire applications. These materials can offer tailored properties, such as enhanced strength and reduced weight.

Pros: Composites can be engineered to provide specific benefits, such as increased resistance to temperature fluctuations and improved durability. This adaptability makes them suitable for a wide range of applications, including tire inflation systems.

Contras: The manufacturing complexity of composites can lead to higher costs and longer production times. Additionally, the performance of composites can be highly dependent on the specific materials used in the composite.

Illustrative image related to tire inflation pressure in cold weather

International buyers should consider the manufacturing capabilities of suppliers when sourcing composite materials. Ensuring that suppliers can meet the required performance standards is essential for the successful application of these materials in tire inflation systems.

| Material | Typical Use Case for tire inflation pressure in cold weather | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | Tire manufacturing and inflation systems | Excellent grip and elasticity | Degrades under UV exposure | Bajo |

| Acero | Tire reinforcement and valve components | Alta resistencia a la tracción | Can corrode if untreated | Med |

| Thermoplastic Elastomers | Flexible components in tire applications | Lightweight and temperature stable | Higher cost than traditional rubber | Alta |

| Materiales compuestos | Tailored applications in tire inflation systems | Propiedades personalizables | Manufacturing complexity and cost | Med |

This analysis provides a comprehensive overview of material options for tire inflation pressure management in cold weather, allowing B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

The manufacturing of tires designed to maintain optimal inflation pressure in cold weather involves several critical stages: material preparation, forming, assembly, and finishing.

Preparación del material: The process begins with sourcing high-quality raw materials, including natural rubber, synthetic rubber, fabric, and steel. Each component plays a pivotal role in the tire’s durability and performance. For cold weather, manufacturers often select materials that exhibit lower thermal expansion properties, ensuring that tires maintain their shape and inflation pressure even as temperatures fluctuate.

Formando: During the forming stage, the prepared materials are shaped into tire components. This includes the creation of the tread, sidewalls, and inner linings. Advanced techniques such as extrusion and calendaring are used to create rubber sheets, while steel belts are formed to enhance structural integrity. Cold weather tires typically feature specialized tread patterns designed to improve grip on icy surfaces, which is critical for maintaining proper inflation pressure and traction.

Montaje: The assembly process involves combining the various components into a complete tire. This stage requires precision, as the alignment of the steel belts, tread, and sidewalls significantly impacts the tire’s performance. Manufacturers often utilize automated machinery to enhance consistency and reduce human error. For winter tires, special attention is given to the adhesion of the tread to the casing, as this affects how well the tire can maintain inflation under cold conditions.

Acabado: In the finishing stage, tires undergo quality checks and surface treatments. This includes curing, which solidifies the rubber and enhances its durability. Additionally, the tires are marked with relevant specifications and performance ratings. For cold weather performance, tires are often tested under simulated winter conditions to ensure they maintain their pressure and functionality when exposed to low temperatures.

Quality assurance (QA) in tire manufacturing is crucial for ensuring that products meet international standards and perform reliably in cold weather conditions. Key aspects of QA include adherence to international standards such as ISO 9001, which outlines requirements for a quality management system.

Normas internacionales y específicas del sector: Compliance with ISO standards, along with industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute), is essential. These standards ensure that tires are manufactured to high safety and performance benchmarks, particularly for cold weather applications.

Puntos de control de calidad: Manufacturers implement multiple checkpoints throughout the production process:

– Control de calidad entrante (IQC): This initial stage involves inspecting raw materials upon delivery to ensure they meet specified quality standards.

– Control de calidad durante el proceso (IPQC): During manufacturing, ongoing assessments are performed to identify defects or deviations in real-time. This includes monitoring material properties and adherence to production specifications.

– Control de calidad final (CCF): Completed tires undergo rigorous testing before they are packaged and shipped. This includes pressure tests, tread depth assessments, and performance evaluations under cold conditions.

Testing methods play a significant role in verifying the quality of tires, especially regarding their ability to maintain inflation pressure in cold weather. Some common testing techniques include:

Pressure Testing: Tires are subjected to pressure tests to ensure they can withstand temperature fluctuations without significant loss of inflation. This involves simulating cold weather conditions to assess how the tire retains air pressure over time.

Tread Wear and Grip Testing: Specialized equipment measures the tread’s performance on icy surfaces, ensuring that the tire maintains adequate traction even as temperatures drop. This is particularly important for winter tires, where tread design impacts both grip and air retention.

Dynamic Testing: This involves mounting tires on vehicles and assessing their performance under various driving conditions. Data collected from these tests can help manufacturers identify how well a tire maintains pressure and performs in cold weather.

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, ensuring supplier quality is critical. Here are effective strategies to verify a supplier’s quality control processes:

Auditorías de proveedores: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality assurance protocols. This includes examining their compliance with international standards and verifying their testing methods.

Quality Reports and Certifications: Requesting documentation of quality certifications, such as ISO 9001, and detailed quality reports can help buyers assess the reliability of a supplier. These documents should outline the supplier’s QA processes, testing results, and any corrective actions taken.

Inspecciones de terceros: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can conduct tests and evaluations to ensure that the tires meet specified performance criteria.

When dealing with suppliers across different regions, B2B buyers must be aware of certain nuances in quality control:

Cumplimiento de la normativa: Different countries have varying regulations regarding tire safety and performance. Buyers should ensure that their suppliers comply with local regulations in addition to international standards.

Consideraciones culturales: Understanding cultural differences in manufacturing practices can help buyers navigate potential challenges. For instance, some regions may prioritize cost over quality, which could impact the overall performance of tires in cold weather.

Logistical Challenges: Importing tires from various regions may present logistical issues that affect quality. Buyers should consider the entire supply chain, from manufacturing to delivery, to ensure that tires maintain their quality and performance standards throughout the process.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices related to tire inflation pressure in cold weather is essential for B2B buyers. By focusing on supplier quality control and compliance with international standards, businesses can ensure they procure tires that deliver optimal performance and safety in challenging winter conditions.

To ensure optimal tire performance during cold weather, it is essential for businesses to maintain proper tire inflation pressure. This guide serves as a comprehensive checklist for B2B buyers to effectively manage tire inflation in colder climates, enhancing safety, fuel efficiency, and tire longevity.

Recognizing how temperature influences tire pressure is critical. Tire pressure typically decreases by 1-2 PSI for every 10°C drop in temperature. Understanding this relationship allows you to anticipate adjustments needed for your fleet, particularly in regions prone to significant temperature fluctuations.

Illustrative image related to tire inflation pressure in cold weather

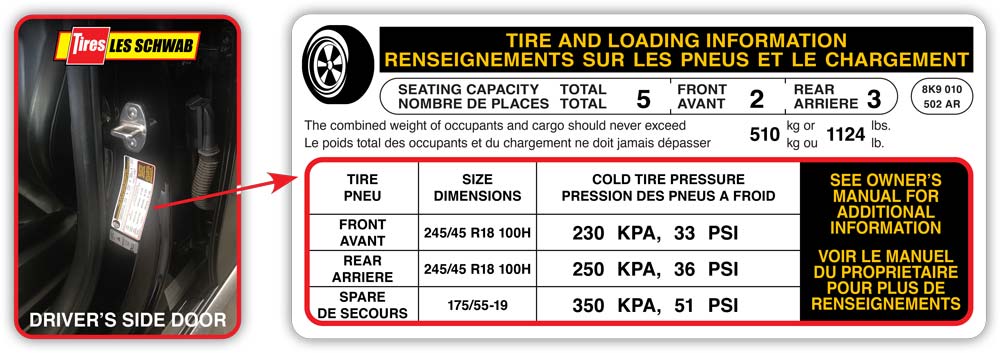

Identify the recommended tire pressure for each vehicle in your fleet. This information is usually found in the vehicle’s manual or on a sticker inside the driver’s door. Using the correct pressure ensures optimal handling, safety, and fuel efficiency, which is vital for maintaining operational costs in a competitive market.

Establish a routine for checking tire pressures, ideally every two weeks. Use a reliable tire pressure gauge and ensure tires are cold when checking to get accurate readings. Frequent checks help prevent under-inflation, which can lead to reduced grip and increased wear, impacting overall vehicle performance.

When filling tires, do so when they are cold. If you must fill them after driving, note the increased pressure due to heat and adjust accordingly. This practice minimizes the risk of over-inflation, which can compromise tire integrity and safety.

While TPMS can alert you to low tire pressure, they shouldn’t replace manual checks. Familiarize yourself with the specific alerts your TPMS provides and ensure that your team understands how to respond to these notifications. Regularly monitoring TPMS performance can prevent reliance on potentially faulty sensors.

Training your team on the importance of tire maintenance in cold weather is crucial. Provide resources or workshops that cover the implications of improper tire pressure and maintenance practices. An informed team is essential for implementing effective tire care, which directly influences safety and efficiency.

Illustrative image related to tire inflation pressure in cold weather

When sourcing tires or services, assess suppliers based on their understanding of cold weather challenges. Look for suppliers that provide detailed product specifications, including pressure recommendations and performance in cold conditions. Partnering with knowledgeable suppliers ensures you receive products that meet your operational needs and enhance safety.

By following these steps, businesses can effectively manage tire inflation pressure during cold weather, ensuring enhanced safety, improved fuel efficiency, and prolonged tire life.

When evaluating the costs associated with tire inflation pressure systems in cold weather, several components come into play:

Materiales: The quality of materials used in tire manufacturing directly influences costs. High-grade rubber and advanced composites enhance durability and performance, especially in colder climates. Suppliers should provide detailed specifications on the materials used to ensure compliance with regional safety standards and certifications.

Trabajo: Labor costs can vary significantly based on geographic location and local wage standards. In regions like Africa or South America, lower labor costs may benefit manufacturers, but quality and expertise should not be compromised. Skilled labor is essential for ensuring that tires are produced to precise specifications, especially for winter models.

Gastos generales de fabricación: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs, which ultimately influences the pricing of the final product.

Herramientas: The cost of tooling is crucial, particularly for customized tire designs. Precision engineering is required to produce tires that can withstand the unique challenges posed by cold weather. Buyers should inquire about the tooling costs and how they impact the overall pricing.

Control de calidad: Rigorous QC processes ensure that tires meet safety and performance standards, which is particularly critical in cold climates. These processes add to the cost but are essential for minimizing the risk of product failure and ensuring customer satisfaction.

Logística: Transportation and distribution costs can vary greatly depending on the region. Factors such as distance, transportation mode, and local infrastructure can affect logistics costs significantly. International buyers should be aware of potential delays and additional costs associated with cross-border shipping.

Margen: The profit margin applied by manufacturers will vary based on market conditions, competition, and the perceived value of the product. Buyers should aim to understand the typical margins in their region to negotiate effectively.

Several factors can influence the pricing of tire inflation solutions:

Volumen y cantidad mínima de pedido (MOQ): Larger orders typically lead to lower per-unit costs. Negotiating volume discounts can be advantageous for B2B buyers, especially for companies with fleets requiring substantial tire purchases.

Especificaciones y personalización: Custom tires designed for specific vehicles or conditions may incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

Calidad y certificaciones: Tires that meet international safety and performance standards often command higher prices. Buyers should prioritize quality certifications relevant to their region, as these can significantly impact safety and liability.

Factores del proveedor: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge premium prices, but they often provide better warranties and after-sales support, which can be a cost-saving in the long run.

Incoterms: Understanding the terms of shipment can significantly impact the total cost. Buyers should clarify responsibilities for shipping, insurance, and customs duties, as these can add to overall expenses.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

Illustrative image related to tire inflation pressure in cold weather

Negociación: Leverage your purchasing power to negotiate better terms. Understanding the supplier’s cost structure can provide leverage in discussions.

Rentabilidad: Analyze the total cost of ownership rather than just the purchase price. This includes potential savings from improved fuel efficiency and reduced tire wear due to proper inflation.

Matices en la fijación de precios: Be aware of local market conditions, currency fluctuations, and trade tariffs that can affect pricing. Establishing good relationships with suppliers can also lead to more favorable terms.

Regular Monitoring: Implement a system for regular tire pressure checks and maintenance. This can prevent long-term costs associated with tire failure and ensure optimal performance.

In conclusion, understanding the cost structure and pricing influences of tire inflation solutions in cold weather can empower B2B buyers to make informed purchasing decisions. Always consider the total cost of ownership and negotiate terms that align with your operational needs.

In the realm of vehicle maintenance, particularly for businesses operating in regions with cold climates, maintaining optimal tire inflation pressure is crucial. However, various alternative solutions can assist in mitigating the challenges posed by cold weather. This analysis compares traditional tire inflation pressure management against other viable methods, focusing on their performance, cost, ease of implementation, maintenance requirements, and best use cases.

| Aspecto comparativo | Tire Inflation Pressure In Cold Weather | Tire Pressure Monitoring Systems (TPMS) | Nitrogen Inflation |

|---|---|---|---|

| Rendimiento | Essential for traction and safety; affected by temperature fluctuations | Alerts for low pressure; may not prevent pressure loss | Maintains pressure longer; reduces fluctuations |

| Coste | Minimal ongoing costs for monitoring and air | Initial investment; may require professional installation | Higher initial cost; nitrogen refills can be more expensive |

| Facilidad de aplicación | Simple; requires regular manual checks | Requires installation and calibration; some systems are easier to use than others | Installation needed; requires specialized equipment for refilling |

| Mantenimiento | Regular checks needed every two weeks | Requires periodic checks and battery maintenance | Minimal maintenance; nitrogen stays stable longer |

| El mejor caso de uso | General use in varied climates | Fleets and vehicles operating in extreme conditions | Long-distance travel or racing environments |

Tire Pressure Monitoring Systems (TPMS) offer a modern solution to tire pressure management, alerting drivers when tire pressure falls below a predetermined level. This technology enhances safety by providing real-time data, which is particularly beneficial for businesses with fleets that operate in cold climates. However, the initial cost of installation and potential need for professional calibration can be a drawback for some companies. Additionally, while TPMS provides alerts, it does not prevent the natural drop in tire pressure that occurs with temperature changes, necessitating regular manual checks.

Nitrogen inflation is an alternative method that involves filling tires with nitrogen gas instead of regular air. Nitrogen molecules are larger than oxygen molecules, which minimizes the rate of pressure loss through the tire walls. This method can be particularly advantageous for long-distance travel or in racing environments where consistent tire performance is essential. However, the initial cost of nitrogen inflation systems can be higher than standard air inflation. Additionally, businesses may find it less convenient, as specialized equipment for filling tires with nitrogen is required, which may not be readily available at standard service stations.

Choosing the right solution for tire inflation pressure in cold weather depends on a company’s specific needs, budget, and operational conditions. For businesses that prioritize cost-effectiveness and simplicity, regular manual checks may suffice. In contrast, companies operating in extreme conditions or managing fleets might benefit from investing in TPMS for enhanced safety and efficiency. Alternatively, for those focused on maximizing performance in specialized applications, nitrogen inflation could be a worthwhile consideration despite the higher upfront costs. Ultimately, understanding the pros and cons of each method will help B2B buyers make informed decisions that align with their operational requirements and financial constraints.

When dealing with tire inflation pressure in cold weather, several technical properties are essential for ensuring safety and performance. Understanding these specifications allows businesses to make informed decisions regarding tire purchases and maintenance.

Tire pressure is typically measured in pounds per square inch (PSI) or bar. The recommended tire pressure is crucial for optimal vehicle handling, fuel efficiency, and tire longevity. In cold weather, tire pressure can drop by 1-2 PSI for every 10°C decrease in temperature. For B2B buyers, maintaining the correct tire pressure can prevent premature tire wear and enhance safety, especially in regions with extreme temperature fluctuations.

Tread depth is a critical property that influences traction, particularly in icy or snowy conditions. A minimum tread depth of 4mm is often recommended for winter tires. Buyers should prioritize tires with adequate tread depth to ensure safety and compliance with local regulations. Inadequate tread can lead to reduced grip, increasing the risk of accidents, which is a significant concern for fleet operators and logistics companies.

Tires are designed to operate within specific temperature ranges. Cold weather can cause rubber to harden, reducing grip and increasing the likelihood of tire failure. B2B buyers should consider tires that are engineered for low-temperature performance, which often feature specialized compounds to maintain flexibility. This is particularly important for businesses operating in regions where temperatures can plummet, ensuring the safety of their vehicles and drivers.

Illustrative image related to tire inflation pressure in cold weather

Inflation stability refers to the tire’s ability to maintain its pressure over time, even in fluctuating temperatures. Quality tires will feature materials and designs that minimize air loss, which is crucial during cold months when pressure naturally decreases. Companies should look for tires with robust construction and sealing technologies to ensure consistent performance and reduce maintenance costs.

This specification indicates the maximum weight a tire can support while maintaining proper inflation. Each tire’s load capacity is influenced by its construction and design. B2B buyers must match tire load ratings with the intended vehicle use, particularly for commercial fleets where carrying heavy loads is common. Incorrect load ratings can lead to tire failure, posing risks to both safety and business operations.

Understanding industry jargon is essential for effective communication and decision-making in the tire market. Here are some key terms that B2B buyers should be familiar with:

OEM refers to the original manufacturer of a vehicle or tire. When sourcing tires, businesses often prefer OEM products for their reliability and compatibility with specific vehicle models. This term is crucial for ensuring that the tires meet the manufacturer’s specifications and performance standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For tire purchases, understanding MOQ is vital for businesses, as it affects inventory management and cost per unit. Buyers should negotiate MOQs to align with their operational needs while ensuring they receive competitive pricing.

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers should use RFQs to obtain detailed proposals from multiple suppliers, enabling them to compare costs and services. This process is essential for making informed purchasing decisions and managing budgets effectively.

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for B2B transactions involving tire imports or exports. They dictate who is responsible for shipping, insurance, and tariffs, impacting overall costs and logistics strategies.

Illustrative image related to tire inflation pressure in cold weather

TPMS is an electronic system that monitors tire pressure and alerts drivers when levels are low. While beneficial, B2B buyers should not rely solely on TPMS, as it may not provide real-time accuracy in cold weather conditions. Regular manual checks are essential for maintaining optimal tire performance.

By comprehending these technical properties and trade terms, B2B buyers can enhance their decision-making processes regarding tire purchases and maintenance, ultimately leading to safer and more efficient operations.

The tire inflation pressure market in cold weather is shaped by several global drivers that affect both demand and sourcing strategies for international B2B buyers. One of the primary drivers is the increasing awareness of vehicle safety and efficiency, particularly in regions with harsh winter conditions. As a result, businesses are investing in high-quality winter tires and monitoring systems to ensure optimal performance. Additionally, the expansion of the automotive sector in emerging markets such as Nigeria, Saudi Arabia, and Brazil is driving demand for reliable tire inflation solutions.

Technological advancements, such as smart tire monitoring systems that provide real-time data on tire pressure, are also gaining traction. These innovations not only enhance safety but can also lead to fuel savings and reduced carbon emissions, making them attractive to cost-conscious businesses. Furthermore, as environmental regulations tighten globally, companies are looking for suppliers who can provide compliant and advanced tire inflation solutions.

In terms of market dynamics, fluctuations in raw material prices, such as rubber and steel, can impact sourcing strategies. Buyers must stay informed about these market trends to make educated decisions regarding procurement, especially when considering the influence of geopolitical factors on supply chains.

Sustainability is becoming increasingly important in the tire inflation pressure sector. The environmental impact of tire production and disposal, including pollution and waste, has prompted many companies to seek out sustainable and ethical sourcing practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainability, such as those who use recycled materials or offer ‘green’ certifications.

Ethical supply chains are essential not only for compliance with international regulations but also for enhancing brand reputation among environmentally conscious consumers. Sourcing from suppliers that adhere to ethical labor practices ensures a more responsible supply chain, which is especially important in markets like Africa and South America, where labor practices can vary significantly.

Moreover, the integration of sustainable materials in tire production can lead to innovations in tire inflation technology, such as the development of tires that maintain optimal pressure longer, reducing the need for frequent inflation and thereby minimizing resource consumption. Buyers should seek out partners who are investing in research and development to create eco-friendly tire solutions that align with their corporate social responsibility goals.

The tire inflation pressure market has undergone significant evolution over the decades, influenced by advancements in automotive technology and changing consumer demands. Initially, tire pressure management was a manual task, relying on basic gauges and physical checks. However, the introduction of tire pressure monitoring systems (TPMS) in the early 2000s transformed how businesses and consumers approached tire maintenance, providing real-time data and enhancing safety.

As consumer awareness of vehicle safety and efficiency has grown, so too has the demand for winter-specific tire inflation solutions, especially in colder regions. This shift has led manufacturers to innovate, introducing specialized winter tires designed to perform optimally in low temperatures, alongside advanced inflation technologies.

Today, the market continues to adapt, with a strong focus on sustainability and the integration of smart technologies that cater to the evolving needs of international B2B buyers. As businesses navigate this landscape, understanding the historical context can provide valuable insights into future trends and opportunities within the tire inflation pressure sector.

How do I ensure accurate tire pressure in cold weather?

To ensure accurate tire pressure in cold weather, regularly check your tire inflation levels every two weeks or before long trips. Use a reliable tire pressure gauge when the tires are cold, ideally first thing in the morning or after the vehicle has been stationary for several hours. Remember that for every 10°C drop in temperature, tire pressure can decrease by 1-2 PSI. Adjust the pressure according to the manufacturer’s recommendations found in the vehicle’s handbook or on the driver’s side door frame.

What is the best tire pressure for winter tires?

The best tire pressure for winter tires is typically specified by the vehicle manufacturer and can be found in the vehicle’s handbook or on a sticker inside the driver’s door. Generally, maintaining the recommended PSI ensures optimal traction and handling in cold conditions. Under-inflated tires can lead to reduced grip, increased wear, and even safety hazards, particularly on icy or snowy roads. Always adjust the tire pressure according to temperature changes to maximize performance.

How can I vet suppliers for tire inflation products?

When vetting suppliers for tire inflation products, consider their industry reputation, certifications, and customer reviews. Request samples to evaluate product quality and reliability. Additionally, inquire about their compliance with international standards and regulations, especially if you’re importing to regions like Africa or South America. Establish clear communication regarding lead times, minimum order quantities (MOQ), and payment terms to ensure a smooth purchasing process.

What are the typical payment terms for international tire suppliers?

Payment terms for international tire suppliers can vary widely but typically include options like letters of credit, advance payments, or net 30-90 days. It’s crucial to negotiate terms that align with your cash flow and operational needs. Always confirm the currency of the transaction and any additional fees related to currency conversion. Consider using escrow services for larger transactions to mitigate risks associated with overseas purchases.

What logistics considerations should I keep in mind when sourcing tires?

Logistics considerations when sourcing tires include shipping methods, customs regulations, and delivery timelines. Evaluate whether the supplier can handle logistics or if you need to arrange this separately. Be aware of import duties and taxes that may apply when bringing tires into your country. Additionally, consider the reliability of the supplier’s shipping partners and their ability to track shipments, especially if you’re operating in regions with less developed infrastructure.

Can I customize tire inflation systems for my fleet?

Yes, many suppliers offer customization options for tire inflation systems tailored to specific fleet needs. This can include adjustments to tire pressure monitoring systems or automated inflation solutions. When inquiring about customization, provide detailed specifications and performance requirements. Discuss minimum order quantities and lead times for custom solutions to ensure they fit within your operational timeline.

What quality assurance measures should I expect from tire suppliers?

Expect tire suppliers to have robust quality assurance measures in place, such as ISO certifications or adherence to specific industry standards. Inquire about their testing processes for tire performance, durability, and safety. Request documentation of quality checks and any warranties offered on the products. Reliable suppliers should also have a clear process for handling defects or returns, ensuring that your investment is protected.

How does temperature variation affect tire performance in different regions?

Temperature variations significantly impact tire performance, particularly in regions with extreme climates. In colder areas, tire pressure decreases, which can lead to reduced traction and increased wear. Conversely, in hotter regions, tire pressure may rise, affecting handling and safety. For international buyers, understanding these variations is crucial for selecting appropriate tire types and maintaining proper inflation, ensuring optimal performance across diverse conditions.

Dominio: continental-tires.com

Matriculado: 2000 (25 años)

Introducción: Tire pressure in winter is affected by cold weather, causing air pressure to drop by 1-2 PSI or 0.07 to 0.14 bar for every 10°C decrease in temperature. It is recommended to check tire pressure every two weeks and to find the vehicle’s recommended tire pressure. Maintaining correct tire pressure ensures optimal traction, grip, better fuel mileage, and reduced CO2 emissions. Regular maintenance is …

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Cooler temperatures can drop car tire pressures by 1-2 psi for every 10 degrees Fahrenheit decrease in temperature, impacting handling, braking, and tire lifespan. A drop from 90 to 60 degrees can reduce tire pressure by up to 6 psi. It’s important to check tire pressure when tires are cold, and the correct air pressure can be found on the driver’s side inside door jamb.

Dominio: facebook.com

Inscrita: 1997 (28 años)

Introducción: This company, Facebook – Tire Pressure Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: community.cartalk.com

Matriculado: 1995 (30 años)

Introducción: Tire pressure changes about 1 psi for every 10ºF change in temperature; recommended tire pressure for the car is 32/30 psi; maximum inflation pressure on the tires is 50 psi; suggested over-inflation by 10 psi for cold temperatures, bringing pressure to 42/40 psi; alternative suggestion to set tires for -20 temperature as a compromise, starting with 40/38 psi in the garage.

In summary, maintaining optimal tire inflation pressure during cold weather is crucial for enhancing vehicle safety and performance. For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the impact of temperature fluctuations on tire pressure is essential. It is well-documented that tire pressure can drop significantly—by 1 to 2 PSI for every 10°C decrease, which can lead to reduced traction, increased tire wear, and compromised fuel efficiency. Regular checks, ideally every two weeks, and adherence to manufacturer guidelines are vital practices for ensuring the longevity and effectiveness of tires.

Strategic sourcing of quality tires and related services can yield substantial benefits, including improved operational efficiency and reduced costs. As markets continue to evolve, prioritizing partnerships with reliable suppliers who offer innovative tire solutions and proactive maintenance support will be key to navigating the complexities of cold weather driving conditions.

Looking ahead, B2B buyers should leverage this knowledge to refine their procurement strategies and enhance their fleet performance. Investing in the right tire technology and maintenance practices can result in significant long-term savings and operational resilience. Engage with suppliers today to ensure your fleet is prepared for the challenges of winter driving.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.