In today’s competitive logistics landscape, sourcing efficient tire inflation systems for semi trucks is crucial for fleet operators aiming to enhance operational efficiency and minimize costs. One of the most pressing challenges faced by international B2B buyers is ensuring that their fleet maintains optimal tire pressure, which directly impacts fuel efficiency, tire longevity, and overall safety. This guide delves into the diverse types of tire inflation systems available in the market, including automatic and manual solutions, and their applications across various regions, from Africa to Europe and South America to the Middle East.

By providing a comprehensive overview of leading suppliers, advanced technologies, and key features such as ease of installation and maintenance, this guide empowers decision-makers to make informed purchasing choices. Additionally, we explore critical factors such as cost considerations, potential ROI, and supplier vetting processes that are essential for successful procurement. Understanding the nuances of tire inflation systems enables international buyers, particularly in emerging markets like Vietnam and Brazil, to streamline their operations, reduce downtime, and ultimately enhance profitability. Equip your fleet with the knowledge needed to navigate this essential aspect of fleet management and take your operations to the next level.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Automatic Tire Inflation System (ATIS) | Continuously monitors and adjusts tire pressure; can be controlled remotely. | Fleets, long-haul trucking, logistics. | Pros: Increases fuel efficiency; reduces downtime. Contras: Mayor inversión inicial. |

| TIREMAAX® Control System | Uses patented technology to maintain tire pressure; compatible with multiple axle configurations. | Trailers, integrated air suspension systems. | Pros: Extends tire life; minimizes maintenance costs. Contras: Installation may require professional assistance. |

| Halo Tire Inflator | Compact, easy installation; maintenance-free design; robust durability. | Construction, heavy-duty trucking. | Pros: Quick setup; reliable in harsh conditions. Contras: Limited to specific wheel configurations. |

| Manual Inflation Systems | Traditional systems requiring manual checks and adjustments; basic pressure gauges. | Smaller fleets, budget-conscious operations. | Pros: Lower initial cost; simple operation. Contras: Time-consuming; less effective in maintaining optimal pressure. |

| Digital Tire Management Systems | Integrates with fleet management software; provides data analytics on tire performance. | Large fleets, data-driven logistics companies. | Pros: Comprehensive monitoring; optimizes tire usage. Contras: Requires tech investment; may need training for staff. |

Automatic Tire Inflation Systems (ATIS) are designed to monitor and adjust tire pressure automatically, ensuring optimal performance. These systems are particularly beneficial for fleets engaged in long-haul trucking and logistics, where maintaining proper tire pressure can significantly impact fuel efficiency and safety. While they require a higher initial investment, the long-term savings in fuel costs and reduced downtime make them a sound choice for businesses looking to optimize their operations.

The TIREMAAX® Control System employs patented technology to keep trailer tires properly inflated. This system is compatible with various axle configurations, making it versatile for different types of trailers. It is ideal for businesses that operate integrated air suspension systems, as it helps extend tire life and minimize maintenance costs. Although installation may require professional assistance, the long-term benefits of reduced tire wear and improved fuel economy often justify the investment.

The Halo Tire Inflator stands out for its compact design and ease of installation, taking only 5-10 minutes to set up without specialized tools. Its rugged durability makes it suitable for heavy-duty applications, such as construction and long-haul trucking. Buyers should consider this option if they operate in harsh environments where tire maintenance is challenging. However, it’s important to note that this system may be limited to specific wheel configurations.

Manual inflation systems, which rely on traditional pressure gauges and require manual adjustments, are often favored by smaller fleets or budget-conscious operations. They offer a lower initial cost and straightforward operation. However, the time-consuming nature of manual checks can lead to inconsistent tire pressure, ultimately affecting fuel efficiency and safety. Businesses considering this option should weigh the benefits of cost savings against the potential for increased maintenance and operational inefficiencies.

Illustrative image related to tire inflation system for semi trucks

Digital Tire Management Systems integrate with fleet management software to provide real-time data analytics on tire performance. These systems are particularly advantageous for large fleets and data-driven logistics companies, allowing for comprehensive monitoring of tire conditions. While they require a technological investment and may necessitate staff training, the insights gained can lead to optimized tire usage and significant cost savings over time.

| Industria/Sector | Specific Application of tire inflation system for semi trucks | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Logistics and Freight | Automated tire pressure monitoring for long-haul trucking | Reduces fuel consumption and maintenance costs | Compatibility with existing fleet systems, durability in diverse climates |

| Mining and Construction | Tire inflation systems for heavy-duty vehicles | Extends tire life, minimizes downtime | Robustness for harsh environments, ease of installation |

| Agricultura | Inflation systems for agricultural transport vehicles | Enhances operational efficiency and safety | Adaptability to various tire sizes, support for remote areas |

| Public Transportation | Tire management for buses and coaches | Improves passenger safety and comfort | Compliance with local regulations, reliability under high usage |

| International Shipping | Tire inflation for container trucks | Ensures optimal performance during international transit | Global service support, compatibility with diverse tire types |

In the logistics and freight industry, automated tire pressure monitoring systems are integral for long-haul trucking operations. These systems continuously monitor tire pressure, ensuring that tires are always inflated to optimal levels. This not only enhances fuel efficiency—potentially saving thousands in fuel costs—but also extends tire life by preventing uneven wear. For international buyers, compatibility with existing fleet systems and durability in varying climates are essential considerations when sourcing these systems.

In mining and construction, where heavy-duty vehicles operate under extreme conditions, tire inflation systems are crucial. These systems help maintain appropriate tire pressure, reducing the risk of blowouts and enhancing safety. By extending the life of tires, companies can significantly minimize downtime due to tire failures. Buyers in these sectors should prioritize the robustness of the systems to withstand harsh environments and the ease of installation, ensuring minimal disruption to operations.

Agricultural transport vehicles, such as those used for harvesting and distribution, benefit greatly from tire inflation systems. Properly inflated tires improve traction and fuel efficiency, enhancing overall operational effectiveness. These systems can be particularly advantageous in remote areas where access to maintenance services may be limited. When sourcing, buyers should look for systems that are adaptable to various tire sizes and designed for reliability in rural settings.

Illustrative image related to tire inflation system for semi trucks

Public transportation systems, including buses and coaches, utilize tire inflation systems to ensure passenger safety and comfort. These systems help maintain consistent tire pressure, reducing the likelihood of tire-related incidents. Additionally, they promote better fuel economy, which can be a significant cost-saving factor for public transit authorities. Compliance with local regulations and the reliability of the systems under high usage conditions are critical factors for buyers in this sector.

For international shipping, tire inflation systems are vital for container trucks that traverse long distances. These systems ensure that tires maintain optimal pressure, which is essential for performance during international transit. Proper tire inflation can prevent costly delays and damage to cargo. When sourcing these systems, buyers should consider global service support and compatibility with a variety of tire types to ensure seamless integration into their fleets.

El problema: Many B2B buyers operating fleets of semi trucks face the challenge of maintaining optimal tire pressure in varying environmental conditions. For instance, companies in regions with extreme temperatures, such as the deserts of the Middle East or the cold climates in Northern Europe, struggle with tires losing pressure due to heat expansion or cold contraction. This can lead to uneven tire wear, increased fuel consumption, and potentially dangerous blowouts, all of which can significantly impact operational costs and safety.

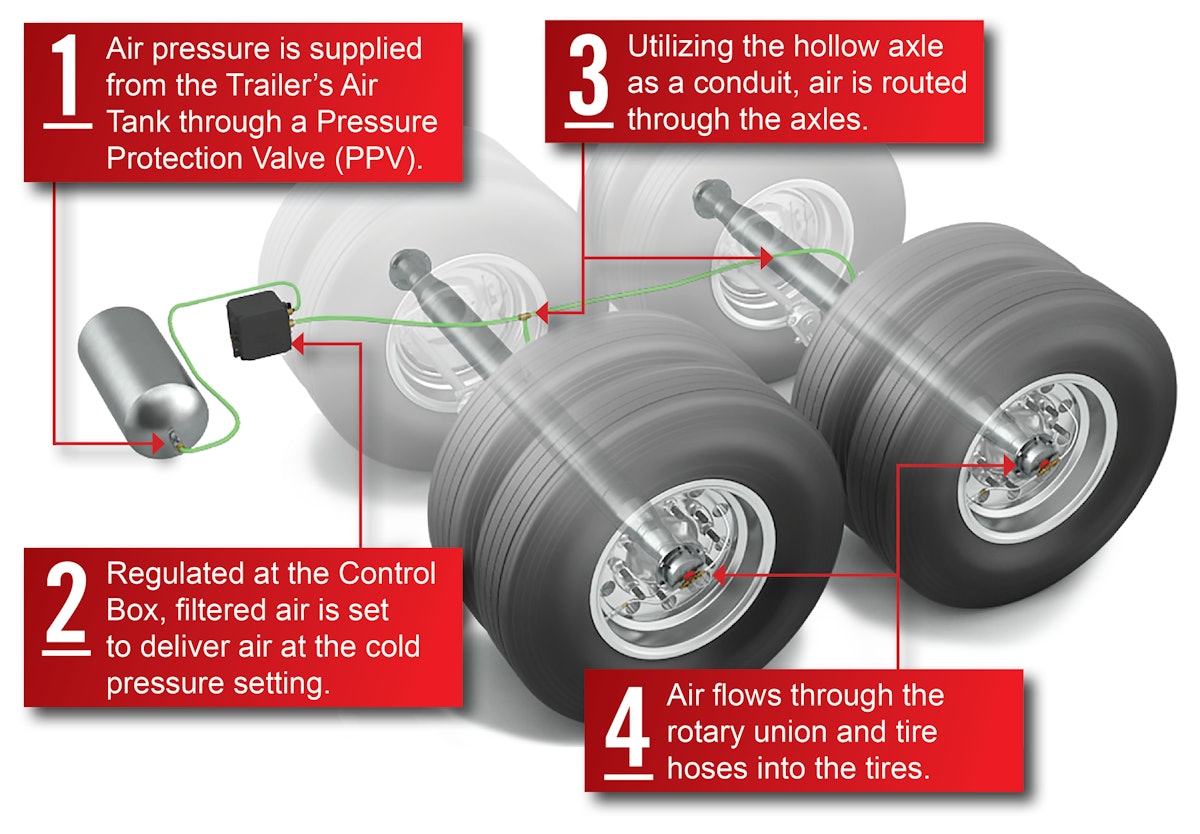

La solución: To effectively manage tire inflation across diverse environments, investing in an advanced automatic tire inflation system (ATIS) is crucial. Systems like the TIREMAAX CP or PRO from Hendrickson continuously monitor and adjust tire pressure, ensuring that tires are always at their optimal inflation levels, regardless of external conditions. Buyers should look for systems that are designed to withstand extreme weather, featuring durable materials and robust technology to prevent failure. Proper installation is also vital; ensure that the system is integrated with existing air suspension systems to provide seamless operation. By proactively managing tire pressure, fleets can enhance safety, prolong tire life, and improve fuel efficiency.

El problema: One of the most pressing issues for fleet operators is the rising cost of tire maintenance and replacement. Improperly inflated tires can lead to premature wear, necessitating more frequent replacements, which adds significant costs to the bottom line. Additionally, the downtime associated with tire failures can disrupt logistics and lead to missed deliveries, further increasing expenses and damaging customer relationships.

Illustrative image related to tire inflation system for semi trucks

La solución: Implementing a tire inflation system like the Halo Tire Inflator can mitigate these costs effectively. This system is designed for easy installation and requires minimal maintenance, making it an attractive option for fleet operators looking to streamline operations. The Halo system monitors tire pressure continuously and automatically inflates tires to the desired PSI, reducing the risk of under-inflation. Buyers should conduct a cost-benefit analysis to evaluate the potential savings from reduced tire wear and fuel consumption against the initial investment in the system. By choosing a reliable, durable solution, fleets can achieve significant long-term savings while enhancing operational efficiency.

El problema: Safety is a paramount concern for B2B buyers operating semi trucks, especially in industries like logistics and transportation where the risk of accidents can lead to serious liabilities. Improper tire inflation is a leading cause of tire blowouts, which can result in costly accidents, injuries, and vehicle damage. Fleet managers are under pressure to minimize these risks while ensuring compliance with safety regulations.

La solución: To enhance safety and reduce the likelihood of tire-related incidents, companies should invest in a comprehensive tire management system that includes automatic tire inflation technology. Systems such as those offered by Haltec not only maintain tire pressure but also provide real-time monitoring and alerts for tire health. By integrating this technology into their fleets, companies can proactively address tire issues before they escalate into major problems. Furthermore, establishing a regular maintenance schedule alongside the use of these systems can ensure that all components are functioning optimally. Buyers should prioritize systems with proven durability and support, as this can significantly enhance fleet reliability and safety, ultimately leading to reduced liability and increased operational uptime.

When selecting materials for tire inflation systems in semi trucks, it is crucial to consider properties that directly impact performance, durability, and overall cost-effectiveness. Here, we analyze four common materials: aluminum, stainless steel, rubber, and plastic.

Aluminum is a lightweight metal known for its excellent corrosion resistance and strength-to-weight ratio. It typically has a temperature rating of up to 150°C (302°F) and can withstand pressures of approximately 200 PSI, making it suitable for tire inflation applications.

Illustrative image related to tire inflation system for semi trucks

Pros: Aluminum is durable and lightweight, which enhances fuel efficiency. Its corrosion resistance is particularly beneficial in humid or saline environments, such as coastal regions or areas with heavy rainfall.

Contras: However, aluminum can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized techniques such as extrusion or machining.

Impacto en la aplicación: Aluminum is compatible with air and nitrogen, commonly used in tire inflation. It is essential for international buyers to ensure that the aluminum used meets local standards, such as ASTM or DIN.

Illustrative image related to tire inflation system for semi trucks

Stainless steel is another material widely used in tire inflation systems due to its exceptional strength and corrosion resistance. It can handle high temperatures (up to 300°C or 572°F) and pressures exceeding 300 PSI.

Pros: Its durability makes it ideal for harsh environments, and it can withstand mechanical wear and tear, reducing the need for frequent replacements.

Contras: The primary drawback is its higher cost compared to aluminum and rubber. Additionally, stainless steel is heavier, which can negatively impact fuel efficiency.

Illustrative image related to tire inflation system for semi trucks

Impacto en la aplicación: Buyers should consider the specific grades of stainless steel that comply with local regulations. For instance, AISI 304 or 316 grades are often preferred for their corrosion resistance in various climates.

Rubber is commonly used for seals and gaskets in tire inflation systems due to its flexibility and ability to create airtight seals. It can withstand temperatures ranging from -40°C to 100°C (-40°F to 212°F) and pressures up to 150 PSI.

Pros: Rubber is cost-effective and easy to manufacture, making it a popular choice for various components. Its elasticity allows it to absorb vibrations, enhancing system longevity.

Contras: However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures, leading to potential failures in sealing.

Impacto en la aplicación: International buyers must ensure that the rubber used meets specific standards for ozone and UV resistance, particularly in regions with high sun exposure.

Illustrative image related to tire inflation system for semi trucks

Plastic, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), is increasingly used in tire inflation systems for components like valves and fittings. These materials can handle temperatures up to 80°C (176°F) and pressures around 100 PSI.

Pros: Plastics are lightweight, resistant to corrosion, and generally less expensive than metals, making them attractive for cost-sensitive applications.

Contras: However, plastics may not offer the same durability as metals, particularly in high-stress environments. They can also be less effective at sealing under high-pressure conditions.

Impacto en la aplicación: Buyers should verify that the plastics used comply with relevant safety and environmental standards, especially in regions with stringent regulations.

| Material | Typical Use Case for tire inflation system for semi trucks | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Housings, brackets, and valves | Ligero y resistente a la corrosión | Coste más elevado y fabricación más compleja | Medio |

| Acero inoxidable | Structural components and fittings | Exceptional strength and durability | Más pesado y más caro | Alta |

| Goma | Juntas y empaquetaduras | Cost-effective and flexible | Se degrada con el tiempo | Bajo |

| Plástico | Valves and fittings | Lightweight and resistant to corrosion | Less durable under high stress | Bajo |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions that align with their operational needs and regional compliance requirements.

Illustrative image related to tire inflation system for semi trucks

The manufacturing process for tire inflation systems, particularly those designed for semi trucks, consists of several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the durability and performance of the final product.

Material preparation begins with sourcing high-quality raw materials, including metals, plastics, and rubber components. Manufacturers often prioritize materials that can withstand harsh environmental conditions, such as extreme temperatures and exposure to road debris. Rigorous testing of these materials is essential to ensure they meet industry standards for durability and performance.

Once the materials are sourced, they undergo various treatments such as cleaning, cutting, and machining. This preparation ensures that all components are ready for the forming stage, where they will be shaped into specific parts of the tire inflation system.

The forming stage involves several techniques tailored to the specific components of the tire inflation system. Common methods include:

Each forming method is selected based on the material properties and the required tolerances for the system components.

Assembly is a critical phase where all the pre-formed components come together. This process typically involves:

Quality checks during assembly are vital to ensure that each system meets the required specifications before moving on to the finishing stage.

The finishing stage includes surface treatment, coating, and packaging. Common techniques include:

Quality assurance is paramount in the manufacturing of tire inflation systems. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. Specific industry certifications, such as CE for European markets and API for the oil and gas sector, further validate the quality and safety of the products.

El control de calidad implica varios puntos de comprobación a lo largo del proceso de fabricación:

For international B2B buyers, verifying the quality control processes of suppliers is crucial for ensuring product reliability. Here are several strategies to consider:

Illustrative image related to tire inflation system for semi trucks

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying standards and expectations regarding manufacturing practices. It’s crucial for buyers to familiarize themselves with local regulations and industry standards to ensure compliance.

Additionally, consider the logistical aspects of quality assurance. Shipping products internationally can introduce risks, such as damage during transport. Therefore, selecting suppliers with robust packaging and handling processes is vital to ensure that the products arrive in perfect condition.

Understanding the manufacturing processes and quality assurance standards for tire inflation systems is essential for B2B buyers looking to invest in reliable solutions for semi trucks. By familiarizing themselves with the stages of manufacturing, key quality control checkpoints, and verification methods, buyers can make informed decisions that enhance their fleet’s efficiency and safety.

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for tire inflation systems specifically for semi trucks. With the right system, companies can enhance fuel efficiency, extend tire life, and minimize maintenance costs. This checklist will streamline your decision-making and ensure you acquire a system that aligns with your operational needs.

Illustrative image related to tire inflation system for semi trucks

Start by establishing the specific technical requirements for your tire inflation system. Consider factors such as the size of the tires, the type of trucks in your fleet, and the operating conditions (e.g., terrain, climate).

– Tire Size Compatibility: Ensure the system can accommodate the tire sizes in your fleet, such as 19.5″, 22.5″, or 24.5″.

– Operating Environment: Identify whether the system needs to withstand extreme temperatures or rough conditions, which may affect durability and performance.

Evaluate the features of potential tire inflation systems to determine their suitability for your needs. Look for systems that offer automatic inflation, remote control options, and real-time monitoring capabilities.

– Fuel Efficiency: Systems that maintain optimal tire pressure can lead to significant fuel savings and reduced operational costs.

– Maintenance Requirements: Opt for systems that are easy to install and require minimal maintenance, such as those with a self-contained design.

Conduct thorough due diligence on potential suppliers before making a commitment. Request detailed company profiles and assess their experience in the industry.

– References and Case Studies: Ask for references from other buyers, particularly those in similar regions or industries, to gauge supplier reliability.

– Certifications and Compliance: Verify that the supplier meets relevant international standards and certifications, ensuring product quality and safety.

Illustrative image related to tire inflation system for semi trucks

Analyze the total cost of ownership associated with the tire inflation systems, beyond just the initial purchase price.

– Long-term Savings: Consider potential savings from improved fuel efficiency and reduced tire wear.

– Installation and Operational Costs: Factor in installation fees, maintenance costs, and any necessary training for your staff.

Before finalizing your purchase, request demonstrations or trials of the tire inflation systems. This will provide insight into their functionality and ease of use.

– Hands-on Experience: Test the system’s automatic inflation features and user interface to ensure they meet your operational needs.

– Métricas de rendimiento: Evaluate how effectively the system maintains tire pressure and responds to changes in driving conditions.

Investigate the warranty and support services offered by the supplier. A robust warranty and reliable customer service can significantly impact your experience with the product.

– Warranty Coverage: Ensure that the warranty covers all major components and is comprehensive enough to protect your investment.

– After-Sales Support: Assess the availability of technical support and training resources to assist your team post-installation.

Finally, consolidate all the gathered information to make an informed purchasing decision. Compare suppliers based on your criteria and select the one that offers the best overall value.

– Decision Matrix: Create a decision matrix to weigh the pros and cons of each supplier and system based on your defined specifications and requirements.

– Stakeholder Input: Involve key stakeholders in the decision-making process to ensure alignment with company goals and operational strategies.

By following these steps, B2B buyers can effectively navigate the procurement process for tire inflation systems, ensuring they choose a solution that maximizes efficiency and reduces costs in their operations.

Illustrative image related to tire inflation system for semi trucks

When sourcing tire inflation systems for semi trucks, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materiales: The quality of materials directly impacts the durability and performance of the tire inflation systems. High-grade components, such as die-cast aluminum and advanced sensors, can increase initial costs but may yield long-term savings through enhanced performance and longevity.

Trabajo: Labor costs can vary significantly by region. In countries with higher wage standards, such as those in Europe, labor costs may be higher, affecting overall pricing. Conversely, regions with lower labor costs may provide more competitive pricing but could compromise on quality if not managed carefully.

Gastos generales de fabricación: This includes costs related to facilities, utilities, and equipment maintenance. Manufacturers with advanced automated processes may have lower overhead costs, allowing them to offer more competitive pricing.

Herramientas: The setup for manufacturing can require significant investment, particularly for custom or specialized systems. Buyers should consider whether the supplier has the necessary tooling in place to meet their specifications efficiently.

Control de calidad: Implementing robust QC measures ensures product reliability, which is crucial in industries where safety is paramount. Suppliers with strict QC processes may charge higher prices but can ultimately reduce costs associated with defects and failures.

Logística: International shipping can significantly impact the total cost. Factors such as distance, shipping method, and customs duties should be carefully considered. Moreover, Incoterms will dictate who bears the responsibility for various logistics costs, which can affect pricing negotiations.

Margen: Suppliers typically include a profit margin that can vary based on their positioning in the market, brand reputation, and overall demand.

Several key factors influence pricing for tire inflation systems beyond the basic cost components:

Volumen/MOQ (Cantidad mínima de pedido): Purchasing in larger quantities can lead to significant discounts. Buyers should assess their needs carefully and consider stockpiling to negotiate better terms.

Especificaciones y personalización: Customized solutions tailored to specific operational needs often come at a premium. Buyers should evaluate whether the benefits of customization justify the additional costs.

Calidad y certificaciones: Systems that meet international standards and certifications may command higher prices. However, these systems can provide peace of mind regarding reliability and safety, which is crucial for fleet operations.

Factores del proveedor: The reputation and reliability of the supplier can greatly affect pricing. Established brands may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of pricing can lead to better negotiation outcomes:

Conduct Thorough Research: Understand the market rates and cost structures of different suppliers. This knowledge will empower buyers during negotiations.

Leverage Total Cost of Ownership (TCO): Focus on the TCO rather than just the upfront cost. Consider factors such as fuel savings, maintenance costs, and potential downtime to evaluate the true value of the investment.

Negociar las condiciones: Engage in discussions about payment terms, delivery schedules, and warranties. Favorable terms can significantly enhance the overall value of the deal.

Consider Currency Fluctuations: For international transactions, currency volatility can impact pricing. Buyers should monitor exchange rates and consider locking in prices when favorable.

Explore Local Suppliers: Sourcing from local suppliers can reduce logistics costs and facilitate easier communication. This can be particularly beneficial for buyers in regions with developing markets.

Prices for tire inflation systems can vary widely based on the factors mentioned above. It is advisable for buyers to request detailed quotes from multiple suppliers and to clarify all terms before making procurement decisions.

Illustrative image related to tire inflation system for semi trucks

When considering tire inflation systems for semi trucks, it’s essential to explore alternative solutions that can achieve similar goals of enhancing tire performance, safety, and operational efficiency. Various technologies and methods are available, each with its own set of advantages and limitations. This analysis will compare tire inflation systems with two viable alternatives: manual tire inflation and centralized air supply systems.

| Aspecto comparativo | Tire Inflation System For Semi Trucks | Manual Tire Inflation | Centralized Air Supply System |

|---|---|---|---|

| Rendimiento | Automatically maintains optimal PSI | Inconsistent pressure levels | Provides continuous pressure |

| Coste | Moderate initial investment | Low initial cost | High setup and maintenance cost |

| Facilidad de aplicación | Quick installation (5-10 minutes) | Requires manual effort | Complex installation |

| Mantenimiento | Low maintenance required | Frequent checks needed | Regular maintenance required |

| El mejor caso de uso | Long-haul fleets needing efficiency | Short-haul or occasional use | Fleets with high tire usage |

Manual Tire Inflation

Manual tire inflation involves using a handheld air compressor or a portable inflation tool to check and adjust tire pressures. The primary advantage of this method is its low cost and simplicity, as it requires minimal initial investment. However, the effectiveness can be inconsistent, as it relies on the operator’s diligence and skill. Regular checks can be time-consuming and may lead to human error, resulting in either under-inflation or over-inflation, both of which can negatively impact tire life and fuel efficiency.

Centralized Air Supply System

Centralized air supply systems are designed to provide a constant supply of air to multiple tires simultaneously, often used in larger fleets. These systems can maintain optimal tire pressure without the need for manual checks, making them highly efficient. However, the initial setup costs are significantly higher, and the complexity of installation can pose a challenge. Additionally, these systems require regular maintenance to ensure reliability, which can increase operational costs over time. They are best suited for fleets with high tire usage, where the benefits of continuous pressure outweigh the investment.

For B2B buyers evaluating tire inflation solutions, the decision should hinge on specific operational needs and budget constraints. Tire inflation systems for semi trucks offer a balance of performance, ease of use, and low maintenance, making them ideal for long-haul operations. In contrast, manual tire inflation may suit smaller fleets or those with less frequent tire use, while centralized air supply systems are better for larger operations that prioritize efficiency and can manage higher upfront costs. By assessing the unique requirements of your fleet, including the type of routes, frequency of use, and maintenance capabilities, you can select the most appropriate tire inflation solution that aligns with your business objectives.

When evaluating tire inflation systems for semi trucks, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties:

Calidad del material

Tire inflation systems are typically constructed from high-grade materials such as die-cast aluminum or reinforced plastics. These materials provide durability and resistance to environmental factors like moisture, heat, and physical impacts. For B2B buyers, selecting high-grade materials can result in longer service life and reduced maintenance costs, ultimately improving ROI.

Pressure Tolerance

The ability of a tire inflation system to maintain specific tire pressures is critical. Systems are designed to operate within a defined pressure range, often between 70 and 120 PSI. Understanding pressure tolerance is essential for ensuring safety and efficiency; improper tire pressure can lead to increased fuel consumption, reduced tire lifespan, and heightened risk of tire blowouts.

Installation Time

The ease of installation is a significant factor for fleet operators. Many modern systems can be installed within 5-10 minutes without specialized tools, which minimizes downtime. Quick installation is particularly advantageous for fleets operating in regions where service availability may be limited, allowing for faster fleet deployment and enhanced operational efficiency.

Calibration Accuracy

Tire inflation systems typically feature calibration capabilities that ensure they maintain the correct tire pressure. Accuracy is often rated at ±0.5% of full scale. For B2B buyers, this precision is vital to prevent overinflation or underinflation, both of which can lead to safety hazards and increased operational costs.

Maintenance Requirements

Maintenance-free systems are increasingly popular due to their ability to operate under harsh conditions without frequent servicing. Systems like the Halo Tire Inflator are designed to be virtually maintenance-free, which is a compelling selling point for fleet managers looking to streamline operations and reduce labor costs.

Environmental Protection Rating

Many tire inflation systems come with an International Protection (IP) rating, indicating their resistance to dust and water. An IP66 rating, for example, ensures that the system is completely protected from dust and can withstand powerful water jets. This is particularly important for fleets operating in diverse climates, as it ensures reliability and longevity.

Navigating the procurement process involves understanding industry-specific terminology. Here are some key trade terms that B2B buyers should be familiar with:

Illustrative image related to tire inflation system for semi trucks

OEM (fabricante de equipos originales)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the tire inflation system context, buyers may prefer OEM products to ensure compatibility and reliability with existing fleet equipment.

MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and budget constraints effectively.

RFQ (solicitud de presupuesto)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process helps buyers compare costs and terms from multiple vendors, ensuring they make the most cost-effective purchasing decision.

Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is essential for B2B transactions, as they clarify who bears the cost and risk at various points in the shipping process.

Tire Pressure Monitoring System (TPMS)

TPMS is a system that monitors the air pressure inside the tires and alerts the driver to any discrepancies. Understanding TPMS is critical for buyers looking to enhance safety and compliance with regulations.

Telematics

This refers to the integrated use of telecommunications and monitoring systems to collect and analyze data. In the context of tire inflation systems, telematics can provide real-time data on tire performance, enabling proactive maintenance and operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when investing in tire inflation systems for semi trucks, ultimately enhancing fleet performance and reducing operational costs.

The tire inflation system market for semi trucks is shaped by several global drivers. Firstly, the increasing emphasis on fuel efficiency directly correlates with the proper maintenance of tire pressure. In regions like Africa and South America, where fuel costs can significantly impact operational budgets, automatic tire inflation systems (ATIS) present a viable solution to enhance fuel economy and reduce tire wear. Furthermore, the rising demand for logistics and freight services, particularly in the Middle East and Europe, drives the need for reliable and efficient transportation solutions, making tire maintenance a priority.

Current and emerging trends in B2B technology also influence sourcing decisions. Innovations such as predictive tire management systems, which utilize IoT technology to monitor tire conditions, are gaining traction. These systems not only provide real-time data but also enable fleet managers to take proactive measures, reducing downtime and maintenance costs. Additionally, the integration of wireless and remote-controlled systems allows for easier management of tire pressure adjustments, appealing to international buyers who prioritize efficiency and safety.

Moreover, market dynamics are shifting towards more sustainable practices. B2B buyers are increasingly considering suppliers who demonstrate a commitment to environmental responsibility, making it essential for manufacturers to adopt eco-friendly materials and processes in their tire inflation systems.

Sustainability and ethical sourcing are becoming critical factors for B2B buyers in the tire inflation system sector. The environmental impact of traditional tire maintenance practices, including the disposal of improperly inflated tires, contributes to significant waste and pollution. As global awareness of environmental issues grows, buyers are seeking solutions that not only enhance performance but also minimize ecological footprints.

Incorporating ‘green’ certifications and materials into the tire inflation systems is a vital consideration. Manufacturers who utilize sustainable materials and demonstrate compliance with environmental regulations can appeal to a broader customer base. For instance, systems designed with recyclable materials or those that reduce energy consumption during operation are increasingly favored.

Additionally, ethical supply chains that prioritize fair labor practices and transparency are gaining importance. B2B buyers are scrutinizing their suppliers more closely, opting for those who align with their corporate social responsibility goals. This shift towards ethical sourcing not only enhances brand reputation but also fosters long-term partnerships built on trust and shared values.

The evolution of tire inflation systems for semi trucks has been marked by significant technological advancements aimed at enhancing efficiency and safety. Initially, tire maintenance relied heavily on manual checks and adjustments, which often led to inconsistent tire pressures and increased risk of blowouts. As the trucking industry expanded, particularly in the late 20th century, the need for more reliable tire management solutions became apparent.

The introduction of automatic tire inflation systems in the 1990s revolutionized the market. These systems allowed for continuous monitoring and adjustment of tire pressure, significantly reducing maintenance costs and improving fuel efficiency. Over the years, advancements in technology, such as the integration of IoT and predictive analytics, have further transformed tire inflation systems, making them smarter and more user-friendly.

Today, the focus is not only on functionality but also on sustainability and ethical sourcing, reflecting the broader trends within the B2B landscape. As the industry continues to evolve, tire inflation systems will likely play a pivotal role in meeting the demands of a more efficient and environmentally conscious market.

1. How do I solve the issue of improper tire inflation in my fleet?

To address improper tire inflation, consider investing in an Automatic Tire Inflation System (ATIS). These systems continuously monitor and adjust tire pressure to optimal levels, enhancing fuel efficiency and extending tire life. Leading brands like TIREMAAX and Halo offer robust solutions that are easy to install and maintain. By implementing these systems, you can reduce the risk of blowouts and downtime, which ultimately translates into significant cost savings for your fleet.

2. What is the best tire inflation system for semi trucks?

The best tire inflation system for semi trucks depends on your specific needs, such as fleet size and operational conditions. TIREMAAX and Halo are industry leaders, known for their durability and effectiveness in maintaining tire pressure. TIREMAAX systems are designed to provide precise pressure control, while Halo systems offer a compact design with quick installation. Evaluate your fleet’s requirements and consult with manufacturers to identify the most suitable solution.

3. What are the key benefits of using an automatic tire inflation system?

Using an automatic tire inflation system can significantly improve your fleet’s operational efficiency. Benefits include enhanced fuel economy due to optimal tire pressure, extended tire life through reduced wear, and minimized downtime from tire failures. Additionally, these systems can lower maintenance costs and improve safety by preventing blowouts. The initial investment is often offset by the long-term savings realized through decreased fuel and tire replacement costs.

4. How can I vet suppliers for tire inflation systems?

When vetting suppliers for tire inflation systems, consider their industry reputation, product certifications, and customer reviews. Request references from existing clients to understand their experiences. Evaluate the supplier’s technical support and warranty policies, as well as their ability to provide timely service and parts. Engaging in direct communication can also help gauge their responsiveness and willingness to address your specific needs.

5. What customization options are available for tire inflation systems?

Many manufacturers offer customization options for tire inflation systems, such as tailored PSI settings, branded faceplates, and specific configurations for different tire sizes. It’s essential to discuss your requirements with the supplier to ensure that the system can be adapted to fit your fleet’s unique operational demands. Custom solutions can enhance system effectiveness and integration with existing fleet management practices.

6. What are the minimum order quantities (MOQ) for tire inflation systems?

Minimum order quantities for tire inflation systems can vary widely between suppliers. Some manufacturers may have a low MOQ, while others might require bulk orders to offer competitive pricing. When negotiating with suppliers, inquire about potential discounts for larger orders and the possibility of trial units to assess system performance before committing to a larger purchase.

7. What payment terms should I expect when purchasing tire inflation systems?

Payment terms for tire inflation systems typically depend on the supplier’s policies and your negotiation. Common terms include upfront payment, partial payment upon order confirmation, and the remainder upon delivery. Some suppliers may offer financing options or payment plans for large orders. Be sure to clarify all terms, including payment methods accepted and any potential penalties for late payments.

8. How can I ensure quality assurance (QA) for tire inflation systems?

To ensure quality assurance for tire inflation systems, select suppliers that adhere to industry standards and possess relevant certifications, such as ISO. Request detailed product specifications and testing reports to verify performance claims. It is also beneficial to inquire about the supplier’s QA processes, including routine inspections and customer feedback mechanisms. Building a strong relationship with your supplier can facilitate ongoing quality assessments and improvements.

Dominio: shop.aperiatech.com

Registrado: 2010 (15 años)

Introducción: Halo Tire Inflator – Aperia Halo

Price: $600.00

Limited Time Offer: 22% Off (Enter code “22” at checkout)

Features:

– Only Tire Management Platform for All Wheel Positions

– Over 100 Billion Industry Proven Miles

– Extends Tire Life, Improves Fuel Economy, Maximizes Uptime, Enhances Safety

Includes:

– All Halos, Brackets, and necessary Hoses for full vehicle installation

– Each Halo pre-set to fle…

Dominio: cummins.com

Registered: 1990 (35 years)

Introducción: Meritor Tire Inflation System (MTIS™) helps maintain proper tire inflation, reducing wear and increasing fuel economy. It has been equipped on over 1 million trailers and can be installed on all major trailer axle models in North America, available for both new and retrofitted trailers. Key features include:

– Standard ThermALERT wheel-end heat-sensing technology that alerts drivers to overheating…

Dominio: haltec.com

Inscrito: 1998 (27 años)

Introducción: Automatic Tire Inflation Systems (ATIS) by Haltec are designed for trucks, trailers, fleets, and aircraft. Key features include:

– Customizable branded faceplates available upon request.

– Hardwired and mountable to mobile service trucks.

– Calibration confirmation every 6 minutes during use and upon power on.

– Accuracy of 0.5% FS.

– Die cast aluminum housing for durability and weather protection…

Dominio: parts.ectts.com

Matriculado: 1999 (26 años)

Introducción: {“product_name”: “TIREMAXX Tire Inflation Kit 19.5”, “brand”: “Hendrickson”, “sku”: “15392”, “price”: “$799.00”, “weight”: “0.00 LBS”, “shipping”: “FREE SHIPPING”, “features”: [“Enhances tire life”, “Reduces maintenance”, “Conserves fuel”, “Trims labor costs”, “Designed for 19.5 in. wheels”, “Draws from trailer air supply to keep tires properly inflated”, “Simple mechanical design with no pressure…

Dominio: ti.systems

Introducción: STIS | Semi-automatic Tire Inflation System

– Precise tire pressure adjustment when vehicle is stationary

– Can be retrofitted to any vehicle

– Inflate/deflate all tires simultaneously

– No preparations required

– Patented ti.systems tire valve, screws directly onto regular tire valve after inner valve core is removed

– Airflow up to 900l/min

– Easy to use with quick coupling system

– Simultaneous…

Dominio: anythingtruck.com

Matriculado: 2000 (25 años)

Introducción: {“products”:[{“name”:”Meritor 31314-21 Tire Inflation System Stator and Filter”,”part_number”:”650-3131421″,”price”:”$23.57 USD”,”rating”:”5 out of 5″,”recommendation”:”Would recommend this product.”},{“name”:”Meritor 31317-03 Tire Inflation System Thru Tee, Dual Wheels, 3.5″ Long”,”part_number”:”650-3131703″,”price”:”$68.60 USD”,”rating”:”Not Yet Rated”},{“name”:”Meritor 31317-03-S Tire Inflation…

Dominio: rollofftrucktrailerparts.com

Inscrito: 2015 (10 años)

Introducción: {“product_name”: “Meritor H2712-22 PSI Tire Inflation System – Tandem Axle”, “manufacturer”: “Meritor”, “sku”: “AS114”, “price”: “$1,298.00 USD”, “features”: [“Keeps tires inflated when they leak due to nails or metal pieces”, “Senses overheating at axle bearings with THERMALERT”, “Reduces road service calls”, “Saves money due to fewer flats”, “Reduces DOT fines for flat tires”, “Reduces axle dama…

In the ever-evolving landscape of the transportation industry, the importance of efficient tire inflation systems for semi trucks cannot be overstated. These systems, such as the TIREMAAX and Halo Tire Inflator, not only enhance fuel efficiency but also significantly extend tire life and minimize maintenance costs. By strategically sourcing these advanced solutions, businesses can achieve substantial long-term savings and reduce downtime due to tire failures.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, investing in reliable tire inflation systems represents an opportunity to optimize fleet performance while ensuring safety on the roads. As the market continues to innovate, embracing technologies that offer predictive management and real-time monitoring will be essential for maintaining a competitive edge.

Looking ahead, it is vital for businesses to prioritize the integration of automated tire inflation systems into their operations. By doing so, they will not only enhance operational efficiency but also contribute to a sustainable future for the transportation sector. Now is the time to act—invest in tire inflation solutions that will drive your business forward and secure your position in a rapidly changing market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.