In the rapidly evolving landscape of the global market, sourcing the right tire pressure hose can pose significant challenges for international B2B buyers. With diverse applications across industries—from automotive to manufacturing—the demand for reliable and efficient tire pressure hoses has never been more critical. This guide aims to equip buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—with the insights necessary to navigate this complex marketplace.

We will delve into various types of tire pressure hoses, their applications, and the essential criteria for supplier vetting. Understanding the differences between standard and specialized hoses, as well as the benefits of innovative features like self-locking connectors and durable materials, will empower you to make informed purchasing decisions. Additionally, this guide will explore cost considerations, ensuring you achieve optimal value for your investment.

By providing a comprehensive overview of the tire pressure hose market, this resource is designed to enhance your procurement strategy, streamline sourcing processes, and ultimately contribute to your business’s operational efficiency. Whether you are looking for hoses for industrial applications or for personal use, our guide will serve as a valuable tool in ensuring you select the right products for your specific needs.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Self-Locking Nozzle Hoses | Quick-release mechanism, compatible with various inflators | Tire shops, automotive service centers | Pros: Fast connection, reduced air loss. Contras: May require specific adapters. |

| OEM Tire Hoses | Designed for specific models, high durability | Fleet maintenance, OEM replacements | Pros: Exact fit, reliable performance. Contras: Higher cost, limited compatibility. |

| Inflation Extension Hoses | Longer reach, flexible design | Mobile tire services, roadside assistance | Pros: Versatile use, easy maneuverability. Contras: Bulkier storage, potential for kinks. |

| Dual Tire Hoses | Enables simultaneous inflation of dual tires | Heavy-duty vehicles, commercial fleets | Pros: Time-efficient, consistent pressure. Contras: More complex setup, higher initial investment. |

| Air Hose Reels | Integrated storage, retractable design | Workshops, garages | Pros: Organized storage, reduces wear on hoses. Contras: Requires installation space, potential maintenance. |

Self-locking nozzle hoses feature a quick-release mechanism that allows for rapid connection and disconnection from tire valves. These hoses are particularly beneficial for tire shops and automotive service centers, where efficiency is paramount. The reduced air loss during inflation enhances the overall performance of tire inflators. However, buyers should ensure compatibility with existing equipment, as some models may require specific adapters.

OEM tire hoses are specifically designed to fit certain vehicle models, ensuring high durability and reliability. This makes them ideal for fleet maintenance and OEM replacements, where consistent performance is crucial. Although they come at a higher cost, their exact fit and reliability can lead to lower long-term maintenance costs. Buyers should weigh the initial investment against the potential for reduced downtime and increased safety.

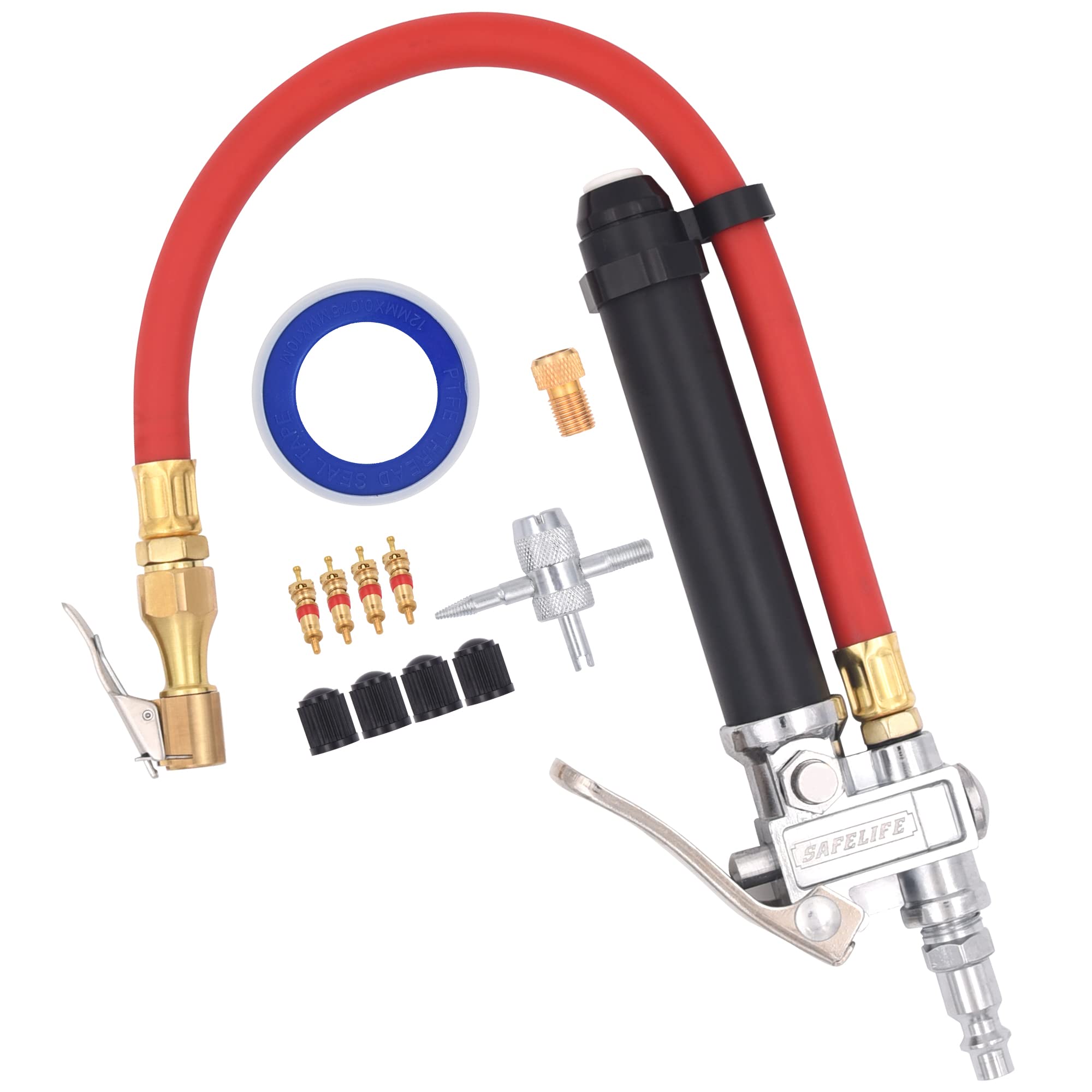

Illustrative image related to tire pressure hose

Inflation extension hoses offer a longer reach and a flexible design, making them essential for mobile tire services and roadside assistance. They allow technicians to easily maneuver around vehicles without compromising the inflation process. While they provide versatility, buyers must consider their storage requirements, as these hoses can be bulkier and may be prone to kinking if not managed properly.

Dual tire hoses are designed to inflate two tires simultaneously, making them particularly useful for heavy-duty vehicles and commercial fleets. This feature significantly reduces inflation time and ensures consistent pressure across both tires. However, the setup can be more complex, and the initial investment is generally higher than standard hoses. Buyers should assess their specific needs and the potential time savings offered by dual tire hoses.

Air hose reels provide integrated storage and a retractable design, making them a valuable addition to workshops and garages. They help keep workspaces organized and reduce wear on hoses, contributing to longer service life. However, the need for installation space and potential maintenance of the reel mechanism should be considered. Buyers seeking efficiency and organization in their operations will find significant value in investing in air hose reels.

| Industria/Sector | Specific Application of tire pressure hose | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Automoción | Tire inflation systems in service stations | Enhances customer service by providing quick tire inflation solutions | Compatibility with various tire valve types and pressure ratings |

| Transportation & Logistics | Fleet maintenance for commercial vehicles | Reduces downtime and enhances safety through optimal tire pressure management | Durability and resistance to wear in harsh operating conditions |

| Construcción | Heavy machinery tire inflation | Ensures operational efficiency and safety on job sites | Length and flexibility to access hard-to-reach valve positions |

| Agricultura | Tire pressure management for agricultural vehicles | Improves fuel efficiency and crop yield through better traction | Adaptability to different tire sizes and environmental conditions |

| Mining | Tire pressure monitoring for mining equipment | Increases equipment lifespan and reduces maintenance costs | Robustness to withstand extreme conditions and potential abrasions |

In the automotive industry, tire pressure hoses are integral to service stations and workshops, facilitating efficient tire inflation. They connect tire inflators to valve stems, ensuring that vehicles receive the correct tire pressure for optimal performance and safety. For international buyers, particularly in regions like Africa and South America, sourcing hoses that are compatible with various tire valve types is essential. Additionally, these hoses must withstand diverse weather conditions, making durability a key consideration.

In transportation and logistics, tire pressure hoses are vital for maintaining the fleets of commercial vehicles. Regular tire inflation ensures safety and enhances fuel efficiency, reducing operational costs. Buyers should focus on sourcing hoses that can withstand rigorous use, given the high mileage and wear-and-tear associated with fleet operations. The ability to monitor tire pressure remotely can also be an added benefit, providing real-time data for fleet management in regions like the Middle East and Europe.

Illustrative image related to tire pressure hose

Heavy machinery used in construction relies heavily on proper tire pressure for performance and safety. Tire pressure hoses facilitate the inflation of tires on machinery such as excavators and bulldozers, ensuring they operate efficiently on rugged terrains. For buyers in the construction sector, sourcing hoses with the appropriate length and flexibility is crucial to reach tire valves in tight spaces. Additionally, hoses must be robust enough to endure the harsh conditions typical of construction sites.

In agriculture, tire pressure management is critical for vehicles that traverse varying terrains. Properly inflated tires enhance traction, improve fuel efficiency, and ultimately lead to better crop yields. For agricultural equipment, international buyers should prioritize hoses that can adapt to different tire sizes and withstand environmental challenges, such as mud and moisture. This ensures reliable performance during peak farming seasons, particularly in regions like Brazil and other agricultural hubs.

Mining operations depend on tire pressure hoses for the maintenance of heavy equipment, which is subject to extreme conditions. Proper tire inflation extends the lifespan of tires and reduces the frequency of maintenance, which can be costly in terms of both time and resources. Buyers in the mining sector need to focus on sourcing hoses that are robust and resistant to abrasions, ensuring they can withstand the rigors of mining environments. This is especially critical in areas with harsh conditions, where equipment reliability is paramount.

El problema: B2B buyers often face the challenge of sourcing tire pressure hoses that are compatible with a wide range of vehicle types, especially when dealing with diverse fleets. For instance, a logistics company operating in regions like South America or Africa may utilize a mix of trucks, vans, and passenger vehicles, each with different tire valve designs. This variability can lead to complications in maintaining proper tire pressure, risking vehicle efficiency and safety. Additionally, the lack of a standardized hose can result in increased inventory costs, as businesses may need to stock multiple types of hoses.

La solución: To effectively address this compatibility issue, buyers should focus on sourcing universal tire pressure hoses that come equipped with adjustable fittings or adapters. When selecting hoses, consider those with a range of connector options, such as self-locking or quick-release systems, which can accommodate various valve types. It’s beneficial to partner with suppliers who offer comprehensive product specifications, including compatibility charts. This allows for informed purchasing decisions, ensuring that the chosen hoses can serve multiple vehicle types without the need for excessive inventory. Furthermore, conducting a thorough market analysis for regional suppliers can help identify those who specialize in versatile tire pressure solutions tailored to specific local needs.

Illustrative image related to tire pressure hose

El problema: Another prevalent issue for B2B buyers is the frequent damage to tire pressure hoses, particularly in harsh working environments. Industries such as mining or construction, common in the Middle East or parts of Africa, often expose hoses to rough handling, extreme temperatures, and abrasive materials. This leads to frequent replacements, downtime, and increased operational costs, as damaged hoses can result in inefficiencies in tire inflation, potentially impacting vehicle performance and safety.

La solución: To mitigate the risk of hose damage, it’s essential to invest in high-quality, industrial-grade tire pressure hoses that are designed for durability. Look for hoses made from robust materials, such as reinforced rubber or thermoplastic elastomers, which can withstand extreme conditions. Additionally, implementing a regular maintenance schedule can help identify wear and tear before it leads to hose failure. Educating staff on proper handling techniques and the importance of storing hoses away from potential hazards can also significantly extend their lifespan. Suppliers that offer warranties or performance guarantees can provide added peace of mind regarding the reliability of their products.

El problema: B2B buyers often encounter inefficiencies caused by slow tire inflation processes, which can be particularly detrimental in sectors that rely on quick turnaround times, such as logistics or transportation. For instance, a fleet manager may find that standard hoses take too long to inflate tires, leading to delays in operations and increased labor costs. This problem is exacerbated in regions where rapid service is essential for maintaining competitive advantage.

La solución: To enhance efficiency, buyers should consider investing in high-flow tire pressure hoses that facilitate quicker inflation rates. Look for hoses that are specifically designed for high-volume air delivery, which can significantly reduce the time required for tire inflation. Pairing these hoses with advanced inflators that feature automatic shut-off technology can further streamline the process, ensuring tires are inflated to the correct pressure without manual oversight. Additionally, regular training for personnel on the best practices for using these hoses and inflators can help optimize the inflation process, ultimately leading to increased productivity and reduced operational delays.

When selecting materials for tire pressure hoses, it’s essential to consider factors such as temperature and pressure ratings, durability, and compatibility with various media. This analysis will focus on four common materials used in tire pressure hoses: rubber, thermoplastic elastomers (TPE), polyurethane, and nylon. Each material has unique properties and implications for performance, cost, and suitability for international markets.

Rubber is a traditional choice for tire pressure hoses due to its excellent elasticity and flexibility. It can withstand a wide range of temperatures, typically from -40°F to 212°F (-40°C to 100°C), and offers good pressure ratings, often exceeding 300 PSI. Additionally, rubber exhibits decent resistance to abrasion and wear, making it suitable for rugged environments.

Pros: Rubber hoses are generally durable and cost-effective, providing a good balance of performance and affordability. They are also easy to manufacture and can be molded into various shapes.

Illustrative image related to tire pressure hose

Contras: However, rubber is susceptible to degradation from UV exposure and ozone, which can limit its lifespan in outdoor applications. Furthermore, it may not perform well with certain chemicals, which can restrict its use in specific industries.

Consideraciones internacionales: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, as rubber hoses may need to meet specific safety and performance criteria.

Thermoplastic elastomers combine the characteristics of rubber and plastics, offering flexibility and durability. They typically have a temperature range of -40°F to 140°F (-40°C to 60°C) and can handle pressures up to 250 PSI. TPE is also resistant to UV and ozone, making it suitable for outdoor applications.

Pros: TPE hoses are lightweight and can be produced in various colors, which may appeal to branding needs. They are also recyclable, aligning with sustainability initiatives.

Contras: The cost of TPE can be higher than traditional rubber, and they may not be as durable under extreme conditions. Additionally, TPE can be less resistant to certain chemicals, limiting its application scope.

Illustrative image related to tire pressure hose

Consideraciones internacionales: Buyers should check for compliance with international standards such as DIN or JIS, particularly in Europe and the Middle East, where regulatory requirements may be stringent.

Polyurethane is known for its superior abrasion resistance and flexibility, making it an excellent choice for tire pressure hoses. It can typically handle temperatures from -40°F to 180°F (-40°C to 82°C) and pressures up to 300 PSI. Polyurethane hoses are also lightweight and resistant to kinking.

Pros: The durability of polyurethane hoses makes them ideal for heavy-duty applications, and they tend to have a longer lifespan than rubber hoses. They also maintain their flexibility in cold temperatures.

Contras: On the downside, polyurethane can be more expensive than rubber and TPE. It may also be less resistant to certain chemicals, which could limit its application in specific industries.

Consideraciones internacionales: Buyers from regions like Brazil and Saudi Arabia should ensure that polyurethane hoses meet local and international standards, especially if used in critical applications.

Nylon hoses are known for their high strength and resistance to abrasion. They can typically withstand temperatures from -40°F to 200°F (-40°C to 93°C) and can handle pressures up to 300 PSI. Nylon also has excellent chemical resistance, making it suitable for various applications.

Pros: The lightweight nature of nylon hoses makes them easy to handle, and their resistance to chemicals allows for broader use in different environments. They are also less prone to kinking compared to other materials.

Illustrative image related to tire pressure hose

Contras: However, nylon can be more expensive than rubber and may not be as flexible, which could hinder performance in certain applications. Additionally, nylon hoses may require more complex manufacturing processes.

Consideraciones internacionales: For buyers in Europe and the Middle East, ensuring compliance with relevant standards is crucial, as nylon hoses may be subject to specific regulations depending on their intended use.

| Material | Typical Use Case for tire pressure hose | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | General tire inflation | Cost-effective and durable | UV and ozone susceptibility | Bajo |

| Thermoplastic Elastomers (TPE) | Lightweight applications | UV and ozone resistant | Higher cost and chemical limitations | Medio |

| Polyurethane | Heavy-duty tire inflation | Superior abrasion resistance | Higher cost and chemical limitations | Alta |

| Nylon | Chemical-resistant applications | High strength and lightweight | More complex manufacturing | Medio |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their tire pressure hose procurement based on material properties, performance, and compliance considerations in various international markets.

Illustrative image related to tire pressure hose

The manufacturing process of tire pressure hoses involves several critical stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

Preparación del material

The first step in the manufacturing process is material selection and preparation. Tire pressure hoses are commonly made from durable materials such as rubber, thermoplastic elastomers (TPE), or reinforced synthetic compounds. These materials are chosen for their ability to withstand high pressures and extreme temperatures. The raw materials undergo a thorough inspection to ensure they meet the required specifications before being cut and shaped for further processing.

Formando

In the forming stage, the prepared materials are shaped into hoses. This is often achieved through extrusion, where the material is heated and forced through a die to create a continuous hose of the desired diameter. For hoses requiring additional strength, reinforcement materials such as nylon or polyester may be integrated during this stage. This process can also include braiding or spiraling techniques to enhance flexibility and resistance to kinking.

Montaje

After forming, the hoses are cut to specific lengths and fitted with connectors and fittings. This assembly may involve various techniques, including crimping or bonding, to ensure secure connections that can handle the pressures involved in tire inflation. Special attention is paid to the design of these fittings to ensure compatibility with various tire valve types, providing ease of use for end-users.

Acabado

The final stage is finishing, where the hoses undergo treatments to enhance their durability and performance. This may include surface treatments to improve resistance to abrasion, UV exposure, and other environmental factors. The hoses are then tested for leaks and overall integrity before being packaged for distribution.

Quality assurance (QA) is a critical aspect of manufacturing tire pressure hoses, ensuring that products meet both international and industry-specific standards. The QA process typically involves multiple checkpoints and testing methods.

International and Industry Standards

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may be relevant, particularly for products intended for specific markets. Compliance with these standards not only ensures product safety and reliability but also enhances the credibility of suppliers in the global market.

Puntos de control de calidad

To maintain high-quality standards, manufacturers implement various quality control checkpoints throughout the production process:

Control de calidad entrante (IQC): This initial stage involves inspecting raw materials before production begins. Ensuring that materials meet specified standards is crucial for the integrity of the final product.

Control de calidad durante el proceso (IPQC): During the manufacturing process, continuous monitoring and testing are conducted. This includes assessing the quality of extruded hoses, verifying dimensions, and ensuring proper assembly of fittings.

Control de calidad final (CCF): Once production is complete, finished hoses undergo rigorous testing to verify performance under pressure. This may involve burst testing, leakage testing, and environmental testing to ensure that the hoses can withstand their intended use.

Testing is an integral part of the quality assurance process for tire pressure hoses. Common testing methods include:

Burst Testing: This test measures the maximum pressure a hose can withstand before failure. It helps ensure that the product can handle the pressures involved in tire inflation without rupturing.

Leak Testing: This involves applying pressure to the hose and checking for any signs of leakage. It is essential for ensuring the safety and reliability of the hose during operation.

Environmental Testing: Hoses are subjected to various environmental conditions, including exposure to UV light, extreme temperatures, and ozone, to assess their durability and longevity.

Flexibility and Kink Resistance Testing: These tests evaluate how well the hose can bend and twist without kinking, which is critical for ease of use in practical applications.

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

Illustrative image related to tire pressure hose

Auditorías de proveedores

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. These audits can evaluate adherence to international standards and the effectiveness of their QA processes.

Quality Reports and Documentation

Requesting quality reports and documentation from suppliers is another effective way to verify their quality control practices. This may include certificates of compliance with international standards, test results from FQC, and records of any corrective actions taken in response to quality issues.

Inspecciones de terceros

Engaging third-party inspection services can provide an additional layer of assurance. Independent inspectors can evaluate the manufacturing process, conduct random testing, and verify compliance with specified standards, ensuring that the products meet the buyer’s requirements.

International B2B buyers face unique challenges when it comes to quality control and certification. Understanding these nuances is essential for successful procurement.

Illustrative image related to tire pressure hose

Regional Certification Requirements

Different regions may have specific certification requirements that suppliers must meet. For instance, products sold in the European market may require CE marking, while those in North America may need to comply with ANSI (American National Standards Institute) standards. Buyers should be familiar with these requirements to avoid complications during importation.

Diferencias culturales y normativas

Cultural differences can impact communication and expectations regarding quality. Buyers should ensure clear communication regarding quality requirements and standards, taking into account the regulatory landscape in their respective regions.

Long-term Relationships with Suppliers

Building long-term relationships with reliable suppliers can facilitate better understanding and adherence to quality standards. This can lead to improved product consistency and a more streamlined procurement process, ultimately benefiting both parties.

In summary, understanding the manufacturing processes and quality assurance practices for tire pressure hoses is vital for B2B buyers. By familiarizing themselves with the key stages of production, quality checkpoints, testing methods, and verification strategies, buyers can make informed decisions that enhance their procurement strategies and ensure product reliability.

Sourcing a reliable tire pressure hose is crucial for ensuring the efficient operation of tire inflation systems, whether for commercial vehicles or personal use. This guide provides a step-by-step checklist for B2B buyers, enabling you to make informed decisions and find the right products for your needs.

Understanding the precise requirements for your tire pressure hose is the first step in the sourcing process. Consider factors such as diameter, length, and material type. Specifications should also include pressure ratings and compatibility with existing equipment to ensure optimal performance.

Conduct thorough research to identify potential suppliers who specialize in tire pressure hoses. Look for suppliers with a solid reputation in the industry and a proven track record of reliability. Utilize resources such as online directories, trade shows, and industry forums to gather a list of candidates.

Before engaging with suppliers, verify their certifications and compliance with international standards. Certifications like ISO or SAE indicate that the supplier adheres to quality management systems and industry norms. This step is essential for ensuring product safety and reliability in various operating environments.

Always request samples of the tire pressure hose before finalizing any orders. Testing samples allows you to assess the quality, flexibility, and durability of the hose in real-world conditions. Pay attention to the ease of installation and whether the hose meets your operational requirements.

Illustrative image related to tire pressure hose

Once you have narrowed down your options, compare pricing from different suppliers. Look beyond just the base price; consider shipping costs, payment terms, and bulk order discounts. Establishing favorable payment terms can enhance your cash flow and overall procurement strategy.

Investigate customer feedback and testimonials to gauge the reliability of your shortlisted suppliers. Reach out to existing clients or request references to gain insights into the supplier’s service quality, response time, and how they handle issues. This step is vital for minimizing risks associated with new partnerships.

After selecting a supplier, carefully review and finalize contracts. Ensure that all terms, including delivery schedules, warranties, and return policies, are clearly stated. A well-defined contract protects both parties and sets expectations for performance and accountability.

Illustrative image related to tire pressure hose

By following this checklist, B2B buyers can streamline the sourcing process for tire pressure hoses, ensuring they find products that meet their specific needs while minimizing risk and maximizing value.

When analyzing the cost structure of tire pressure hoses, several critical components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materiales: The type of materials used significantly affects the price. High-quality rubber or synthetic compounds that withstand extreme temperatures and pressures tend to be more expensive. Additionally, incorporating specialized features, such as self-locking connectors or patented designs, can further increase material costs.

Trabajo: Labor costs vary based on the complexity of the manufacturing process. Skilled labor is often required for quality assembly and testing, which can drive up expenses, particularly in regions with higher wage standards.

Gastos generales de fabricación: This includes utilities, equipment maintenance, and facility costs. Efficient production processes can help minimize these overheads, making it vital for suppliers to optimize their operations.

Herramientas: Initial tooling costs can be substantial, particularly for custom designs. Buyers should inquire about tooling amortization when discussing bulk orders, as this can significantly impact unit pricing.

Control de calidad: Ensuring the hoses meet industry standards and certifications may require additional testing and inspection, contributing to overall costs.

Logística: Transportation and warehousing add another layer of expense. The choice of shipping methods and Incoterms will influence logistics costs, especially for international buyers.

Margen: Suppliers will typically add a profit margin that reflects their operational efficiency and market competition.

Several factors can influence the pricing of tire pressure hoses, making it essential for buyers to understand these dynamics:

Volumen/MOQ: Suppliers often have minimum order quantities (MOQs) that can affect unit pricing. Larger orders usually yield better pricing due to economies of scale.

Especificaciones y personalización: Custom specifications can lead to higher costs due to unique tooling and material requirements. Buyers should balance their need for customization with budget constraints.

Calidad del material y certificaciones: Higher quality materials and certifications (such as ISO standards) can increase costs but may result in better performance and durability, ultimately reducing the total cost of ownership.

Factores del proveedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and customer service capabilities.

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can significantly affect the total price, including who bears the cost of shipping and insurance.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Illustrative image related to tire pressure hose

Negotiate for Better Terms: Establishing long-term relationships with suppliers can provide leverage for better pricing and terms. Don’t hesitate to discuss volume discounts or favorable payment terms.

Considere el coste total de propiedad: Evaluate the long-term costs associated with a product, including maintenance, durability, and potential downtime. Investing in higher-quality hoses may result in lower overall costs.

Entender los matices de los precios: Be aware of regional pricing variations and market conditions. Prices can fluctuate based on demand, currency exchange rates, and geopolitical factors, particularly in emerging markets.

Realizar estudios de mercado: Familiarize yourself with industry benchmarks and competitor pricing to strengthen your negotiating position. This knowledge can help you identify fair pricing and avoid overpaying.

Leverage Multiple Suppliers: Engaging with multiple suppliers can foster competition and provide insights into the best available options. It also allows you to compare pricing and quality more effectively.

Prices for tire pressure hoses can vary widely based on the factors discussed above. The figures mentioned in various references are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and conduct thorough due diligence before finalizing purchases.

In the realm of tire maintenance, various solutions exist to ensure optimal tire pressure. While tire pressure hoses are a popular choice for inflating tires, exploring alternatives can provide buyers with tailored options that suit their operational needs. This analysis will compare tire pressure hoses with two viable alternatives: tire inflator systems and automated tire inflation systems.

| Aspecto comparativo | Tire Pressure Hose | Tire Inflator System | Automated Tire Inflation System |

|---|---|---|---|

| Rendimiento | Reliable for manual inflation | Quick and efficient inflation | Continuous monitoring and inflation |

| Coste | Moderate initial cost | Higher initial investment | Higher upfront cost, potential savings long-term |

| Facilidad de aplicación | Simple, requires minimal training | Requires some setup and familiarity | Installation may require professional assistance |

| Mantenimiento | Low maintenance | Moderate maintenance | Generalmente de bajo mantenimiento |

| El mejor caso de uso | Individual or small fleet use | Medium to large fleets | Large fleets or high-traffic environments |

Tire inflator systems, such as portable or integrated inflators, offer quick and efficient tire inflation. They are especially useful for medium to large fleets that require frequent tire maintenance. The primary advantage is their speed; they can inflate tires significantly faster than manual methods. However, they come with a higher initial investment and require some degree of user training to operate effectively. Maintenance is moderate, as inflator systems may require periodic checks to ensure functionality.

Automated tire inflation systems provide a sophisticated solution for tire maintenance, particularly in environments where tire pressure can fluctuate frequently, such as logistics centers or trucking fleets. These systems continuously monitor tire pressure and automatically inflate tires when needed, ensuring optimal performance and fuel efficiency. While the upfront costs are higher compared to both tire pressure hoses and inflator systems, they can lead to significant savings over time through reduced tire wear and improved fuel economy. The installation may require professional assistance, but once in place, these systems typically require minimal maintenance.

When selecting a tire inflation solution, B2B buyers should consider factors such as the scale of their operations, budget constraints, and maintenance capabilities. For smaller fleets or individual users, a tire pressure hose remains a cost-effective and reliable choice. For medium-sized operations, a tire inflator system may offer the right balance of performance and convenience. In contrast, businesses managing large fleets or high-traffic environments may find that an automated tire inflation system justifies its higher initial investment through enhanced efficiency and long-term savings. Ultimately, aligning the chosen solution with operational needs will ensure effective tire management and optimal performance.

When evaluating tire pressure hoses, several critical specifications must be considered to ensure optimal performance and reliability. Understanding these properties is essential for making informed purchasing decisions.

The material composition of a tire pressure hose significantly influences its durability and flexibility. Common materials include rubber, PVC, and polyurethane. Rubber hoses are known for their resilience and ability to withstand high pressures, making them suitable for heavy-duty applications. PVC hoses are lighter and more flexible, ideal for lighter tasks. Polyurethane offers a balance of strength and flexibility, often used in portable tire inflators. Choosing the right material is vital for ensuring the hose meets the specific demands of your operations.

The pressure rating of a tire pressure hose indicates its maximum operating pressure. Typically measured in psi (pounds per square inch), this specification is crucial for safety and efficiency. A hose with a higher pressure rating can handle more demanding applications without risk of rupture. For B2B buyers, ensuring that the selected hose meets or exceeds the required pressure levels is critical to avoid operational downtime and potential hazards.

Tire pressure hoses are often exposed to varying temperatures, especially in outdoor settings or during specific applications. The ability of a hose to maintain performance under extreme temperatures is a key property. Hoses designed for high-temperature resistance will not degrade or lose flexibility, ensuring a longer lifespan and consistent performance. This characteristic is particularly important for industries operating in regions with extreme weather conditions.

The length and diameter of a tire pressure hose affect its ease of use and the efficiency of air transfer. Common diameters include 1/4 inch, 3/8 inch, and 1/2 inch, with the length varying based on application needs. Longer hoses provide flexibility in reaching tires in hard-to-access locations, while larger diameters facilitate higher air flow rates. Selecting the appropriate size is crucial for maximizing efficiency and ensuring that the hose fits the specific requirements of the job.

Compatibility with various connectors and fittings is essential for seamless integration into existing systems. Many hoses come with standardized fittings, but it’s important to verify compatibility with tire inflators and other equipment. This consideration helps avoid additional costs and delays caused by the need for adapters or modifications.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms you should be familiar with:

This term refers to companies that produce components that are used in another company’s end product. For tire pressure hoses, OEM products are designed to meet specific manufacturer standards, ensuring quality and reliability. When sourcing hoses, buyers often prefer OEM parts to maintain equipment integrity.

Illustrative image related to tire pressure hose

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it can impact inventory levels and overall costs. Understanding MOQ helps businesses plan their purchases more effectively and avoid overstocking or stockouts.

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products or services. This term is vital for procurement teams as it enables them to compare pricing, terms, and capabilities from multiple vendors, ensuring they secure the best deal.

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Incoterms define who is responsible for shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers involved in cross-border transactions, ensuring clear communication regarding responsibilities and costs.

Lead time refers to the time between placing an order and receiving the product. For tire pressure hoses, understanding lead times is crucial for planning and maintaining operational efficiency. This term helps businesses manage their supply chains effectively and avoid delays in production or service delivery.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies and ensure they make well-informed decisions when sourcing tire pressure hoses.

Illustrative image related to tire pressure hose

The tire pressure hose market is experiencing notable growth, driven by several global factors. Increasing vehicle ownership in emerging economies such as Brazil, Saudi Arabia, and across Africa is propelling demand for effective tire inflation solutions. Moreover, the rise of e-commerce platforms has facilitated easier access to tire pressure hoses for international B2B buyers. Technological advancements in hose materials and designs are also emerging as significant trends. For instance, self-locking and quick-release connectors are gaining popularity due to their convenience and efficiency, appealing to both professional and consumer markets.

Another critical trend is the shift towards integrated solutions, where tire pressure hoses are part of broader tire management systems. Such systems not only monitor pressure but also provide predictive maintenance alerts, enhancing operational efficiency for fleet operators. International buyers should be aware of the varying regulations and standards across regions, particularly concerning product safety and durability, as compliance is crucial for market entry.

Sustainability has become a vital consideration in the tire pressure hose sector. As environmental concerns rise globally, buyers are increasingly prioritizing products that minimize ecological impact. This shift prompts manufacturers to explore sustainable materials and processes, such as using recycled plastics or bio-based materials for hose production.

Moreover, ethical sourcing is gaining traction, with companies seeking suppliers who adhere to fair labor practices and environmentally responsible methods. Certifications such as ISO 14001 (Environmental Management) and other green labels are becoming essential for B2B buyers looking to ensure their supply chains align with sustainability goals. This focus not only enhances brand reputation but also meets the growing consumer demand for eco-friendly products, particularly in markets like Europe, where regulations are stricter.

The tire pressure hose has evolved significantly from its early iterations. Initially made from basic rubber materials, these hoses lacked durability and efficiency. Over the decades, advancements in material science have led to the development of hoses that are lighter, more flexible, and resistant to wear and tear.

Illustrative image related to tire pressure hose

The introduction of features such as self-locking connectors and quick-release mechanisms has further transformed the user experience, offering convenience and reliability. This evolution reflects broader trends in the automotive industry, where efficiency, safety, and user-friendliness are paramount. As technology continues to advance, international B2B buyers can expect even more innovative solutions that cater to the growing demands of modern vehicle maintenance.

How do I solve issues with tire pressure hose leaks?

To address leaks in tire pressure hoses, first inspect the hose for any visible damage or wear. Ensure that all fittings and connections are secure and tight. If leaks persist, consider using a hose repair kit or replacing the hose entirely. Opt for high-quality hoses that are resistant to wear and tear, especially in challenging environments. Always conduct regular maintenance checks to prevent future issues.

What is the best tire pressure hose for heavy-duty applications?

For heavy-duty applications, look for tire pressure hoses made from durable materials such as reinforced rubber or thermoplastic elastomers. These hoses should be capable of withstanding high pressures and extreme temperatures. Brands that offer patented features, like self-locking connectors, can enhance usability and reliability. Always check the specifications to ensure compatibility with your tire inflator system.

How can I verify the quality of tire pressure hoses from suppliers?

When sourcing tire pressure hoses, request product certifications and quality assurance documentation from suppliers. Look for third-party testing results that demonstrate durability and performance under various conditions. Additionally, consider asking for samples to conduct your own testing. Online reviews and references from other businesses can also provide insights into a supplier’s reliability and product quality.

What customization options are available for tire pressure hoses?

Many manufacturers offer customization options for tire pressure hoses, including length, diameter, and fitting types. You can request specific materials that suit your operational needs, such as abrasion-resistant covers for harsher environments. Ensure to communicate your requirements clearly during the negotiation phase, as custom orders may have different lead times and costs associated.

What are the typical minimum order quantities (MOQs) for tire pressure hoses?

Minimum order quantities for tire pressure hoses vary by supplier and the type of product. Generally, MOQs can range from 100 to 1,000 units, depending on the customization and material specifications. For international buyers, it’s beneficial to discuss MOQs upfront to avoid unexpected costs. Some suppliers may offer flexibility on MOQs for repeat customers or larger contracts.

What payment terms should I expect when ordering tire pressure hoses internationally?

Payment terms for international orders of tire pressure hoses typically include options such as advance payment, letters of credit, or net payment terms (e.g., 30, 60, or 90 days). It’s crucial to negotiate terms that protect your interests while ensuring the supplier is comfortable. Always verify payment methods accepted by the supplier and consider using escrow services for larger transactions to mitigate risks.

How can I manage logistics for shipping tire pressure hoses internationally?

To manage logistics effectively for international shipping, partner with a reliable freight forwarder experienced in handling industrial goods. Ensure you understand the customs regulations and import duties for your destination country. It’s advisable to track your shipment and communicate with your supplier about delivery timelines. Packaging should also be robust to prevent damage during transit.

What quality assurance measures should I look for in tire pressure hose suppliers?

When assessing suppliers, inquire about their quality assurance processes, including regular inspections, material sourcing standards, and adherence to international safety regulations. Suppliers should be willing to share their quality control documentation and any certifications they hold, such as ISO standards. Establishing a clear QA agreement before placing orders can help ensure the products meet your expectations consistently.

Dominio: morrflate.com

Matriculado: 2019 (6 años)

Introducción: This company, Morrflate – Multi-Tire Inflation Kits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: jacosuperiorproducts.com

Registrado: 2014 (11 años)

Introducción: Lightning S2X Tire Inflator Hose Extension Self-Locking Nozzle | Patented Air Hose Adapter for Tire Pumps (Open Flow) – Price: $27.99 (originally $39.99)\nLightning L2X Tire Inflator Hose Extension Self-Locking Nozzle | Patented Lock-on Air Hose Adapter for Tire Pumps (Open Flow) – Price: $29.99 (originally $39.99)\nFeatures: Self-locking + quick-release hose extension designed to replace standard…

Dominio: shop.aperiatech.com

Registrado: 2010 (15 años)

Introducción: {“product_name”: “Inner Hose, Dual Tires”, “brand”: “Aperia Halo”, “price”: “$34.99”, “sizes_available”: [“12”, “13”, “14”, “15”], “common_applications”: {“12”: “22.5\” rim, aluminum or 2-hand-holes”, “13”: “22.5\” rim, aluminum or 2-hand-holes”, “14”: [“22.5\” rim, 5 hand holes”, “24.5\” rim, aluminum or 2-hand-holes”], “15”: “with Flowbelow aerodynamic wheel covers fitting 22.5\” rim, aluminum o…

Dominio: autometer.com

Matriculado: 1996 (29 años)

Introducción: Air Hose Assembly for Tire Pressure Replacement, 24 inches long, includes strain reliefs, bleed valve, and bullet foot air chuck.

In the rapidly evolving landscape of tire pressure hose procurement, strategic sourcing has emerged as a pivotal approach for international buyers, particularly those in Africa, South America, the Middle East, and Europe. By prioritizing quality, durability, and ease of installation, businesses can significantly enhance operational efficiency and reduce long-term costs. The shift towards high-performance products, such as patented self-locking adapters and durable hoses tested for extreme conditions, underscores the importance of selecting suppliers that offer proven reliability and innovation.

Furthermore, understanding the regional market dynamics is essential for optimizing supply chains. Engaging with local distributors and manufacturers can facilitate better pricing strategies and quicker response times. As demand for sustainable and efficient solutions continues to grow, aligning procurement strategies with environmental considerations will also be critical.

Looking ahead, international B2B buyers are encouraged to leverage these insights to refine their sourcing strategies. By investing in quality tire pressure hoses and fostering strong supplier relationships, companies can position themselves for success in a competitive marketplace. Now is the time to take proactive steps toward enhancing your sourcing strategy, ensuring your business is well-equipped to meet future challenges and opportunities.

Illustrative image related to tire pressure hose

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.