In the ever-evolving landscape of industrial machinery, sourcing reliable air compressor tires has become a critical challenge for B2B buyers across the globe. Whether you’re operating in the bustling markets of Nigeria, Brazil, or the Middle East, the need for durable, high-performance tires is paramount for maintaining operational efficiency. This comprehensive guide addresses the multifaceted aspects of air compressor tires, including types, applications, and the intricacies of supplier vetting.

With insights into the cost structures and quality benchmarks, this resource is designed to empower international B2B buyers to make informed purchasing decisions. Understanding the nuances of air compressor tire specifications can significantly impact not only the performance of your equipment but also the overall safety and cost-effectiveness of your operations.

From portable inflators suitable for personal vehicles to heavy-duty tires designed for industrial compressors, the guide covers a wide array of options tailored to diverse needs. Additionally, it delves into strategies for evaluating suppliers to ensure you partner with manufacturers who prioritize quality and reliability. By leveraging the insights presented here, you can confidently navigate the global market and secure the best air compressor tires to optimize your business operations.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Tire Inflators | Compact, battery-operated, often cordless | Automotive repair shops, roadside assistance | Pros: Easy to transport, quick inflation. Contras: Limited power for larger tires. |

| Heavy-Duty Compressors | High PSI output, often with robust construction | Construction, agriculture, industrial | Pros: Suitable for large vehicles, durable. Contras: Bulkier, higher cost. |

| Digital Tire Inflators | Integrated digital pressure gauges, preset settings | Fleet management, logistics | Pros: Accurate readings, user-friendly. Contras: May require charging or power source. |

| Dual Power Inflators | Operate on both battery and AC power | Garages, workshops | Pros: Versatile, can be used anywhere. Contras: Heavier due to dual functionality. |

| Multi-Purpose Inflators | Adapters for various inflatables (balls, pool toys) | Recreational vehicle businesses | Pros: Versatile for different applications. Contras: May lack high PSI for heavy-duty tires. |

Portable tire inflators are designed for convenience, often featuring battery operation and a compact design. These units are ideal for automotive repair shops and roadside assistance services, where mobility is essential. B2B buyers should consider battery life and inflation speed, particularly for vehicles with larger tires that require more power. While they are easy to transport, their limitations in power output make them less suitable for heavy-duty applications.

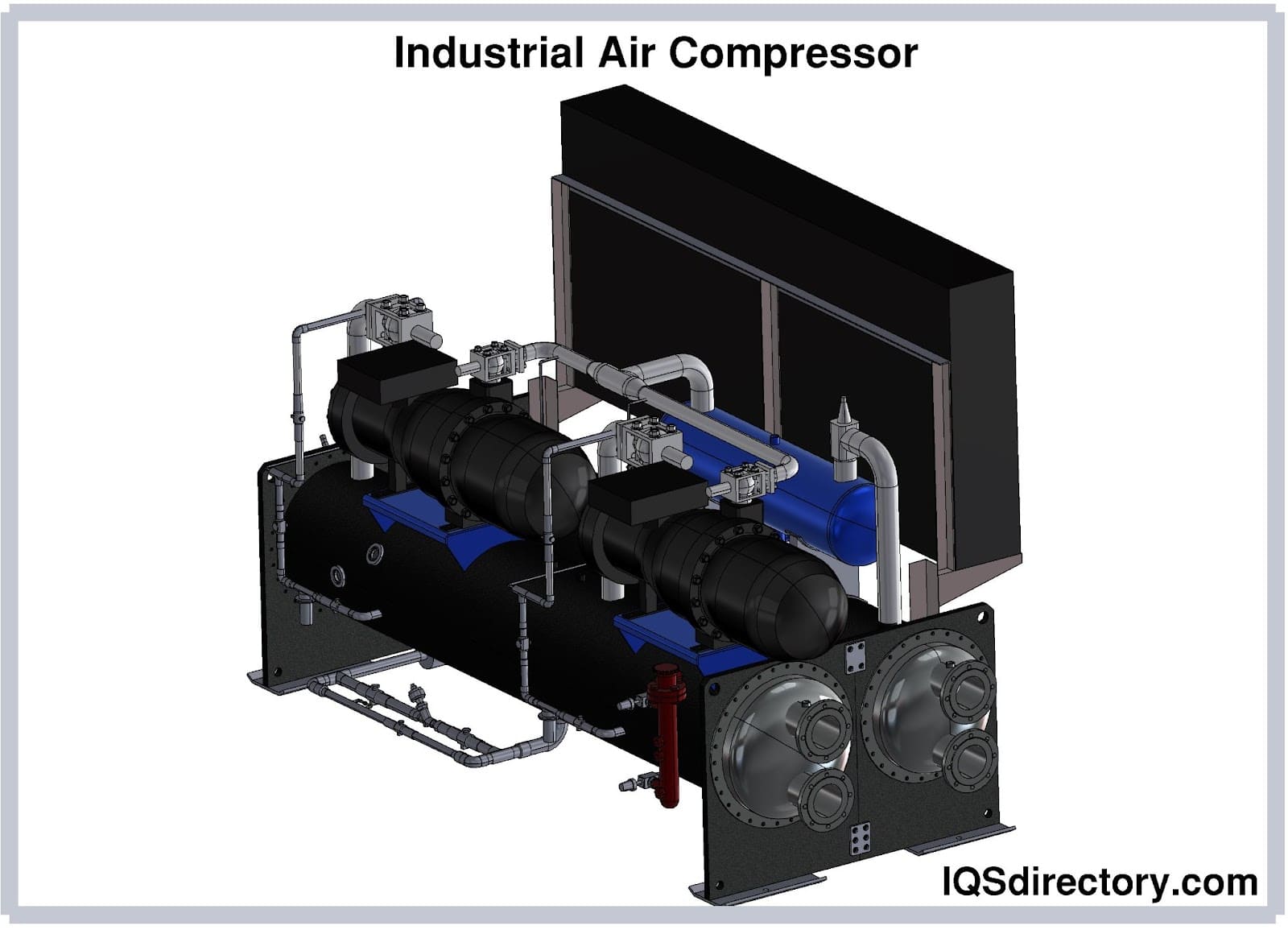

Heavy-duty compressors are characterized by their ability to deliver high PSI outputs and robust construction. These compressors are essential in industries such as construction, agriculture, and transportation, where they are used to inflate large vehicle tires and heavy machinery. When purchasing, businesses should assess the compressor’s durability and maintenance requirements. While these units are more expensive and bulkier, their reliability in demanding environments justifies the investment.

Digital tire inflators integrate advanced technology with user-friendly interfaces, often featuring digital pressure gauges and preset inflation settings. These inflators are particularly beneficial for fleet management and logistics companies that require consistent tire pressure monitoring. B2B buyers should consider the accuracy of the pressure gauge and the ease of use. Although they provide precise readings, some models may require a power source, limiting their portability.

Dual power inflators can operate on both battery and AC power, making them versatile tools for garages and workshops. This flexibility allows businesses to utilize them in various settings without worrying about power availability. Buyers should evaluate the weight and portability of these units, as their dual functionality often results in a heavier design. While they can be more cumbersome, the ability to operate anywhere is a significant advantage for many B2B applications.

Multi-purpose inflators come with various adapters to accommodate different inflatable items, such as sports balls and pool toys, in addition to tires. They are particularly useful for recreational vehicle businesses and service providers that cater to diverse customer needs. When considering a multi-purpose inflator, businesses should assess the range of attachments and the maximum PSI capabilities. While they offer versatility, they may not provide the high-pressure performance required for heavy-duty tires.

| Industria/Sector | Specific Application of air compressor tires | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Tire inflation for various vehicles | Ensures optimal tire pressure, enhancing vehicle safety and efficiency | Compatibility with different vehicle types and tire sizes |

| Construcción | Inflating heavy machinery tires | Increases operational uptime and reduces maintenance costs | Durability under rugged conditions and high-pressure capabilities |

| Agricultura | Tire inflation for agricultural vehicles | Maximizes productivity by maintaining optimal tire performance | Resistance to agricultural chemicals and terrain adaptability |

| Logistics and Transportation | Regular tire maintenance for fleet vehicles | Reduces fuel consumption and prolongs tire lifespan | Portability and ease of use for on-site maintenance |

| Mining and Quarrying | Tire inflation for heavy-duty mining equipment | Enhances safety and performance in challenging environments | High PSI capabilities and robust construction for harsh conditions |

In the automotive repair industry, air compressor tires are essential for maintaining proper tire pressure across various vehicles. Regular tire inflation ensures vehicles operate efficiently, improving fuel economy and safety. For international B2B buyers, particularly in regions like Africa and South America, sourcing durable inflators that can handle diverse tire sizes and pressures is crucial, especially in areas with varying road conditions.

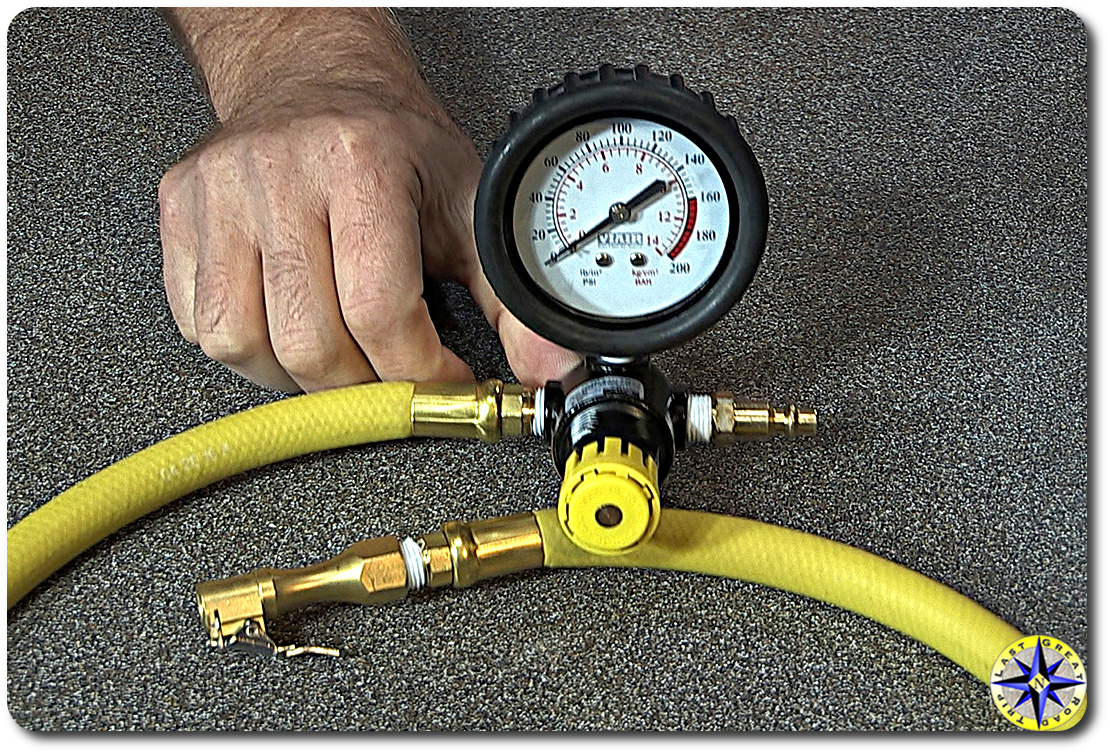

Illustrative image related to air compressor tires

In construction, air compressor tires are vital for inflating heavy machinery tires, such as those on bulldozers and excavators. Proper inflation minimizes downtime due to tire failures and optimizes the performance of construction equipment. Buyers in the Middle East and Europe should prioritize high-pressure capabilities and durability when sourcing, as these machines often operate in rugged environments.

Agricultural vehicles, including tractors and harvesters, require consistent tire pressure for optimal performance. Air compressor tires allow farmers to inflate their equipment quickly, maximizing productivity during critical farming seasons. For buyers in regions like Nigeria and Brazil, selecting inflators that can withstand exposure to agricultural chemicals and rough terrains is essential for longevity and reliability.

In logistics and transportation, maintaining tire pressure in fleet vehicles is crucial to reducing fuel consumption and enhancing tire lifespan. Air compressor tires enable quick and efficient inflation, ensuring that vehicles remain operational and safe on the road. B2B buyers should consider the portability of inflators for on-site maintenance, especially in regions with limited access to service stations.

Air compressor tires are indispensable in the mining and quarrying sectors, where heavy-duty machinery operates in extreme conditions. Proper tire inflation enhances safety and performance, reducing the risk of accidents and equipment failures. Buyers in these sectors must focus on sourcing robust inflators that can handle high PSI requirements and withstand harsh environments, ensuring consistent and reliable operation.

El problema:

For B2B buyers in industries reliant on fleet vehicles, maintaining optimal tire pressure can be a constant challenge. Inconsistent tire pressure can lead to increased fuel consumption, reduced tire lifespan, and compromised vehicle safety. Buyers often struggle with traditional manual methods of checking and inflating tires, which can be time-consuming and prone to human error. This is particularly problematic in regions with fluctuating temperatures or varying load conditions, where tire pressure may change rapidly.

Illustrative image related to air compressor tires

La solución:

Investing in high-quality air compressor tires equipped with built-in pressure monitoring systems can significantly alleviate this issue. These systems provide real-time pressure readings, allowing fleet managers to ensure that tires are always inflated to the optimal level. Additionally, sourcing portable air compressors with automatic shut-off features can streamline the inflation process. When specifying air compressor tires, look for options that support higher psi ratings, which are essential for commercial vehicles. Implementing regular maintenance schedules that include checking tire pressure and using these advanced inflators can help mitigate risks associated with under-inflation.

El problema:

B2B buyers often face the challenge of time management, especially when dealing with tire inflation for multiple vehicles. Traditional inflators can be slow and inefficient, causing delays in logistics and operations. This inefficiency can lead to increased downtime for vehicles, which directly impacts productivity and operational costs. In regions with limited access to service stations, the need for quick and reliable tire inflation solutions becomes even more critical.

La solución:

To overcome this pain point, businesses should consider investing in high-capacity air compressors that can inflate multiple tires quickly. Look for models that offer high CFM (Cubic Feet per Minute) ratings and are designed for commercial use. These compressors can rapidly inflate multiple tires in a single session, drastically reducing downtime. Additionally, integrating a centralized tire inflation system within the fleet maintenance routine can facilitate faster servicing. This system can be installed in maintenance facilities to allow for quick and easy access to tire inflation, ensuring that vehicles can return to operations without unnecessary delays.

El problema:

For industries utilizing heavy-duty vehicles, such as construction and mining, inadequate tire support can lead to significant operational challenges. Standard air compressors may not provide the necessary power or pressure required for larger tires, leading to under-inflation and potential tire failure. This situation not only endangers worker safety but also results in costly repairs and delays.

Illustrative image related to air compressor tires

La solución:

B2B buyers should focus on sourcing specialized air compressor tires designed for heavy-duty applications. These tires should be capable of withstanding higher pressures and larger volumes of air. When selecting air compressors, prioritize models that can handle the demands of heavy-duty tires, ensuring they can inflate to the required psi levels efficiently. It’s also advisable to invest in high-performance inflators that include rugged features suitable for harsh working environments. Regular training for maintenance personnel on the specific needs of heavy-duty tire inflation can further enhance safety and operational efficiency, ensuring that all vehicles are properly equipped for the tasks at hand.

By addressing these common pain points with targeted solutions, businesses can improve their tire maintenance processes, enhance vehicle performance, and ultimately drive operational success.

When selecting materials for air compressor tires, it is essential to consider their properties, advantages, and limitations. The right material can significantly influence the performance, durability, and cost-effectiveness of the tires, especially for B2B buyers operating in diverse international markets.

Rubber is the most common material used in the construction of air compressor tires. It offers excellent elasticity and flexibility, allowing the tire to withstand varying pressures and temperatures. Key properties include a temperature rating of -40°F to 180°F and good abrasion resistance.

Pros: Rubber is durable, cost-effective, and easy to manufacture. It provides excellent traction and is resistant to wear, making it suitable for various terrains.

Illustrative image related to air compressor tires

Contras: However, rubber can degrade when exposed to certain chemicals and UV light, leading to potential failure in harsh environments. Its manufacturing process can also be complex, requiring precise control of temperature and pressure.

Impacto en la aplicación: Rubber tires are compatible with a wide range of media, including air and water, but may not be suitable for corrosive substances.

Consideraciones para compradores internacionales: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM and ISO, as rubber quality can vary significantly.

Polyurethane is increasingly being used in air compressor tires due to its superior performance characteristics. It offers a temperature range from -30°F to 200°F and excellent resistance to abrasion and tear.

Illustrative image related to air compressor tires

Pros: The main advantage of polyurethane is its durability and resistance to chemicals, making it suitable for harsh environments. It also has a lower weight compared to rubber, which can enhance fuel efficiency.

Contras: However, polyurethane can be more expensive than rubber and may require specialized manufacturing techniques, which can complicate production.

Impacto en la aplicación: Polyurethane tires are ideal for applications involving exposure to oils and solvents, making them a preferred choice in industrial settings.

Consideraciones para compradores internacionales: Compliance with international standards such as DIN and JIS is crucial, especially for buyers in Europe and the Middle East.

Nylon is often used as a reinforcing material in air compressor tires, enhancing strength and durability. It can withstand high pressures and has a temperature rating similar to rubber.

Illustrative image related to air compressor tires

Pros: The incorporation of nylon increases the overall tensile strength of the tire, making it less prone to punctures and tears. It also improves the tire’s performance in high-load situations.

Contras: On the downside, nylon can absorb moisture, which may lead to degradation over time. Additionally, it can increase manufacturing complexity and costs.

Impacto en la aplicación: Nylon-reinforced tires are particularly effective in heavy-duty applications where high pressure and load-bearing capabilities are required.

Consideraciones para compradores internacionales: Buyers should be aware of the moisture absorption characteristics when sourcing nylon-reinforced tires, particularly in humid climates like those found in parts of Africa and South America.

Steel is another material that can be used in air compressor tires, primarily for reinforcement. It has a high tensile strength and can withstand high pressures and temperatures.

Pros: Steel offers exceptional durability and resistance to deformation under load. It is also highly resistant to wear and tear, making it suitable for heavy-duty applications.

Contras: However, steel can be heavy and may increase the overall weight of the tire, which can affect fuel efficiency. Additionally, it is susceptible to corrosion, which can be a significant drawback in humid or corrosive environments.

Illustrative image related to air compressor tires

Impacto en la aplicación: Steel-reinforced tires are ideal for applications requiring high strength and durability, such as in construction or mining.

Consideraciones para compradores internacionales: Buyers in regions with high humidity or corrosive environments should consider corrosion-resistant coatings or treatments to enhance the longevity of steel-reinforced tires.

| Material | Typical Use Case for air compressor tires | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | General-purpose air compressor tires | Cost-effective and durable | Degrades under UV and chemical exposure | Bajo |

| Polyurethane | Industrial applications | High durability and chemical resistance | Coste más elevado y fabricación más compleja | Alta |

| Nylon | Aplicaciones pesadas | Increased tensile strength | Moisture absorption can lead to degradation | Medio |

| Acero | Construction and mining | Exceptional strength and durability | Heavy and prone to corrosion | Medio |

This guide provides B2B buyers with actionable insights into the materials used in air compressor tires, enabling informed decision-making that aligns with their operational needs and compliance requirements.

The manufacturing process of air compressor tires is a complex series of stages that requires precision and expertise. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

The first stage involves selecting and preparing raw materials, which typically include rubber compounds, fabric reinforcements, and steel belts. Each material serves a specific purpose: rubber provides flexibility and durability, while fabric and steel enhance structural integrity.

Illustrative image related to air compressor tires

During material preparation, suppliers often conduct tests to ensure that the raw materials meet specified standards for hardness, tensile strength, and elasticity. This involves utilizing advanced machinery to mix the rubber compounds, ensuring uniformity and consistency. B2B buyers should inquire about the sourcing of these materials and any certifications that may apply, such as compliance with environmental regulations.

The next stage is the forming process, where prepared materials are shaped into tire components. Techniques such as extrusion, molding, and calendaring are commonly employed.

B2B buyers should consider asking about the technology used in these processes, as innovations can lead to improved performance and longevity of the tires.

Illustrative image related to air compressor tires

The assembly stage is where all the individual components come together. This is typically done in a controlled environment to minimize contamination and defects.

Quality during assembly is critical; any misalignment can lead to performance issues. B2B buyers should evaluate suppliers on their assembly techniques and the skill level of their workforce.

After assembly, finishing techniques enhance the tire’s performance and aesthetics. This includes processes such as:

Illustrative image related to air compressor tires

Understanding the finishing techniques can help B2B buyers ascertain the quality of the final product. It is advisable to ask suppliers about their inspection processes and the technology they use for quality control.

Quality assurance in the manufacturing of air compressor tires is governed by various international standards, which are critical for ensuring safety, reliability, and performance.

ISO 9001 is a widely recognized standard for quality management systems. Adhering to this standard means that manufacturers have established processes to monitor and improve product quality continuously. B2B buyers should seek suppliers that are ISO 9001 certified, as this indicates a commitment to quality.

In addition to ISO 9001, there are several industry-specific certifications that can be important:

B2B buyers should inquire about these certifications to ensure that the tires meet the necessary safety and performance standards for their specific applications.

Quality control checkpoints are essential for ensuring that air compressor tires meet industry standards. These checkpoints typically include:

Illustrative image related to air compressor tires

B2B buyers can enhance their supplier evaluation by requesting detailed reports on these quality control checkpoints.

Verifying the quality control practices of potential suppliers is crucial for B2B buyers, especially in international markets.

Conducting supplier audits can provide insight into their manufacturing processes and quality control measures. B2B buyers should consider:

Requesting quality reports and certifications from suppliers is another effective way to verify their commitment to quality. Buyers should look for:

This information can be invaluable for B2B buyers looking to ensure that they are sourcing high-quality air compressor tires.

For B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe, there are unique challenges and considerations in quality control.

Different regions may have varying regulations regarding product safety and quality. B2B buyers should familiarize themselves with local regulations and standards that may affect the importation and use of air compressor tires.

In emerging markets, the level of quality assurance practices may differ significantly from established markets. Buyers should conduct thorough due diligence, understanding the local manufacturing landscape and the specific challenges suppliers may face.

Illustrative image related to air compressor tires

By keeping these considerations in mind, B2B buyers can make informed decisions when sourcing air compressor tires, ensuring that they receive products that meet their quality and performance expectations.

When sourcing air compressor tires, it is essential to follow a structured approach to ensure that you make informed decisions. This guide outlines the critical steps to help B2B buyers, particularly in diverse regions like Africa, South America, the Middle East, and Europe, procure high-quality products that meet their operational needs.

Establishing clear technical specifications is vital to sourcing the right air compressor tires. Consider factors such as the tire size, pressure rating, and compatibility with your existing equipment. Additionally, outline the intended applications, whether for heavy-duty vehicles or lighter machinery, as this will guide your selection process.

Conduct thorough research to identify potential suppliers who specialize in air compressor tires. Look for suppliers with a strong reputation in your target market and those that have been in business for several years. Utilize platforms like trade shows, industry directories, and online marketplaces to gather a list of potential candidates.

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control measures, and customer service responsiveness to ensure they can meet your specific needs.

Illustrative image related to air compressor tires

Ensure that the suppliers comply with international standards and possess relevant certifications. This may include ISO certifications or compliance with regional regulations. Validating these credentials can help mitigate risks associated with product quality and safety.

Before finalizing your order, request samples to evaluate the quality and performance of the air compressor tires. Testing the samples in real-world conditions can provide insights into durability, ease of installation, and overall functionality. This step is crucial to avoid potential issues after bulk purchasing.

Once you have identified a suitable supplier, negotiate terms that align with your budget and procurement policies. Discuss pricing structures, payment terms, and delivery timelines. It’s beneficial to establish a long-term relationship with favorable terms, especially if you anticipate ongoing procurement needs.

Illustrative image related to air compressor tires

After placing your order, implement a quality assurance process to monitor the received products. This may include inspecting the tires upon arrival and conducting periodic checks during usage. Establishing this process ensures that you maintain operational efficiency and can address any issues promptly.

By following this practical checklist, B2B buyers can streamline their sourcing process for air compressor tires, ensuring they select high-quality products that meet their operational needs while fostering reliable supplier relationships.

When sourcing air compressor tires, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to air compressor tires

Materiales: The type of rubber, steel belts, and other materials used significantly affect the overall cost. High-quality materials enhance durability and performance but come at a higher price point.

Trabajo: Labor costs can vary widely by region. Countries with lower labor costs may offer more competitive pricing, but this can impact quality and manufacturing speed.

Gastos generales de fabricación: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

Herramientas: Custom molds and equipment for specific tire designs can incur significant upfront costs. These are often amortized over larger production runs, making them more cost-effective for high-volume orders.

Control de calidad: Rigorous QC processes ensure that tires meet safety and performance standards. Investing in quality control can mitigate risks associated with product failures and liability.

Logística: Shipping and handling costs can vary based on the origin and destination of the tires. Factors such as shipping method, freight charges, and customs duties must be factored into the total cost.

Margen: Suppliers typically add a profit margin to cover their operational costs and desired profit. This margin can vary based on market conditions and competitive landscape.

Several factors influence the pricing of air compressor tires, making it essential for buyers to consider:

Volumen/MOQ (Cantidad mínima de pedido): Higher order volumes often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

Especificaciones/Personalización: Customized tires that meet specific requirements or certifications often carry a premium. Buyers should clearly define their needs to avoid unnecessary costs.

Materiales: The choice of materials impacts pricing. Premium materials can enhance performance and longevity but will increase initial costs.

Calidad y certificaciones: Tires that comply with international standards or have specific certifications (e.g., ISO, DOT) may be priced higher due to the assurance of quality and safety.

Factores del proveedor: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge more due to their proven track record.

Incoterms: The agreed terms of shipping and delivery can affect total costs. Understanding Incoterms helps buyers anticipate additional charges related to shipping, insurance, and customs.

B2B buyers should leverage several strategies to negotiate better pricing:

Realizar estudios de mercado: Understanding the market rates for air compressor tires can empower buyers during negotiations. Knowledge of competitor pricing and supplier capabilities is invaluable.

Negociar las condiciones: Beyond price, negotiating favorable payment terms and delivery schedules can lead to significant cost savings. Consider options like longer payment periods or early payment discounts.

Evaluar el coste total de propiedad (TCO): Rather than focusing solely on upfront costs, assess the long-term value and performance of the tires. A higher initial investment may yield lower maintenance and replacement costs.

Assess Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should consider local economic conditions, tariffs, and import regulations that may influence pricing.

Establecer relaciones con los proveedores: Establishing strong relationships with suppliers can lead to better pricing and service. Long-term partnerships may provide opportunities for volume discounts and priority in production.

While this analysis provides a framework for understanding costs and pricing in air compressor tire sourcing, actual prices can vary significantly based on numerous factors. Buyers are encouraged to obtain detailed quotations from multiple suppliers to ensure competitive pricing tailored to their specific needs.

In the realm of tire inflation and maintenance, air compressor tires are a popular choice for businesses seeking reliable performance. However, various alternative solutions exist that can also meet the demands of tire maintenance. This analysis provides a comparison of air compressor tires against two prominent alternatives: portable electric tire inflators and manual hand pumps. Understanding these options can help B2B buyers make informed decisions based on their specific operational requirements.

| Aspecto comparativo | Air Compressor Tires | Portable Electric Tire Inflators | Manual Hand Pumps |

|---|---|---|---|

| Rendimiento | High inflation speed, suitable for heavy-duty use | Moderate inflation speed, ideal for quick fixes | Low inflation speed, labor-intensive |

| Coste | Typically higher initial investment | Affordable, ranging from $30-$100 | Very low cost, generally under $30 |

| Facilidad de aplicación | Requires an air compressor setup and power source | Plug-and-play, easy to use | Simple to use but requires physical effort |

| Mantenimiento | Requires regular maintenance of compressor | Minimal maintenance, battery checks for cordless models | Very low maintenance, but physical wear can occur |

| El mejor caso de uso | Heavy-duty vehicles, frequent usage in commercial settings | Personal vehicles, emergency situations | Occasional use, bicycles, or low-frequency tasks |

Portable electric tire inflators are compact devices powered by either batteries or a vehicle’s 12V outlet. They are designed for quick tire inflation and can often inflate tires to standard pressures efficiently. The main advantages include their affordability and ease of use. However, they may have limitations in terms of battery life, and some models can be slower than air compressors. B2B buyers should consider these inflators for scenarios where rapid response is needed, but heavy-duty applications may require a more robust solution.

Illustrative image related to air compressor tires

Manual hand pumps offer a low-cost alternative for tire inflation, requiring no power source and minimal maintenance. These pumps are portable and can be easily stored, making them suitable for occasional use or in remote locations. However, they are labor-intensive and can be time-consuming, especially for larger tires. While they might not be ideal for regular commercial use, they are practical for infrequent tasks such as inflating bike tires or providing a backup option in emergencies.

When selecting the appropriate tire maintenance solution, B2B buyers must assess their specific needs, including the frequency of use, types of vehicles, and budget constraints. Air compressor tires excel in high-performance environments, especially for heavy-duty applications. In contrast, portable electric tire inflators serve well for quick fixes and personal use, while manual hand pumps provide a cost-effective backup option. By evaluating these factors, businesses can make informed choices that align with their operational requirements and financial considerations.

When considering air compressor tires, understanding their technical specifications is crucial for optimizing performance, safety, and longevity. Here are some essential properties to consider:

Illustrative image related to air compressor tires

The material grade of air compressor tires typically refers to the quality and type of rubber used in manufacturing. High-grade rubber provides better durability, resistance to wear and tear, and can withstand extreme temperatures. For B2B buyers, selecting tires made from superior materials can reduce maintenance costs and enhance operational efficiency.

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum inflation pressure a tire can safely handle. This is critical for ensuring that the tires perform optimally under heavy loads. Understanding the appropriate PSI for specific applications can prevent tire blowouts and enhance safety, making it a vital consideration for businesses that rely on air compressor tires for operational tasks.

Tread depth is an important specification that affects traction and performance. A deeper tread provides better grip, especially in wet or off-road conditions, which is essential for vehicles operating in diverse environments. For B2B buyers, assessing tread depth can lead to better decision-making regarding tire longevity and performance in specific applications.

Tolerance levels refer to the permissible limits of variation in tire dimensions, such as diameter and width. Tight tolerances ensure uniformity and compatibility with air compressor systems, leading to smoother operations. Businesses should prioritize suppliers who adhere to strict tolerance standards to minimize operational issues and ensure reliability.

Load capacity defines the maximum weight a tire can support while maintaining safe performance levels. This specification is crucial for businesses that operate heavy machinery or transport goods. Understanding load capacity helps in selecting the right tire for specific applications, ensuring safety and efficiency in operations.

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some common terms that B2B buyers should know:

Illustrative image related to air compressor tires

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of air compressor tires, OEM parts are often preferred for their guaranteed compatibility and quality. Buyers should consider OEM products to ensure reliability and performance.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B transactions as it affects inventory management and procurement strategies. Understanding MOQ can help businesses plan their purchasing effectively, avoiding excess stock or insufficient supply.

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. This process is essential for B2B buyers to compare costs, negotiate terms, and ensure they receive competitive pricing for air compressor tires. A well-prepared RFQ can streamline procurement and foster better supplier relationships.

Illustrative image related to air compressor tires

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms is vital for international B2B transactions, as they dictate who is responsible for shipping costs, insurance, and risk during transit. Understanding these terms can help businesses avoid disputes and clarify obligations.

Lead time refers to the time between placing an order and receiving it. For air compressor tires, understanding lead times is essential for effective inventory management and operational planning. Buyers should inquire about lead times when negotiating with suppliers to ensure timely delivery and minimize downtime.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operations and ensure the longevity and safety of their air compressor tires.

The air compressor tires market is experiencing notable growth, driven by increasing demand for efficient tire inflation solutions across various sectors, including automotive, construction, and logistics. The global rise in vehicle ownership, especially in emerging economies like Nigeria and Brazil, is a significant factor. Businesses are increasingly prioritizing tire maintenance to enhance fuel efficiency and reduce operational costs, leading to a surge in demand for high-quality tire inflators.

Emerging technologies are reshaping the landscape, with innovations such as smart tire inflators that integrate digital pressure gauges, automatic shut-off features, and mobile app connectivity. These advancements not only improve usability but also ensure precision in tire pressure management, which is critical for safety and performance. Additionally, the adoption of portable and cordless inflators is on the rise, catering to the needs of diverse consumers, from individual vehicle owners to fleet managers.

For international B2B buyers, understanding regional preferences is crucial. In Africa and South America, the focus is on affordability and durability, while European markets may prioritize advanced features and eco-friendliness. Furthermore, the supply chain dynamics are evolving, with a shift toward localized sourcing to mitigate risks associated with global logistics disruptions. This trend allows companies to respond more rapidly to market demands and reduce lead times, enhancing competitiveness.

Sustainability is becoming a cornerstone of sourcing strategies in the air compressor tires sector. As businesses recognize their environmental responsibilities, the demand for sustainable products is increasing. This shift is prompting manufacturers to adopt eco-friendly materials and processes, such as the use of recycled rubber and biodegradable components, which not only minimize environmental impact but also appeal to a growing base of environmentally-conscious consumers.

Ethical sourcing is equally important, as companies strive to ensure that their supply chains are free from exploitative practices. B2B buyers are increasingly seeking suppliers that can provide transparency in their sourcing processes, including certifications that validate ethical practices. Green certifications, such as ISO 14001 for environmental management and Cradle to Cradle for sustainable product design, are becoming essential in supplier evaluation criteria.

Moreover, the environmental impact of tire disposal is prompting the development of recycling initiatives, which convert used tires into new products, thus reducing waste and promoting a circular economy. As sustainability becomes a key differentiator, companies that prioritize ethical sourcing and environmentally friendly practices are likely to gain a competitive edge in the marketplace.

The evolution of air compressor tires can be traced back to the early 20th century when the first pneumatic tires were introduced, revolutionizing vehicle performance and safety. Initially, these tires were primarily used in passenger vehicles; however, their adoption expanded to commercial applications as industries recognized their benefits for load-bearing and shock absorption.

In the late 20th century, advancements in manufacturing processes and materials led to the development of more durable and efficient tires. The introduction of air compressors as a necessary tool for tire maintenance further enhanced the importance of maintaining optimal tire pressure, improving safety and fuel efficiency for both personal and commercial vehicles. Today, the integration of technology in tire inflators, alongside a growing emphasis on sustainability, marks the latest chapter in the ongoing evolution of air compressor tires, positioning them as essential components in modern transportation and logistics.

How do I choose the right air compressor tire for my business needs?

Choosing the right air compressor tire depends on various factors, including the type of vehicles you service, the terrain they operate on, and the typical load they carry. Consider the tire’s size, construction, and pressure ratings. Additionally, evaluate the specific applications, such as whether you need tires for heavy-duty trucks or lighter vehicles. Consulting with suppliers for recommendations based on your operational requirements can also streamline the selection process.

What is the best air compressor tire for off-road vehicles?

For off-road vehicles, look for tires that offer superior traction, durability, and puncture resistance. Tires with an aggressive tread pattern and reinforced sidewalls are essential for navigating rugged terrains. Brands like Michelin or Goodyear often provide specialized off-road tires designed to handle extreme conditions. Ensure the selected tire meets the specific load and pressure requirements for your vehicles to optimize performance.

What are the minimum order quantities (MOQ) for air compressor tires?

Minimum order quantities for air compressor tires can vary significantly depending on the supplier and the type of tires. Typically, MOQs range from 50 to 500 units, but some manufacturers may offer lower quantities for specific models. Discussing your needs with potential suppliers can help negotiate favorable terms, especially if you’re looking to establish a long-term partnership or if you’re a new business entering the market.

What payment terms should I expect when sourcing air compressor tires internationally?

Payment terms can vary widely among international suppliers. Common arrangements include payment in advance, letters of credit, or payment upon delivery. Ensure to clarify the terms before finalizing any agreements. It’s prudent to discuss currency options and any additional fees, such as tariffs or taxes, that may apply to the transaction. Establishing clear terms will help mitigate financial risks and streamline the purchasing process.

How can I ensure the quality of air compressor tires from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for those with certifications, such as ISO 9001, which indicate adherence to international quality standards. Request samples for testing before placing large orders and consider visiting the manufacturing facility if feasible. Establishing a quality assurance protocol, including regular inspections and testing of incoming products, will also help maintain standards.

What logistics considerations should I keep in mind when importing air compressor tires?

Logistics is critical when importing tires, as factors like shipping methods, customs clearance, and transportation can impact costs and delivery times. Choose a reliable freight forwarder experienced in handling tire shipments. Be aware of import regulations specific to your region, including duties and tariffs. Planning for potential delays and ensuring you have adequate storage upon arrival will also facilitate a smooth supply chain operation.

Can I customize air compressor tires for my specific requirements?

Yes, many manufacturers offer customization options for air compressor tires. Customization can include specific tread patterns, sizes, or compounds tailored to your business needs. However, customization may require a higher MOQ and longer lead times. Discuss your requirements with potential suppliers to understand the available options and ensure they align with your operational demands.

What are the common challenges faced when sourcing air compressor tires internationally?

Sourcing internationally can present challenges such as language barriers, cultural differences, and varying standards in quality and service. Time zone differences can complicate communication, while logistics issues may lead to delays. To mitigate these challenges, establish clear lines of communication, consider working with local representatives, and conduct due diligence on suppliers. Building strong relationships with your suppliers can also facilitate smoother transactions and problem resolution.

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: User is considering an air compressor for topping off tires and other occasional tasks. Initially looking at the Makita MAC100Q for its quiet operation but is open to other options. User is contemplating a larger compressor than 1 gallon for potential future uses, such as blowing areas clear, but doubts they will use air tools. Also considering a portable inflator like the Dewalt 20V. Suggestions …

In the competitive landscape of air compressor tires, strategic sourcing emerges as a pivotal strategy for B2B buyers looking to enhance operational efficiency and cost-effectiveness. By leveraging data-driven insights and supplier relationships, organizations can optimize their procurement processes, ensuring access to high-quality products that meet specific performance standards. This is particularly crucial for businesses operating in diverse regions like Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly.

Investing in reliable air compressor tires not only reduces maintenance costs but also enhances productivity by minimizing downtime. As international markets continue to evolve, the importance of sourcing durable and efficient products cannot be overstated. Buyers are encouraged to evaluate suppliers based on their ability to deliver innovative solutions tailored to regional needs, ensuring they remain competitive in their respective markets.

Looking ahead, the demand for advanced tire inflators and compressors is set to rise, driven by the growing emphasis on sustainability and efficiency. Now is the time for B2B buyers to reassess their sourcing strategies and align them with future market trends. Engage with trusted suppliers who can provide the latest technologies and insights to stay ahead in this dynamic industry.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.