In the fast-evolving global market for air compressors, sourcing the right equipment can be a daunting challenge for B2B buyers. With diverse applications ranging from manufacturing and construction to automotive and food processing, the need for reliable and efficient air compression solutions is paramount. This comprehensive guide delves into the multifaceted world of air compressors, covering various types—including rotary screw, reciprocating, and oil-free options—as well as their specific applications.

International buyers, particularly those from Africa, South America, the Middle East, and Europe (notably Germany and Nigeria), face unique challenges in their procurement processes. From understanding the intricacies of supplier vetting to evaluating total cost of ownership, this guide empowers decision-makers by providing actionable insights that facilitate informed purchasing decisions. By addressing key considerations such as energy efficiency, maintenance requirements, and compliance with regional standards, this resource aims to streamline your sourcing journey.

As you navigate the complexities of the air compressor market, this guide serves as your roadmap, equipping you with the knowledge necessary to choose the best solutions for your operational needs. Whether you are looking to enhance productivity, reduce downtime, or ensure quality air supply, our expert recommendations and best practices will help you make strategic investments that align with your business objectives.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Reciprocating Compressors | Piston-driven, can be single or multi-stage, generally portable | Construction, automotive repair, HVAC | Pros: Rentable y versátil. Contras: Noisy, requires maintenance. |

| Rotary Screw Compressors | Continuous operation, quieter, typically oil-injected or oil-free | Manufacturing, food processing, textiles | Pros: Efficient for high-volume needs, low maintenance. Contras: Higher initial cost. |

| Centrifugal Compressors | Uses high-speed rotating impellers, best for large volumes | Power generation, petrochemical industry | Pros: Highly efficient for large-scale applications. Contras: Complex and costly to install. |

| Scroll Compressors | Compact design, fewer moving parts, oil-free options available | Medical equipment, refrigeration | Pros: Quiet operation, reliable. Contras: Limited output capacity. |

| Diaphragm Compressors | Uses a diaphragm instead of pistons, ideal for clean air needs | Laboratories, pharmaceuticals | Pros: Produces contaminant-free air. Contras: Lower flow rates, higher price. |

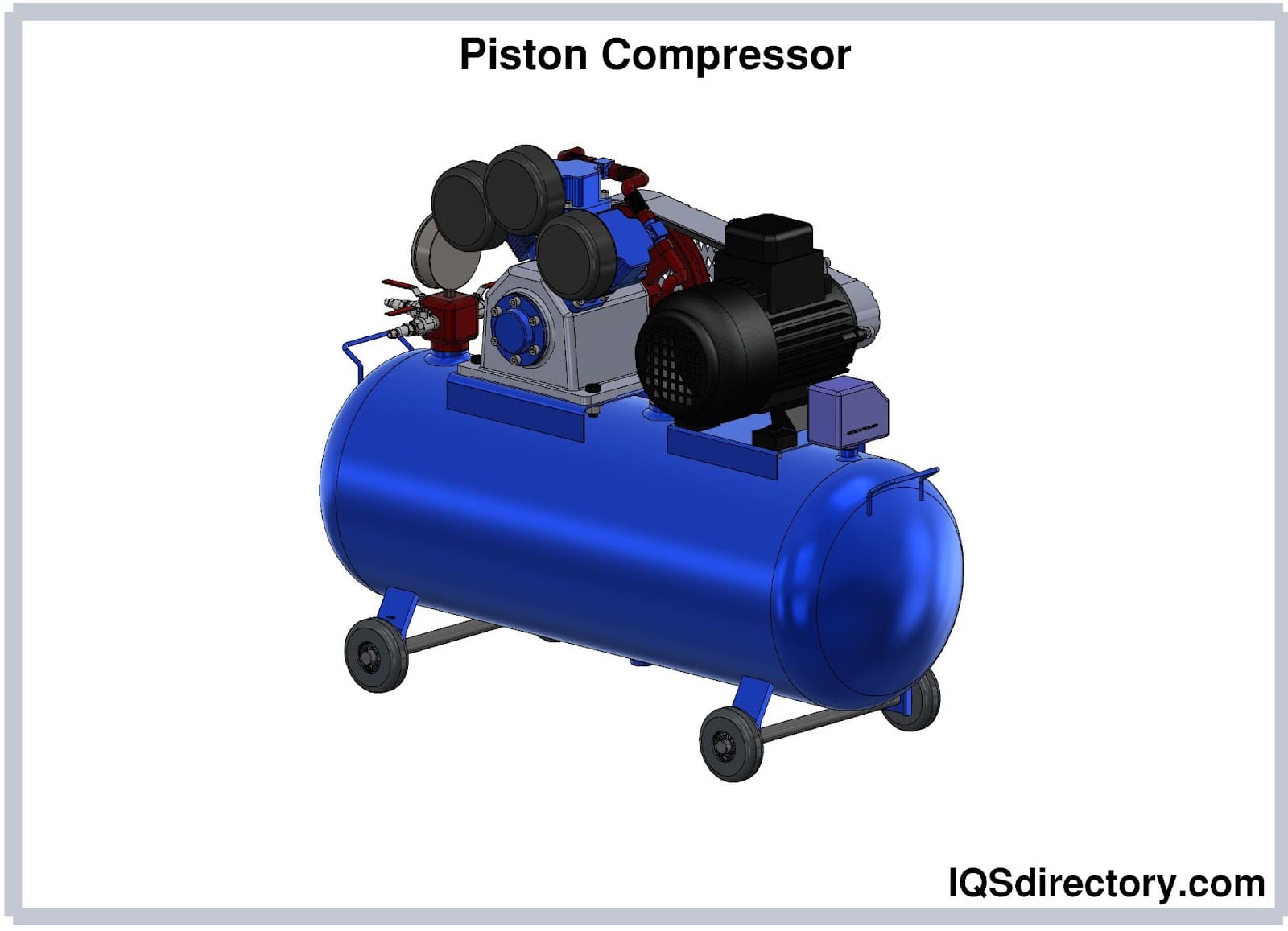

Reciprocating compressors utilize pistons driven by a crankshaft to compress air. They are available in both single-stage and multi-stage designs, making them suitable for various pressure requirements. Their portability makes them a popular choice in industries such as construction and automotive repair. However, they can be noisy and require regular maintenance, which is a consideration for businesses looking to minimize operational disruptions.

Rotary screw compressors are designed for continuous operation, making them ideal for manufacturing and food processing industries that require a steady air supply. They operate more quietly than reciprocating compressors and typically have lower maintenance needs. While the initial investment is higher, their efficiency and longevity can lead to significant cost savings over time, making them a smart choice for businesses with high air demand.

Centrifugal compressors use high-speed rotating impellers to compress air, making them suitable for applications that require large volumes of compressed air, such as power generation and the petrochemical industry. They are highly efficient but come with higher installation costs and complexity. For businesses that can leverage their capabilities, they provide long-term operational benefits, particularly in high-demand environments.

Scroll compressors feature a compact design with fewer moving parts, which reduces the likelihood of mechanical failure. They are often used in medical equipment and refrigeration systems where quiet operation and reliability are critical. While their output capacity may be limited compared to other types, their ability to deliver clean, oil-free air makes them a preferred choice for applications where air quality is paramount.

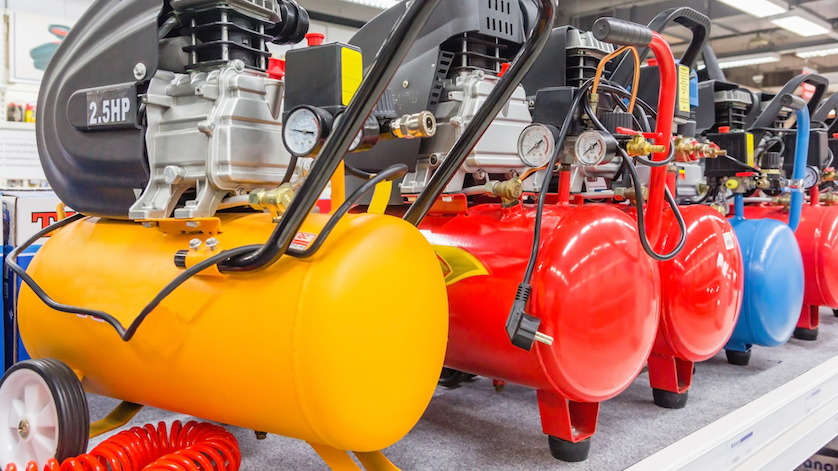

Illustrative image related to air compressure

Diaphragm compressors utilize a diaphragm mechanism to compress air, making them ideal for applications in laboratories and pharmaceuticals where air purity is essential. They produce contaminant-free air but may have lower flow rates compared to other compressor types, which can limit their use in high-demand situations. Their higher price point is often justified by the critical need for clean air in sensitive applications.

| Industria/Sector | Specific Application of Air Compressors | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Fabricación | Pneumatic Tool Operation | Increases productivity and efficiency in assembly lines | Reliability and maintenance support, power requirements |

| Construcción | Concrete and Material Handling | Enhances site productivity and reduces labor costs | Mobility, tank size, and durability in harsh environments |

| Automoción | Spray Painting and Finishing | Ensures high-quality finishes and reduces waste | Air purity standards, compressor size, and noise levels |

| Food and Beverage | Packaging and Bottling | Maintains hygiene and product quality | Compliance with food safety regulations, oil-free options |

| Oil and Gas | Drilling and Well Maintenance | Improves operational efficiency and safety | Pressure ratings, portability, and compatibility with tools |

In the manufacturing sector, air compressors are essential for operating pneumatic tools, such as drills, wrenches, and riveters. They provide a reliable source of compressed air, which enhances productivity on assembly lines. The ability to automate processes reduces labor costs and minimizes human error. Buyers in this sector need to consider the reliability of the compressor, maintenance support, and compatibility with existing systems to ensure smooth operations.

Air compressors are vital on construction sites for tasks like concrete mixing, pneumatic nail driving, and powering jackhammers. Their ability to deliver high-pressure air efficiently enhances site productivity and reduces manual labor. For international buyers, especially in regions with varying climates like Africa and the Middle East, factors such as mobility, tank size, and durability are crucial. Compressors must withstand harsh environments while maintaining consistent performance.

In the automotive industry, air compressors are integral for spray painting and finishing processes. They ensure a smooth and even application of paint, which is critical for aesthetic quality and customer satisfaction. The use of oil-free air compressors is particularly important to prevent contamination of paint. Buyers should prioritize compressors that meet specific air purity standards, are sized appropriately for their operations, and operate at acceptable noise levels to ensure a conducive working environment.

In the food and beverage industry, air compressors facilitate packaging and bottling processes while adhering to strict hygiene standards. Oil-free air compressors are preferred to prevent contamination, ensuring product safety and quality. International buyers must consider compliance with local food safety regulations, the availability of oil-free options, and the overall efficiency of the compressor to enhance operational reliability.

In the oil and gas industry, air compressors are crucial for drilling operations and well maintenance. They improve operational efficiency by powering various tools and equipment, leading to safer and more effective drilling processes. Buyers in this sector should focus on compressors with appropriate pressure ratings, portability for field use, and compatibility with specialized tools to meet the demands of their operations.

El problema: In many manufacturing environments, maintaining consistent air pressure is crucial for the operation of pneumatic tools and machinery. A B2B buyer may find that their air compressor struggles to keep up with the demands of their production line, leading to interruptions, decreased productivity, and potential damage to tools. This inconsistency can stem from several issues, including inadequate compressor capacity, poor maintenance, or incorrect pressure settings. Such problems not only affect the workflow but can also result in increased operational costs due to downtime and equipment failure.

La solución: To address the issue of inconsistent air pressure, buyers should first assess their operational needs and ensure that their air compressor is appropriately sized for their application. Conducting an air audit can help identify peak demand times and the total volume of air required. Once the needs are established, consider investing in a two-stage air compressor, which can provide higher pressure and is more efficient for heavy-duty applications. Regular maintenance, such as checking for leaks, replacing filters, and ensuring proper lubrication, is also critical. Furthermore, implementing a pressure regulator can stabilize the output, allowing for more precise control over the air pressure delivered to different tools and machinery.

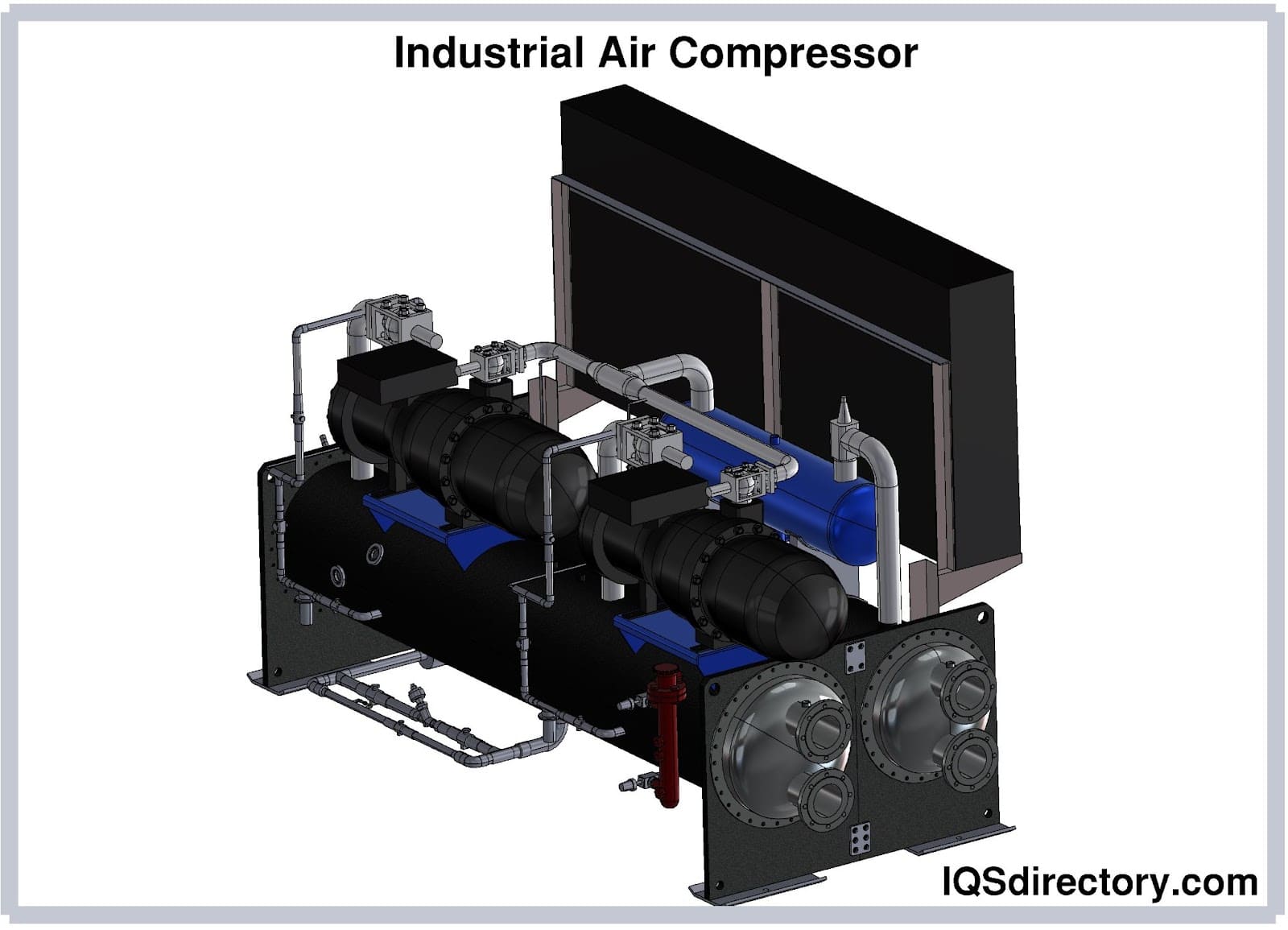

Illustrative image related to air compressure

El problema: Energy costs can be a significant part of operational expenses for businesses utilizing air compressors. Many B2B buyers may be unaware that their existing compressors are energy inefficient, leading to inflated electricity bills. This inefficiency can arise from older models, improper sizing, or lack of proper airflow management. As businesses strive to reduce overhead costs, the search for energy-efficient solutions becomes paramount, especially in regions where energy prices are high.

La solución: To mitigate high operating costs, buyers should consider upgrading to rotary-screw air compressors, known for their energy efficiency and lower operational costs compared to piston compressors. These compressors often feature variable-speed drives that adjust the motor speed based on air demand, ensuring energy is not wasted during low-demand periods. Additionally, implementing a comprehensive maintenance plan can improve compressor efficiency. Regularly inspecting and cleaning air intake filters, as well as ensuring that all connections are leak-free, will help maintain optimal performance. Finally, investing in energy-efficient models that comply with international energy standards can further decrease operational expenses while contributing to sustainability goals.

El problema: In industries such as food processing, pharmaceuticals, and electronics, the quality of compressed air is critical. B2B buyers may face challenges with contaminants in the compressed air supply, such as moisture, oil, and particulate matter. These contaminants can compromise product quality and lead to costly recalls or compliance violations. Buyers must find reliable solutions to ensure clean and dry air without compromising production efficiency.

La solución: To prevent contamination in compressed air, buyers should invest in high-quality air treatment solutions, such as refrigerated air dryers and filtration systems. Refrigerated dryers remove moisture from the air, while additional filters can eliminate particulates and oil. It’s essential to choose air compressors designed for clean air applications, such as oil-free compressors, which significantly reduce the risk of oil contamination. Regular maintenance of air treatment equipment is also vital; this includes changing filters as recommended and monitoring the performance of dryers. By integrating advanced air treatment systems and ensuring proper maintenance, businesses can safeguard product quality and meet industry standards effectively.

Illustrative image related to air compressure

When selecting materials for air compressors, it is essential to consider their properties and how they impact performance and application. Here are four common materials used in the construction of air compressors, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum is a popular choice for many components of air compressors due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 200°C (392°F) and can withstand moderate pressures, making it suitable for various applications.

Pros: Aluminum is durable, lightweight, and offers good thermal conductivity, which helps in managing heat during operation. Its resistance to corrosion makes it ideal for environments with high humidity or exposure to various chemicals.

Contras: While aluminum is generally less expensive than some other materials, it can be more costly than steel. Additionally, it may not be suitable for high-pressure applications beyond its rated limits.

Impacto en la aplicación: Aluminum is particularly well-suited for portable air compressors where weight is a concern. However, buyers should ensure compatibility with specific media, especially if the air contains moisture or corrosive elements.

Illustrative image related to air compressure

Consideraciones para compradores internacionales: Compliance with international standards such as ASTM or DIN is crucial. Buyers from regions like Africa and South America should consider local availability and cost implications of aluminum.

Steel, particularly carbon steel, is widely used in the construction of air compressor tanks and frames due to its high strength and durability. It can handle high pressures and temperatures, typically rated up to 350°C (662°F).

Pros: Steel is robust and can withstand significant wear and tear, making it ideal for heavy-duty applications. It is also relatively inexpensive compared to other materials.

Contras: Steel is heavier than aluminum, which can be a disadvantage in portable applications. It is also susceptible to corrosion if not properly treated, requiring regular maintenance.

Impacto en la aplicación: Steel is excellent for stationary compressors used in industrial settings where weight is less of a concern. However, it may not be suitable for environments with high moisture content unless treated with protective coatings.

Illustrative image related to air compressure

Consideraciones para compradores internacionales: Buyers should be aware of local regulations regarding the use of steel, particularly in regions with strict environmental standards. Compliance with ISO or JIS standards is also important.

Stainless steel is often used in air compressors where corrosion resistance is paramount. It can handle high temperatures (up to 600°C or 1112°F) and pressures, making it suitable for various applications.

Pros: Stainless steel is highly resistant to corrosion and staining, making it ideal for environments where exposure to moisture or chemicals is a concern. It also has a long lifespan, reducing the need for frequent replacements.

Illustrative image related to air compressure

Contras: The primary drawback of stainless steel is its higher cost compared to aluminum and carbon steel. Additionally, it can be more challenging to machine, increasing manufacturing complexity.

Impacto en la aplicación: Stainless steel is ideal for compressors used in food processing or chemical industries where air purity is critical. Its compatibility with various media makes it a versatile choice.

Consideraciones para compradores internacionales: Buyers should ensure compliance with food safety and environmental standards, particularly in Europe and the Middle East, where regulations can be stringent.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is increasingly used in air compressor components such as tanks and covers. While it may not be suitable for high-pressure applications, it offers unique advantages.

Pros: Plastic is lightweight, resistant to corrosion, and can be molded into complex shapes, allowing for innovative designs. It is also cost-effective for low-pressure applications.

Illustrative image related to air compressure

Contras: Plastic has lower temperature and pressure ratings compared to metals, limiting its use in certain applications. It may also degrade over time when exposed to UV light or extreme temperatures.

Impacto en la aplicación: Plastic is suitable for small, portable air compressors and applications where weight and corrosion resistance are more critical than pressure handling.

Consideraciones para compradores internacionales: Buyers should consider the availability of specific plastics and their compliance with local regulations, especially in regions like Africa where material availability may vary.

Illustrative image related to air compressure

| Material | Typical Use Case for Air Compressor | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Portable air compressors | Ligero y resistente a la corrosión | Higher cost than steel | Medio |

| Acero | Industrial stationary compressors | Alta resistencia y durabilidad | Susceptible to corrosion | Bajo |

| Acero inoxidable | Food processing and chemical industries | Excellent corrosion resistance | Mayor coste y complejidad de fabricación | Alta |

| Plástico | Small, portable air compressors | Ligero y rentable | Low pressure and temperature limits | Bajo |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions based on their specific needs and regional considerations.

The manufacturing process of air compressors is complex, involving several key stages to ensure efficiency, reliability, and high performance. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

The first stage in manufacturing air compressors involves the selection and preparation of raw materials. Common materials include:

Material inspection is critical at this stage. Suppliers should adhere to international material standards, ensuring that the materials meet specified quality criteria. This is often validated through certificates of compliance.

Once materials are prepared, the forming process begins. This includes techniques such as:

Automation in forming processes is becoming increasingly common, enhancing precision and reducing human error. B2B buyers should inquire about the technologies employed by their suppliers to ensure quality and efficiency.

The assembly of air compressors combines various components into a functional unit. This stage typically includes:

During assembly, it’s crucial to maintain cleanliness to prevent contamination. B2B buyers should check if suppliers implement cleanroom standards or similar practices during assembly to ensure product integrity.

Finishing processes are vital for enhancing the performance and longevity of air compressors. Typical techniques include:

Effective finishing not only improves the aesthetics of the product but also its durability in demanding environments. Buyers should request information on finishing processes to gauge the quality of the final product.

Illustrative image related to air compressure

Quality assurance (QA) is a critical aspect of air compressor manufacturing, ensuring that products meet industry standards and customer expectations.

B2B buyers should be aware of the following international and industry-specific quality standards:

Understanding these standards can help buyers assess the credibility of potential suppliers.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

These checkpoints help maintain high standards throughout the manufacturing process, reducing the likelihood of defects.

Testing is an essential part of the QC process. Common methods include:

Buyers should inquire about the specific testing methods used by suppliers to ensure they meet their operational standards.

Verifying the quality control processes of potential suppliers is crucial for B2B buyers. Here are some actionable steps:

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

Illustrative image related to air compressure

By being proactive in these areas, B2B buyers can establish strong relationships with suppliers and ensure they receive high-quality air compressors that meet their needs.

When sourcing air compressors for your business, it’s vital to ensure that you select the right equipment that meets your operational needs while also aligning with your budget and supplier capabilities. This checklist serves as a practical guide for international B2B buyers, helping you navigate the complexities of procuring air compressors effectively.

Understanding your specific requirements is the first step in sourcing an air compressor. Consider factors such as the type of compressor needed (e.g., portable, stationary, oil-free, or oil-lubricated) and the required capacity (measured in CFM – cubic feet per minute) for your applications. Defining these specifications will help narrow down your options and ensure you choose a compressor that can handle your workload efficiently.

Different air compressors operate on varying power sources, such as electricity or gasoline. Evaluate the power supply available at your facility and determine the voltage and phase requirements of the compressors you are considering. This is crucial as it ensures compatibility with your existing infrastructure, preventing costly modifications or downtime.

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies that demonstrate their experience in your industry. Additionally, ask for references from other buyers in similar regions or sectors to gauge their reliability and customer service.

Ensure that the compressors you are considering comply with relevant industry standards and certifications, such as ISO or CE marking. Compliance not only guarantees quality and safety but also ensures that the equipment meets international regulations, which is particularly important when importing equipment to regions like Africa or South America.

Once you have a shortlist of suppliers, request detailed quotes that outline the costs involved, including shipping, installation, and any additional accessories. Compare these quotes carefully, taking note of the warranty and after-sales support offered. A comprehensive understanding of the total cost will aid in making an informed decision.

Air compressors require regular maintenance to ensure optimal performance. Inquire about the maintenance services offered by the supplier, including availability of spare parts and support for repairs. A supplier that provides robust after-sales support can significantly reduce downtime and extend the lifespan of your equipment.

Finally, factor in logistics and delivery times when making your decision. Understand the shipping methods and timelines that each supplier offers, especially if you are operating in regions with potential supply chain challenges. Timely delivery can be critical in maintaining your production schedules and avoiding disruptions.

By following this checklist, you can navigate the sourcing process for air compressors more effectively, ensuring that you make a well-informed purchasing decision that supports your business objectives.

Illustrative image related to air compressure

When sourcing air compressors, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materiales: This includes the cost of metals, plastics, and electronic components used in the compressor. The quality and source of materials can significantly influence the final price. For instance, high-grade steel and advanced electronic controls will increase costs but enhance performance and durability.

Trabajo: Labor costs vary based on the geographic location of the manufacturing facility. For example, labor costs in Europe are generally higher than in some African or South American countries. Understanding local wage standards can help buyers gauge the labor component of pricing.

Gastos generales de fabricación: This covers indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which may be reflected in lower prices.

Herramientas: Tooling costs are often significant, especially for customized or specialized compressors. These costs can be amortized over large production runs, making it essential for buyers to consider the Minimum Order Quantity (MOQ) when negotiating prices.

Control de calidad: Ensuring that the compressors meet international standards can increase costs, but it is essential for long-term reliability. Certifications such as ISO can add to the cost but also provide assurance of quality.

Logística: Shipping and handling costs, including customs duties and insurance, can vary widely based on the shipping terms (Incoterms) and the destination. Buyers should factor in these costs when evaluating the total price of the compressor.

Margen: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s market position and the competitiveness of the sector.

Several factors can influence the pricing of air compressors beyond the basic cost components.

Volumen y cantidad mínima de pedido (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have a tiered pricing structure that rewards larger orders, making it beneficial for businesses with high demand.

Especificaciones y personalización: Custom-built compressors tailored to specific needs can increase costs. Buyers should assess whether standard models could meet their requirements to maintain cost-efficiency.

Calidad del material y certificaciones: Higher-quality materials and certifications can lead to increased prices, but these investments often result in lower maintenance costs and longer lifespan, contributing to a favorable Total Cost of Ownership (TCO).

Factores del proveedor: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge higher prices, but they often provide better customer service and support.

Incoterms: Different shipping agreements can influence the final cost. Terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can affect who bears the shipping costs and risks.

To achieve cost-effective sourcing of air compressors, buyers should consider several negotiation strategies:

Research and Benchmarking: Understanding market prices and common practices can empower buyers during negotiations. Comparing multiple suppliers can reveal pricing trends and help identify competitive offers.

Total Cost of Ownership (TCO) Considerations: Buyers should evaluate the long-term costs associated with maintenance, energy consumption, and potential downtime. Highlighting these factors can provide leverage in negotiations.

Flexibility in Specifications: Being open to alternative specifications can allow buyers to access more competitively priced options. This flexibility can include considering different brands or models that meet essential criteria without premium costs.

Building Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Suppliers are often more willing to negotiate with buyers who demonstrate loyalty and consistent purchasing behavior.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances. Currency fluctuations, import tariffs, and varying local regulations can impact overall costs. It is crucial to factor in these elements when negotiating prices and finalizing contracts.

Prices for air compressors can vary widely based on multiple factors and are subject to change. Buyers should conduct thorough market research and consider all cost components when making purchasing decisions.

In today’s industrial landscape, businesses are constantly seeking efficient solutions to power tools and machinery. While air compressors are widely recognized for their versatility, it’s essential to explore alternative technologies that can fulfill similar roles. This analysis compares air compressors against two viable alternatives: electric-powered tools and hydraulic systems. Each option has its strengths and weaknesses, making it crucial for B2B buyers to understand which solution best meets their operational needs.

| Aspecto comparativo | Air Compressors | Electric-Powered Tools | Hydraulic Systems |

|---|---|---|---|

| Rendimiento | High pressure and volume capabilities; suitable for pneumatic tools. | Generally lower power; best for lighter applications. | Very high force output; ideal for heavy machinery. |

| Coste | Initial investment can be high; ongoing maintenance costs. | Typically lower upfront costs; minimal maintenance. | Higher initial costs; maintenance can be expensive. |

| Facilidad de aplicación | Requires space and installation of air lines; setup can be complex. | Plug-and-play design; easy to integrate into existing systems. | Requires specialized setup and space for hydraulic lines. |

| Mantenimiento | Regular maintenance needed to prevent breakdowns; oil changes for oil-lubricated models. | Minimal maintenance; battery management for cordless tools. | Regular checks needed for fluid levels and leaks; can be complex. |

| El mejor caso de uso | Ideal for workshops needing consistent air supply for tools. | Best for tasks that require mobility and ease of use. | Suited for heavy-duty applications, such as construction or manufacturing. |

Electric-powered tools provide a convenient alternative to air compressors, especially in scenarios where mobility and ease of use are paramount. They typically come with lower initial costs and require minimal maintenance compared to air compressors. This makes them attractive for smaller operations or those with limited budgets. However, their performance is often limited to lighter applications, and they may not deliver the high pressure required for more demanding tasks.

Hydraulic systems are another strong alternative, particularly in industries where heavy machinery is used. They offer extremely high force output, making them suitable for heavy-duty applications like construction and manufacturing. However, the initial investment for hydraulic systems can be substantial, and ongoing maintenance costs can add up, especially if leaks occur. Their complexity in setup and maintenance might also deter businesses looking for simpler solutions.

When selecting the right solution, B2B buyers should consider their specific operational requirements, budget constraints, and the nature of the tasks at hand. Air compressors are unmatched for their versatility and capability in powering pneumatic tools, making them ideal for workshops and manufacturing environments. Electric-powered tools excel in mobility and ease of use, perfect for smaller tasks or projects in diverse locations. Conversely, hydraulic systems are the go-to choice for heavy-duty applications where maximum force is necessary.

In conclusion, the decision between air compressors, electric-powered tools, and hydraulic systems hinges on a careful evaluation of performance needs, costs, and operational contexts. By aligning their choice with these factors, businesses can enhance efficiency and productivity in their operations.

Understanding the technical specifications of air compressors is crucial for B2B buyers looking to make informed purchasing decisions. Here are some key properties to consider:

CFM measures the volume of air that an air compressor can deliver per minute. This metric is critical for determining whether a compressor can meet the demands of specific tools or applications. Higher CFM ratings indicate greater air delivery capacity, making them suitable for heavy-duty tasks. For businesses, selecting the right CFM is essential to avoid operational inefficiencies and ensure that pneumatic tools function optimally.

PSI indicates the pressure level at which the air is delivered. Different applications require varying PSI levels; for instance, nail guns might need around 70-100 PSI, while spray painting may require up to 120 PSI. Understanding the PSI requirements of your tools can prevent damage and optimize performance, ensuring productivity across various operations.

The tank size, measured in gallons, determines how much compressed air can be stored. Larger tanks provide a more consistent air supply for tools that require prolonged use without interruption. However, larger tanks also take up more space and can be more costly. For B2B buyers, balancing tank size with workspace constraints and operational needs is vital for effective planning.

Air compressors can be powered by electricity, gasoline, or diesel. Electric compressors are generally quieter and more suited for indoor use, while gasoline or diesel models are preferred for outdoor or remote applications. Understanding the power source is essential for operational logistics and compliance with local regulations regarding emissions and noise.

Oil-free compressors are designed for applications where clean air is paramount, such as food processing or painting. Conversely, oil-lubricated compressors are built for durability and are ideal for heavy-duty applications. B2B buyers must assess their specific needs to choose between these options, as the wrong choice can lead to increased maintenance costs or product contamination.

Familiarizing yourself with industry jargon can enhance your understanding and negotiation capabilities in the B2B market. Here are some commonly used terms:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the air compressor industry, buying OEM parts ensures compatibility and reliability, which is crucial for maintaining operational efficiency.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for budgeting and inventory management, especially for businesses looking to maintain consistent supply levels without overcommitting financially.

An RFQ is a document sent to suppliers requesting pricing and other relevant details for specific products. For B2B buyers, issuing an RFQ can lead to competitive pricing and better terms, facilitating informed purchasing decisions.

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify issues such as shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers manage risk and understand their obligations in cross-border transactions.

TCO encompasses all costs associated with acquiring and operating an asset over its entire lifecycle, including purchase price, maintenance, and energy consumption. For air compressors, understanding TCO helps businesses make economically sound decisions that extend beyond the initial purchase price.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of air compressor procurement more effectively, ensuring that they choose equipment that meets their operational needs and aligns with their business goals.

The air compressor market is experiencing significant growth, driven by a surge in demand across various industries such as manufacturing, automotive, and construction. Key factors fueling this growth include the increasing adoption of automation in industrial processes and the expanding use of pneumatic tools. In regions like Africa, South America, and the Middle East, infrastructure development and urbanization are pivotal drivers, while European markets, particularly Germany, are focusing on efficiency and sustainability.

Emerging technologies such as IoT (Internet of Things) are reshaping the sector, enabling real-time monitoring and predictive maintenance of air compressors. This tech trend enhances operational efficiency and minimizes downtime, which is crucial for B2B buyers looking to optimize their supply chains. Additionally, the shift towards energy-efficient and quieter models is gaining traction, appealing to businesses keen on reducing operational costs and adhering to environmental regulations.

Illustrative image related to air compressure

Sustainability is becoming a cornerstone of sourcing strategies in the air compressor sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental stewardship and ethical practices. The production and operation of air compressors can have considerable environmental impacts, including energy consumption and emissions. As such, companies are seeking out models that utilize energy-efficient technologies and have lower carbon footprints.

The importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about the sourcing of materials, opting for suppliers who adhere to fair labor practices and sustainable resource management. Certifications such as ISO 14001 for environmental management and Energy Star ratings for energy efficiency are becoming essential criteria in the purchasing process. This focus on ‘green’ certifications not only helps in compliance with regulatory standards but also enhances corporate social responsibility profiles.

The evolution of the air compressor industry reflects broader technological advancements and changing market needs. Initially designed for basic tasks, modern air compressors now incorporate advanced features such as variable speed drives and integrated air treatment systems. This evolution has been driven by the need for greater efficiency, reliability, and versatility in diverse applications—from powering pneumatic tools to providing clean, dry air in manufacturing processes.

The transition from traditional piston compressors to rotary screw compressors marked a significant turning point, allowing for continuous operation and improved energy efficiency. This evolution continues today, with innovations focusing on smart technology integration and sustainability, ensuring that air compressors remain integral to industrial operations while meeting contemporary demands for efficiency and environmental responsibility.

In conclusion, understanding these market dynamics, sustainability imperatives, and the historical evolution of air compressors will empower international B2B buyers to make informed sourcing decisions, aligning with both operational goals and ethical considerations.

How do I select the right air compressor for my business needs?

Choosing the right air compressor involves assessing your specific applications and requirements. Consider factors such as the type of tools you will be using, the air pressure (PSI) needed, and the volume of air (CFM) required. Determine whether you need a portable or stationary model, and decide between oil-lubricated and oil-free options based on maintenance preferences and air quality needs. Consulting with suppliers or industry experts can also provide valuable insights tailored to your operations.

What are the key specifications to look for in an air compressor?

When sourcing an air compressor, focus on specifications like horsepower (HP), tank size, maximum PSI, and CFM ratings. Additionally, consider the compressor type—rotary screw vs. piston—and whether it meets your noise level requirements. Other important features include energy efficiency ratings, maintenance needs, and available warranties. Ensuring these specifications align with your operational demands will lead to better performance and longevity.

What are the typical payment terms for purchasing air compressors internationally?

Payment terms for international purchases can vary widely based on the supplier and region. Common terms include advance payment, letters of credit, and payment upon delivery. It is essential to negotiate terms that safeguard your interests, such as partial payments linked to milestones like shipment confirmation or installation. Additionally, consider using escrow services for larger transactions to ensure security for both parties.

How can I vet suppliers for air compressors in international markets?

To vet suppliers, start by researching their business reputation through online reviews and industry forums. Request references from existing customers and verify their compliance with international quality standards, such as ISO certifications. Conducting site visits or virtual audits can also provide insights into their manufacturing processes. Additionally, inquire about their experience in exporting to your region to ensure they understand local regulations and logistics.

What is the minimum order quantity (MOQ) for air compressors from suppliers?

The MOQ for air compressors can vary significantly based on the supplier and model. Some manufacturers may offer single units for smaller operations, while others may require bulk orders to achieve cost-effectiveness. Discuss your needs with potential suppliers to find flexible options that suit your purchasing power, especially if you are a startup or a smaller business.

What customization options are typically available for air compressors?

Many manufacturers offer customization options, such as tailored tank sizes, specific motor configurations, and additional features like integrated air dryers or filtration systems. Some suppliers may also provide branding options for your equipment. Clearly communicate your requirements during the negotiation phase to ensure that the final product aligns with your operational needs.

How do I ensure quality assurance for air compressors purchased internationally?

To ensure quality assurance, request documentation of quality control processes from the supplier. This may include certificates of compliance, test results, and warranty information. Additionally, consider third-party inspections before shipping to verify that the equipment meets specified standards. Establishing a clear agreement on quality expectations upfront can prevent issues upon delivery.

What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider factors such as shipping methods (air vs. sea), customs regulations, and import duties specific to your country. Collaborate with experienced freight forwarders who understand the intricacies of international shipping to facilitate smooth transit. Planning for potential delays and ensuring proper insurance coverage can also mitigate risks associated with logistics challenges.

Dominio: haastooling.com

Inscrito: 2009 (16 años)

Introducción: Haas Air Compressors – Upgrade to Dry & Clean Air

– Type: Rotary-screw air compressor

– Package: 3-in-1 rotary-screw air compressor with refrigerated air dryer mounted on a 52.8-gallon (200-liter) tank

– Motor: 15 hp (11 kW), direct-drive motor

– Air Production: Up to 52.8 cfm (1.5 m3/min) at 145 psi (10 bar)

– Ideal for: Small- to medium-size shops, typically enough to run up to 10 Haas machines

…

Dominio: lowes.com

Matriculado: 1995 (30 años)

Introducción: Air Tools & Compressors at Lowe’s include a variety of options such as portable air compressors, stationary and industrial air compressors, electric and gas air compressors, and quiet air compressors. Portable models are ideal for DIY projects and come in styles like pancake, hot dog, twin stack, and wheelbarrow. Stationary models are suited for garage or workshop use, providing longer runtime and…

Dominio: compressorworld.com

Matriculado: 1999 (26 años)

Introducción: Industrial Air Compressors, Rotary Screw Air Compressors (4 – 3169 CFM), Light Industrial Rotary Screw Air Compressors (3 to 30 HP, 10 to 125 CFM), Piston Pumps, Oilless Engine Driven Air Dryers, Filtration Tanks, Nitrogen Blowers, Vacuum Air Pipe Accessories, Aftercoolers, Lubricants, Hose & Reels, Tank Accessories, Monitors, Dew Point Meter, Pressure & Flow Control, Flow Meters, Regulators, Cond…

As the demand for air compressors continues to grow across diverse industries, strategic sourcing becomes paramount for international buyers. Understanding the various types of compressors—ranging from portable to rotary-screw models—allows businesses to select equipment that aligns with their operational needs while optimizing costs. Buyers should prioritize suppliers that offer comprehensive support, including installation, maintenance, and training services, ensuring that their investment is protected and maximized.

Moreover, as global supply chains evolve, sourcing air compressors from reliable manufacturers can mitigate risks associated with quality and performance. Engaging with suppliers who emphasize energy efficiency and low maintenance can lead to long-term savings and sustainability benefits, critical in today’s eco-conscious market.

Illustrative image related to air compressure

Looking ahead, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are encouraged to leverage strategic partnerships. Embrace innovations in air compression technology that not only enhance productivity but also contribute to operational efficiency. Take action now to evaluate your sourcing strategies and connect with reputable suppliers to secure the best solutions for your air compression needs.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.