In today’s dynamic global market, sourcing reliable air plugs for tires is a critical challenge faced by businesses involved in vehicle maintenance and repair. As puncture incidents can lead to downtime and increased costs, the ability to quickly and effectively repair tires is essential for maintaining operational efficiency. This comprehensive guide provides B2B buyers with in-depth insights into the various types of air plugs available, their applications across different vehicle types, and practical advice on supplier vetting to ensure quality and reliability.

The guide further explores cost considerations and the importance of understanding regional market dynamics, particularly for international buyers from Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam. By addressing these pivotal aspects, this resource empowers businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

Navigating the complexities of the air plug market can be daunting, but this guide aims to simplify the process. From evaluating product specifications to understanding the nuances of different repair methods, buyers will gain the knowledge necessary to choose the right solutions for their specific requirements. Ultimately, this guide is designed to enhance your procurement strategy, ensuring you can effectively tackle tire repair challenges while optimizing your supply chain for success in a competitive landscape.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Tubeless Tire Plugs | Simple insertion, no adhesive required | Automotive, motorcycles, bicycles | Pros: Quick repairs; Contras: Not suitable for larger punctures. |

| Air Plugger Kits | Combines plug insertion with air inflation | Motorcycles, ATVs, lawn equipment | Pros: Dual functionality; Contras: Requires air source. |

| Bacon Strip Plugs | Flexible rubber strips for larger punctures | Heavy-duty vehicles, construction | Pros: Strong hold; Contras: Requires reaming. |

| Self-Contained Kits | Compact, portable kits with all necessary tools | Emergency roadside assistance | Pros: Easy to carry; Contras: Limited plug quantity. |

| Puncture Repair Sealants | Liquid sealant that fills punctures automatically | Fleet maintenance, long-haul trucks | Pros: Prevents leaks; Contras: May not work on larger holes. |

Tubeless tire plugs are designed for quick and effective repairs without the need for adhesives. They are particularly useful in automotive and bicycle applications where downtime needs to be minimized. B2B buyers should consider the types of tires they are servicing; these plugs are ideal for smaller punctures but may not hold up for larger damages. The ease of use makes them a favorite among maintenance teams looking for efficient solutions.

Air plugger kits not only allow for the insertion of plugs but also include an inflating mechanism. This dual functionality is particularly advantageous for businesses that deal with motorcycles and ATVs, where quick repairs are essential. B2B buyers should evaluate the compatibility of these kits with their existing tools, as they require an air source for operation. Their lightweight design enhances portability, making them suitable for on-the-go repairs.

Bacon strip plugs are made from flexible rubber and are suitable for larger punctures, making them ideal for heavy-duty vehicles and construction equipment. These plugs require a reaming tool to enlarge the puncture, ensuring a secure fit. B2B buyers in sectors like construction should consider the trade-off between the strength of the repair and the additional steps required for application. Their robust nature provides long-lasting repairs, which is crucial for minimizing equipment downtime.

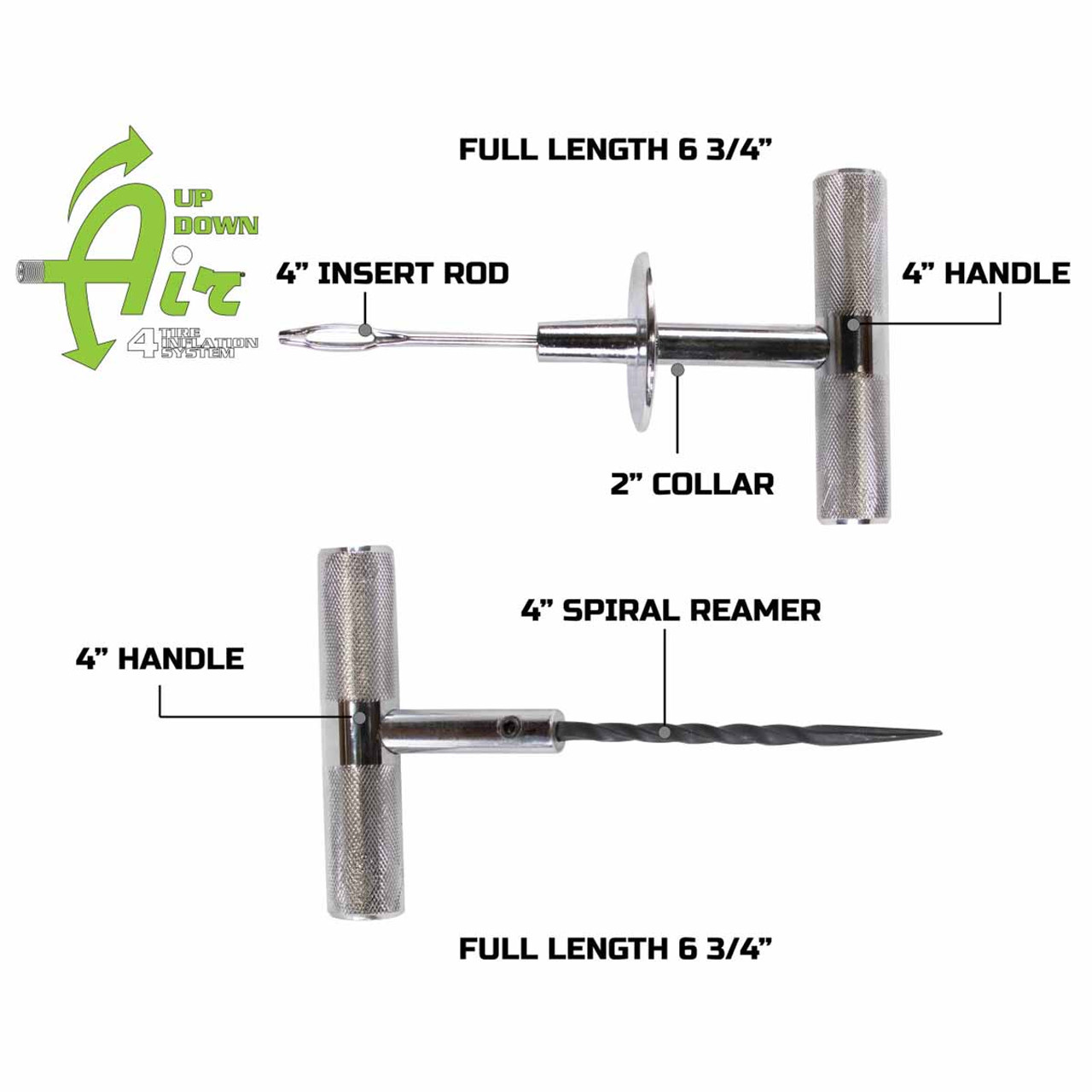

Illustrative image related to air plug for tire

Self-contained kits are compact and include all necessary tools for tire repair, making them perfect for emergency roadside assistance. Their portability is a significant advantage for businesses that operate fleets or provide mobile repair services. However, the limited number of plugs in these kits may necessitate frequent replenishment. B2B buyers should assess the balance between portability and the quantity of repairs needed when selecting these kits.

Puncture repair sealants are liquid solutions that automatically fill punctures as the tire rotates. They are particularly beneficial for fleet maintenance, where minimizing tire-related downtime is critical. While these sealants can prevent small leaks, they may not be effective for larger punctures. B2B buyers should consider the type of vehicles in their fleet and the nature of their operations, as the effectiveness of sealants can vary based on tire conditions and puncture sizes.

| Industria/Sector | Specific Application of air plug for tire | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Emergency tire repairs for vehicles | Reduces downtime and costs associated with tire replacement | Quality of plugs, compatibility with various tire types, bulk purchasing options |

| Transportation & Logistics | Fleet maintenance for trucks and delivery vehicles | Enhances operational efficiency by minimizing tire-related disruptions | Durability of plugs, ease of use, and training for staff on application |

| Agricultura | Puncture repairs for farm equipment tires | Ensures continuous operation of machinery, increasing productivity | Resistance to harsh conditions, availability of refill plugs, and compatibility with different tire sizes |

| Recreational Vehicles (RV) | Quick repairs for RV tires during travel | Improves customer satisfaction by providing a reliable solution on the road | Compact design for portability, ease of use, and effectiveness in various weather conditions |

| Construcción | Tire repairs for heavy machinery on job sites | Minimizes equipment downtime, ensuring project timelines are met | Ability to handle larger punctures, compatibility with heavy-duty tires, and bulk availability |

In the automotive repair sector, the air plug for tire serves as a vital tool for quickly addressing tire punctures in vehicles. This application is particularly beneficial for repair shops that need to minimize vehicle downtime and reduce costs associated with tire replacements. For international buyers, especially in regions like Africa and South America where access to immediate repair services may be limited, sourcing high-quality, durable plugs that are compatible with various tire types is crucial. This ensures a reliable repair solution that can withstand diverse driving conditions.

In the transportation and logistics industry, the air plug is essential for maintaining fleet vehicles. Quick tire repairs can drastically reduce operational disruptions caused by flat tires, leading to enhanced efficiency in delivery schedules. Companies must consider the durability and ease of use of these plugs, as staff may need to perform repairs on-site. Sourcing plugs that are effective and require minimal training can help logistics companies maintain their service levels, particularly in regions with challenging road conditions.

In agriculture, the air plug is indispensable for repairing punctures in tires of various farm equipment. Ensuring that machinery such as tractors and harvesters remain operational is critical for maintaining productivity during peak seasons. Buyers in this sector should look for plugs that resist harsh environmental conditions and can handle larger punctures. Availability of refill packs is also a key consideration, as continuous operation of equipment is paramount in agricultural settings.

For the RV industry, the air plug provides an essential solution for tire repairs during travel. Quick fixes can significantly enhance customer satisfaction by preventing lengthy delays on the road. Buyers should prioritize compact and portable designs that are easy to use, as well as plugs that perform well in various weather conditions. This is particularly important for RV enthusiasts who frequently travel to remote areas where access to repair services may be limited.

In the construction sector, the air plug is crucial for maintaining the functionality of heavy machinery on job sites. Quick tire repairs help minimize equipment downtime, ensuring that project timelines are adhered to. Buyers in this industry should focus on plugs that can handle larger punctures and are compatible with heavy-duty tires. Additionally, sourcing plugs in bulk can ensure that construction companies have a ready supply for ongoing projects, thereby enhancing operational efficiency.

El problema: Many B2B buyers operating fleets or heavy machinery face significant downtime due to tire punctures. When a vehicle is out of commission, it can lead to delayed deliveries and increased operational costs. The challenge is exacerbated in remote areas where access to repair facilities is limited. Fleet managers need a solution that allows for quick and efficient repairs without requiring specialized training.

La solución: Investing in high-quality, user-friendly air plug tools such as the Dynaplug® Racer Pro can significantly reduce repair time. These tools allow operators to fix punctures without removing the tire, making them ideal for on-the-go repairs. To implement this solution effectively, ensure that each vehicle in your fleet is equipped with a repair kit and that staff are trained in its use. Consider organizing brief training sessions that demonstrate the repair process, emphasizing the importance of regular maintenance checks and having the necessary tools readily available. Additionally, sourcing plugs that are specifically designed to create a permanent seal can offer peace of mind, knowing that the repairs will hold up under various operational conditions.

El problema: B2B buyers often face challenges with the reliability and quality of tire repair products available in their regions. Some suppliers may offer low-cost options that fail to provide a lasting solution, leading to repeated repairs and frustrated customers. This inconsistency can damage relationships with clients and harm the reputation of the business.

Illustrative image related to air plug for tire

La solución: To overcome this issue, buyers should prioritize sourcing air plugs and repair kits from reputable manufacturers known for their high-quality products, such as ARI AirPlugger or Dynaplug®. Conducting thorough market research and reading product reviews can help identify reliable brands. Establishing partnerships with trusted suppliers can also lead to better product consistency and customer service. Additionally, implementing a quality control process for incoming repair products can ensure that only reliable tools and plugs are used in repairs. Regularly evaluating supplier performance and customer feedback can help maintain high standards and ensure that the products meet the specific needs of your operations.

El problema: With a diverse fleet comprising various types of vehicles, B2B buyers often encounter compatibility issues with air plugs and tire repair kits. Different vehicles may require different types of plugs, which complicates inventory management and can lead to delays in repairs when the correct product isn’t readily available.

La solución: To address compatibility challenges, B2B buyers should adopt a standardized approach to tire repair products across their fleet. This means selecting a versatile air plug solution that works with multiple tire types, such as those offered by Dynaplug® or ARI AirPlugger. Create a comprehensive inventory list that specifies which plugs and tools are compatible with each vehicle type. This can streamline the purchasing process and ensure that staff can quickly access the correct tools during repairs. Additionally, consider investing in an all-in-one repair kit that includes various plug sizes and types, allowing for flexibility in repairs. Regular training sessions for staff on identifying the right products for different vehicles can further enhance efficiency and reduce downtime.

Illustrative image related to air plug for tire

When selecting materials for air plugs used in tire applications, it is crucial for B2B buyers to understand the properties, advantages, and limitations of each material. This knowledge aids in making informed decisions that align with operational requirements and regional standards.

Key Properties:

Rubber is known for its excellent elasticity, flexibility, and ability to withstand a wide range of temperatures. It typically has a pressure rating suitable for standard tire applications and offers good resistance to wear and tear.

Pros y contras:

The primary advantage of rubber is its durability and ability to create a tight seal, which is essential for maintaining tire pressure. However, it can degrade over time when exposed to certain chemicals or extreme temperatures, leading to potential failures. Additionally, while rubber is relatively inexpensive, it may require more complex manufacturing processes to ensure quality.

Impacto en la aplicación:

Rubber is compatible with air and various tire sealants, making it a versatile choice for different tire types. However, it may not perform well in environments with high temperatures or exposure to oils and solvents.

Illustrative image related to air plug for tire

Consideraciones para compradores internacionales:

Buyers from regions like Africa and South America should be aware of local climate conditions that may affect rubber performance. Compliance with standards such as ASTM D2000 for rubber materials is essential to ensure reliability.

Key Properties:

TPE combines the properties of rubber and plastic, offering flexibility and resilience while being easier to process. It can withstand moderate temperatures and pressures, making it suitable for various tire applications.

Pros y contras:

The key advantage of TPE is its lightweight nature and ease of manufacturing, which can reduce production costs. However, it may not be as durable as traditional rubber, particularly in extreme conditions. Its cost is generally moderate, making it an attractive option for manufacturers.

Impacto en la aplicación:

TPE is compatible with air and can provide a reliable seal in standard tire applications. However, its performance may decline in extreme temperatures or exposure to harsh chemicals.

Consideraciones para compradores internacionales:

For buyers in Europe and the Middle East, ensuring compliance with EU regulations regarding material safety and environmental impact is crucial. TPE may also need to meet specific industry standards, such as ISO 9001 for quality management.

Illustrative image related to air plug for tire

Key Properties:

Polyurethane is known for its high abrasion resistance, flexibility, and ability to withstand a wide range of temperatures. It offers excellent mechanical properties, making it suitable for high-performance applications.

Pros y contras:

The main advantage of polyurethane is its durability and resistance to wear, which can enhance the longevity of the air plug. However, it is generally more expensive than rubber and TPE, which may impact cost-sensitive projects. The manufacturing process can also be more complex, requiring specialized equipment.

Impacto en la aplicación:

Polyurethane plugs are well-suited for high-pressure applications and environments where durability is paramount. They are compatible with air but may not perform well with certain chemicals.

Illustrative image related to air plug for tire

Consideraciones para compradores internacionales:

Buyers in regions like Nigeria and Vietnam should consider the availability of polyurethane materials and compliance with local standards. Understanding the specific performance requirements for local vehicle types is also essential.

Key Properties:

Metal components, such as aluminum, are often used in conjunction with other materials to enhance structural integrity. They offer excellent strength and resistance to corrosion.

Pros y contras:

The primary advantage of using metal is its strength and durability, which can enhance the overall performance of the air plug. However, metal components can add weight and increase production costs. Additionally, they may require more complex manufacturing processes.

Impacto en la aplicación:

Metal components are ideal for applications requiring high strength and reliability, especially in heavy-duty tires. However, they may not be suitable for all tire types due to weight considerations.

Consideraciones para compradores internacionales:

For buyers in the Middle East and Europe, compliance with standards such as DIN for metal components is critical. Understanding local preferences for materials can also influence purchasing decisions.

| Material | Typical Use Case for air plug for tire | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | Standard tire applications | Excellent durability and seal | Degrades under extreme conditions | Bajo |

| Thermoplastic Elastomers (TPE) | General tire repairs | Lightweight and easy to manufacture | Menos duradero en condiciones extremas | Med |

| Polyurethane | High-performance tire applications | High abrasion resistance | Coste más elevado y fabricación más compleja | Alta |

| Metal Components (e.g., Aluminum) | Heavy-duty tire applications | Alta resistencia y durabilidad | Increased weight and cost | Med |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for air plugs in tires, helping them make informed decisions that align with their operational needs and regional standards.

The manufacturing process of air plugs for tires involves several critical stages, each designed to ensure that the final product meets performance and safety standards. Understanding these stages can help B2B buyers evaluate suppliers and their capabilities.

Preparación del material: The first step in manufacturing air plugs is sourcing high-quality materials, typically rubber or viscoelastic compounds that offer durability and resilience. Suppliers often perform material tests to verify that the raw materials meet specific performance criteria, such as flexibility, temperature resistance, and longevity. This step is vital as the quality of the raw materials directly impacts the effectiveness of the final product.

Formando: The next stage involves forming the plugs. This can be achieved through various methods, including extrusion and molding. In extrusion, the rubber is forced through a die to create a continuous shape, which is then cut into individual plugs. Molding involves placing the raw material into a mold and applying heat and pressure to form the desired shape. Each method has its advantages; for instance, extrusion allows for higher production rates, while molding can produce more intricate designs.

Montaje: For air plugs that come with additional components (like applicators or tools), the assembly stage is crucial. This involves integrating various parts, such as the plug itself, insertion tools, and any packaging. Precision is key, as improper assembly can lead to product failure in the field.

Acabado: The final stage is finishing, which includes processes like trimming excess material, surface treatment, and packaging. Quality control measures are implemented at this stage to ensure that each product meets the established standards before it is shipped to customers.

Quality assurance (QA) is critical in the manufacturing of air plugs for tires, ensuring that products are reliable and safe for consumers.

Illustrative image related to air plug for tire

Normas internacionales: Many manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, specific industry standards, such as CE marking for European markets or API specifications for automotive products, may also apply, depending on the intended use of the air plugs.

Puntos de control de calidad: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Control de calidad entrante (IQC): This stage assesses the quality of incoming raw materials before they are used in production. Suppliers should provide certificates of analysis (COA) for the materials.

– Control de calidad durante el proceso (IPQC): During manufacturing, random samples may be tested to ensure they meet specifications. This might include dimensional checks or material property assessments.

– Control de calidad final (CCF): After production, a final inspection is conducted to verify that the air plugs conform to quality standards and specifications before shipment.

Common Testing Methods: Various testing methods are employed to ensure the quality of air plugs. These include:

– Pruebas de tracción: Measures the strength and elasticity of the rubber material.

– Leak Testing: Ensures the plugs can hold air without leaking, which is critical for their performance.

– Pruebas de durabilidad: Simulates real-world conditions to assess how the plugs perform over time.

B2B buyers need to ensure their suppliers maintain rigorous quality control practices. Here are key strategies to verify supplier QA:

Auditorías de proveedores: Conducting audits allows buyers to assess the manufacturer’s quality control processes firsthand. This can include reviewing documentation, inspecting facilities, and observing production practices. Regular audits help build a transparent relationship and ensure compliance with quality standards.

Informes de calidad: Request detailed quality reports from suppliers, including information on testing methods, results, and any corrective actions taken for non-conformities. These reports should detail compliance with both international and industry-specific standards.

Inspecciones de terceros: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can validate the findings from supplier audits and quality reports, offering additional assurance to buyers.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential.

Regional Standards and Compliance: Different regions may have varying requirements for product certification. For instance, European buyers may require CE certification, while buyers in other regions might prioritize compliance with local regulations. It’s crucial to understand these regional standards to avoid potential compliance issues.

Cultural and Logistical Considerations: When dealing with international suppliers, cultural differences can impact communication and expectations regarding quality. Buyers should be aware of these differences and establish clear communication channels. Additionally, logistical challenges such as shipping times and customs regulations can affect the timely delivery of certified products.

Building Relationships: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and certifications. Frequent engagement can also help in addressing any quality issues promptly, ensuring a smoother procurement process.

By understanding the manufacturing processes and quality assurance measures for air plugs for tires, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only ensures product reliability but also fosters long-term partnerships that enhance business success.

This guide provides a practical checklist for B2B buyers seeking to procure air plugs for tires. Air plugs are essential for quickly addressing punctures in tubeless tires, ensuring minimal downtime for vehicles across various industries. By following this step-by-step approach, buyers can make informed decisions that align with their operational needs.

Before sourcing air plugs, it’s vital to clearly outline your technical requirements. Consider factors such as the types of vehicles you service (e.g., motorcycles, cars, heavy machinery) and the specific sizes and materials needed for the plugs. This clarity will help you narrow down suppliers who can meet your exact needs.

Conduct thorough research to identify suppliers specializing in tire repair products. Look for companies with a strong reputation in your target markets, such as Africa, South America, the Middle East, and Europe. Key aspects to consider include:

– Market Presence: Established suppliers often have better quality assurance processes.

– Gama de productos: Ensure they offer a variety of air plugs suitable for different applications.

It’s crucial to verify that potential suppliers hold relevant certifications and comply with industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, consider:

– Safety Standards: Check for compliance with regional safety regulations.

– Environmental Policies: Suppliers with eco-friendly practices may align better with corporate sustainability goals.

Before making a bulk purchase, request samples of the air plugs for testing. This allows you to evaluate their performance and compatibility with your specific tire types. Pay attention to:

– Ease of Use: Ensure the plugs are user-friendly for your technicians.

– Durability: Assess the longevity of the plugs under various conditions to ensure they provide reliable repairs.

Once you’ve identified a shortlist of suppliers, compare their pricing structures and payment terms. Look for:

– Bulk Purchase Discounts: Many suppliers offer discounts for larger orders, which can significantly reduce costs.

– Flexibilidad de pago: Favor suppliers that provide flexible payment options, which can ease cash flow constraints.

Evaluate the level of customer support offered by suppliers, as this can be crucial for ongoing maintenance and troubleshooting. A supplier that provides:

– Technical Support: Access to knowledgeable staff can assist with any issues that arise post-purchase.

– Warranty Policies: Clear warranty terms will protect your investment and ensure product quality.

Once you have selected a supplier, ensure that all agreements are documented clearly. This includes pricing, delivery schedules, and service commitments. Pay attention to:

– Plazos de entrega: Confirm that the supplier can meet your delivery requirements to avoid operational delays.

– Terms and Conditions: Review the fine print to understand your rights and responsibilities in the partnership.

Illustrative image related to air plug for tire

By following this checklist, B2B buyers can streamline the sourcing process for air plugs for tires, ensuring they select high-quality products from reliable suppliers that meet their specific needs.

When sourcing air plugs for tires, understanding the cost structure is crucial for effective budgeting and profitability. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Materials: The choice of materials significantly impacts cost. High-quality viscoelastic rubber and durable aluminum for tools can increase the price but also enhance product longevity and performance.

Labor: Labor costs vary based on geographic location and workforce availability. In regions with higher labor costs, such as Europe, the overall product cost may increase.

Manufacturing Overhead: This includes utilities, rent, and other operational costs. Efficient manufacturing processes can help reduce these costs.

Tooling: Initial tooling costs for custom designs can be high but are amortized over larger production runs, making them more economical at scale.

Quality Control: Investing in rigorous QC processes ensures product reliability and compliance with international standards, which may increase upfront costs but reduce long-term liabilities.

Logistics: Transportation and shipping costs are influenced by distance, shipping methods, and local tariffs. Sourcing from nearby suppliers can mitigate these costs.

Margin: Supplier margins can vary widely. Established brands may command higher prices due to perceived quality and brand trust.

Several factors influence the pricing of air plugs for tires, particularly for B2B buyers.

Volume/MOQ: Bulk purchasing often leads to significant discounts. Establishing a Minimum Order Quantity (MOQ) can optimize cost per unit.

Specifications and Customization: Custom designs or specifications can lead to increased costs. Standardized products typically offer better pricing due to economies of scale.

Materials and Quality Certifications: Products with certifications (e.g., ISO, CE) may have higher costs due to compliance and testing requirements. However, they can offer better marketability and assurance of quality.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer warranties and better customer service, justifying a higher price.

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for assessing total costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can shift financial responsibility and risk between buyer and seller.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiate Terms: Engage in negotiations to secure better pricing, especially for larger orders. Don’t hesitate to ask for discounts on volume purchases or favorable payment terms.

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, warranty, and potential replacements. A lower upfront cost may not always equate to overall savings.

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and service. Suppliers may be more willing to negotiate with loyal clients.

Understand Regional Pricing Nuances: Be aware of local market conditions that may affect pricing, such as import tariffs, currency fluctuations, and regional demand.

Research Competitors: Compare multiple suppliers to understand market pricing better. This knowledge can be a powerful negotiation tool.

Prices for air plugs for tires can vary widely based on the factors mentioned above. The figures provided in market analysis are indicative and should be treated as such. Always conduct thorough market research and obtain formal quotes from suppliers to ensure accurate pricing for your specific needs.

Illustrative image related to air plug for tire

In the realm of tire maintenance and repair, selecting the right solution is crucial for operational efficiency and cost management. While air plugs for tires offer a convenient way to fix punctures, there are various alternative methods available that may better suit specific needs or preferences. This analysis will compare air plugs with traditional patch kits and self-sealing tires, providing B2B buyers with comprehensive insights to make informed decisions.

| Aspecto comparativo | Air Plug For Tire | Traditional Patch Kit | Self-Sealing Tires |

|---|---|---|---|

| Rendimiento | Effective for quick, temporary repairs; suitable for most tubeless tires | Provides a permanent fix; effective for most punctures | Prevents air loss automatically; effective for small punctures |

| Coste | Generally low-cost; plugs and tools are affordable | Moderate cost; kits vary by brand and quality | Higher initial investment; typically more expensive than other options |

| Facilidad de aplicación | Easy to use; requires minimal tools and no special skills | Requires more skill; involves several steps including cement application | No user intervention needed; self-repairing |

| Mantenimiento | Low maintenance; plugs may need replacement after multiple uses | Moderate maintenance; patches can degrade over time and require reapplication | Minimal maintenance; tires last longer but may require eventual replacement |

| El mejor caso de uso | Ideal for emergency repairs on the go; suitable for motorcycles and bicycles | Best for permanent repairs on cars and trucks; recommended for regular maintenance | Excellent for fleet vehicles where downtime must be minimized |

Traditional patch kits are a time-tested solution for tire repair, offering a more permanent fix than air plugs. They typically include rubber cement and various patch sizes, allowing for repairs on a range of puncture sizes. The main advantages of patch kits are their durability and effectiveness against larger punctures. However, the process can be labor-intensive, requiring skill to ensure a proper seal. Furthermore, if not applied correctly, patches may fail, leading to additional costs and downtime.

Self-sealing tires represent a modern approach to tire maintenance, integrating a special sealant within the tire that automatically fills punctures as they occur. This technology is particularly beneficial for fleet operators, as it minimizes downtime and eliminates the need for immediate repairs. While self-sealing tires can significantly reduce the frequency of flat tires, they come with a higher upfront cost and may not be suitable for all tire types. Additionally, once the sealant is depleted or the tire is significantly damaged, traditional repair methods may still be necessary.

When evaluating tire repair solutions, B2B buyers should consider the specific requirements of their operations. Air plugs offer a quick and cost-effective solution for emergency repairs, particularly for motorcycles and bicycles. Conversely, traditional patch kits are ideal for businesses that prioritize long-term durability and performance. For organizations focused on minimizing downtime and operational efficiency, self-sealing tires may be the best investment, despite their higher initial costs. Ultimately, the choice will depend on factors such as vehicle types, repair frequency, and budget constraints.

Illustrative image related to air plug for tire

When selecting an air plug for tire applications, understanding the technical properties is crucial for ensuring reliability, safety, and efficiency. Here are some key specifications to consider:

Air plugs are typically made from materials such as rubber, viscoelastic compounds, or specialized polymers. The choice of material affects durability, flexibility, and the ability to form a seal against air leakage. For instance, viscoelastic materials can conform better to the tire’s inner surface, ensuring a tighter fit and minimizing the risk of air loss. B2B buyers should prioritize suppliers who provide detailed material specifications to ensure compatibility with their specific tire types.

The dimensions of the air plug are critical for effective sealing. Most plugs range from 4 to 6 inches in length and have a diameter that fits standard punctures. A proper fit is essential to prevent air from escaping and to ensure the plug remains in place during tire operation. Buyers should verify that the dimensions align with their tire specifications to avoid performance issues.

Air plugs must withstand a range of temperatures depending on the environment and the tire’s operational conditions. High-quality plugs can endure extreme heat from road friction or cold temperatures during winter months without degrading. This property is vital for ensuring long-term performance and minimizing the need for frequent replacements, thereby reducing operational costs.

Each air plug comes with a maximum pressure rating, which indicates the level of air pressure it can safely contain without failure. This rating is particularly important for high-performance vehicles or heavy-duty applications. Buyers should ensure that the air plugs they select exceed the maximum operational pressure of the tires they are using to prevent blowouts or failures.

Illustrative image related to air plug for tire

Understanding the repair methodology associated with the air plug is essential. Many modern plugs allow for easy insertion without needing adhesives or curing times. This facilitates quick repairs, which is especially valuable for businesses with a fleet of vehicles that require minimal downtime. Buyers should inquire about the specific repair process to ensure that their teams can efficiently utilize the plugs.

Familiarity with industry jargon can streamline communication and negotiations in the B2B landscape. Here are some key terms related to air plugs for tires:

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of air plugs, an OEM may manufacture plugs that are used by tire manufacturers. Understanding OEM relationships can help buyers ensure they are sourcing high-quality products that meet industry standards.

Illustrative image related to air plug for tire

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and procurement strategies. Understanding MOQ can help businesses negotiate better terms and manage their stock levels effectively.

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Issuing an RFQ for air plugs can help buyers compare prices, terms, and product specifications from various suppliers, facilitating informed purchasing decisions.

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. They clarify who is responsible for shipping, insurance, and tariffs, which is vital when sourcing air plugs from international suppliers. Familiarity with Incoterms can help avoid misunderstandings and ensure compliance with international shipping regulations.

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times for air plugs is essential for effective inventory management and planning, especially for businesses that rely on timely deliveries to maintain operations.

Illustrative image related to air plug for tire

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing air plugs for tires, ultimately enhancing their operational efficiency and product reliability.

The air plug for tire sector is witnessing significant transformations driven by various global factors. One of the primary market drivers is the increasing prevalence of tubeless tire technology across multiple vehicle categories, including motorcycles, cars, and heavy-duty vehicles. This shift is largely due to the advantages of tubeless tires, such as reduced weight and lower chances of blowouts, which enhances safety and performance. Additionally, the growing consumer demand for quick and efficient tire repair solutions is propelling the adoption of air plug tools that can facilitate immediate repairs without the need for extensive equipment.

Emerging B2B technologies, such as mobile applications and IoT solutions, are transforming how buyers interact with suppliers. For instance, buyers in regions like Africa and South America can leverage mobile platforms to procure high-quality air plug products efficiently. Furthermore, automation in manufacturing is leading to cost-effective production processes, making advanced repair tools more accessible to international markets.

Illustrative image related to air plug for tire

The market dynamics also indicate a rising focus on product durability and ease of use. Many manufacturers are innovating their product lines to include multi-functional tools that combine plugging and inflation capabilities, catering to the needs of both casual users and professionals. This trend is particularly relevant in developing regions where users prioritize versatility in their repair kits.

As environmental concerns gain prominence, the demand for sustainable and ethically sourced materials in the air plug for tire sector is on the rise. Manufacturers are increasingly adopting eco-friendly materials and production processes to minimize environmental impact. For example, the use of viscoelastic rubber for plugs, which is both durable and recyclable, has gained traction. This aligns with the global trend towards sustainability and can enhance brand reputation among environmentally conscious consumers and businesses.

Ethical supply chains are becoming non-negotiable for B2B buyers, especially in regions where consumers are more aware of the social implications of their purchases. Buyers are encouraged to seek manufacturers with certifications that verify responsible sourcing practices, such as Fair Trade or ISO certifications related to environmental management. This not only supports ethical labor practices but also ensures compliance with international environmental regulations.

Furthermore, companies that invest in sustainable practices can leverage these initiatives as a marketing advantage, appealing to a broader customer base. As buyers increasingly prefer suppliers that demonstrate a commitment to sustainability, investing in ‘green’ certifications and materials can be a strategic move.

The evolution of air plug technology for tire repair has been marked by significant advancements in both design and functionality. Initially, tire repair methods relied heavily on traditional patching techniques, which were labor-intensive and often required removing the tire from the wheel. The introduction of tubeless tires in the late 20th century paved the way for innovative repair solutions, including the air plug.

Illustrative image related to air plug for tire

Over the years, manufacturers have focused on creating user-friendly tools that facilitate quick repairs without compromising safety. Modern air plugs are designed to fuse directly with the tire material, providing a permanent solution to punctures. This evolution has not only enhanced the efficiency of tire repairs but has also made it easier for consumers to manage tire maintenance independently.

The ongoing innovation in materials and design—such as the integration of inflation capabilities into plug tools—reflects the industry’s response to the growing demand for convenience and reliability. This historical context underscores the importance of staying updated with technological advancements for B2B buyers looking to procure the latest and most efficient air plug solutions.

1. How do I effectively repair a tubeless tire puncture using an air plug?

To effectively repair a tubeless tire puncture using an air plug, start by locating the puncture. Remove any foreign objects from the tire, then use a reamer tool to clean and enlarge the hole. Insert the air plug into the puncture using the insertion tool provided in your repair kit. Ensure that the plug is properly seated, and then inflate the tire as needed. Most air plugs provide a permanent seal, allowing you to continue your journey without immediate professional intervention.

2. What is the best air plug kit for commercial use in various vehicles?

The best air plug kit for commercial use should include a variety of plugs suitable for different vehicle types, such as trucks, motorcycles, and ATVs. Look for kits that contain high-quality viscoelastic rubber plugs, a reliable insertion tool, and a reaming tool for preparing the puncture. Additionally, consider kits that are compact and portable for ease of use. Brands like Dynaplug and ARI AirPlugger offer versatile solutions that can handle multiple puncture sizes and types, making them ideal for diverse applications.

3. What are the minimum order quantities (MOQ) for air plug supplies?

Minimum order quantities (MOQ) for air plug supplies can vary significantly among suppliers. Many manufacturers might set an MOQ ranging from 100 to 1,000 units, depending on the type and complexity of the product. When sourcing from international suppliers, inquire about their specific MOQs, as some may offer flexibility for first-time buyers or bulk orders. Always negotiate to find a balance between your needs and the supplier’s requirements to ensure optimal pricing and availability.

4. How can I vet suppliers of air plugs for tires?

To vet suppliers of air plugs, start by researching their reputation and experience in the industry. Check for customer reviews, testimonials, and case studies that demonstrate their reliability and product quality. Evaluate their certifications, such as ISO or other relevant standards, to ensure compliance with international quality norms. Additionally, request product samples to assess quality firsthand and establish communication to gauge their responsiveness and willingness to support your needs.

5. What payment terms should I expect when sourcing air plugs internationally?

Payment terms for international sourcing can vary widely, but common practices include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer letters of credit or escrow services for larger transactions. Always clarify the payment terms before finalizing orders and consider using secure payment methods to protect against fraud. Negotiating favorable terms can help manage cash flow and reduce financial risks associated with international transactions.

6. Are customization options available for air plugs, and how can I request them?

Yes, many suppliers offer customization options for air plugs, such as branding, packaging, or specific plug sizes to meet your business needs. To request customization, communicate directly with the supplier, detailing your requirements and any specific designs or features you desire. Discuss lead times and potential costs associated with custom orders. Providing clear specifications will facilitate a smoother process, ensuring that the final product aligns with your brand and operational requirements.

7. How do I ensure quality assurance (QA) for air plugs sourced internationally?

To ensure quality assurance for internationally sourced air plugs, establish clear specifications and standards before placing an order. Request quality control documentation from suppliers, including inspection reports and compliance certificates. Consider conducting third-party inspections or audits to verify that products meet your quality criteria. Maintaining open communication with your supplier throughout the production process can also help address any potential issues early, ensuring that the final products align with your expectations.

8. What logistics considerations should I keep in mind when importing air plugs?

When importing air plugs, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s import requirements. Be aware of potential tariffs and taxes that may apply, and ensure all paperwork is in order to avoid delays. Additionally, factor in the shipping time when planning your inventory needs, as international shipping can lead to longer lead times than domestic sourcing.

Could not verify enough suppliers for air plug for tire to create a list at this time.

The demand for effective air plugs for tires continues to rise as global markets seek reliable solutions for tire maintenance and repair. Strategic sourcing in this sector not only enhances operational efficiency but also ensures access to high-quality products that meet diverse market needs. Key insights for international B2B buyers highlight the importance of selecting suppliers that offer innovative and user-friendly repair tools, such as tubeless tire repair kits that simplify the repair process without compromising on durability.

Investing in reputable brands and understanding local market dynamics can significantly impact supply chain efficiency and customer satisfaction. For regions like Africa, South America, the Middle East, and Europe, establishing strong partnerships with manufacturers can lead to competitive pricing and improved product availability.

Looking ahead, the tire repair industry is poised for growth driven by advancements in technology and increasing vehicle usage. B2B buyers are encouraged to actively seek out suppliers who prioritize innovation and sustainability in their products. Embrace these opportunities to enhance your inventory and meet the evolving needs of your customers, ensuring that your business remains at the forefront of the tire maintenance market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.