In the ever-evolving landscape of the global market, sourcing reliable air chuck tire inflators poses a significant challenge for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With a multitude of options available, selecting the right inflator can be daunting, as it requires balancing quality, functionality, and cost-effectiveness. This comprehensive guide is designed to streamline that process, offering insights into various types of air chuck tire inflators, their specific applications, and crucial supplier vetting strategies.

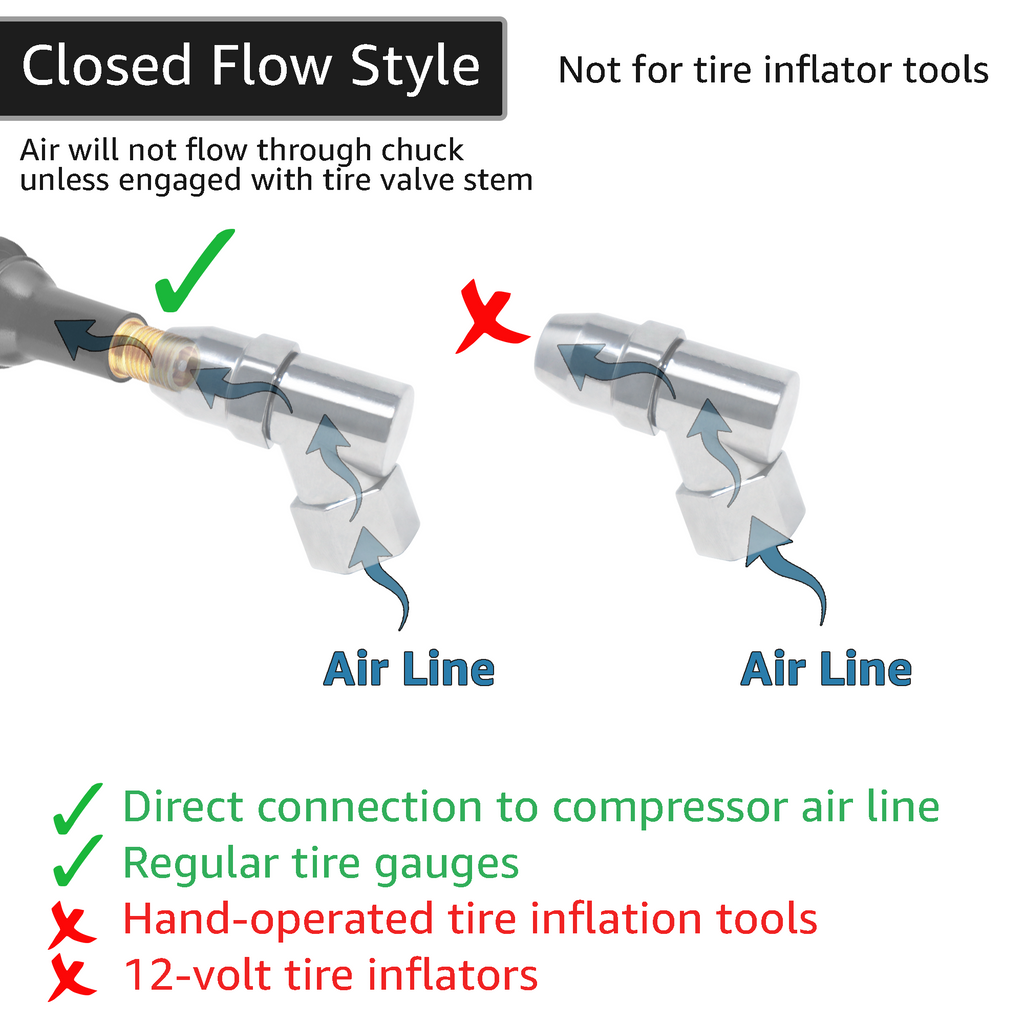

Buyers will discover a range of inflators, from open flow designs ideal for quick tire inflation to closed flow models that prevent air loss during use. Additionally, the guide will delve into essential considerations such as pricing structures, common materials used in manufacturing, and performance metrics that ensure long-lasting durability. By equipping B2B purchasers with actionable insights and expert recommendations, this resource empowers them to make informed decisions that align with their operational needs and budget constraints.

Navigating the complexities of tire inflator sourcing is no longer a daunting task. With the right information at hand, businesses can confidently select products that enhance their service offerings and meet the demands of their clientele, ensuring success in a competitive marketplace.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Open Flow Air Chuck | Allows continuous air flow when connected; no check valve. | General tire inflation, workshops, and garages. | Pros: Quick inflation; versatile. Contras: Potential air wastage. |

| Closed Flow Air Chuck | Features a check valve that prevents air flow unless engaged. | Tire pressure checks and inflation in precision tasks. | Pros: Reduces air wastage; precise control. Contras: Slower inflation process. |

| Lock-On Air Chuck | Secure locking mechanism for a tight seal on the valve. | Heavy-duty applications, fleet services, and commercial vehicles. | Pros: Prevents leaks; reliable for high-pressure tires. Contras: May require more effort to attach. |

| Angled Air Chuck | 45-degree design for easier access to tight spaces. | Automotive repair shops, motorcycle maintenance. | Pros: Improved accessibility; ergonomic design. Contras: Limited to specific applications. |

| Presta Valve Air Chuck | Designed specifically for Presta valves found on bicycles. | Bicycle shops and cycling events. | Pros: Specialized for cycling; lightweight. Contras: Not compatible with Schrader valves. |

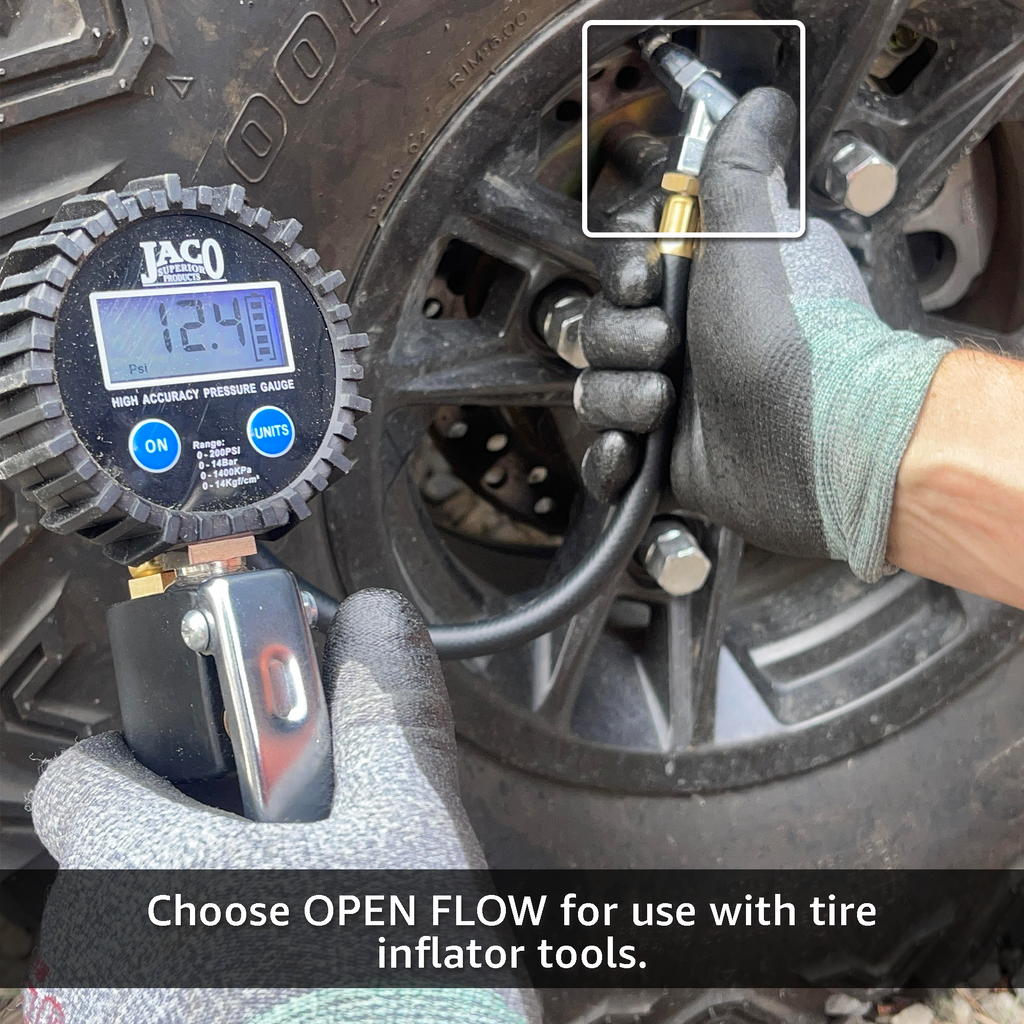

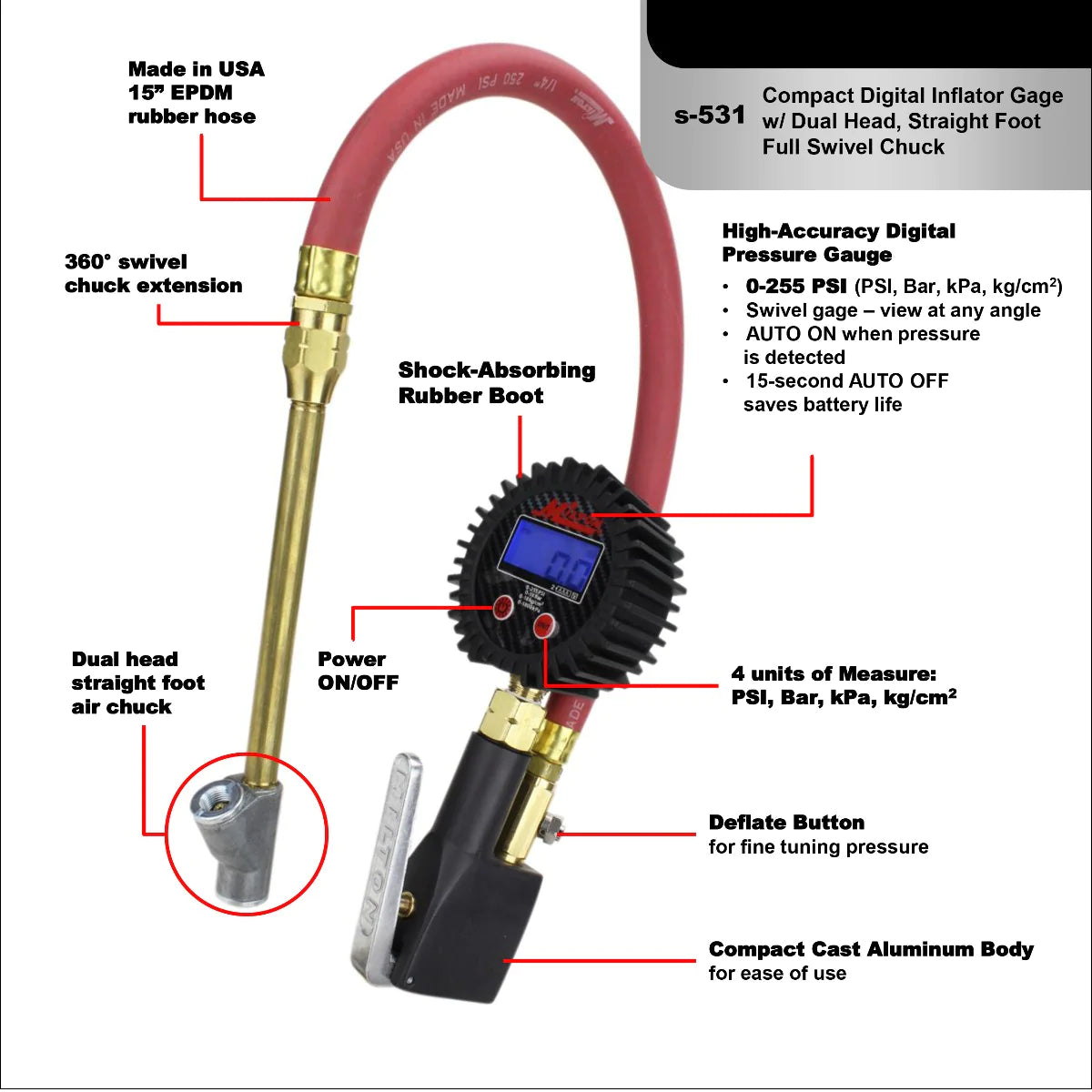

Open flow air chucks are characterized by their ability to allow air to flow continuously as soon as they are connected to an air source. This type of chuck is ideal for general tire inflation in environments such as workshops and garages, where speed and efficiency are crucial. When considering purchasing an open flow air chuck, B2B buyers should evaluate their air compressor’s output and ensure compatibility with their tire inflators to avoid air wastage.

Closed flow air chucks incorporate a check valve that prevents air from flowing unless the chuck is securely connected to the tire valve. This feature makes them particularly useful for precision tasks, such as tire pressure checks and inflation, where minimizing air loss is essential. B2B buyers should consider the operational environment when selecting closed flow chucks, as their slower inflation speed may not be suitable for all applications.

Lock-on air chucks utilize a secure locking mechanism to create a tight seal on the tire valve, which is especially beneficial in high-pressure scenarios. This type of chuck is prevalent in heavy-duty applications, including fleet services and commercial vehicle maintenance. When purchasing lock-on air chucks, buyers should assess the durability of materials and the ease of use, as a tight fit can sometimes require additional effort to attach.

Angled air chucks are designed with a 45-degree nozzle, allowing for easier access to tight or awkwardly positioned tire valves. This design is particularly advantageous in automotive repair shops and for motorcycle maintenance, where space can be limited. B2B buyers should consider the ergonomic benefits and the specific applications where angled chucks can save time and effort during tire maintenance.

Presta valve air chucks are specifically engineered for use with Presta valves, commonly found on high-performance bicycles. These chucks are lightweight and designed for quick inflation, making them essential in bicycle shops and during cycling events. B2B buyers should ensure that their equipment is compatible with Presta valves, as these chucks are not suitable for Schrader valves, which are standard in most automobiles.

| Industria/Sector | Specific Application of air chuck tire inflator | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Automotive Service | Tire maintenance and inflation for passenger vehicles | Enhances vehicle safety and performance | Durability, compatibility with various tire valves |

| Transportation & Logistics | Fleet tire management for trucks and delivery vehicles | Reduces downtime and improves fuel efficiency | Quick-connect features, ease of use, and portability |

| Construction & Heavy Equipment | Inflation of tires on construction machinery and vehicles | Ensures operational efficiency and minimizes accidents | Heavy-duty construction, pressure range, and reliability |

| Agricultura | Tire inflation for farm equipment and vehicles | Optimizes equipment performance and reduces operational costs | Adaptability for different tire sizes and types |

| Bicycle Retail & Repair | Inflation of bike tires in retail settings | Improves customer satisfaction and increases sales | Compatibility with Presta and Schrader valves, portability |

In the automotive service sector, air chuck tire inflators are essential for maintaining optimal tire pressure in passenger vehicles. Service centers utilize these inflators to quickly and accurately inflate tires, which enhances vehicle safety and performance. Buyers in this sector should consider durability and compatibility with various tire valves when sourcing inflators, as these factors ensure reliable service and customer satisfaction.

In the transportation and logistics industry, air chuck tire inflators are crucial for managing tire pressures across fleets of trucks and delivery vehicles. Proper tire inflation reduces fuel consumption and minimizes the risk of tire blowouts, thereby reducing downtime. When sourcing, businesses should prioritize inflators with quick-connect features and ease of use, ensuring that drivers can maintain tire pressure efficiently in various operational conditions.

Construction sites rely on air chuck tire inflators to maintain the tires of heavy machinery, such as bulldozers and excavators. Ensuring that these machines operate with the correct tire pressure is vital for safety and efficiency. Buyers in this industry should seek inflators that are heavy-duty and reliable, with a suitable pressure range to accommodate the demands of rugged environments.

Illustrative image related to air chuck tire inflator

In agriculture, air chuck tire inflators are used to maintain the tires of various farming equipment, including tractors and harvesters. Properly inflated tires improve traction and reduce fuel consumption, leading to cost savings and enhanced productivity. Buyers should focus on inflators that can adapt to different tire sizes and types, ensuring versatility across the diverse machinery used in agricultural operations.

Bicycle retailers and repair shops rely on air chuck tire inflators to quickly inflate bike tires for customers. This service enhances customer satisfaction and can lead to increased sales, as properly inflated tires improve riding performance. Retailers should consider inflators that are compatible with both Presta and Schrader valves and prioritize portability for ease of use in busy shop environments.

El problema: One of the most frustrating challenges B2B buyers face with air chuck tire inflators is the inability to achieve a secure seal on the tire valve. This often results in air loss during inflation, which can lead to increased downtime, wasted resources, and even potential safety hazards if tires are not properly inflated. This issue can be particularly pronounced when dealing with heavy-duty vehicles or specialized equipment that require precise tire pressure. Buyers need reliable tools that can withstand various environmental conditions and deliver consistent performance.

Illustrative image related to air chuck tire inflator

La solución: To address this problem, B2B buyers should consider investing in air chucks with advanced locking mechanisms, such as the “push-to-lock” feature. This design ensures an airtight connection to the tire valve, eliminating air loss during inflation. Additionally, sourcing air chucks with a longer reach can help in accessing difficult-to-reach valve stems, particularly in dually vehicles or trailers. When specifying products, look for durable materials like brass or high-grade aluminum that can withstand heavy use. Moreover, it’s crucial to regularly maintain and inspect the air chuck for wear and tear to prevent leaks and ensure optimal functionality.

El problema: B2B buyers often experience inefficiencies in the tire inflation process, especially in fleet management or automotive service settings. Manual inflation methods can be time-consuming, and using substandard air chucks can exacerbate this issue, leading to longer wait times for service. Inefficiencies not only affect productivity but can also lead to frustration among staff and customers, impacting overall service quality and business reputation.

La solución: To streamline the tire inflation process, companies should explore automatic or digital inflators that integrate seamlessly with high-quality air chucks. These tools can automatically shut off when the desired pressure is reached, reducing the need for constant monitoring and manual intervention. Additionally, consider training staff on the proper use of these inflators to maximize their efficiency. Implementing a standardized procedure for tire inflation can also help minimize errors and ensure consistent results. Investing in a comprehensive set of tire inflators, including various styles (open flow, closed flow, and locking types), will equip teams with the right tools for any situation, ultimately enhancing productivity.

El problema: Another common pain point for B2B buyers is the compatibility of air chucks with different tire types and valve systems, such as Schrader and Presta valves. This is particularly relevant for businesses dealing with a diverse range of vehicles, including cars, motorcycles, and bicycles. Using the wrong type of air chuck can lead to inefficient inflation or even damage to the valve system, resulting in costly repairs and downtime.

La solución: To mitigate compatibility issues, buyers should opt for multi-functional air chucks that can accommodate various valve types. It’s advisable to source products that come with interchangeable heads or attachments designed specifically for different valve systems. Additionally, maintaining a well-organized inventory of air chucks tailored to specific vehicle types can prevent mix-ups and ensure that the right tool is readily available for each task. Regular training sessions can also be beneficial in educating staff about the different valve types and the appropriate air chuck to use for each, minimizing the risk of errors and enhancing operational efficiency.

Illustrative image related to air chuck tire inflator

When selecting materials for air chuck tire inflators, it’s essential to consider properties such as durability, resistance to corrosion, and compatibility with various media. The following analysis covers four common materials used in air chuck manufacturing, providing insights into their performance, advantages, disadvantages, and considerations for international B2B buyers.

Brass is a popular choice for air chucks due to its excellent corrosion resistance and strength. It can withstand high pressures, making it suitable for various tire inflating applications. Brass also offers good thermal conductivity, which can be beneficial in dissipating heat generated during inflation.

Pros: Brass is durable and resistant to rust, which is crucial for maintaining performance in humid or corrosive environments. It is also relatively easy to machine, allowing for complex designs.

Contras: The primary drawback of brass is its cost, which can be higher than other materials like plastic or aluminum. Additionally, brass can be susceptible to dezincification, a form of corrosion in specific environments, which may limit its use in certain applications.

Impacto en la aplicación: Brass is compatible with air and gas applications, making it suitable for tire inflation. However, buyers should ensure that the brass used complies with international standards like ASTM B36 for brass alloys.

Illustrative image related to air chuck tire inflator

Aluminum is another commonly used material for air chucks, known for its lightweight and high strength-to-weight ratio. It is often anodized to enhance corrosion resistance, making it suitable for outdoor and industrial applications.

Pros: The lightweight nature of aluminum allows for easier handling and reduces fatigue during prolonged use. Additionally, aluminum is generally more affordable than brass, making it an attractive option for cost-sensitive buyers.

Contras: While aluminum is corrosion-resistant, it may not be as durable as brass under extreme conditions. It can also be more prone to deformation under high pressure if not properly engineered.

Impacto en la aplicación: Aluminum air chucks are effective for air and gas applications but should be evaluated for compatibility with specific media. Buyers should consider compliance with standards like DIN EN 573 for aluminum alloys.

Illustrative image related to air chuck tire inflator

Steel, particularly stainless steel, is favored for its exceptional strength and durability. It can withstand high pressures and is resistant to wear, making it suitable for heavy-duty applications.

Pros: Steel’s robustness makes it ideal for industrial settings where air chucks are subjected to frequent use. Stainless steel is also resistant to corrosion, which is crucial for maintaining the integrity of the product over time.

Contras: The primary disadvantage of steel is its weight, which can make handling more cumbersome. Additionally, the manufacturing process for steel components can be more complex, potentially increasing production costs.

Impacto en la aplicación: Steel air chucks are versatile and can handle various media, including air and gases. Buyers should ensure compliance with standards such as ASTM A276 for stainless steel products.

Plastic is increasingly used in air chuck designs, particularly for lightweight applications. Common types include nylon and polycarbonate, which offer good chemical resistance.

Pros: Plastic air chucks are lightweight and often less expensive to produce, making them an attractive option for budget-conscious buyers. They also provide good resistance to chemicals and moisture.

Contras: However, plastic may not withstand high pressures as effectively as metals, which limits its application in heavy-duty scenarios. It can also be less durable over time compared to metal options.

Impacto en la aplicación: Plastic air chucks are suitable for low-pressure applications and should be evaluated for compatibility with specific gases. Buyers should consider compliance with relevant standards like ISO 1043 for plastic materials.

Illustrative image related to air chuck tire inflator

| Material | Typical Use Case for air chuck tire inflator | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Brass | General tire inflation | Excellent corrosion resistance | Higher cost, susceptible to dezincification | Alta |

| Aluminio | Lightweight applications | Lightweight and affordable | Less durable under extreme conditions | Medio |

| Acero | Heavy-duty industrial use | Exceptional strength and durability | Heavier and more complex manufacturing process | Media a alta |

| Plástico | Low-pressure applications | Ligero y rentable | Limited pressure resistance and durability | Bajo |

This strategic material selection guide provides valuable insights for B2B buyers looking to choose the right air chuck tire inflator for their specific needs, ensuring compliance with international standards and suitability for various applications.

The manufacturing process for air chuck tire inflators involves several critical stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

The first step in the manufacturing process is the selection and preparation of materials. Air chucks are primarily made from durable metals like brass or steel, which provide the necessary strength and resistance to wear. Manufacturers often source materials that meet international standards to ensure consistency and reliability. The raw materials undergo thorough inspections to check for defects, ensuring that only high-quality materials are used in production.

Once the materials are prepared, they are shaped using various forming techniques. Common methods include machining, casting, and forging. Machining involves cutting the metal into precise shapes and sizes using computer numerical control (CNC) machines, which enhances accuracy. Casting is used for creating complex geometries, while forging improves the material’s structural integrity by altering its grain structure through high pressure and temperature. These techniques are crucial in producing components that can withstand high pressure during tire inflation.

The assembly stage involves putting together all the individual components of the air chuck. This typically includes the body, valve mechanisms, and any additional features such as pressure gauges or locking mechanisms. Skilled technicians perform this assembly, ensuring that each part fits correctly and functions as intended. The use of automated assembly lines can enhance efficiency and reduce the risk of human error.

After assembly, finishing processes are applied to enhance the durability and aesthetics of the product. This may include surface treatments like plating, anodizing, or painting to prevent corrosion and wear. Finishing also involves quality checks to ensure that the product meets the desired specifications before it is packaged and shipped.

Quality assurance is a crucial aspect of the manufacturing process, particularly for B2B suppliers aiming to meet international standards. Manufacturers typically adhere to ISO 9001, which outlines criteria for quality management systems. Compliance with this standard ensures that processes are consistently controlled and improved.

Quality control involves several checkpoints throughout the production process:

Control de calidad entrante (IQC): This stage involves inspecting raw materials and components upon arrival. Any materials that do not meet specified standards are rejected.

Control de calidad durante el proceso (IPQC): During production, regular inspections ensure that processes are being followed correctly and that the products are being manufactured to the required specifications. This may involve measuring dimensions, testing for leaks, and checking for surface defects.

Control de calidad final (CCF): Once the air chuck is fully assembled, a final inspection is conducted to ensure that the product functions correctly and meets all quality standards. This may involve performance testing under simulated conditions.

In addition to ISO 9001, B2B buyers should look for additional certifications that can indicate quality and safety. For instance, the CE mark is essential for products sold in the European market, demonstrating compliance with health, safety, and environmental protection standards. In some sectors, certification from organizations like the American Petroleum Institute (API) may also be relevant, particularly for products used in industrial applications.

B2B buyers looking to verify the quality control practices of their suppliers should consider several approaches:

Conducting Audits: Regular audits of the manufacturing facility can provide insights into the quality management processes and adherence to standards. Buyers can assess the supplier’s compliance with ISO 9001 and other relevant standards during these audits.

Solicitud de informes de calidad: Suppliers should be able to provide documentation detailing their quality control processes and results from recent inspections. This transparency is essential for establishing trust.

Engaging Third-Party Inspection Services: For added assurance, buyers can engage third-party inspection services to conduct independent quality assessments. These inspections can help identify any potential issues before products are shipped.

International buyers, particularly those from diverse markets such as Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances. Different regions may have varying standards and expectations regarding product quality.

Cultural Differences in Quality Expectations: Buyers should understand that cultural perceptions of quality can differ significantly. What is considered acceptable in one region may not meet the standards of another.

Cumplimiento de la normativa: Buyers must ensure that the products comply with local regulations and standards in their respective markets. This may involve understanding specific testing and certification requirements in regions like the EU or Middle Eastern countries.

Supply Chain Considerations: International logistics can introduce additional risks in quality assurance. Buyers should verify that their suppliers have robust supply chain management practices to ensure consistent quality from raw material sourcing to final delivery.

For B2B buyers, understanding the manufacturing processes and quality assurance measures for air chuck tire inflators is crucial. By focusing on material preparation, forming techniques, assembly, and finishing processes, as well as rigorous quality control measures, buyers can make informed decisions. Ensuring compliance with international standards and effectively verifying supplier quality practices will ultimately lead to more reliable products and successful business partnerships.

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure air chuck tire inflators. The aim is to streamline the purchasing process, ensuring that buyers make informed decisions that align with their operational needs and regional requirements. By following these steps, you can effectively evaluate suppliers and products to enhance your inventory of tire inflation tools.

Establishing clear technical specifications is essential before initiating your search for air chuck tire inflators. Consider factors such as the type of vehicles you will be servicing, the required pressure range, and compatibility with existing equipment. This clarity will help you narrow down options and ensure that the inflators meet your operational demands.

Illustrative image related to air chuck tire inflator

Conduct thorough research on potential suppliers to ensure they have a solid reputation and reliable products. Look for established companies with a history in the tire inflator market, particularly those that serve your geographical region.

Quality is non-negotiable when it comes to air chuck tire inflators. Request samples or detailed product specifications to assess material durability, design features, and performance capabilities.

Ensure that your potential suppliers hold necessary certifications and comply with international quality standards. This verification is crucial for minimizing risks associated with product defects and ensuring the safety of your operations.

Once you have identified potential suppliers, request detailed quotations that include not only pricing but also shipping terms, payment options, and lead times. This information is vital for budgeting and planning purposes.

After-sales support can significantly impact your experience with the inflators. Inquire about warranty policies, product training, and technical support availability.

Finally, establish clear communication channels with your chosen supplier. Open lines of communication will facilitate smoother transactions and help address any issues that may arise post-purchase.

Following this checklist will empower B2B buyers to make informed, strategic decisions when sourcing air chuck tire inflators, ultimately enhancing operational efficiency and customer satisfaction.

When sourcing air chuck tire inflators, understanding the breakdown of costs is crucial for effective budgeting and decision-making. The primary cost components include:

Materiales: The quality and type of materials used directly influence the price. Common materials include brass, steel, and plastic. Higher-quality materials typically lead to better durability and performance, which can justify a higher price point.

Trabajo: Labor costs vary significantly depending on the region and manufacturing practices. Skilled labor may increase costs but can result in superior craftsmanship and fewer defects.

Gastos generales de fabricación: This encompasses indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient operations can help minimize these overhead costs.

Herramientas: Investment in tooling is necessary for the production of air chucks. Custom tooling for specialized designs can add to the upfront costs, but it may be essential for achieving specific performance standards.

Control de calidad: Implementing stringent QC processes ensures that each unit meets industry standards. While this adds to the cost, it is vital for maintaining product reliability and avoiding costly returns.

Logística: Shipping and handling costs must be factored into the total cost. This includes transportation fees, tariffs, and handling charges, which can vary based on the supplier’s location and chosen shipping method.

Margen: Suppliers will add their profit margin to the base cost, which can vary widely. Understanding the market average can help buyers negotiate better pricing.

Several factors can influence the pricing of air chuck tire inflators:

Volumen/MOQ: Minimum order quantities (MOQs) and bulk purchasing often lead to lower unit prices. Suppliers are more willing to offer discounts for larger orders, which can significantly reduce the overall cost.

Especificaciones/Personalización: Customized products tailored to specific needs may incur additional costs. Buyers should assess whether the benefits of customization outweigh the higher price.

Materiales y calidad/certificaciones: Products made from premium materials or those with industry certifications (like ISO or CE) will typically command higher prices. Buyers must balance the need for quality with budget constraints.

Factores del proveedor: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their track record, while newer suppliers might offer competitive rates to gain market share.

Incoterms: The choice of Incoterms (International Commercial Terms) can have a substantial impact on logistics costs. Understanding who bears the cost and risk at each stage of shipping can help buyers optimize their total costs.

To ensure a cost-effective sourcing strategy, buyers should consider the following tips:

Negociar con eficacia: Always enter negotiations with a clear understanding of the market rates and your desired price range. Leverage bulk purchasing power to negotiate lower prices.

Centrarse en el coste total de propiedad (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential failure rates. A cheaper product may lead to higher long-term costs due to replacements or repairs.

Understand Pricing Nuances for International Purchases: When sourcing from regions like Africa, South America, the Middle East, or Europe, be aware of potential tariffs, customs duties, and import regulations that can affect the final price.

Manténgase informado sobre las tendencias del mercado: Regularly review market trends and competitor pricing to make informed purchasing decisions. This awareness can provide leverage during negotiations.

Prices for air chuck tire inflators can vary widely based on the aforementioned factors. The figures presented in reference materials are indicative and may fluctuate based on changes in material costs, labor rates, and market demand. Buyers should conduct thorough market research and supplier evaluations to obtain accurate pricing tailored to their specific needs.

In the realm of tire inflation, air chuck tire inflators are a popular choice among professionals and businesses for their efficiency and reliability. However, there are several alternative solutions that can also effectively meet tire inflation needs. Understanding these options can help B2B buyers make informed decisions based on their specific operational requirements and constraints.

| Aspecto comparativo | Air Chuck Tire Inflator | Straight Chuck Tire Inflator | Digital Tire Inflator |

|---|---|---|---|

| Rendimiento | High; suitable for various vehicles | Moderate; best for standard tires | High; often includes automatic shut-off |

| Coste | $15 – $30 depending on features | $21.99 – moderate | $30 – $100, varies by brand |

| Facilidad de aplicación | Simple; compatible with most compressors | Easy; push-on feature | Moderate; requires power source |

| Mantenimiento | Low; minimal upkeep required | Low; durable materials | Moderate; may require battery changes |

| El mejor caso de uso | Heavy-duty applications (trucks, RVs) | General use for standard vehicles | Quick and precise inflation for cars |

Straight Chuck Tire Inflator

The straight chuck tire inflator is a straightforward alternative that features a tapered design for ease of use. Its built-in gauge provides a pressure range of 10 to 90 PSI, making it suitable for standard tires. The 12-inch hose allows access to hidden valve stems, enhancing its utility. However, its performance may be limited when used on larger vehicles or in more demanding environments. Overall, it is a cost-effective option for businesses that primarily service passenger vehicles.

Digital Tire Inflator

Digital tire inflators are gaining popularity due to their technological advantages. Equipped with digital displays, these inflators allow for precise pressure readings and often include features like automatic shut-off when the desired pressure is reached. This can minimize the risk of over-inflation, making them safer for users. While they tend to be more expensive than traditional inflators, their ease of use and accuracy can justify the investment, particularly in environments where tire pressure is critical for safety and performance.

When selecting the appropriate tire inflation solution, B2B buyers should consider their specific operational requirements, including the types of vehicles serviced, frequency of use, and budget constraints. Air chuck tire inflators offer versatility and high performance for heavy-duty applications, while straight chuck inflators provide a simple, cost-effective solution for standard vehicles. Digital tire inflators, though pricier, deliver precision and convenience, making them ideal for businesses that prioritize accuracy. By evaluating these factors, buyers can select the most suitable tire inflation method to enhance their operations.

Understanding the technical properties of air chuck tire inflators is crucial for B2B buyers who aim to make informed purchasing decisions. Here are key specifications that matter:

Calidad del material

Air chucks are typically made from materials like brass, steel, or aluminum. Brass is favored for its corrosion resistance and durability, while steel offers robustness. Material choice impacts the longevity and reliability of the product, which is critical for businesses that rely on frequent tire inflation.

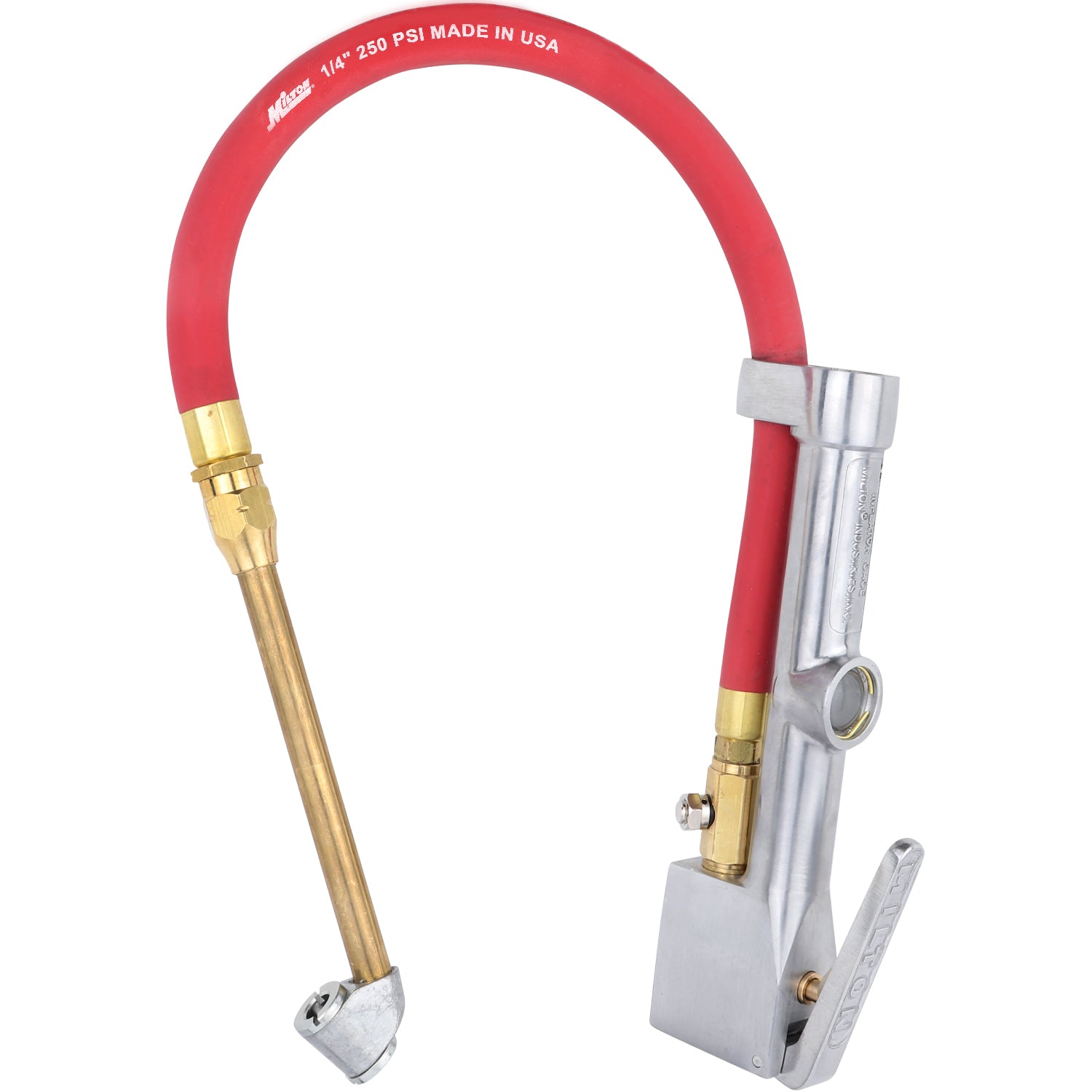

Flow Type: Open vs. Closed

Air chucks come in two primary flow types: open and closed. Open flow chucks allow air to pass through freely, making them suitable for quick inflation tasks, whereas closed flow chucks are designed to prevent air loss until connected to a tire. Understanding this distinction helps businesses select the appropriate type based on their operational needs and efficiency requirements.

Thread Size

Common thread sizes for air chucks include 1/4″ NPT, which is a standard in the industry. The correct thread size ensures compatibility with various hoses and inflators, reducing the risk of air leaks and improving inflation efficiency. Buyers should verify that the thread size matches their existing equipment to avoid costly modifications.

Pressure Rating

The pressure rating indicates the maximum pressure the air chuck can handle, usually expressed in PSI (pounds per square inch). A higher pressure rating is essential for commercial applications, especially in industries dealing with heavy-duty vehicles. Ensuring the chuck meets the required pressure specifications is vital for safety and performance.

Ergonomic Design

Many modern air chucks feature ergonomic designs, such as angled nozzles or thumb plates, to enhance usability. These design elements facilitate easier access to hard-to-reach valve stems, improving efficiency in high-volume tire inflation scenarios. For businesses, investing in ergonomic tools can lead to increased productivity and employee satisfaction.

Locking Mechanisms

Some air chucks incorporate locking mechanisms to secure the connection to the tire valve. This feature prevents accidental air loss during inflation, ensuring a consistent and efficient process. For B2B buyers, this translates to time savings and reduced operational costs.

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are several important terms:

Illustrative image related to air chuck tire inflator

OEM (fabricante de equipos originales)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems.

MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for businesses looking to manage inventory and costs effectively. Knowing the MOQ helps in budgeting and planning procurement strategies.

RFQ (solicitud de presupuesto)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is vital for comparing prices and terms among different suppliers, enabling businesses to make cost-effective decisions.

Incoterms (Términos comerciales internacionales)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps businesses navigate shipping, insurance, and risk management, which is particularly important for international buyers from diverse regions.

Plazos de entrega

Lead time refers to the time taken from placing an order to its delivery. Knowing the lead time is essential for planning and ensuring that products arrive when needed, especially in industries that require just-in-time inventory.

Garantía

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the product. Understanding warranty terms is essential for B2B buyers as it impacts long-term costs and product reliability.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the best air chuck tire inflators for their operational needs.

The air chuck tire inflator market is witnessing significant transformations driven by technological advancements, increased vehicle ownership, and the rising need for efficient tire maintenance. Globally, the demand for air chucks is propelled by the growing automotive industry, particularly in emerging markets in Africa, South America, and parts of Asia such as Vietnam. These regions are experiencing a surge in vehicle sales, leading to greater requirements for tire inflators and maintenance tools.

In recent years, the incorporation of smart technology has become a notable trend. Many manufacturers are integrating digital pressure gauges and automatic shut-off features in tire inflators, enhancing user convenience and safety. Additionally, the trend toward mobile and compact designs caters to the needs of consumers seeking portability and ease of use, especially in urban settings where space is at a premium.

Illustrative image related to air chuck tire inflator

Furthermore, the rise of e-commerce platforms has transformed sourcing channels for international B2B buyers, allowing them to access a wider variety of products and suppliers. Buyers can now evaluate options across global markets, facilitating competitive pricing and innovation. Sustainability is also becoming a critical consideration, with suppliers increasingly focusing on environmentally friendly materials and manufacturing processes.

Sustainability and ethical sourcing are becoming paramount in the air chuck tire inflator sector as environmental awareness rises among consumers and businesses alike. The production of air chucks and tire inflators often involves materials and processes that can have significant ecological impacts. Consequently, international B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainability through responsible sourcing practices.

Buyers are increasingly seeking products that utilize recycled materials and sustainable manufacturing methods. Certifications such as ISO 14001 (Environmental Management) or other green certifications are becoming essential criteria for evaluating suppliers. Furthermore, the use of eco-friendly packaging and reduced carbon footprints in logistics are becoming critical factors influencing purchasing decisions.

Ethical supply chains are not just about environmental impact; they also encompass fair labor practices and transparency. Buyers are now more inclined to partner with suppliers who can provide clear insights into their sourcing processes and labor conditions, ensuring that their products align with their corporate social responsibility goals.

Illustrative image related to air chuck tire inflator

The evolution of air chuck tire inflators dates back to the early days of automotive innovation. Initially designed as simple mechanical devices, air chucks have transformed into sophisticated tools with enhanced functionalities. The introduction of pneumatic systems in vehicles increased the demand for reliable tire maintenance tools, leading to the development of more advanced inflators.

Over the decades, improvements in material science have enabled manufacturers to produce durable and lightweight products, enhancing usability and efficiency. The integration of technology, such as digital pressure displays and automatic inflation features, reflects the ongoing trend toward automation and user-friendliness in the automotive sector.

Today, the air chuck tire inflator market is characterized by a blend of traditional craftsmanship and modern technology, catering to a diverse range of consumer needs—from casual users to professional mechanics. This evolution is crucial for B2B buyers looking for products that not only meet performance standards but also align with contemporary expectations for sustainability and ethical sourcing.

1. How do I choose the right air chuck tire inflator for my business needs?

Selecting the right air chuck tire inflator involves assessing your specific requirements, such as the types of vehicles you service, the range of tire pressures you need to accommodate, and the inflator’s compatibility with your existing equipment. Consider the design features, like the type of flow (open or closed), reach of the nozzle, and durability of materials. For B2B operations, prioritize products that offer ease of use and maintenance, as well as those that provide optimal performance in demanding environments, ensuring they meet international safety and quality standards.

2. What are the key features to look for in a tire inflator for commercial use?

When sourcing a tire inflator for commercial use, focus on features such as a built-in pressure gauge for accurate measurements, a durable construction to withstand heavy use, and compatibility with various tire valve types. Additionally, consider the length of the hose for accessibility, whether the chuck has a locking mechanism for secure attachment, and if it supports both closed and open flow designs. These features will enhance efficiency and reliability, which are crucial for maintaining high productivity levels in a business setting.

3. What are the typical payment terms for B2B purchases of air chuck tire inflators?

Payment terms for B2B purchases can vary significantly based on the supplier and the buyer’s relationship. Common terms include net 30, net 60, or even payment in advance for first-time orders. It is essential to clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit, especially for international transactions. Always negotiate terms that suit your cash flow while ensuring the supplier is comfortable with the arrangement to foster a good working relationship.

4. How can I ensure the quality of air chuck tire inflators from international suppliers?

To ensure quality, conduct thorough supplier vetting by checking their certifications, such as ISO standards, and requesting samples before placing bulk orders. It’s also advisable to read reviews or testimonials from other businesses that have sourced similar products. Consider collaborating with suppliers who offer warranties or guarantees on their products. Additionally, arranging third-party quality inspections during manufacturing and prior to shipment can help mitigate risks associated with product quality.

5. What is the minimum order quantity (MOQ) for air chuck tire inflators?

Minimum order quantities (MOQs) for air chuck tire inflators can vary based on the manufacturer and the specific model. Typically, MOQs can range from as low as 50 to several hundred units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are a smaller business or new to the market. Some suppliers may offer lower MOQs for first-time buyers or allow for a mixed order of different models to meet MOQ requirements.

6. How do logistics and shipping impact the cost of air chuck tire inflators?

Logistics and shipping significantly influence the overall cost of air chuck tire inflators, particularly for international buyers. Factors to consider include shipping method (air vs. sea), freight rates, customs duties, and insurance. It’s crucial to evaluate the total landed cost, which encompasses product price, shipping fees, and any additional charges incurred during transit. Collaborating with a reliable freight forwarder can help streamline the process and potentially reduce costs through better shipping rates and efficient customs handling.

7. What customization options are available for air chuck tire inflators?

Many manufacturers offer customization options for air chuck tire inflators, including branding, color choices, and specific features tailored to your business needs. Customization can enhance brand recognition and ensure the product aligns with your operational requirements. When discussing customization with suppliers, be clear about your specifications and inquire about associated costs and lead times. It’s advisable to request prototypes or mock-ups to evaluate the customizations before committing to a larger order.

8. What are the common challenges when sourcing air chuck tire inflators internationally?

Sourcing air chuck tire inflators internationally may present challenges such as navigating different regulations, language barriers, and varying quality standards. Additionally, issues with logistics, including shipping delays and customs clearance, can impact delivery timelines. To mitigate these challenges, establish clear communication with suppliers, understand the regulatory landscape in both your country and the supplier’s, and consider working with local representatives or agents who can assist with the process.

Dominio: jacosuperiorproducts.com

Registrado: 2014 (11 años)

Introducción: – Lightning™ T-Series Tire Air Chuck: Open Flow, 1/4″ F-NPT, $29.99 (originally $49.99), 7 inch extended neck for hard-to-access valve stems.

– Dually Tire Air Chuck: Closed Flow, 1/4″ NPT, $14.95 (originally $19.99), integrates check valves for tire gauges or air compressor lines.

– Lightning™ S-Series Tire Air Chuck: Open Flow, 1/4″ F-NPT, $16.99 (originally $29.99), no check valve, air flows fr…

As the demand for high-quality air chuck tire inflators continues to grow globally, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing has never been more crucial for B2B buyers. Key takeaways highlight the importance of selecting durable, efficient, and versatile inflators to meet diverse market needs. Investing in products with advanced features, such as locking mechanisms and extended reach, enhances operational efficiency and customer satisfaction.

Illustrative image related to air chuck tire inflator

Furthermore, understanding regional preferences and compliance standards can significantly improve sourcing decisions, allowing businesses to tailor their offerings and maintain competitive advantages. By leveraging reliable suppliers and fostering long-term partnerships, B2B buyers can ensure a steady supply of innovative products that align with market trends.

Looking ahead, it is essential for international buyers to actively seek out suppliers who demonstrate a commitment to quality and sustainability. Embracing these principles not only positions your business for success but also contributes to a more responsible industry. Take action now by evaluating your sourcing strategy and engaging with suppliers who can provide the reliability and innovation necessary to thrive in this dynamic market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.