Navigating the complexities of sourcing fast tire inflators can be a daunting task for international B2B buyers, especially in dynamic markets across Africa, South America, the Middle East, and Europe. With the increasing demand for efficient and reliable tire maintenance solutions, understanding the nuances of tire inflator technologies is essential. This guide offers a comprehensive overview of various types of fast tire inflators, their applications, and critical factors to consider when making purchasing decisions.

From portable inflators suitable for individual vehicles to heavy-duty models designed for commercial use, this guide delves into the specifications and performance metrics that matter most. We’ll explore the importance of supplier vetting, ensuring that you partner with reputable manufacturers who can deliver quality products consistently. Additionally, we will examine cost considerations, helping you balance budget constraints with the need for durability and efficiency.

Equipped with actionable insights, this guide empowers B2B buyers to make informed decisions that enhance operational efficiency and customer satisfaction. By understanding the features, benefits, and potential applications of fast tire inflators, you can streamline your procurement process and ensure that your fleet or service offering remains competitive in the global market. Whether you’re based in Brazil, Nigeria, or anywhere in between, this resource will be your trusted companion in navigating the fast tire inflator landscape.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

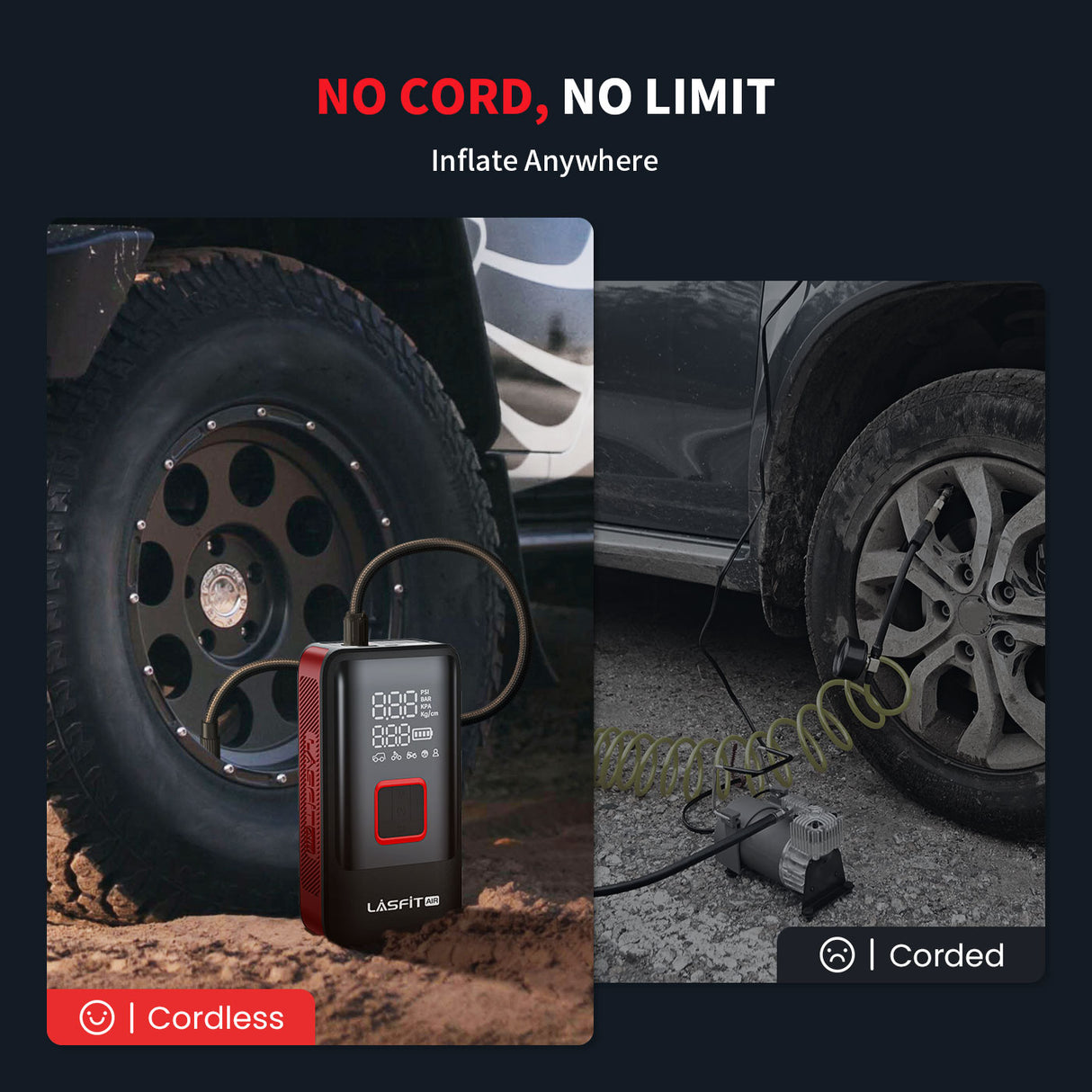

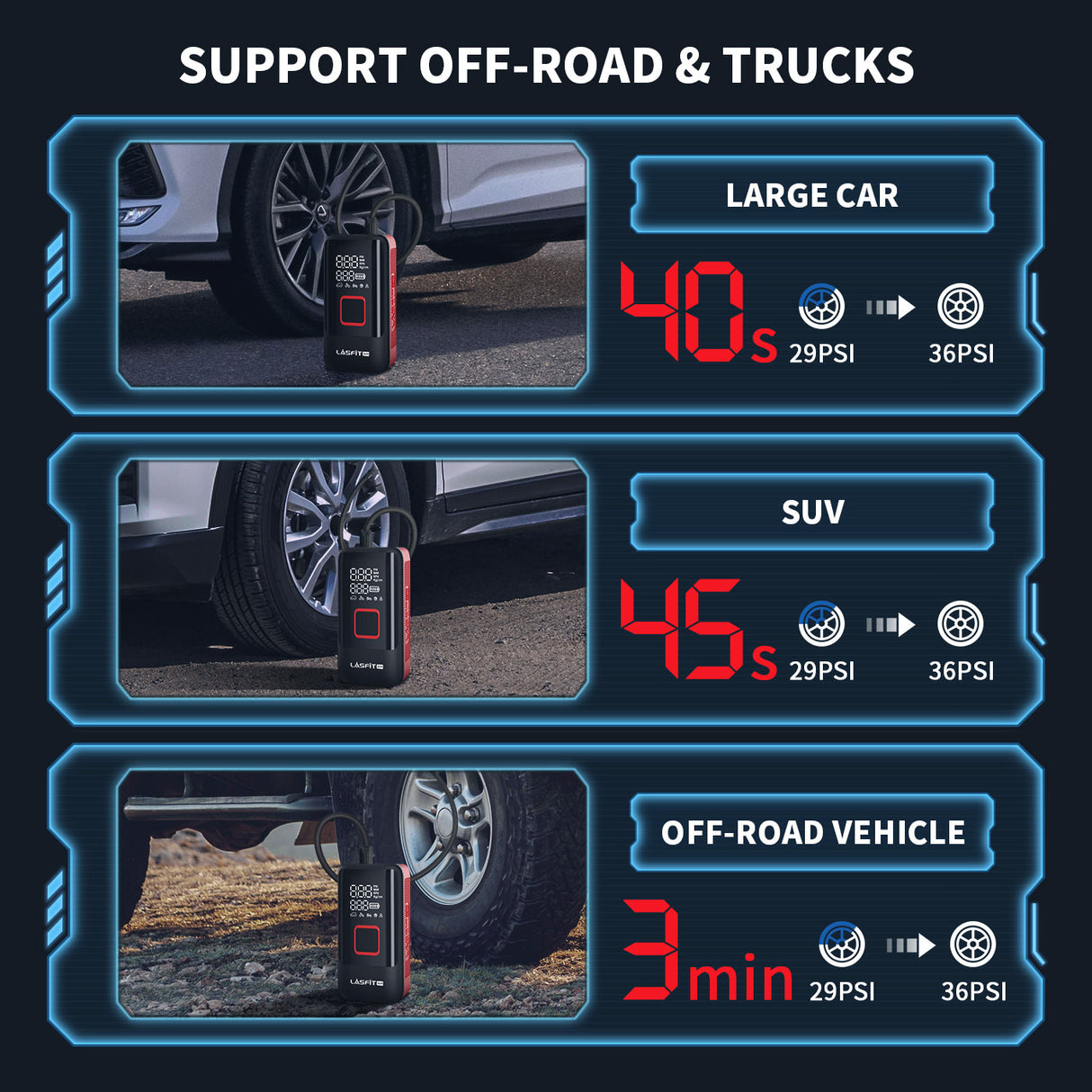

| Cordless Tire Inflators | Battery-operated, portable, easy to use | Automotive repair shops, roadside assistance | Pros: Highly portable, easy to use. Contras: Limited battery life, may require multiple charges for larger tires. |

| 12V Tire Inflators | Connects to vehicle’s 12V outlet, compact design | Fleet maintenance, emergency services | Pros: Continuous power supply, can inflate larger tires. Contras: Requires vehicle access, less portable. |

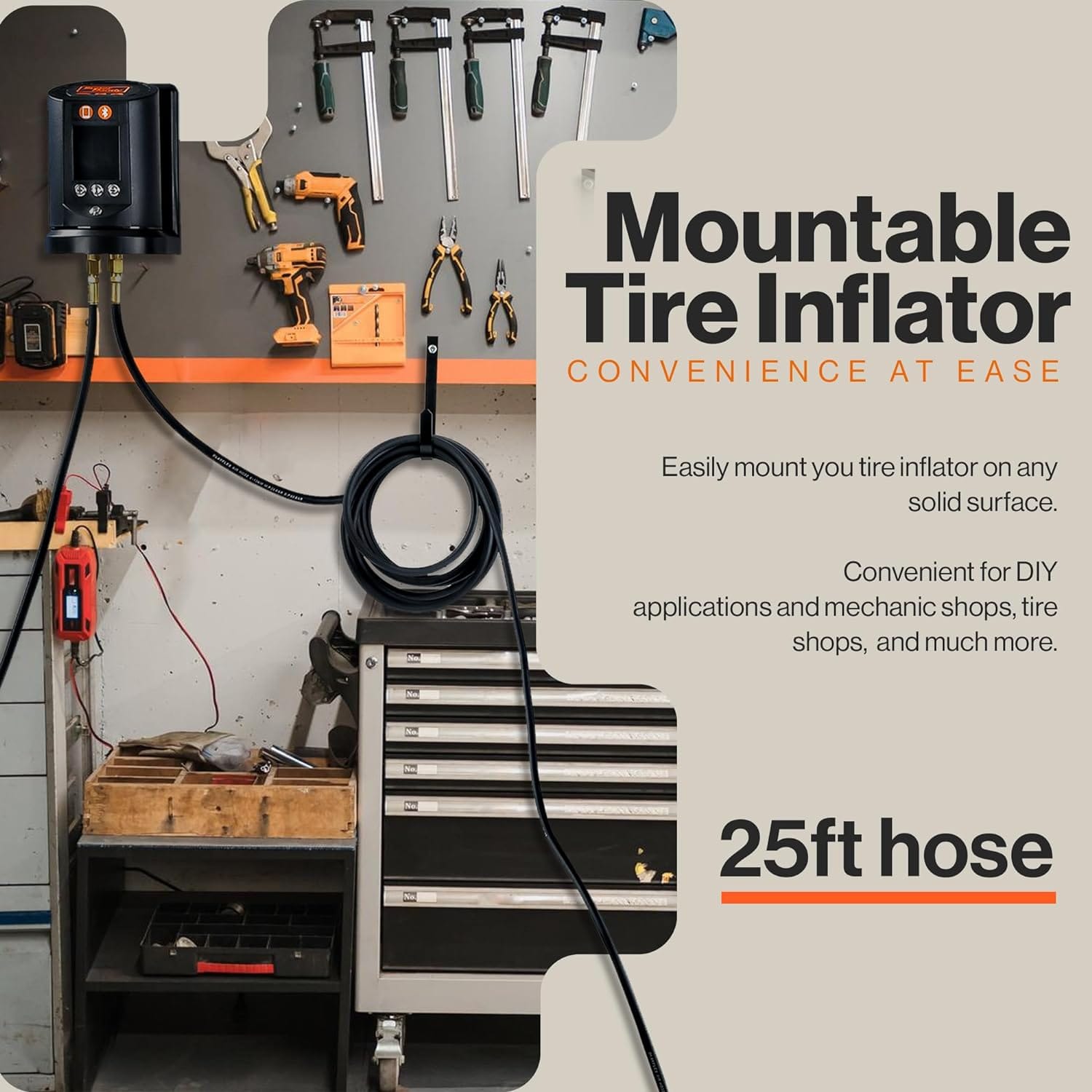

| Heavy-Duty Tire Inflators | Designed for high-pressure applications, rugged build | Construction, agricultural machinery | Pros: Fast inflation for large tires, robust design. Contras: Bulkier, often more expensive. |

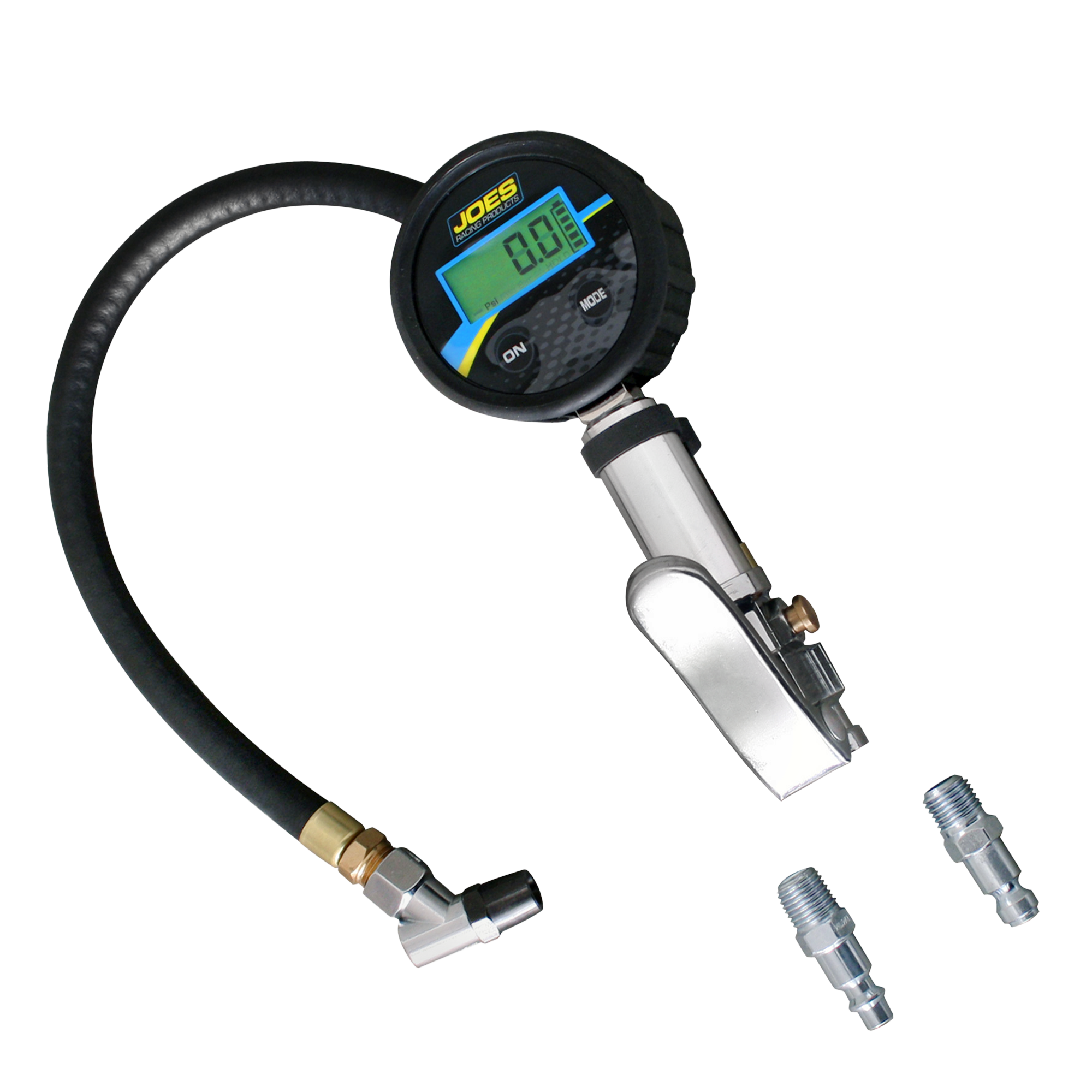

| Digital Tire Inflators | Digital pressure gauges, preset pressure settings | Automotive dealerships, tire retailers | Pros: Accurate readings, easy to set desired pressure. Contras: May be pricier than analog models. |

| Compact Tire Inflators | Ultra-portable, lightweight, designed for small spaces | Personal use, motorcycle shops | Pros: Convenient storage, ideal for quick fixes. Contras: Limited capacity, may not handle larger tires well. |

Cordless tire inflators are battery-operated tools that provide exceptional portability and ease of use, making them ideal for B2B applications such as automotive repair shops and roadside assistance services. They typically allow users to inflate tires without being tethered to a power source. However, their battery life may limit their effectiveness for inflating larger tires, necessitating a careful assessment of battery capacity when making a purchasing decision.

12V tire inflators connect directly to a vehicle’s 12V outlet, offering a continuous power supply. This feature makes them suitable for fleet maintenance and emergency services where quick and reliable tire inflation is essential. While they can handle larger tires more effectively than cordless models, their reliance on vehicle access can be a drawback in certain situations, making it crucial for buyers to consider their operational environments.

Heavy-duty tire inflators are designed for high-pressure applications, making them indispensable in industries such as construction and agriculture. These inflators can quickly inflate large tires, ensuring minimal downtime for machinery and vehicles. However, their bulkier design and higher price point can be a consideration for B2B buyers. Evaluating the specific needs of the business will help determine if the investment is justified.

Digital tire inflators come equipped with digital pressure gauges and preset pressure settings, providing a high level of accuracy and user convenience. These inflators are particularly beneficial for automotive dealerships and tire retailers where precise inflation is critical. While they tend to be more expensive than analog models, the investment can lead to increased efficiency and reduced errors in tire maintenance.

Compact tire inflators are ultra-portable and lightweight, making them perfect for personal use and motorcycle shops that require quick tire fixes. Their small size allows for convenient storage in tight spaces, but they may have limited capacity for larger tires. B2B buyers should weigh the trade-offs between portability and functionality to ensure they select a model that aligns with their operational needs.

Illustrative image related to fast tire inflator

| Industria/Sector | Specific Application of fast tire inflator | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Talleres de reparación de automóviles | Quick tire inflation for customer vehicles | Reduces wait time, enhances customer satisfaction | Reliability, ease of use, and speed of inflation |

| Logistics and Transportation | Maintenance of fleet vehicles’ tire pressure | Increases fuel efficiency and extends tire lifespan | Durability, portability, and compatibility with various vehicle types |

| Construction and Heavy Equipment | Inflation of construction vehicle tires | Minimizes downtime and ensures operational efficiency | Robustness, high-pressure capability, and power source options |

| Sports and Recreation | Inflating recreational vehicle tires and equipment | Enhances safety and performance during activities | Compact size, battery life, and versatility for different inflatables |

| Agricultura | Tire maintenance for farming machinery | Reduces operational delays and improves productivity | Adaptability to various tire sizes and ease of transport |

In automotive repair shops, fast tire inflators are essential tools for quickly addressing customer needs. These inflators allow technicians to swiftly inflate tires, reducing wait times for customers and improving overall service efficiency. Buyers in this sector should prioritize inflators that are reliable, easy to use, and capable of delivering high inflation speeds. The ability to handle multiple tire sizes and types is crucial, especially in regions like Africa and South America, where diverse vehicle models are common.

In the logistics and transportation industry, maintaining optimal tire pressure is vital for fleet vehicles. Fast tire inflators are used to quickly address tire pressure issues, which can significantly enhance fuel efficiency and prolong tire life. Businesses in this sector should consider inflators that are durable and portable, as they may need to be used in various locations, including remote areas. Compatibility with different vehicle types is also a key factor, particularly in regions with varying vehicle specifications.

Fast tire inflators are critical in the construction sector, where machinery often operates in challenging environments. These inflators ensure that construction vehicles maintain proper tire pressure, minimizing downtime due to flat tires. Buyers should look for inflators that are robust and capable of high-pressure inflation, as construction vehicles typically require more air than standard passenger vehicles. The ability to operate in harsh conditions is essential, especially in regions like the Middle East where dust and heat can affect equipment performance.

In the sports and recreation industry, fast tire inflators are utilized to maintain the tire pressure of recreational vehicles, such as ATVs and bicycles, as well as inflatables like boats and rafts. Proper inflation enhances safety and performance during recreational activities. Buyers should seek compact and lightweight inflators with good battery life, as these features allow for easy transport and use in outdoor settings. Versatility in inflating different types of equipment is also a significant consideration for B2B buyers.

In agriculture, fast tire inflators are essential for maintaining the tire pressure of farming machinery, which can significantly impact productivity. These inflators help farmers quickly address tire issues, reducing operational delays during critical farming periods. Buyers in this sector should prioritize inflators that can adapt to various tire sizes and are easy to transport across large agricultural fields. Efficiency and reliability are key, especially in regions like Brazil and Nigeria, where agricultural activities are often time-sensitive.

El problema: In sectors such as logistics and transportation, downtime due to flat tires can significantly impact operational efficiency. B2B buyers, particularly in industries like freight and delivery, face the challenge of ensuring their fleet is always ready to go. A flat tire not only delays deliveries but can also lead to financial losses and decreased customer satisfaction. The traditional inflators may take too long or be cumbersome to use, making the situation worse during emergencies.

La solución: To address this issue, B2B buyers should invest in high-performance fast tire inflators that are designed for quick response. When sourcing a tire inflator, look for models that can inflate a flat tire in under 10 minutes, such as the AstroAI Cordless Tire Inflator, which boasts rapid inflation times and user-friendly features. It’s essential to select a product that can operate on both battery and vehicle power, ensuring versatility in various situations. Additionally, incorporating a routine maintenance schedule that includes regular checks of tire pressures will help preemptively address issues before they escalate into emergencies.

El problema: Companies with mixed fleets, including cars, vans, and heavy trucks, often struggle with maintaining optimal tire pressure across various vehicle types. This challenge is compounded by differing psi requirements for each vehicle, which can lead to confusion and inefficiency in operations. Inconsistent tire pressure not only reduces fuel efficiency but also increases wear and tear on tires, leading to more frequent replacements and higher operational costs.

Illustrative image related to fast tire inflator

La solución: To streamline tire management, B2B buyers should consider investing in fast tire inflators that come with digital pressure gauges and pre-set inflation settings. This feature allows users to set the desired psi for different vehicle types, eliminating guesswork and ensuring that tires are inflated correctly every time. When selecting an inflator, prioritize models that can accommodate a wide range of pressures—some should be capable of reaching up to 160 psi for heavy-duty vehicles. Additionally, consider creating a standardized training program for staff to familiarize them with the inflator’s features and proper usage, ensuring that every team member can effectively manage tire pressures.

El problema: Industries that rely on heavy-duty vehicles, such as construction and agriculture, require equipment that can withstand harsh conditions. Many fast tire inflators on the market may not be built for heavy use, leading to frequent breakdowns or malfunctions. B2B buyers in these sectors face the risk of downtime due to unreliable inflators that cannot meet the demanding needs of their operations.

La solución: To combat reliability issues, B2B buyers should focus on sourcing fast tire inflators that are specifically designed for heavy-duty applications. Look for inflators with robust construction, such as the Viair 88P, which is known for its durability and quick inflation capabilities. Additionally, consider the inflator’s duty cycle—models with longer duty cycles can handle continuous use without overheating. It’s also beneficial to establish relationships with suppliers who offer warranties and support services, ensuring that if an inflator does fail, repairs or replacements can be expedited to minimize downtime. Regularly reviewing equipment performance and soliciting feedback from end-users can help identify any weaknesses and foster continuous improvement in tire management practices.

Illustrative image related to fast tire inflator

Selecting the right materials for fast tire inflators is crucial for ensuring optimal performance, durability, and user satisfaction. Below, we analyze several common materials used in the manufacturing of fast tire inflators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is frequently used in the casing and internal components of tire inflators.

Propiedades clave: Plastics offer excellent resistance to corrosion and can withstand a range of temperatures, making them suitable for various climates. They are lightweight, which enhances portability.

Ventajas e inconvenientes: The durability of plastics can vary; while they are resistant to impact, they may not withstand extreme temperatures as well as metals. Cost-wise, plastics are generally low to medium, making them an economical choice. However, manufacturing complexity can increase if intricate designs are required.

Impacto en la aplicación: Plastics are compatible with air and do not react with the gases typically found in tires. However, they may not be suitable for high-pressure applications beyond a certain threshold.

Illustrative image related to fast tire inflator

Consideraciones para compradores internacionales: Buyers in regions like Africa and South America should ensure compliance with local standards regarding material safety and environmental impact, as regulations can differ significantly.

Aluminum is often used for components requiring a balance of strength and weight, such as the body of the inflator or internal mechanisms.

Propiedades clave: Aluminum has a high strength-to-weight ratio and excellent corrosion resistance, particularly when anodized. It can handle higher pressures than most plastics.

Ventajas e inconvenientes: While aluminum is durable and lightweight, it can be more expensive than plastic. The manufacturing process is generally straightforward, but recycling can be more complex than for plastics.

Illustrative image related to fast tire inflator

Impacto en la aplicación: Aluminum components can handle high-pressure environments, making them suitable for inflators designed for larger vehicles or heavy-duty applications.

Consideraciones para compradores internacionales: Compliance with standards such as ASTM or DIN is essential, especially in Europe. Buyers should also consider the availability of aluminum in their region, as sourcing can affect lead times and costs.

Steel is commonly used in tire inflators, particularly for components that require high strength and durability, such as pressure chambers.

Propiedades clave: Steel offers exceptional strength and can withstand high pressures, making it ideal for heavy-duty applications. It also has good thermal conductivity.

Ventajas e inconvenientes: While steel is highly durable, it is heavier than aluminum and plastic, which can affect portability. The cost is generally medium to high, and manufacturing can be complex due to the need for precision engineering.

Illustrative image related to fast tire inflator

Impacto en la aplicación: Steel is compatible with air and can handle high-pressure situations, making it suitable for inflators designed for trucks and SUVs.

Consideraciones para compradores internacionales: Buyers should be aware of corrosion resistance, especially in humid or coastal regions. Compliance with local standards is also critical, as steel quality can vary by region.

Rubber is primarily used for seals and hoses in tire inflators due to its flexibility and durability.

Propiedades clave: Rubber can withstand a wide range of temperatures and provides excellent sealing capabilities to prevent air leaks.

Illustrative image related to fast tire inflator

Ventajas e inconvenientes: While rubber is effective in sealing, it can degrade over time, especially when exposed to UV light or extreme temperatures. The cost is generally low, making it an economical choice for manufacturers.

Impacto en la aplicación: Rubber is compatible with air and provides a reliable seal, essential for maintaining tire pressure. However, its lifespan may be a concern in harsh environments.

Consideraciones para compradores internacionales: Buyers should ensure that the rubber used meets international standards for durability and safety, particularly in regions with extreme weather conditions.

| Material | Typical Use Case for fast tire inflator | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plástico | Casing and internal components | Ligero y resistente a la corrosión | Capacidad limitada de alta presión | Bajo |

| Aluminio | Body and internal mechanisms | Elevada relación resistencia/peso | More expensive than plastic | Medio |

| Acero | Pressure chambers | Exceptional strength | Heavier and complex manufacturing | Media a alta |

| Goma | Seals and hoses | Excelente capacidad de sellado | Degrades over time in harsh conditions | Bajo |

This strategic material selection guide provides a comprehensive overview to assist B2B buyers in making informed decisions regarding fast tire inflators, taking into account performance, cost, and regional considerations.

The production of fast tire inflators involves several critical stages, each aimed at ensuring the final product meets both performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

The manufacturing process begins with material selection, where high-quality plastics and metals, such as aluminum for the casing and rubber for the seals, are chosen for their durability and lightweight properties. Material preparation involves cutting, molding, and treating these raw materials to enhance their performance characteristics. For instance, plastic components may undergo injection molding, while metal parts might be stamped or machined to precise specifications.

Forming techniques play a vital role in shaping the components of tire inflators. Injection molding is the most common technique for producing plastic parts, allowing for intricate designs and uniform thickness. For metal components, processes such as die-casting or CNC machining are employed to ensure accuracy and consistency. These techniques not only affect the aesthetic appeal but also the functionality, ensuring that each inflator can withstand the pressures and conditions it will face in the field.

The assembly process involves bringing together all the components, including the motor, pump, pressure gauge, and casing. This stage may involve manual labor or automated assembly lines, depending on the scale of production. Workers or machines perform checks at this stage to ensure that parts fit correctly and function as intended. For example, the integration of the electronic pressure gauge must be precise to ensure accurate readings.

Illustrative image related to fast tire inflator

Finishing processes enhance the aesthetic and functional quality of the inflators. This may include surface treatments such as painting, powder coating, or adding protective layers to prevent corrosion. Additionally, branding elements are applied, ensuring that the product aligns with the company’s identity. Quality checks during this stage ensure that the final product is visually appealing and free from defects.

Quality assurance is paramount in the manufacturing of fast tire inflators, especially for international markets. Adherence to established standards like ISO 9001 ensures that manufacturers maintain consistent quality across their production processes. This standard focuses on a quality management system that emphasizes continuous improvement and customer satisfaction.

In addition to ISO 9001, compliance with industry-specific standards such as CE marking for safety and environmental requirements is crucial. For tire inflators intended for specific markets, certifications from organizations like the American Petroleum Institute (API) may also be necessary, especially for products designed for commercial or heavy-duty applications.

Quality control (QC) is integrated at various stages of the manufacturing process, ensuring that each inflator meets the required specifications.

Incoming Quality Control (IQC) involves inspecting raw materials and components upon arrival at the manufacturing facility. This step is essential to verify that materials meet predetermined quality standards before they are used in production. Suppliers should provide certificates of conformity or material safety data sheets to facilitate this process.

In-Process Quality Control (IPQC) occurs during manufacturing, where specific checkpoints are established to monitor the production process. This may include verifying the accuracy of molding machines or the proper assembly of components. Regular audits during this phase help catch defects early, reducing waste and rework.

Final Quality Control (FQC) is performed on completed tire inflators before they are packaged for shipment. This includes functional testing, where each inflator is checked for performance, durability, and safety. Tests may simulate real-world conditions, such as measuring inflation speed and accuracy under various loads.

For international B2B buyers, ensuring that suppliers adhere to rigorous quality control practices is vital.

Conducting supplier audits provides an opportunity to assess the quality management systems in place. Buyers can verify compliance with international standards and evaluate the effectiveness of the supplier’s quality assurance processes. Audits can be performed by the buyer’s quality team or through third-party inspectors who specialize in manufacturing practices.

Requesting quality control reports from suppliers can give buyers insights into the manufacturer’s performance metrics, defect rates, and compliance with standards. These reports often include data from IQC, IPQC, and FQC stages, providing a comprehensive view of the product’s journey through the manufacturing process.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Each market may have specific requirements that differ from international norms. Buyers should work closely with suppliers to ensure that all regional compliance issues are addressed, which may involve additional certifications or testing.

Illustrative image related to fast tire inflator

The manufacturing and quality assurance processes for fast tire inflators are complex and critical to delivering reliable products to the market. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet international standards and specific regional requirements. As the demand for efficient and durable tire inflators grows, so too does the importance of rigorous manufacturing and quality assurance practices.

This guide serves as a comprehensive checklist for B2B buyers aiming to procure fast tire inflators. Given the increasing demand for reliable tire maintenance solutions across various industries, it’s essential to ensure that your sourcing process is efficient and effective. By following these steps, you can make informed decisions that align with your operational needs and budget constraints.

Establish clear technical specifications for the tire inflators you wish to purchase. Consider factors such as the maximum pressure required (e.g., up to 80 psi for trucks), power source options (cordless vs. corded), and desired features like built-in pressure gauges or additional adapters. A well-defined specification ensures that the inflators will meet your operational needs and performance expectations.

Stay informed about the latest market trends and product reviews related to tire inflators. Look for expert evaluations and user feedback to identify which models consistently perform well. Platforms like MotorTrend provide insights into product reliability and effectiveness, which can help you narrow down your options and avoid subpar products.

Before finalizing a supplier, conduct a thorough evaluation. Request detailed company profiles, product catalogs, and case studies from similar industries. It’s vital to check references from other buyers to gauge supplier reliability and customer service quality. This step minimizes the risk of procurement issues down the line.

Illustrative image related to fast tire inflator

Ensure that the tire inflators comply with relevant industry standards and certifications. This might include safety certifications or quality assurance marks. Compliance not only guarantees product safety but also enhances the credibility of your purchase, especially when dealing with international suppliers.

Evaluate the warranty terms and after-sales support offered by the supplier. A robust warranty can protect your investment against defects, while reliable after-sales support ensures that you have access to maintenance and repairs if needed. Inquire about the supplier’s response times and the availability of replacement parts.

Negotiate bulk pricing and favorable payment terms with your chosen supplier. Many suppliers offer discounts for larger orders, which can significantly reduce your overall costs. Understanding payment options—such as credit terms or upfront payments—can also help manage cash flow effectively.

Discuss logistics and delivery schedules with your supplier to ensure timely procurement. Consider factors such as shipping times, customs clearance (for international orders), and delivery methods. A well-planned logistics strategy minimizes delays and ensures that you have the inflators on hand when needed.

Illustrative image related to fast tire inflator

By following this checklist, B2B buyers can streamline their sourcing process for fast tire inflators, ensuring that they make informed decisions that align with their operational requirements.

When considering the sourcing of fast tire inflators, it’s essential to understand the fundamental cost components involved in the manufacturing process. The primary elements include:

Several factors can influence the pricing of fast tire inflators, impacting how international B2B buyers approach sourcing:

Illustrative image related to fast tire inflator

To maximize value when sourcing fast tire inflators, buyers should adopt effective negotiation strategies:

International buyers should be aware of specific pricing nuances when sourcing fast tire inflators:

Prices for fast tire inflators can vary widely based on specifications, order size, and supplier relationships. The figures provided in this analysis are indicative and should be verified with suppliers for accurate quotes tailored to specific requirements.

In the realm of tire maintenance, the need for efficient inflation solutions is critical for vehicle performance and safety. While fast tire inflators have gained popularity due to their convenience and speed, various alternative methods and technologies exist that also serve the purpose of tire inflation. Understanding these alternatives can help B2B buyers make informed decisions based on their specific operational needs, budget constraints, and the environments in which they operate.

| Aspecto comparativo | Fast Tire Inflator | Compresor de aire portátil | Manual Pump |

|---|---|---|---|

| Rendimiento | Quick inflation (up to 80 psi) | High volume, versatile use | Slower, limited to low psi |

| Coste | $40 – $90 | $50 – $150 | $20 – $50 |

| Facilidad de aplicación | Very easy, plug-and-play | Requires setup and power source | Requires manual effort |

| Mantenimiento | Low maintenance | Moderado, depende del uso | Minimal, mechanical wear |

| El mejor caso de uso | Personal vehicles, emergencies | Workshops, heavy-duty vehicles | Bicycles, low-pressure needs |

Portable air compressors provide a versatile solution for tire inflation and other pneumatic needs. They can deliver high volumes of air and are capable of inflating tires to higher pressures, making them suitable for a range of vehicles, including trucks and SUVs. While they tend to be more expensive than fast tire inflators and may require more setup (like connecting to a power source), they are highly efficient for businesses with diverse inflation requirements. However, their bulkiness and weight can be a downside for mobile operations.

Manual pumps are the most basic solution for tire inflation, relying on human power to compress air into the tire. They are cost-effective, typically priced between $20 and $50, making them an attractive option for budget-conscious buyers. However, the manual effort required can be a significant drawback, especially for large vehicles or multiple tires. They are best suited for low-pressure applications, such as bicycles or smaller vehicles, where speed and convenience are not as critical. Maintenance is minimal, but the physical labor involved may deter some users.

When selecting the appropriate tire inflation solution, B2B buyers must consider their specific operational requirements, including the types of vehicles serviced, frequency of use, and budget. Fast tire inflators offer speed and ease of use for personal vehicles and emergencies, while portable air compressors provide versatility for commercial applications. In contrast, manual pumps are ideal for low-pressure needs and budget constraints. By evaluating these aspects, businesses can effectively choose a tire inflation method that aligns with their operational goals and enhances their service capabilities.

When selecting a fast tire inflator for B2B purposes, understanding the technical specifications is crucial for ensuring performance, reliability, and compatibility with various applications. Here are some essential technical properties to consider:

Illustrative image related to fast tire inflator

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates the highest pressure the inflator can achieve. For instance, inflators designed for passenger vehicles usually range from 80 to 150 PSI, while those for larger vehicles like trucks may go up to 200 PSI. Understanding this property is vital for ensuring the inflator can meet the pressure requirements of various tire sizes, particularly in regions with diverse vehicle types.

The duty cycle refers to the amount of time an inflator can operate continuously before needing to cool down. This is especially important in high-demand environments, such as tire repair shops or service stations. For example, a duty cycle of 25 minutes of continuous use followed by a 30-minute cooling period may be suitable for quick tire top-offs, but in a busy setting, a higher duty cycle may be necessary to avoid downtime.

Fast tire inflators can be powered by various sources, including battery, 12-volt car adapters, or AC outlets. Each power source offers different advantages. Battery-powered inflators provide portability, while those that connect to a vehicle’s power supply are useful for roadside assistance. Understanding the power options available helps businesses choose an inflator that fits their operational needs, especially in remote or varied locations.

The length of the hose can significantly impact usability, particularly in environments where tire access may be limited. A longer hose allows for greater flexibility in reaching tires without needing to move the inflator. For instance, inflators with hoses extending to 12 feet or more are advantageous for larger vehicles or multi-tire servicing.

Illustrative image related to fast tire inflator

An accurate built-in pressure gauge is essential for monitoring tire pressure during inflation. Digital gauges are preferred for their precision and ease of reading, while analog gauges may be less reliable. This feature is critical for preventing over-inflation or under-inflation, which can lead to tire damage or safety issues.

The design and weight of the inflator impact its portability. Compact models that come with carrying cases can facilitate easy storage and transport. This aspect is particularly important for businesses that need to move equipment frequently, such as roadside service providers or fleet maintenance teams.

Navigating the procurement and sales processes involves understanding industry jargon. Here are some essential terms relevant to fast tire inflators:

OEM refers to companies that manufacture products that may be marketed under another company’s brand. For tire inflators, sourcing from OEMs can ensure quality and reliability, as these manufacturers often have established reputations and industry standards.

Illustrative image related to fast tire inflator

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and cost-effectiveness. For example, if a supplier has an MOQ of 100 units, businesses must assess whether they can sell or utilize that quantity effectively.

An RFQ is a standard business process where a buyer solicits price offers from multiple suppliers. This is vital for ensuring competitive pricing and securing the best deal for fast tire inflators. A well-crafted RFQ can lead to better negotiations and partnerships.

Incoterms define the responsibilities of buyers and sellers in international transactions. These terms clarify aspects like shipping costs, insurance, and risk management. Understanding Incoterms is essential for B2B buyers engaged in global sourcing of tire inflators, ensuring clarity in logistics and legal obligations.

While not a technical term, warranty and after-sales support are critical in B2B transactions. A robust warranty can indicate product quality and the manufacturer’s confidence, while effective after-sales support ensures that businesses can resolve issues quickly, minimizing downtime.

Illustrative image related to fast tire inflator

Certification standards, such as ISO or CE markings, indicate that a product meets specific safety and quality benchmarks. Understanding these certifications helps buyers ensure that the inflators they procure comply with local regulations and industry standards, especially in diverse markets like Africa, South America, and Europe.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing fast tire inflators, ensuring they select the most suitable products for their operational needs.

The fast tire inflator market is witnessing robust growth, fueled by several global drivers. The rising vehicle ownership, particularly in developing regions such as Africa and South America, is significantly increasing the demand for tire maintenance products. Moreover, the growing awareness of the importance of tire pressure in fuel efficiency and vehicle safety is prompting consumers and businesses to invest in reliable inflators. This trend is further amplified by the expansion of e-commerce platforms, which facilitate easier access to a wider range of inflator options for B2B buyers.

Illustrative image related to fast tire inflator

Current B2B tech trends are leaning towards smart tire inflators equipped with digital pressure gauges, automatic shut-off features, and even mobile app connectivity. These innovations enhance user experience and ensure accuracy, catering to the evolving expectations of customers. Additionally, the shift towards battery-powered and portable inflators is notable, as businesses seek more versatile solutions that can be used in various scenarios, from personal vehicles to commercial fleets.

International buyers, particularly from regions like Brazil and Nigeria, must also navigate diverse sourcing dynamics. Local regulations regarding product standards, safety certifications, and import tariffs can vary significantly. Understanding these factors is crucial for optimizing procurement strategies and ensuring compliance with local market demands. Furthermore, the competitive landscape is increasingly characterized by a mix of established brands and emerging players, necessitating thorough market research to identify reliable suppliers.

Sustainability is becoming an essential consideration in the fast tire inflator market, influencing both product development and sourcing strategies. Environmental impacts associated with tire maintenance products, such as energy consumption and waste generation, are prompting manufacturers to adopt greener practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability, whether through energy-efficient production processes or the use of recycled materials.

Ethical sourcing is equally important, as businesses recognize the value of transparent supply chains. Buyers are encouraged to seek out manufacturers that adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and Eco-Labeling can serve as indicators of a supplier’s commitment to sustainability and responsible sourcing.

Moreover, the demand for “green” products is influencing the design of fast tire inflators. Manufacturers are exploring alternatives to traditional materials, opting for biodegradable or recyclable components. This shift not only helps reduce the environmental footprint but also appeals to eco-conscious consumers and businesses. For B2B buyers, aligning procurement practices with sustainability goals can enhance brand reputation and meet the growing consumer demand for environmentally friendly products.

The evolution of the fast tire inflator market can be traced back to the early 20th century when manual pumps were the only option available for tire inflation. As automobile usage surged, the need for more efficient solutions led to the development of electric and portable inflators in the latter half of the century.

The introduction of battery-powered inflators revolutionized the market, providing users with greater convenience and flexibility. Recent advancements have seen the integration of smart technology, offering features like digital displays and automatic shut-offs, which enhance user experience and safety. As the market continues to evolve, the focus is shifting towards sustainability and ethical sourcing, reflecting broader consumer trends that prioritize environmental responsibility and transparency in supply chains.

This ongoing evolution presents significant opportunities for B2B buyers to engage with innovative suppliers and adopt cutting-edge products that meet the demands of modern consumers.

1. How do I solve quality concerns when sourcing fast tire inflators?

To address quality concerns, conduct thorough supplier vetting. Begin by requesting samples to evaluate the product’s durability, performance, and compliance with international safety standards. Utilize third-party inspection services to assess quality during production. Additionally, ensure that the supplier provides certifications such as ISO 9001, which indicates adherence to quality management principles. Establish clear quality assurance (QA) protocols in your purchase agreement to mitigate risks and ensure consistent product quality.

2. What is the best tire inflator for heavy-duty vehicles?

For heavy-duty vehicles like trucks and SUVs, the Viair 88P is an excellent choice. It features robust construction and can inflate larger tires quickly, making it ideal for off-road and commercial applications. Its capacity to reach high pressures (up to 120 psi) ensures that it can handle the demands of heavy-duty vehicles. However, it requires connection to the vehicle’s battery, so ensure your team is comfortable with this setup. Always consider the specific requirements of your fleet when selecting inflators.

3. What customization options are available for fast tire inflators?

Many manufacturers offer customization options for fast tire inflators, including branding, color variations, and specific features tailored to your market needs. You can discuss private labeling to enhance your brand visibility. Additionally, inquire about adjusting specifications such as maximum PSI, power sources (battery, AC, or DC), and added functionalities like built-in pressure gauges or LED lights. Customizing products can differentiate your offering in competitive markets.

4. What are the typical minimum order quantities (MOQs) for tire inflators?

MOQs for tire inflators can vary widely depending on the supplier and the specific model. Typically, manufacturers may set MOQs ranging from 100 to 1,000 units. When negotiating with suppliers, it’s crucial to clarify the MOQ upfront, as it can impact your initial investment. If you’re uncertain about meeting high MOQs, consider partnering with other businesses or seeking suppliers that cater to smaller orders, especially for pilot projects or market testing.

5. How should I approach payment terms when sourcing inflators internationally?

When negotiating payment terms, aim for conditions that minimize risk while ensuring supplier trust. Common terms include a deposit (usually 30%) upfront with the balance paid upon shipment or delivery. Consider utilizing letters of credit for larger orders to secure both parties’ interests. Additionally, explore options like PayPal or escrow services for smaller transactions. Ensure that payment terms are clearly outlined in the contract to prevent misunderstandings.

6. What logistics considerations should I keep in mind for importing tire inflators?

Logistics is crucial when importing tire inflators. First, choose a reliable freight forwarder familiar with international shipping regulations and customs procedures. Evaluate shipping options—air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure all documentation, including invoices and packing lists, is accurate to prevent customs delays. Additionally, consider warehousing solutions in the destination country to streamline distribution.

7. How do I verify a supplier’s reliability and reputation?

To verify a supplier’s reliability, start by researching their business history and customer reviews. Request references from other clients to gauge their experiences. Utilize platforms like Alibaba or Global Sources, which often feature supplier ratings and transaction histories. Conduct background checks through local business registries in the supplier’s country. Engaging in a trial order can also provide insight into their reliability before committing to larger purchases.

8. What certifications should I look for in fast tire inflators?

When sourcing fast tire inflators, look for essential certifications that ensure product safety and performance. Common certifications include CE (European Conformity) for compliance with EU safety standards, RoHS (Restriction of Hazardous Substances), and ISO certifications like ISO 9001 for quality management. Depending on your market, UL (Underwriters Laboratories) certification may also be relevant. These certifications not only enhance product credibility but also reduce liability risks.

Dominio: automoblog.com

Inscrito: 2004 (21 años)

Introducción: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX – Robust and powerful with four memory settings. 5. Milwaukee M18 – Built for lifetime usage with various memory settings. Price range: $80 to $180. Features include ro…

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Durable tire inflator suitable for airport use, needs to be portable and powerful. Previous models tested were either too weak (battery jumper/inflator combo taking 20+ minutes to fill a tire) or too fragile (Rigid portable inflator breaking after a few months). Recommendations include Milwaukee, VIAIR, Dewalt, and Makita models.

As international B2B buyers assess the market for fast tire inflators, several critical insights emerge. First, the emphasis on efficiency and portability cannot be overstated; products like the AstroAI Cordless Tire Inflator exemplify the ideal balance of performance and ease of use. The ability to inflate multiple tires quickly and accurately is a key selling point, especially for buyers in regions where vehicle maintenance is essential for daily operations.

Moreover, strategic sourcing plays a vital role in ensuring access to high-quality, reliable products that meet the diverse needs of customers across different markets, such as Africa, South America, the Middle East, and Europe. By partnering with reputable suppliers who prioritize quality and innovation, businesses can enhance their service offerings and build customer loyalty.

Looking ahead, the tire inflator market is poised for growth, driven by advances in technology and increasing awareness of vehicle maintenance. International B2B buyers should actively engage with suppliers to explore the latest innovations and ensure they are well-positioned to meet evolving customer demands. Prioritize partnerships that emphasize sustainability and efficiency, as these factors will increasingly influence purchasing decisions.

In conclusion, as you navigate the competitive landscape of tire inflators, leverage strategic sourcing to secure the best products for your clientele. The future is bright for those who adapt and innovate in this essential market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.