In today’s fast-paced global market, sourcing reliable tire car pumps presents a unique challenge for B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the need for efficient tire inflators is critical for maintaining vehicle performance and safety. With an array of options available, understanding the types, applications, and key features of tire car pumps is essential for making informed purchasing decisions. This comprehensive guide will delve into various inflator types, including cordless models and heavy-duty options suited for trucks, while also addressing the importance of supplier vetting to ensure quality and reliability.

As you navigate the complexities of the tire car pump market, this guide aims to empower international B2B buyers with actionable insights. From evaluating cost-effectiveness to assessing the suitability of different inflators for specific applications, you will find valuable information that can streamline your procurement process. Understanding the nuances of tire inflators not only enhances operational efficiency but also contributes to long-term cost savings. By equipping yourself with the knowledge presented in this guide, you will be better positioned to meet your organization’s needs, ensure vehicle safety, and foster strong supplier relationships across diverse markets.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Tire Inflators | Compact, battery-operated, often cordless | Automotive repair shops, roadside assistance | Pros: Easy to use, lightweight; Contras: Limited battery life for large jobs. |

| Heavy-Duty Air Compressors | High PSI capacity, often stationary, powered by electricity or gas | Commercial garages, construction sites | Pros: Fast inflation, suitable for large tires; Contras: Requires a power source, bulky. |

| 12V Tire Pumps | Connects to vehicle’s power outlet, compact size | Fleet management, emergency kits | Pros: Convenient for vehicles; Contras: Limited to 12V systems, slower than other types. |

| Floor Pumps | Manual operation, typically foot-operated | Bicycle shops, small vehicle service | Pros: No power needed, durable; Contras: Labor-intensive, less suitable for larger vehicles. |

| Digital Tire Inflators | Built-in digital gauges, programmable pressure settings | Automotive service providers | Pros: Accurate readings, automatic shut-off; Contras: May be more expensive, requires battery or power. |

Portable tire inflators are designed for ease of use and convenience, making them ideal for B2B applications where mobility is crucial. They are typically battery-operated and lightweight, allowing technicians to carry them easily to various job sites. However, their battery life can be a limitation when inflating larger tires or multiple tires at once. Businesses should consider the trade-off between portability and the ability to handle heavy-duty tasks.

Heavy-duty air compressors are powerful units that can inflate tires quickly and efficiently, making them essential for commercial garages and construction sites. These compressors can handle high PSI levels, making them suitable for larger vehicles and equipment. However, they require a stable power source and can be bulky, which may limit their use in smaller facilities. Buyers should assess their space and power availability before investing.

12V tire pumps are specifically designed to connect to a vehicle’s power outlet, making them a practical choice for fleet management and emergency kits. Their compact size allows for easy storage in vehicles, ensuring that they are readily available when needed. However, they are generally slower than other inflators and limited to 12V systems, which may not meet the demands of larger fleets. Businesses should evaluate the frequency of use and the types of vehicles in their fleet.

Floor pumps are manual, foot-operated devices that do not require electricity, making them a sustainable option for small vehicle service and bicycle shops. They are known for their durability and reliability, as they can be used in various conditions without the need for a power source. However, they require more physical effort to operate, making them less ideal for high-volume service environments. B2B buyers should consider the trade-offs between ease of use and operational efficiency.

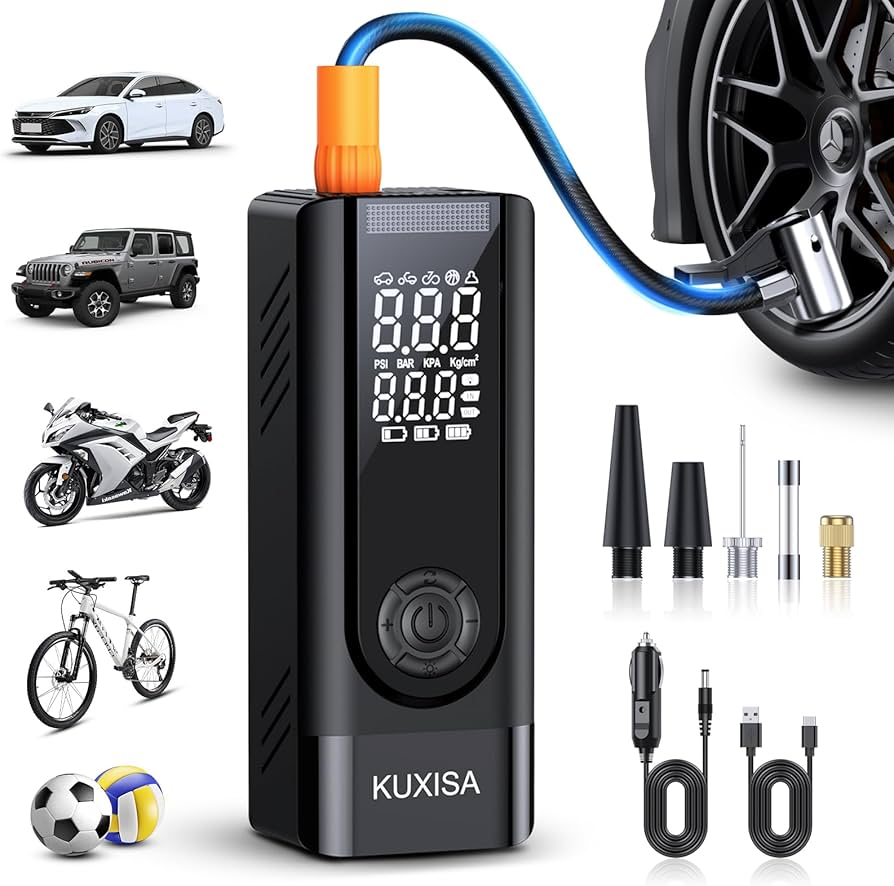

Illustrative image related to tire car pump

Digital tire inflators come equipped with built-in digital gauges and programmable pressure settings, allowing for precise inflation. This feature is particularly beneficial for automotive service providers aiming to maintain high service standards. While they may come at a higher price point and require a power source, the accuracy and convenience they offer can lead to improved customer satisfaction and operational efficiency. Businesses should assess their budget against the potential quality improvements.

| Industria/Sector | Specific Application of tire car pump | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Routine tire pressure maintenance | Enhances vehicle safety and performance, reducing liability | Quality, reliability, ease of use, and support for various tire types |

| Logistics & Transportation | Emergency tire inflation for fleet vehicles | Minimizes downtime, ensuring timely deliveries | Portability, battery life, and compatibility with different vehicles |

| Construcción | Inflation of construction equipment tires | Maintains operational efficiency, reducing equipment failure | Robustness, high PSI capability, and quick inflation times |

| Retail Automotive Parts | Retail sales of tire pumps to consumers | Generates additional revenue and customer satisfaction | Product range, pricing, and after-sales service |

| Recreational Vehicles | Tire inflation for RVs and trailers | Ensures safety and comfort during travel | Compact design, multi-functionality, and power options |

In the automotive repair sector, tire car pumps are essential for routine tire pressure maintenance. Proper tire inflation is crucial for vehicle safety, fuel efficiency, and prolonging tire life. By regularly checking and inflating tires, businesses can reduce the risk of accidents and enhance customer satisfaction. For international B2B buyers, sourcing a reliable tire pump that can handle various tire types and pressures is critical, especially in regions with diverse vehicle fleets.

In logistics and transportation, tire car pumps are vital for maintaining fleet vehicles. They serve as emergency inflation tools that can quickly address flat tires, minimizing downtime and ensuring timely deliveries. This is particularly important in regions like Africa and South America, where road conditions can be unpredictable. Buyers in this sector should consider portability, battery life, and the ability to work with different vehicle types when sourcing tire pumps.

In the construction industry, tire car pumps are used to inflate tires on heavy machinery and vehicles. Maintaining proper tire pressure is essential for operational efficiency and preventing equipment failures that could lead to costly delays. Buyers from the construction sector should focus on robust pumps capable of high PSI levels and rapid inflation times, especially in challenging environments typical of construction sites.

Retail automotive parts businesses can benefit from stocking tire car pumps as they provide a value-added service to consumers. Offering a range of tire pumps can enhance customer satisfaction and generate additional revenue. Key considerations for sourcing include product variety, pricing competitiveness, and the availability of after-sales support to address customer inquiries and issues.

Illustrative image related to tire car pump

Recreational vehicles (RVs) and trailers require reliable tire inflation solutions to ensure safe and comfortable travels. Tire car pumps designed for this sector must be compact and multifunctional, allowing users to inflate tires and other inflatable items easily. International buyers should look for pumps with diverse power options and quick inflation capabilities, catering to the unique needs of RV enthusiasts across different regions.

El problema:

B2B buyers often face the challenge of selecting the appropriate tire car pump that meets the varying needs of their fleet or customers. Whether it’s for passenger vehicles, trucks, or specialized vehicles, the diversity in tire sizes and inflation requirements can lead to confusion. Additionally, many pumps may not provide accurate pressure readings or lack the necessary features for different applications, resulting in wasted time and resources. This indecision can be compounded in markets across Africa, South America, the Middle East, and Europe, where different vehicle types and local conditions may influence tire performance.

La solución:

To effectively source the right tire car pump, B2B buyers should conduct a thorough analysis of their specific requirements. Begin by categorizing the types of vehicles in your fleet or the needs of your customers. For instance, if your operation includes both light passenger vehicles and heavy-duty trucks, consider multi-function pumps like the Viair 88P, which caters to larger tires, alongside compact options such as the AstroAI Cordless Tire Inflator for smaller vehicles.

Ensure that the pumps you consider have features like digital pressure gauges for accuracy and built-in shut-off capabilities to prevent over-inflation. It’s also beneficial to evaluate user reviews and performance tests from trusted automotive sources to ascertain reliability and performance in real-world scenarios. By matching the pump specifications to the intended applications, you can mitigate the risk of purchasing unsuitable products.

El problema:

Another common pain point for B2B buyers is the inconsistency in performance of tire pumps, which can lead to significant frustration among users. Many pumps may take longer to inflate tires than advertised, or they may fail to deliver the required pressure, especially when used in a busy workshop or roadside service. This inconsistency can harm customer satisfaction and lead to increased downtime, especially in regions where tire pressure management is crucial due to harsh environmental conditions.

Illustrative image related to tire car pump

La solución:

To overcome this issue, it is essential to prioritize quality and performance in your selection process. Look for tire pumps that have undergone rigorous testing and have a proven track record in diverse conditions. For example, the AstroAI Cordless Tire Inflator has been recognized for its speed and reliability, making it suitable for both personal and professional use.

Additionally, B2B buyers should consider establishing a testing protocol for any tire pumps prior to bulk purchasing. By evaluating units in a controlled environment, you can assess their performance against specific benchmarks, such as inflation speed and accuracy. Implementing a return policy for underperforming pumps can also safeguard against poor investments.

El problema:

B2B buyers frequently encounter challenges related to the portability and usability of tire pumps, especially in regions where mobility is essential for service efficiency. Bulkier inflators may be cumbersome to transport, while those with complicated operating procedures can lead to delays in service. This is particularly relevant in markets with diverse terrains, where quick access to reliable tire inflation can be crucial for fleet management or roadside assistance.

Illustrative image related to tire car pump

La solución:

To address these issues, focus on sourcing compact, user-friendly tire pumps that prioritize ease of use without compromising performance. For instance, portable models like the Craftsman 12V Max Portable Air Inflator are designed for convenience and can easily fit into glove compartments or toolkits.

When procuring these pumps, consider features such as easy-to-read digital displays, one-button operation, and versatile power options (like rechargeable batteries or car adaptors). Additionally, providing training for users on effective pump operation can enhance efficiency and reduce service time. To further support usability, create a maintenance schedule for the pumps to ensure they remain in optimal working condition, thus enhancing their longevity and reliability in the field.

When selecting materials for tire car pumps, it’s essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of tire car pumps: plastic, aluminum, steel, and rubber.

Illustrative image related to tire car pump

Plastic is often used in the casing and components of tire car pumps due to its lightweight and corrosion-resistant properties. Common types include polypropylene and ABS (Acrylonitrile Butadiene Styrene).

Key Properties: Plastic can withstand moderate temperatures and pressures, typically rated up to 150 psi. It is resistant to rust and corrosion, making it ideal for varied environmental conditions.

Pros y contras: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for intricate designs. However, it may not be as durable as metals, particularly under extreme conditions, and can degrade over time when exposed to UV light.

Impacto en la aplicación: Plastic is suitable for lightweight, portable inflators but may not be ideal for high-performance applications requiring robust durability.

Consideraciones para compradores internacionales: Compliance with regional standards such as ASTM for plastics is crucial. Buyers should ensure that the chosen plastic meets local environmental regulations, particularly in regions with stringent waste management policies.

Aluminum is frequently used for components that require strength without excessive weight. It is particularly favored for the body and nozzle of tire inflators.

Key Properties: Aluminum has a high strength-to-weight ratio, with a pressure rating typically exceeding 200 psi. It exhibits excellent corrosion resistance, especially when anodized.

Pros y contras: The advantages of aluminum include its durability and lightweight nature, making it suitable for portable applications. However, it can be more expensive than plastic and may require specialized manufacturing processes, increasing production complexity.

Impacto en la aplicación: Aluminum is well-suited for high-performance tire inflators that need to withstand rigorous use, such as those used in off-road vehicles.

Illustrative image related to tire car pump

Consideraciones para compradores internacionales: Buyers should verify compliance with international standards like ISO and ASTM. In regions like Europe, adherence to environmental directives regarding aluminum production and recycling can also be a factor.

Steel is often used in heavy-duty tire inflators, particularly for components that require maximum durability and strength.

Key Properties: Steel can handle high pressures, typically rated up to 300 psi or more, and offers excellent resistance to wear and tear.

Pros y contras: The main advantage of steel is its robustness and longevity, making it ideal for industrial applications. However, it is heavier than other materials and can be prone to rust if not properly coated.

Impacto en la aplicación: Steel is ideal for stationary tire pumps or those used in commercial settings where durability is paramount.

Consideraciones para compradores internacionales: Compliance with standards such as JIS in Japan or DIN in Germany is essential. Buyers should also consider the implications of steel tariffs and sourcing challenges in regions like South America and Africa.

Rubber is primarily used for seals and hoses in tire pumps, providing flexibility and airtightness.

Key Properties: Rubber can withstand a wide range of temperatures and pressures, typically rated around 100 psi for standard applications, but specialized compounds can handle higher pressures.

Pros y contras: The flexibility of rubber allows for easy connection to various tire types, enhancing usability. However, it can degrade over time due to exposure to ozone and UV light, necessitating regular inspections.

Illustrative image related to tire car pump

Impacto en la aplicación: Rubber is essential for ensuring airtight connections, which is crucial for efficient inflation.

Consideraciones para compradores internacionales: Buyers should ensure that rubber components comply with local health and safety regulations, particularly in regions with strict environmental policies.

| Material | Typical Use Case for tire car pump | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plástico | Lightweight portable inflators | Low cost and ease of manufacturing | Less durable under extreme conditions | Bajo |

| Aluminio | High-performance tire inflators | Elevada relación resistencia/peso | Más caro y complejo de fabricar | Medio |

| Acero | Heavy-duty industrial tire pumps | Durabilidad excepcional | Más pesado y propenso a oxidarse | Alta |

| Goma | Seals and hoses in tire pumps | Provides flexibility and airtightness | Se degrada con el tiempo y la exposición | Medio |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in tire car pumps, enabling informed decisions that align with their operational needs and regional compliance requirements.

The manufacturing process of tire car pumps involves several critical stages that ensure the production of high-quality, reliable products. The primary stages are material preparation, forming, assembly, and finishing.

Preparación del material

The first step involves selecting and preparing the raw materials, typically high-grade plastics, metals, and rubber for seals. Suppliers must provide materials that meet specific industry standards to ensure durability and performance. Quality checks on these materials are crucial to prevent defects in the final product.

Formando

In the forming stage, raw materials are shaped into the components of the tire pump. Techniques such as injection molding for plastic parts and metal stamping for structural components are commonly used. These processes require precision to ensure that parts fit together seamlessly in the assembly phase.

Montaje

After forming, components are assembled. This stage may include the installation of motors, pressure gauges, and hoses. Automated assembly lines are often employed to increase efficiency and minimize human error. Each assembly line worker is typically trained to perform specific tasks, ensuring consistency across products.

Acabado

The final stage involves finishing touches such as painting, labeling, and packaging. Quality control inspections are performed at this stage to verify that each pump meets aesthetic and functional standards. Additionally, pumps are tested for functionality, ensuring they can achieve the required pressure levels before being packaged for shipping.

Manufacturers employ various techniques tailored to enhance efficiency and product quality. Notable techniques include:

Quality assurance (QA) is integral to the manufacturing of tire car pumps, ensuring that products meet both customer expectations and regulatory requirements. Key international standards include ISO 9001, which outlines requirements for a quality management system, and CE marking, which indicates compliance with European safety standards.

ISO 9001: This standard focuses on quality management systems and aims to enhance customer satisfaction through effective processes. Compliance with ISO 9001 is often a prerequisite for doing business in international markets.

Marcado CE: In Europe, CE marking indicates that the product meets safety, health, and environmental protection requirements. This is crucial for manufacturers targeting European buyers.

Normas API: For tire pumps used in industrial applications, adherence to American Petroleum Institute (API) standards may be necessary, particularly for pumps that may come into contact with petroleum products.

Quality control in tire pump manufacturing typically involves several checkpoints throughout the production process, including:

Control de calidad entrante (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. It ensures that all materials meet specified standards.

Control de calidad durante el proceso (IPQC): During manufacturing, periodic inspections are conducted to identify defects or deviations from quality standards. This may involve testing the functionality of components as they are assembled.

Control de calidad final (CCF): Before products are shipped, a final inspection is conducted. This includes testing the functionality of the tire pumps, ensuring they can reach the required pressure and operate as intended.

Manufacturers utilize various testing methods to ensure quality and performance, including:

Pressure Testing: Pumps are tested under simulated conditions to ensure they can handle the maximum pressure specified. This is crucial for safety and performance.

Leak Testing: This involves checking for any leaks in the system, which could lead to failure during operation. Tests may include submersion in water or using pressure decay methods.

Pruebas de durabilidad: Pumps may undergo repeated cycles of inflation and deflation to assess their longevity and performance under stress.

B2B buyers must ensure that their suppliers maintain rigorous quality control standards. Here are some methods to verify this:

Auditorías de proveedores: Conducting on-site audits of the manufacturing facilities allows buyers to assess quality management systems and processes directly.

Revisión de los informes de calidad: Suppliers should provide documentation detailing their quality control processes, including test results and compliance with international standards.

Inspecciones de terceros: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures and the products being manufactured.

For international B2B buyers, understanding local regulations and certification requirements is critical. Each region may have different standards that affect product acceptance. For instance:

Africa: Buyers should be aware of local certifications and standards, which may vary significantly between countries.

South America: In countries like Brazil, compliance with INMETRO regulations is essential for market entry.

Middle East: Buyers must consider local certifications such as the Gulf Conformity Mark (G-Mark) to ensure products meet regional safety and performance standards.

Europe: The CE marking is crucial for products sold within the European Union, and buyers should ensure that suppliers can provide this certification.

Understanding these factors can help B2B buyers make informed decisions when sourcing tire car pumps, ensuring they partner with reliable manufacturers who prioritize quality and compliance.

This sourcing guide is designed to assist B2B buyers in procuring tire car pumps effectively and efficiently. By following this checklist, you will ensure that you make informed decisions, select quality products, and establish reliable supplier relationships that meet your business needs.

Clearly outlining your requirements is crucial before beginning the sourcing process. Consider factors such as the type of vehicles (passenger cars, trucks, SUVs) you will be servicing, the maximum PSI needed, and the power source (battery-operated or plug-in). This clarity helps narrow down options and ensures that you select pumps that fit your operational needs.

Stay updated on the latest trends and advancements in tire pump technology. Innovations such as digital pressure gauges, cordless models, and multi-functional inflators can enhance efficiency and user experience. Understanding market dynamics will allow you to identify products that offer competitive advantages.

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of quality and reliability, and consider those who can provide after-sales support and warranty options.

Not all tire pumps are created equal. Evaluate features such as inflation speed, accuracy of pressure gauges, and additional functionalities like built-in lights or USB ports for charging devices. Prioritize durability and ease of use, particularly for models intended for frequent, heavy-duty use.

Ensure that the tire pumps comply with safety and quality standards relevant to your target market, especially if you are importing products. Different regions may have specific regulations regarding electrical appliances or automotive accessories. Compliance not only minimizes legal risks but also enhances your brand’s credibility.

Once you’ve identified suitable suppliers and products, enter into negotiations with an emphasis on securing favorable terms. Discuss pricing, payment terms, minimum order quantities, and delivery schedules. Building a mutually beneficial relationship can lead to discounts and better service over time.

Consider how you will manage the logistics of receiving and distributing the tire pumps. Evaluate shipping options, customs duties, and storage needs. Effective logistics planning will ensure that you can meet customer demand promptly and efficiently, especially in diverse markets like Africa, South America, and the Middle East.

Illustrative image related to tire car pump

By following this structured checklist, B2B buyers can navigate the complexities of sourcing tire car pumps with confidence, ensuring quality products that meet the demands of their operations.

When analyzing the cost structure of tire car pumps, several key components come into play. Materiales represent a significant portion of the cost, with various plastics, metals, and rubber being essential for durability and functionality. The quality of materials directly influences the pump’s performance, affecting both the initial cost and the long-term reliability of the product.

Trabajo costs are another critical factor, including wages for assembly line workers and technicians involved in quality control. The geographical location of production can impact labor costs significantly; for instance, manufacturing in regions with lower labor costs can result in savings for buyers.

Gastos generales de fabricación includes expenses related to facility maintenance, utilities, and equipment depreciation. Additionally, tooling costs for specialized machinery used in production can affect pricing. Companies must also factor in quality control (QC) measures to ensure that every unit meets safety and performance standards, as defects can lead to costly recalls and damage to brand reputation.

Illustrative image related to tire car pump

Logística costs are crucial in the overall pricing strategy. These encompass shipping fees, warehousing, and distribution expenses, which can vary widely based on the supplier’s location and the destination market.

Por último, el margen added by manufacturers and suppliers must be considered. This margin reflects not only profit expectations but also market positioning and competitive factors.

Several price influencers can significantly impact the cost of tire car pumps. Volumen o cantidad mínima de pedido (MOQ) is often a key determinant; larger orders typically result in lower per-unit costs due to economies of scale.

Especificaciones y personalización also play a role. Custom features, such as integrated digital pressure gauges or unique designs, can drive up costs. Conversely, standardized models can be sourced at lower prices.

La elección de materiales affects both the quality and pricing. High-grade materials may enhance durability and performance but will also increase production costs. Certifications for quality and safety standards can further add to costs but are often necessary for market acceptance, particularly in regions with strict regulations.

Illustrative image related to tire car pump

Factores del proveedor such as reputation, reliability, and payment terms can also influence pricing. Strong relationships with reputable suppliers may lead to better pricing and terms.

Lastly, Incoterms can affect the total cost of ownership. Understanding the responsibilities for shipping, insurance, and duties between buyer and seller can help avoid unexpected expenses.

B2B buyers should adopt several strategies to maximize cost efficiency when sourcing tire car pumps. Negociación is key; establishing clear expectations and understanding the supplier’s cost structure can lead to better terms. Buyers should also be prepared to leverage volume orders to negotiate lower prices.

Focusing on the Coste total de propiedad (TCO) rather than just the initial purchase price can yield long-term savings. This includes considering factors like maintenance, replacement parts, and warranty coverage. A lower-priced pump may end up costing more in the long run if it requires frequent repairs or replacements.

Buyers in international markets should be aware of pricing nuances, such as tariffs and import duties, which can significantly impact overall costs. Understanding local market conditions and supplier capabilities is essential for making informed decisions.

In conclusion, while tire car pump sourcing involves various cost components and pricing influencers, strategic negotiation and a focus on the total cost of ownership can lead to more favorable outcomes for B2B buyers, especially in emerging markets like Africa, South America, the Middle East, and Europe. Always approach negotiations with a clear understanding of your requirements and the current market landscape.

Disclaimer: Prices and costs mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements.

Illustrative image related to tire car pump

In the realm of vehicle maintenance, tire car pumps serve as essential tools for ensuring optimal tire pressure. However, there are various alternative solutions that can achieve similar outcomes, each with unique benefits and drawbacks. This analysis will compare the traditional tire car pump with two viable alternatives: portable air compressors and electric tire inflators. By understanding these options, B2B buyers can make informed purchasing decisions tailored to their specific needs.

| Aspecto comparativo | Tire Car Pump | Compresor de aire portátil | Electric Tire Inflator |

|---|---|---|---|

| Rendimiento | Varies by model; generally effective for small tires | High PSI output; suitable for heavy-duty tires | Generally lower PSI; good for passenger vehicles |

| Coste | $20 – $100 depending on type | $50 – $300+ | $30 – $150 |

| Facilidad de aplicación | Manual operation; may require physical effort | Requires AC power or car battery | Usually plug-and-play; easy to use |

| Mantenimiento | Minimal; requires occasional checks | Moderate; needs regular cleaning and oiling | Low; usually requires no maintenance |

| El mejor caso de uso | Ideal for emergencies and small vehicles | Best for garages and heavy-duty applications | Suitable for regular use and compact spaces |

Portable air compressors are versatile tools that use an electric motor to compress air, delivering high PSI outputs. They are particularly advantageous for commercial settings where heavy-duty tires, such as those on trucks or construction vehicles, are prevalent. The significant performance benefit is their ability to inflate larger tires quickly and efficiently. However, they can be bulky and require a power source, which may not be available in all situations. Additionally, they may involve higher costs and moderate maintenance, as they need regular upkeep to function optimally.

Electric tire inflators are compact devices designed for convenience and ease of use. They can be plugged into a vehicle’s power outlet or a standard electrical socket, making them user-friendly for those who may not have mechanical expertise. While electric inflators are generally less powerful than portable air compressors, they are ideal for regular passenger vehicle maintenance and emergencies. Their low maintenance requirements and compact design make them a favorable choice for everyday users. However, their performance may be limited when dealing with larger tires or multiple tires simultaneously.

Illustrative image related to tire car pump

When selecting between a tire car pump and its alternatives, B2B buyers should consider several factors, including the specific applications, budget constraints, and the environments in which the equipment will be used. For businesses involved in commercial transport or heavy machinery, investing in a portable air compressor may yield the best performance and efficiency. Conversely, smaller enterprises or those focused on passenger vehicles might find that electric tire inflators meet their needs without the bulk and cost associated with larger compressors. By aligning the choice of tire inflation solution with operational requirements, businesses can enhance their service efficiency and maintain optimal vehicle performance.

When evaluating tire car pumps for B2B procurement, understanding their technical specifications is crucial. Here are several essential properties that influence performance and reliability:

The maximum pressure rating, measured in pounds per square inch (PSI), indicates how much air pressure the pump can generate. Most passenger vehicle tires operate between 30-35 PSI, while larger vehicles, such as trucks, may require pumps capable of reaching up to 80 PSI. For businesses, selecting a pump with a suitable PSI ensures efficient inflation and can prevent equipment failure, thereby minimizing downtime.

Illustrative image related to tire car pump

Tire pumps can be powered by different sources, including AC power, DC power from vehicle batteries, or rechargeable batteries. Understanding the power source is vital for operational flexibility. Businesses that require mobility may favor battery-operated models, while those with fixed locations might prefer AC-powered units for their higher performance. This choice affects usage scenarios and maintenance requirements.

The duty cycle describes how long a pump can operate before needing to cool down. For example, a tire inflator with a 25% duty cycle can run for 15 minutes but must cool for 45 minutes afterward. This property is crucial for businesses needing to inflate multiple tires quickly, as a longer duty cycle reduces waiting time and increases productivity.

Inflation speed, typically measured in liters per minute (L/min) or cubic feet per minute (CFM), indicates how quickly the pump can inflate a tire. A faster inflation speed can significantly improve service times in automotive workshops or roadside assistance scenarios. Businesses should assess their operational needs to select pumps that align with their service speed requirements.

The materials used in the construction of tire pumps, such as high-grade plastics or metal components, impact durability and performance. Pumps made from robust materials withstand wear and tear better, ensuring longevity and reliability. For B2B buyers, investing in high-quality materials reduces the total cost of ownership by minimizing maintenance and replacement costs.

The hose length affects the pump’s accessibility and ease of use. A longer hose allows for greater flexibility when reaching tires in various positions, which is particularly important in busy workshops or for mobile service providers. Understanding hose length specifications helps businesses ensure that their tire inflators can effectively meet the demands of their operations.

Familiarity with industry-specific terminology can facilitate smoother transactions and better understanding among B2B buyers. Here are some commonly used terms:

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of tire pumps, knowing whether a product is OEM can assure buyers of its quality and compatibility with existing systems.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses to manage inventory costs effectively and ensure they are purchasing sufficient quantities to meet demand without overstocking.

An RFQ is a document that businesses send to suppliers to request pricing and terms for specific products. This process is crucial for obtaining competitive pricing on tire pumps and ensuring that suppliers meet the buyer’s specifications.

Illustrative image related to tire car pump

Incoterms define the responsibilities of buyers and sellers in international trade transactions. Familiarity with these terms helps businesses understand shipping costs, risks, and logistics, ensuring smoother cross-border procurement of tire pumps.

The warranty period refers to the time frame during which a buyer can claim repairs or replacements for defects. A longer warranty period can indicate a manufacturer’s confidence in their product, providing peace of mind for businesses investing in tire pumps.

Lead time is the amount of time it takes from placing an order to receiving the product. Understanding lead times helps businesses plan their procurement schedules, especially when dealing with high-demand situations or urgent repairs.

Illustrative image related to tire car pump

In conclusion, grasping the technical properties and trade terminology associated with tire car pumps empowers B2B buyers to make informed purchasing decisions. By understanding these elements, businesses can enhance their operational efficiency and ensure they select the right equipment for their needs.

The global tire car pump market is experiencing dynamic shifts driven by several factors, including technological advancements, changing consumer preferences, and the increasing emphasis on vehicle maintenance. The rise of electric vehicles (EVs) is a notable trend, with tire inflators now designed to accommodate the specific needs of EVs, such as higher pressure requirements and compact storage solutions. Additionally, the growing popularity of mobile and portable tire inflators reflects a demand for convenience, particularly among consumers in regions like Africa and South America, where road conditions can be unpredictable.

Emerging technologies, such as smart tire inflators equipped with digital pressure gauges and automatic shut-off features, are becoming standard. These innovations not only enhance usability but also align with the increasing focus on safety and efficiency among international B2B buyers. Moreover, the integration of IoT (Internet of Things) capabilities into tire maintenance products is paving the way for predictive maintenance solutions, enabling businesses to monitor tire conditions in real-time.

For international buyers, particularly from Brazil and Saudi Arabia, navigating the competitive landscape requires awareness of local market nuances. Understanding regional preferences and compliance with local regulations is crucial for successful sourcing. As the market expands, leveraging data analytics for demand forecasting and supply chain optimization will be essential for maintaining a competitive edge.

Sustainability has become a pivotal consideration in the tire car pump sector, influencing both product design and sourcing strategies. The environmental impact of manufacturing processes and the materials used in tire pumps is under scrutiny, prompting a shift toward eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through their practices and product offerings.

Illustrative image related to tire car pump

Ethical sourcing is also gaining traction, with businesses seeking to ensure that their supply chains adhere to environmental and social governance (ESG) standards. This includes transparency in sourcing materials, such as recycled plastics and metals, which not only minimizes waste but also appeals to environmentally conscious consumers. Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials can enhance a company’s reputation and marketability.

In addition to regulatory compliance, sustainable practices can lead to cost savings in the long run. By investing in energy-efficient manufacturing processes and sustainable materials, companies can reduce operational costs and improve their overall profit margins. For B2B buyers in regions like Europe and the Middle East, aligning sourcing strategies with sustainability goals is not just a trend but a necessity for long-term viability.

The tire car pump sector has evolved significantly over the decades, transitioning from manual hand pumps to sophisticated electric inflators. Early tire pumps were primarily mechanical devices requiring significant manual effort, which limited their appeal to the average consumer. With the advent of electric pumps in the late 20th century, the market saw a surge in popularity due to the convenience and efficiency these devices offered.

As automotive technology advanced, so did the functionality of tire pumps. The introduction of portable and battery-operated inflators in the 21st century marked a turning point, catering to the growing consumer preference for on-the-go solutions. This evolution has been particularly relevant in emerging markets, where road conditions and vehicle maintenance practices differ significantly from developed regions. Today, the focus is not only on functionality but also on integrating smart technology and sustainable practices, reflecting a broader shift in consumer expectations and environmental responsibility.

1. How do I choose the right tire car pump for my business needs?

Selecting the right tire car pump involves assessing your specific requirements, such as the types of vehicles you service and the volume of tires you inflate. Consider factors such as maximum PSI, power source (cordless vs. corded), and size for portability. For B2B buyers, evaluating the pump’s durability, ease of use, and additional features like built-in pressure gauges or extra attachments can enhance operational efficiency. Conducting a comparative analysis of various models and reading reviews can also help you make an informed decision.

2. What is the best tire car pump for high-performance vehicles?

For high-performance vehicles, look for tire pumps that can deliver high PSI, typically around 80 PSI or more, and feature fast inflation capabilities. Models like the AstroAI Cordless Tire Inflator or the Viair 88P are excellent choices, as they offer robust performance and are designed for quick inflation of larger tires. Additionally, consider features like automatic shutoff and digital pressure gauges to ensure accuracy and convenience during use.

3. What are the key features to look for in a tire car pump?

When sourcing a tire car pump, prioritize features such as maximum PSI capabilities, power options (battery or plug-in), portability, and ease of use. A built-in pressure gauge is essential for monitoring tire pressure accurately. Additional features like LED lights for nighttime use, multiple nozzle attachments for different inflatables, and compact storage solutions can also enhance the pump’s functionality. Assessing the warranty and customer support options can further ensure a reliable purchase.

4. What are the typical minimum order quantities (MOQs) for tire car pumps?

Minimum order quantities (MOQs) for tire car pumps can vary significantly depending on the supplier and the type of pump. Generally, MOQs can range from as low as 50 units to several hundred. It’s essential to discuss your specific needs with suppliers during the initial inquiry to determine their flexibility. Some manufacturers may offer lower MOQs for customized orders, while bulk purchasing can lead to better pricing and terms.

5. How can I vet suppliers for tire car pumps effectively?

To vet suppliers for tire car pumps, start by checking their industry reputation through online reviews and ratings. Request samples to evaluate product quality firsthand and verify compliance with international safety standards. Engage in direct communication to assess responsiveness and willingness to accommodate your needs. Additionally, consider suppliers with established export experience, particularly in your target regions, to ensure they understand local regulations and logistics.

6. What payment terms should I negotiate when sourcing tire car pumps?

When negotiating payment terms, consider options that balance risk and cash flow. Common arrangements include a deposit upfront (usually 30% to 50%) with the balance due upon shipment or delivery. Depending on your relationship with the supplier, you might also explore net payment terms (e.g., net 30 or net 60 days) to allow time for sales. Always ensure that payment methods are secure and that any agreements are documented in writing to avoid future disputes.

7. What quality assurance practices should I expect from suppliers?

Reputable suppliers should have clear quality assurance practices in place, including regular inspections and testing of their products. Ask for documentation of quality certifications (e.g., ISO) and any specific testing protocols they follow for tire pumps. It’s beneficial to establish a clear return policy and warranty terms to protect your investment. Additionally, consider conducting a factory audit if feasible to observe their quality control processes firsthand.

8. How do logistics and shipping impact my procurement of tire car pumps?

Logistics and shipping are crucial in the procurement process, affecting delivery timelines and costs. Discuss shipping options with suppliers, including freight terms (FOB, CIF) and estimated lead times. Be aware of potential customs duties and import regulations in your region, as they can impact overall costs. Collaborating with logistics partners experienced in international trade can streamline the shipping process, ensuring timely delivery and minimizing disruptions to your supply chain.

Dominio: fanttik.com

Matriculado: 2020 (5 años)

Introducción: 2X Faster Electric Tire Inflators, various models including X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Sale prices range from $48.99 to $199.97 with discounts up to 50%. Regular prices vary, with savings indicated for each model. Customer ratings around 4.8 for most products. Black Friday sale from 11.20-12.7.

Dominio: target.com

Inscrita: 1997 (28 años)

Introducción: This company, Target – Portable Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the rapidly evolving landscape of tire car pumps, strategic sourcing remains critical for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Key insights reveal that investing in high-quality tire inflators not only enhances operational efficiency but also contributes to long-term cost savings through improved vehicle maintenance. Buyers should prioritize features such as portability, power source versatility, and accurate pressure gauges to meet diverse market needs.

Understanding local market demands and aligning them with product specifications can significantly impact procurement strategies. Leveraging partnerships with reputable manufacturers can also ensure access to innovative products that enhance customer satisfaction. As sustainability becomes a focal point in global trade, sourcing eco-friendly tire inflators could provide a competitive edge.

Looking ahead, the tire inflator market is poised for growth, driven by increasing vehicle ownership and the demand for efficient maintenance solutions. International B2B buyers are encouraged to explore emerging technologies and trends that can drive value in their supply chains. By embracing strategic sourcing practices, businesses can position themselves favorably in this dynamic market landscape.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.