In today’s competitive landscape, sourcing electric portable air compressors poses a significant challenge for B2B buyers. The need for reliable, efficient, and versatile air compressors is paramount for businesses across diverse sectors such as manufacturing, construction, and automotive services. This guide aims to navigate the complexities of the global market, offering insights into the various types of electric portable air compressors, their applications, and the essential factors to consider when selecting suppliers.

Understanding the nuances of electric portable air compressors is crucial for making informed purchasing decisions. This comprehensive resource covers critical topics, including the differences between oil-free and oil-lubricated models, the importance of tank capacity, and the implications of power ratings. Additionally, we delve into supplier vetting processes, cost considerations, and the logistics of importing to regions such as Africa, South America, the Middle East, and Europe—specifically targeting markets like Germany and Nigeria.

By providing actionable insights and a structured approach to procurement, this guide empowers international B2B buyers to confidently invest in electric portable air compressors that meet their operational needs. Whether you are expanding your fleet or seeking to upgrade existing equipment, this resource will equip you with the knowledge necessary to enhance your purchasing strategy and drive business success.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Oil-Free Compressors | Require no oil, resulting in cleaner air and minimal maintenance. | Automotive repair, food & beverage. | Pros: Lower maintenance; cleaner output. Contras: Typically lower power output. |

| Oil-Lubricated Compressors | Use oil to lubricate internal components, enhancing durability. | Construction, industrial applications. | Pros: Higher efficiency; longer lifespan. Contras: Requires regular maintenance; potential oil leaks. |

| Silent Compressors | Designed to operate quietly, ideal for noise-sensitive environments. | Workshops, dental offices. | Pros: Minimal noise; user-friendly. Contras: Often more expensive; may have lower power. |

| Battery-Powered Compressors | Operate on rechargeable batteries, offering portability. | Outdoor work, remote locations. | Pros: High portability; no need for power outlets. Contras: Limited runtime; longer charging times. |

| Compact Air Compressors | Smaller, lightweight designs for easy transport and storage. | DIY projects, small workshops. | Pros: Easy to transport; space-saving. Contras: Limited air capacity; may not handle heavy-duty tasks. |

Oil-free compressors are designed to operate without lubrication oil, making them ideal for applications where air quality is paramount, such as in the food and beverage industry. They produce cleaner air, which is crucial for sensitive processes. When considering an oil-free compressor, B2B buyers should evaluate the compressor’s PSI output and tank size to ensure it meets their operational needs while benefiting from reduced maintenance costs.

Oil-lubricated compressors utilize oil to lubricate their internal components, resulting in increased efficiency and durability. These compressors are well-suited for heavy-duty applications like construction and industrial uses. Buyers should consider factors such as the compressor’s horsepower and tank capacity, as these will impact performance and suitability for demanding tasks. While they require regular maintenance, their longevity and efficiency can justify the investment.

Silent compressors are specifically engineered to operate at lower noise levels, making them suitable for environments where noise reduction is a priority, such as dental offices or workshops. These compressors offer a quieter alternative without sacrificing performance. B2B purchasers should assess the noise levels (measured in decibels) and compare them with their operational requirements to ensure a suitable fit for their work environment.

Battery-powered compressors provide significant portability advantages, allowing them to function in remote locations without access to electrical outlets. They are particularly useful for outdoor work or in construction sites where mobility is crucial. Buyers need to consider battery life and recharge time, as these factors will influence the compressor’s usability throughout the workday. Despite their convenience, potential buyers should also be aware of the limitations in terms of power and runtime.

Compact air compressors are designed for portability and ease of storage, making them ideal for DIY projects and small workshops. Their lightweight design allows for easy transport, while their smaller size can fit into tight spaces. B2B buyers should assess the compressor’s air output and tank size to ensure it meets their specific needs. While compact models may not handle heavy-duty tasks, they are perfect for light applications, providing flexibility and convenience for smaller operations.

| Industria/Sector | Specific Application of Electric Portable Air Compressor | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Construcción | Powering pneumatic tools on job sites | Increases productivity by enabling quick tool operation | Durability, portability, and noise levels are critical factors |

| Reparación de automóviles | Tire inflation and air tool operation | Enhances service efficiency and customer satisfaction | Compatibility with various air tools and ease of transport |

| Fabricación | Cleaning and maintenance of machinery | Improves equipment lifespan and reduces downtime | Power output and energy efficiency should be prioritized |

| Agricultura | Operating irrigation systems and pneumatic sprayers | Facilitates efficient water distribution and crop management | Reliability under varying environmental conditions is key |

| Painting and Finishing | Spray painting and finishing applications | Delivers high-quality finishes and reduces material waste | Air pressure consistency and portability are essential |

In the construction industry, electric portable air compressors are vital for powering pneumatic tools such as nail guns, drills, and impact wrenches. They enable workers to perform tasks efficiently and quickly, ultimately increasing productivity on job sites. For international buyers, especially in regions like Africa and South America, sourcing compressors that are durable and can withstand harsh conditions is essential. Additionally, noise levels should be considered to comply with local regulations.

In automotive repair shops, electric portable air compressors are used for tire inflation and powering air tools like impact wrenches and sanders. This application significantly enhances service efficiency, allowing mechanics to complete jobs faster and improve customer satisfaction. Buyers in Europe, particularly in Germany, should focus on compressors that offer high compatibility with various air tools and are easy to transport, ensuring they can meet diverse service demands.

Manufacturing facilities utilize electric portable air compressors for cleaning machinery and providing air for various pneumatic applications. This practice helps improve equipment longevity and minimizes downtime, which is crucial for maintaining productivity. For manufacturers in the Middle East, sourcing compressors that deliver consistent power output and high energy efficiency can lead to significant cost savings and operational improvements.

In agriculture, electric portable air compressors are often employed to operate irrigation systems and pneumatic sprayers. This application allows for efficient water distribution and effective crop management, which is vital for maximizing yield. Buyers from regions like Africa should prioritize reliability and performance in varying environmental conditions to ensure the compressors can handle the rigors of agricultural use.

Electric portable air compressors are essential in painting and finishing applications, particularly for spray painting. They provide the necessary air pressure for a smooth, high-quality finish while minimizing material waste. For businesses in South America, ensuring that the compressor maintains consistent air pressure and is portable enough for various job sites will enhance operational efficiency and product quality.

El problema: B2B buyers, especially in regions with unstable electricity supply such as parts of Africa and South America, often face challenges when trying to operate electric portable air compressors. These compressors require a reliable power source, and fluctuations or outages can lead to downtime, affecting productivity and operational efficiency. Buyers may be concerned about how to ensure consistent performance without investing heavily in backup power solutions.

La solución: To mitigate this issue, businesses should consider sourcing electric portable air compressors with dual-voltage capabilities. These models can operate on different voltage levels, allowing users to switch between power sources as needed. Additionally, investing in a high-quality inverter generator can provide a stable power supply during outages. It is also advisable to work with suppliers who offer on-site support and training, ensuring that your team knows how to optimize compressor use in low-power conditions. Lastly, maintaining a good relationship with local utility providers can help buyers stay informed about planned outages or maintenance schedules.

El problema: Many B2B buyers experience issues with overheating when using electric portable air compressors for extended periods, particularly in high-temperature environments like construction sites in the Middle East or during summer in South America. Overheating can lead to mechanical failures, reduced lifespan of the equipment, and costly repairs, creating frustration and impacting project timelines.

La solución: To address overheating concerns, buyers should select compressors with built-in thermal overload protection and efficient cooling systems. Models designed with oil-free motors are often more effective in managing heat and are ideal for continuous operation. Additionally, implementing scheduled breaks during usage can help prevent overheating; for instance, running the compressor in intervals allows it to cool down while still maintaining productivity. Regular maintenance checks, including cleaning air filters and ensuring proper ventilation, are crucial for sustaining optimal performance. Lastly, educating operators about the importance of monitoring temperature and recognizing signs of overheating can help in early intervention.

El problema: B2B buyers, especially those in industries like automotive repair or construction, often find it challenging to transport electric portable air compressors to various job sites. The weight, size, and design of some models can hinder mobility, leading to inefficiencies and increased labor costs as teams struggle to move equipment.

La solución: To overcome portability issues, buyers should prioritize sourcing lightweight, compact models specifically designed for easy transport. Look for compressors equipped with wheels and ergonomic handles that facilitate movement across job sites. Additionally, consider purchasing modular systems that can be disassembled for easier transport. Suppliers that offer rental options can also provide flexibility for businesses that require portable air compressors on an as-needed basis without the long-term investment. It’s beneficial to evaluate the total weight and dimensions of the compressor against the transport capabilities of your vehicles to ensure compatibility. Investing in proper lifting equipment or trolleys can also streamline the process of moving heavier units safely and efficiently.

Electric portable air compressors rely on various materials that significantly impact their performance, durability, and cost. Understanding these materials helps B2B buyers make informed decisions tailored to their specific needs, especially in diverse international markets.

Aluminum is a popular choice for the construction of air compressor components due to its excellent strength-to-weight ratio and corrosion resistance. It typically withstands operating temperatures up to 150°C (302°F) and can handle pressures of around 150 psi, making it suitable for most portable applications.

Pros: Aluminum is lightweight, which aids in portability and ease of handling. It also offers good thermal conductivity, promoting efficient cooling during operation.

Contras: The primary downside is its relatively higher cost compared to steel and its susceptibility to deformation under high-stress conditions.

Impacto en la aplicación: Aluminum is particularly effective for components exposed to moisture, as it resists rust and corrosion. However, it may not be suitable for applications requiring extreme durability or heavy-duty use.

Consideraciones para compradores internacionales: Buyers in regions like Africa and South America should ensure compliance with local standards regarding aluminum quality and treatment processes, as these can vary significantly.

Steel is a traditional material used in air compressor construction, especially for tanks and frames. It boasts high tensile strength, allowing it to withstand high pressures (often exceeding 200 psi) and temperatures.

Pros: Steel’s durability makes it ideal for heavy-duty applications. It is also relatively cost-effective, especially in bulk manufacturing.

Contras: The main drawback is its weight, which can hinder portability. Additionally, steel is prone to rust and corrosion without proper treatment.

Impacto en la aplicación: Steel is suitable for applications involving high pressure and demanding environments. However, it requires regular maintenance to prevent rust, particularly in humid climates.

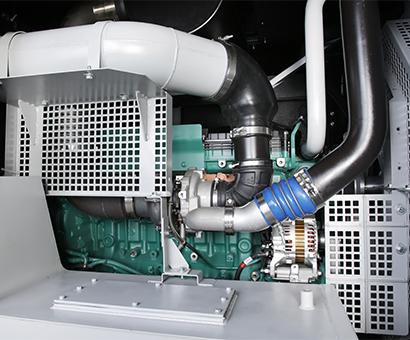

Illustrative image related to electric portable air compressor

Consideraciones para compradores internacionales: Buyers should look for steel components that meet ASTM or DIN standards to ensure quality and performance, especially in regions with varying environmental conditions.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used for non-structural components in electric portable air compressors, such as housing and guards.

Pros: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, enhancing design flexibility.

Contras: They generally have lower temperature and pressure ratings compared to metals, which can limit their use in high-performance applications.

Impacto en la aplicación: Plastic components are ideal for portable air compressors used in light-duty tasks, such as inflating tires or powering small tools. However, they may not withstand harsh conditions or heavy usage.

Consideraciones para compradores internacionales: Ensure that plastic materials comply with local regulations regarding safety and environmental impact, particularly in regions with stringent waste management laws.

Composite materials, which combine plastics with fibers (like fiberglass or carbon fiber), offer a unique blend of strength and lightweight properties. They can handle pressures up to 200 psi and temperatures around 120°C (248°F).

Pros: Composites provide excellent strength-to-weight ratios and are resistant to corrosion and environmental degradation.

Contras: The manufacturing process can be complex and more expensive than traditional materials, which may impact overall product pricing.

Impacto en la aplicación: Composites are suitable for high-performance applications where weight savings are critical, such as in mobile or automotive air compressor systems.

Consideraciones para compradores internacionales: Buyers should verify the manufacturing standards and certifications of composite materials to ensure they meet relevant international quality benchmarks.

| Material | Typical Use Case for electric portable air compressor | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Lightweight components, tanks | Resistencia a la corrosión | Higher cost, deformation risk | Medio |

| Acero | Heavy-duty tanks and frames | Gran durabilidad y resistencia | Heavy, rust-prone without treatment | Bajo |

| Plástico | Housing and guards | Lightweight, design flexibility | Valores nominales de temperatura/presión más bajos | Bajo |

| Compuesto | High-performance, lightweight applications | Excelente relación resistencia-peso | Complex manufacturing, higher cost | Alta |

Understanding these materials and their implications will empower B2B buyers to choose the right electric portable air compressor tailored to their operational needs and environmental conditions.

The manufacturing process of electric portable air compressors involves several critical stages, each essential to ensuring the final product’s reliability and efficiency. Understanding these stages can help B2B buyers make informed decisions when sourcing from suppliers.

The first step in manufacturing involves material preparation. High-quality materials, such as aluminum and steel, are commonly chosen for their strength and lightweight properties. Suppliers often conduct a thorough assessment of material specifications to ensure compliance with industry standards. This includes verifying the chemical composition and mechanical properties of the materials used, which directly impact the compressor’s performance and durability.

Once materials are prepared, the next step is forming. This process typically involves cutting, bending, and shaping the materials into the required components. Techniques such as CNC machining and stamping are commonly employed to achieve precise dimensions and tolerances. Advanced manufacturers may utilize 3D printing for prototyping, allowing for rapid iteration and testing of design concepts before mass production.

Illustrative image related to electric portable air compressor

After forming, components move to the assembly stage. This is where the various parts, including the motor, tank, and controls, are put together. Automated assembly lines are often utilized to enhance efficiency, but manual assembly remains crucial for complex components that require skilled labor. During this stage, manufacturers may employ techniques such as torque testing to ensure that all fasteners are secured to the correct specifications.

Finishing processes are essential for enhancing the compressor’s appearance and protecting it from environmental factors. Common techniques include powder coating, anodizing, and painting. These processes not only improve aesthetics but also provide a protective layer that prevents rust and corrosion, particularly important for units intended for diverse climates in regions like Africa and South America.

Quality assurance (QA) is a vital aspect of the manufacturing process, especially in industries where reliability is critical. B2B buyers should be familiar with international standards and industry-specific certifications to ensure they are sourcing high-quality products.

ISO 9001 is one of the most recognized quality management standards globally. It outlines requirements for a quality management system (QMS) and is essential for manufacturers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) indicate compliance with European safety, health, and environmental protection standards, which can be critical for buyers in Europe.

In the context of electric portable air compressors, industry-specific certifications such as API (American Petroleum Institute) may be relevant, particularly for compressors used in oil and gas applications. These certifications ensure that products meet stringent industry standards for safety and performance. B2B buyers should inquire about these certifications during the sourcing process to confirm that suppliers adhere to industry norms.

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that products meet specified standards before reaching the market.

Incoming Quality Control (IQC) involves the inspection of raw materials and components upon arrival at the manufacturing facility. This step ensures that only materials that meet predefined specifications are used in production. B2B buyers can ask suppliers for IQC reports to verify that materials have been rigorously tested and approved.

In-Process Quality Control (IPQC) occurs during the manufacturing process. This involves regular inspections and testing of components as they are being assembled. Techniques such as visual inspections, dimensional checks, and functional tests are common. B2B buyers can request documentation of IPQC procedures to understand how suppliers maintain quality throughout production.

Final Quality Control (FQC) is the last checkpoint before products are shipped to customers. This stage typically includes a comprehensive inspection and testing of the finished product to ensure it meets all specified standards and functions correctly. Common testing methods include pressure testing, noise level assessments, and performance evaluations. Buyers should inquire about FQC procedures and results, as these are critical indicators of product reliability.

Illustrative image related to electric portable air compressor

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers.

Conducting audits of potential suppliers is a vital step in the verification process. Buyers can perform on-site audits to assess manufacturing processes, quality control measures, and overall compliance with international standards. Auditing helps buyers ensure that suppliers are not only compliant but also committed to continuous improvement.

Suppliers should provide documentation of their quality control measures, including detailed reports on IQC, IPQC, and FQC. Additionally, certifications such as ISO 9001 and CE should be available for review. Buyers should request these documents as part of the supplier assessment process to ensure transparency and accountability.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. These services can conduct inspections at various stages of production, offering buyers peace of mind that products meet specified standards before shipment. This is particularly important for international buyers who may face challenges in verifying compliance from afar.

Understanding the manufacturing processes and quality assurance standards for electric portable air compressors is essential for B2B buyers. By familiarizing themselves with the key stages of manufacturing, relevant international standards, and effective verification methods, buyers can make informed decisions and ensure they procure high-quality products that meet their operational needs. This knowledge is especially crucial for buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, where product reliability and compliance can significantly impact business success.

Illustrative image related to electric portable air compressor

This guide serves as a practical checklist for B2B buyers looking to procure electric portable air compressors. By following these steps, you will ensure that your sourcing process is efficient, thorough, and aligned with your operational needs. This checklist will help you navigate the complexities of supplier selection, product specifications, and compliance, making your purchasing decision more informed.

Understanding your specific requirements is crucial before reaching out to suppliers. Consider factors such as the intended use, required pressure levels, and portability needs.

– Key specifications to evaluate:

– PSI (pounds per square inch) requirements for your applications.

– Tank size and capacity, which affect the compressor’s performance and run time.

Conduct a thorough market analysis to identify available models and features. This research helps you understand what products are on the market and how they compare.

– Consider:

– Brands known for reliability and performance in your region.

– Reviews and ratings from other users to gauge satisfaction and potential issues.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– What to look for:

– Longevity and reputation in the market.

– Evidence of successful supply chain management and customer service responsiveness.

Ensure that the suppliers’ products meet relevant industry standards and safety regulations. This step is particularly important for international purchases, where compliance can vary significantly.

– Focus on:

– CE marking for European markets or ANSI certification in the U.S.

– Any additional certifications relevant to your specific industry or application.

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, shipping terms, and lead times. This transparency helps in making informed comparisons.

– Key elements to compare:

– Total cost, including hidden fees like shipping or handling.

– Warranty terms and after-sales support options, which can impact long-term costs.

A strong after-sales support system is vital for ongoing maintenance and troubleshooting. Understand the warranty terms and what services are included.

– Look for:

– Length and coverage of the warranty.

– Availability of technical support and spare parts in your region.

Before making a final decision, ensure that you are clear on the payment terms and conditions. This helps to avoid any misunderstandings later in the transaction.

– Important considerations:

– Payment methods accepted and any financing options available.

– Terms regarding order cancellations or modifications, which can be crucial in dynamic business environments.

By following this checklist, B2B buyers can streamline the procurement process for electric portable air compressors, ensuring that they select the right product from a reputable supplier while minimizing risks.

When sourcing electric portable air compressors, understanding the cost structure is crucial for B2B buyers. The main cost components include:

Materiales: The quality and type of materials used—such as steel for the tank, copper for wiring, and plastic for housing—directly impact costs. Higher-grade materials may increase the initial price but can enhance durability and performance.

Trabajo: Labor costs vary significantly by region and can be influenced by local wage rates and skill levels. In countries like Germany, labor costs may be higher due to strict labor laws and standards, whereas in regions like Nigeria, labor may be more cost-effective.

Gastos generales de fabricación: This includes costs related to utilities, rent, and equipment depreciation. Factories with advanced technology may incur higher overheads but can produce compressors more efficiently.

Herramientas: The investment in specialized tools for production can be significant, particularly for custom designs. This cost may be amortized over larger production runs, thus affecting unit pricing.

Control de calidad: Rigorous QC processes ensure that products meet specified standards, which can add to costs. Certifications such as ISO or CE may also involve fees but are crucial for international sales.

Logística: Shipping costs, including freight charges and customs duties, vary based on the shipping method and destination. These costs can become substantial for international transactions, especially for bulky items like air compressors.

Margen: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market competition and the perceived value of the product.

Several factors influence the pricing of electric portable air compressors:

Volumen/MOQ: Bulk orders often lead to lower prices per unit due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to secure better pricing.

Especificaciones y personalización: Custom features such as enhanced noise reduction or specific tank sizes can increase costs. Buyers must weigh the benefits of customization against the additional expenses.

Materiales y certificaciones de calidad: The choice of materials and certifications impacts both the cost and marketability. High-quality, certified products may command higher prices but often lead to lower total costs of ownership due to reduced maintenance and longer lifespans.

Factores del proveedor: The reliability and reputation of the supplier play a significant role in pricing. Established suppliers may charge premium prices due to their brand value and proven track record.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital. They define the responsibilities of buyers and sellers in international transactions, affecting shipping costs, insurance, and risks.

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

Precios de mercado: Familiarize yourself with the market rates for electric portable air compressors in your region. This knowledge can empower you during negotiations.

Emphasize Long-Term Relationships: Suppliers are often willing to offer discounts for long-term partnerships. Highlighting your potential for repeat business can encourage them to provide better pricing.

Considere el coste total de propiedad: Focus on long-term value rather than just upfront costs. A higher initial price may be justified by lower operational costs and higher reliability.

Be Prepared to Walk Away: Establish a budget and stick to it. If the supplier cannot meet your financial expectations, be ready to explore other options.

Leverage Local Regulations: Understanding local import duties and taxes can provide leverage in negotiations, especially if the supplier is unfamiliar with your market.

Prices for electric portable air compressors can vary widely based on specifications, supplier location, and shipping arrangements. It is essential for buyers to request detailed quotes from multiple suppliers to ensure accurate pricing and to account for potential additional costs associated with international shipping and customs.

In the realm of portable air compressors, the electric portable air compressor stands out as a versatile solution for various industrial and commercial applications. However, understanding alternatives is crucial for B2B buyers seeking the most effective and cost-efficient solution. This section delves into viable alternatives, allowing buyers to make informed decisions based on their specific needs.

| Aspecto comparativo | Electric Portable Air Compressor | Gas-Powered Air Compressor | Bomba manual |

|---|---|---|---|

| Rendimiento | High pressure and flow rates, suitable for powering tools | Very high pressure and flow rates, ideal for heavy-duty applications | Limited pressure; suitable for small tasks |

| Coste | Moderate initial investment, low operating costs | Higher initial investment, higher fuel costs | Very low cost, no operating costs |

| Facilidad de aplicación | Easy to set up and operate; requires power source | Requires fuel and more complex setup; less portable | Extremely simple; no setup required |

| Mantenimiento | Low maintenance; periodic checks needed | High maintenance; regular oil changes and fuel management required | Minimal maintenance; just periodic cleaning |

| El mejor caso de uso | Ideal for construction, automotive, and maintenance work | Best for heavy construction, large workshops, and remote sites | Perfect for inflating tires or small inflatables |

Gas-powered air compressors provide significant advantages in terms of performance, particularly in demanding environments where high pressure and flow rates are essential. They are not reliant on electricity, making them suitable for remote job sites without power access. However, they come with higher operational costs due to fuel consumption and maintenance requirements, such as regular oil changes and servicing. Additionally, noise levels can be a concern, making them less desirable in noise-sensitive environments.

Manual hand pumps are an inexpensive alternative, requiring no electricity or fuel. They are incredibly easy to use and maintain, making them a practical choice for small tasks like inflating tires or sports equipment. However, their performance is limited, and they cannot achieve the high pressure levels that electric or gas-powered compressors can. This makes them unsuitable for more demanding applications in industrial settings.

Illustrative image related to electric portable air compressor

When selecting an air compressor, B2B buyers should evaluate their specific operational requirements, budget constraints, and the environments in which the compressor will be used. For those needing high performance in remote areas, gas-powered compressors might be the best choice, despite their higher costs. Conversely, if the application is less demanding and cost is a primary concern, a manual hand pump may suffice. Electric portable air compressors offer a balanced approach, combining performance and ease of use, making them ideal for a wide range of applications. Ultimately, the right choice will depend on a careful assessment of operational needs, cost considerations, and maintenance capabilities.

When evaluating electric portable air compressors, several technical properties are essential for ensuring the equipment meets specific operational needs. Understanding these specifications is crucial for B2B buyers to make informed purchasing decisions.

Horsepower (HP): This rating indicates the power output of the compressor. Higher horsepower typically correlates with greater air delivery capacity, which is vital for demanding applications. For instance, a compressor with 2 HP can power multiple pneumatic tools simultaneously, making it suitable for construction or manufacturing environments.

Cubic Feet per Minute (CFM): CFM measures the volume of air the compressor can deliver at a given pressure. This metric is crucial for determining the compressor’s efficiency and suitability for particular tasks. For example, tools like nail guns or paint sprayers require specific CFM ratings to operate effectively, making this a key consideration for buyers.

Tank Size (Gallon): The tank size affects how much compressed air can be stored and the duration the compressor can operate before needing to refill. Larger tanks provide a more consistent air supply, reducing the frequency of compressor cycling. This is particularly important in industries where continuous air supply is critical, such as automotive repair or woodworking.

Voltage and Phase: Electric compressors typically operate on either 110V or 220V power supplies, with single-phase and three-phase options available. Understanding the electrical requirements is essential for ensuring compatibility with existing power sources, especially in international markets where voltage standards may vary.

Noise Level (Decibels): The noise generated by an air compressor can significantly impact work environments. Portable models often range from 60 to 80 decibels. Buyers should consider this factor based on the intended use, particularly in residential or noise-sensitive areas where quieter operation is preferred.

Weight and Portability: For B2B applications, the weight of the compressor can influence its mobility and ease of transport. Lightweight models are often favored in industries like construction, where equipment needs to be moved frequently. Buyers should assess their specific needs regarding portability and storage.

Navigating the procurement process for electric portable air compressors involves familiarity with industry jargon. Here are several key terms that every buyer should know:

OEM (fabricante de equipos originales): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for specific brands or quality assurances in their compressor purchases.

MOQ (Cantidad mínima de pedido): This is the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps buyers assess budget constraints and negotiate terms, particularly when sourcing from international suppliers where bulk purchasing may be necessary.

RFQ (solicitud de presupuesto): An RFQ is a document that a buyer sends to potential suppliers requesting price quotes for specific products. Crafting a detailed RFQ can streamline the procurement process, ensuring that suppliers provide comparable offers based on the same specifications.

Incoterms (Términos comerciales internacionales): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for understanding shipping costs, insurance, and liability issues when sourcing compressors from different countries.

Plazos de entrega: This term indicates the time between placing an order and receiving the product. Lead time is critical for project planning, particularly in industries where delays can impact operations or profitability.

Garantía: A warranty is a guarantee provided by the manufacturer regarding the performance and reliability of the compressor. Understanding warranty terms is essential for B2B buyers to ensure they are protected against defects or failures during the product’s lifespan.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of purchasing electric portable air compressors more effectively, ensuring they select the right equipment for their operational needs.

The electric portable air compressor market is experiencing significant growth, driven by advancements in technology and increasing demand across various sectors. Factors such as urbanization, the rise of DIY culture, and a growing emphasis on energy efficiency are propelling this market forward. In regions like Africa and South America, where infrastructure development is a priority, electric portable air compressors are becoming essential tools for construction and maintenance projects. In Europe, particularly in Germany, the focus is on compact, energy-efficient models that meet stringent environmental regulations.

Emerging trends include the integration of smart technology into electric portable air compressors, allowing for remote monitoring and control via mobile apps. This tech-savvy approach not only enhances user experience but also improves operational efficiency. Additionally, the shift towards battery-operated models is gaining traction, particularly in areas where access to power sources is limited. B2B buyers should pay attention to these innovations as they can provide competitive advantages in their respective markets.

International buyers should also consider sourcing from manufacturers that offer customization options. This flexibility allows businesses to tailor products to their specific needs, which can be particularly beneficial in diverse markets with varying requirements. Understanding local market dynamics, such as the regulatory landscape and consumer preferences, will be crucial for successful sourcing.

Sustainability is no longer just a trend; it has become a critical factor in the decision-making process for B2B buyers. The electric portable air compressor industry is increasingly prioritizing environmentally friendly practices, from production to end-of-life disposal. Manufacturers are being urged to adopt sustainable materials and processes, minimizing waste and reducing carbon footprints. This shift is particularly relevant in regions such as the Middle East and Europe, where regulatory frameworks are promoting green initiatives.

Ethical sourcing has gained importance as buyers become more conscious of their supply chain impacts. Businesses are seeking suppliers that adhere to fair labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and other ‘green’ credentials can serve as important indicators of a supplier’s commitment to sustainability. B2B buyers should actively seek partnerships with manufacturers who prioritize these values, as they align with corporate social responsibility goals and can enhance brand reputation.

Additionally, the push for electric models over traditional gas-powered compressors is a significant step towards reducing air pollution. With electric compressors producing fewer emissions, they are increasingly favored in urban settings where air quality is a concern. Buyers should consider the environmental impact of their purchasing decisions and opt for products that reflect a commitment to sustainability.

The evolution of electric portable air compressors can be traced back to the early 20th century, when the need for portable power sources began to emerge. Initially, air compressors were predominantly powered by gas engines, which limited their usability in enclosed spaces. The introduction of electric models in the mid-20th century revolutionized the industry, offering a cleaner and quieter alternative.

As technology advanced, the development of more compact and efficient electric motors led to a surge in the popularity of portable air compressors, particularly in construction and automotive sectors. By the 21st century, the focus shifted towards energy efficiency and noise reduction, responding to growing environmental concerns and regulatory pressures. Today, electric portable air compressors are essential tools for various applications, from powering pneumatic tools to inflating tires, and their importance in the B2B landscape continues to grow.

Understanding this historical context helps buyers appreciate the technological advancements that have shaped the current market, enabling them to make informed purchasing decisions that align with future trends.

How do I choose the right electric portable air compressor for my business needs?

Selecting the appropriate electric portable air compressor involves assessing your specific applications. Consider factors such as the required pressure (PSI), airflow (CFM), and tank size. Identify whether you need a lightweight model for easy transport or a more robust unit for heavy-duty tasks. Additionally, evaluate features like noise levels, energy efficiency, and maintenance requirements. Engaging with suppliers who offer a range of models can help you find the best fit tailored to your operational demands.

What are the key benefits of using electric portable air compressors over gas-powered models?

Electric portable air compressors are often favored for their quieter operation, reduced emissions, and lower maintenance costs compared to gas-powered options. They are ideal for indoor use and can be plugged into standard outlets, making them convenient for many applications. Additionally, they typically provide consistent power without the need for refueling, which enhances operational efficiency. These benefits make electric models particularly appealing for businesses focused on sustainability and cost-effectiveness.

What should I consider regarding international shipping and logistics for air compressors?

When sourcing electric portable air compressors internationally, it’s crucial to understand shipping regulations, import duties, and tariffs that may apply in your country. Work with suppliers who have experience in international trade and can provide documentation such as bills of lading and certificates of origin. Also, consider the logistics of transport, including whether the supplier offers direct shipping or if you need to arrange for freight forwarding. Ensure that the products are adequately packaged to prevent damage during transit.

What are the minimum order quantities (MOQs) for electric portable air compressors?

Minimum order quantities can vary significantly by supplier and are often influenced by manufacturing capabilities and product types. Many manufacturers may have MOQs ranging from a few units to several dozen. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Smaller businesses may benefit from suppliers who offer flexible ordering options or those willing to consolidate shipments, allowing you to meet your demand without overcommitting.

How can I ensure the quality and reliability of electric portable air compressors from suppliers?

To ensure product quality, vet suppliers by checking their certifications, such as ISO standards, and requesting product samples. Investigate their manufacturing processes and quality control measures. Look for reviews or testimonials from other international buyers, and consider engaging with third-party inspection services for additional assurance. Establishing a solid communication channel with your supplier can also help address any concerns regarding product specifications and quality expectations.

What payment terms should I negotiate with suppliers for electric portable air compressors?

When negotiating payment terms, consider factors such as the total order value, your business’s cash flow, and the supplier’s policies. Common terms include deposits (often 30-50% upfront) and the balance upon delivery or before shipment. Explore options like letters of credit or escrow services for larger orders to mitigate risks. It’s also wise to discuss currency options and any additional fees that may arise during international transactions to ensure transparency and avoid surprises.

Can I customize electric portable air compressors to fit my specific needs?

Many manufacturers offer customization options, allowing you to tailor electric portable air compressors to your business requirements. Customizations can include modifications to tank size, pressure ratings, or even branding and color specifications. Discuss your needs directly with potential suppliers to understand the feasibility and costs associated with customization. Be mindful that customized products may have longer lead times, so plan accordingly to meet your operational timelines.

What warranties and after-sales support should I expect from suppliers?

When sourcing electric portable air compressors, inquire about warranty terms and after-sales support. A good warranty typically covers defects in materials and workmanship for a specified period, often ranging from one to three years. Additionally, assess the supplier’s commitment to after-sales service, including access to spare parts, maintenance support, and technical assistance. Establishing a relationship with suppliers who prioritize customer service can enhance your experience and ensure long-term satisfaction with your purchase.

Dominio: compressorpros.com

Registrado: 2014 (11 años)

Introducción: Portable Electric Air Compressors

Dominio: dewalt.com

Inscrita: 1997 (28 años)

Introducción: DEWALT offers a range of air compressors including electric and gas models designed for performance and durability. Key products include: 1. DXCMS15016US – 1.6 Gal Quiet Roll Cage Oil Free Air Compressor 2. DXCMS13513US – 1.3 Gal XTREME Quiet Roll Cage Oil Free Air Compressor 3. DXCM20020US – 20 Gal XTREME Quiet 2 Stage Oil Free Air Compressor 4. DXCMS20045US – 4.5 Gal XTREME Quiet 2 Stage Oil Fre…

In the competitive landscape of electric portable air compressors, strategic sourcing emerges as a critical component for international B2B buyers. By understanding the unique requirements of different markets, such as those in Africa, South America, the Middle East, and Europe, businesses can better align their purchasing strategies with supplier capabilities. Key takeaways include the importance of evaluating product specifications, considering energy efficiency, and leveraging local sourcing opportunities to reduce costs and improve supply chain reliability.

Investing in high-quality portable air compressors not only enhances operational efficiency but also supports sustainability goals through advanced, eco-friendly technologies. As industries evolve, the demand for versatile and reliable air compressors will continue to grow, making it essential for buyers to stay informed about emerging trends and innovations.

Illustrative image related to electric portable air compressor

Looking ahead, B2B buyers are encouraged to engage with suppliers who prioritize transparency, quality, and innovation. By forging strategic partnerships and utilizing data-driven insights, companies can position themselves for success in this dynamic market. Embrace the future of sourcing—equip your business with the right tools to thrive in a global economy.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.